Fluid-Structure Interaction Analysis on Membrane Behavior of a Microfluidic Passive Valve

Abstract

:1. Introduction

2. Numerical Methods

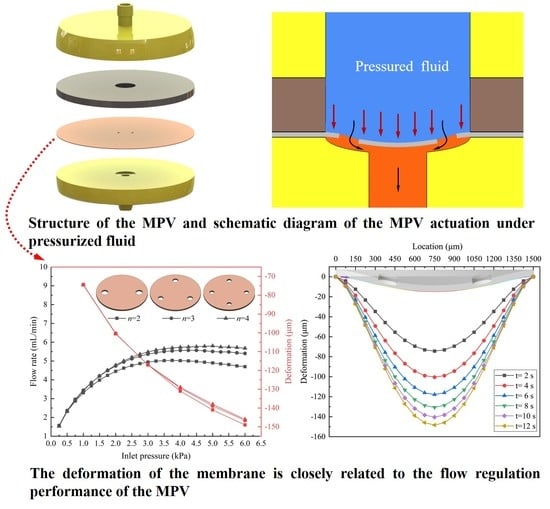

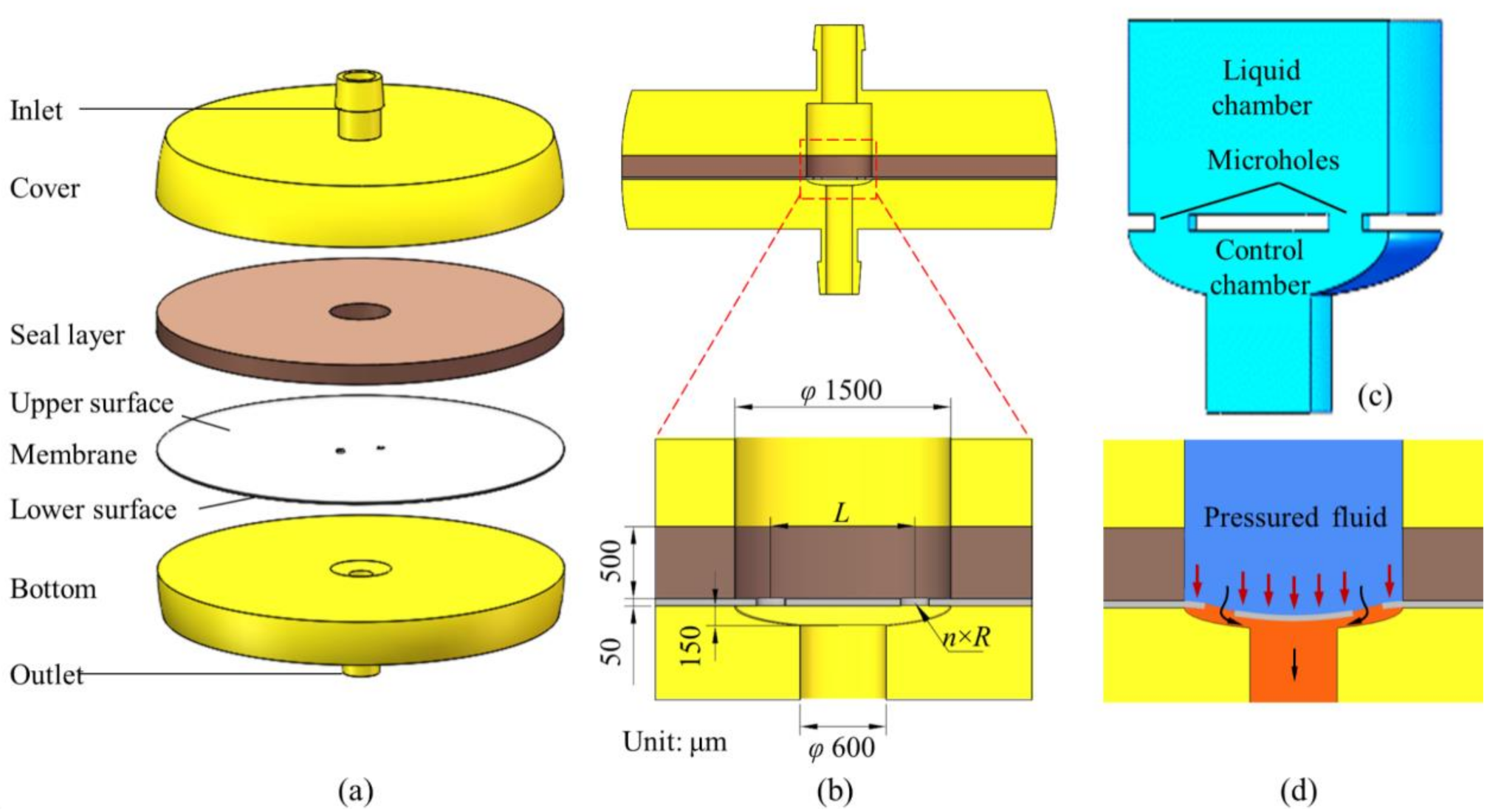

2.1. Microvalve Model

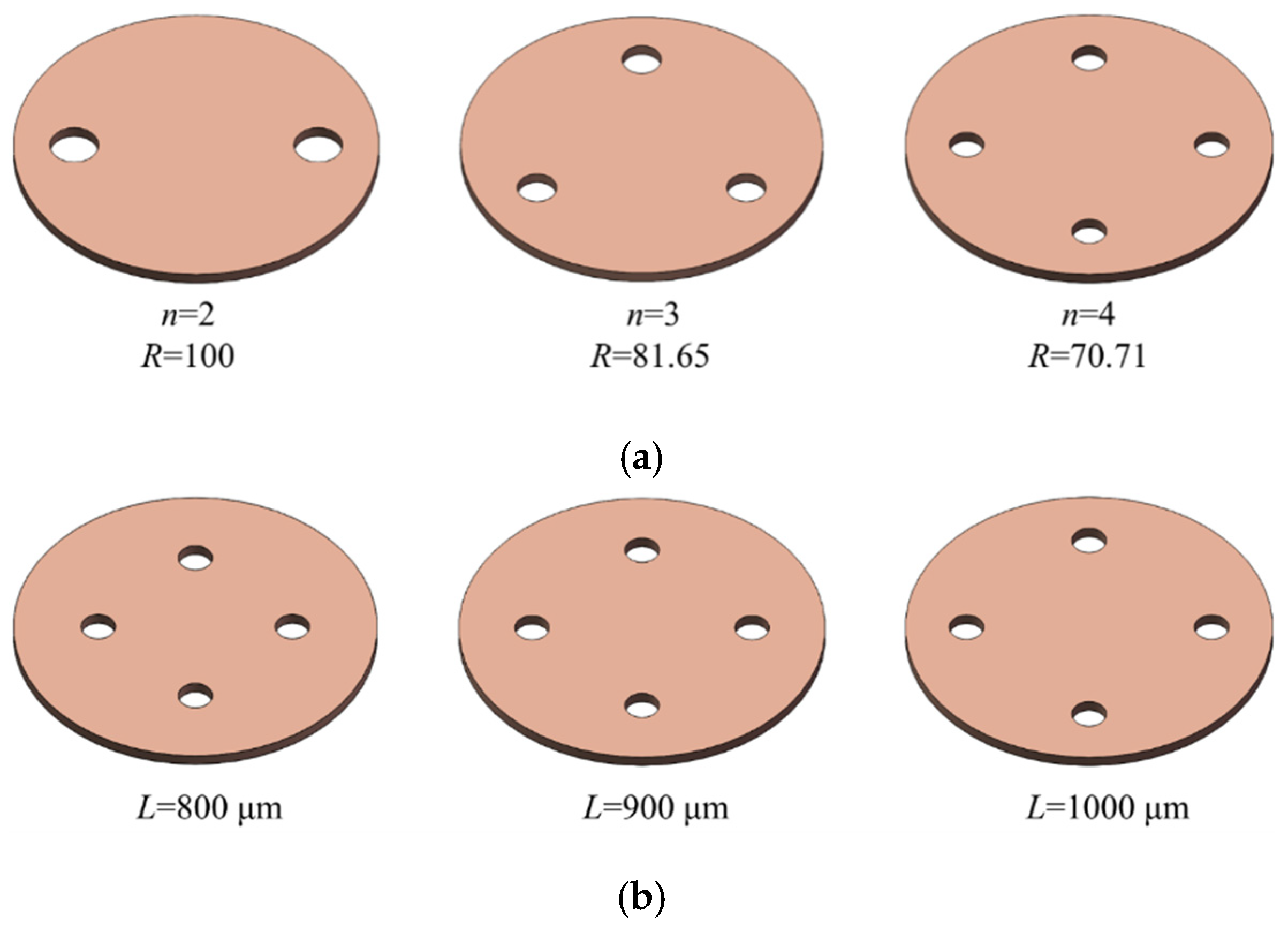

2.2. Mathematical Model in FSI

2.2.1. Fluid Formulation

2.2.2. Solid Formulation

2.2.3. FSI Interface Conditions

2.2.4. Moving Mesh

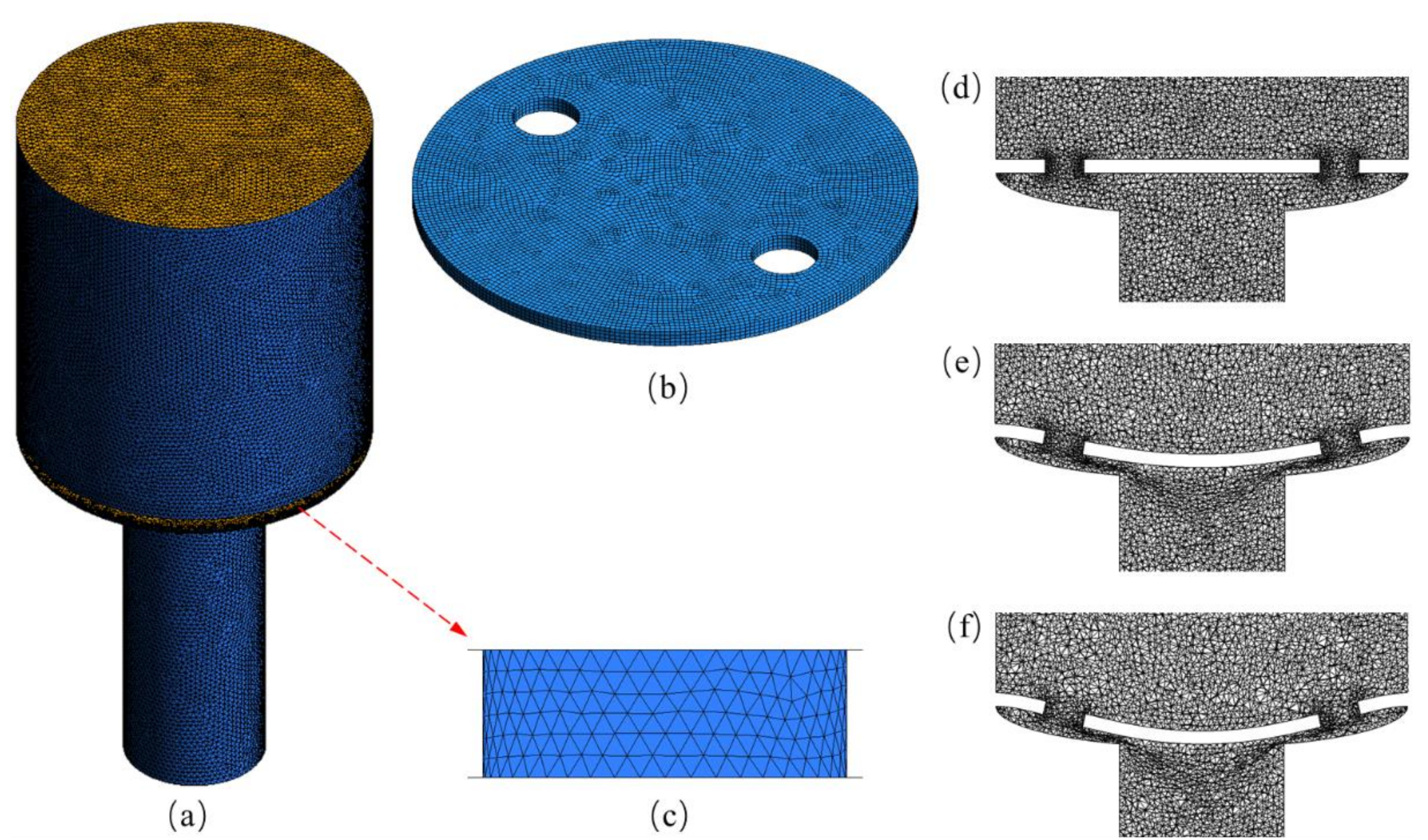

2.3. Mesh and Boundary Conditions

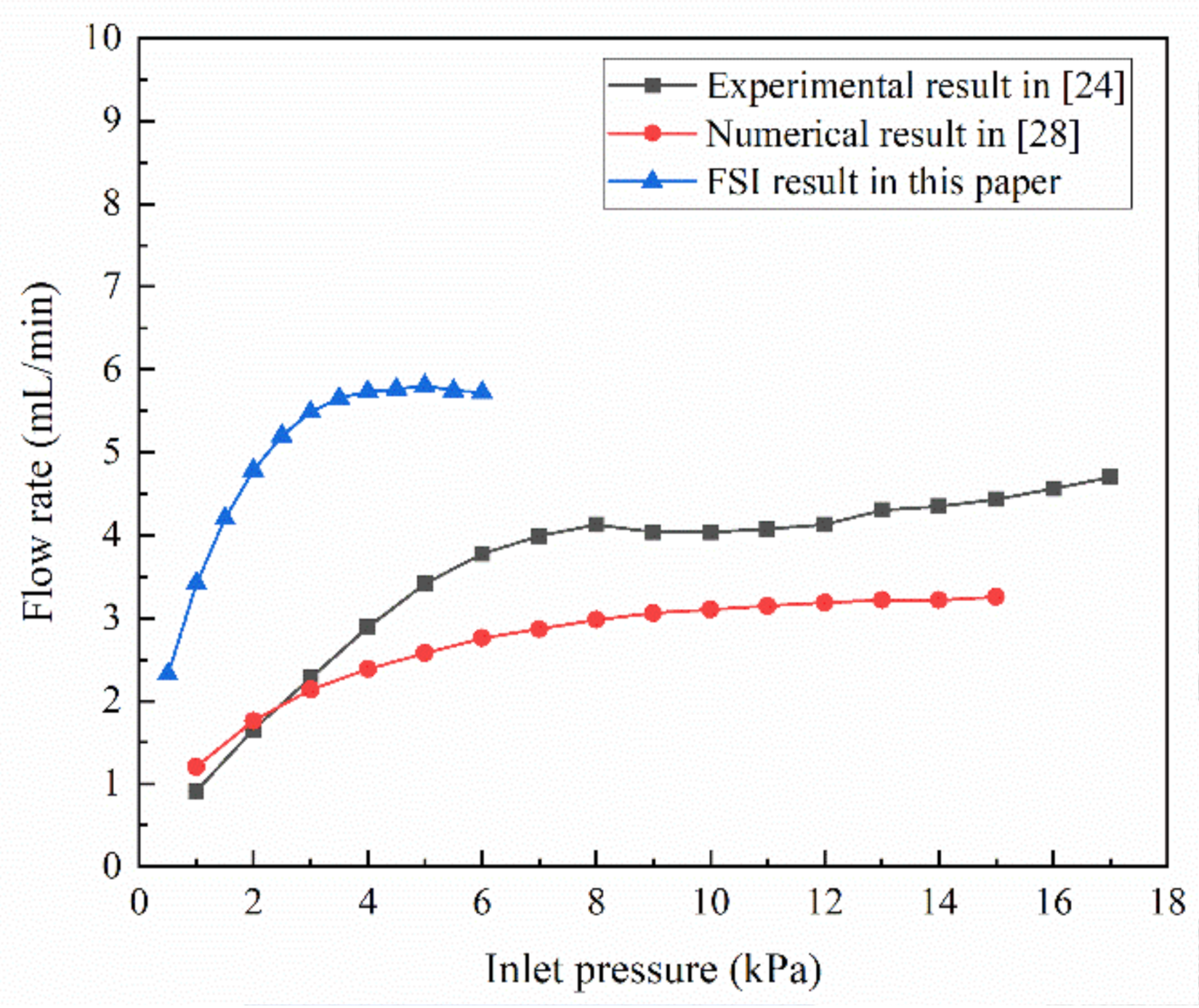

2.4. Numerical Method Validation

3. Results and Discussion

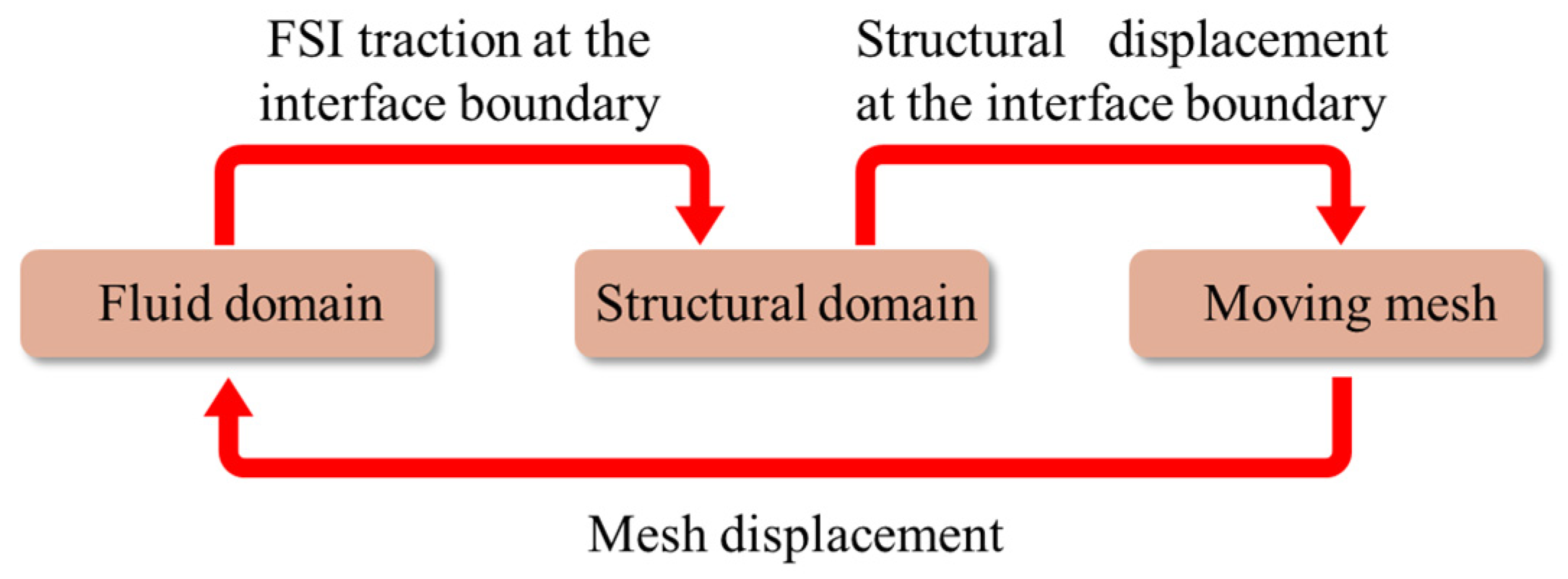

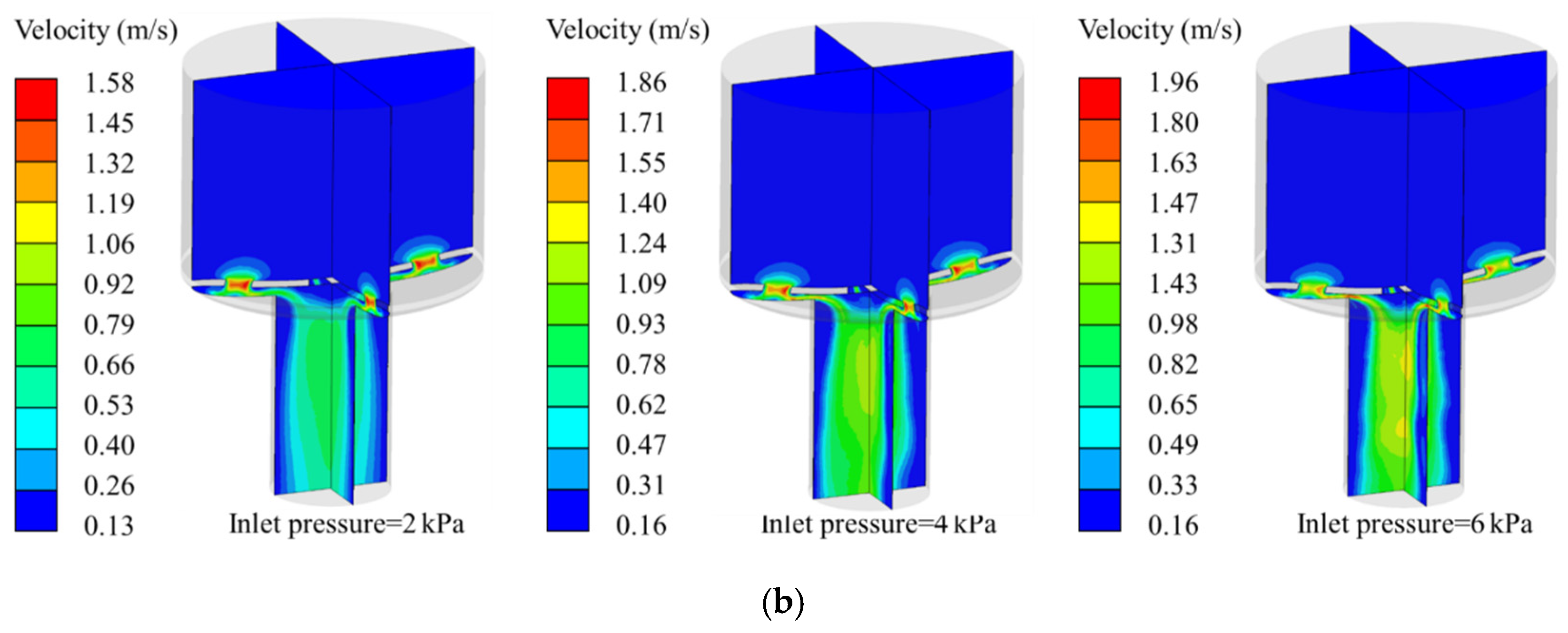

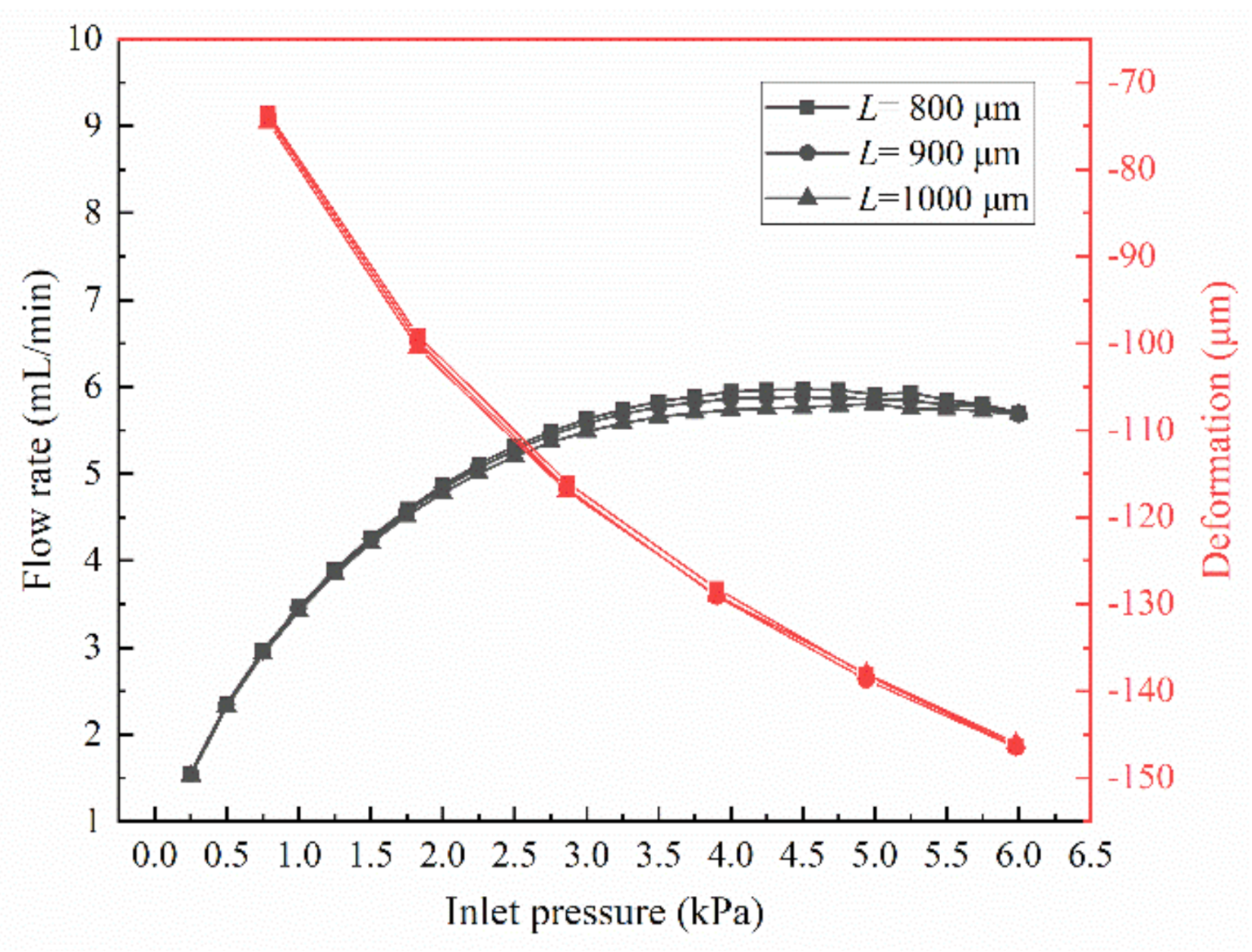

3.1. Flow Characteristics

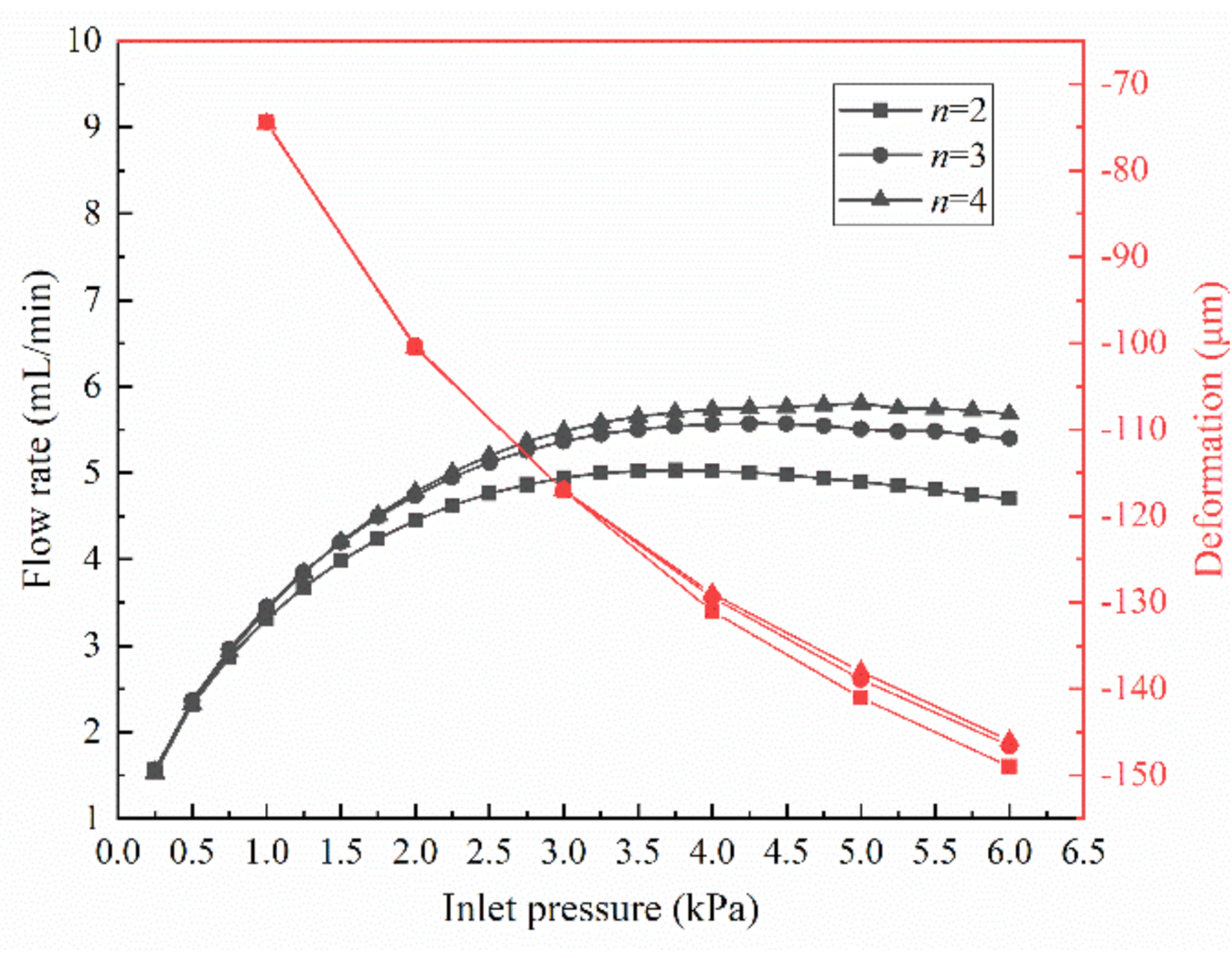

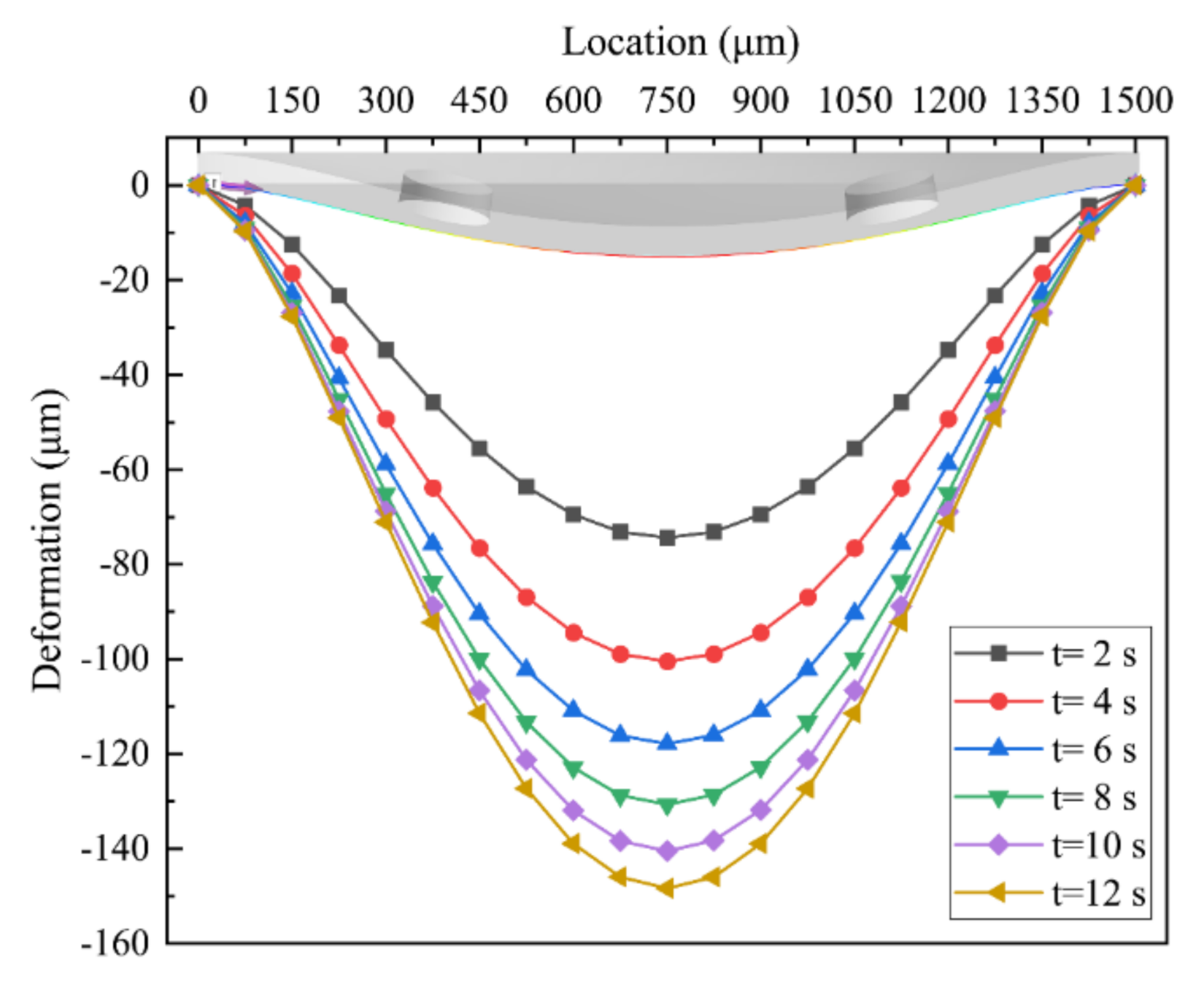

3.2. Membrane Deformation against Fluid Flow

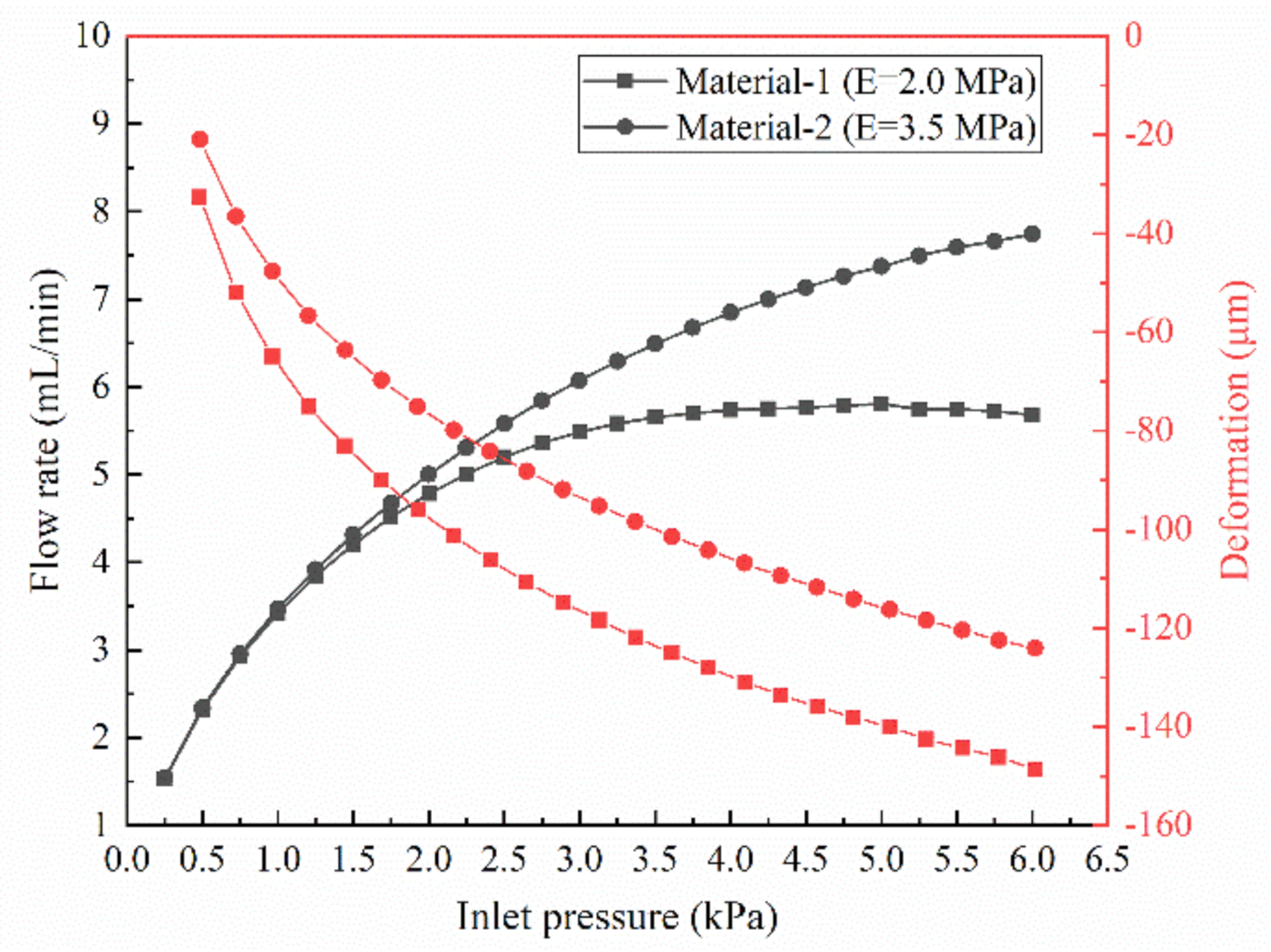

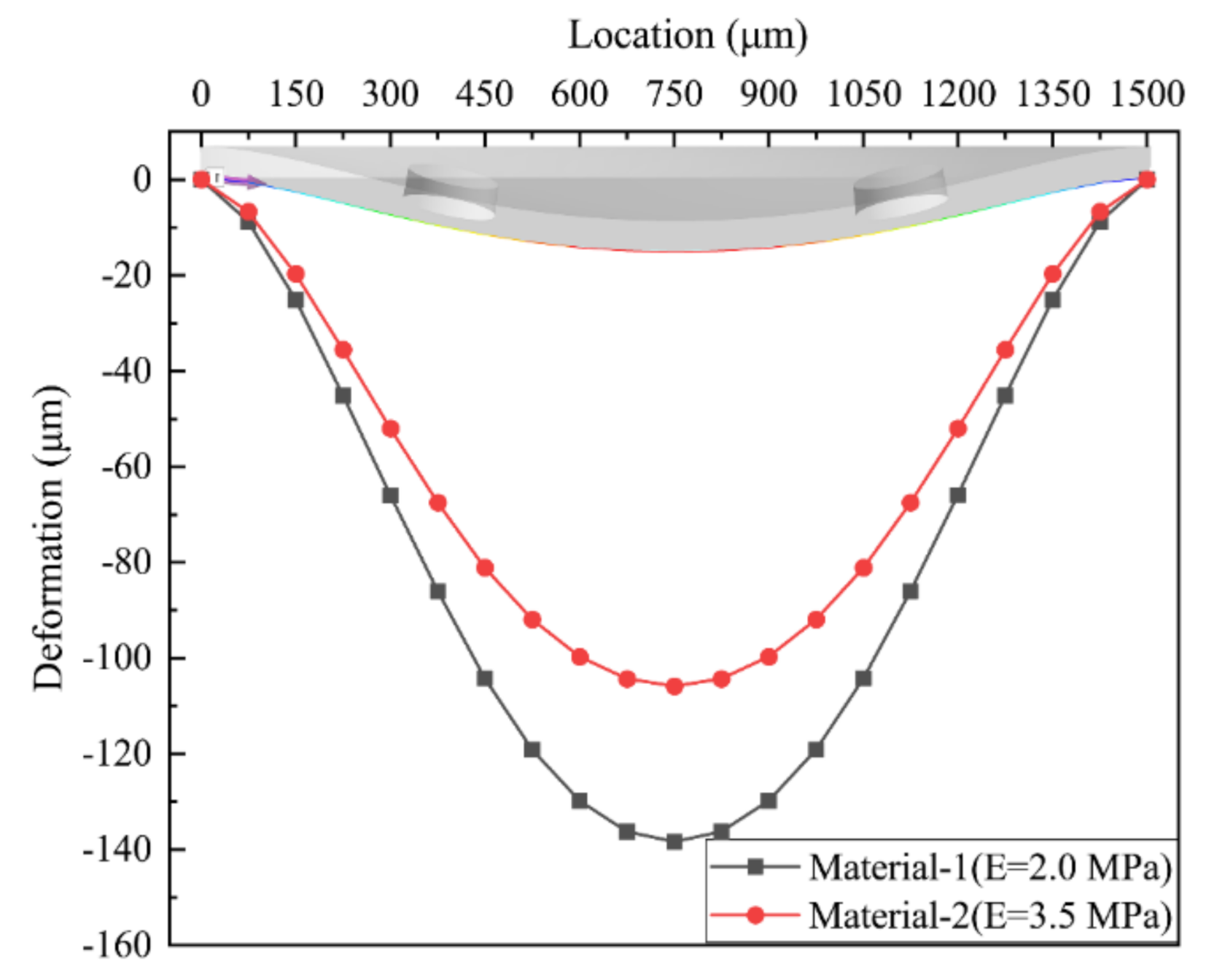

3.3. Effect of Membrane Material Properties on MPV

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Whitesides, G.M. The origins and the future of microfluidics. Nat. Cell Biol. 2006, 442, 368–373. [Google Scholar] [CrossRef]

- Mitchell, M.C.; Spikmans, V.; Manz, A.; De Mello, A.J. Microchip-based synthesis and total analysis systems (µSYNTAS): Chemical microprocessing for generation and analysis of compound libraries. J. Chem. Soc. Perkin Trans. 1 2001, 1, 514–518. [Google Scholar] [CrossRef]

- Qian, J.-Y.; Chen, M.-R.; Liu, X.-L.; Qian, J.-Y. A numerical investigation of the flow of nanofluids through a micro Tesla valve. J. Zhejiang Univ. Sci. A 2018, 20, 50–60. [Google Scholar] [CrossRef]

- Mashaghi, S.; Abbaspourrad, A.; Weitz, D.A.; Van Oijen, A.M. Droplet microfluidics: A tool for biology, chemistry and nanotechnology. TrAC Trends Anal. Chem. 2016, 82, 118–125. [Google Scholar] [CrossRef] [Green Version]

- Barea, J.S.; Lee, J.; Kang, D.-K. Recent Advances in Droplet-based Microfluidic Technologies for Biochemistry and Molecular Biology. Micromachines 2019, 10, 412. [Google Scholar] [CrossRef] [Green Version]

- Kim, T.-H.; Park, J.; Kim, C.-J.; Cho, Y.-K. Fully Integrated Lab-on-a-Disc for Nucleic Acid Analysis of Food-Borne Pathogens. Anal. Chem. 2014, 86, 3841–3848. [Google Scholar] [CrossRef]

- Lei, M.; Pan, J.-Z.; Xu, G.-M.; Du, P.-Z.; Tian, M.; Zhang, H. Automated microfluidic chip system for radiosynthesis of PET imaging probes. J. Zhejiang Univ. Sci. B 2019, 20, 865–867. [Google Scholar] [CrossRef]

- Jin, Z.; Hou, C.-W.; Li, X.-J.; Jin, Z.-J. Actuation Mechanism of Microvalves: A Review. Micromachines 2020, 11, 172. [Google Scholar] [CrossRef] [Green Version]

- Au, A.K.; Lai, H.; Utela, B.R.; Folch, A. Microvalves and Micropumps for BioMEMS. Micromachines 2011, 2, 179–220. [Google Scholar] [CrossRef] [Green Version]

- Oh, K.W.; Ahn, C.H. A review of microvalves. J. Micromech. Microeng. 2006, 16, 13–39. [Google Scholar] [CrossRef]

- Cheng, C.; Nair, A.R.; Thakur, R.; Fridman, G. Normally closed plunger-membrane microvalve self-actuated electrically using a shape memory alloy wire. Microfluid. Nanofluidics 2018, 22, 1–9. [Google Scholar] [CrossRef]

- Guevara-Pantoja, P.E.; Jiménez-Valdés, R.J.; Garcia-Cordero, J.L.; Caballero-Robledo, G.A. Microchip-based synthesis and total analysis systems (µSYNTAS): Chemical microprocessing for generation and analysis of compound libraries. Lab. A Chip 2018, 18, 662–669. [Google Scholar] [CrossRef]

- Pourmand, A.; Shaegh, S.A.M.; Ghavifekr, H.B.; Aghdam, E.N.; Dokmeci, M.R.; Khademhosseini, A.; Zhang, Y.S. Fabrication of whole-thermoplastic normally closed microvalve, micro check valve, and micropump. Sens. Actuators B Chem. 2018, 262, 625–636. [Google Scholar] [CrossRef]

- Yalikun, Y.; Tanaka, Y. Large-Scale Integration of All-Glass Valves on a Microfluidic Device. Micromachines 2016, 7, 83. [Google Scholar] [CrossRef] [Green Version]

- Xia, Y.; Whitesides, G.M. SOFT LITHOGRAPHY. Annu. Rev. Mater. Res. 1998, 28, 153–184. [Google Scholar] [CrossRef]

- Selyanchyn, R.; Ariyoshi, M.; Fujikawa, S. Thickness Effect on CO2/N2 Separation in Double Layer Pebax-1657®/PDMS Membranes. Membranes 2018, 8, 121. [Google Scholar] [CrossRef] [Green Version]

- Jin, Z.-J.; Qiu, C.; Jiang, C.-H.; Wu, J.-Y.; Qian, J.-Y. Effect of valve core shapes on cavitation flow through a sleeve regulating valve. J. Zhejiang Univ. Sci. A 2020, 21, 1–14. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, D.; Xu, B.; Gan, M.-Y.; Pan, M.; Yang, H. Experimental and numerical investigation of flow forces in a seat valve using a damping sleeve with orifices. J. Zhejiang Univ. Sci. A 2018, 19, 417–430. [Google Scholar] [CrossRef]

- Kartalov, E.P.; Walker, C.; Taylor, C.R.; Anderson, W.F.; Scherer, A. Microfluidic vias enable nested bioarrays and autoregulatory devices in Newtonian fluids. Proc. Natl. Acad. Sci. USA 2006, 103, 12280–12284. [Google Scholar] [CrossRef] [Green Version]

- Doh, I.; Cho, Y.-H. Passive flow-rate regulators using pressure-dependent autonomous deflection of parallel membrane valves. Lab. A Chip 2009, 9, 2070–2075. [Google Scholar] [CrossRef]

- Shin, J.; Park, H.; Van Dang, B.; Kim, C.-W.; Kim, S.-J. Elastomeric microfluidic valve with low, constant opening threshold pressure. RSC Adv. 2015, 5, 23239–23245. [Google Scholar] [CrossRef]

- Natarajan, G.P.; Kim, S.-J.; Kim, C.-W. Analysis of Membrane Behavior of a Normally Closed Microvalve Using a Fluid-Structure Interaction Model. Micromachines 2017, 8, 355. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chakraborty, D.; Prakash, J.R.; Friend, J.; Yeo, L.Y. Fluid-structure interaction in deformable microchannels. Phys. Fluids 2012, 24, 102002. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Oseyemi, A.E. Microfluidic Passive Valve with Ultra-Low Threshold Pressure for High-Throughput Liquid Delivery. Micromachines 2019, 10, 798. [Google Scholar] [CrossRef] [Green Version]

- Demir, A.; Dincer, A.E.; Bozkus, Z.; Tijsseling, A.S. Numerical and experimental investigation of damping in a dam-break problem with fluid-structure interaction. J. Zhejiang Univ. Sci. A 2019, 20, 258–271. [Google Scholar] [CrossRef]

- Afrasiab, H.; Movahhedy, M.R.; Assempuor, A. Fluid-structure interaction analysis in microfluidic devices: A dimensionless finite element approach. Int. J. Numer. Methods Fluids 2011, 68, 1073–1086. [Google Scholar] [CrossRef]

- Slone, A.; Pericleous, K.; Bailey, C.; Cross, M.; Bennett, C. A finite volume unstructured mesh approach to dynami c fluid–structure interaction: An assessment of the challenge of predicting the onset of flutter. Appl. Math. Model. 2004, 28, 211–239. [Google Scholar] [CrossRef]

- Zhang, X.J.; Chen, J.M. Design and Characterization of Passive Microvalve for High-throughput Flow Control Under Low Threshold pressure. Instrum. Technol. Sens. 2020, 5, 24–27. (In Chinese) [Google Scholar]

| Materials | Density (kg/m3) | Elastic Modulus (MPa) | Poisson’s Ratio |

|---|---|---|---|

| Material-1 (PDMS) | 960 | 2 | 0.49 |

| Material-2 (PDMS) | 960 | 3.5 | 0.49 |

| Number of Microholes | Constant Flow Rate (mL/min) | Threshold Pressure (kPa) | Pressure Range of Constant Flow Rate (kPa) |

|---|---|---|---|

| 2 | 5 | 3.25 | (3.25, 4.25) |

| 3 | 5.54 | 3.75 | (3.75, 5) |

| 4 | 5.75 | 4 | (4, 6) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Z.-h.; Li, X.-j.; Jin, Z.-j.; Qian, J.-y. Fluid-Structure Interaction Analysis on Membrane Behavior of a Microfluidic Passive Valve. Membranes 2020, 10, 300. https://doi.org/10.3390/membranes10100300

Lin Z-h, Li X-j, Jin Z-j, Qian J-y. Fluid-Structure Interaction Analysis on Membrane Behavior of a Microfluidic Passive Valve. Membranes. 2020; 10(10):300. https://doi.org/10.3390/membranes10100300

Chicago/Turabian StyleLin, Zhen-hao, Xiao-juan Li, Zhi-jiang Jin, and Jin-yuan Qian. 2020. "Fluid-Structure Interaction Analysis on Membrane Behavior of a Microfluidic Passive Valve" Membranes 10, no. 10: 300. https://doi.org/10.3390/membranes10100300

APA StyleLin, Z.-h., Li, X.-j., Jin, Z.-j., & Qian, J.-y. (2020). Fluid-Structure Interaction Analysis on Membrane Behavior of a Microfluidic Passive Valve. Membranes, 10(10), 300. https://doi.org/10.3390/membranes10100300