High-Level Expression of Recombinant VHSV Glycoprotein Using Transformed C. vulgaris and Verification of Vaccine Efficacy

Abstract

1. Introduction

2. Materials and Methods

2.1. Culture Conditions for Chlorella vulgaris

2.2. Construction of Chlorella Transformation Vector

2.3. Chlorella Transformation

2.4. Selection and Confirmation of Transformed Cells

2.5. Detection of Expressed Protein by Western Blotting

2.6. Analysis of Growth of Transformed Chlorella vulgaris According to NaCl Concentration

2.7. Induction of Protein Expression by NaCl Treatment

2.8. Vaccination

2.9. VHSV Challenge

2.10. VHSV Neutralization Assay

2.11. Statistical Analysis

3. Results

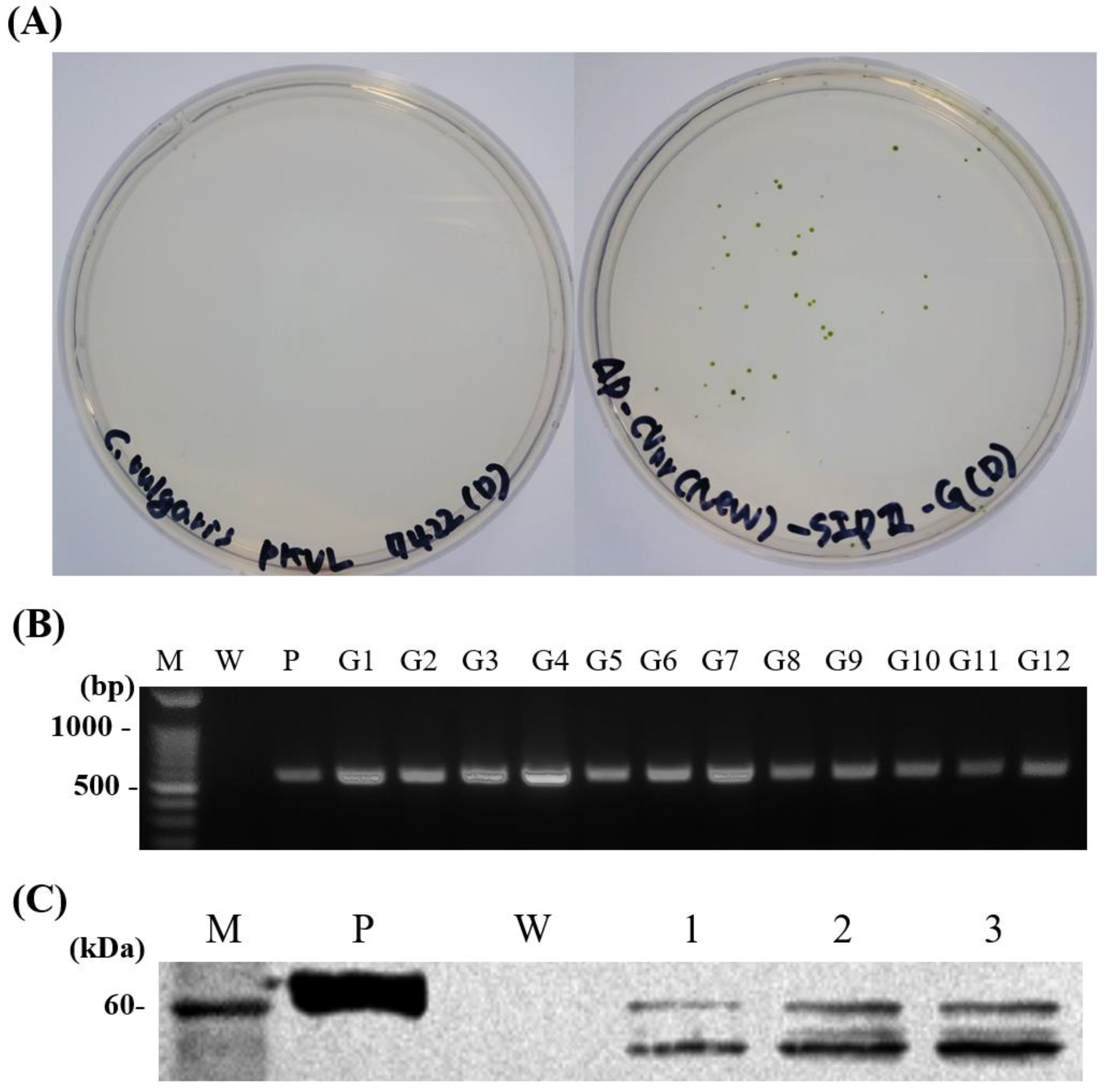

3.1. Transformation of Chlorella vulgaris

3.2. Growth of Transformed Chlorella vulgaris in Media Containing NaCl

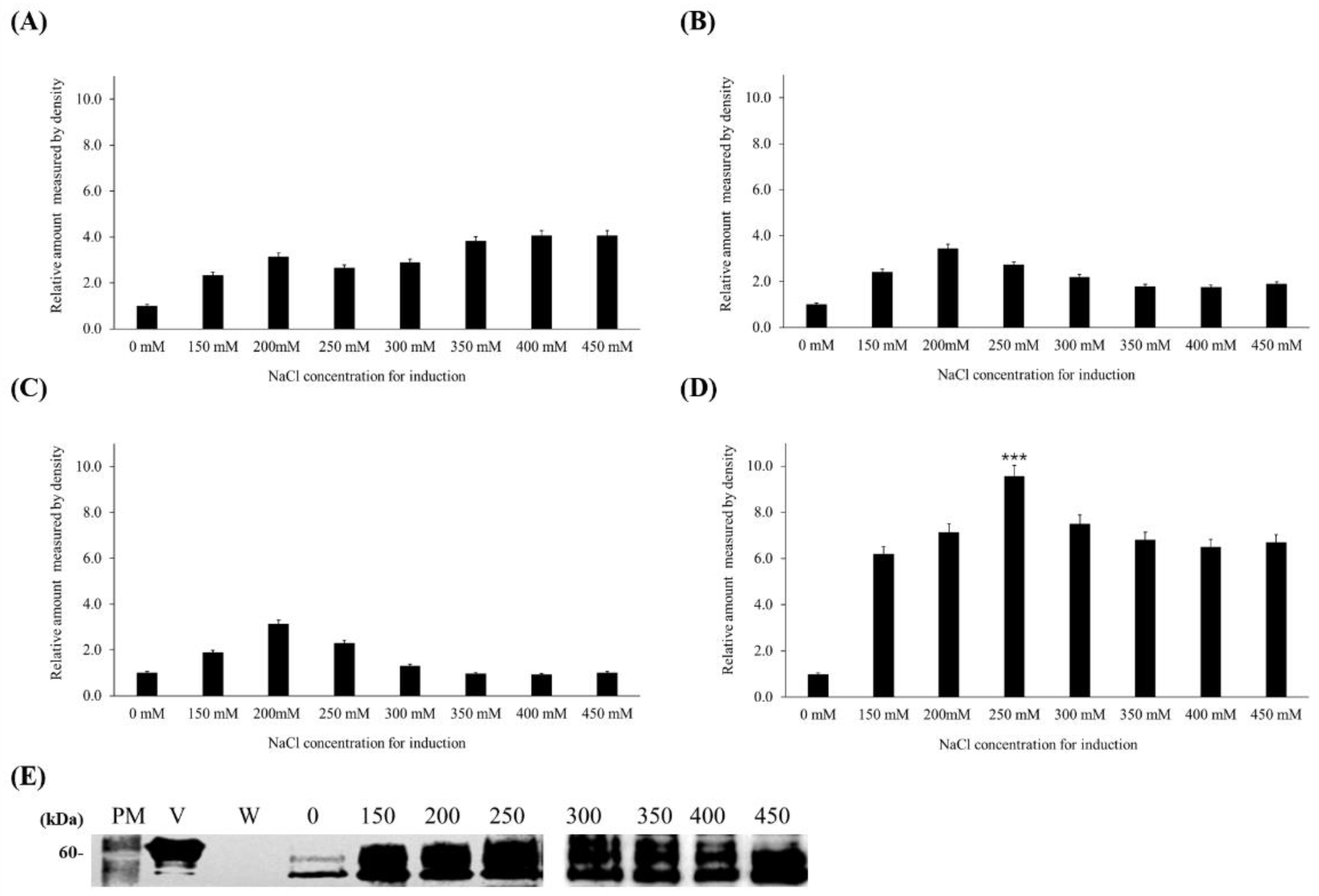

3.3. Induction of Target Protein Expression by NaCl Treatment

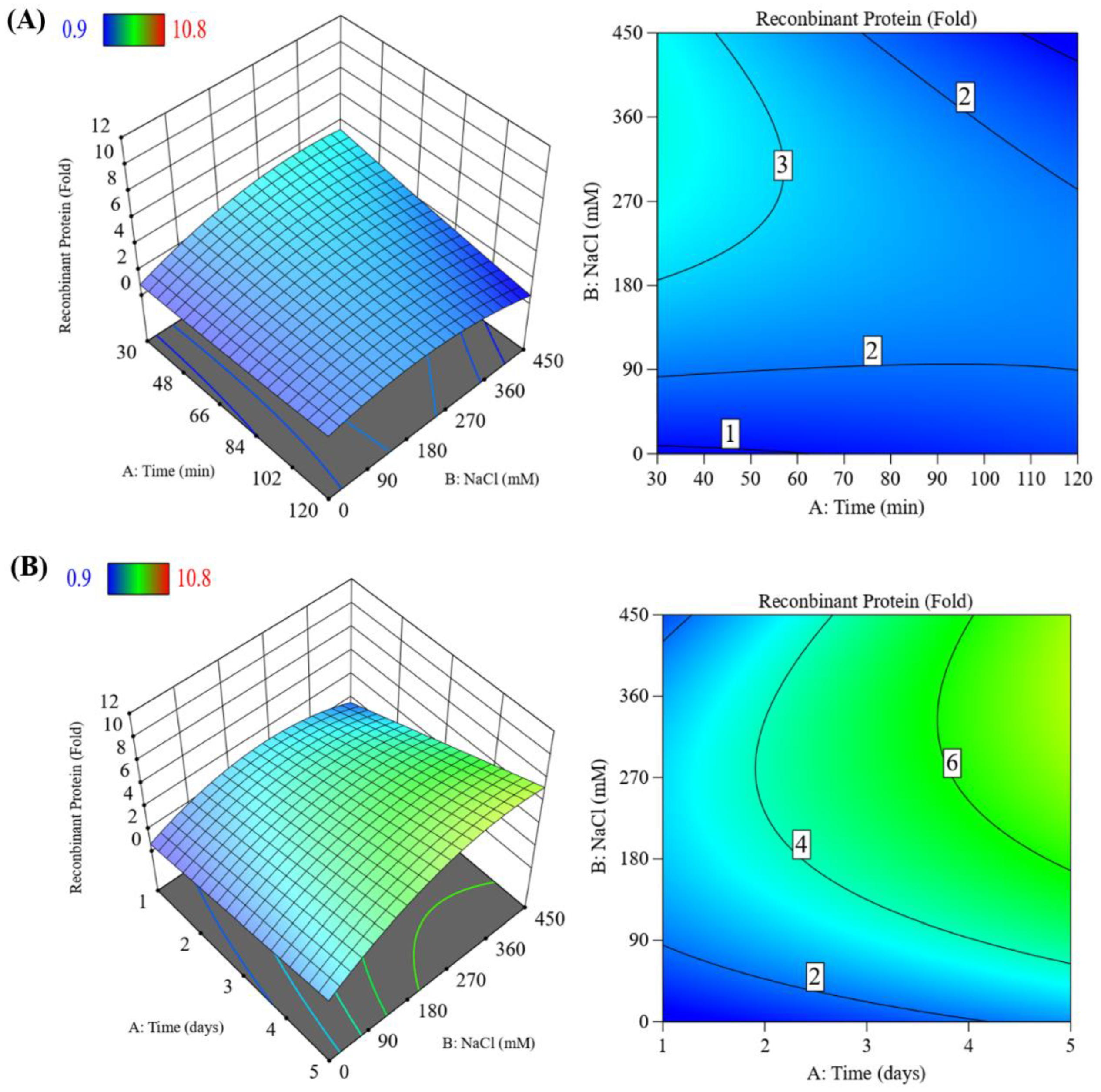

3.4. Optimization of Induction Parameters

3.5. Quantification of VHSV Glycoprotein Expression

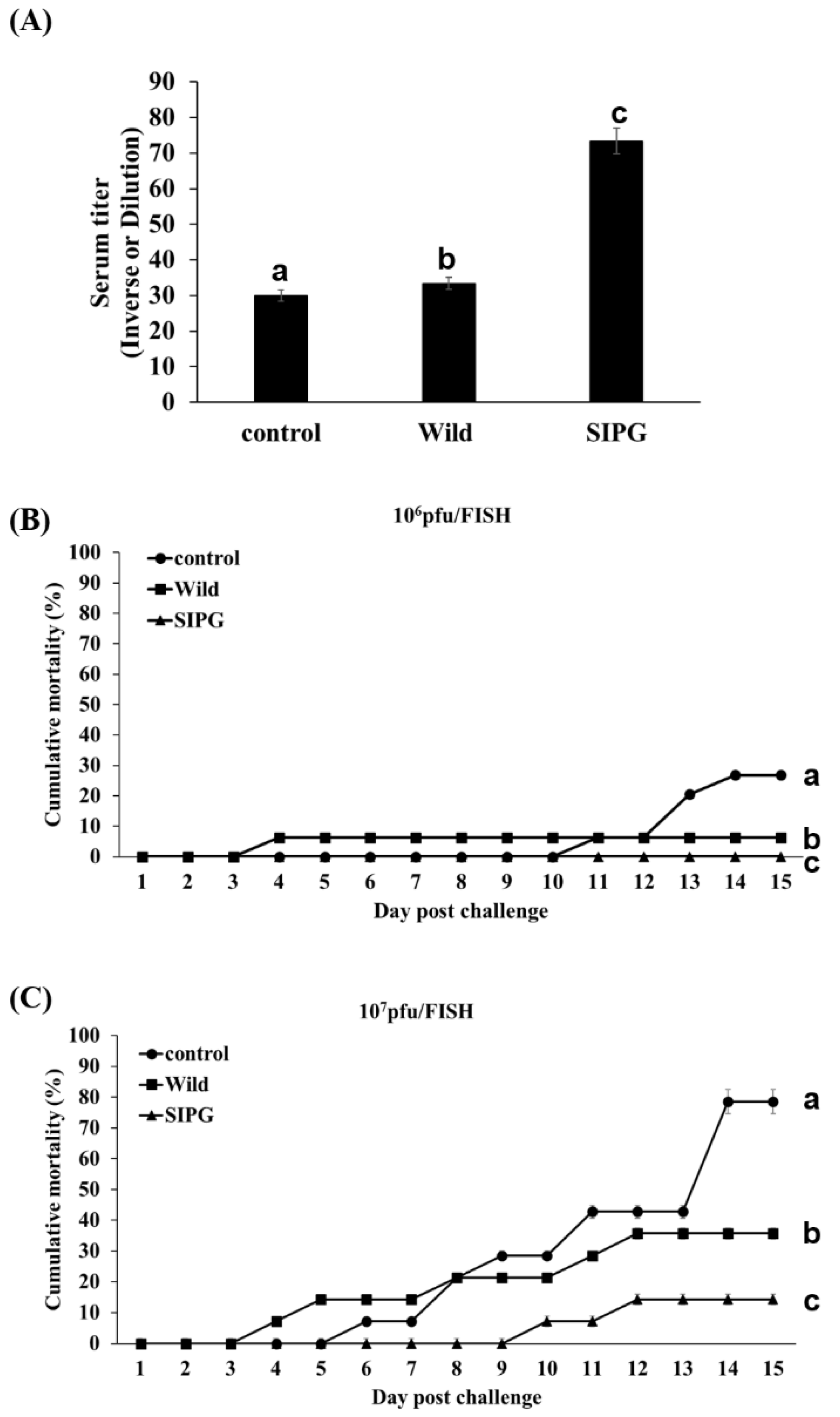

3.6. Vaccine Efficacy of VHSV Glycoprotein-Expressing Chlorella vulgaris

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pauly, D.; Zeller, D. Comments on FAOs state of world fisheries and aquaculture (SOFIA 2016). Mar. Policy 2017, 77, 176–181. [Google Scholar] [CrossRef]

- Pauly, D.; Zeller, D. Agreeing with FAO: Comments on SOFIA 2018. Mar. Policy 2019, 100, 332–333. [Google Scholar] [CrossRef]

- Lafferty, K.D.; Harvell, C.D.; Conrad, J.M.; Friedman, C.S.; Kent, M.L.; Kuris, A.M.; Powell, E.N.; Rondeau, D.; Saksida, S.M. Infectious diseases affect marine fisheries and aquaculture economics. Annu. Rev. Mar. Sci. 2015, 7, 471–496. [Google Scholar] [CrossRef] [PubMed]

- Ajayi, O.; Akinrinlola, A.; Usman, A.; Muhammed, A.; Van der Knaap, M. Aquaculture Development in Nigeria and FAO’s Role. FAO Aquac. Newsl. 2022, 65, 21–24. [Google Scholar]

- Rana, K.J.; Siriwardena, S.; Hasan, M.R. Impact of Rising Feed Ingredient Prices on Aquafeeds and Aquaculture Production; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy, 2009. [Google Scholar]

- Fry, J.P.; Mailloux, N.A.; Love, D.C.; Milli, M.C.; Cao, L. Feed conversion efficiency in aquaculture: Do we measure it correctly? Environ. Res. Lett. 2018, 13, 024017. [Google Scholar] [CrossRef]

- Nagappan, S.; Das, P.; AbdulQuadir, M.; Thaher, M.; Khan, S.; Mahata, C.; Al-Jabri, H.; Vatland, A.K.; Kumar, G. Potential of microalgae as a sustainable feed ingredient for aquaculture. J. Biotechnol. 2021, 341, 1–20. [Google Scholar] [CrossRef]

- Nagarajan, D.; Varjani, S.; Lee, D.-J.; Chang, J.-S. Sustainable aquaculture and animal feed from microalgae–nutritive value and techno-functional components. Renew. Sustain. Energy Rev. 2021, 150, 111549. [Google Scholar] [CrossRef]

- Madeira, M.S.; Cardoso, C.; Lopes, P.A.; Coelho, D.; Afonso, C.; Bandarra, N.M.; Prates, J.A. Microalgae as feed ingredients for livestock production and meat quality: A review. Livest. Sci. 2017, 205, 111–121. [Google Scholar] [CrossRef]

- Annamalai, S.N.; Das, P.; Thaher, M.I.; Abdul Quadir, M.; Khan, S.; Mahata, C.; Al Jabri, H. Nutrients and energy digestibility of microalgal biomass for fish feed applications. Sustainability 2021, 13, 13211. [Google Scholar] [CrossRef]

- Miccoli, A.; Manni, M.; Picchietti, S.; Scapigliati, G. State-of-the-art vaccine research for aquaculture use: The case of three economically relevant fish species. Vaccines 2021, 9, 140. [Google Scholar] [CrossRef]

- Abdellaoui, N.; Kim, M.J.; Choi, T.J. Transcriptome analysis of gene expression in Chlorella vulgaris under salt stress. World J. Microbiol. Biotechnol. 2019, 35, 141. [Google Scholar] [CrossRef]

- Adams, A. Progress, challenges and opportunities in fish vaccine development. Fish Shellfish Immunol. 2019, 90, 210–214. [Google Scholar] [CrossRef]

- Matsuura, Y.; Terashima, S.; Takano, T.; Matsuyama, T. Current status of fish vaccines in Japan. Fish Shellfish Immunol. 2019, 95, 236–247. [Google Scholar] [CrossRef]

- Hwang, J.Y.; Kwon, M.G.; Seo, J.S.; Hwang, S.D.; Jeong, J.M.; Lee, J.H.; Jeong, A.R.; Jee, B.Y. Current use and management of commercial fish vaccines in Korea. Fish Shellfish Immunol. 2020, 102, 20–27. [Google Scholar] [CrossRef]

- Wang, Q.; Ji, W.; Xu, Z. Current use and development of fish vaccines in China. Fish Shellfish Immunol. 2020, 96, 223–234. [Google Scholar] [CrossRef]

- Ji, Q.; Wang, S.; Ma, J.; Liu, Q. A review: Progress in the development of fish Vibrio spp. vaccines. Immunol. Lett. 2020, 226, 46–54. [Google Scholar] [CrossRef]

- Kibenge, F.S. Emerging viruses in aquaculture. Curr. Opin. Virol. 2019, 34, 97–103. [Google Scholar] [CrossRef]

- Skall, H.F.; Olesen, N.J.; Mellergaard, S. Viral haemorrhagic septicaemia virus in marine fish and its implications for fish farming—A review. J. Fish Dis. 2005, 28, 509–529. [Google Scholar] [CrossRef]

- Shim, J.-D.; Hwang, S.-D.; Jang, S.-Y.; Kim, T.-W.; Jeong, J.-M. Monitoring of the mortalities in oliver flounder (Paralichthys olivaceus) farms of Korea. J. Fish Pathol. 2019, 32, 29–35. [Google Scholar]

- Moattari, G.; Izadi, Z.; Shakhsi-Niaei, M. Development of an electrochemical genosensor for detection of viral hemorrhagic septicemia virus (VHSV) using glycoprotein (G) gene probe. Aquaculture 2021, 536, 736451. [Google Scholar] [CrossRef]

- Kim, H.J.; Kwon, S.R.; Olesen, N.J.; Cuenca, A. Development of a novel real-time RT-PCR method using peptide nucleic acid (PNA) probes for detecting and genotyping of viral haemorrhagic septicaemia virus (VHSV). Aquaculture 2023, 570, 739408. [Google Scholar] [CrossRef]

- WOAH. Infection with viral haemorrhagic septicaemia virus. In Manual of Diagnostic Tests for Aquatic Animals (2021) Chapter 2.3.10; WOAH: Paris, France, 2021. [Google Scholar]

- (OIE) World Organization for Animal Health. Manual of Diagnostic Tests for Aquatic Animals; Viral Haemorrhagic Septicaemia. 2018, Chapter 2.3.10. Available online: http://www.oie.int/fileadmin/Home/eng/Health_standards/aahm/current/chapitre_vhs.pdf (accessed on 14 November 2019).

- Kembou-Ringert, J.E.; Steinhagen, D.; Readman, J.; Daly, J.M.; Adamek, M. Tilapia Lake Virus Vaccine Development: A Review on the Recent Advances. Vaccines 2023, 11, 251. [Google Scholar] [CrossRef] [PubMed]

- Berg, A.; Bergh, Ø.; Fjelldal, P.G.; Hansen, T.; Juell, J.-E.; Nerland, A.H. Animal welfare and fish vaccination—Effects and side-effects. Fisk. Og Havet 2006, 9. [Google Scholar]

- Erkinharju, T.; Lundberg, M.R.; Isdal, E.; Hordvik, I.; Dalmo, R.A.; Seternes, T. Studies on the antibody response and side effects after intramuscular and intraperitoneal injection of Atlantic lumpfish (Cyclopterus lumpus L.) with different oil-based vaccines. J. Fish Dis. 2017, 40, 1805–1813. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Ma, S.; Woo, N.Y. Vaccination of Silver Sea Bream (Sparus sarba) against Vibrio alginolyticus: Protective evaluation of different vaccinating modalities. Int. J. Mol. Sci. 2015, 17, 40. [Google Scholar] [CrossRef]

- Bøgwald, J.; Dalmo, R.A. Protection of teleost fish against infectious diseases through oral administration of vaccines: Update 2021. Int. J. Mol. Sci. 2021, 22, 10932. [Google Scholar] [CrossRef]

- Alishah Aratboni, H.; Rafiei, N.; Garcia-Granados, R.; Alemzadeh, A.; Morones-Ramírez, J.R. Biomass and lipid induction strategies in microalgae for biofuel production and other applications. Microb. Cell Factories 2019, 18, 178. [Google Scholar] [CrossRef]

- Dehghani, J.; Adibkia, K.; Movafeghi, A.; Maleki-Kakelar, H.; Saeedi, N.; Omidi, Y. Towards a new avenue for producing therapeutic proteins: Microalgae as a tempting green biofactory. Biotechnol. Adv. 2020, 40, 107499. [Google Scholar] [CrossRef]

- Mathieu-Rivet, E.; Mati-Baouche, N.; Walet-Balieu, M.-L.; Lerouge, P.; Bardor, M. N-and O-glycosylation pathways in the microalgae polyphyletic group. Front. Plant Sci. 2020, 11, 609993. [Google Scholar] [CrossRef]

- Barolo, L.; Abbriano, R.M.; Commault, A.S.; George, J.; Kahlke, T.; Fabris, M.; Padula, M.P.; Lopez, A.; Ralph, P.J.; Pernice, M. Perspectives for glyco-engineering of recombinant biopharmaceuticals from microalgae. Cells 2020, 9, 633. [Google Scholar] [CrossRef]

- Sun, M.; Qian, K.; Su, N.; Chang, H.; Liu, J.; Shen, G. Foot-and-mouth disease virus VP1 protein fused with cholera toxin B subunit expressed in Chlamydomonas reinhardtii chloroplast. Biotechnol. Lett. 2003, 25, 1087–1092. [Google Scholar] [CrossRef]

- Specht, E.A.; Mayfield, S.P. Algae-based oral recombinant vaccines. Front. Microbiol. 2014, 5, 60. [Google Scholar] [CrossRef]

- Kim, M.-J.; Kim, S.-H.; Kim, Y.-R.; Choi, T.-J. Enhancement of Chlorella transformation efficacy by insert fragmentation. Algal Res. 2023, 72, 103146. [Google Scholar] [CrossRef]

- Naderi-Samani, M.; Soltani, M.; Dadar, M.; Taheri-Mirghaed, A.; Zargar, A.; Ahmadivand, S.; Hassanzadeh, R.; Goudarzi, L.M. Oral immunization of trout fry with recombinant Lactococcus lactis NZ3900 expressing G gene of viral hemorrhagic septicaemia virus (VHSV). Fish Shellfish Immunol. 2020, 105, 62–70. [Google Scholar] [CrossRef] [PubMed]

- Marsella, A.; Pascoli, F.; Pretto, T.; Buratin, A.; Biasini, L.; Abbadi, M.; Cortinovis, L.; Berto, P.; Manfrin, A.; Vanelli, M. Efficacy of DNA Vaccines in Protecting Rainbow Trout against VHS and IHN under Intensive Farming Conditions. Vaccines 2022, 10, 2062. [Google Scholar] [CrossRef] [PubMed]

- Kole, S.; Qadiri, S.S.N.; Shin, S.-M.; Kim, W.-S.; Lee, J.; Jung, S.-J. PLGA encapsulated inactivated-viral vaccine: Formulation and evaluation of its protective efficacy against viral haemorrhagic septicaemia virus (VHSV) infection in olive flounder (Paralichthys olivaceus) vaccinated by mucosal delivery routes. Vaccine 2019, 37, 973–983. [Google Scholar] [CrossRef]

- Einer-Jensen, K.; Delgado, L.; Lorenzen, E.; Bovo, G.; Evensen, Ø.; LaPatra, S.; Lorenzen, N. Dual DNA vaccination of rainbow trout (Oncorhynchus mykiss) against two different rhabdoviruses, VHSV and IHNV, induces specific divalent protection. Vaccine 2009, 27, 1248–1253. [Google Scholar] [CrossRef]

- Li, J.; Tang, L.; Li, S.; Li, G.; Mo, Z. The efficacy and side-effects of oil-based adjuvants emulsified Vibrio anguillarum bivalent inactivated vaccine in turbot (Scophthalmus maximus) under production mode. Aquaculture 2020, 524, 735259. [Google Scholar] [CrossRef]

- Ahmadivand, S.; Soltani, M.; Behdani, M.; Evensen, Ø.; Alirahimi, E.; Hassanzadeh, R.; Soltani, E. Oral DNA vaccines based on CS-TPP nanoparticles and alginate microparticles confer high protection against infectious pancreatic necrosis virus (IPNV) infection in trout. Dev. Comp. Immunol. 2017, 74, 178–189. [Google Scholar] [CrossRef]

- Plant, K.P.; LaPatra, S.E. Advances in fish vaccine delivery. Dev. Comp. Immunol. 2011, 35, 1256–1262. [Google Scholar] [CrossRef]

- Ahmad, M.T.; Shariff, M.; Yusoff, F.; Goh, Y.M.; Banerjee, S. Applications of microalga Chlorella vulgaris in aquaculture. Rev. Aquac. 2020, 12, 328–346. [Google Scholar] [CrossRef]

- Banerjee, A.; Ward, V. Production of recombinant and therapeutic proteins in microalgae. Curr. Opin. Biotechnol. 2022, 78, 102784. [Google Scholar] [CrossRef]

- An, N.; Ou, J.; Jiang, D.; Zhang, L.; Liu, J.; Fu, K.; Dai, Y.; Yang, D. Expression of a functional recombinant human basic fibroblast growth factor from transgenic rice seeds. Int. J. Mol. Sci. 2013, 14, 3556–3567. [Google Scholar] [CrossRef]

- Chen, R.; John, J.; Lavrentieva, A.; Müller, S.; Tomala, M.; Zhao, Y.; Zweigerdt, R.; Beutel, S.; Hitzmann, B.; Kasper, C. Cytokine production using membrane adsorbers: Human basic fibroblast growth factor produced by Escherichia coli. Eng. Life Sci. 2012, 12, 29–38. [Google Scholar] [CrossRef]

- Rout, S.S.; de Grahl, I.; Yu, X.; Reumann, S. Production of a viral surface protein in Nannochloropsis oceanica for fish vaccination against infectious pancreatic necrosis virus. Appl. Microbiol. Biotechnol. 2022, 106, 6535–6549. [Google Scholar] [CrossRef]

- Siddiqui, A.; Wei, Z.; Boehm, M.; Ahmad, N. Engineering microalgae through chloroplast transformation to produce high-value industrial products. Biotechnol. Appl. Biochem. 2020, 67, 30–40. [Google Scholar] [CrossRef]

- Kim, M.-J.; Kim, S.-H.; Abdellaoui, N.; Choi, T.-J. Isolation and characterization of a salt inducible promoter from Chlorella vulgaris PKVL7422. J. Microbiol. Biotechnol. 2023, 33, 1–9. [Google Scholar] [CrossRef]

- Stirk, W.A.; van Staden, J. Potential of phytohormones as a strategy to improve microalgae productivity for biotechnological applications. Biotechnol. Adv. 2020, 44, 107612. [Google Scholar] [CrossRef]

- Barahoei, M.; Hatamipour, M.S.; Afsharzadeh, S. Direct brackish water desalination using Chlorella vulgaris microalgae. Process Saf. Environ. Prot. 2021, 148, 237–248. [Google Scholar] [CrossRef]

- Carrera-Pacheco, S.E.; Hankamer, B.; Oey, M. Light and heat-shock mediated TDA1 overexpression as a tool for controlled high-yield recombinant protein production in Chlamydomonas reinhardtii chloroplasts. Algal Res. 2020, 48, 101921. [Google Scholar] [CrossRef]

- Ruecker, O.; Zillner, K.; Groebner-Ferreira, R.; Heitzer, M. Gaussia-luciferase as a sensitive reporter gene for monitoring promoter activity in the nucleus of the green alga Chlamydomonas reinhardtii. Mol. Genet. Genom. 2008, 280, 153–162. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.; Upadhyay, A.; Chandra, P.; Singh, D. Sodium chloride incites reactive oxygen species in green algae Chlorococcum humicola and Chlorella vulgaris: Implication on lipid synthesis, mineral nutrients and antioxidant system. Bioresour. Technol. 2018, 270, 489–497. [Google Scholar] [CrossRef] [PubMed]

- Rao, A.R.; Dayananda, C.; Sarada, R.; Shamala, T.; Ravishankar, G. Effect of salinity on growth of green alga Botryococcus braunii and its constituents. Bioresour. Technol. 2007, 98, 560–564. [Google Scholar] [CrossRef] [PubMed]

- Lorenzen, N.; Lapatra, S.E. Immunity to rhabdoviruses in rainbow trout: The antibody response. Fish Shellfish Immunol. 1999, 9, 345–360. [Google Scholar] [CrossRef]

- Yadav, G.; Meena, D.K.; Sahoo, A.K.; Das, B.K.; Sen, R. Effective valorization of microalgal biomass for the production of nutritional fish-feed supplements. J. Clean. Prod. 2020, 243, 118697. [Google Scholar] [CrossRef]

- Munang’andu, H.M.; Evensen, Ø. Correlates of protective immunity for fish vaccines. Fish Shellfish Immunol. 2019, 85, 132–140. [Google Scholar] [CrossRef]

- Tamer, C.; Albayrak, H.; Gumusova, S. Comparison of immune response between Escherichia coli-derived recombinant subunit vaccine and formol-inactivated whole particle vaccine against viral haemorrhagic septicaemia virus (VHSV) in rainbow trout. Aquac. Res. 2021, 52, 2706–2714. [Google Scholar] [CrossRef]

- Rahimnejad, S.; Lee, S.M.; Park, H.G.; Choi, J. Effects of dietary inclusion of Chlorella vulgaris on growth, blood biochemical parameters, and antioxidant enzyme activity in olive flounder, Paralichthys olivaceus. J. World Aquac. Soc. 2017, 48, 103–112. [Google Scholar] [CrossRef]

- Kim, S.Y.; Kim, J.Y.; Kim, H.J.; Kim, M.S.; Kim, K.H. Protection of rainbow trout (Oncorhynchus mykiss) against VHSV genotype Ia and IHNV by immunization with VHSV genotype IVa backbone-based single-cycle viruses. Fish Shellfish Immunol. 2023, 132, 108476. [Google Scholar] [CrossRef]

- Carbone, D.A.; Pellone, P.; Lubritto, C.; Ciniglia, C. Evaluation of microalgae antiviral activity and their bioactive compounds. Antibiotics 2021, 10, 746. [Google Scholar] [CrossRef]

- Mahmoud, E.A.; El-Sayed, B.M.; Mahsoub, Y.H.; Neamat-Allah, A.N. Effect of Chlorella vulgaris enriched diet on growth performance, hemato-immunological responses, antioxidant and transcriptomics profile disorders caused by deltamethrin toxicity in Nile tilapia (Oreochromis niloticus). Fish Shellfish Immunol. 2020, 102, 422–429. [Google Scholar] [CrossRef]

- Kole, S.; Qadiri, S.S.N.; Shin, S.-M.; Kim, W.-S.; Lee, J.; Jung, S.-J. Nanoencapsulation of inactivated-viral vaccine using chitosan nanoparticles: Evaluation of its protective efficacy and immune modulatory effects in olive flounder (Paralichthys olivaceus) against viral haemorrhagic septicaemia virus (VHSV) infection. Fish Shellfish Immunol. 2019, 91, 136–147. [Google Scholar] [CrossRef]

| Target | Primer Name | Sequences | PCR Product |

|---|---|---|---|

| NR | NRF | 5′-ATGGACAAGACAGGGTTCGG-3′ | 5013 bp |

| NRR | 5′-AATACAGGCGGAGCCCAAAC-3′ | ||

| vG | vGF | 5′-CAATTTCAGAAAGAATGCTAACC-3′ | 559 bp |

| vGR | 5′-CACTATCTTCACAATAAAGTGAC-3′ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.-J.; Kim, S.-Y.; Kim, K.-H.; Yoo, S.-S.; Lee, T.-K.; Choi, T.-J. High-Level Expression of Recombinant VHSV Glycoprotein Using Transformed C. vulgaris and Verification of Vaccine Efficacy. Vaccines 2023, 11, 1205. https://doi.org/10.3390/vaccines11071205

Kim M-J, Kim S-Y, Kim K-H, Yoo S-S, Lee T-K, Choi T-J. High-Level Expression of Recombinant VHSV Glycoprotein Using Transformed C. vulgaris and Verification of Vaccine Efficacy. Vaccines. 2023; 11(7):1205. https://doi.org/10.3390/vaccines11071205

Chicago/Turabian StyleKim, Min-Jeong, Seon-Young Kim, Ki-Hong Kim, Sung-Sik Yoo, Taek-Kyun Lee, and Tae-Jin Choi. 2023. "High-Level Expression of Recombinant VHSV Glycoprotein Using Transformed C. vulgaris and Verification of Vaccine Efficacy" Vaccines 11, no. 7: 1205. https://doi.org/10.3390/vaccines11071205

APA StyleKim, M.-J., Kim, S.-Y., Kim, K.-H., Yoo, S.-S., Lee, T.-K., & Choi, T.-J. (2023). High-Level Expression of Recombinant VHSV Glycoprotein Using Transformed C. vulgaris and Verification of Vaccine Efficacy. Vaccines, 11(7), 1205. https://doi.org/10.3390/vaccines11071205