Production of Lambic-like Fruit Sour Beer with Lachancea thermotolerans

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of the Wort

2.2. Yeast Strains and Culture Media

2.3. Fermentation and Storage

2.4. Bottling and Secondary Fermentation

2.5. Instrumental Analysis

2.5.1. Density

2.5.2. pH

2.5.3. Glucose

2.5.4. Color

2.5.5. Alcoholic Content

2.5.6. Bitterness

2.5.7. Determination of Volatile Compounds

2.5.8. Determination of Antioxidant Activity

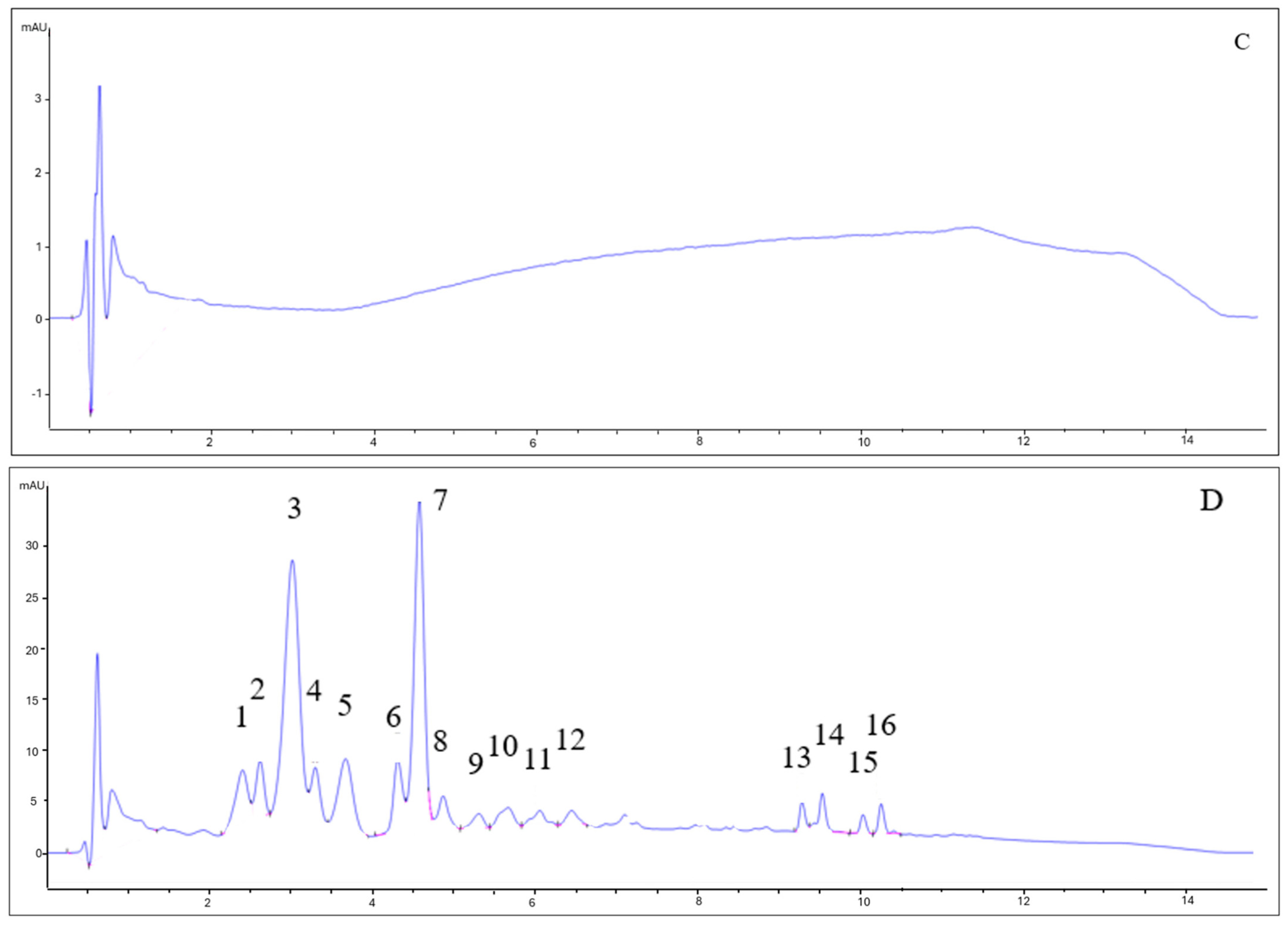

2.5.9. Analysis of Anthocyanins Using HPLC-DAD

2.6. Sensory Analysis

2.7. Statistical Analysis

3. Results

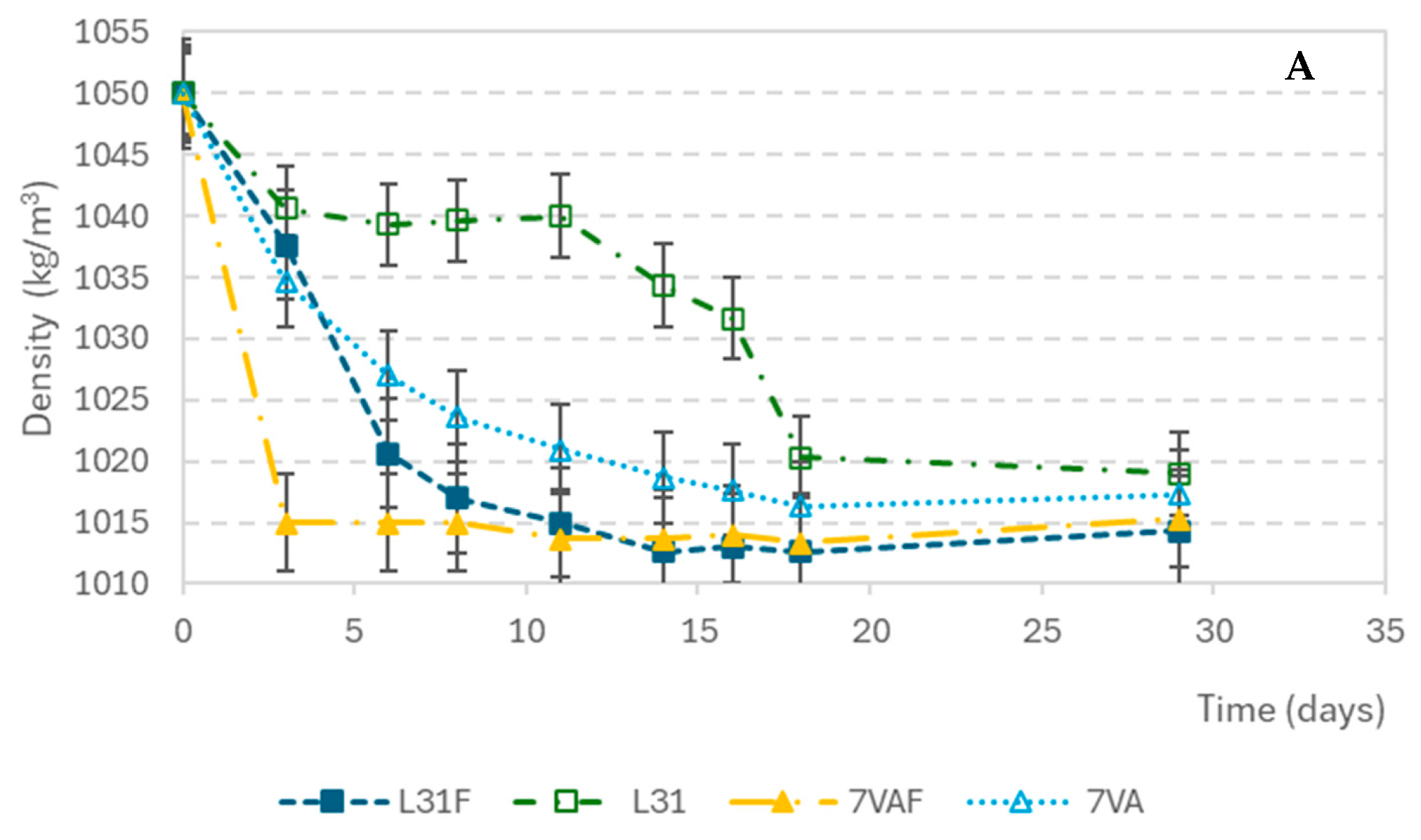

3.1. Fermentation

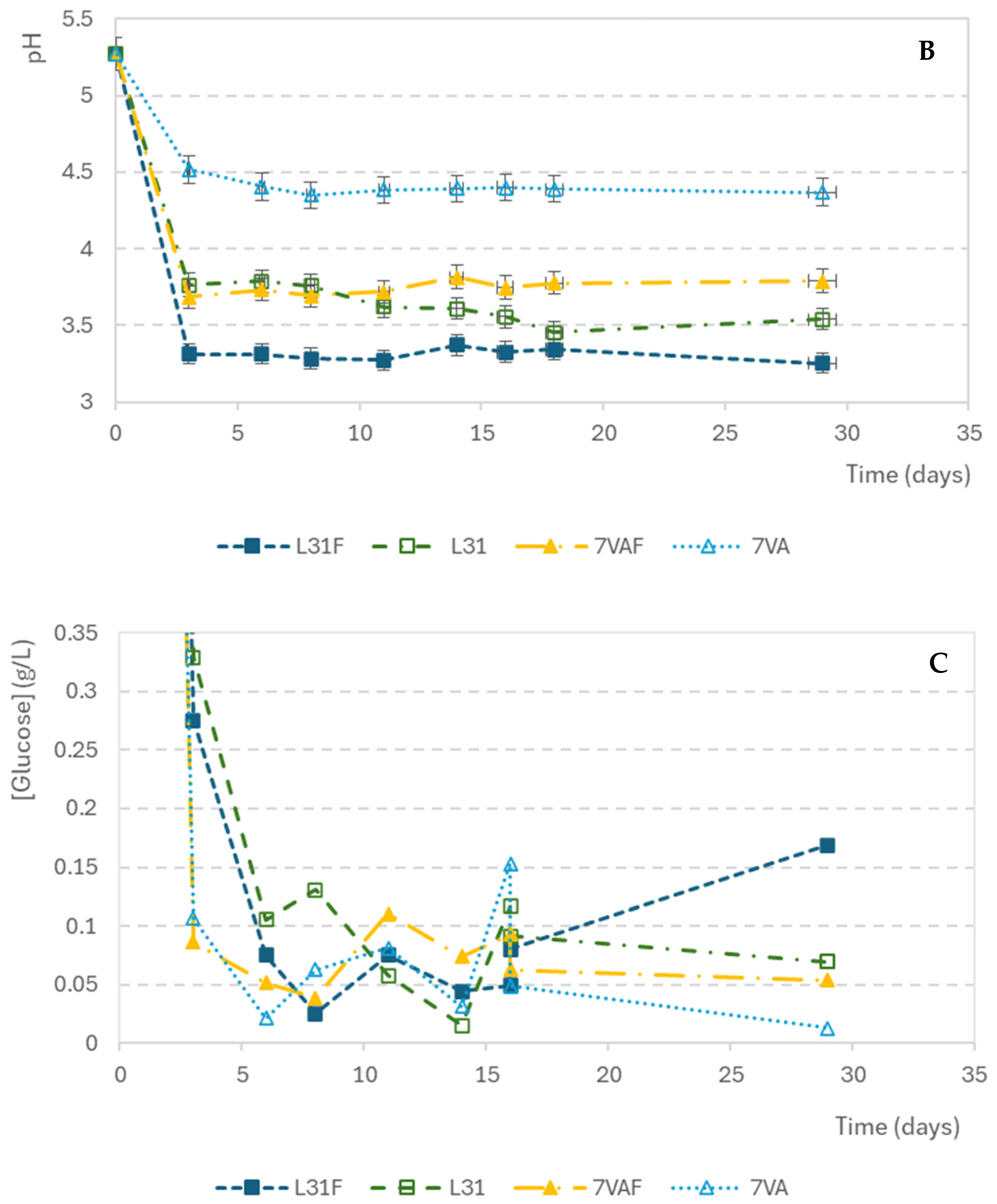

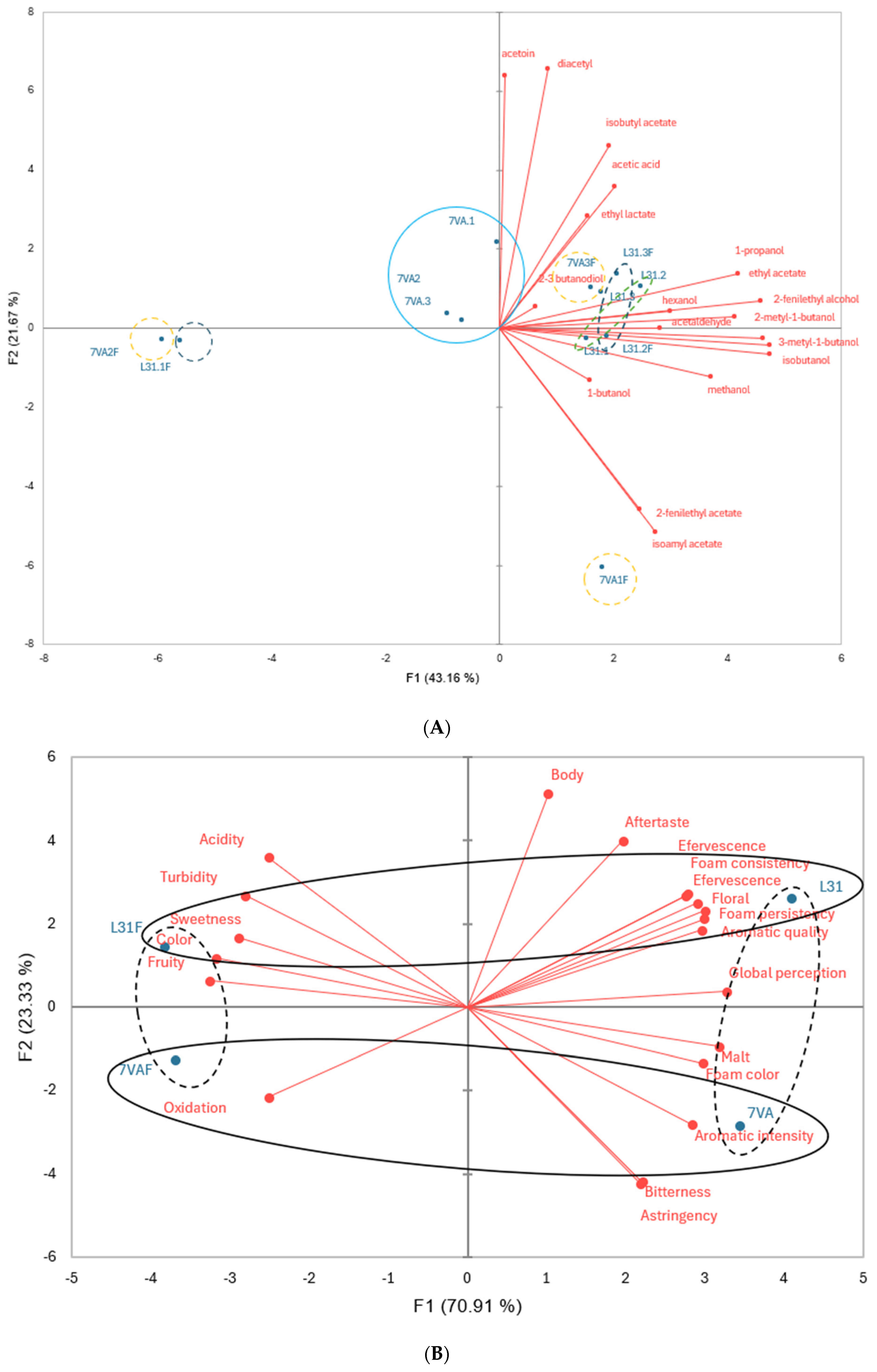

3.2. Volatile Compounds by GC-FID

3.3. Sensory Analysis

3.4. Correlation Between Volatile Compounds Identified by GC-FID and Sensory Analysis

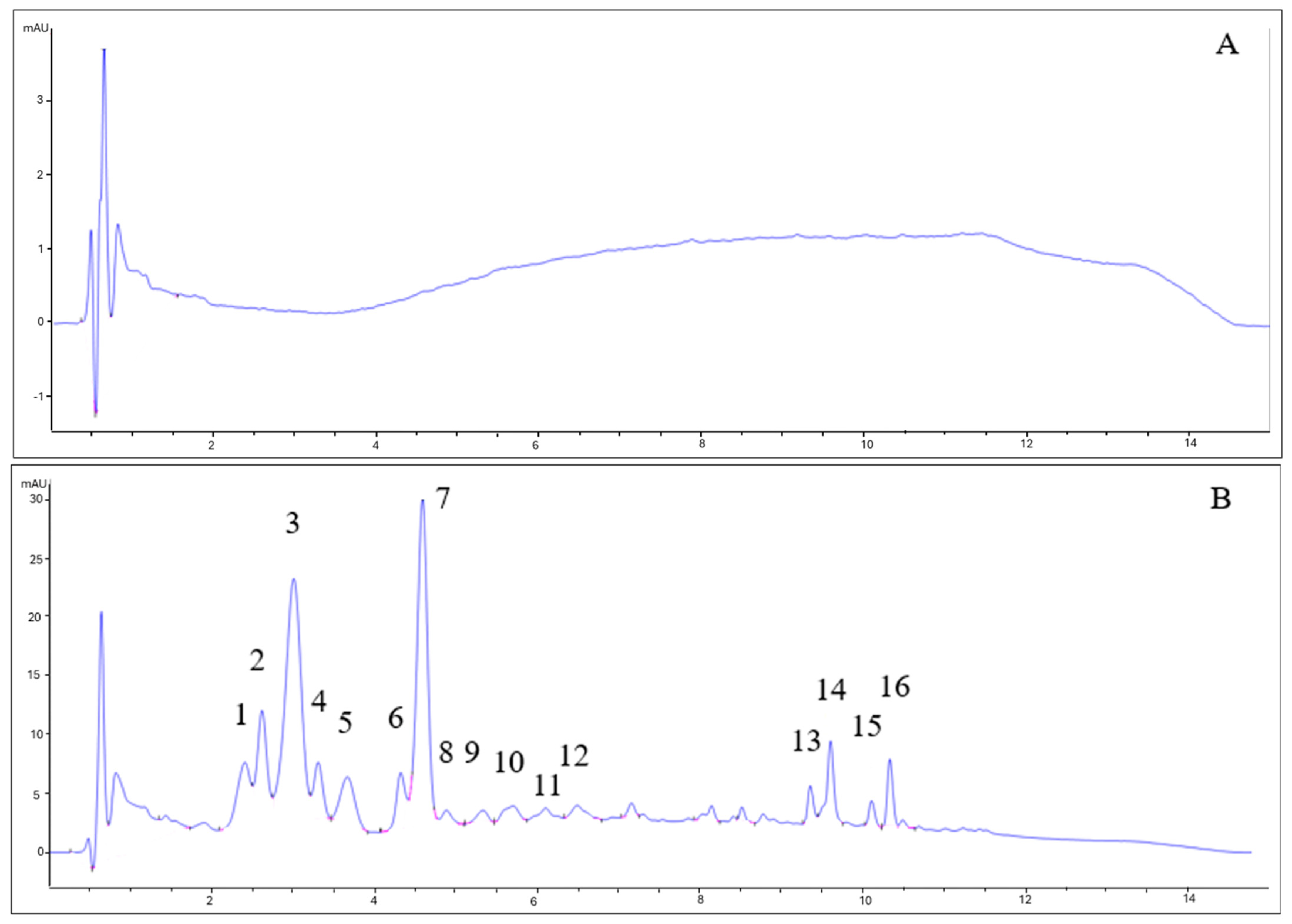

3.5. Anthocyanin Levels and Antioxidant Activity

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Steensels, J.; Verstrepen, K.J. Taming wild yeast: Potential of conventional and nonconventional yeasts in industrial fermentations. Annu. Rev. Microbiol. 2014, 68, 61–80. [Google Scholar] [CrossRef]

- Guido, L.F. Brewing and craft beer. Beverages 2019, 5, 51. [Google Scholar] [CrossRef]

- Meußdoerffer, F.; Zarnkow, M. Das Bier: Eine Geschichte von Hopfen und Malz, 1st ed.; C.H. Beck: Munich, Germany, 2014. [Google Scholar]

- Bokulich, N.A.; Bamforth, C.W. The microbiology of malting and brewing. Microbiol. Mol. Biol. Rev. 2013, 77, 157–172. [Google Scholar] [CrossRef] [PubMed]

- Michel, M.; Meier-Dörnberg, T.; Jacob, F.; Methner, F.J.; Wagner, R.S.; Hutzler, M. Review: Pure non-Saccharomyces starter cultures for beer fermentation with a focus on secondary metabolites and practical applications. J. Inst. Brew. 2016, 122, 569–587. [Google Scholar] [CrossRef]

- Vanderhaegen, B.; Neven, H.; Verachtert, H.; Derdelinckx, G. The chemistry of beer aging—A critical review. Food Chem. 2006, 95, 357–381. [Google Scholar] [CrossRef]

- Dysvik, A.; La Rosa, S.L.; De Rouck, G.; Rukke, E.O.; Westereng, B.; Wicklund, T. Microbial dynamics in traditional and modern sour beer production. Appl. Environ. Microbiol. 2020, 86, e00566-20. [Google Scholar] [CrossRef]

- Tonsmeire, M. American Sour Beer: Innovative Techniques for Mixed Fermentations, 1st ed.; Brewers Publications: Boulder, CO, USA, 2014. [Google Scholar]

- Capece, A.; Romaniello, R.; Siesto, G.; Romano, P. Conventional and non-conventional yeasts in beer production. Fermentation 2018, 4, 38. [Google Scholar] [CrossRef]

- De Roos, J.; De Vuyst, L. Microbial acidification, alcoholization, and aroma production during spontaneous lambic beer production. J. Sci. Food Agric. 2019, 99, 25–38. [Google Scholar] [CrossRef]

- Klimczak, K.; Cioch-Skoneczny, M.; Ciosek, A.; Poreda, A. Application of non-Saccharomyces yeast for the production of low-alcohol beer. Foods 2024, 13, 3214. [Google Scholar] [CrossRef]

- Tolosa, J.J.M.; Prieto, S.M. Non-Saccharomyces yeasts: An enzymatic unexplored world to be exploited. In Enzymes in Food Biotechnology; Kuddus, M., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 433–450. [Google Scholar] [CrossRef]

- Palmer, J.J. How to Brew: Everything You Need to Know to Brew Great Beer Every Time, 4th ed.; Brewers Publications: Boulder, CO, USA, 2017. [Google Scholar]

- Anderson, K. The emergence of lower-alcohol beverages: The case of beer. J. Wine Econ. 2023, 18, 66–86. [Google Scholar] [CrossRef]

- Burini, J.A.; Eizaguirre, J.I.; Loviso, C.; Libkind, D. Non-conventional yeasts as tools for innovation and differentiation in brewing. Rev. Argent. Microbiol. 2021, 53, 359–377. [Google Scholar] [CrossRef]

- Porter, T.J.; Divol, B.; Setati, M.E. Lachancea yeast species: Origin, biochemical characteristics and oenological significance. Food Res. Int. 2019, 119, 378–389. [Google Scholar] [CrossRef] [PubMed]

- Domizio, P.; House, J.F.; Joseph, C.M.L.; Bisson, L.F.; Bamforth, C.W. Lachancea thermotolerans as an alternative yeast for the production of beer. J. Inst. Brew. 2016, 122, 599–604. [Google Scholar] [CrossRef]

- Pirrone, A.; Naselli, V.; Gugino, I.M.; Porrello, A.; Viola, E.; Craparo, V.; Vella, A.; Alongi, D.; Seminerio, V.; Carusi, M.; et al. Use of non-conventional yeasts for enhancing the sensory quality of craft beer. Food Res. Int. 2025, 208, 116164. [Google Scholar] [CrossRef]

- Callejo, M.J.; García Navas, J.J.; Alba, R.; Escott, C.; Loira, I.; González, M.C.; Morata, A. Wort fermentation and beer conditioning with selected non-Saccharomyces yeasts in craft beers. Eur. Food Res. Technol. 2019, 245, 1229–1238. [Google Scholar] [CrossRef]

- Tsaruk, A.; Filip, K.; Sibirny, A.; Ruchala, J. Native and recombinant yeast producers of lactic acid: Characteristics and perspectives. Int. J. Mol. Sci. 2025, 26, 2007. [Google Scholar] [CrossRef]

- Malina, C.; Yu, R.; Björkeroth, J.; Kerkhoven, E.J.; Nielsen, J. Adaptations in metabolism and protein translation give rise to the crabtree effect in yeast. Proc. Natl. Acad. Sci. USA 2021, 118, e2112836118. [Google Scholar] [CrossRef]

- Vicente, J.; Navascués, E.; Calderón, F.; Santos, A.; Marquina, D.; Benito, S. An integrative view of the role of Lachancea thermotolerans in wine technology. Foods 2021, 10, 2878. [Google Scholar] [CrossRef]

- Vilela, A. Lachancea thermotolerans, the non-Saccharomyces yeast that reduces the volatile acidity of wines. Fermentation 2018, 4, 56. [Google Scholar] [CrossRef]

- Galaz, V.; Franco, W. Lachancea quebecensis a novel isolate for the production of craft beer. Foods 2023, 12, 3347. [Google Scholar] [CrossRef]

- Franco, W.; Benavides, S.; Valencia, P.; Ramírez, C.; Urtubia, A. Native yeasts and lactic acid bacteria isolated from spontaneous fermentation of seven grape cultivars from the maule region (Chile). Foods 2021, 10, 1737. [Google Scholar] [CrossRef] [PubMed]

- Benito, S. The impacts of Lachancea thermotolerans yeast strains on winemaking. Appl. Microbiol. Biotechnol. 2018, 102, 6775–6790. [Google Scholar] [CrossRef] [PubMed]

- Benito, Á.; Calderón, F.; Palomero, F.; Benito, S. Combine use of selected Schizosaccharomyces pombe and Lachancea thermotolerans yeast strains as an alternative to the traditional malolactic fermentation in red wine production. Molecules 2015, 20, 9510–9523. [Google Scholar] [CrossRef]

- American Society of Brewing Chemists. Color. In ASBC Methods of Analysis [Protocol]; American Society of Brewing Chemists: St. Paul, MN, USA, 2011. [Google Scholar] [CrossRef]

- Koren, D.; Hegyesné Vecseri, B.; Kun-Farkas, G.; Urbin, Á.; Nyitrai, Á.; Sipos, L. How to objectively determine the color of beer? J. Food Sci. Technol. 2020, 57, 1183–1189. [Google Scholar] [CrossRef]

- American Society of Brewing Chemists. Beer Bitterness [Protocol]. In ASBC Methods of Analysis; American Society of Brewing Chemists: St. Paul, MN, USA, 2011. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef] [PubMed]

- Peces-Pérez, R.; Vaquero, C.; Callejo, M.J.; Morata, A. Biomodulation of physicochemical parameters, aromas, and sensory profile of craft beers by using non-Saccharomyces yeasts. ACS Omega 2022, 7, 17822–17840. [Google Scholar] [CrossRef]

- Morata, A.; López, C.; Tesfaye, W.; González, C.; Escott, C. Anthocyanins as Natural Pigments in Beverages. In Value-Added Ingredients and Enrichments of Beverages: The Science of Beverages; Woodhead Publishing: Sawston, UK, 2019; Volume 14, pp. 383–428. [Google Scholar]

- Morata, A.; Loira, I.; Tesfaye, W.; Bañuelos, M.A.; González, C.; Suárez Lepe, J.A. Lachancea thermotolerans applications in wine technology. Fermentation 2018, 4, 53. [Google Scholar] [CrossRef]

- Postigo, V.; Esteban, S.; Arroyo, T. Lachancea thermotolerans, an innovative alternative for sour beer production. Beverages 2023, 9, 20. [Google Scholar] [CrossRef]

- Vaquero, C.; Loira, I.; Heras, J.M.; Carrau, F.; González, C.; Morata, A. Biocompatibility in ternary fermentations with Lachancea thermotolerans, other non-Saccharomyces and Saccharomyces cerevisiae to control pH and improve the sensory profile of wines from warm areas. Front. Microbiol. 2021, 12, 656262. [Google Scholar] [CrossRef]

- Fu, X.; Guo, L.; Li, Y.; Chen, X.; Song, Y.; Li, S. Transcriptional analysis of mixed-culture fermentation of Lachancea thermotolerans and Saccharomyces cerevisiae for natural fruity sour beer. Fermentation 2024, 10, 180. [Google Scholar] [CrossRef]

- Francesca, N.; Pirrone, A.; Gugino, I.; Prestianni, R.; Naselli, V.; Settanni, L.; Todaro, A.; Guzzon, R.; Maggio, A.; Porrello, A.; et al. A novel microbiological approach to impact the aromatic composition of sour loquat beer. Food Biosci. 2023, 55, 103011. [Google Scholar] [CrossRef]

- Postigo, V.; García, M.; Cabellos, J.M.; Arroyo, T. Wine Saccharomyces yeasts for beer fermentation. Fermentation 2021, 7, 290. [Google Scholar] [CrossRef]

- Hranilovic, A.; Gambetta, J.M.; Schmidtke, L.; Boss, P.K.; Grbin, P.R.; Masneuf-Pomarede Bely, M.; Albertin, W.; Jiranek, V. Oenological traits of Lachancea thermotolerans show signs of domestication and allopatric differentiation. Sci. Rep. 2018, 8, 14812. [Google Scholar] [CrossRef]

- Polshin, E.; Rudnitskaya, A.; Kirsanov, D.; Legin, A.; Saison, D.; Delvaux, F.; Delvaux, F.R.; Nicolaï, B.M.; Lammertyn, J. Electronic tongue as a screening tool for rapid analysis of beer. Talanta 2010, 81, 88–94. [Google Scholar] [CrossRef]

- Ducruet, J.; Rébénaque, P.; Diserens, S.; Kosińska-Cagnazzo, A.; Héritier, I.; Andlauer, W. Amber ale beer enriched with goji berries—The effect on bioactive compound content and sensorial properties. Food Chem. 2017, 226, 109–118. [Google Scholar] [CrossRef]

- Ocvirk, M.; Mlinarič, N.K.; Košir, I.J. Comparison of sensory and chemical evaluation of lager beer aroma by gas chromatography and gas chromatography/mass spectrometry. J. Sci. Food Agric. 2018, 98, 3627–3635. [Google Scholar] [CrossRef]

- Pavsler, A.; Buiatti, S. Lager beer. In Beer in Health and Disease Prevention; Preedy, V.R., Ed.; Academic Press: Udine, Italy, 2009; pp. 31–43. [Google Scholar] [CrossRef]

- Zapata, P.J.; Martínez-Esplá, A.; Gironés-Vilaplana, A.; Santos-Lax, D.; Noguera-Artiaga, L.; Carbonell-Barrachina, Á.A. Phenolic, volatile, and sensory profiles of beer enriched by macerating quince fruits. LWT 2019, 103, 139–146. [Google Scholar] [CrossRef]

- Martinez-Gomez, A.; Caballero, I.; Blanco, C.A. Phenols and melanoidins as natural antioxidants in beer. structure, reactivity and antioxidant activity. Biomolecules 2020, 10, 400. [Google Scholar] [CrossRef] [PubMed]

- Nardini, M.; Garaguso, I. Characterization of bioactive compounds and antioxidant activity of fruit beers. Food Chem. 2020, 305, 125437. [Google Scholar] [CrossRef] [PubMed]

- Sariburun, E.; Şahin, S.; Demir, C.; Türkben, C.; Uylaşer, V. Phenolic content and antioxidant activity of raspberry and blackberry cultivars. J. Food Sci. 2010, 75, C328–C335. [Google Scholar] [CrossRef]

- Koponen, J.M.; Happonen, A.M.; Mattila, P.H.; Törrönen, A.R. Contents of anthocyanins and ellagitannins in selected foods consumed in Finland. J. Agric. Food Chem. 2007, 55, 1612–1619. [Google Scholar] [CrossRef] [PubMed]

- Tulio, A.Z.; Reese, R.N.; Wyzgoski, F.J.; Rinaldi, P.L.; Fu, R.; Scheerens, J.C.; Raymond, A. Cyanidin 3-rutinoside and cyanidin 3-xylosylrutinoside as primary phenolic antioxidants in black raspberry. J. Agric. Food Chem. 2008, 56, 1880–1888. [Google Scholar] [CrossRef] [PubMed]

- Grace, M.H.; Xiong, J.; Esposito, D.; Ehlenfeldt, M.; Lila, M.A. Simultaneous LC-MS quantification of anthocyanins and non-anthocyanin phenolics from blueberries with widely divergent profiles and biological activities. Food Chem. 2019, 277, 336–346. [Google Scholar] [CrossRef] [PubMed]

| Code | Yeast | Added Fruit (Yes/No) | Replicates |

|---|---|---|---|

| 7VA | Saccharomyces cerevisiae 7VA | No | 3 |

| 7VAF | Saccharomyces cerevisiae 7VA | Yes | 3 |

| L31 | Lachanchea thermotolerans L31 | No | 3 |

| L31F | Lachanchea thermotolerans L31 | Yes | 3 |

| Bitterness (IBUs) | Glucose (g/L) | Density (kg/m3) | pH | Color (EBC) | Alcohol (% v/v) | |

|---|---|---|---|---|---|---|

| L31F | 8.58 ± 0.10 a | 0.10 ± 0.00046 a | 1015.33 ± 0.58 a | 3.37 ± 0.03 a | 18.35 ± 0.81 a | 3.91 ± 0.15 b |

| L31 | 11.47 ± 0.91 b | 0.08 ± 0.00039 a | 1013.33 ± 1.15 a | 3.59 ± 0.03 b | 13.65 ± 0.63 b | 4.37 ± 0.30 d |

| 7VAF | 10.72 ± 0.81 b | 0.06 ± 0.00023 a | 1015.33 ± 0.58 a | 3.74 ± 0.01 c | 18.14 ± 0.46 a | 4.02 ± 0.16 c |

| 7VA | 18.65 ± 1.13 c | 0.03 ± 0.00014 a | 1017 ± 1.00 a | 4.33 ± 0.02 d | 13.73 ± 0.26 b | 3.79 ± 0.12 a |

| Volatile Compound | Perception Threshold (mg/L) | Associated Odors | L31F | L31 | 7VAF | 7VA |

|---|---|---|---|---|---|---|

| Alcohols | ||||||

| 1-Butanol | 450 | n.d. | n.d. | n.d. | n.d. | n.d. |

| 1-Propanol | 3.0–16.0 | alcohol | 11.1 ± 7.3 a | 23.5 ± 1.5 c | 11.5 ± 7.3 a | 14.4 ± 3.2 b |

| 2-Butanol | 16.0 | n.d. | n.d. | n.d. | n.d. | n.d. |

| 2-Methyl-1-butanol | 8.0–30.0 | alcohol, vinous, banana | 13.7 ± 9.4 a | 20.5 ± 0.2 d | 17.1 ± 12.4 c | 16.7 ± 1.0 b |

| 2-Phenylethyl alcohol | 8.0–35.0 | rose petal, bitter | 13.2 ± 3.9 b | 20.9 ± 3.1 d | 15.3 ± 5.8 c | 12.8 ± 0.2 a |

| 3-Methyl-1-butanol | 8.0–30.0 | alcohol, vinous, banana | 23.0 ± 18.0 a | 36.7 ± 2.1 d | 26.9 ± 21.4 c | 25.0 ± 1.1 b |

| Hexanol | 4 | herbaceous | 5.9 ± 4.0 c | 4.3 ± 0.3 b | 3.1 ± 2.7 a | 4.0 ± 0.4 b |

| Isobutanol | 100 | alcohol | 14.9 ± 10.5 a | 21.7 ± 1.2 d | 15.5 ± 11.0 c | 14.3 ± 0.2 b |

| Methanol | 0.5–3.0 | alcohol | 19.6 ± 14.5 c | 15.3 ± 7.2 b | 19.0 ± 14.0 c | 13.9 ± 0.7 a |

| Esters | ||||||

| 2-Phenylethyl acetate | 0.05–2.0 | roses, honey, apple | 5.9 ± 1.2 a | 67.0 ± 0.5 b | 7.9 ± 4.2 c | 7.9 ± 0.5 c |

| Ethyl acetate | 30 | fruity | 20.3 ± 16.9 c | 34.7 ± 2.5 d | 17.6 ± 14.7 b | 16.6 ± 0.8 a |

| Ethyl butyrate | 0.4 | fruity, tropical | n.d. | n.d. | n.d. | n.d. |

| Ethyl lactate | 1.54 | sweet, fruity, buttery | 13.4 ± 9.9 d | 5.7 ± 5.7 b | 2.3 ± 4.0 a | 9.4 ± 3.6 c |

| Isoamyl acetate | 0.5 | banana | 2.4 ± 1.0 b | 2.6 ± 0.3 c | 2.9 ± 1.8 d | 2.0 ± 0.2 a |

| Isobutyl acetate | 1.6 | banana, sweet, fruit | 2.1 ± 2.4 b | 2.6 ± 2.3 c | 1.2 ± 1.3 a | 3.0 ± 1.7 d |

| Carbonyl compounds | ||||||

| Acetaldehyde | 2.0–20.0 | apple, green leaves | 3.0 ± 2.1 b | 7.8 ± 3.9 c | 2.4 ± 1.6 a | 3.1 ± 0.5 b |

| Acetoin | 1.0–10.0 | fruity, musty, woody | 5.2 ± 0.6 b | 5.5 ± 0.2 bc | 3.3 ± 2.9 a | 5.6 ± 0.5 c |

| Diacetyl | 0.01–0.4 | butter | 1.4 ± 0.2 b | 1.7 ± 0.2 c | 1.0 ± 0.9 a | 1.7 ± 0.4 c |

| Aromatic Intensity | Aromatic Quality | Malt | Floral | Fruit Tree | |

|---|---|---|---|---|---|

| Acetaldehyde | 0.219 | 0.771 * | 0.491 | 0.901 * | −0.586 |

| Methanol | −0.968 * | −0.801 * | −0.986 * | −0.775 * | 0.988 * |

| 1-Propanol | 0.419 | 0.816 * | 0.638 | 0.948 * | −0.736 * |

| Diacetyl | 0.736 * | 0.944 * | 0.912 * | 0.816 * | −0.850 * |

| Ethyl acetate | 0.019 | 0.656 | 0.310 | 0.801 * | −0.411 |

| Isobutanol | 0.063 | 0.590 | 0.305 | 0.779 * | −0.433 |

| Acetic acid | 0.992 * | 0.734 * | 0.972 * | 0.680 | −0.955 * |

| 1-Butanol | −0.173 | −0.241 | −0.206 | −0.511 | 0.382 |

| Acetoin | 0.518 | 0.883 * | 0.749 * | 0.712 * | −0.657 |

| 3-Methyl-1-butanol | 0.215 | 0.572 | 0.390 | 0.784 * | −0.534 |

| 2-Methyl-1-butanol | 0.437 | 0.525 | 0.508 | 0.743 * | −0.657 |

| Isobutyl acetate | 0.769 * | 0.908 * | 0.918 * | 0.762 * | −0.844 * |

| Ethyl lactate | −0.059 | 0.264 | 0.102 | −0.005 | 0.066 |

| 2,3-Butanediol | 0.945 * | 0.857 * | 0.999 * | 0.800 * | −0.983 * |

| Isoamyl acetate | −0.623 | −0.567 | −0.672 | −0.313 | 0.524 |

| Hexanol | −0.355 | 0.266 | −0.089 | 0.078 | 0.207 |

| 2-Phenylethyl alcohol | 0.031 | 0.471 | 0.227 | 0.696 | −0.376 |

| 2-Phenylethyl acetate | 0.598 | −0.133 | 0.309 | −0.029 | −0.378 |

| Beer | Antioxidant Activity (µmol TE/mL) | Anthocyanin Content (mg/L) |

|---|---|---|

| 7VA | 0.81 ± 0.23 a | n.d. |

| 7VAF | 1.03 ± 0.35 a | 9.24 ± 5.40 b |

| L31 | 1.03 ± 0.36 a | n.d. |

| L31F | 1.49 ± 0.38 b | 6.70 ± 2.56 a,b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartolomé, R.; Alonso, E.; Morata, A.; López, C. Production of Lambic-like Fruit Sour Beer with Lachancea thermotolerans. Antioxidants 2025, 14, 826. https://doi.org/10.3390/antiox14070826

Bartolomé R, Alonso E, Morata A, López C. Production of Lambic-like Fruit Sour Beer with Lachancea thermotolerans. Antioxidants. 2025; 14(7):826. https://doi.org/10.3390/antiox14070826

Chicago/Turabian StyleBartolomé, Rubén, Elena Alonso, Antonio Morata, and Carmen López. 2025. "Production of Lambic-like Fruit Sour Beer with Lachancea thermotolerans" Antioxidants 14, no. 7: 826. https://doi.org/10.3390/antiox14070826

APA StyleBartolomé, R., Alonso, E., Morata, A., & López, C. (2025). Production of Lambic-like Fruit Sour Beer with Lachancea thermotolerans. Antioxidants, 14(7), 826. https://doi.org/10.3390/antiox14070826