Optimization of YF17D-Vectored Zika Vaccine Production by Employing Small-Molecule Viral Sensitizers to Enhance Yields

Abstract

1. Introduction

2. Materials and Methods

2.1. Cell Lines, Media, and Viral Seed Stock

2.2. Tolerability Screening of Small Molecules in Spin Tubes

2.3. Effect of VSEs on Virus Titers

2.4. Multi-Compound VSE Optimization Using Design of Experiments

2.5. Generation of 3D-Printed Down-Scaled Reactors

2.6. Scale-Up to 1 L Benchtop Reactors and Evaluation of 3D-Printed Down-Scaled Reactors

2.7. Plaque Assay and Real-Time Quantitative PCR

2.8. Calculations

2.9. Statistical Analysis

2.10. Bioprocess Cost Modeling

3. Results

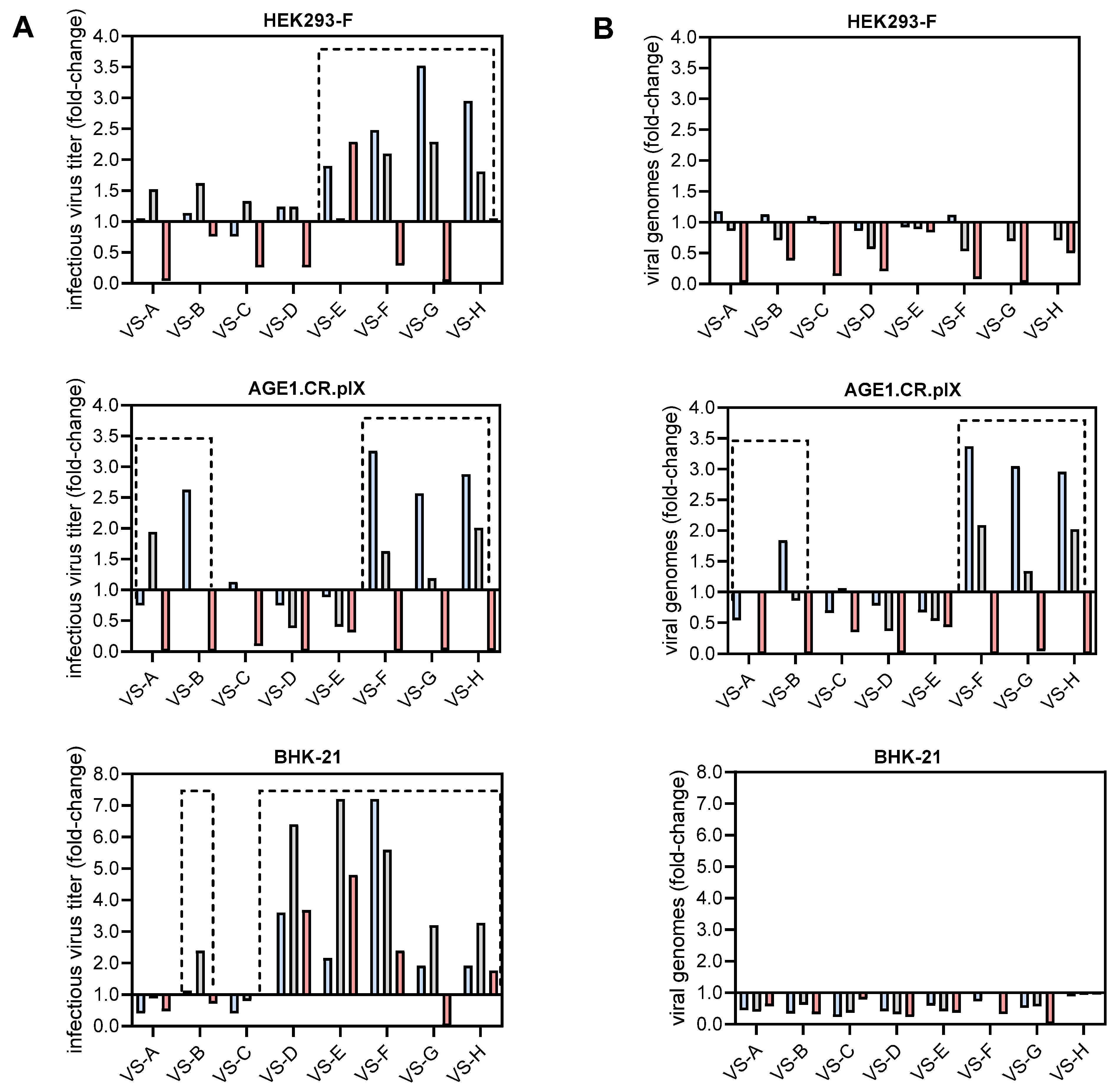

3.1. Evaluation of the Tolerability of VSEs in Host Cell Lines

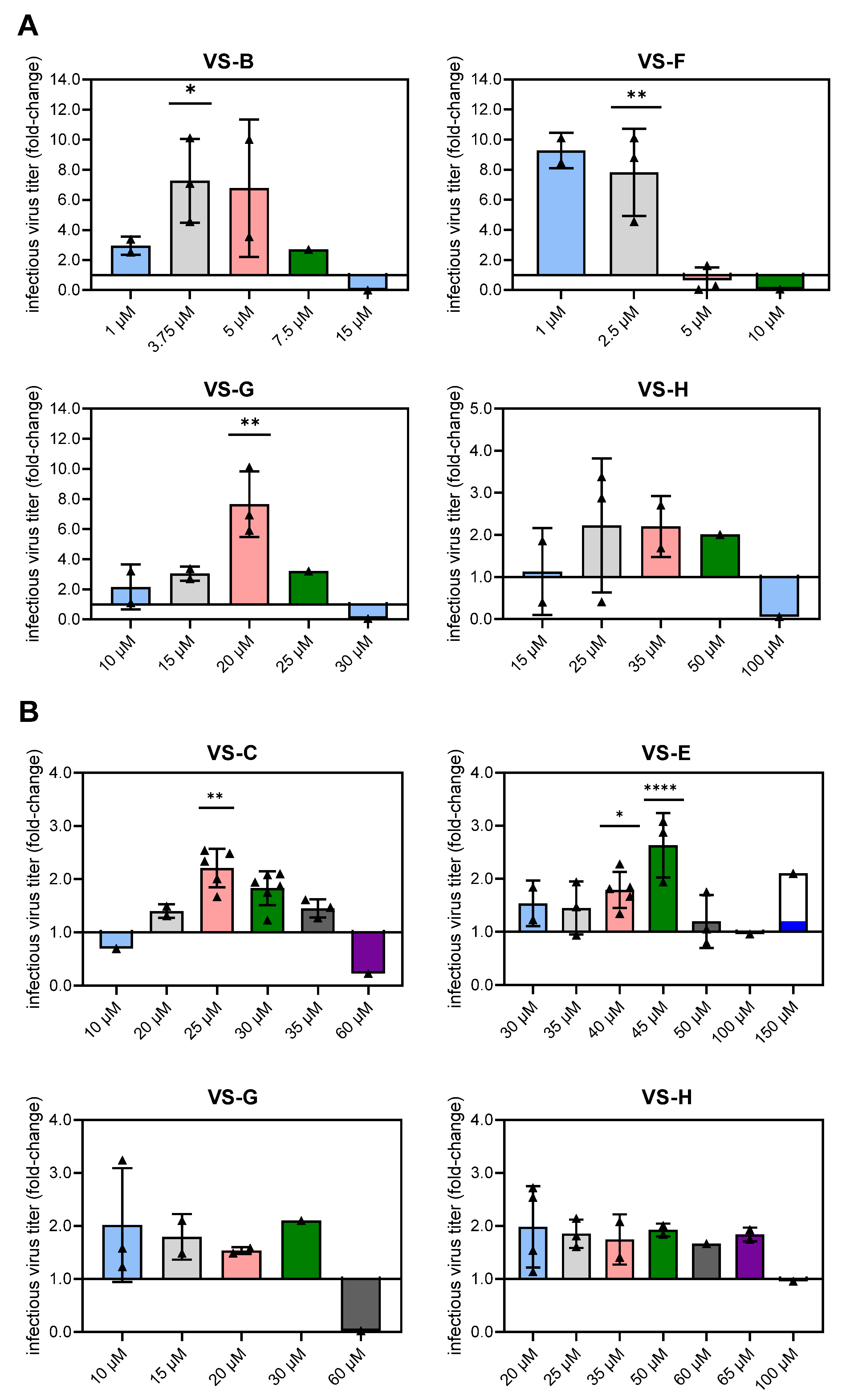

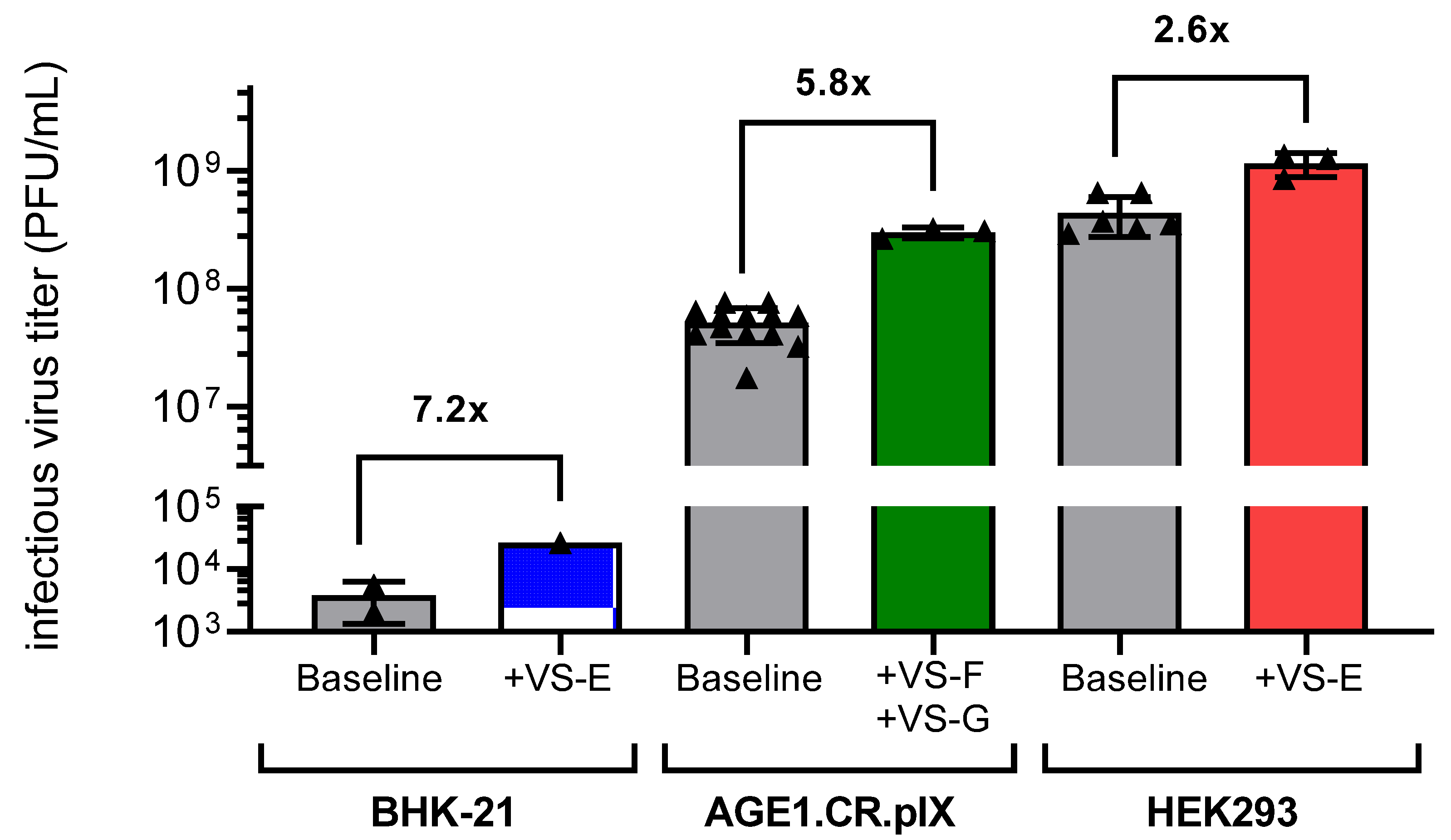

3.2. Effect of VSEs on YF-ZIK Titers

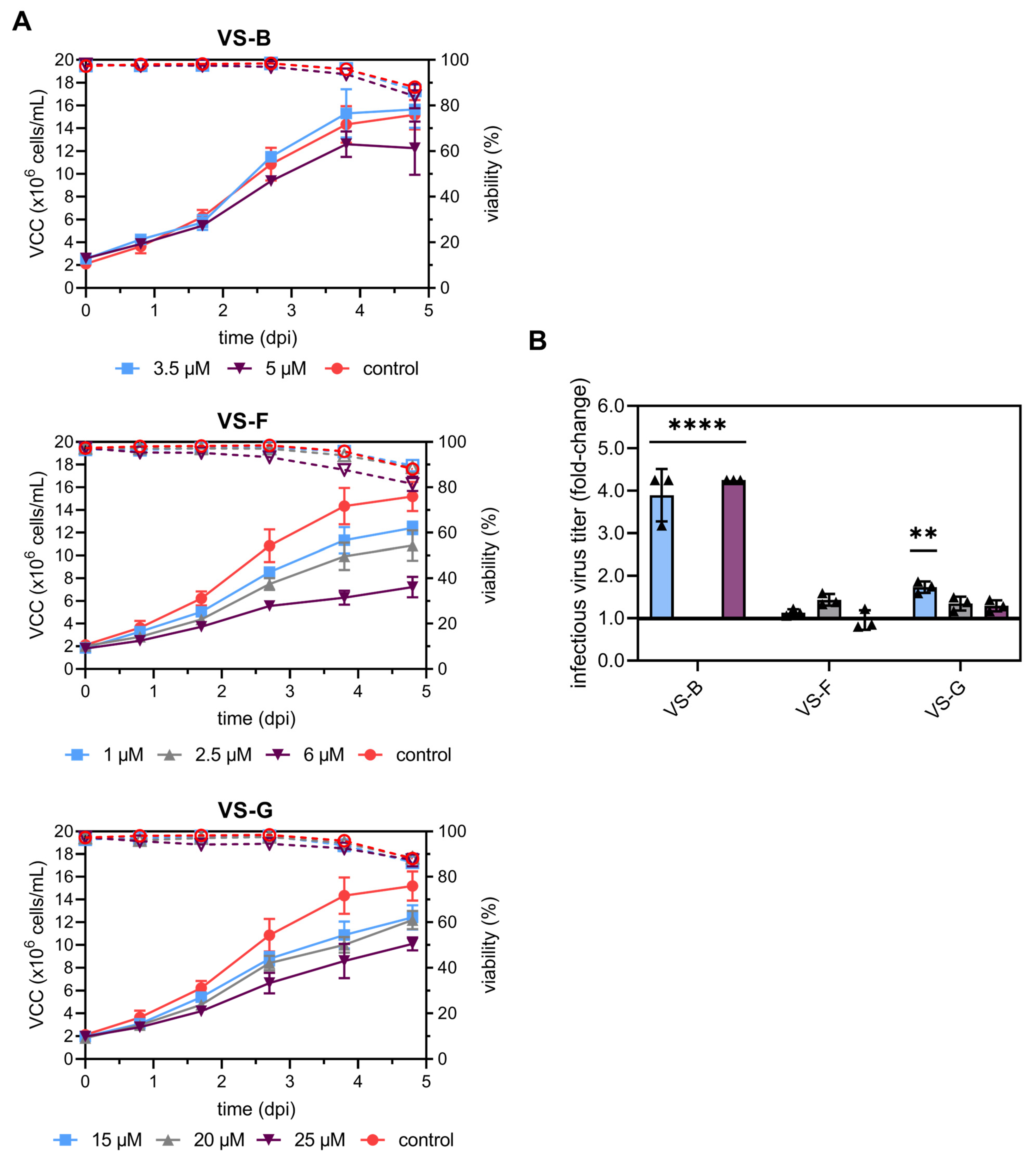

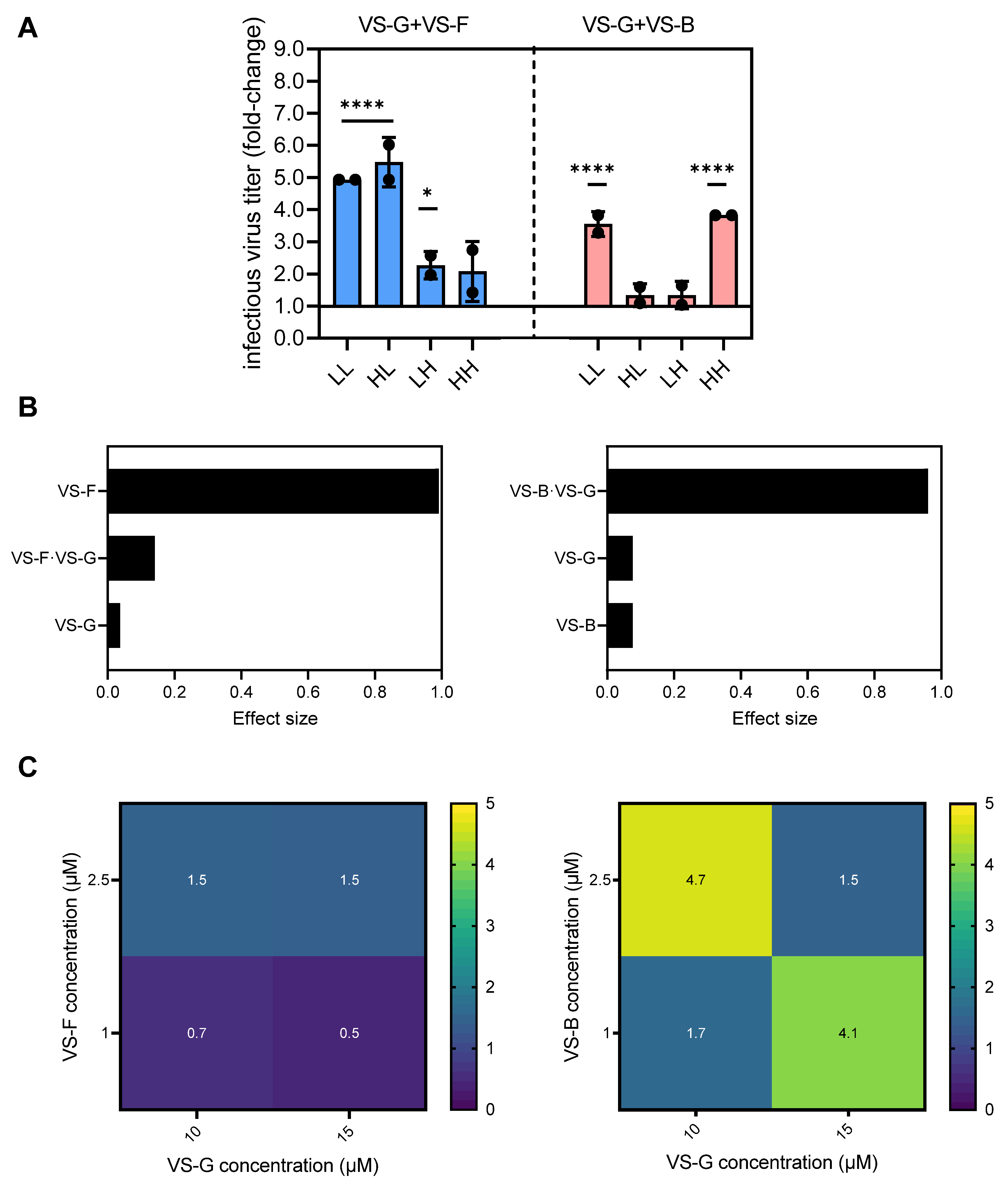

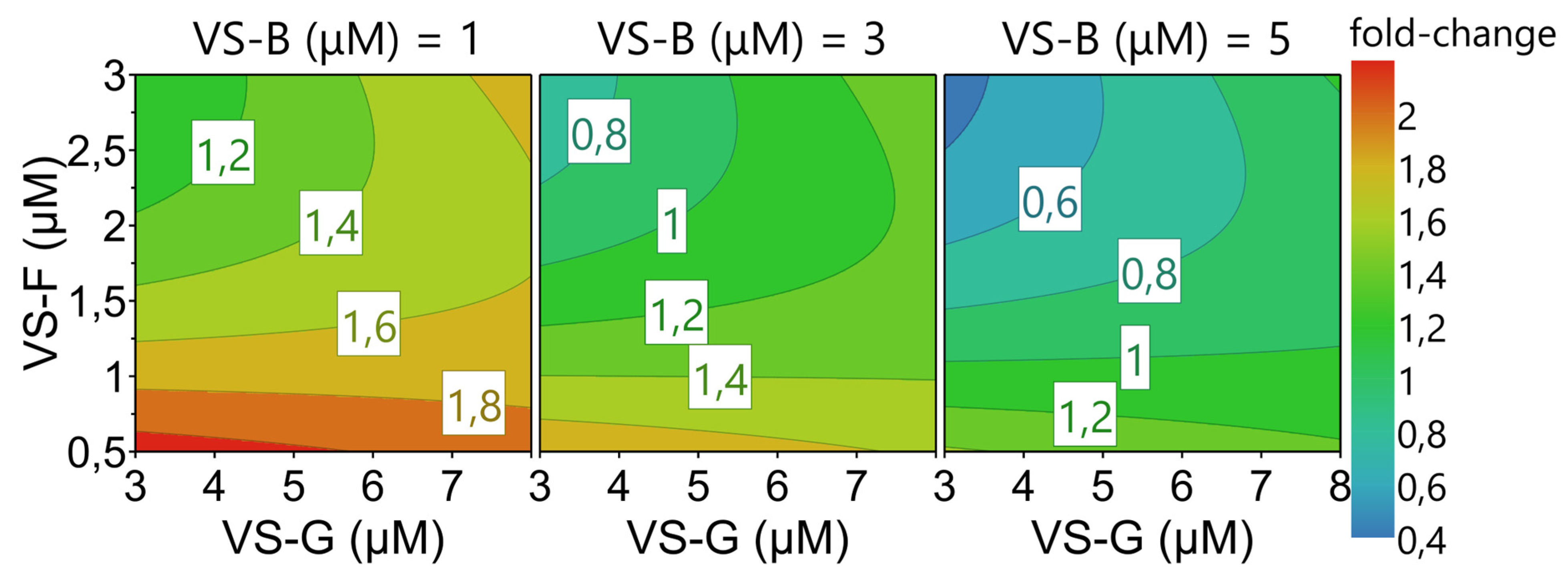

3.3. Multi-Compound VSE Optimization Using DoE

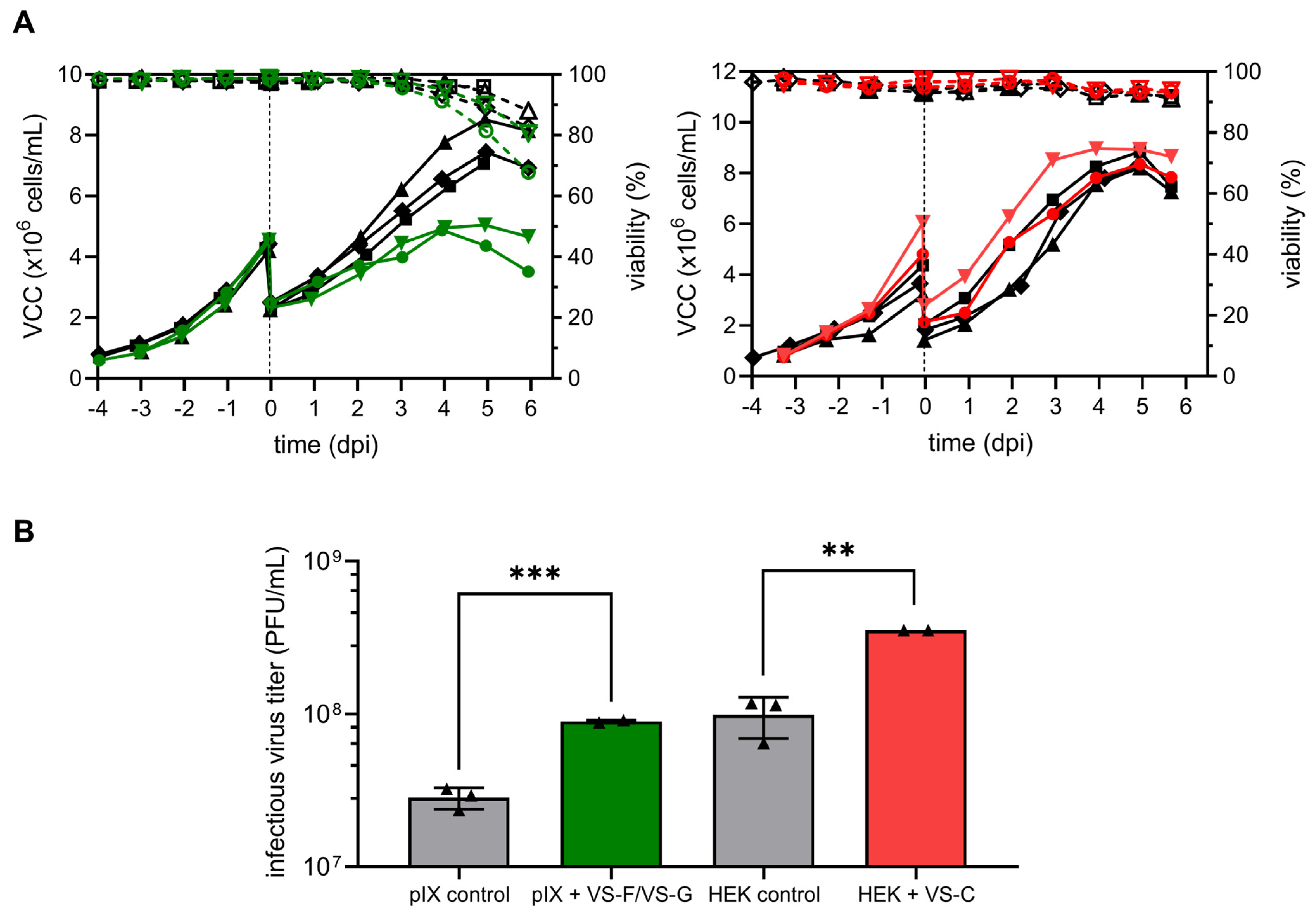

3.4. Scale-Up to a Laboratory-Scale Stirred Tank Bioreactor

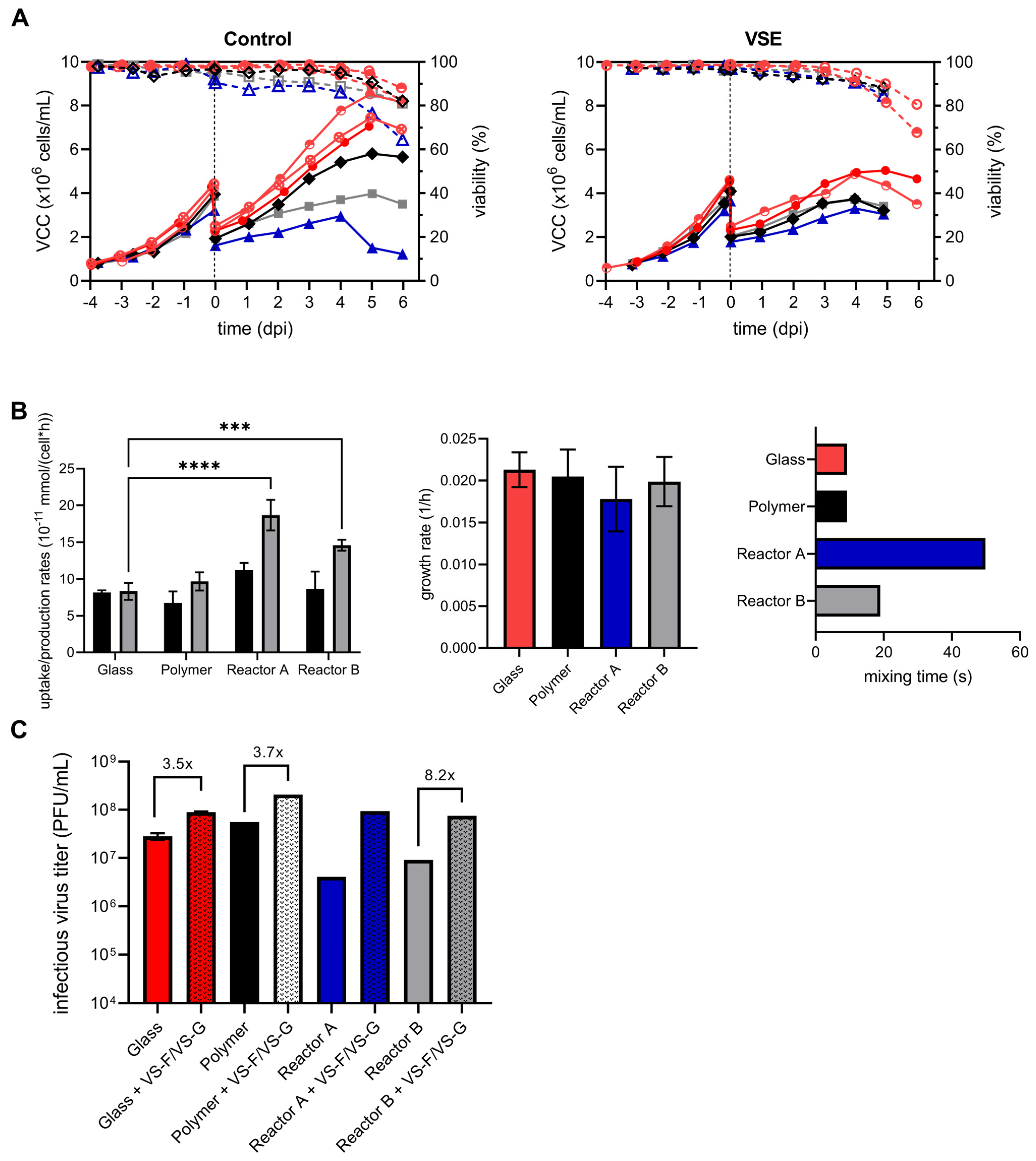

3.5. Mimicking Large-Scale Production Conditions in Small-Scale 3D-Printed Reactors

4. Discussion

4.1. Effects of Single- and Multi-VSE Addition on YF-ZIK Titers

4.2. Proof of Concept for Translatability and Scale-Up

4.3. Mimicking Large-Scale Production Conditions in Small-Scale 3D-Printed pDS Reactors

4.4. Implications of Improved Yields

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Abbreviation | Meaning |

| µ | cell-specific growth rate |

| AI | artificial intelligence |

| CCF | reduced face-centered composite design |

| CFD | computational fluid dynamics |

| CI | combination index |

| DO | dissolved oxygen |

| DoE | design of experiments |

| FF | full factorial design |

| LC-MS | liquid chromatography mass spectrometry |

| MOI | multiplicity of infection |

| pDS | perfect down-scale system |

| P/V | volumetric power |

| PFU | plaque forming units |

| p.i. | Post-infection |

| STD | standard deviation |

| STR | stirred tank bioreactor |

| VCC | viable cell concentration |

| VCCmax | maximum viable cell concentration |

| VSE | viral sensitizer |

| wv | working volume |

| YF17D | yellow fever vaccine strain 17D |

| YF | yellow fever virus |

| YF-ZIK | chimeric YF-ZIKprM/E vaccine virus |

References

- Bonaldo, M.C.; Sequeira, P.C.; Galler, R. The yellow fever 17D virus as a platform for new live attenuated vaccines. Hum. Vaccines Immunother. 2014, 10, 1256–1265. [Google Scholar] [CrossRef]

- Sanchez-Felipe, L.; Alpizar, Y.A.; Ma, J.; Coelmont, L.; Dallmeier, K. YF17D-based vaccines—Standing on the shoulders of a giant. Eur. J. Immunol. 2024, 54, e2250133. [Google Scholar] [CrossRef] [PubMed]

- Kum, D.B.; Boudewijns, R.; Ma, J.; Mishra, N.; Schols, D.; Neyts, J.; Dallmeier, K. A chimeric yellow fever-Zika virus vaccine candidate fully protects against yellow fever virus infection in mice. Emerg. Microbes Infect. 2020, 9, 520–533. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Felipe, L.; Vercruysse, T.; Sharma, S.; Ma, J.; Lemmens, V.; Van Looveren, D.; Javarappa, M.P.A.; Boudewijns, R.; Malengier-Devlies, B.; Liesenborghs, L.; et al. A single-dose live-attenuated YF17D-vectored SARS-CoV-2 vaccine candidate. Nature 2021, 590, 320–325. [Google Scholar] [CrossRef] [PubMed]

- Lemmens, V.; Kelchtermans, L.; Debaveye, S.; Chiu, W.; Vercruysse, T.; Ma, J.; Thibaut, H.J.; Neyts, J.; Sanchez-Felipe, L.; Dallmeier, K. YF17D-vectored Ebola vaccine candidate protects mice against lethal surrogate Ebola and yellow fever virus challenge. npj Vaccines 2023, 8, 99. [Google Scholar] [CrossRef]

- Jones, C.H.; Jenkins, M.P.; Williams, B.A.; Welch, V.L.; True, J.M. Exploring the future adult vaccine landscape—Crowded schedules and new dynamics. npj Vaccines 2024, 9, 27. [Google Scholar] [CrossRef]

- Freire, M.S.; Mann, G.F.; Marchevsky, R.S.; Yamamura, A.M.; Almeida, L.F.; Jabor, A.V.; Malachias, J.M.; Coutinho, E.S.; Galler, R. Production of yellow fever 17DD vaccine virus in primary culture of chicken embryo fibroblasts: Yields, thermo and genetic stability, attenuation and immunogenicity. Vaccine 2005, 23, 2501–2512. [Google Scholar] [CrossRef][Green Version]

- De Souza, Y.R.M.; Manso, P.P.d.A.; de Oliveira, B.C.D.; Terra, M.A.B.L.; Paschoal, T.; Caminha, G.; Ribeiro, I.P.; Raphael, L.M.S.; Bonaldo, M.C.; Pelajo-Machado, M. Generation of Yellow Fever virus vaccine in skeletal muscle cells of chicken embryos. Mem. Do Inst. Oswaldo Cruz 2019, 114, e190187. [Google Scholar] [CrossRef]

- Göbel, S.; Kazemi, O.; Ma, J.; Jordan, I.; Sandig, V.; Paulissen, J.; Kerstens, W.; Thibaut, H.J.; Reichl, U.; Dallmeier, K.; et al. Parallel Multifactorial Process Optimization and Intensification for High-Yield Production of Live YF17D-Vectored Zika Vaccine. Vaccines 2024, 12, 755. [Google Scholar] [CrossRef]

- Zhang, J.; Qiu, Z.; Wang, S.; Liu, Z.; Qiao, Z.; Wang, J.; Duan, K.; Nian, X.; Ma, Z.; Yang, X. Suspended cell lines for inactivated virus vaccine production. Expert Rev. Vaccines 2023, 22, 468–480. [Google Scholar] [CrossRef]

- Genzel, Y.; Rödig, J.; Rapp, E.; Reichl, U. Animal Cell Biotechnology: Methods and Protocols; Pörtner, R., Ed.; Humana Press: Totowa, NJ, USA, 2014; pp. 371–393. [Google Scholar]

- Silva, C.A.T.; Kamen, A.A.; Henry, O. Intensified Influenza Virus Production in Suspension HEK293SF Cell Cultures Operated in Fed-Batch or Perfusion with Continuous Harvest. Vaccines 2023, 11, 1819. [Google Scholar] [CrossRef]

- Zinnecker, T.; Reichl, U.; Genzel, Y. Innovations in cell culture-based influenza vaccine manufacturing—From static cultures to high cell density cultivations. Hum. Vaccines Immunother. 2024, 20, 2373521. [Google Scholar] [CrossRef] [PubMed]

- Nikolay, A. Intensified Yellow Fever and Zika Virus Production in Animal Cell Culture; Otto-von-Guericke-Universität Magdeburg: Magdeburg, Germany, 2020. [Google Scholar]

- Tapia, F.; Vázquez-Ramírez, D.; Genzel, Y.; Reichl, U. Bioreactors for high cell density and continuous multi-stage cultivations: Options for process intensification in cell culture-based viral vaccine production. Appl. Microbiol. Biotechnol. 2016, 100, 2121–2132. [Google Scholar] [CrossRef] [PubMed]

- Gränicher, G.; Tapia, F.; Behrendt, I.; Jordan, I.; Genzel, Y.; Reichl, U. Production of Modified Vaccinia Ankara Virus by Intensified Cell Cultures: A Comparison of Platform Technologies for Viral Vector Production. Biotechnol. J. 2021, 16, e2000024. [Google Scholar] [CrossRef] [PubMed]

- Chung, C.-H.; Murphy, C.M.; Wingate, V.P.; Pavlicek, J.W.; Nakashima, R.; Wei, W.; McCarty, D.; Rabinowitz, J.; Barton, E. Production of rAAV by plasmid transfection induces antiviral and inflammatory responses in suspension HEK293 cells. Mol. Ther.-Methods Clin. Dev. 2023, 28, 272–283. [Google Scholar] [CrossRef]

- Bartok, E.; Hartmann, G. Immune Sensing Mechanisms that Discriminate Self from Altered Self and Foreign Nucleic Acids. Immunity 2020, 53, 54–77. [Google Scholar] [CrossRef]

- Honke, N.; Shaabani, N.; Cadeddu, G.; Sorg, U.R.; Zhang, D.-E.; Trilling, M.; Klingel, K.; Sauter, M.; Kandolf, R.; Gailus, N.; et al. Enforced viral replication activates adaptive immunity and is essential for the control of a cytopathic virus. Nat. Immunol. 2011, 13, 51–57. [Google Scholar] [CrossRef]

- Hamamoto, I.; Takaku, H.; Tashiro, M.; Yamamoto, N.; Guan, Y. High Yield Production of Influenza Virus in Madin Darby Canine Kidney (MDCK) Cells with Stable Knockdown of IRF7. PLoS ONE 2013, 8, e59892. [Google Scholar] [CrossRef]

- Van der Sanden, S.M.G.; Wu, W.; Dybdahl-Sissoko, N.; Weldon, W.C.; Brooks, P.; O’DOnnell, J.; Jones, L.P.; Brown, C.; Tompkins, S.M.; Oberste, M.S.; et al. Engineering Enhanced Vaccine Cell Lines To Eradicate Vaccine-Preventable Diseases: The Polio End Game. J. Virol. 2016, 90, 1694–1704. [Google Scholar] [CrossRef]

- Wu, W.; Orr-Burks, N.; Karpilow, J.; Tripp, R.A. Development of improved vaccine cell lines against rotavirus. Sci. Data 2017, 4, 170021. [Google Scholar] [CrossRef]

- Zinnecker, T.; Badri, N.; Araujo, D.; Thiele, K.; Reichl, U.; Genzel, Y. From single-cell cloning to high-yield influenza virus production—Implementing advanced technologies in vaccine process development. Eng. Life Sci. 2024, 24, 2300245. [Google Scholar] [CrossRef]

- Beck, H.; Härter, M.; Haß, B.; Schmeck, C.; Baerfacker, L. Small molecules and their impact in drug discovery: A perspective on the occasion of the 125th anniversary of the Bayer Chemical Research Laboratory. Drug Discov. Today 2022, 27, 1560–1574. [Google Scholar] [CrossRef] [PubMed]

- Merten, O.-W.; Hebben, M.; Bovolenta, C. Production of lentiviral vectors. Mol. Ther.-Methods Clin. Dev. 2016, 3, 16017. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.-H.; Naik, N.G.; Liao, L.-L.; Wei, S.-C.; Chao, Y.-C. Global Screening of Antiviral Genes that Suppress Baculovirus Transgene Expression in Mammalian Cells. Mol. Ther.-Methods Clin. Dev. 2017, 6, 194–206. [Google Scholar] [CrossRef] [PubMed]

- Scarrott, J.M.; Johari, Y.B.; Pohle, T.H.; Liu, P.; Mayer, A.; James, D.C. Increased recombinant adeno-associated virus production by HEK293 cells using small molecule chemical additives. Biotechnol. J. 2023, 18, e2200450. [Google Scholar] [CrossRef]

- Gaugler, L.; Hofmann, S.; Schlüter, M.; Takors, R. Mimicking CHO large-scale effects in the single multicompartment bioreactor: A new approach to access scale-up behavior. Biotechnol. Bioeng. 2024, 121, 1243–1255. [Google Scholar] [CrossRef]

- Anane, E.; Knudsen, I.M.; Wilson, G.C. Scale-down cultivation in mammalian cell bioreactors—The effect of bioreactor mixing time on the response of CHO cells to dissolved oxygen gradients. Biochem. Eng. J. 2021, 166, 107870. [Google Scholar] [CrossRef]

- Nienow, A.W.; Scott, W.H.; Hewitt, C.J.; Thomas, C.R.; Lewis, G.; Amanullah, A.; Kiss, R.; Meier, S.J. Scale-down studies for assessing the impact of different stress parameters on growth and product quality during animal cell culture. Chem. Eng. Res. Des. 2013, 91, 2265–2274. [Google Scholar] [CrossRef]

- Zakrzewski, R.; Lee, K.; Lye, G.J. Development of a miniature bioreactor model to study the impact of pH and DOT fluctuations on CHO cell culture performance as a tool to understanding heterogeneity effects at large-scale. Biotechnol. Prog. 2022, 38, e3264. [Google Scholar] [CrossRef]

- Paul, K.; Herwig, C. Scale-down simulators for mammalian cell culture as tools to access the impact of inhomogeneities occurring in large-scale bioreactors. Eng. Life Sci. 2020, 20, 197–204. [Google Scholar] [CrossRef]

- Bauer, I.; Dreher, T.; Eibl, D.; Glöckler, R.; Husemann, U.; John, G.T.; Kaiser, S.C.; Kampeis, P.; Kampeis, J.; Kleebank, S.; et al. Recommendations for Process Engineering Characterisation of Single-Use Bioreactors and Mixing Systems by Using Experimental Methods; DECHEMA Gesellschaft für Chemische Technik und Biotechnologie eV: Frankfurt am Main, Germany, 2020. [Google Scholar]

- Satzer, P. Scalable Physical Reactor Representation. 2023. Available online: https://patentscope2.wipo.int/search/en/WO2024133134?docId=WO2024133134 (accessed on 10 July 2025).

- Diallo, J.-S.; Le Boeuf, F.; Lai, F.; Cox, J.; Vaha-Koskela, M.; Abdelbary, H.; MacTavish, H.; Waite, K.; Falls, T.; Wang, J.; et al. A High-throughput Pharmacoviral Approach Identifies Novel Oncolytic Virus Sensitizers. Mol. Ther. 2010, 18, 1123–1129. [Google Scholar] [CrossRef]

- Nguyên, T.L.-A.; Abdelbary, H.; Arguello, M.; Breitbach, C.; Leveille, S.; Diallo, J.-S.; Yasmeen, A.; Bismar, T.A.; Kirn, D.; Falls, T.; et al. Chemical targeting of the innate antiviral response by histone deacetylase inhibitors renders refractory cancers sensitive to viral oncolysis. Proc. Natl. Acad. Sci. USA 2008, 105, 14981–14986. [Google Scholar] [CrossRef]

- Fisher, K.; Grafton, F.; Ispaso, F.; Tworig, J.; Derler, R.; Sonntag, F.; Hörer, M.; Schulze, A.; Reid, C.A.; Mandegar, M.A. Polo-like kinase inhibitors increase AAV production by halting cell cycle progression. Mol. Ther.-Methods Clin. Dev. 2025, 33, 101412. [Google Scholar] [CrossRef]

- Wong, B.; Bergeron, A.; Maznyi, G.; Ng, K.; Jirovec, A.; Birdi, H.K.; Serrano, D.; Spinelli, M.; Thomson, M.; Taha, Z.; et al. Pevonedistat, a first-in-class NEDD8-activating enzyme inhibitor, sensitizes cancer cells to VSVΔ51 oncolytic virotherapy. Mol. Ther. 2023, 31, 3176–3192. [Google Scholar] [CrossRef] [PubMed]

- Arulanandam, R.; Batenchuk, C.; Varette, O.; Zakaria, C.; Garcia, V.; Forbes, N.E.; Davis, C.; Krishnan, R.; Karmacharya, R.; Cox, J.; et al. Microtubule disruption synergizes with oncolytic virotherapy by inhibiting interferon translation and potentiating bystander killing. Nat. Commun. 2015, 6, 6410. [Google Scholar] [CrossRef] [PubMed]

- Fuenmayor, J.; Cervera, L.; Rigau, C.; Gòdia, F. Enhancement of HIV-1 VLP production using gene inhibition strategies. Appl. Microbiol. Biotechnol. 2018, 102, 4477–4487. [Google Scholar] [CrossRef]

- Slinker, B.K. The Statistics of Synergism. J. Mol. Cell. Cardiol. 1998, 30, 723–731. [Google Scholar] [CrossRef]

- Duarte, D.; Vale, N. Evaluation of synergism in drug combinations and reference models for future orientations in oncology. Curr. Res. Pharmacol. Drug Discov. 2022, 3, 100110. [Google Scholar] [CrossRef]

- Foucquier, J.; Guedj, M. Analysis of drug combinations: Current methodological landscape. Pharmacol. Res. Perspect. 2015, 3, e00149. [Google Scholar] [CrossRef]

- Lederer, S.; Dijkstra, T.M.H.; Heskes, T. Additive Dose Response Models: Defining Synergy. Front. Pharmacol. 2019, 10, 1384. [Google Scholar] [CrossRef]

- Fitschen, J.; Hofmann, S.; Wutz, J.; Kameke, A.; Hoffmann, M.; Wucherpfennig, T.; Schlüter, M. Novel evaluation method to determine the local mixing time distribution in stirred tank reactors. Chem. Eng. Sci. X 2021, 10, 100098. [Google Scholar] [CrossRef]

- Nikolay, A.; Castilho, L.R.; Reichl, U.; Genzel, Y. Propagation of Brazilian Zika virus strains in static and suspension cultures using Vero and BHK cells. Vaccine 2018, 36, 3140–3145. [Google Scholar] [CrossRef] [PubMed]

- Frensing, T.; Pflugmacher, A.; Bachmann, M.; Peschel, B.; Reichl, U. Impact of defective interfering particles on virus replication and antiviral host response in cell culture-based influenza vaccine production. Appl. Microbiol. Biotechnol. 2014, 98, 8999–9008. [Google Scholar] [CrossRef] [PubMed]

- Alavijeh, M.K.; Baker, I.; Lee, Y.Y.; Gras, S.L. Digitally enabled approaches for the scale up of mammalian cell bioreactors. Digit. Chem. Eng. 2022, 4, 100040. [Google Scholar] [CrossRef]

- Lara, A.R.; Galindo, E.; Ramírez, O.T.; Palomares, L.A. Living with heterogeneities in bioreactors: Understanding the effects of environmental gradients on cells. Mol. Biotechnol. 2006, 34, 355–382. [Google Scholar] [CrossRef]

- Xu, S.; Jiang, R.; Mueller, R.; Hoesli, N.; Kretz, T.; Bowers, J.; Chen, H. Probing lactate metabolism variations in large-scale bioreactors. Biotechnol. Prog. 2018, 34, 756–766. [Google Scholar] [CrossRef]

- Gaugler, L.; Mast, Y.; Fitschen, J.; Hofmann, S.; Schlüter, M.; Takors, R. Scaling-down biopharmaceutical production processes via a single multi-compartment bioreactor (SMCB). Eng. Life Sci. 2023, 23, e2100161. [Google Scholar] [CrossRef]

- Zurbia-Flores, G.M.; Rollier, C.S.; Reyes-Sandoval, A. Re-thinking yellow fever vaccines: Fighting old foes with new generation vaccines. Hum. Vaccines Immunother. 2022, 18, 1895644. [Google Scholar] [CrossRef]

- Konstantinov, K.B.; Cooney, C.L. White paper on continuous bioprocessing may 20–21 2014 Continuous Manufacturing Symposium. J. Pharm. Sci. 2015, 104, 813–820. [Google Scholar] [CrossRef]

- Bielser, J.-M.; Wolf, M.; Souquet, J.; Broly, H.; Morbidelli, M. Perfusion mammalian cell culture for recombinant protein manufacturing—A critical review. Biotechnol. Adv. 2018, 36, 1328–1340. [Google Scholar] [CrossRef]

- Gränicher, G.; Babakhani, M.; Göbel, S.; Jordan, I.; Marichal-Gallardo, P.; Genzel, Y.; Reichl, U. A high cell density perfusion process for Modified Vaccinia virus Ankara production: Process integration with inline DNA digestion and cost analysis. Biotechnol. Bioeng. 2021, 118, 4720–4734. [Google Scholar] [CrossRef]

- Langer, E.S.; Rader, R.A. Continuous bioprocessing and perfusion: Wider adoption coming as bioprocessing matures. Bioprocess J. 2014, 13, 50–55. [Google Scholar] [CrossRef]

- Jordan, I.; Sandig, V. Matrix and backstage: Cellular substrates for viral vaccines. Viruses 2014, 6, 1672–1700. [Google Scholar] [CrossRef]

- Kallel, H.; Rourou, S.; Majoul, S.; Loukil, H. A novel process for the production of a veterinary rabies vaccine in BHK-21 cells grown on microcarriers in a 20-l bioreactor. Appl. Microbiol. Biotechnol. 2003, 61, 441–446. [Google Scholar] [CrossRef] [PubMed]

- Clarke, J.; Spier, R. An investigation into causes of resistance of a cloned line of BHK cells to a strain of foot-and-mouth disease virus. Veter- Microbiol. 1983, 8, 259–270. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Mulligan, M.J.; Baldwin, D.N.; Linial, M.L. Endogenous virus of BHK-21 cells complicates electron microscopy studies of foamy virus maturation. J. Virol. 1999, 73, 8917. [Google Scholar] [CrossRef] [PubMed]

- Hare, D.; Collins, S.; Cuddington, B.; Mossman, K. The Importance of Physiologically Relevant Cell Lines for Studying Virus–Host Interactions. Viruses 2016, 8, 297. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Y.; Cao, Y.; Wu, Y.; Cheng, G. The Role of Noncoding RNA in the Transmission and Pathogenicity of Flaviviruses. Viruses 2024, 16, 242. [Google Scholar] [CrossRef]

- Gao, W.; Guo, L.; Yang, Y.; Wang, Y.; Xia, S.; Gong, H.; Zhang, B.-K.; Yan, M. Dissecting the Crosstalk Between Nrf2 and NF-κB Response Pathways in Drug-Induced Toxicity. Front. Cell Dev. Biol. 2021, 9, 809952. [Google Scholar] [CrossRef]

- Mulukutla, B.C.; Gramer, M.; Hu, W.-S. On metabolic shift to lactate consumption in fed-batch culture of mammalian cells. Metab. Eng. 2012, 14, 138–149. [Google Scholar] [CrossRef]

- Kruh, J. Effects of sodium butyrate, a new pharmacological agent, on cells in culture. Mol. Cell. Biochem. 1982, 42, 65–82. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Göbel, S.; Zinnecker, T.; Jordan, I.; Sandig, V.; Vervoort, A.; de Jong, J.; Diallo, J.-S.; Satzer, P.; Satzer, M.; Dallmeier, K.; et al. Optimization of YF17D-Vectored Zika Vaccine Production by Employing Small-Molecule Viral Sensitizers to Enhance Yields. Vaccines 2025, 13, 757. https://doi.org/10.3390/vaccines13070757

Göbel S, Zinnecker T, Jordan I, Sandig V, Vervoort A, de Jong J, Diallo J-S, Satzer P, Satzer M, Dallmeier K, et al. Optimization of YF17D-Vectored Zika Vaccine Production by Employing Small-Molecule Viral Sensitizers to Enhance Yields. Vaccines. 2025; 13(7):757. https://doi.org/10.3390/vaccines13070757

Chicago/Turabian StyleGöbel, Sven, Tilia Zinnecker, Ingo Jordan, Volker Sandig, Andrea Vervoort, Jondavid de Jong, Jean-Simon Diallo, Peter Satzer, Manfred Satzer, Kai Dallmeier, and et al. 2025. "Optimization of YF17D-Vectored Zika Vaccine Production by Employing Small-Molecule Viral Sensitizers to Enhance Yields" Vaccines 13, no. 7: 757. https://doi.org/10.3390/vaccines13070757

APA StyleGöbel, S., Zinnecker, T., Jordan, I., Sandig, V., Vervoort, A., de Jong, J., Diallo, J.-S., Satzer, P., Satzer, M., Dallmeier, K., Reichl, U., & Genzel, Y. (2025). Optimization of YF17D-Vectored Zika Vaccine Production by Employing Small-Molecule Viral Sensitizers to Enhance Yields. Vaccines, 13(7), 757. https://doi.org/10.3390/vaccines13070757