Designing 3D Membrane Modules for Gas Separation Based on Hollow Fibers from Poly(4-methyl-1-pentene)

Abstract

:1. Introduction

2. Materials and Methods

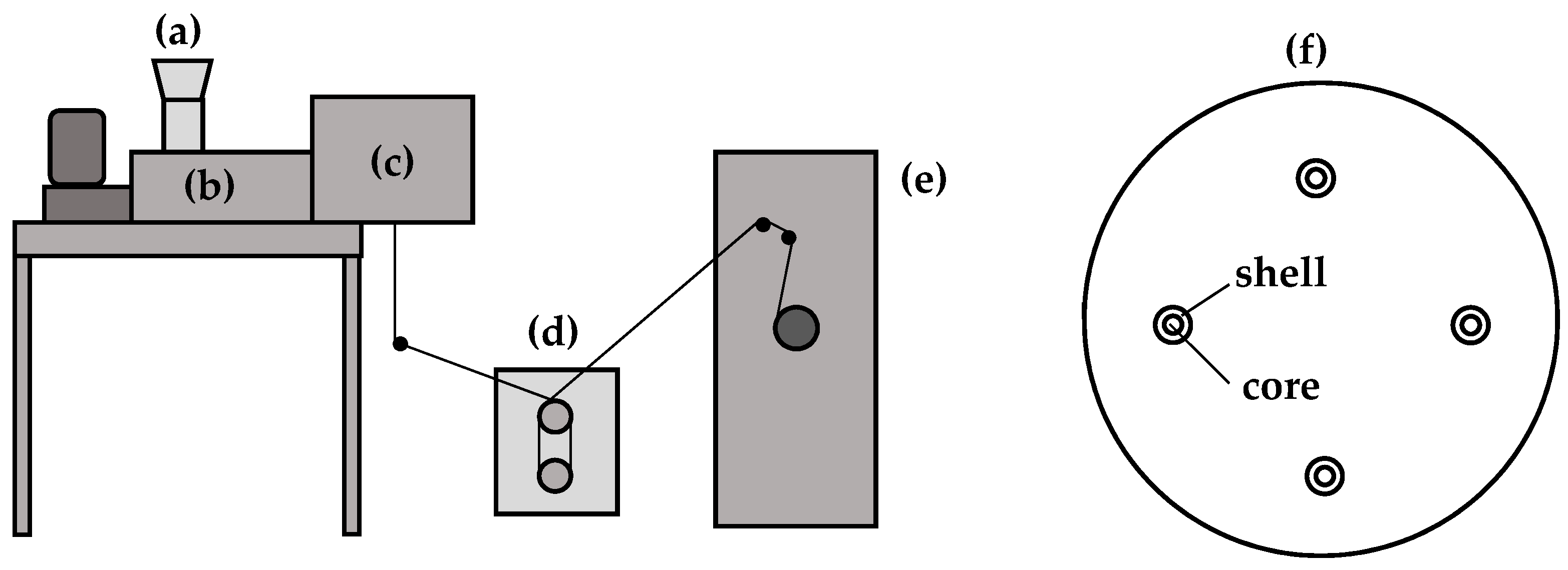

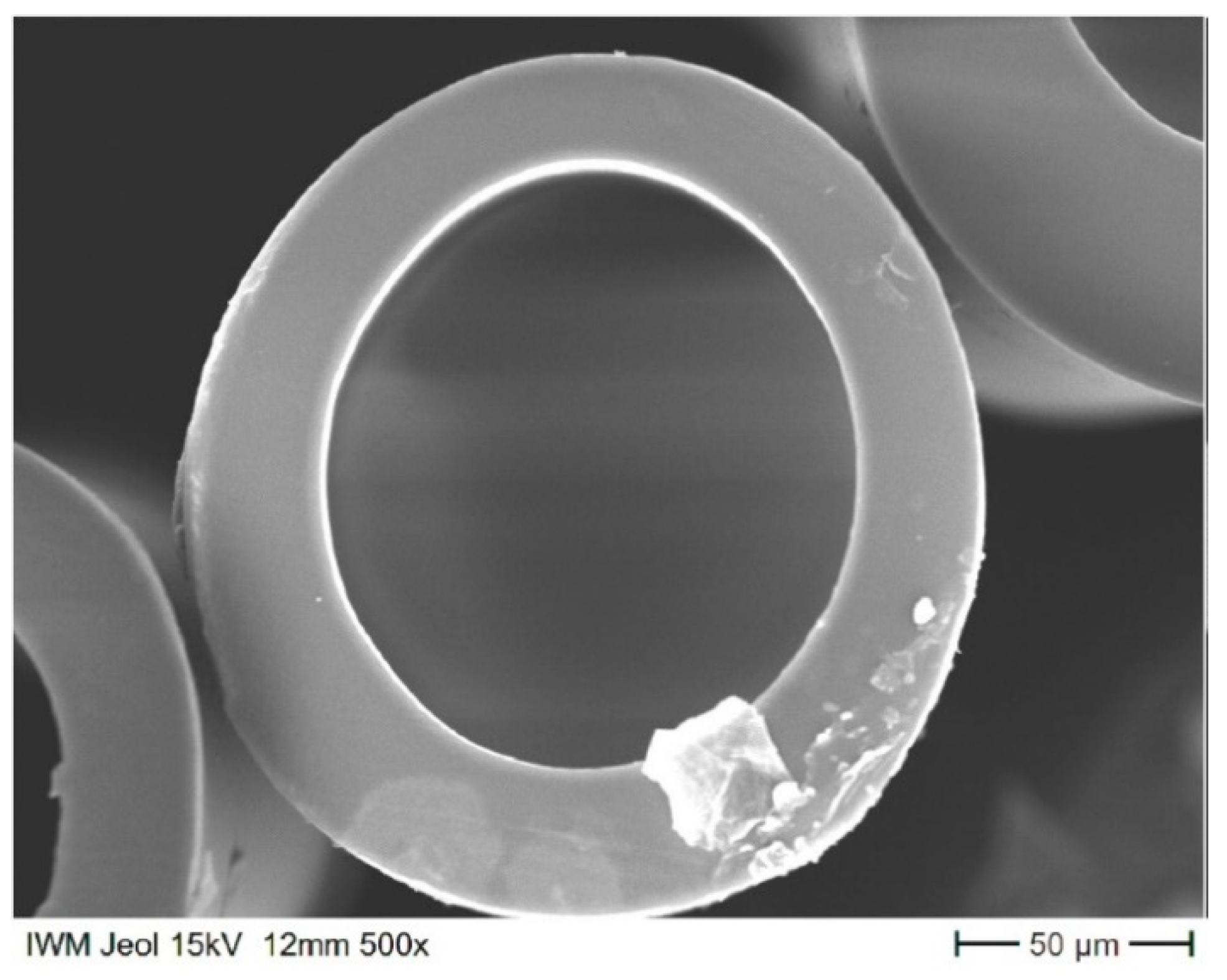

2.1. Hollow Fiber Preparation

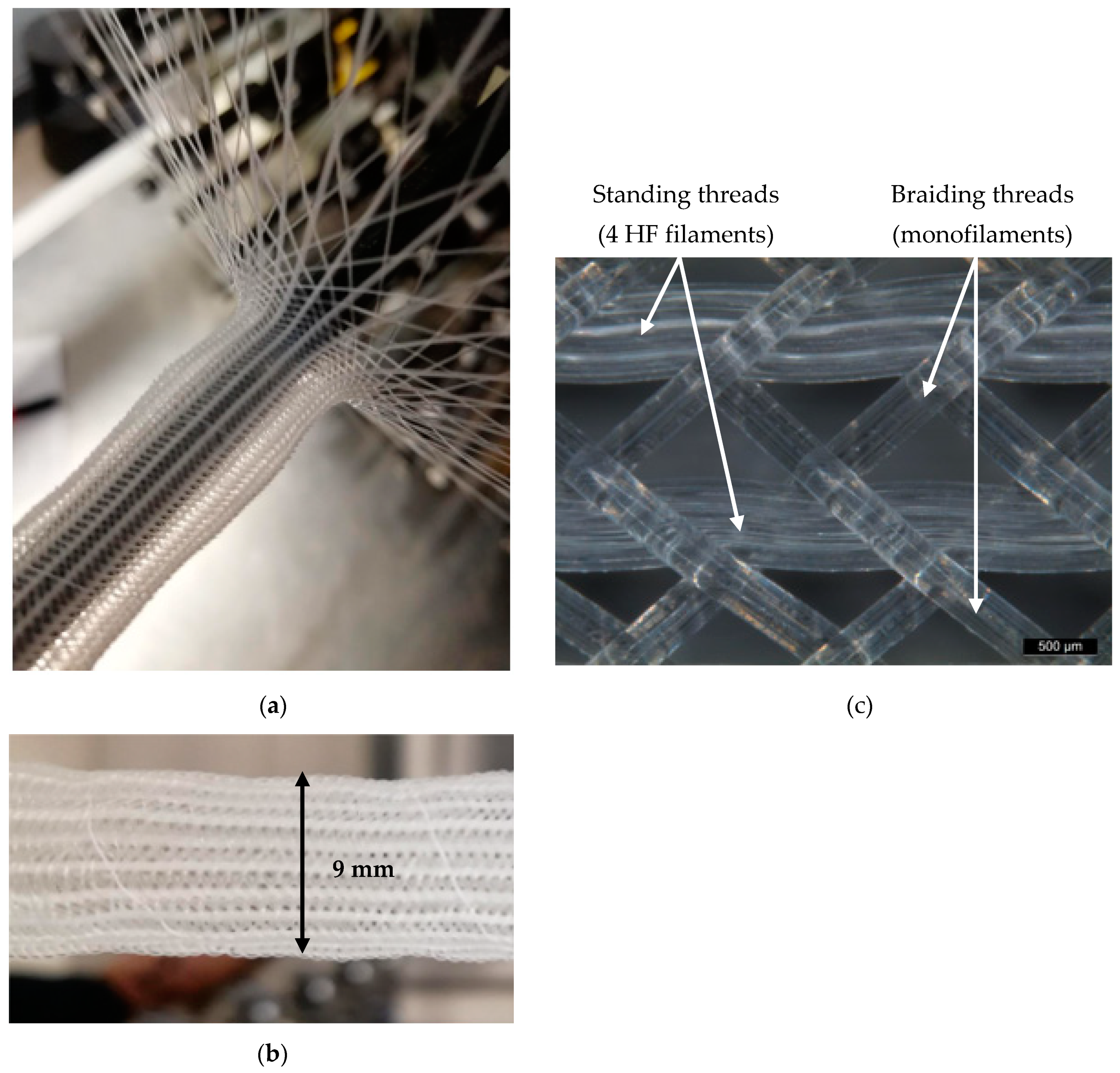

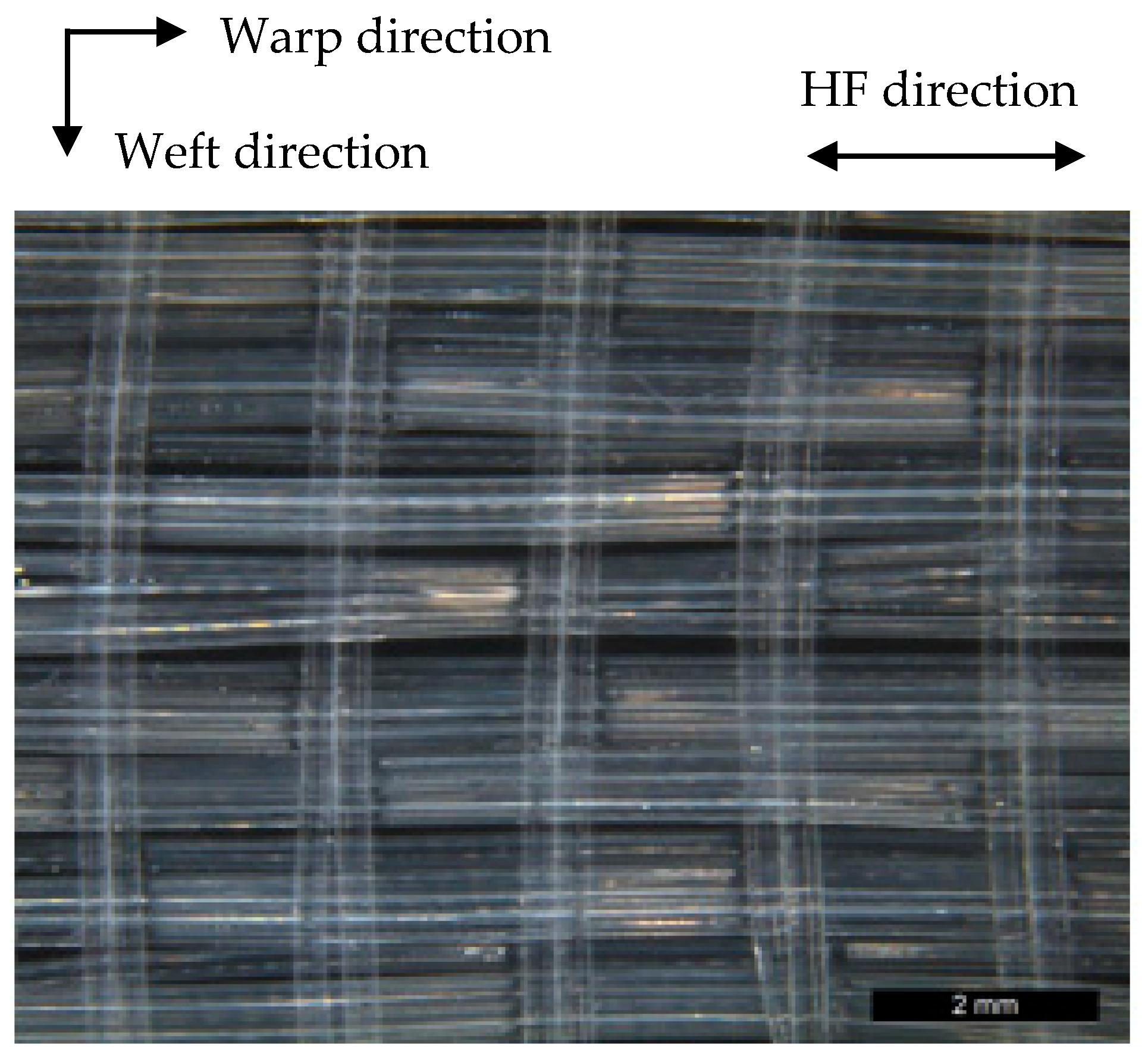

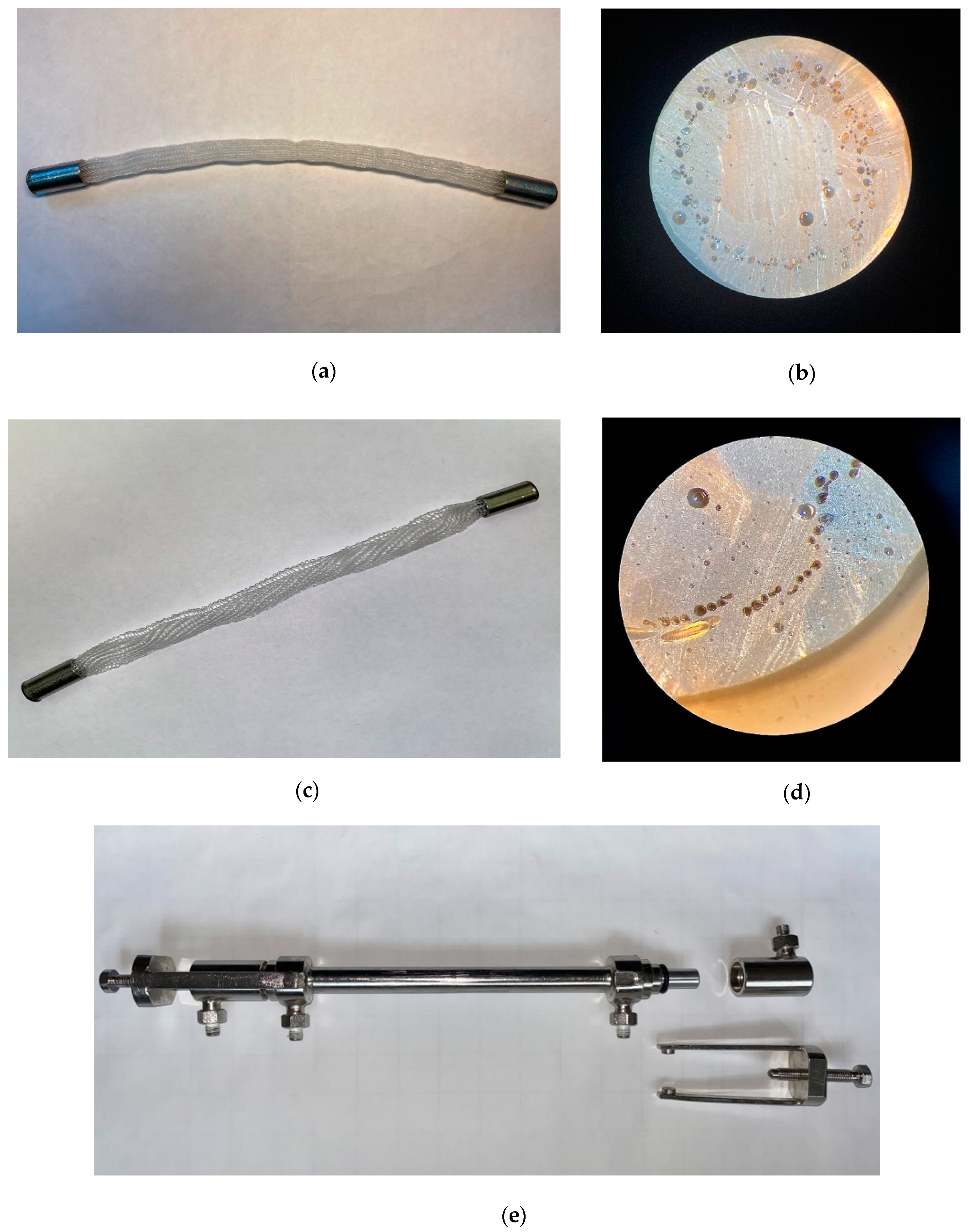

2.2. 3D Braided and Woven Tape Fabrics

2.3. Gas Permeability Measurements

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Khulbe, K.C.; Feng, C.; Matsuura, T.; Khayet, M. Polymeric Hollow Fibers: State of the Art Review of Their Preparation, Characterization and Applications in Different Research Areas. J. Appl. Membr. Sci. Technol. 2006, 4, 53–88. [Google Scholar] [CrossRef]

- Crank, J.; Park, G. Diffusion in Polymers; Academic Press: London, UK; New York, NY, USA, 1969. [Google Scholar]

- Paul, D.R.; Yampol’skii, Y.P. Polymeric Gas Separation Membranes; CRC Press, Inc.: Boca Raton, FL, USA, 1994. [Google Scholar]

- Mulder, M. Basic Principles of Membrane Technology; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1999. [Google Scholar]

- Baker, R.W. Membrane Technology and Applications, 2nd ed.; John Wiley & Sons Ltd: Chichester, UK, 2004. [Google Scholar]

- Beckman, I.N.; Shalygin, M.G.; Teplyakov, V.V. Particularities of membrane gas separation under unsteady state conditions. In Mass Transfer in Chemical Engineering Processes; Markoš, J., Ed.; InTech: Rijeka, Croatia, 2011; pp. 205–232. [Google Scholar]

- Henis, J.M.S.; Tripodi, M.K. A novel approach to gas separations using composite hollow fiber membrabnes. Sep. Sci. Technol. 1980, 15, 1059–1068. [Google Scholar] [CrossRef]

- Wen, X.; Tresco, P.A. Fabrication and characterization of permeable degradable poly(DL-lactide-co-glycolide) (PLGA) hollow fiber phase inversion membranes for use as nerve tract guidance channels. Biomaterials 2006, 27, 3800–3809. [Google Scholar] [CrossRef]

- Ashtiani, S.; Khoshnamvand, M.; Cihal, P.; Dendisova, M.; Randova, A.; Bousa, D.; Shaliutina-Kolesova, A.; Sofer, Z.; Friess, K. Fabrication of a PVDF membrane with tailored morphology and properties via exploring and computing its ternary phase diagram for wastewater treatment and gas separation applications. RSC Adv. 2020, 10, 40373. [Google Scholar] [CrossRef]

- Ashtiani, S.; Khoshnamvand, M.; Regmi, C.; Friess, K. Interfacial Design of Mixed Matrix Membranes via Grafting PVA on UiO-66-NH2 to Enhance the Gas Separation Performance. Membranes 2021, 11, 419. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Xiao, C.; Huang, Q.; Liu, H.; Zhao, J. Progress on polymeric hollow fiber membrane preparation technique from the perspective of green and sustainable development. Chem. Eng. J. 2021, 403, 126295. [Google Scholar] [CrossRef]

- Pelzer, M.; Vad, T.; Becker, A.; Gries, T.; Markova, S.; Teplyakov, V. Melt Spinning and Characterization of Hollow Fibres from Poly(4-methyl-1-pentene). J. Appl. Polym. Sci. 2020, 138, e49630. [Google Scholar] [CrossRef]

- Lopez, L.C. Synthesis, structure and properties of poly(4-methyl-1-pentene). J. Macromol. Sci. Part C 1992, 32, 301–406. [Google Scholar] [CrossRef]

- Mitsui Chemicals. TPX Properties. Available online: https://jp.mitsuichemicals.com/en/special/tpx/properties/ (accessed on 15 December 2021).

- Zhang, G.; Baer, E.; Hiltner, A. Gas permeability of poly(4-methylpentene-1) in a confined nanolayered film system. Polymer 2013, 54, 4298–4308. [Google Scholar] [CrossRef]

- Nematollahi, M.H.; Dehaghani, A.H.S.; Abedini, R. CO2/CH4 separation with poly(4-methyl-1-pentyne) (TPX) based mixed matrix membrane filled with Al2O3 nanoparticles. Korean J. Chem. Eng. 2016, 33, 657–665. [Google Scholar] [CrossRef]

- Dehaghani, A.H.S.; Pirouzfar, V.; Alihosseini, A. Novel nanocomposite membranes-derived poly(4-methyl-1-pentene)/functionalized titanium dioxide to improve the gases transport properties and separation performance. Polym. Bull. 2020, 77, 6467–6489. [Google Scholar] [CrossRef]

- Shafie, Z.M.H.M.; Ahmad, A.L.; Rode, S.; Belaissaoui, B.; Roizard, D.; Low, S.C. Prospect of Oxyplus Hollow Fibre Membrane with Dense Polymethylpentene (PMP) Skin as Support-gutter Layer of Thin Film Composite (TFC) for Biogas Upgrading. J. Phys. Sci. 2019, 30, 179–189. [Google Scholar] [CrossRef] [Green Version]

- Kostrov, Y.A.; Mostovaya, G.B.; Ignatenko, T.I.; Ardashnikov, A.Y.; Khutorskii, B.Y. Graviton hollow gas-separating fibre. Fibre Chem. 1987, 18, 479–481. [Google Scholar] [CrossRef]

- Evseev, A.K.; Zhuravel, S.V.; Alentiev, A.Y.; Goroncharovskaya, I.V.; Petrikov, S.S. Membranes in Extracorporeal Blood Oxygenation Technology. Membr. Membr. Technol. 2019, 1, 201–211. [Google Scholar] [CrossRef] [Green Version]

- LivaNova. EOS ECMO. Available online: https://www.livanova.com/en-GB/Home/Products-Therapies/Cardiovascular/Healthcare-Professionals/Advanced-Circulatory-Support/ExtraCorporeal-Life-Support/Eos-ECMO.aspx (accessed on 25 October 2021).

- Xenios Campus. Available online: https://www.xenios-campus.com/tutorial/trailer_whitepaper_ecmo_in_covid-19_disease/ (accessed on 25 October 2021).

- Li, D.; Wang, R.; Chung, T.-S. Fabrication of lab-scale hollow fiber membrane modules with high packing density. Sep. Purif. Technol. 2004, 40, 15–30. [Google Scholar] [CrossRef]

- Wey, M.-Y.; Chen, H.-H.; Lin, Y.-T.; Tseng, H.-H. Thin carbon hollow fiber membrane with Knudsen diffusion for hydrogen/alkane separation: Effects of hollow fiber module design and gas flow mode. Int. J. Hydrog. Energy 2020, 45, 7290–7302. [Google Scholar] [CrossRef]

- Scovazzo, P.; MacNeill, R. Membrane module design, construction, and testing for vacuum sweep dehumidification (VSD): Part I, prototype development and module design. J. Membr. Sci. 2019, 576, 96–107. [Google Scholar] [CrossRef]

- Yang, X.; Wang, R.; Fane, A.G.; Tang, C.Y.; Wenten, I.G. Membrane module design and dynamic shear-induced techniques to enhance liquid separation by hollow fiber modules: A review. Desalination Water Treat. 2013, 51, 3604–3627. [Google Scholar] [CrossRef] [Green Version]

- Luelf, T.; Tepper, M.; Breisig, H.; Wessling, M. Sinusoidal shaped hollow fibers for enhanced mass transfer. J. Membr. Sci. 2017, 533, 302–308. [Google Scholar] [CrossRef] [Green Version]

- Pabby, A.K.; Wickramasinghe, S.R.; Sirkar, K.K.; Sastre, A.-M. Hollow Fiber Membrane Contactors: Module Fabrication, Design and Operation, and Potential Applications; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Huang, X.; Wang, W.; Zheng, Z.; Fan, W.; Mao, C.; Shi, J.; Li, L. Surface monofunctionalized polymethyl pentene hollow fiber membranes by plasma treatment and hemocompatibility modification for membrane oxygenators. Appl. Surf. Sci. 2016, 362, 355–363. [Google Scholar] [CrossRef]

- Wan, C.F.; Yang, T.; Lipscomb, G.G.; Stookey, D.J.; Chung, T.-S. Design and fabrication of hollow fiber membrane modules. In Hollow Fiber Membranes Fabrication and Applications; Chung, T.-S., Feng, Y., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 225–252. [Google Scholar]

- Ghogomu, J.; Guigui, C.; Rouch, J.; Clifton, M.; Aptel, P. Hollow-fibre membrane module design: Comparison of different curved geometries with Dean vortices. J. Membr. Sci. 2001, 181, 71–80. [Google Scholar] [CrossRef]

- Park, S.R.; Kim, J.-H.; Ali, A.; Macedonio, F.; Drioli, E. A novel approach to synthesize helix wave hollow fiber membranes for separation applications. J. Membr. Sep. Technol. 2015, 4, 8–14. [Google Scholar]

- Wang, P.; Chung, T.-S. Design and fabrication of lotus-root-like multi-bore hollow fiber membrane for direct contact membrane distillation. J. Membr. Sci. 2012, 421–422, 361–374. [Google Scholar] [CrossRef]

- Singh, D.; Li, L.; Obusckovic, G.; Chau, J.; Sirkar, K.K. Novel cylindrical cross-flow hollow fiber membrane module for direct contact membrane distillation-based desalination. J. Membr. Sci. 2018, 545, 312–322. [Google Scholar] [CrossRef]

- Tanaka, Y.; Yasukawa, M.; Goda, S.; Sakurai, H.; Shibuya, M.; Takahashi, T.; Matsuyama, H. Experimental and simulation studies of two types of 5-inch scale hollow fiber membrane modules for pressure-retarded osmosis. Desalination 2018, 447, 133–146. [Google Scholar] [CrossRef]

- Shibuya, M.; Yasukawa, M.; Goda, S.; Sakurai, H.; Takahashi, T.; Higa, M.; Matsuyama, H. Experimental and theoretical study of a forward osmosis hollow fiber membrane module with a cross-wound configuration. J. Membr. Sci. 2016, 504, 10–19. [Google Scholar] [CrossRef]

- Ma, C.; Liu, Y.; Li, F.; Shen, C.; Huang, M.; Wang, Z.; Sand, W. CFD simulations of fiber-fiber interaction in a hollow fiber membrane bundle: Fiber distance and position matters. Sep. Purif. Technol. 2019, 209, 707–713. [Google Scholar] [CrossRef]

- Wang, K.L.; Cussler, E.L. Baffled membrane modules made with hollow fiber fabric. J. Membr. Sci. 1993, 85, 265–278. [Google Scholar] [CrossRef]

- Castel, C.; Bounaceur, R.; Favre, E. Engineering of membrane gas separation processes: State of the art and prospects. J. Membr. Sci. Res. 2020, 6, 295–303. [Google Scholar]

- Markova, S.Y.; Pelzer, M.; Shalygin, M.G.; Vad, T.; Gries, T.; Teplyakov, V.V. Gas separating hollow fibres from poly(4-methyl-1-pentene): A new development. Sep. Purif. Technol. 2022, 278, 119534. [Google Scholar] [CrossRef]

- Mohr, J.M.; Paul, D.R.; Taru, Y. Surface fluorination of composite membranes. Part II. Characterization of the fluorinated layer. J. Memb. Sci. 1991, 55, 149–171. [Google Scholar] [CrossRef]

- Abedini, R.; Omidkhah, M.; Dorosti, F. Highly permeable poly (4-methyl-1-pentene)/NH2-MIL 53 (Al) mixed matrix membrane for CO2/CH4 separation. RSC Adv. 2014, 4, 36522–36537. [Google Scholar] [CrossRef]

- Chen, X.Y.; Vinh-Thang, H.; Ramirez, A.A.; Rodrigue, D.; Kaliaguine, S. Membrane gas separation technologies for biogas upgrading. RSC Adv. 2015, 5, 24399–24448. [Google Scholar] [CrossRef]

- Fernández-Castro, P.; Ortiz, A.; Gorri, D. Exploring the Potential Application of Matrimid® and ZIFs-Based Membranes for Hydrogen Recovery: A Review. Polymers 2021, 13, 1292. [Google Scholar] [CrossRef] [PubMed]

- Vrbová, V.; Ciahotný, K. Upgrading Biogas to Biomethane Using Membrane Separation. Energy Fuels 2017, 31, 9393–9401. [Google Scholar] [CrossRef]

- Bao, L.; Lipscomb, G.G. Mass transfer in axial flows through randomly packed fiber bundles. In Membrane Science and Technology; Bhattacharyya, D., Butterfield, D.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2003; pp. 5–26. [Google Scholar]

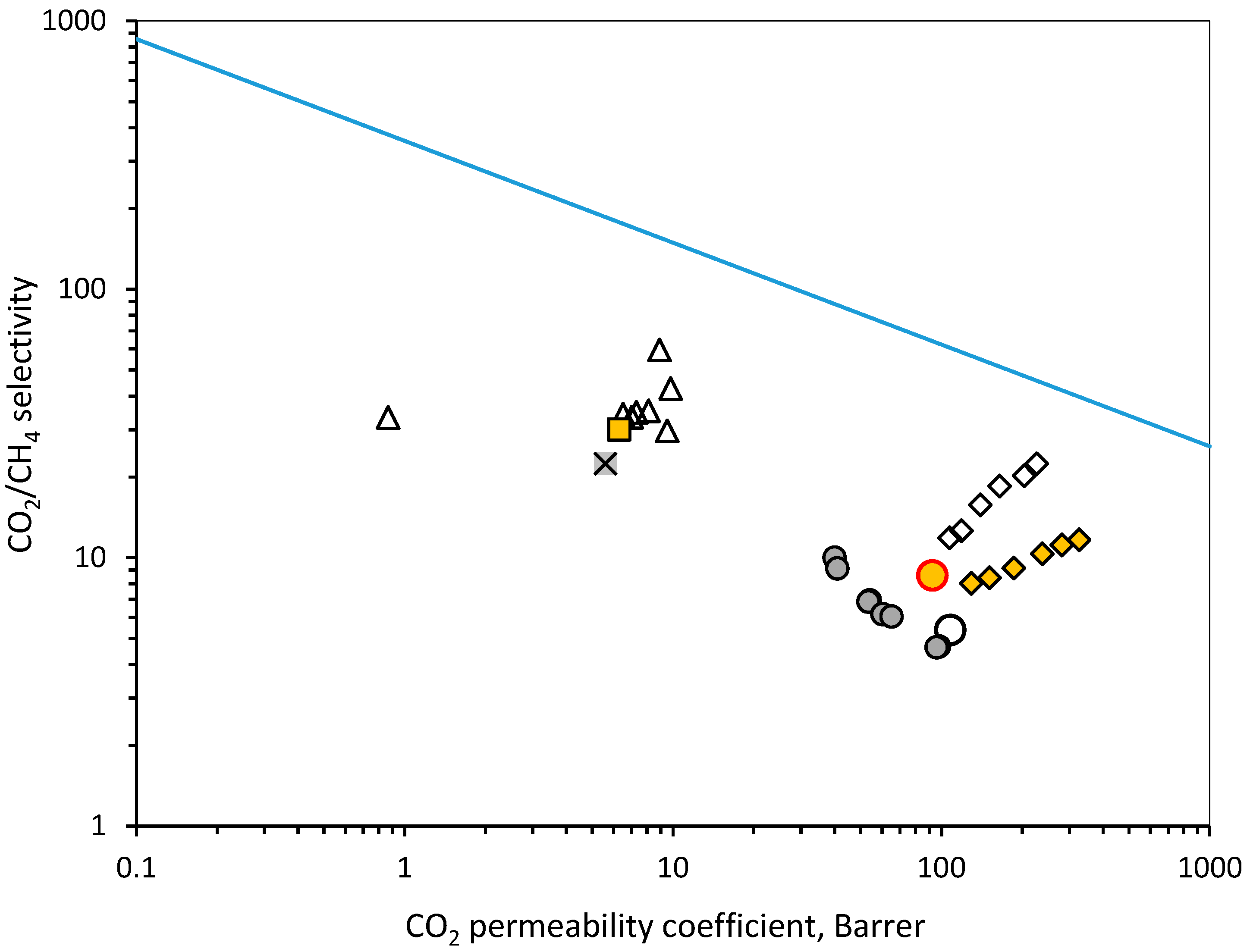

2008 Upperbound;

2008 Upperbound;  PMP [13];

PMP [13];  PMP [41];

PMP [41];  PMP this work (0–40 °C);

PMP this work (0–40 °C);  PMP MMMs with MIL53 [42];

PMP MMMs with MIL53 [42];  PMP MMMs with Al2O3 [16];

PMP MMMs with Al2O3 [16];  Commercial polyimides [43,44];

Commercial polyimides [43,44];  Cellulose acetate [45];

Cellulose acetate [45];  Polysulfone [45].

Polysulfone [45].

| Purpose of the Membrane Module | Improvement Area | Improvement Method | Remark | Ref. |

|---|---|---|---|---|

| Gas separation | Increasing the packing density | Modeling (know-how-based technique) on lab-scale HF membrane modules | Recommendations for upscaling gas separation process on industrial membrane modules | [23] |

| Gas separation | Design of technological systems | Consideration of variable permeability, drop pressure and/or non-isothermal conditions. Multi-component, multi-membrane, multi-operation processes | Possibilities for future applications are discussed | [24] |

| Hydrogen/alkane separation | Olefins and paraffins C2-C4 extraction from gas streams | Effects of hollow fiber module design and gas flow mode | Separation of H2/CO2, H2/C2H6 and H2/C3H8 gas mixtures | [25] |

| Vacuum sweep for the dehumidification of air | Control of water vapor and air permeance; heat and mass transfer | Varying the geometry of modules and schemes with partial recycling | Decrease in the resistance of the membrane boundary layer towards mass transfer | [26] |

| Gas/liquid membrane contactors | Mass transfer in HF module | (1) module design with optimized flow geometry (2) use of external energy | Increase in the productivity factor by 3 to 15 | [27] |

| Gas/liquid membrane contactors | Improving mass transfer | Development of a pulsation module that imposes a sinusoidally fluctuating bore liquid flow rate | New method of HF spinning | [28] |

| HF membrane contactors (HFMC) | HFMC: module fabrication, design and operation, potential applications | Gas/liquid contacting; liquid/liquid contacting; supported liquid membrane; supported gas membrane; fluid/fluid contacting | Special focus on membrane distillation, dehumidification of air and gas absorption and stripping | [29] |

| Membrane oxygenators | Improvement of hemocompatibility | HF membranes treated by plasma | Surface-modified polymeric HF membranes | [30] |

| Liquid/liquid membrane contactors | Hydrodynamics and mass transfer | Design of internal HF packing in the module and selection of operating conditions | (1) creating an even flow within the module and (2) improving mixing | [31,32] |

| Liquid/liquid membrane contactors | HFs with improved homogeneous distribution of fluid inside the module | Dry and wet phase inversion method using asymmetric coagulation conditions | Helix wave HF | [33] |

| Membrane distillation | Improving the design and mechanical stability of the membrane | Design of lotus-root-like multi-bore HF membrane | Improving the mechanical strength of the membranes | [34] |

| Membrane distillation | Improving the design of the membrane module | Novel cylindrical cross-flow HF membrane module for direct contact membrane distillation | Good accordance with model predictions | [35] |

| Power generation from seawater, desalination forward osmosis (FO) and pressure-retarded osmosis (PRO) | Energy efficiency | New types of modules with shorter lengths and larger diameters | Energy recovery increases by 10–15% | [36] |

| FO | Recuperation factor and energy consumption of FO processes | Experimental and theoretical study of an FO HF membrane module with a cross-wound configuration | Particular attention is paid to the frequency of the transverse winding of the HFs in the module | [37] |

| Membrane filtration | Fouling | Computational fluid dynamics (CFD) simulations of fiber–fiber interaction in a HF membrane bundle | Fouling can be lowered by proper fiber distance and position in the bundle | [38] |

| Membrane separation processes | Improvement of mass transfer coefficients | New baffled membrane modules made with HF fabric | The performance of such modules is routinely better than that in more conventional designs | [39] |

| Volumetric Polymer Feed (cm3/Rotation) | Extruder Rotation Speed (Rotations/min) | Spin Head Temperature (°C) | Specific Mass Throughput (g mm−2 h−1) | Winding Speed (m/min) |

|---|---|---|---|---|

| 0.16 | 13.13 | 280 | 103 | 25 |

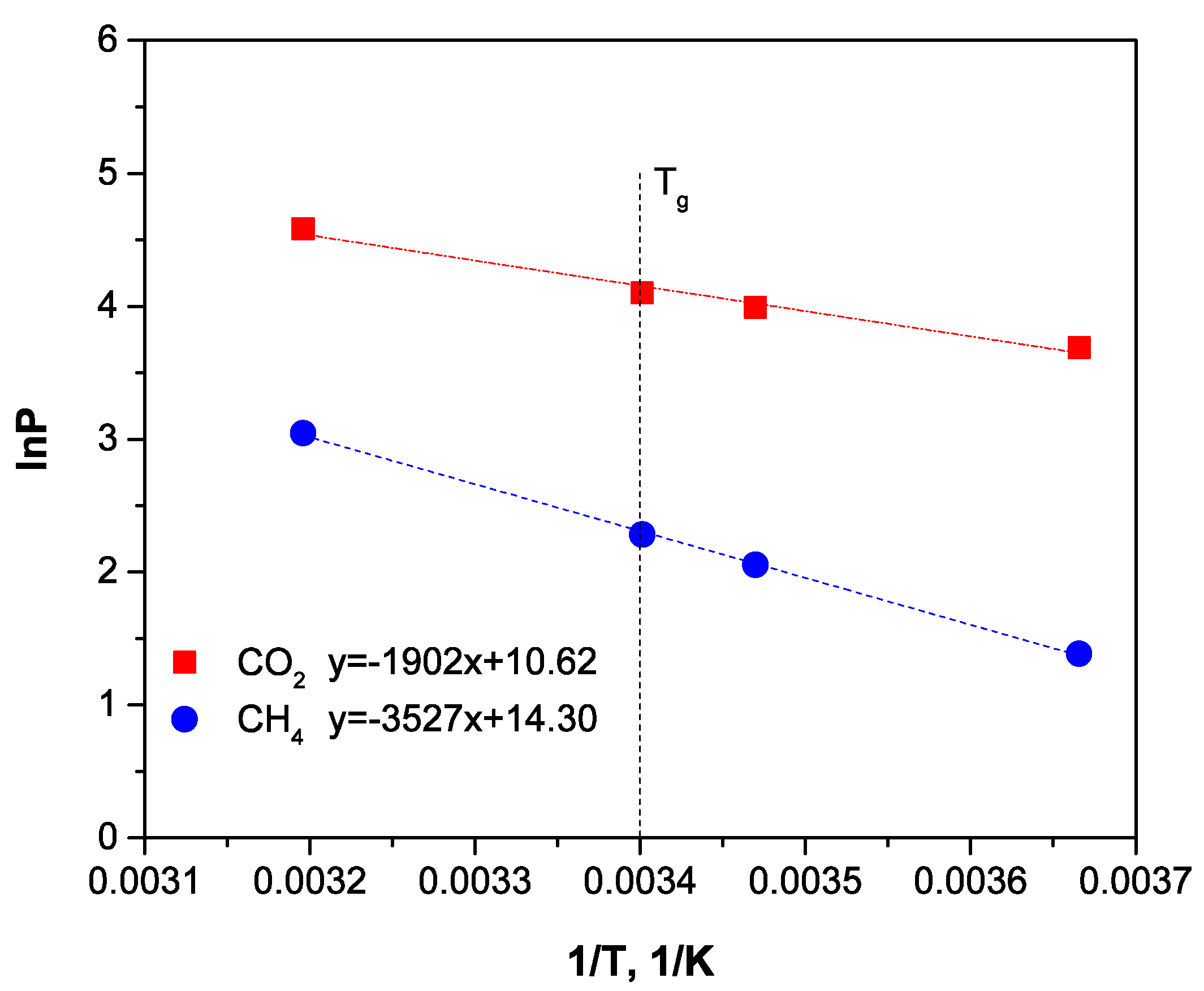

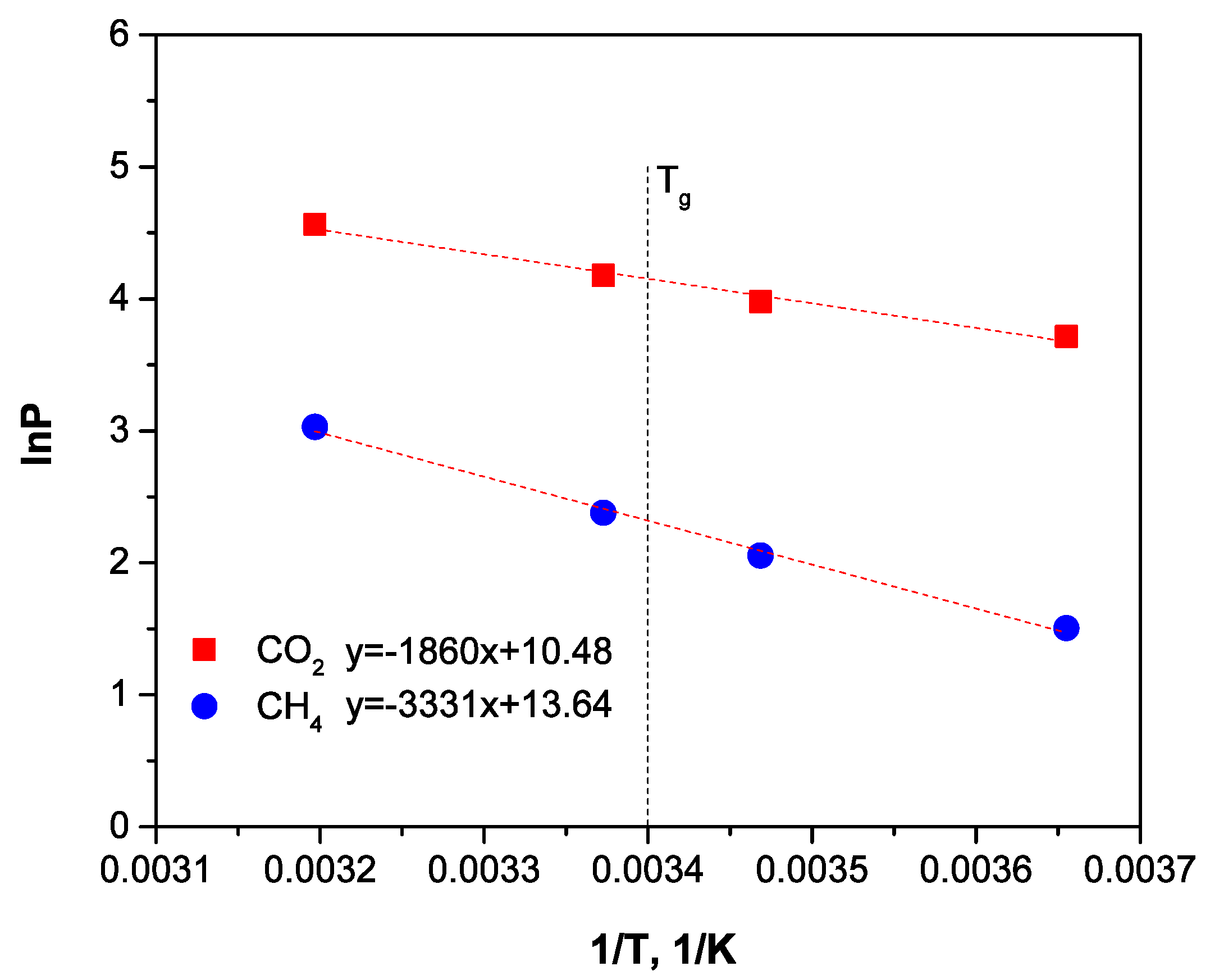

| T, °C | Permeability Coefficients P, Barrer | Selectivity of CO2/CH4 | Type | |

|---|---|---|---|---|

| CO2 | CH4 | |||

| −0.2 | 40.0 | 4.0 | 10.0 | Triaxial braided hose |

| 0.6 | 41.0 | 4.5 | 9.2 | Tape-woven fabric |

| 15.2 | 54.1 | 7.8 | 6.9 | Triaxial braided hose |

| 15.3 | 53.5 | 7.8 | 6.9 | Tape-woven fabric |

| 21.0 | 60.3 | 9.8 | 6.2 | Triaxial braided hose |

| 23.5 | 65.2 | 10.8 | 6.0 | Tape-woven fabric |

| 39.9 | 97.9 | 21.0 | 4.7 | Triaxial braided hose |

| 39.8 | 95.9 | 20.7 | 4.6 | Tape-woven fabric |

| Lab-Scale Membrane HF Module | Apparent Activation Energy of Permeability, EP, kJ/mol | Reference | |

|---|---|---|---|

| CO2 | CH4 | ||

| Industrial “Graviton” HFs | 14.3 | 27.7 | [40] |

| Laboratory HFs | 12.9 | 25.0 | [40] |

| Triaxial braided hose | 15.8 | 29.3 | Present work |

| Tape-woven fabric | 15.5 | 27.7 | Present work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Markova, S.Y.; Dukhov, A.V.; Pelzer, M.; Shalygin, M.G.; Vad, T.; Gries, T.; Teplyakov, V.V. Designing 3D Membrane Modules for Gas Separation Based on Hollow Fibers from Poly(4-methyl-1-pentene). Membranes 2022, 12, 36. https://doi.org/10.3390/membranes12010036

Markova SY, Dukhov AV, Pelzer M, Shalygin MG, Vad T, Gries T, Teplyakov VV. Designing 3D Membrane Modules for Gas Separation Based on Hollow Fibers from Poly(4-methyl-1-pentene). Membranes. 2022; 12(1):36. https://doi.org/10.3390/membranes12010036

Chicago/Turabian StyleMarkova, Svetlana Yu., Anton V. Dukhov, Martin Pelzer, Maxim G. Shalygin, Thomas Vad, Thomas Gries, and Vladimir V. Teplyakov. 2022. "Designing 3D Membrane Modules for Gas Separation Based on Hollow Fibers from Poly(4-methyl-1-pentene)" Membranes 12, no. 1: 36. https://doi.org/10.3390/membranes12010036

APA StyleMarkova, S. Y., Dukhov, A. V., Pelzer, M., Shalygin, M. G., Vad, T., Gries, T., & Teplyakov, V. V. (2022). Designing 3D Membrane Modules for Gas Separation Based on Hollow Fibers from Poly(4-methyl-1-pentene). Membranes, 12(1), 36. https://doi.org/10.3390/membranes12010036