Enhanced Downstream Processing for a Cell-Based Avian Influenza (H5N1) Vaccine

Abstract

1. Introductions

2. Materials and Methods

2.1. Cells and Strains

2.2. Virus Harvesting and Pretreatment

2.3. CaptoTM Core 700 Chromatography

2.3.1. Bed Height

2.3.2. Linear Flow Rates

2.3.3. Sample Volume

2.4. Hydrophobic Chromatography

2.5. Sodium Dodecyl Sulfate Polyacrylamide Gel Electrophoresis (SDS-PAGE) and Western Blot Analysis

2.6. HPLC Analysis

2.7. Transmission Electron Microscopy (TEM) Inspection

2.8. Total Protein Content Assay

2.9. Host Cell Residual DNA Detection

2.10. Host Cell Residual Protein Detection

2.11. Hemagglutinin Content Testing

2.12. Statistical Analysis

3. Results

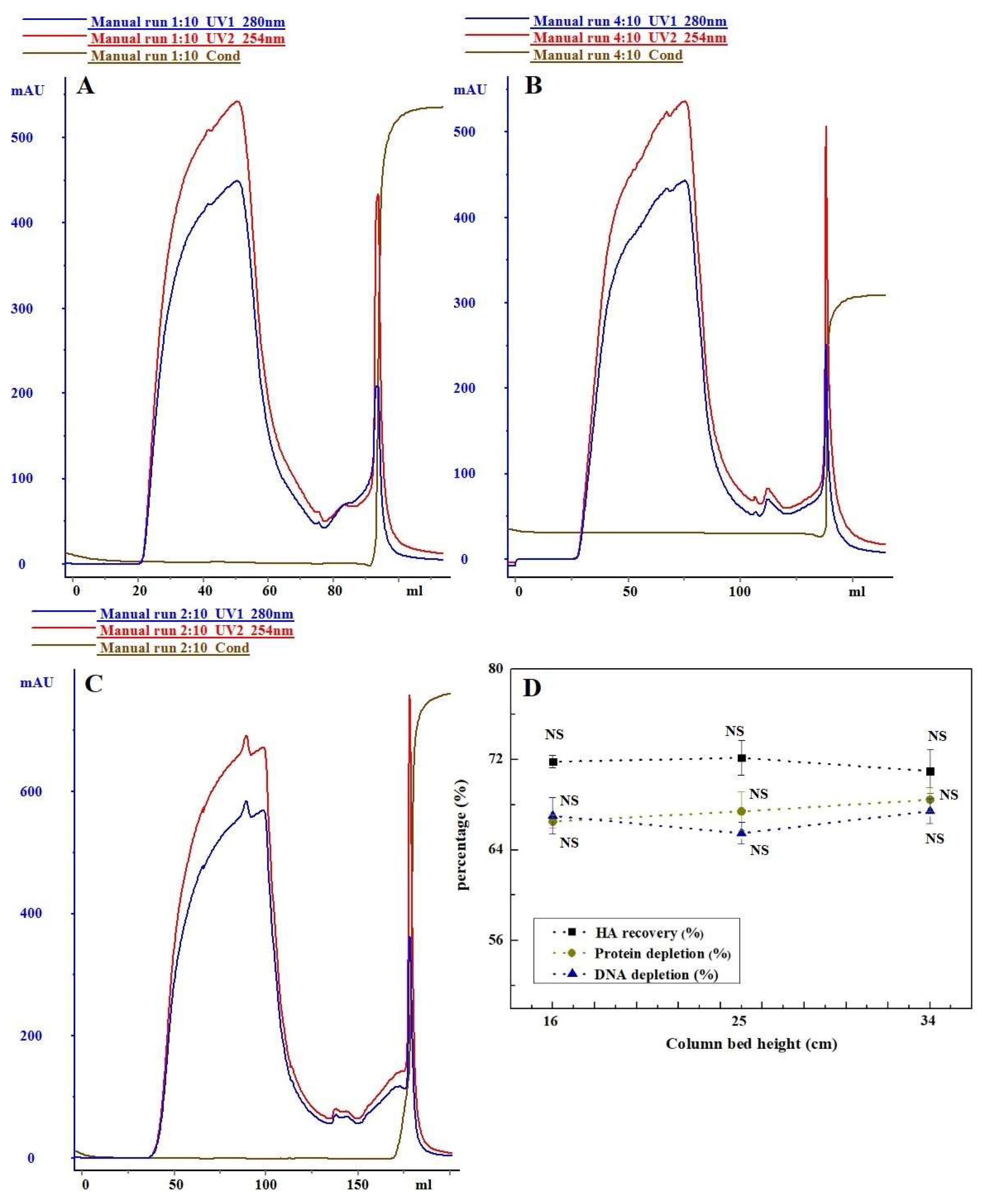

3.1. Flow Rate, Column Bed Height, and Sample Volume Affect Purification of CaptoTM Core 700

3.1.1. The Influence of Column Bed Height on Purification Effect

3.1.2. The Influence of Flow Rate on Purification Effect

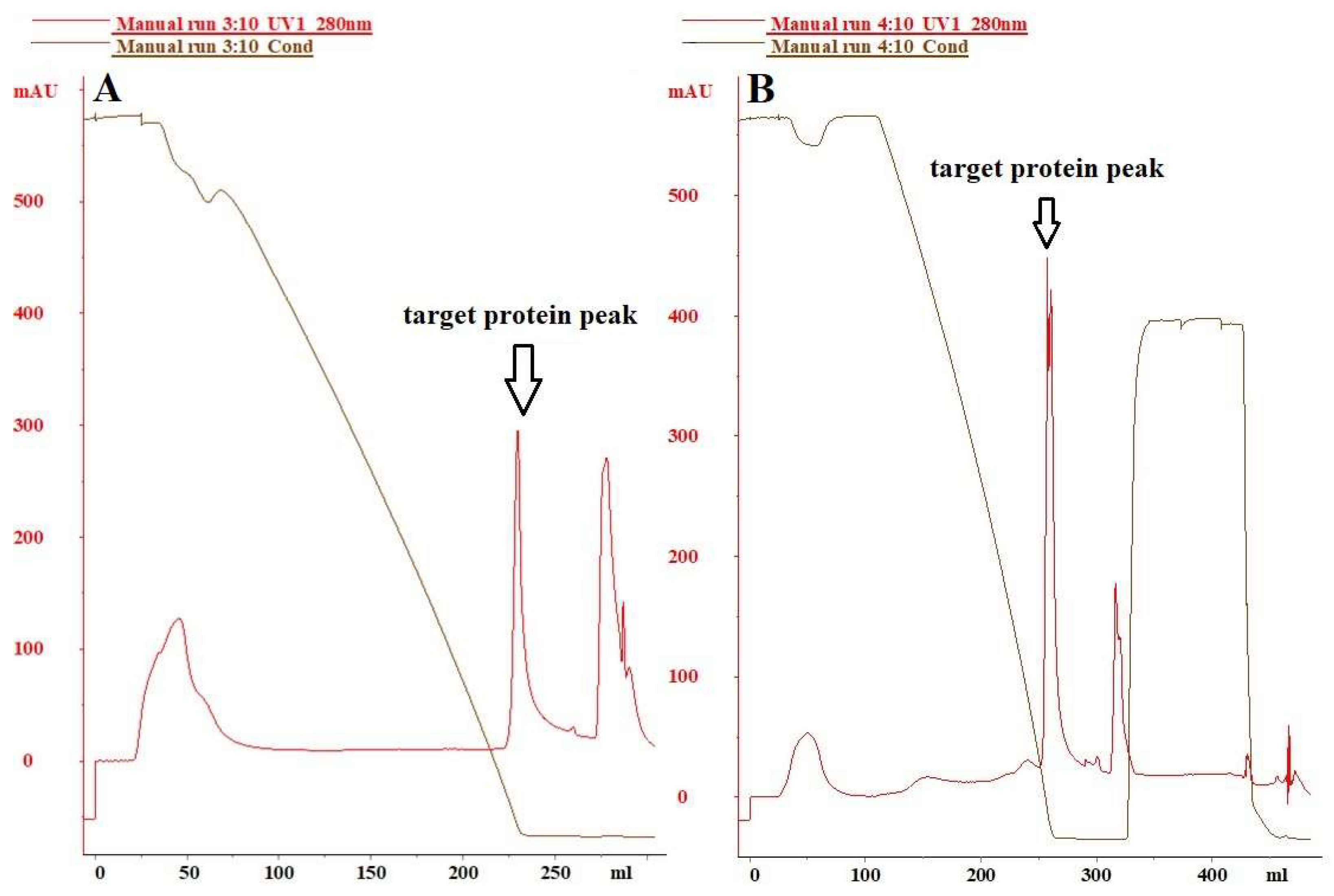

3.1.3. The Influence of Sample Loading Volume on Purification Effect

3.2. The Selection of Hydrophobic Chromatography Media

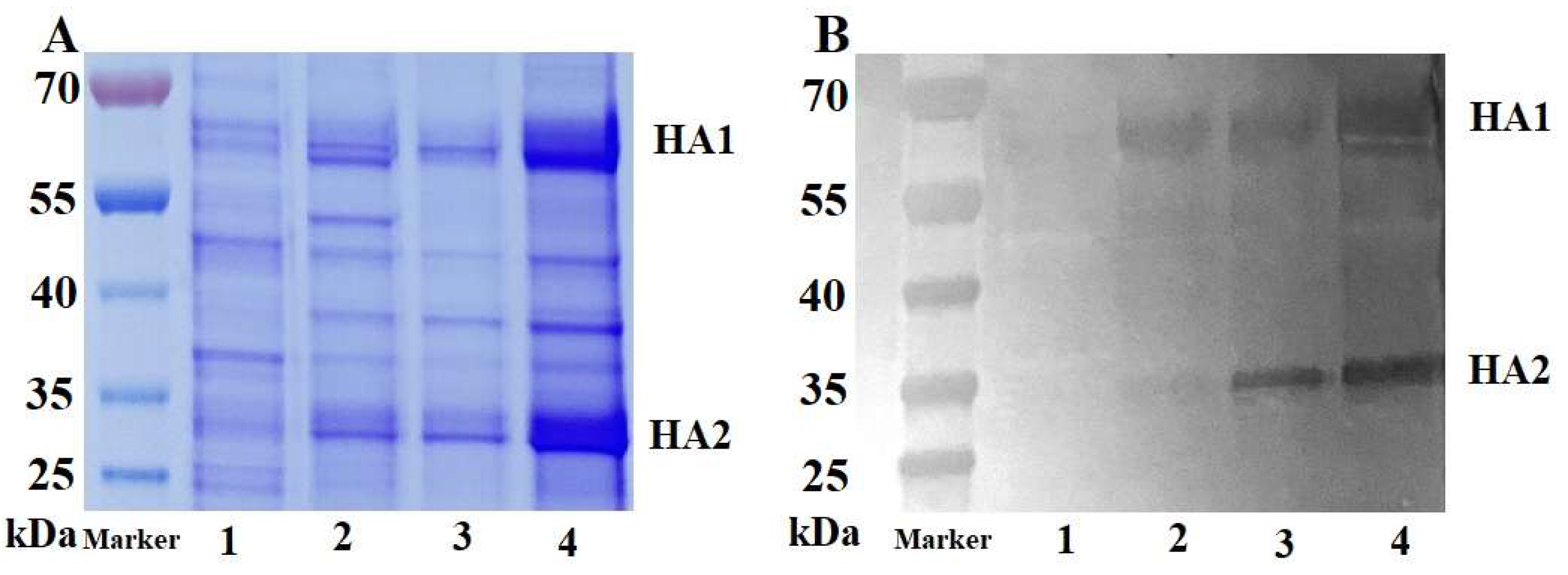

3.3. The Characterization, Purity, and Morphological Analysis of Purified Virus

3.3.1. SDS-PAGE and Western Blot Analysis

3.3.2. HPLC Analysis

3.3.3. TEM Analysis

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- WHO. Antigenic and genetic characteristics of influenza A(H5N1) and influenza A(H9N2) viruses and candidate vaccine viruses developed for potential use in human vaccines. Wkly Epidemiol. Rec. 2010, 85, 100–107. [Google Scholar]

- WHO. Cumulative Number of Confirmed Human Cases of Avian Influenza A/(H5N1) Reported to WHO. 2010. Available online: https://cir.nii.ac.jp/crid/1370285709587166730 (accessed on 2 July 2023).

- Zhao, G.; Lin, Y.; Du, L.; Guan, J.; Sun, S.; Sui, H.; Kou, Z.; Chan, C.C.; Guo, Y.; Jiang, S.; et al. An M2e-based multiple antigenic peptide vaccine protects mice from lethal challenge with divergent H5N1 influenza viruses. Virol. J. 2010, 7, 9. [Google Scholar] [CrossRef]

- Wang, H.; Feng, Z.; Shu, Y.; Yu, H.; Zhou, L.; Zu, R.; Huai, Y.; Dong, J.; Bao, C.; Wen, L.; et al. Probable limited person-to-person transmission of highly pathogenic avian influenza A (H5N1) virus in China. Lancet 2008, 371, 1427. [Google Scholar] [CrossRef]

- Gruenberg, D.A.; Shaker, M.S. An update on influenza vaccination in patients with egg allergy. Curr. Opin. Pediatr. 2011, 23, 566–572. [Google Scholar] [CrossRef]

- Yeolekar, L.R.; Ganguly, M.; Tyagi, P.; Ingle, N.B.; Stittelaar, K.J.; de Waal, L.; Berlanda Scorza, F.; Mahmood, K.; Dhere, R.M. Immunogenicity and efficacy of the monovalent, trivalent and quadrivalent intranasal live attenuated influenza vaccines containing different pdmH1N1 strains. Vaccine 2018, 36, 6944–6952. [Google Scholar] [CrossRef]

- Cell culture as a substrate for the production of influenza vaccines: Memorandum from a WHO Meeting. Bull. World Health Organ. 1995, 73, 431.

- Hegde, N.R.; Kumar, D.; Rao, P.P.; Kumari, P.K.; Kaushik, Y.; Ravikrishnan, R.; Prasad, S.D.; Ella, K.M. Development and preclinical testing of HNVAC, a cell culture-based H1N1 pandemic influenza vaccine from India. Vaccine 2014, 32, 3636–3643. [Google Scholar] [CrossRef]

- Basavaraj, V.H.; Sampath, G.; Hegde, N.R.; Mohan, V.K.; Ella, K.M. Evaluation of safety and immunogenicity of HNVAC, an MDCK-based H1N1 pandemic influenza vaccine, in Phase I single centre and Phase II/III multi-centre, double-blind, randomized, placebo-controlled, parallel assignment studies. Vaccine 2014, 32, 4592–4597. [Google Scholar] [CrossRef]

- Qiu, Z.; Guo, S.; Liu, G.; Pei, M.; Liao, Y.; Wang, J.; Zhang, J.; Yang, D.; Qiao, Z.; Li, Z.; et al. TGM2 inhibits the proliferation, migration and tumorigenesis of MDCK cells. PLoS ONE 2023, 18, e0285136. [Google Scholar] [CrossRef] [PubMed]

- Qiao, Z.; Liao, Y.; Pei, M.; Qiu, Z.; Liu, Z.; Jin, D.; Zhang, J.; Ma, Z.; Yang, X. RSAD2 is an effective target for high-yield vaccine production in MDCK Cells. Viruses 2022, 14, 2587. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Pei, M.; Liu, G.; Qiu, Z.; Wang, S.; Qiao, Z.; Wang, J.; Jin, D.; Zhang, J.; Duan, K.; et al. CDC20 is a potential target gene to inhibit the tumorigenesis of MDCK cells. Biologicals 2023, 83, 1045–1056. [Google Scholar] [CrossRef] [PubMed]

- Asanzhanova, N.N.; Ryskeldinova, S.Z.; Chervyakova, O.V.; Khairullin, B.M.; Kasenov, M.M.; Tabynov, K.K. Comparison of different methods of purification and concentration in production of influenza vaccine. Bull. Exp. Biol. Med. 2017, 164, 229–232. [Google Scholar] [CrossRef] [PubMed]

- Schwartzberg, L.S.; Navari, R.M. Safety of polysorbate 80 in the oncology setting. Adv. Ther. 2018, 35, 754–767. [Google Scholar] [CrossRef] [PubMed]

- Neog, S.; Kumar, S.; Trivedi, V. Isolation and characterization of Newcastle disease virus from biological fluids using column chromatography. Biomed. Chromatogr. 2023, 37, e5527. [Google Scholar] [CrossRef] [PubMed]

- Túlio, M.L.; Souza, M.O.; Castilho, L.R. Purification of flavivirus VLPs by a two-step chomatographic process. Vaccine 2019, 37, 7061–7069. [Google Scholar]

- Kalbfuss, B.; Wolff, M.; Morenweiser, R.; Reichl, U. Purification of cell culture-derived human influenza A virus by size-exclusion and anion-exchange chromatography. Biotechnol. Bioeng. 2010, 96, 932–944. [Google Scholar] [CrossRef] [PubMed]

- Mi, X.; Fuks, P.; Wang, S.-C.; Winters, M.A.; Carta, G. Protein adsorption on core-shell particles: Comparison of Capto Core 400 and 700 Resins. J. Chromatogr. A 2021, 1651, 462314. [Google Scholar] [CrossRef] [PubMed]

- Pato, T.P.; Souza, M.C.; Mattos, D.A.; Caride, E.; Ferreira, D.F.; Gaspar, L.P.; Freire, M.S.; Castilho, L.R. Purification of yellow fever virus produced in Vero cells for inactivated vaccine manufacture. Vaccine 2019, 37, 3214–3220. [Google Scholar] [CrossRef]

- Brekkan, E. Multimodal Chromatography in Biopharmaceutical Processing; Elsevier: Amsterdam, The Netherlands, 2018; pp. 409–419. [Google Scholar]

- Trabelsi, K.; Zakour, M.B.; Kallel, H. Purification of rabies virus produced in Vero cells grown in serum free medium. Vaccine 2019, 37, 7052–7060. [Google Scholar] [CrossRef]

- Lothert, K.; Pagallies, F.; Feger, T.; Amann, R.; Wolff, M.W. Selection of chromatographic methods for the purification of cell culture-derived Orf virus for its application as a vaccine or viral vector. J. Biotechnol. 2020, 323, 62–72. [Google Scholar] [CrossRef]

- Gooding, K.M.; Regnier, F.E. HPLC of Biological Macro-Molecules, Revised and Expanded; Marcel Dekker Inc.: New York, NY, USA, 2002. [Google Scholar]

- McCue, J.T. Use and application of hydrophobic interaction chromatography for protein purification. Methods Enzymol. 2014, 541, 51–65. [Google Scholar] [PubMed]

- Mccue, J.T. Theory and use of hydrophobic interaction chromatography in protein purification applications. Methods Enzymol. 2009, 463, 405–414. [Google Scholar] [PubMed]

- Kennedy, R.M. Hydrophobic-interaction chromatography. Curr. Protoc. Protein Sci. 2001, 8.4.1–8.4.21. [Google Scholar] [CrossRef] [PubMed]

- Weigel, T.; Solomaier, T.; Peuker, A.; Pathapati, T.; Wolff, M.W.; Reichl, U. A flow-through chromatography process for influenza A and B virus purification. J. Virol. Methods 2014, 207, 45–53. [Google Scholar] [CrossRef]

- Zhang, F.; Luo, J.; Teng, M.; Xing, G.; Guo, J.; Zhang, Y. Purification of cell-derived Japanese encephalitis virus by dual-mode chromatography. Biotechnol. Appl. Biochem. 2021, 68, 547–553. [Google Scholar] [CrossRef]

- Li, H.; Yang, Y.; Zhang, Y.; Zhang, S.; Zhao, Q.; Zhu, Y.; Zou, X.; Yu, M.; Ma, G.; Su, Z. A hydrophobic interaction chromatography strategy for purification of inactivated foot-and-mouth disease virus. Protein Expr. Purif. 2015, 113, 23–29. [Google Scholar] [CrossRef]

- Chand, P.; Kitching, R.P.; Black, D.N. Western blot analysis of virus-specific antibody responses for capripox and contagious pustular dermatitis viral infections in sheep. Epidemiol Infect 1994, 113, 377–385. [Google Scholar] [CrossRef]

- Yang, Z.S.; Huang, S.W.; Wang, W.H.; Lin, C.Y.; Wang, C.F.; Urbina, A.N.; Thitithanyanont, A.; Tseng, S.P.; Lu, P.L.; Chen, Y.H.; et al. Identification of important N-linked glycosylation sites in the hemagglutinin protein and their functional impact on DC-SIGN mediated avian influenza H5N1 infection. Int. J. Mol. Sci. 2021, 22, 743. [Google Scholar] [CrossRef]

- Job, E.R.; Bottazzi, B.; Gilbertson, B.; Edenborough, K.M.; Brown, L.E.; Mantovani, A.; Brooks, A.G.; Reading, P.C. Serum amyloid P is a sialylated glycoprotein inhibitor of influenza A viruses. PLoS ONE 2013, 8, e59623. [Google Scholar] [CrossRef]

- Onions, D.; Egan, W.; Jarrett, R.; Novicki, D.; Gregersen, J.-P. Validation of the safety of MDCK cells as a substrate for the production of a cell-derived influenza vaccine. Biologicals 2010, 38, 544–551. [Google Scholar] [CrossRef]

- Wolff, M.; Reichl, U. Downstream processing of cell culture-derived virus particles. Expert Rev. Vaccines 2011, 10, 1451–1475. [Google Scholar] [CrossRef] [PubMed]

- GE Healthcare. Capto Core 700. Application Note 28-9983-07 AA. [2020-03-05]. 2012. Available online: https://www.docin.com/p-402737659.html?qq-pf-to=pcqq.group (accessed on 18 January 2022).

- Nestola, P.; Peixoto, C.; Villain, L.; Alves, P.M.; Carrondo, M.J.; Mota, J.P. Rational developmentof two flowthrough purification strategies for adenovirus type 5and retro virus-like particles. J. Chromatogr. A 2015, 1424, 91–101. [Google Scholar] [CrossRef] [PubMed]

- Blom, H.; Åkerblom, A.; Kon, T.; Shaker, S.; van der Pol, L.; Lundgren, M. Efficient chromatographic reduction of ovalbumin for egg-based influenza virus purification. Vaccine 2014, 32, 3721–3724. [Google Scholar] [CrossRef]

- Wolff, M.W.; Siewert, C.; Hansen, S.P.; Faber, R.; Reichl, U. Purification of cell culture derived modified vaccinia ankara virus by pseudo-affinity membrane adsorbers and hydrophobic interaction chromatography. Biotechnol. Bioeng. 2010, 107, 312–320. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Bi, J.; Zhao, L.; Wang, Y.; Li, Y.; Huang, Y.; Ma, G.; Su, Z. A highly efficient hydrophobic interaction chromatographic absorbent improved the purification of hepatitis B surface antigen (HBsAg) derived from Hansenula polymorpha cell. Process Biochem. 2007, 42, 751–756. [Google Scholar] [CrossRef]

- Sviben, D.; Forcic, D.; Ivancic-Jelecki, J.; Halassy, B.; Brgles, M. Recovery of infective virus particles in ion-exchange and hydrophobic interaction monolith chromatography is influenced by particle charge and total-to-infective particle ratio. J. Chromatogr. B Analyt. Technol. Biomed. Life Sci. 2017, 1054, 10–19. [Google Scholar] [CrossRef]

- Fischer, L.M.; Wolff, M.W.; Reichl, U. Purification of cell culture-derived influenza A virus via continuous anion exchange chromatography on monoliths. Vaccine 2018, 36, 3153–3160. [Google Scholar] [CrossRef]

- Konz, J.O.; Lee, A.L.; Lewis, J.A.; Sagar, S.L. Development of a purification process for adenovirus: Controlling virus aggregation to improve the clearance of host cell DNA. Biotechnol. Prog. 2005, 21, 466–472. [Google Scholar] [CrossRef]

- Weigel, T.; Solomaier, T.; Wehmeyer, S.; Peuker, A.; Wolff, M.W.; Reichl, U. A membrane-based purification process for cell culture-derived influenza A virus. J. Biotechnol. 2016, 220, 12–20. [Google Scholar] [CrossRef]

- Caldwell, K.A. The fractionation and purification of gliadins by hydrophobic interaction chromatography. J. Sci. Food Agr. 2010, 30, 185–196. [Google Scholar] [CrossRef]

- Weigel, T.; Soliman, R.; Wolff, M.W.; Reichl, U. Hydrophobic-interaction chromatography for purification of influenza A and B virus. J. Chromatogr. B Analyt. Technol. Biomed. Life Sci. 2019, 1117, 103–117. [Google Scholar] [CrossRef]

- Chen, G.Y.; Chen, C.Y.; Chang, M.D.; Matsuura, Y.; Hu, Y.C. Concanavalin a affinity chromatography for efficient baculovirus purification. Biotechnol. Prog. 2009, 25, 1669–1677. [Google Scholar] [CrossRef] [PubMed]

- Montomoli, E.; Khadang, B.; Piccirella, S.; Trombetta, C.; Mennitto, E.; Manini, I.; Stanzani, V.; Lapini, G. Cell culture-derived influenza vaccines from Vero cells: A new horizon for vaccine production. Expert Rev. Vaccines 2012, 11, 587–594. [Google Scholar] [CrossRef] [PubMed]

- Bissinger, T.; Wu, Y.; Marichal-Gallardo, P.; Riedel, D.; Liu, X.; Genzel, Y.; Tan, W.S.; Reichl, U. Towards integrated production of an influenza A vaccine candidate with MDCK suspension cells. Biotechnol. Bioeng. 2021, 118, 3996–4013. [Google Scholar] [CrossRef] [PubMed]

- Opitz, L.; Lehmann, S.; Reichl, U.; Wolff, M.W. Sulfated membrane adsorbers for economic pseudo-affinity capture of influenza virus particles. Biotechnol. Bioeng. 2009, 103, 1144–1154. [Google Scholar] [CrossRef]

| Parameters | Variables |

|---|---|

| Bed Heights (cm) | 16 |

| 25 | |

| 34 | |

| Linear flow rates (cm/h) | 50 |

| 100 | |

| 200 | |

| Sample volume (%BV) | 25 |

| 50 | |

| 100 | |

| 175 |

| Step | Parameter |

|---|---|

| System | ÄKTA™ purifier (Cytiva, Uppsala, Sweden) |

| Column | XK16/40 (Cytiva, Uppsala, Sweden), column height = 16 cm, CaptoTM Core 700 |

| Sample | H5N1 HPAIV (NIBSC, Hertfordshire, UK) ultrafiltration concentrate |

| Sample load | 100% BV, 100 cm/h |

| Running buffer | 150 mmol/L NaCl + 20 mmol/L PB, pH 7.5, 100 cm/h |

| Wash | 150 mmol/L NaCl + 20 mmol/L PB, pH 7.5, 100 cm/h |

| Cleaning in place (CIP) | 0.5 M NaOH, 60 cm/h |

| Indicator | Value |

|---|---|

| HA Recovery (%) | 72.26 ± 2.11 |

| Protein depletion (%) | 66.35 ± 1.95 |

| DNA depletion (%) | 65.16 ± 2.18 |

| Total protein concentration/HA concentration | 4.56 ± 0.76 |

| HA (µg/mL) | 45.86 ± 4.29 |

| DNA (ng/mL) | 83 ± 6.86 |

| HCP (ng/mL) | 3145 ± 116.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Liu, B.; Xiong, Y.; Zhang, Z.; Zhang, Q.; Qiu, R.; Peng, F.; Nian, X.; Wu, D.; Li, X.; et al. Enhanced Downstream Processing for a Cell-Based Avian Influenza (H5N1) Vaccine. Vaccines 2024, 12, 138. https://doi.org/10.3390/vaccines12020138

Li F, Liu B, Xiong Y, Zhang Z, Zhang Q, Qiu R, Peng F, Nian X, Wu D, Li X, et al. Enhanced Downstream Processing for a Cell-Based Avian Influenza (H5N1) Vaccine. Vaccines. 2024; 12(2):138. https://doi.org/10.3390/vaccines12020138

Chicago/Turabian StyleLi, Fang, Bo Liu, Yu Xiong, Zhegang Zhang, Qingmei Zhang, Ran Qiu, Feixia Peng, Xuanxuan Nian, Dongping Wu, Xuedan Li, and et al. 2024. "Enhanced Downstream Processing for a Cell-Based Avian Influenza (H5N1) Vaccine" Vaccines 12, no. 2: 138. https://doi.org/10.3390/vaccines12020138

APA StyleLi, F., Liu, B., Xiong, Y., Zhang, Z., Zhang, Q., Qiu, R., Peng, F., Nian, X., Wu, D., Li, X., Liu, J., Li, Z., Tu, H., Wu, W., Wang, Y., Zhang, J., & Yang, X. (2024). Enhanced Downstream Processing for a Cell-Based Avian Influenza (H5N1) Vaccine. Vaccines, 12(2), 138. https://doi.org/10.3390/vaccines12020138