CO2/N2 Gas Separation Using Pebax/ZIF-7—PSf Composite Membranes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Synthesis of ZIF-7

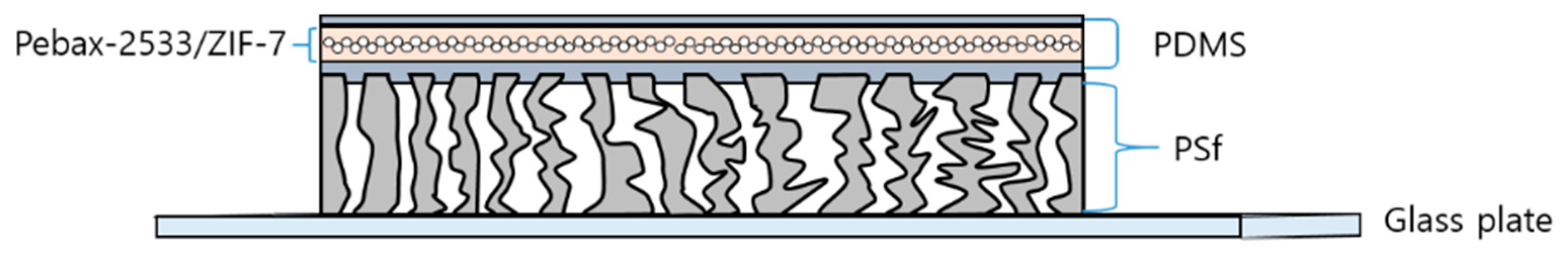

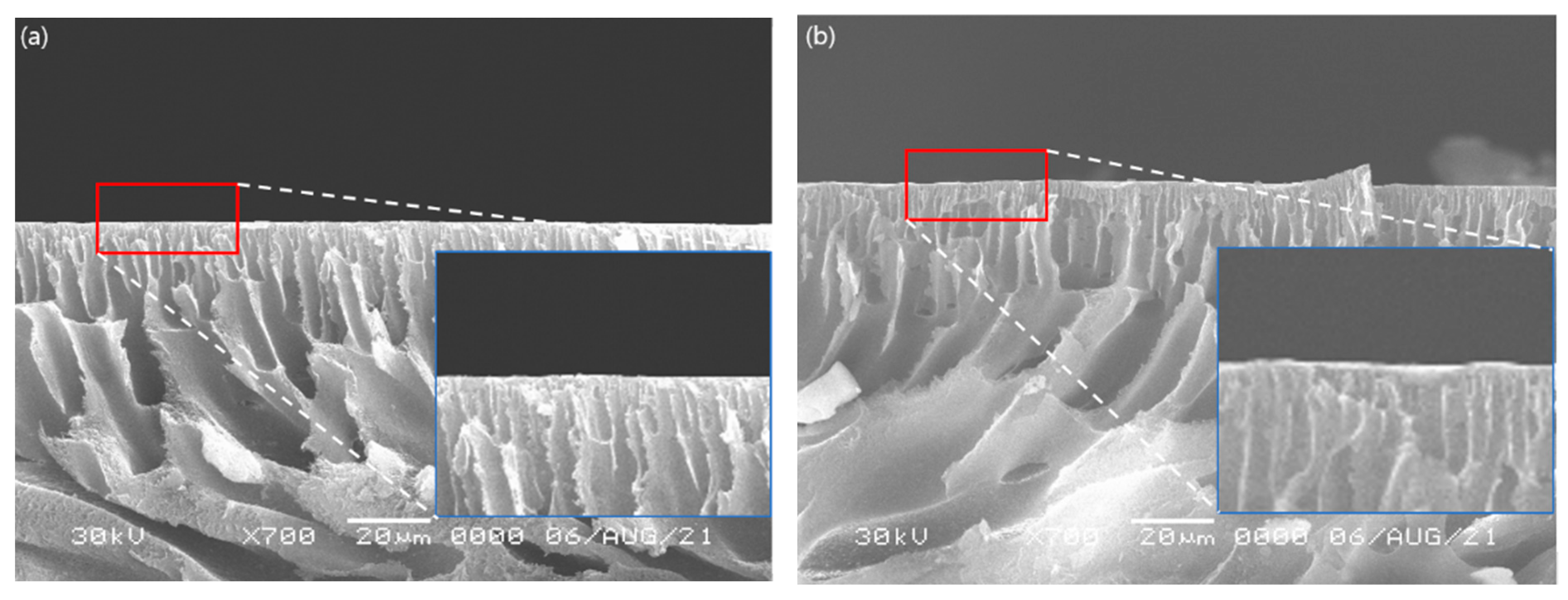

2.3. Fabrication of Composite Membrane

2.4. Analysis Instruments

2.5. Gas Permeation Test

3. Results and Discussion

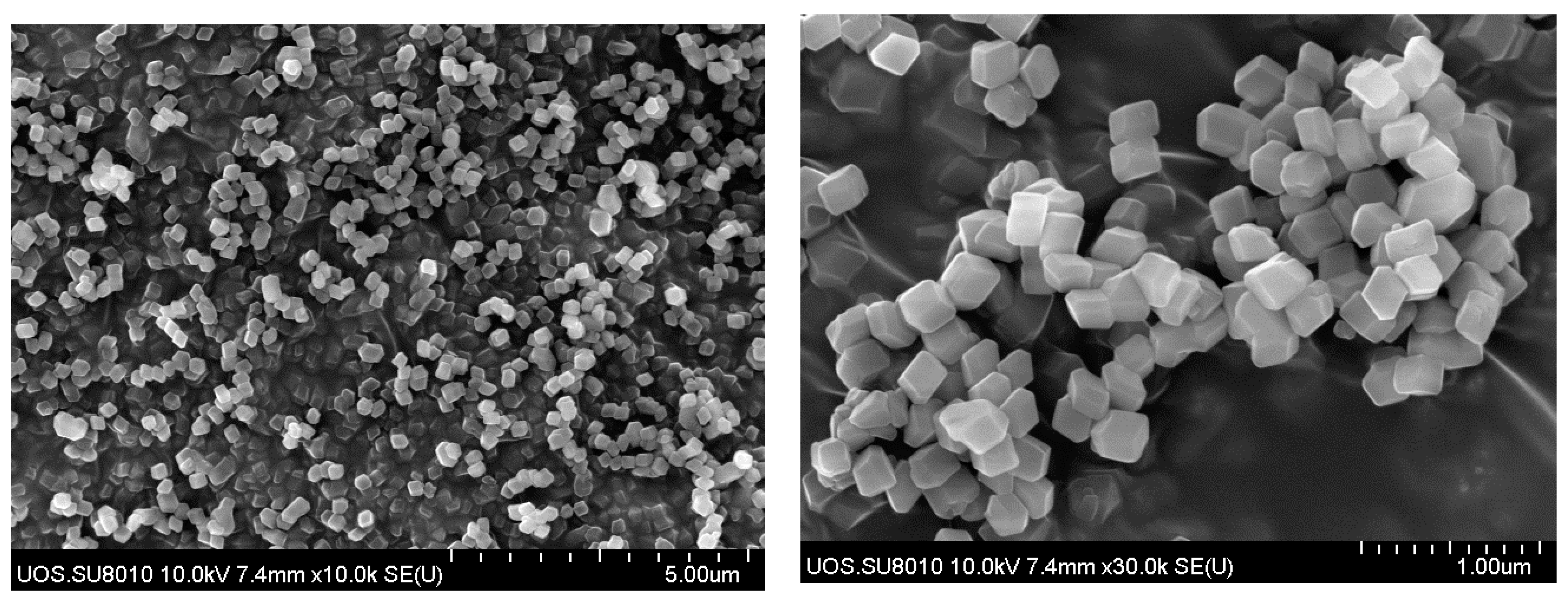

3.1. Properties of ZIF-7 Particles

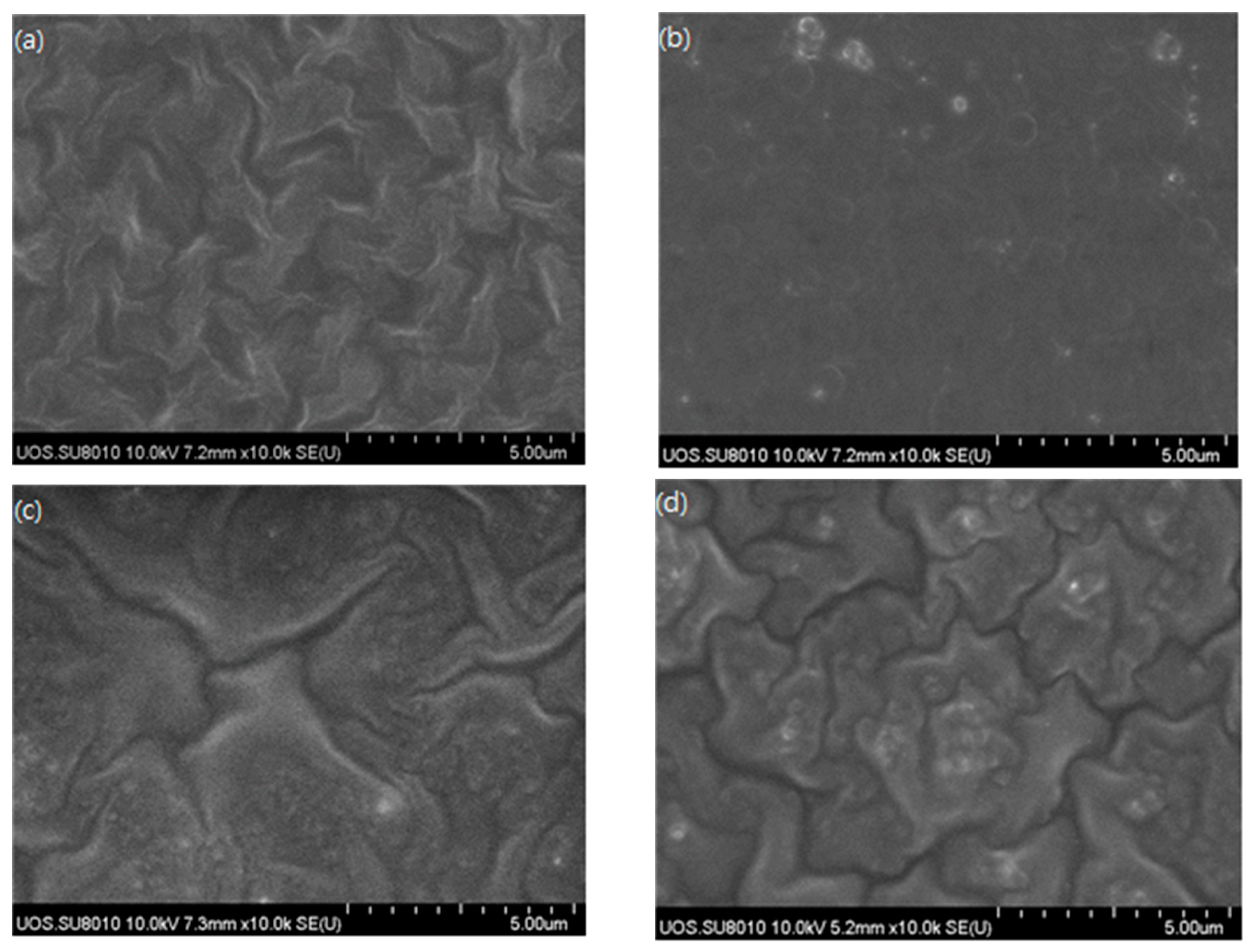

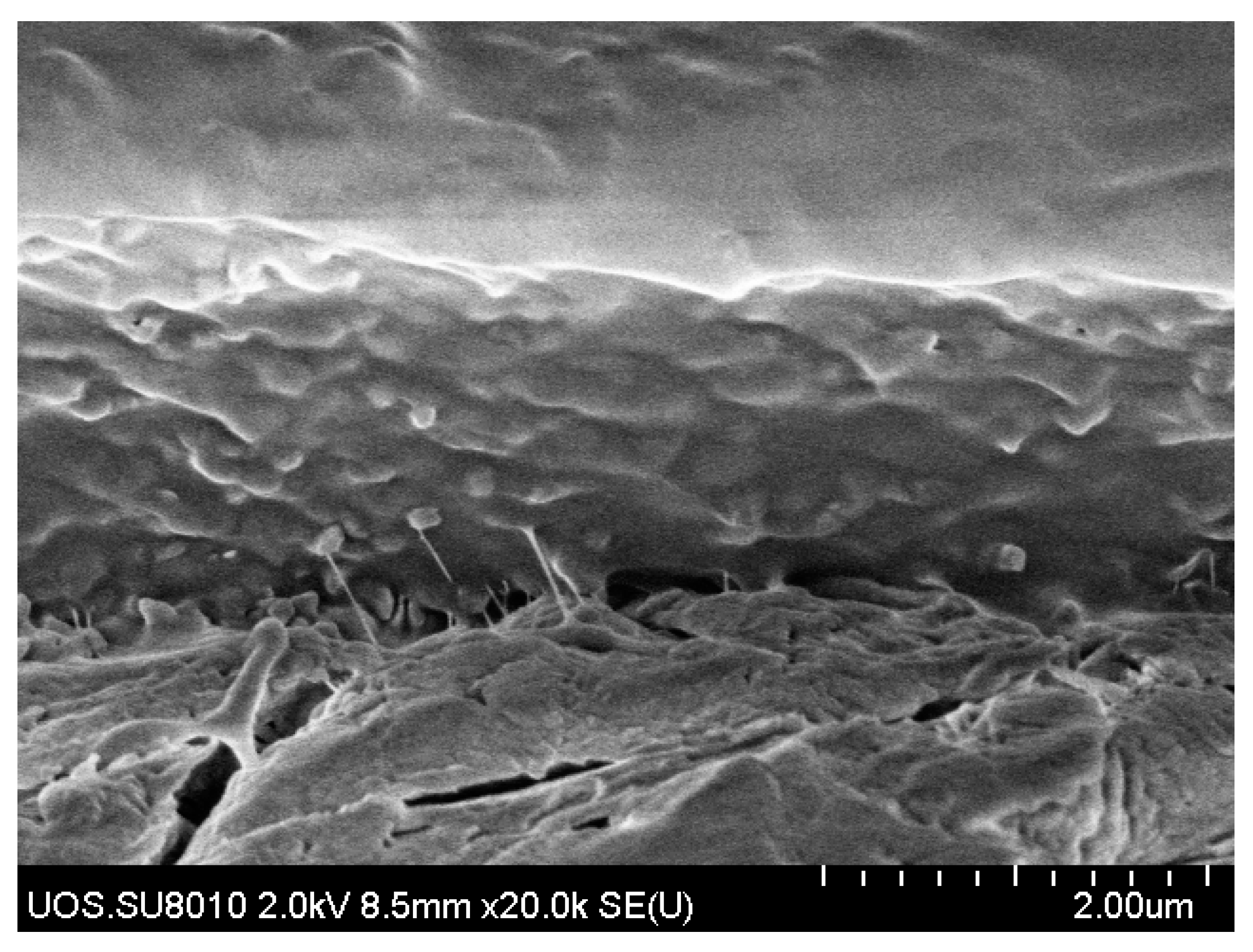

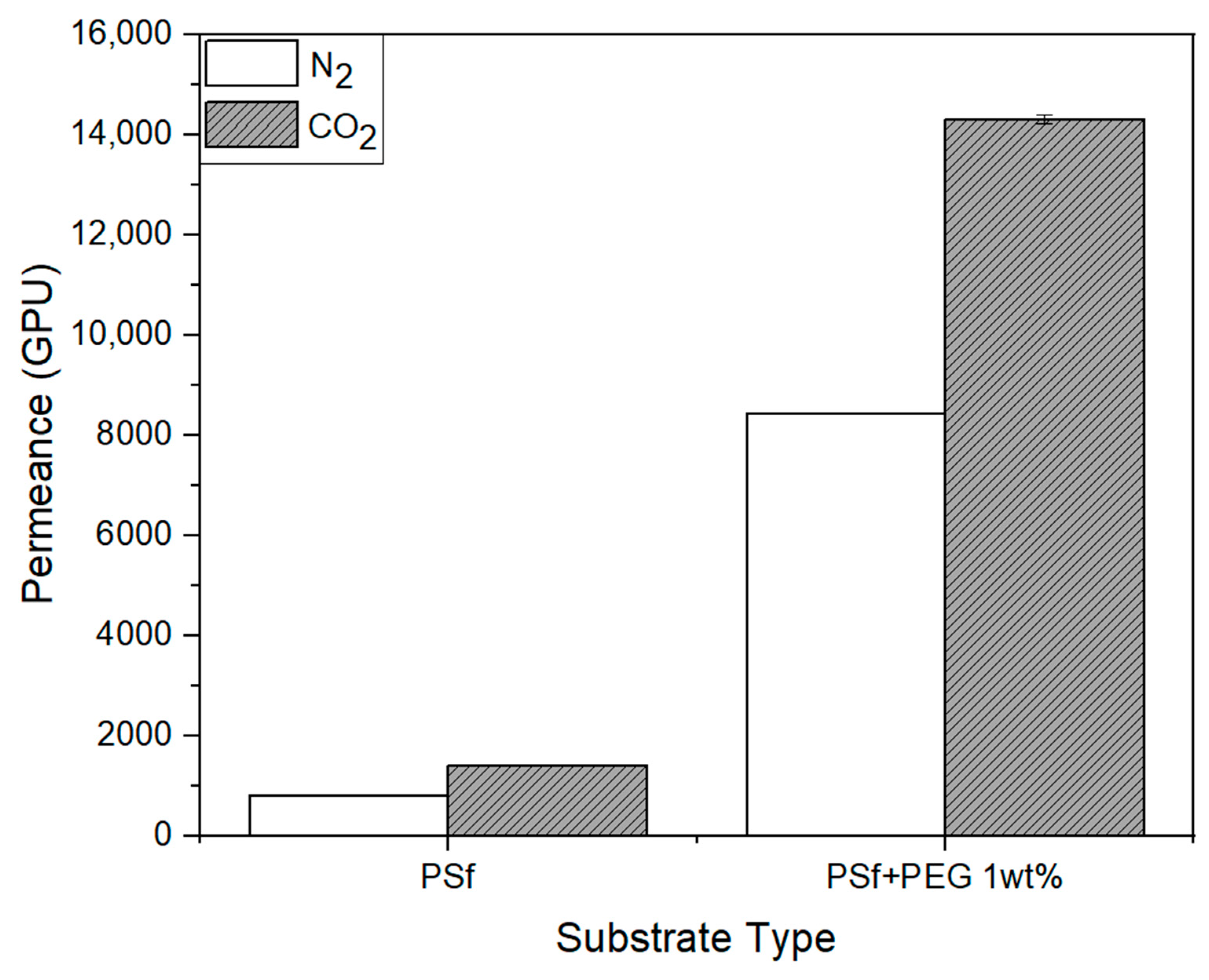

3.2. Properties of Composite Membranes

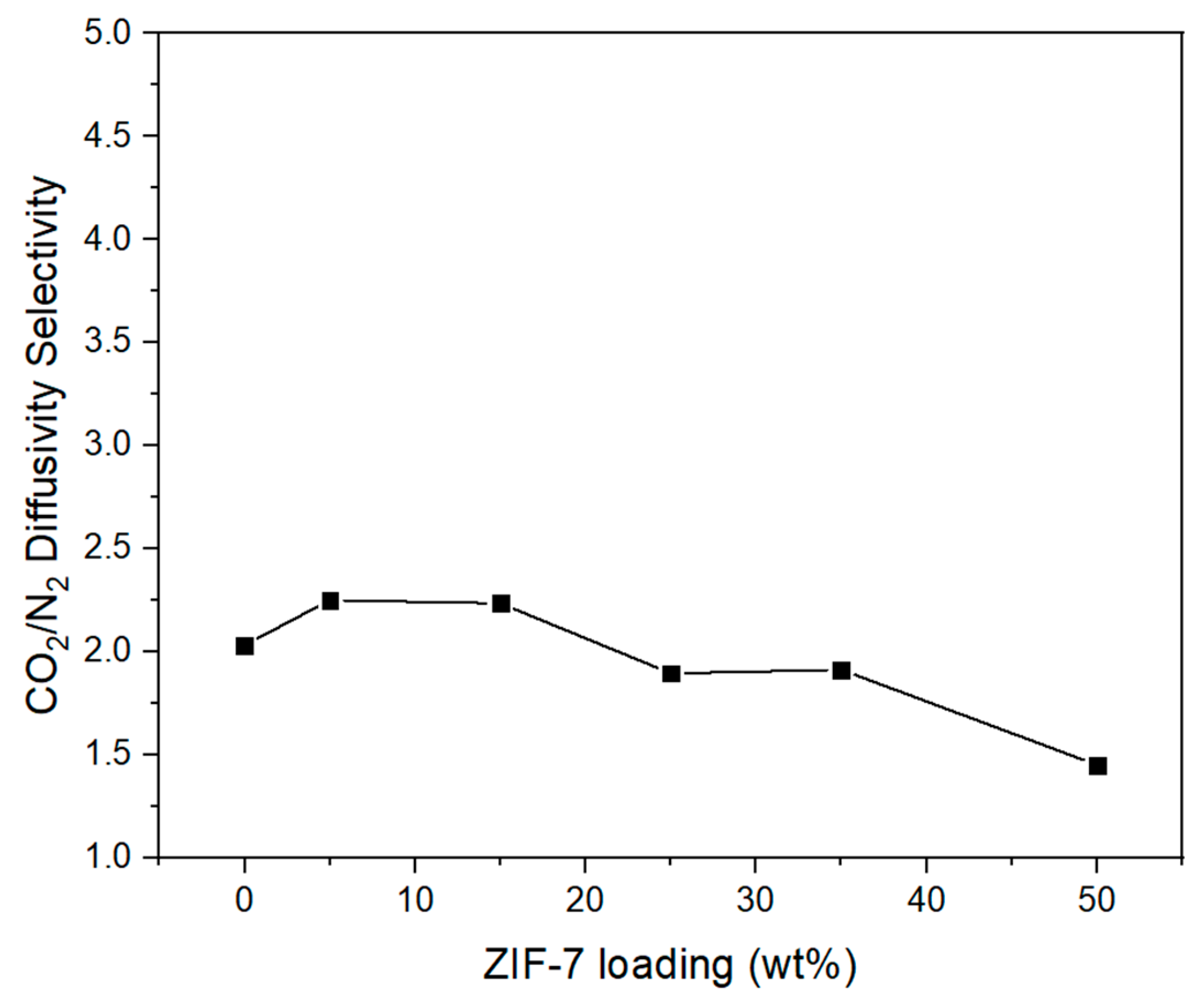

3.3. Gas Permeation Properties of Composite Membranes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Masson-Delmotte, V.; Zhai, P.; Pörtner, H.-O.; Roberts, D.; Skea, J.; Shukla, R.; Pirani, A.; Okia, M.; Péan, C.; Pidcock, R.; et al. Global Warming of 1.5 °C; IPCC: Geneva, Switzerland, 2018. [Google Scholar]

- Shin, J.E.; Han, H.S.; Ha, S.Y.; Park, H.B. The State of the Art of Membrane Technologies for Carbon Dioxide Separation; KIC News: Seoul, Korea, 2018; Volume 21, pp. 2–16. [Google Scholar]

- Ahmadi, M.; Janakiram, S.; Dai, Z.; Ansaloni, L.; Deng, L. Performance of mixed matrix membranes containing porous two-dimensional (2D) and three-dimensional (3D) fillers for CO2 separation: A review. Membranes 2018, 8, 50. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Robeson, L.M. Correlation of separation factor versus permeability for polymeric membranes. J. Membr. Sci. 1991, 62, 165–185. [Google Scholar] [CrossRef]

- Park, H.B.; Kamcev, J.; Robeson, L.M.; Elimelech, M.; Freeman, B.D. Maximizing the right stuff: The trade-off between membrane permeability and selectivity. Science 2017, 356, eaab0530. [Google Scholar] [CrossRef] [Green Version]

- Vinoba, M.; Bhagiyalakshmi, Y.; Alqaheem, Y.; Alomair, A.A.; Pérez, A.; Rana, M.S. Recent progress of fillers in mixed matrix membranes for CO2 separation: A review. Sep. Purif. Technol. 2017, 188, 431–450. [Google Scholar] [CrossRef]

- Dong, G.; Li, H.; Chen, V. Challenges and opportunities for mixed-matrix membranes for gas separation. J. Mater. Chem. A 2013, 1, 4610–4630. [Google Scholar] [CrossRef]

- Liu, M.; Nothling, M.D.; Webley, P.A.; Fu, Q.; Qiao, G.G. Postcombustion carbon capture using thin-film composite membranes. Acc. Chem. Res. 2019, 52, 1905–1914. [Google Scholar] [CrossRef]

- Kattula, M.; Ponnuru, K.; Zhu, L.; Jia, W.; Lin, H.; Furlani, E.P. Designing ultrathin film composite membranes: The impact of a gutter layer. Sci. Rep. 2015, 5, 15016. [Google Scholar] [CrossRef] [Green Version]

- Dai, Z.; Ansaloni, L.; Deng, L. Recent advances in multi-layer composite polymeric membranes for CO2 separation: A review. Green Energy Environ. 2016, 1, 102–128. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Shi, F.; Ma, J.; Wu, M.; Zhang, J.; Gao, C. Effect of PEG additive on the morphology and performance of polysulfone ultrafiltration membranes. Desalination 2011, 272, 51–58. [Google Scholar] [CrossRef]

- Chakrabarty, B.; Ghoshal, A.; Purkait, M. SEM analysis and gas permeability test to characterize polysulfone membrane prepared with polyethylene glycol as additive. J. Colloid Interface Sci. 2008, 320, 245–253. [Google Scholar] [CrossRef]

- Fauzan, N.A.B.; Mannan, H.A.; Nasir, R.; Mohshim, D.F.B.; Mukhtar, H. Various Techniques for Preparation of Thin-Film Composite Mixed-Matrix Membranes for CO2 Separation. Chem. Eng. Technol. 2019, 42, 2608–2620. [Google Scholar] [CrossRef]

- Ma, C.; Wang, M.; Wang, Z.; Gao, M.; Wang, J. Recent progress on thin film composite membranes for CO2 separation. J. CO2 Util. 2020, 42, 101296. [Google Scholar] [CrossRef]

- Shahrak, M.N.; Shahrak, M.N.; Shahsavand, A.; Khazeni, N.; Wu, X.; Deng, S. Synthesis, gas adsorption and reliable pore size estimation of zeolitic imidazolate framework-7 using CO2 and water adsorption. Chin. J. Chem. Eng. 2017, 25, 595–601. [Google Scholar] [CrossRef]

- He, M.; Yao, J.; Li, L.; Wang, K.; Chen, F.; Wang, H. Synthesis of zeolitic imidazolate framework-7 in a water/ethanol mixture and its ethanol-induced reversible phase transition. Chem. Plus. Chem. 2013, 78, 1222–1225. [Google Scholar] [CrossRef] [PubMed]

- Guan, W.; Dai, Y.; Dong, C.; Yang, X.; Xi, Y. Zeolite imidazolate framework (ZIF)-based mixed matrix membranes for CO2 separation: A review. J. Appl. Polym. Sci. 2020, 137, 48968. [Google Scholar] [CrossRef]

- Noguera-Díaz, A.; Villarroel-Rocha, J.; Ting, V.P.; Bimbo, N.; Sapagb, K.; Maysa, T.J. Flexible ZIFs: Probing guest-induced flexibility with CO2, N2 and Ar adsorption. J. Chem. Technol. Biotechnol. 2019, 94, 3787–3792. [Google Scholar] [CrossRef] [Green Version]

- Phan, A.; Doonan, J.; Uribe-Romo, F.J.; Knobler, C.B.; O’keeffe, M.; Yaghi, O.M. Synthesis, structure, and carbon dioxide capture properties of zeolitic imidazolate frameworks. Acc. Chem. Res. 2009, 43, 58–67. [Google Scholar] [CrossRef]

- Zhao, P.; Lampronti, G.I.; Lloyd, G.O.; Wharmby, M.T.; Facq, S.; Cheetham, A.K.; Redfern, S.A. Phase transitions in zeolitic imidazolate framework 7: The importance of framework flexibility and guest-induced instability. Chem. Mater. 2014, 26, 1767–1769. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; Lampronti, G.I.; Lloyd, G.O.; Suard, E.; Redfern, S.A. Direct visualisation of carbon dioxide adsorption in gate-opening zeolitic imidazolate framework ZIF-7. J. Mater. Chem. A 2014, 2, 620–623. [Google Scholar] [CrossRef] [Green Version]

- Arami-Niya, A.; Birkett, G.; Zhu, Z.; Rufford, T.E. Gate opening effect of zeolitic imidazolate framework ZIF-7 for adsorption of CH4 and CO2 from N2. J. Mater. Chem. A 2017, 5, 21389–21399. [Google Scholar] [CrossRef] [Green Version]

- Azizi, N.; Hojjati, M.R. Using Pebax-1074/ZIF-7 mixed matrix membranes for separation of CO2 from CH4. Pet. Sci. Technol. 2018, 36, 993–1000. [Google Scholar] [CrossRef]

- Li, T.; Pan, Y.; Peinemann, K.; Lai, Z. Carbon dioxide selective mixed matrix composite membrane containing ZIF-7 nano-fillers. J. Membr. Sci. 2013, 425, 235–242. [Google Scholar] [CrossRef]

- Chakrabarty, T.; Neelakanda, P.; Peinemann, K. CO2 Selective, Zeolitic Imidazolate Framework-7 Based Polymer Composite Mixed-Matrix Membranes. J. Mater. Sci. Res. 2018, 7, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Gao, J.; Mao, H.; Jin, H.; Chen, C.; Feldhoff, A.; Li, Y. Functionalized ZIF-7/Pebax® 2533 mixed matrix membranes for CO2/N2 separation. Microporous Mesoporous Mater. 2020, 297, 110030. [Google Scholar] [CrossRef]

- Nafisi, V.; Hägg, M. Development of dual layer of ZIF-8/PEBAX-2533 mixed matrix membrane for CO2 capture. J. Membr. Sci. 2014, 459, 244–255. [Google Scholar] [CrossRef]

- Murali, R.S.; Ismail, A.F.; Rahman, M.A.; Sridhar, S. Mixed matrix membranes of Pebax-1657 loaded with 4A zeolite for gaseous separations. Sep. Purif. Technol. 2014, 129, 1–8. [Google Scholar] [CrossRef]

- Zheng, W.; Ding, R.; Yang, K.; Dai, Y.; Yan, X.; He, G. ZIF-8 nanoparticles with tunable size for enhanced CO2 capture of Pebax based MMMs. Sep. Purif. Technol. 2019, 214, 111–119. [Google Scholar] [CrossRef]

- Khoshkharam, A.; Azizi, N.; Behbahani, R.M.; Ghayyem, M.A. Separation of CO2 from CH4 using a synthesized Pebax-1657/ZIF-7 mixed matrix membrane. Pet. Sci. Technol. 2017, 35, 667–673. [Google Scholar] [CrossRef]

- Kim, J.; Park, T.; Chung, E. Effect of 2-MeIM/Zn Molar Ratio on CO2 Permeability of Pebax/ZIF-8 Mixed Matrix Membranes. J. Membr. Sci. Res. 2021, 7, 74–84. [Google Scholar]

- Woo, S.H.; Park, J.; Min, B.R. Relationship between permeate flux and surface roughness of membranes with similar water contact angle values. Sep. Purif. Technol. 2015, 146, 187–191. [Google Scholar] [CrossRef]

- Al-Maythalony, B.A.; Alloush, A.M.; Faizan, M.; Dafallah, H.; Elgzoly, M.A.; Seliman, A.A.; Al-Ahmed, A.; Yamani, Z.H.; Habib, M.A.; Cordova, K.E.; et al. Tuning the interplay between selectivity and permeability of ZIF-7 mixed matrix membranes. ACS Appl. Mater. Interfaces 2017, 9, 33401–33407. [Google Scholar] [CrossRef] [PubMed]

- Yeom, C.K.; Lee, J.M.; Hong, Y.T.; Kim, S.C. Evaluation of Gas Transport Parameters through Dense Polymeric Membranes by Continuous-Flow Technique. Membr. J. 1999, 9, 141–150. [Google Scholar]

- Getie, S.; Belay, A.; Chandra Reddy, A.R.; Belay, Z. Synthesis and characterizations of zinc oxide nanoparticles for antibacterial applications. J. Nanomed. Nanotechnol. 2017, 8. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Mansournia, M. Rapid room temperature synthesis of zeolitic imidazolate framework-7 (ZIF-7) microcrystals. Mater. Lett. 2017, 189, 243–247. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Mansournia, M. Zeolitic imidazolate framework-7: Novel ammonia atmosphere-assisted synthesis, thermal and chemical durability, phase reversibility and potential as highly efficient nanophotocatalyst. Chem. Phys. 2018, 511, 33–45. [Google Scholar] [CrossRef]

- Park, K.S.; Ni, Z.; Côté, A.P.; Choi, J.Y.; Huang, R.; Uribe-Romo, F.J.; Chae, H.K.; O’Keeffe, M.; Yaghi, O.M. Exceptional chemical and thermal stability of zeolitic imidazolate frameworks. Proc. Natl. Acad. Sci. USA 2006, 103, 10186–10191. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.; Shahrak, M.N.; Yuan, B.; Deng, S. Synthesis and characterization of zeolitic imidazolate framework ZIF-7 for CO2 and CH4 separation. Microporous Mesoporous Mater. 2014, 190, 189–196. [Google Scholar] [CrossRef]

- Cuadrado-Collados, C.; Fernández-Català, J.; Fauth, F.; Cheng, Y.Q.; Daemen, L.L.; Ramirez-Cuesta, A.J.; Silvestre-Albero, J. Understanding the breathing phenomena in nano-ZIF-7 upon gas adsorption. J. Mater. Chem. A 2017, 5, 20938–20946. [Google Scholar] [CrossRef] [Green Version]

- Morris, W.; He, N.; Ray, K.G.; Klonowski, P.; Furukawa, H.; Daniels, I.N.; Houndonougbo, Y.A.; Asta, M.; Yaghi, O.M.; Laird, B.B. A combined experimental-computational study on the effect of topology on carbon dioxide adsorption in zeolitic imidazolate frameworks. J. Phys. Chem. C 2012, 116, 24084–24090. [Google Scholar] [CrossRef]

- Lowell, S.; Shields, J.E. Langmuir and BET theories (kinetic isotherms). In Anonymous Powder Surface Area and Porosity; Springer: Dordrecht, The Netherlands, 1991; Volume 2, pp. 14–29. [Google Scholar]

- Guan, P.; Luo, J.; Li, W.; Si, Z. Enhancement of gas permeability for CH4/N2 separation membranes by blending SBS to Pebax polymers. Macromol. Res. 2017, 25, 1007–1014. [Google Scholar] [CrossRef]

- Azizi, N.; Hojjati, M.R.; Zarei, M.M. Study of CO2 and CH4 permeation properties through prepared and characterized blended Pebax-2533/PEG-200 membranes. Silicon 2018, 10, 1461–1467. [Google Scholar] [CrossRef]

- Knozowska, K.; Li, G.; Kujawski, W.; Kujawa, J. Novel heterogeneous membranes for enhanced separation in organic-organic pervaporation. J. Membr. Sci. 2020, 599, 117814. [Google Scholar] [CrossRef]

- Cai, W.; Lee, T.; Lee, M.; Cho, W.; Han, D.Y.; Choi, N.; Choi, J. Thermal structural transitions and carbon dioxide adsorption properties of zeolitic imidazolate framework-7 (ZIF-7). J. Am. Chem. Soc. 2014, 136, 7961–7971. [Google Scholar] [CrossRef] [PubMed]

- Dai, Z.; Bai, L.; Hval, K.N.; Zhang, X.; Zhang, S.; Deng, L. Pebax®/TSIL blend thin film composite membranes for CO2 separation. Sci. China Chem. 2016, 59, 538–546. [Google Scholar] [CrossRef]

- Casadei, R.; Giacinti Baschetti, M.; Yoo, M.J.; Park, H.B.; Giorgini, L. Pebax® 2533/Graphene Oxide Nanocomposite Membranes for Carbon Capture. Membranes 2020, 10, 188. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Alhassan, S.M.; Yang, V.H.; Schiraldi, D.A. Polyether-block-amide copolymer/clay films prepared via a freeze-drying method. Compos. B Eng. 2013, 45, 625–630. [Google Scholar] [CrossRef]

- O’Connor, H.J.; Dowling, D.P. Comparison between the properties of polyamide 12 and glass bead filled polyamide 12 using the multi jet fusion printing process. Addit. Manuf. 2020, 31, 100961. [Google Scholar]

- Xie, K.; Fu, Q.; Qiao, G.G.; Webley, P.A. Recent progress on fabrication methods of polymeric thin film gas separation membranes for CO2 capture. J. Membr. Sci. 2019, 572, 38–60. [Google Scholar] [CrossRef]

- Qian, J.; Wu, T.; Shi, J.; Chang, H.; Liu, D.; Pan, Y. Improved CO2/CH4 separation performance of mixed-matrix membrane by adding ZIF-7-NH2 nanocrystals. J. Appl. Polym. Sci. 2021, 138, 50424. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, Z.; Jiang, J. Metal–organic framework/polymer mixed-matrix membranes for H2/CO2 separation: A fully atomistic simulation study. J. Phys. Chem. C 2012, 116, 19268–19277. [Google Scholar] [CrossRef]

- Pazirofteh, M.; Dehghani, M.; Niazi, S.; Mohammadi, A.H.; Asghari, M. Molecular dynamics simulation and Monte Carlo study of transport and structural properties of PEBA 1657 and 2533 membranes modified by functionalized POSS-PEG material. J. Mol. Liq. 2017, 241, 646–653. [Google Scholar] [CrossRef]

- Caro, J. Diffusion coefficients in nanoporous solids derived from membrane permeation measurements. Adsorption 2021, 27, 283–293. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, T.; Wang, Y.; Li, J.; Liu, C.; Li, N.; Liao, J. Mixed-matrix membranes based on Zn/Ni-ZIF-8-PEBA for high performance CO2 separation. J. Membr. Sci. 2018, 560, 38–46. [Google Scholar] [CrossRef]

- Shafiee, M.; Akbari, A.; Foroutan, R.; Ramavandi, B. The permeability and selectivity of nanocomposite membrane of PEBAx 1657/PEI/SiO2 for separation of CO2, N2, O2, CH4 gases: A data set. Data Brief 2020, 28, 104800. [Google Scholar] [CrossRef] [PubMed]

| Condition | BET Surface Area (m2/g) | Langmuir Surface Area (m2/g) | Reference |

|---|---|---|---|

| N2, 77 K | 303 | 511 | This work |

| 312 | 335 | [39] | |

| 282 | 527 | [15] | |

| 362 | 484 | [24] | |

| 380 | - | [40] | |

| 405 (Simulated) | - | [41] |

| Membranes | Tm (PTMO) [K] | Melting Enthalpy (PTMO) [J/g] | Tm (PA − 12) [K] | Melting Enthalpy (PA − 12) [J/g] | Reference |

|---|---|---|---|---|---|

| Pebax-2533 | 288 | - | 413 | - | [47] |

| 283 | - | 403 | - | [48] | |

| - | 31 | - | 5 | [31] | |

| 288 | 32 | 407 | 6 | This work | |

| Pebax-2533/ZIF-7 5 wt% | 289 | 31 | 405 | 5 | |

| Pebax-2533/ZIF-7 15 wt% | 290 | 26 | 406 | 4 | |

| Pebax-2533/ZIF-7 25 wt% | 291 | 24 | 405 | 6 | |

| Pebax-2533/ZIF-7 35 wt% | 294 | 22 | 408 | 3 | |

| Pebax-2533/ZIF-7 50 wt% | 286 | 13 | 409 | 2 |

| Membranes | Xc(PTMO) [%] | Xc(PA − 12) [%] | Xc [%] |

|---|---|---|---|

| Pebax-2533 | 16 | 3 | 19 |

| Pebax-2533/ZIF-7 5 wt% | 15 | 2 | 18 |

| Pebax-2533/ZIF-7 15 wt% | 13 | 2 | 15 |

| Pebax-2533/ZIF-7 25 wt% | 12 | 3 | 15 |

| Pebax-2533/ZIF-7 35 wt% | 11 | 2 | 13 |

| Pebax-2533/ZIF-7 50 wt% | 6 | 1 | 8 |

| Substrate | N2 Permeance (GPU) | N2 Error | CO2 Permeance (GPU) | CO2 Error | CO2/N2 Ideal Selectivity |

|---|---|---|---|---|---|

| PSf 18 wt% | 800.87 | 2.18 | 1400.88 | 1.74 | 1.74 |

| PSf 18 wt% + PEG 20,000 1 wt% | 8422.11 | 16.73 | 14,300.06 | 1.70 | 1.70 |

| Membranes | Selective Layer (µm) | N2 Permeability (GPU) | N2 Error | CO2 Permeability (GPU) | CO2 Error | CO2/N2 Ideal Selectivity |

|---|---|---|---|---|---|---|

| Pure Pebax-2533 | 1.35 | 2.68 | 0.73 | 18.43 | 1.24 | 6.88 |

| Pebax-2533/ZIF-7 5 wt% | 1.48 | 1.09 | 0.06 | 18.34 | 0.26 | 16.88 |

| Pebax-2533/ZIF-7 15 wt% | 1.42 | 0.53 | 0.07 | 21.48 | 0.03 | 40.68 |

| Pebax-2533/ZIF-7 25 wt% | 1.43 | 0.43 | 0.04 | 21.53 | 0.09 | 50.43 |

| Pebax-2533/ZIF-7 35 wt% | 1.61 | 0.71 | 0.02 | 26.22 | 0.18 | 37.04 |

| Pebax-2533/ZIF-7 50 wt% | 1.86 | 1.57 | 0.04 | 21.07 | 0.13 | 13.40 |

| Membranes | N2 Diffusivity (10−7 cm2/s) | N2 Error | CO2 Diffusivity (10−7 cm2/s) | CO2 Error | CO2/N2 Diffusivity Selectivity |

|---|---|---|---|---|---|

| Pure Pebax-2533 | 96.41 | 24.50 | 196.03 | 10.60 | 2.03 |

| Pebax-2533/ZIF-7 5 wt% | 53.61 | 3.24 | 120.64 | 12.17 | 2.25 |

| Pebax-2533/ZIF-7 15 wt% | 52.78 | 13.89 | 118.00 | 8.22 | 2.24 |

| Pebax-2533/ZIF-7 25 wt% | 64.68 | 5.01 | 122.65 | 6.90 | 1.90 |

| Pebax-2533/ZIF-7 35 wt% | 46.29 | 4.92 | 88.55 | 6.95 | 1.91 |

| Pebax-2533/ZIF-7 50 wt% | 70.53 | 7.94 | 102.37 | 9.22 | 1.45 |

| Membranes | N2 Solubility (10−3 cm3/cm3 atm) | CO2 Solubility (10−3 cm3/cm3 atm) | CO2/N2 Solubility Selectivity |

|---|---|---|---|

| Pure Pebax-2533 | 3.08 | 10.44 | 3.38 |

| Pebax-2533/ZIF-7 5 wt% | 2.19 | 16.45 | 7.50 |

| Pebax-2533/ZIF-7 15 wt% | 1.06 | 19.26 | 18.19 |

| Pebax-2533/ZIF-7 25 wt% | 0.83 | 22.01 | 26.60 |

| Pebax-2533/ZIF-7 35 wt% | 1.63 | 31.51 | 19.36 |

| Pebax-2533/ZIF-7 50 wt% | 2.52 | 23.25 | 9.23 |

| Membranes | CO2 Permeability (Barrer) | CO2/N2 Ideal Selectivity | Reference |

|---|---|---|---|

| Pure Pebax-2533 | 24.83 | 6.88 | This work |

| Pebax-2533/ZIF-7 25 wt% | 30.42 | 50.43 | |

| Pebax-2533/Multiple metal-ion ZIFs 10 wt% | 321 | 42.8 | X. Zhang et al. [56] |

| Pebax-2533/ZIF-7-OH 8 wt% | 249 | 32.5 | J. Gao et al. [26] |

| nZIF-7 5 wt%/PEI | 64.7 | 16.8 | B.A. Al-Maythalony et al. [33] |

| Pebax-1657/PEI | 11.09 | 28.44 | M. Shafiee et al. [57] |

| Pebax-2533/PGO 0.02 wt% | 397.35 | 23.75 | R. Casadei et al. [48] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, S.-S.; Lee, H.-K.; Hong, S.-R. CO2/N2 Gas Separation Using Pebax/ZIF-7—PSf Composite Membranes. Membranes 2021, 11, 708. https://doi.org/10.3390/membranes11090708

Yoon S-S, Lee H-K, Hong S-R. CO2/N2 Gas Separation Using Pebax/ZIF-7—PSf Composite Membranes. Membranes. 2021; 11(9):708. https://doi.org/10.3390/membranes11090708

Chicago/Turabian StyleYoon, Soong-Seok, Hyun-Kyung Lee, and Se-Ryeong Hong. 2021. "CO2/N2 Gas Separation Using Pebax/ZIF-7—PSf Composite Membranes" Membranes 11, no. 9: 708. https://doi.org/10.3390/membranes11090708

APA StyleYoon, S.-S., Lee, H.-K., & Hong, S.-R. (2021). CO2/N2 Gas Separation Using Pebax/ZIF-7—PSf Composite Membranes. Membranes, 11(9), 708. https://doi.org/10.3390/membranes11090708