Polymer Nanocomposite Ultrafiltration Membranes: The Influence of Polymeric Additive, Dispersion Quality and Particle Modification on the Integration of Zinc Oxide Nanoparticles into Polyvinylidene Difluoride Membranes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Nanoparticle Dispersion

2.3. Nanoparticle Surface Modification

2.4. Dynamic Light Scattering for Analysis of Nanoparticle Dispersions

2.5. Hansen Solubility Parameter Evaluation for Nanoparticles

2.6. Stability of the Surface Modification of Nanoparticles

2.7. Thermogravimetric Analysis

2.8. Dope Solution Preparation

2.9. Rheology

2.10. Membrane Casting

2.11. Membrane Performance Evaluation by Crossflow Ultrafiltration

2.12. Total Organic Carbon Analysis

2.13. Scanning Electron Microscopy

2.14. Mechanical Characterization

3. Results and Discussion

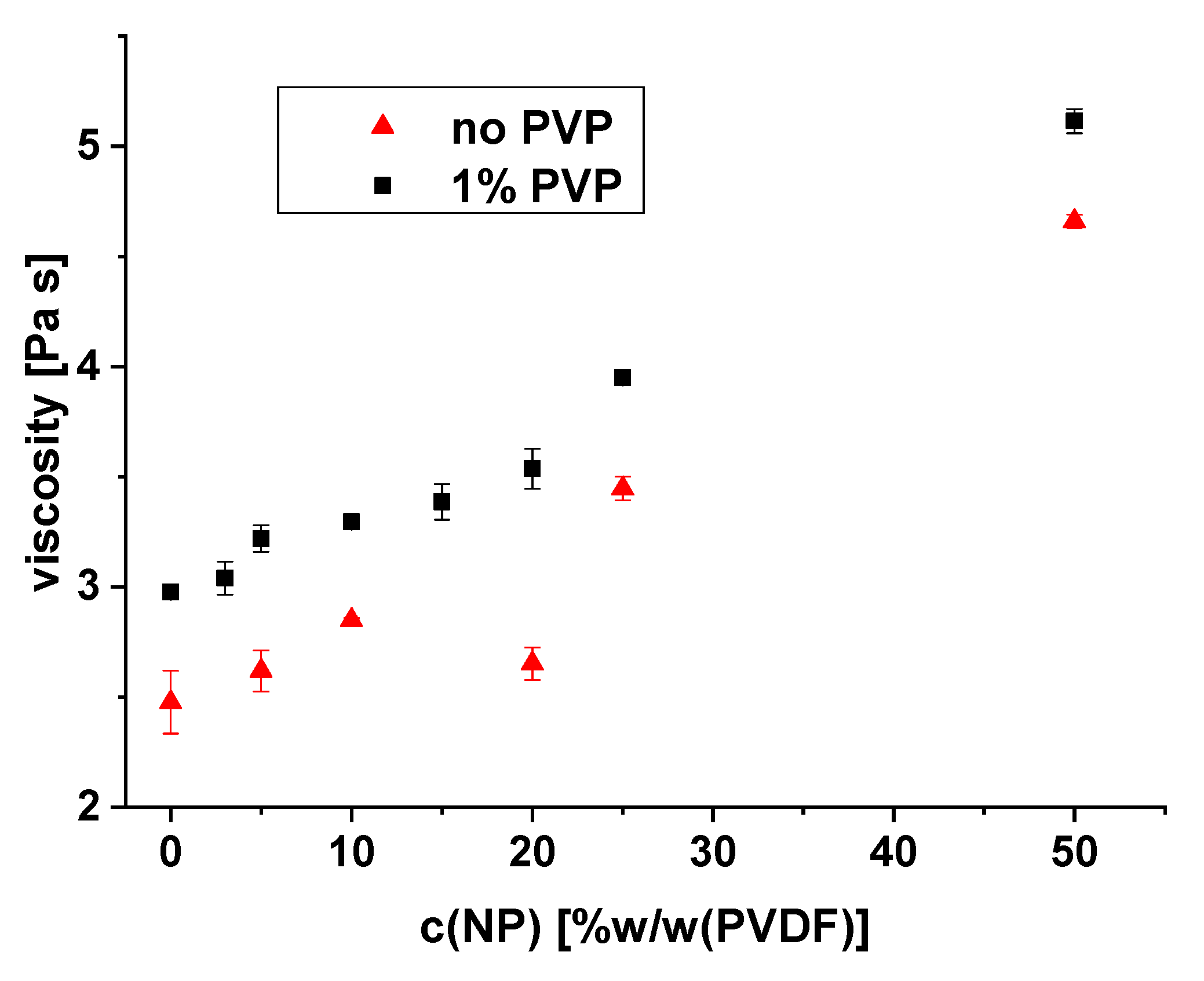

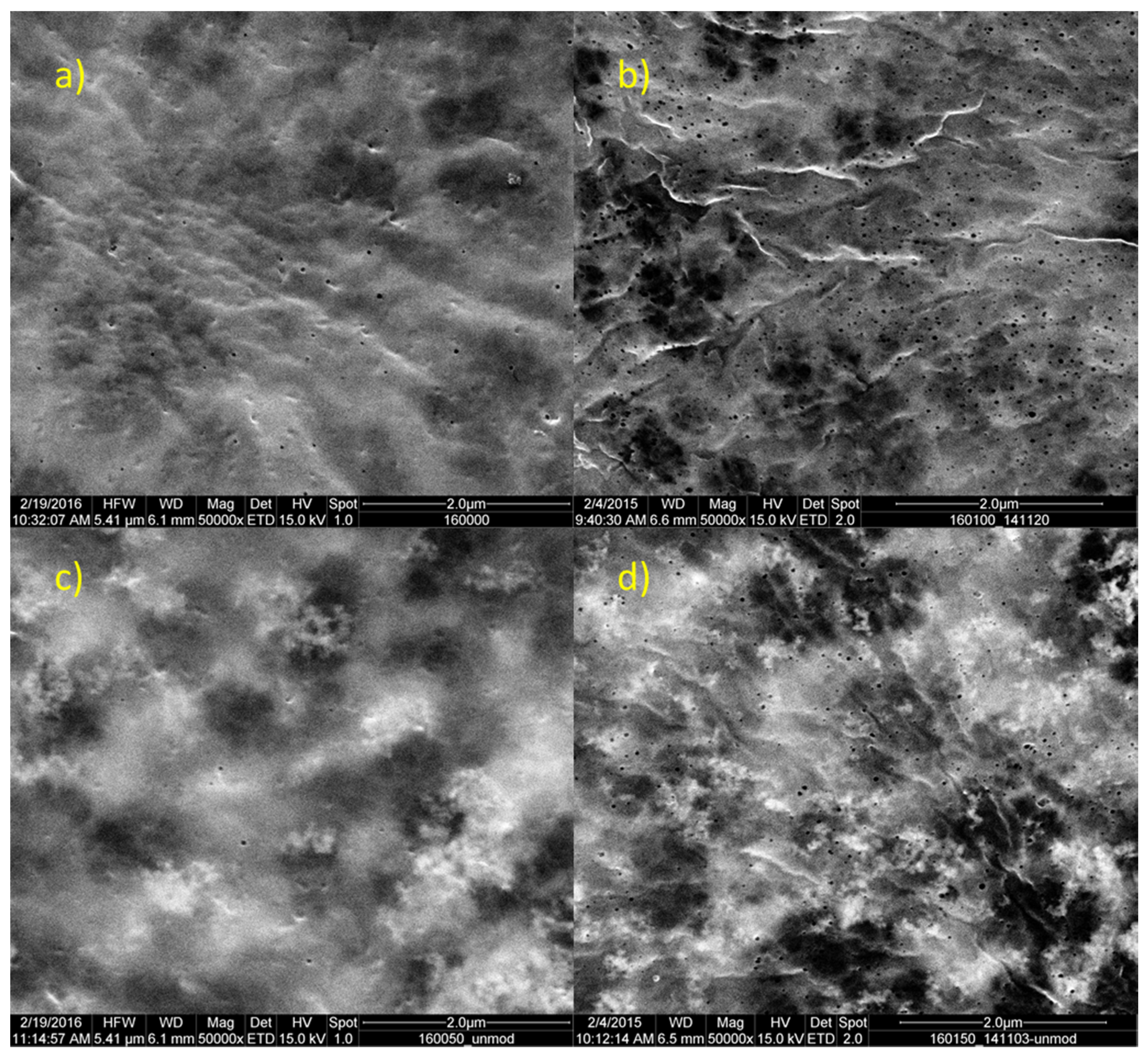

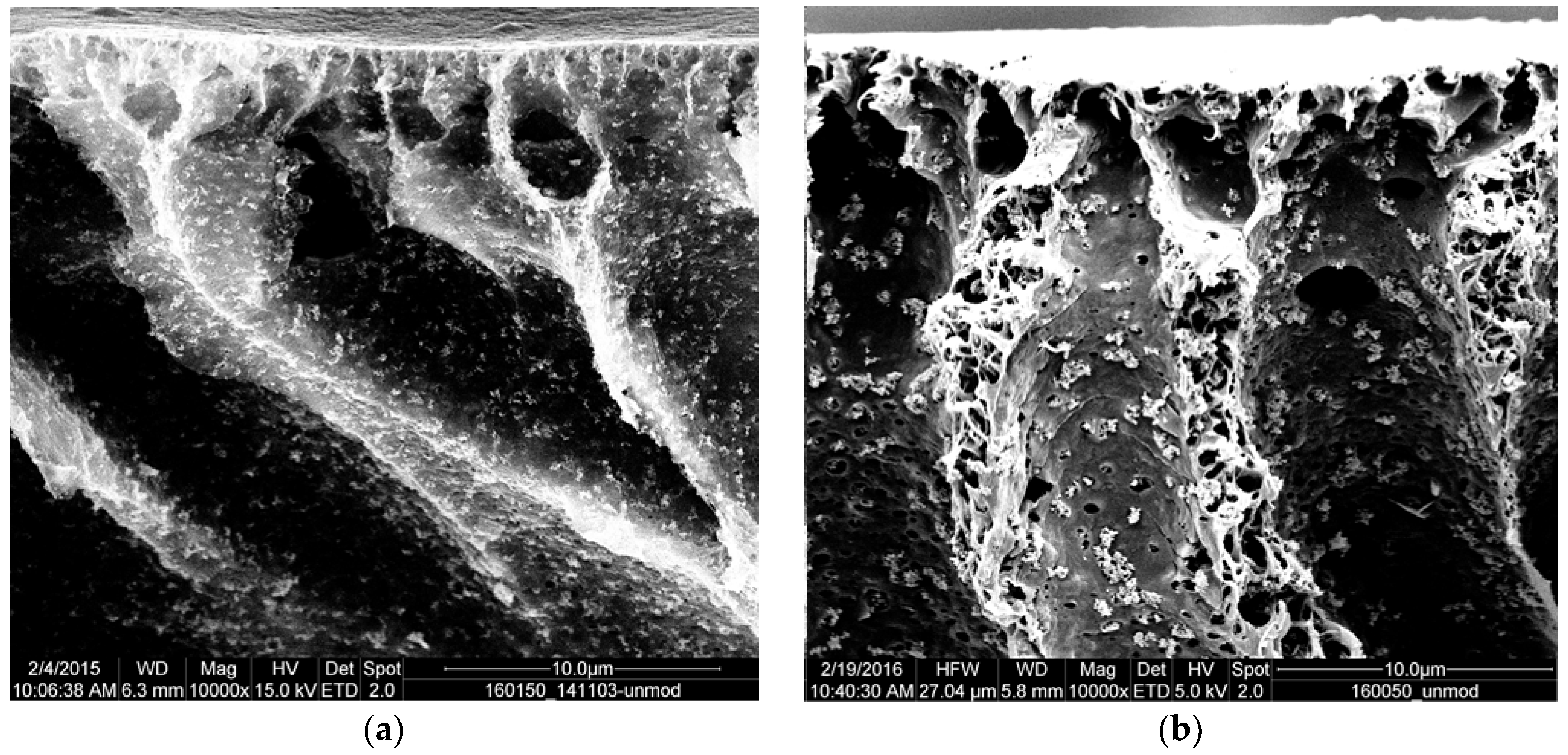

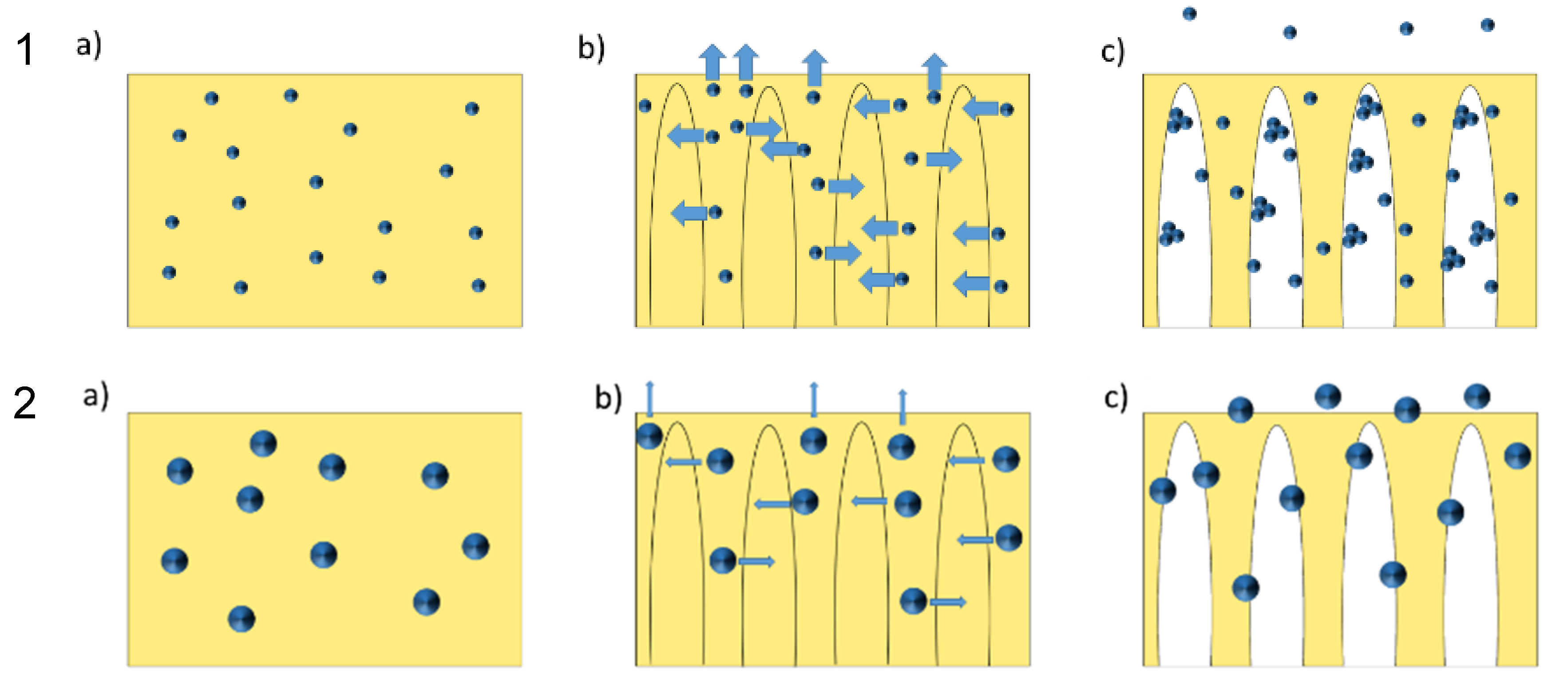

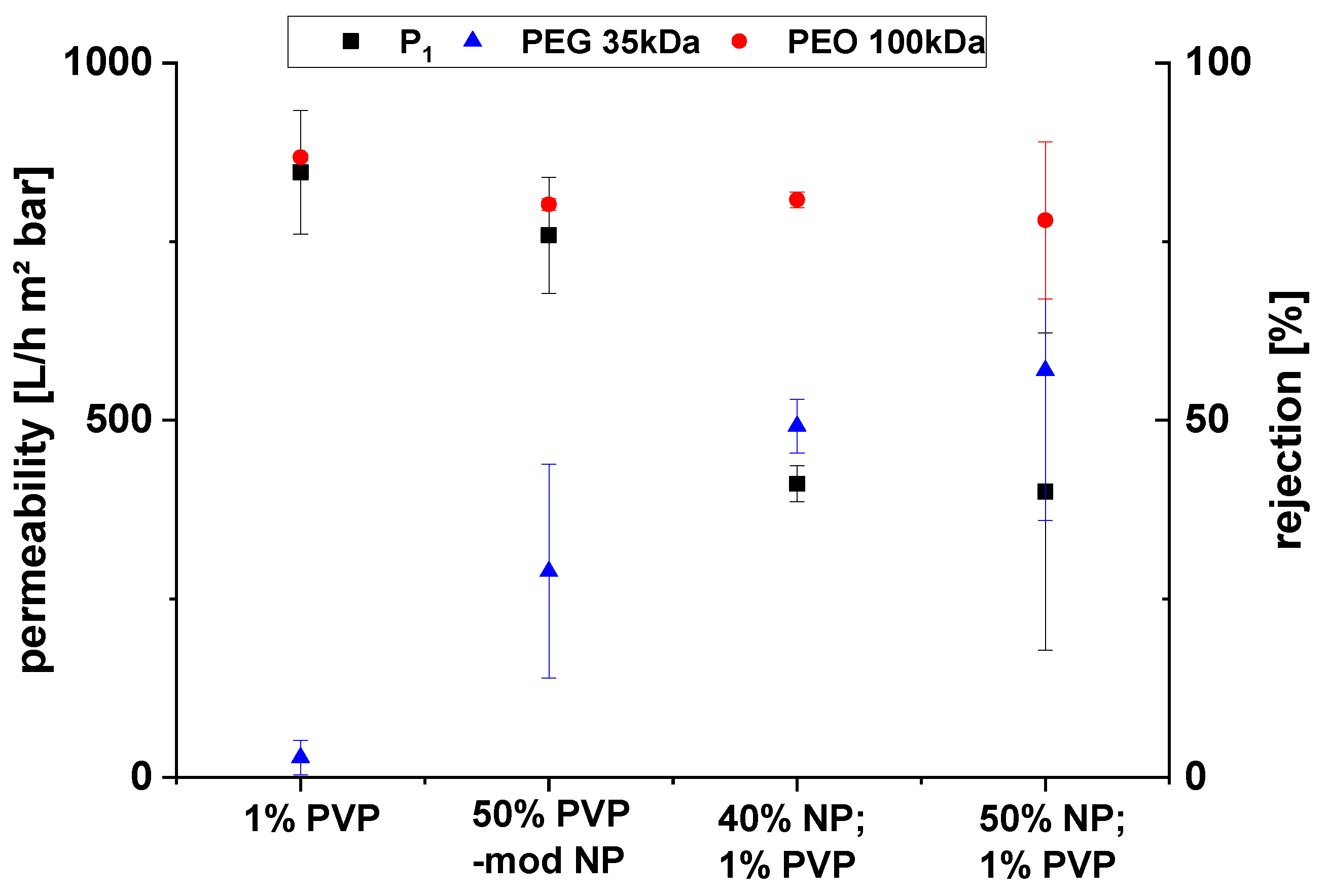

3.1. Influences of the Polymeric Additive Polyvinylpyrrolidone and of the Nanofiller Zinc Oxide

3.2. Influence of Zinc Oxide Nanofiller Dispersion Quality

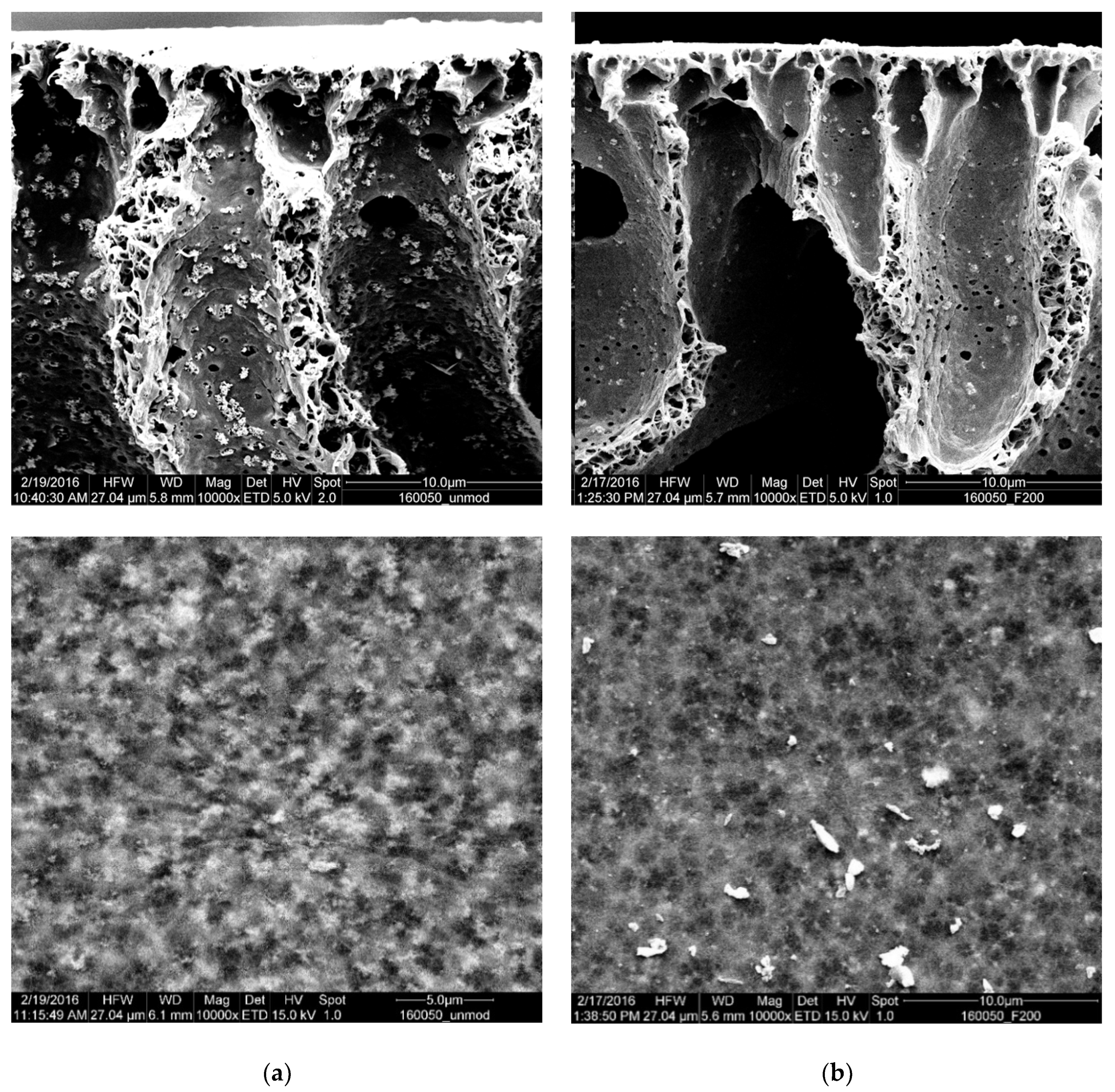

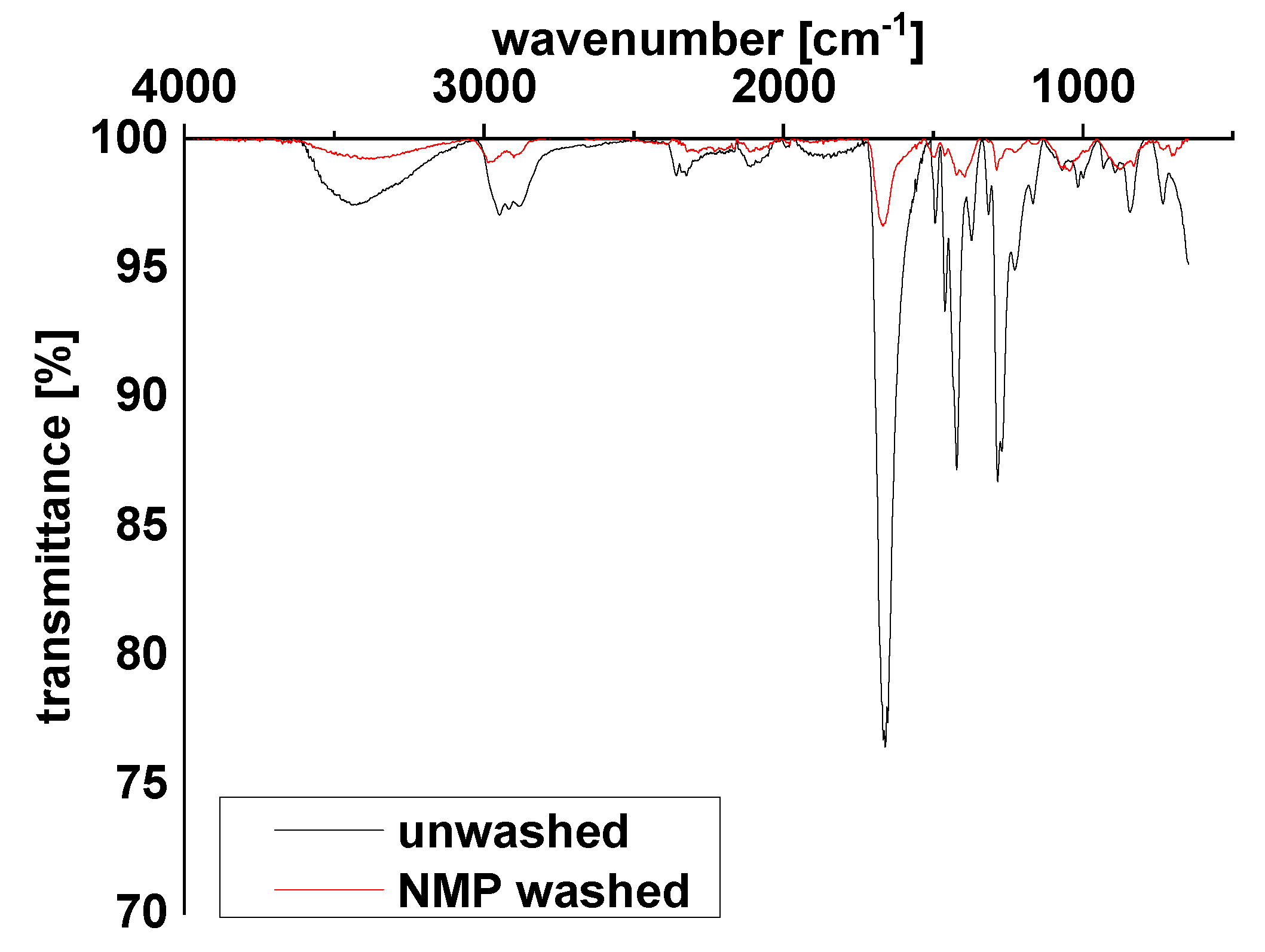

3.3. Influence of Particle Surface Modification

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Ulbricht, M. State of the art and perspectives of organic materials for membrane preparation. Ref. Modul. Chem. Mol. Sci. Chem. Eng. 2017, 1, 85–119. [Google Scholar] [CrossRef]

- Lalia, B.S.; Kochkodan, V.; Hashaikeh, R.; Hilal, N. A Review on Membrane Fabrication: Structure, Properties and Performance Relationship. Desalination 2013, 326, 77–95. [Google Scholar] [CrossRef]

- Guillen, G.R.; Pan, Y.; Li, M.; Hoek, E.M.V. Preparation and Characterization of Membranes Formed by Nonsolvent Induced Phase Separation: A Review. Ind. Eng. Chem. Res. 2011, 50, 3798–3817. [Google Scholar] [CrossRef]

- Liu, F.; Hashim, N.A.; Liu, Y.; Abed, M.R.M.; Li, K. Progress in the Production and Modification of PVDF Membranes. J. Membr. Sci. 2011, 375, 1–27. [Google Scholar] [CrossRef]

- Miller, D.J.; Dreyer, D.R.; Bielawski, C.W.; Paul, D.R.; Freeman, B.D. Surface Modification of Water Purification Membranes. Angew. Chem. Int. Ed. Engl. 2017, 56, 4662–4711. [Google Scholar] [CrossRef] [PubMed]

- Rana, D.; Matsuura, T. Surface Modifications for Antifouling Membranes. Chem. Rev. 2010, 110, 2448–2471. [Google Scholar] [CrossRef]

- Kang, G.; Cao, Y. Application and Modification of Poly(Vinylidene Fluoride) (PVDF) Membranes—A Review. J. Membr. Sci. 2014, 463, 145–165. [Google Scholar] [CrossRef]

- Yin, J.; Deng, B. Polymer-Matrix Nanocomposite Membranes for Water Treatment. J. Membr. Sci. 2015, 479, 256–275. [Google Scholar] [CrossRef]

- Hoek, E.M.V.; Ghosh, A.K.; Huang, X.; Liong, M.; Zink, J.I. Physical-Chemical Properties, Separation Performance, and Fouling Resistance of Mixed-Matrix Ultrafiltration Membranes. Desalination 2011, 283, 89–99. [Google Scholar] [CrossRef]

- Ng, L.Y.; Mohammad, A.W.; Leo, C.P.; Hilal, N. Polymeric Membranes Incorporated with Metal/Metal Oxide Nanoparticles: A Comprehensive Review. Desalination 2013, 308, 15–33. [Google Scholar] [CrossRef]

- Oh, S.J.; Kim, N.; Lee, Y.T. Preparation and Characterization of PVDF/TiO2 Organic-Inorganic Composite Membranes for Fouling Resistance Improvement. J. Membr. Sci. 2009, 345, 13–20. [Google Scholar] [CrossRef]

- Balta, S.; Sotto, A.; Luis, P.; Benea, L.; Van der Bruggen, B.; Kim, J. A New Outlook on Membrane Enhancement with Nanoparticles: The Alternative of ZnO. J. Membr. Sci. 2012, 389, 155–161. [Google Scholar] [CrossRef]

- Yan, L.; Li, Y.S.; Xiang, C.B.; Xianda, S. Effect of Nano-Sized Al2O3 Particle Addition on PVDF Ultrafiltration Membrane Performance. J. Membr. Sci. 2006, 276, 162–167. [Google Scholar] [CrossRef]

- Yu, L.Y.; Shen, H.M.; Xu, Z.L. PVDF-TiO2 Composite Hollow Fiber Ultrafiltration Membranes Prepared by TiO2 Sol-Gel Method and Blending Method. J. Appl. Polym. Sci. 2009, 113, 1763–1772. [Google Scholar] [CrossRef]

- Yari, H.; Pakizeh, M.; Namvar-Mahboub, M. Effect of Silica Nanotubes on Characteristic and Performance of PVDF Nanocomposite Membrane for Nitrate Removal Application. J. Nanopart. Res. 2019, 21, 94. [Google Scholar] [CrossRef]

- Sun, H.; Liu, Y.; Li, D.; Liu, B.; Yao, J. Hydrophobic SiO2 Nanoparticle-Induced Polyvinylidene Fluoride Crystal Phase Inversion to Enhance Permeability of Thin Film Composite Membrane. J. Appl. Polym. Sci. 2019, 136, 1–12. [Google Scholar] [CrossRef]

- Dong, C.; He, G.; Li, H.; Zhao, R.; Han, Y.; Deng, Y. Antifouling Enhancement of Poly(Vinylidene Fluoride) Microfiltration Membrane by Adding Mg(OH)2 Nanoparticles. J. Membr. Sci. 2012, 387–388, 40–47. [Google Scholar] [CrossRef]

- Liu, F.; Abed, M.R.M.; Li, K. Preparation and Characterization of Poly(Vinylidene Fluoride) (PVDF) Based Ultrafiltration Membranes Using Nano γ-Al2O3. J. Membr. Sci. 2011, 366, 97–103. [Google Scholar] [CrossRef]

- Li, J.H.; Yan, B.F.; Shao, X.S.; Wang, S.S.; Tian, H.Y.; Zhang, Q.Q. Influence of Ag/TiO2 Nanoparticle on the Surface Hydrophilicity and Visible-Light Response Activity of Polyvinylidene Fluoride Membrane. Appl. Surf. Sci. 2015, 324, 82–89. [Google Scholar] [CrossRef]

- Moghadam, M.T.; Lesage, G.; Mohammadi, T.; Mericq, J.P.; Mendret, J.; Heran, M.; Faur, C.; Brosillon, S.; Hemmati, M.; Naeimpoor, F. Improved Antifouling Properties of TiO2 /PVDF Nanocomposite Membranes in UV-Coupled Ultrafiltration. J. Appl. Polym. Sci. 2015, 132, 41731. [Google Scholar] [CrossRef]

- Sri Abirami Saraswathi, M.S.; Rana, D.; Divya, K.; Alwarappan, S.; Nagendran, A. Fabrication of Anti-Fouling PVDF Nanocomposite Membranes Using Manganese Dioxide Nanospheres with Tailored Morphology, Hydrophilicity and Permeation. New J. Chem. 2018, 42, 15803–15810. [Google Scholar]

- Cao, X.; Ma, J.; Shi, X.; Ren, Z. Effect of TiO2 Nanoparticle Size on the Performance of PVDF Membrane. Appl. Surf. Sci. 2006, 253, 2003–2010. [Google Scholar] [CrossRef]

- Liang, S.; Xiao, K.; Mo, Y.; Huang, X. A Novel ZnO Nanoparticle Blended Polyvinylidene Fluoride Membrane for Anti-Irreversible Fouling. J. Membr. Sci. 2012, 394–395, 184–192. [Google Scholar] [CrossRef]

- Song, H.; Shao, J.; He, Y.; Liu, B.; Zhong, X. Natural Organic Matter Removal and Flux Decline with PEG-TiO2-Doped PVDF Membranes by Integration of Ultrafiltration with Photocatalysis. J. Membr. Sci. 2012, 405–406, 48–56. [Google Scholar] [CrossRef]

- Yuliwati, E.; Ismail, A.F. Effect of Additives Concentration on the Surface Properties and Performance of PVDF Ultrafiltration Membranes for Refinery Produced Wastewater Treatment. Desalination 2011, 273, 226–234. [Google Scholar] [CrossRef]

- Wei, Y.; Chu, H.Q.; Dong, B.Z.; Li, X.; Xia, S.J.; Qiang, Z.M. Effect of TiO2 Nanowire Addition on PVDF Ultrafiltration Membrane Performance. Desalination 2011, 272, 90–97. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Wang, Q.; Pan, C.; Wu, Z. Comparison of Antifouling Behaviours of Modified PVDF Membranes by TiO2 sols with Different Nanoparticle Size: Implications of Casting Solution Stability. J. Membr. Sci. 2017, 525, 378–386. [Google Scholar]

- Yuliwati, E.; Ismail, A.F.; Matsuura, T.; Kassim, M.A.; Abdullah, M.S. Characterization of Surface-Modified Porous PVDF Hollow Fibers for Refinery Wastewater Treatment Using Microscopic Observation. Desalination 2011, 283, 206–213. [Google Scholar] [CrossRef]

- Koczkur, K.M.; Mourdikoudis, S.; Polavarapu, L.; Skrabalak, S.E. Polyvinylpyrrolidone (PVP) in nanoparticle synthesis. Dalton Trans. 2015, 44, 17883–17905. [Google Scholar] [CrossRef]

- Pattanaik, M.; Bhaumik, S.K. Adsorption behaviour of polyvinyl pyrrolidone on oxide surfaces. Mater. Lett. 2000, 44, 352–360. [Google Scholar] [CrossRef]

- Available online: https://refractiveindex.info/?shelf=main&book=ZnO&page=Bond-e (accessed on 15 August 2020).

- Duan, F.; Kwek, D.; Crivoi, A. Viscosity Affected by Nanoparticle Aggregation in Al2O3-Water Nanofluids. Nanoscale Res. Lett. 2011, 6, 248–252. [Google Scholar] [CrossRef] [PubMed]

- Chakrabarty, B.; Ghoshal, A.K.; Purkait, M.K. Preparation, Characterization and Performance Studies of Polysulfone Membranes Using PVP as an Additive. J. Membr. Sci. 2008, 315, 36–47. [Google Scholar] [CrossRef]

- Wienk, I.M.; Boom, R.M.; Beerlage, M.A.M.; Bulte, A.M.W.; Smolders, C.A.; Strathmann, H. Recent Advances in the Formation of Phase Inversion Membranes Made from Amorphous or Semi-Crystalline Polymers. J. Membr. Sci. 1996, 113, 361–371. [Google Scholar] [CrossRef]

- SDBSWeb, Polyvinylpyrrolidone (SDBS No.: 16268). Available online: http://sdbs.db.aist.go.jp (accessed on 3 March 2020).

- Hesse, M.; Meier, H.; Zeeh, B. Spektroskopische Methoden in Der Organischen Chemie, 7th ed.; Thieme Georg Verlag: Stuttgart, Germany, 2005. [Google Scholar]

- Wieneke, J.U.; Kommoß, B.; Gaer, O.; Prykhodko, I.; Ulbricht, M. Systematic Investigation of Dispersions of Unmodified Inorganic Nanoparticles in Organic Solvents with Focus on the Hansen Solubility Parameters. Ind. Eng. Chem. Res. 2012, 51, 327–334. [Google Scholar] [CrossRef]

- Hansen, C.M. Hansen Solubility Parameters A User’s Handbook, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Wu, G.; Gan, S.; Cui, L.; Xu, Y. Preparation and Characterization of PES/TiO2 Composite Membranes. Appl. Surf. Sci. 2008, 254, 7080–7086. [Google Scholar] [CrossRef]

- Jordan, J.; Jacob, K.I.; Tannenbaum, R.; Sharaf, M.A.; Jasiuk, I. Experimental Trends in Polymer Nanocomposites—A Review. Mater. Sci. Eng. A 2005, 393, 1–11. [Google Scholar] [CrossRef]

| Rating | Criteria |

|---|---|

| 1 | dH ≤ 120 nm and stable over at least 3 days |

| 2 | dH > 120 nm or size unstable |

| 3 | dH > 120 nm and size unstable |

| 4 | size steadily increasing |

| 6 | unstable |

| c(PVP) | c(NP) | Water Permeability | Solute Rejection [%] | n | ||||

|---|---|---|---|---|---|---|---|---|

| [%w] | [%w/w(PVDF)] | [L/h m² bar] | SD | PEG 35 kDa | SD | PEO 100 kDa | SD | |

| 0 | 0 | 31 | 4 | 65 | 17 | 78 | 7 | 4 |

| 0 | 50 | 23 | 1 | 76 | 13 | 85 | 3 | 2 |

| 1 | 0 | 847 | 87 | 3 | 2 | 87 | 0 | 3 |

| 1 | 50 | 400 | 222 | 57 | 21 | 78 | 11 | 3 |

| Type | Water Permeability | Solute Rejection [%] | N | ||||

|---|---|---|---|---|---|---|---|

| [L/h m² bar] | SD | PEG 35 kDa | SD | PEO 100 kDa | SD | ||

| agglomerated | 21 | 0 | 64 | 5 | 70 | 2 | 2 |

| reference | 23 | 1 | 76 | 13 | 85 | 3 | 2 |

| Solvent | Pristine ZnO | PVP Modified ZnO |

|---|---|---|

| Rating | Rating | |

| acetone | 6 | 6 |

| acetonitrile | 6 | 6 |

| 2-butanol | 2 | 2 |

| chloroform | 6 | 3 |

| dimethylacetamide | 2 | 2 |

| dimethylformamide | 1 | 2 |

| dimethyl sulfoxide | 6 | 2 |

| 1,4-dioxane | 3 | 6 |

| ethanol | 1 | 4 |

| ethyl acetate | 2 | 6 |

| n-hexane | 6 | 6 |

| methanol | 1 | 2 |

| methyl ethyl ketone | 4 | 6 |

| N-methylpyrrolidone | 6 | 1 |

| dichloromethane | 6 | 3 |

| tetrahydrofuran | 2 | 6 |

| p-xylene | 6 | 6 |

| Material | δD | δP | δH | δTot | Ro | fit |

|---|---|---|---|---|---|---|

| [MPa1/2] | [MPa1/2] | [MPa1/2] | [MPa1/2] | [–] | [–] | |

| ZnO | 15.8 | 7.9 | 16.8 | 24.4 | 10.0 | 1.00 |

| ZnO PVP-mod | 19.4 | 14.3 | 16.4 | 29.2 | 11.3 | 0.83 |

| PVP [38] | 21.4 | 11.6 | 21.6 | 32.5 | 17.3 | - |

| PVDF [38] | 17.0 | 12.0 | 10.2 | 23.2 | 4.1 | - |

| NP Type | c(NP) in Dope | Tensile Strength | SD | Elongation at Break | SD | E Modulus | SD |

|---|---|---|---|---|---|---|---|

| [% w/w (base Polymer)] | [N] | [%] | [N/mm²] | ||||

| None | 0 | 3.66 | 0.7 | 43.0 | 10.5 | 1.03 | 0.27 |

| Pristine | 50 | 4.45 | 0.3 | 39.4 | 6.5 | 1.75 | 0.14 |

| PVP modified | 50 | 4.12 | 0.4 | 63.5 | 26.8 | 1.01 | 0.13 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

van den Berg, T.; Ulbricht, M. Polymer Nanocomposite Ultrafiltration Membranes: The Influence of Polymeric Additive, Dispersion Quality and Particle Modification on the Integration of Zinc Oxide Nanoparticles into Polyvinylidene Difluoride Membranes. Membranes 2020, 10, 197. https://doi.org/10.3390/membranes10090197

van den Berg T, Ulbricht M. Polymer Nanocomposite Ultrafiltration Membranes: The Influence of Polymeric Additive, Dispersion Quality and Particle Modification on the Integration of Zinc Oxide Nanoparticles into Polyvinylidene Difluoride Membranes. Membranes. 2020; 10(9):197. https://doi.org/10.3390/membranes10090197

Chicago/Turabian Stylevan den Berg, Thorsten, and Mathias Ulbricht. 2020. "Polymer Nanocomposite Ultrafiltration Membranes: The Influence of Polymeric Additive, Dispersion Quality and Particle Modification on the Integration of Zinc Oxide Nanoparticles into Polyvinylidene Difluoride Membranes" Membranes 10, no. 9: 197. https://doi.org/10.3390/membranes10090197

APA Stylevan den Berg, T., & Ulbricht, M. (2020). Polymer Nanocomposite Ultrafiltration Membranes: The Influence of Polymeric Additive, Dispersion Quality and Particle Modification on the Integration of Zinc Oxide Nanoparticles into Polyvinylidene Difluoride Membranes. Membranes, 10(9), 197. https://doi.org/10.3390/membranes10090197