Effect of the Drying Method and Optimization of Extraction on Antioxidant Activity and Phenolic of Rose Petals

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Plant Material

2.3. Drying Treatments

2.4. Color Measurement

2.5. Anthocyanin Content

2.6. Extraction Procedure

2.7. Measurement of Total Phenolic Content

2.8. Measurement of Antioxidant Activity

2.9. Experimental Design

2.10. Effect of Ultrasound-Assisted Extraction

2.11. HPLC-ESI-QTOF/MS Analysis

2.12. Data Analysis

3. Results and Discussion

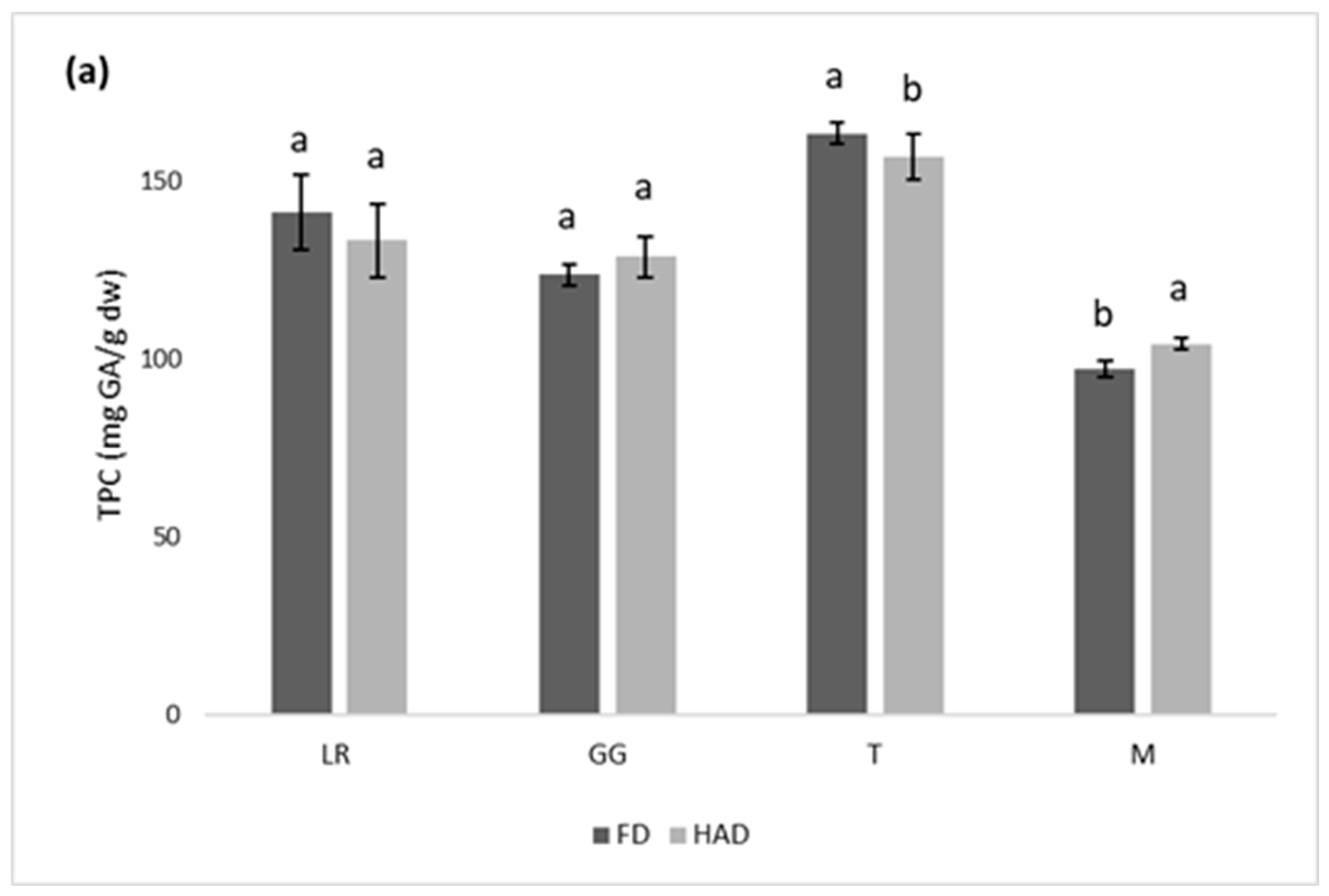

3.1. Effect of the Drying Process on TPC, AA, Anthocyanins and Color

3.2. Optimization of the Extraction Process

3.2.1. Analysis of the Model

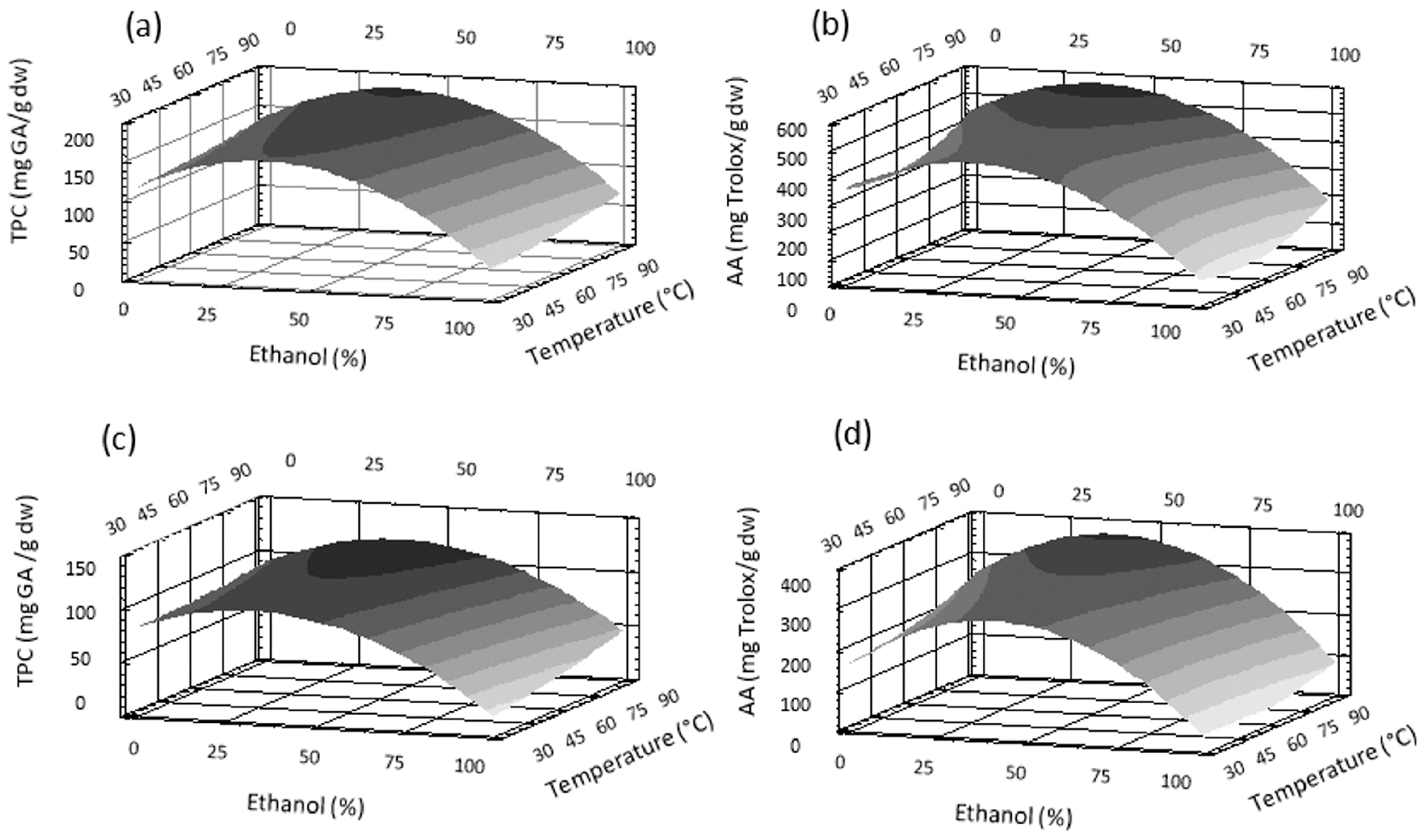

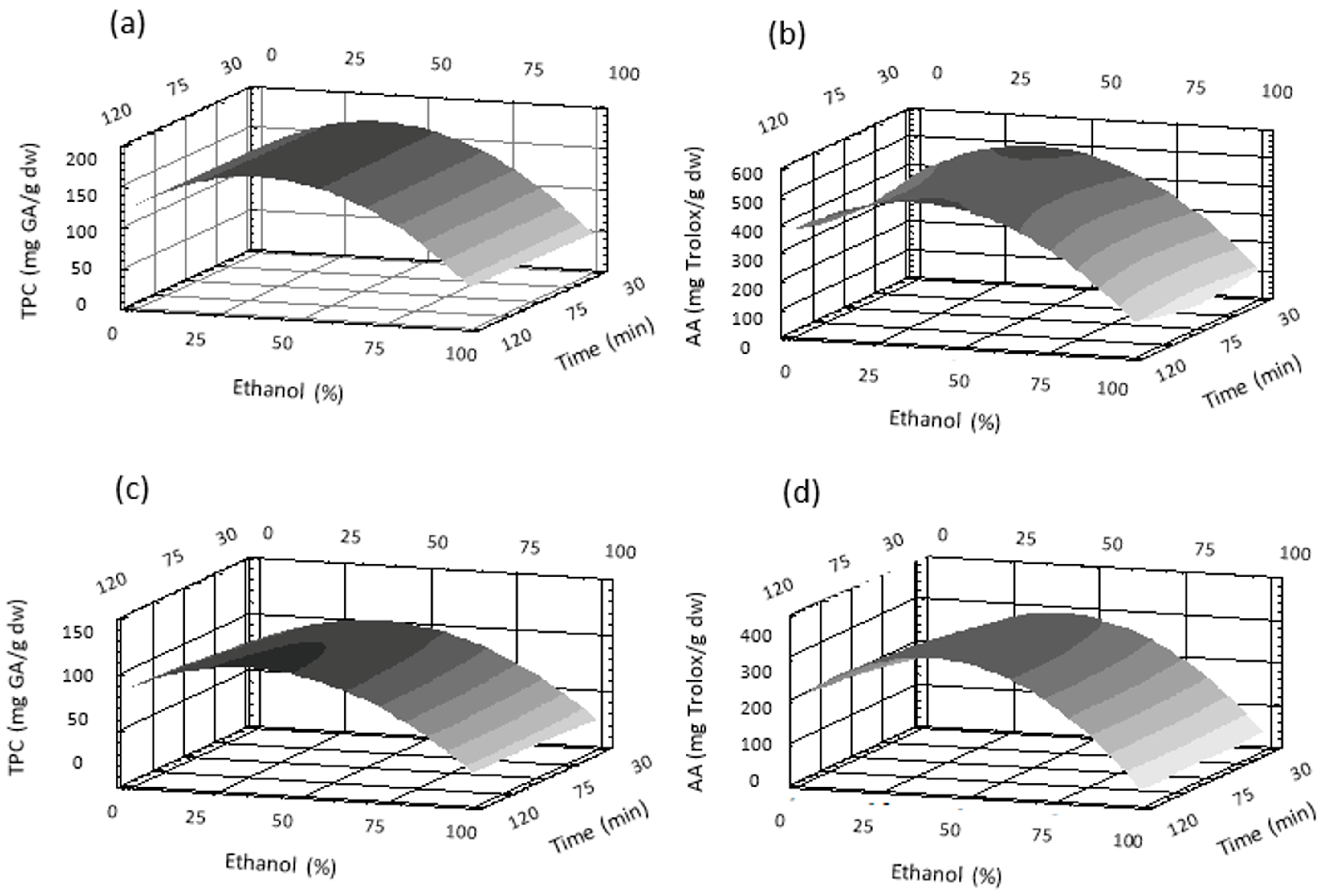

3.2.2. Effect of the Different Variables on TPC and AA Extraction

3.3. Experimental Validation

3.4. Effect of Ultrasound-Assisted Extraction

3.5. Comparison of Drying Methods Using the Selected Conditions

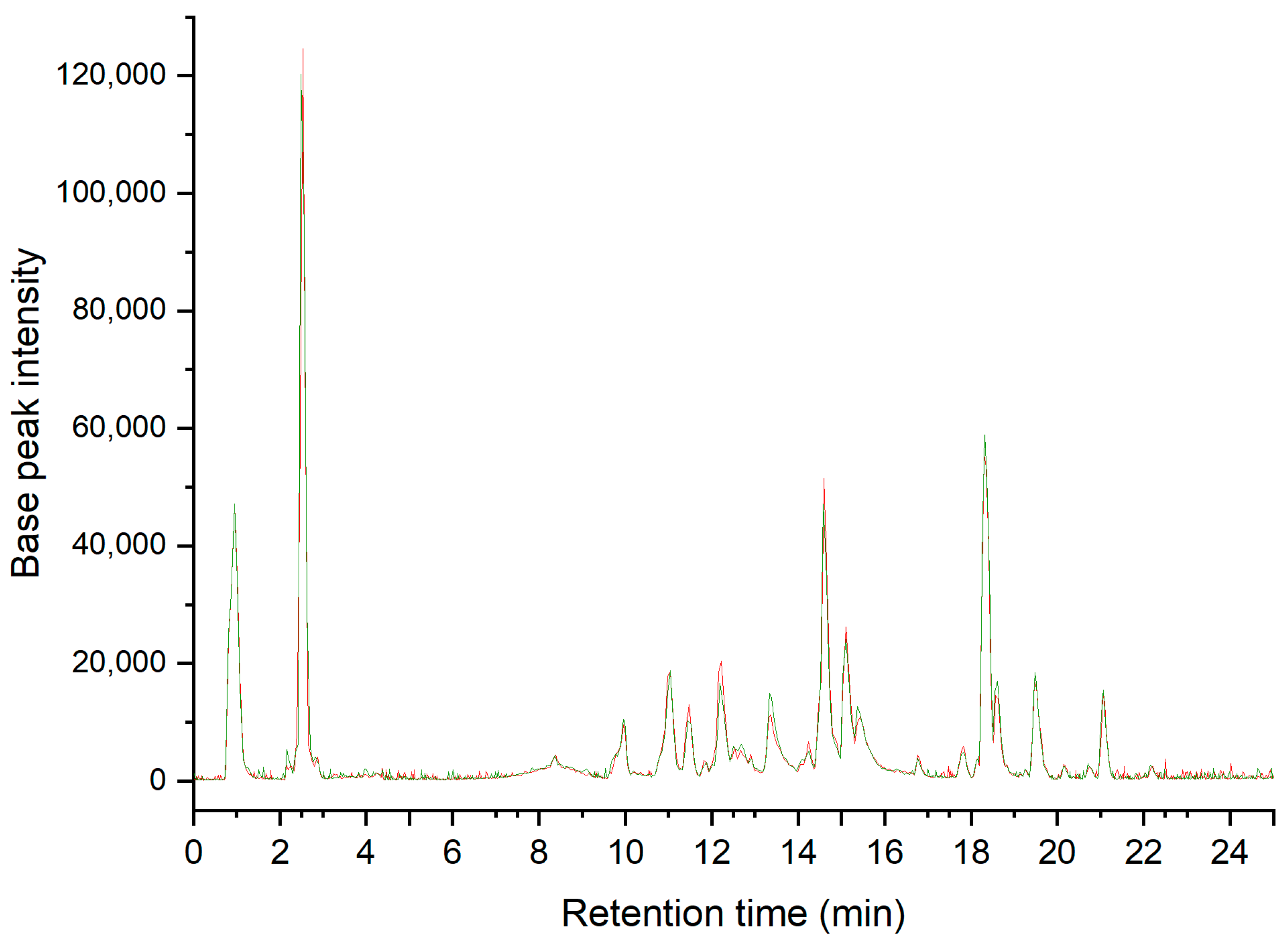

3.6. HPLC-ESI-QTOF/MS Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, A.-N.; Li, S.; Li, H.-B.; Xu, D.-P.; Xu, X.-R.; Chen, F. Total phenolic contents and antioxidant capacities of 51 edible and wild flowers. J. Funct. Foods 2014, 6, 319–330. [Google Scholar] [CrossRef]

- Pires, T.C.S.P.; Dias, M.I.; Barros, L.; Calhelha, R.C.; Alves, M.J.; Oliveira, M.B.P.P.; Santos-Buelga, C.; Ferreira, I.C.F.R. Edible flowers as sources of phenolic compounds with bioactive potential. Food Res. Int. 2018, 105, 580–588. [Google Scholar] [CrossRef]

- Zeng, Y.; Deng, M.; Lv, Z.; Peng, Y. Evaluation of antioxidant activities of extracts from 19 Chinese edible flowers. Springerplus 2014, 3, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, J.A.; Rezende, F.A.G.G.; Moura, M.A.F.; Dominguete, L.C.B.; Sande, D. Edible flowers: Bioactive profile and its potential to be used in food development. Food Res. Int. 2020, 129, 108868. [Google Scholar] [CrossRef] [PubMed]

- Pagliaricci, L.; Arroyo, L. Análisis Técnico y Económico Para La Producción de Plantas de Rosa En El Partido de San Pedro. EEA San Pedro, INTA, Ministerio de Agricultura, Ganadería y Pesca. Available online: https://inta.gob.ar/documentos/analisis-tecnico-economico-rosa (accessed on 4 January 2023).

- Pokorný, J. Are natural antioxidants better–and safer–than synthetic antioxidants? Eur. J. Lipid Sci. Technol. 2007, 109, 629–642. [Google Scholar] [CrossRef]

- Xu, D.-P.; Li, Y.; Meng, X.; Zhou, T.; Zhou, Y.; Zheng, J.; Zhang, J.-J.; Li, H.-B. Natural Antioxidants in Foods and Medicinal Plants: Extraction, Assessment and Resources. Int. J. Mol. Sci. 2017, 18, 96. [Google Scholar] [CrossRef]

- Mikołajczak, N.; Sobiechowska, D.A.; Tańska, M. Edible flowers as a new source of natural antioxidants for oxidative protection of cold-pressed oils rich in omega-3 fatty acids. Food Res. Int. 2020, 134, 109216. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Sun, Y.; Guo, H.-H. Thermal Degradation of Anthocyanins and Its Impact on in Vitro Antioxidant Capacity of Downy Rose-Myrtle Juice. J. Food Agric. Environ. 2013, 11, 110–114. [Google Scholar] [CrossRef]

- Ji, H.; Du, A.; Zhang, L.; Xu, C.; Yang, M.; Li, F. Effects of drying methods on antioxidant properties in Robinia pseudoacacia L. flowers. J. Med. Plants Res. 2012, 6, 3233–3239. [Google Scholar] [CrossRef]

- Brglez Mojzer, E.; Knez Hrnčič, M.; Škerget, M.; Knez, Ž.; Bren, U. Polyphenols: Extraction Methods, Antioxidative Action, Bioavailability and Anticarcinogenic Effects. Molecules 2016, 21, 901. [Google Scholar] [CrossRef]

- Skrajda-Brdak, M.; Dąbrowski, G.; Konopka, I. Edible flowers, a source of valuable phytonutrients and their pro-healthy effects–A review. Trends Food Sci. Technol. 2020, 103, 179–199. [Google Scholar] [CrossRef]

- Pal, A.; Bhushan, B.; Narwal, R.K.; Saharan, V. Extraction and Evaluation of Antioxidant and Free Radical Scavenging Potential Correlated with Biochemical Components of Red Rose Petals. Iran. J. Sci. Technol. Trans. A Sci. 2016, 42, 1027–1036. [Google Scholar] [CrossRef]

- Trinh, L.T.P.; Choi, Y.-S.; Bae, H.-J. Production of phenolic compounds and biosugars from flower resources via several extraction processes. Ind. Crop. Prod. 2018, 125, 261–268. [Google Scholar] [CrossRef]

- Saini, A.; Panesar, P.S.; Bera, M.B. Valorization of fruits and vegetables waste through green extraction of bioactive compounds and their nanoemulsions-based delivery system. Bioresour. Bioprocess. 2019, 6, 1–12. [Google Scholar] [CrossRef]

- Giusti, M.M.; Wrolstad, R.E. Anthocyanins. Characterization and measurement with UV-visible spectroscopy. In Current Protocols in Food Analytical Chemistry; Wrolstad, R.E., Ed.; John Wiley & Sons: New York, NY, USA, 2001; pp. 1–13. [Google Scholar]

- Singleton, V.L.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol. 1999, 299, 152–178. [Google Scholar]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Barman, M.; Soren, M.; Mishra, C.; Mitra, A. Dehydrated jasmine flowers obtained through natural convective solar drying retain scent volatiles and phenolics–A prospective for added-value utility. Ind. Crop. Prod. 2022, 177, 114483. [Google Scholar] [CrossRef]

- Dorozko, J.; Kunkulberga, D.; Sivicka, I.; Kruma, Z. The influence of various drying methods on the quality of edible flower petals. FoodBalt 2019, 182–187. [Google Scholar] [CrossRef]

- Chen, W.; Gast, K.L.; Smithey, S. The effects of different freeze-drying processes on the moisture content, color, and physical strength of roses and carnations. Sci. Hortic. 2000, 84, 321–332. [Google Scholar] [CrossRef]

- Chew, K.K.; Khoo, M.Z.; Ng, S.Y.; Thoo, Y.Y.; Wan Aida, W.M.; Ho, C.W. Effect of Ethanol Concentration, Extraction Time and Extraction Temperature on the Recovery of Phenolic Compounds Andantioxidant Capacity of Centella Asiatica Extracts. Int. Food Res. J. 2011, 18, 1427–1435. [Google Scholar]

- Fernandes, L.; Casal, S.; Pereira, J.A.; Saraiva, J.A.; Ramalhosa, E. Edible flowers: A review of the nutritional, antioxidant, antimicrobial properties and effects on human health. J. Food Compos. Anal. 2017, 60, 38–50. [Google Scholar] [CrossRef]

- Volf, I.; Ignat, I.; Neamtu, M.; Popa, V.I. Thermal stability, antioxidant activity, and photo-oxidation of natural polyphenols. Chem. Pap. 2014, 68, 121–129. [Google Scholar] [CrossRef]

- Murakami, M.; Yamaguchi, T.; Takamura, H.; Atoba, T.M. Effects of Thermal Treatment on Radical-scavenging Activity of Single and Mixed Polyphenolic Compounds. J. Food Sci. 2004, 69, FCT7–FCT10. [Google Scholar] [CrossRef]

- Chen, G.-L.; Chen, S.-G.; Xiao, Y.; Fu, N.-L. Antioxidant capacities and total phenolic contents of 30 flowers. Ind. Crop. Prod. 2018, 111, 430–445. [Google Scholar] [CrossRef]

- Cai, Y.; Luo, Q.; Sun, M.; Corke, H. Antioxidant activity and phenolic compounds of 112 traditional Chinese medicinal plants associated with anticancer. Life Sci. 2004, 74, 2157–2184. [Google Scholar] [CrossRef]

- Li, S.; Li, S.-K.; Gan, R.-Y.; Song, F.-L.; Kuang, L.; Li, H.-B. Antioxidant capacities and total phenolic contents of infusions from 223 medicinal plants. Ind. Crop. Prod. 2013, 51, 289–298. [Google Scholar] [CrossRef]

- Moure, A.; Cruz, J.M.; Franco, D.; Domínguez, J.; Sineiro, J.; Domínguez, H.; Núñez, M.J.; Parajó, J. Natural antioxidants from residual sources. Food Chem. 2001, 72, 145–171. [Google Scholar] [CrossRef]

- Vinatoru, M.; Mason, T.; Calinescu, I. Ultrasonically assisted extraction (UAE) and microwave assisted extraction (MAE) of functional compounds from plant materials. TrAC Trends Anal. Chem. 2017, 97, 159–178. [Google Scholar] [CrossRef]

- Wen, C.; Zhang, J.; Zhang, H.; Dzah, C.S.; Zandile, M.; Duan, Y.; Ma, H.; Luo, X. Advances in ultrasound assisted extraction of bioactive compounds from cash crops–A review. Ultrason. Sonochem. 2018, 48, 538–549. [Google Scholar] [CrossRef]

- Pingret, D.; Fabiano-Tixier, A.-S.; Chemat, F. Degradation during application of ultrasound in food processing: A review. Food Control. 2013, 31, 593–606. [Google Scholar] [CrossRef]

- Abdel-Hameed, E.-S.S.; Bazaid, S.A.; Salman, M.S. Characterization of the Phytochemical Constituents of Taif Rose and Its Antioxidant and Anticancer Activities. BioMed Res. Int. 2013, 2013, 345465. [Google Scholar] [CrossRef] [PubMed]

- Mohsen, E.; Younis, I.Y.; Farag, M.A. Metabolites profiling of Egyptian Rosa damascena Mill. flowers as analyzed via ultra-high-performance liquid chromatography-mass spectrometry and solid-phase microextraction gas chromatography-mass spectrometry in relation to its anti-collagenase skin effect. Ind. Crop. Prod. 2020, 155, 112818. [Google Scholar] [CrossRef]

- Cendrowski, A.; Ścibisz, I.; Mitek, M.; Kieliszek, M.; Kolniak-Ostek, J. Profile of the Phenolic Compounds of Rosa rugosa Petals. J. Food Qual. 2017, 2017, 1–10. [Google Scholar] [CrossRef]

- Feng, M.; Xu, B.; Islam, N.; Zhou, C.; Wei, B.; Wang, B.; Ma, H.; Chang, L. Individual and synergistic effect of multi-frequency ultrasound and electro-infrared pretreatments on polyphenol accumulation and drying characteristics of edible roses. Food Res. Int. 2023, 163, 112120. [Google Scholar] [CrossRef]

- Zhang, J.; Xiao, Y.; Guan, Y.; Rui, X.; Zhang, Y.; Dong, M.; Ma, W. An aqueous polyphenol extract from Rosa rugosa tea has antiaging effects on Caenorhabditis elegans. J. Food Biochem. 2019, 43, e12796. [Google Scholar] [CrossRef]

| Independent Variables | Variables with Their Coded Levels | |||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| Ethanol (%) | X1 | 0 | 50 | 100 |

| Temperature (°C) | X2 | 30 | 60 | 90 |

| Time (min) | X3 | 120 | 75 | 30 |

| Run | Variable Levels | Total Phenolic Content (mg GA/g dw) | Antioxidant Activity (mg Trolox/g dw) | ||||

|---|---|---|---|---|---|---|---|

| Ethanol (%, X1) | Temperature (°C, X2) | Time (min, X3) | Lovely Red | Malu | Lovely Red | Malu | |

| 1 | 100 | 90 | 75 | 75.1 ± 1.2 | 41.4 ± 0.3 | 214.1 ± 3.9 | 83.8 ± 1.2 |

| 2 | 50 | 30 | 30 | 167.2 ± 2.9 | 83.0 ± 1.4 | 535.6 ± 5.6 | 253.3 ± 2.0 |

| 3 | 50 | 90 | 120 | 166.4 ± 3.3 | 118.4 ± 0.9 | 581.8 ± 2.8 | 359.3 ± 4.0 |

| 4 | 100 | 60 | 30 | 46.4 ± 0.8 | 30.5 ± 0.2 | 116.5 ± 0.1 | 26.6 ± 0.0 |

| 5 | 100 | 30 | 75 | 29.1 ± 0.2 | 15.2 ± 0.1 | 69.6 ± 2.7 | 25.5 ± 0.4 |

| 6 | 50 | 30 | 120 | 160.5 ± 2.0 | 100.6 ± 1.6 | 522.9 ± 1.6 | 307.4 ± 1.7 |

| 7 | 0 | 90 | 75 | 148.5 ± 2.3 | 93.1 ± 1.9 | 484.4 ± 5.0 | 267.3 ± 2.1 |

| 8 | 50 | 90 | 30 | 173.9 ± 2.4 | 114.2 ± 0.7 | 562.3 ± 5.2 | 345.3 ± 1.0 |

| 9 | 100 | 60 | 120 | 54.7 ± 0.8 | 34.9 ± 0.1 | 138.6 ± 0.7 | 55.8 ± 0.4 |

| 10 | 0 | 60 | 120 | 130.7 ± 2.3 | 85.1 ± 0.9 | 360.1 ± 13.9 | 204.1 ± 1.2 |

| 11 | 0 | 30 | 75 | 113.1 ± 0.9 | 87.0 ± 1.3 | 331.8 ± 8.9 | 127.9 ± 1.3 |

| 12 | 0 | 60 | 30 | 121.8 ± 1.2 | 73.4 ± 2.2 | 370.5 ± 10.3 | 150.4 ± 10.0 |

| 13 | 50 | 60 | 75 | 163.5 ± 5.9 | 106.9 ± 1.5 | 407.0 ± 10.4 | 307.7 ± 2.0 |

| 14 | 50 | 60 | 75 | 159.5 ± 0.8 | 92.5 ± 1.9 | 498.3 ± 2.2 | 306.8 ± 1.3 |

| 15 | 50 | 60 | 75 | 163.0 ± 1.2 | 105.4 ± 2.7 | 499.7 ± 6.0 | 291.1 ± 7.4 |

| 16 | 100 | 90 | 75 | 72.9 ± 2.5 | 42.3 ± 03 | 220.5 ± 3.2 | 77.4 ± 2.1 |

| 17 | 50 | 30 | 30 | 158.8 ± 4.3 | 97.0 ± 1.6 | 524.2 ± 9.4 | 293.9 ± 5.2 |

| 18 | 50 | 90 | 120 | 173.3 ± 3.5 | 115.7 ± 0.3 | 557.2 ± 3.3 | 338.1 ± 1.8 |

| 19 | 100 | 60 | 30 | 47.0 ± 0.8 | 29.2 ± 0.2 | 116.5 ± 0.1 | 26.5 ± 0.0 |

| 20 | 100 | 30 | 75 | 28.1 ± 1.7 | 16.5 ± 0.2 | 65.0 ± 3.9 | 27.7 ± 1.4 |

| 21 | 50 | 30 | 120 | 162.9 ± 2.4 | 100.6 ± 1.6 | 528.0 ± 8.8 | 264.4 ± 1.8 |

| 22 | 0 | 90 | 75 | 148.2 ± 4.2 | 95.9 ± 1.0 | 473.1 ± 10.6 | 264.2 ± 5.8 |

| 23 | 50 | 90 | 30 | 168.6 ± 3.1 | 112.8 ± 1.4 | 550.9 ± 7.9 | 356.6 ± 3.0 |

| 24 | 100 | 60 | 120 | 51.8 ± 1.3 | 33.3 ± 0.5 | 131.9 ± 0.7 | 53.1 ± 4.1 |

| 25 | 0 | 60 | 120 | 123.4 ± 1.2 | 84.5 ± 2.9 | 375.1 ± 6.3 | 225.8 ± 5.6 |

| 26 | 0 | 30 | 75 | 105.9 ± 2.6 | 85.8 ± 0.5 | 332.6 ± 3.5 | 213.9 ± 0.8 |

| 27 | 0 | 60 | 30 | 126.6 ± 1.7 | 74.3 ± 0.7 | 374.1 ± 6 | 146.2 ± 5.2 |

| 28 | 50 | 60 | 75 | 165.5 ± 1.9 | 109.4 ± 0.6 | 419.4 ± 6.3 | 318.9 ± 3.2 |

| 29 | 50 | 60 | 75 | 167.3 ± 2.4 | 105.0 ± 0.5 | 432.3 ± 1.0 | 299.1 ± 0.8 |

| 30 | 50 | 60 | 75 | 164.9 ± 2.6 | 105.8 ± 0.5 | 457.5 ± 11.8 | 298.5 ± 3.3 |

| Source | DF | Sum of Squares | F Ratio | p Value | |||

|---|---|---|---|---|---|---|---|

| Lovely Red | Malu | Lovely Red | Malu | Lovely Red | Malu | ||

| TPC | |||||||

| X1 | 1 | 23,492.5 | 11,871.7 | 325.2 | 475.58 | 0.0000 * | 0.0000 * |

| X2 | 1 | 2535.1 | 1372.6 | 35.1 | 54.97 | 0.0000 * | 0.0000 * |

| X3 | 1 | 11.7 | 215.2 | 0.2 | 8.62 | 0.6925 | 0.0085 * |

| X12 | 1 | 42,902.0 | 16,376.2 | 593.9 | 656.03 | 0.0000 * | 0.0000 * |

| X1X2 | 1 | 20.0 | 161.0 | 0.29 | 6.45 | 0.5961 | 0.0200 ** |

| X1X3 | 1 | 6.8 | 22.4 | 0.09 | 0.90 | 0.7619 | 0.3556 |

| X22 | 1 | 42.5 | 48.1 | 0.59 | 1.93 | 0.4522 | 0.1813 |

| X2 X3 | 1 | 0.0018 | 25.2 | 0.00 | 1.01 | 0.9961 | 0.3276 |

| X32 | 1 | 0.09 | 15.6 | 0.00 | 0.63 | 0.9719 | 0.4384 |

| Blocks | 1 | 2.3 | 23.4 | 0.03 | 0.94 | 0.8599 | 0.3447 |

| Lack of fit | 15 | 1359.6 | 28.2 | 28.2 | 0.66 | 0.0027 | 0.7493 |

| Total error | 19 | 1372.4 | 474.3 | ||||

| Total (corr.) | 29 | 71,067.5 | 30,846.9 | ||||

| R2 | 0.981 | 0.985 | |||||

| R2 adj | 0.972 | 0.978 | |||||

| AA | |||||||

| X1 | 1 | 260,899 | 93,535.0 | 255.02 | 207.81 | 0.0000 * | 0.0000 * |

| X2 | 1 | 33,718.10 | 20,891.8 | 32.96 | 46.42 | 0.0000 * | 0.0000 * |

| X3 | 1 | 220.00 | 2732.15 | 0.22 | 6.07 | 0.6481 | 0.0235 ** |

| X12 | 1 | 403,924 | 254,709 | 394.83 | 565.89 | 0.0000 * | 0.0000 * |

| X1X2 | 1 | 5.80 | 832.93 | 0.01 | 1.85 | 0.9408 | 0.1896 |

| X1X3 | 1 | 133.17 | 751.75 | 0.13 | 1.67 | 0.7222 | 0.2117 |

| X22 | 1 | 28,201.3 | 2392.67 | 27.57 | 5.32 | 0.0000 * | 0.0326 ** |

| X2X3 | 1 | 150.43 | 105.78 | 0.15 | 0.24 | 0.7056 | 0.6334 |

| X32 | 1 | 10,439.4 | 353.09 | 10.20 | 0.78 | 0.0048 * | 0.3869 |

| Blocks | 1 | 592.474 | 281.58 | 0.58 | 0.63 | 0.4560 | 0.4387 |

| Lack of fit | 15 | 14,076.8 | 8107.48 | 0.70 | 4.86 | 0.7272 | 0.0687 |

| Total error | 19 | 19,437.8 | 8551.95 | ||||

| Total (corr.) | 29 | 784,957 | 390,327 | ||||

| R2 | 0.975 | 0.978 | |||||

| R2 adj | 0.964 | 0.968 | |||||

| Extraction Conditions | Independent Variables | Predictive TPC (mg GA/g dw) | Predictive AA (mg Trolox/g dw) | ||||

|---|---|---|---|---|---|---|---|

| Ethanol (%, X1) | Temperature, (°C, X2) | Time, (min, X3) | Lovely Red | Malu | Lovely Red | Malu | |

| Optimal conditions | 38 | 90 | 117 | 202.7 | |||

| 38 | 90 | 112 | 119.2 | ||||

| 38 | 90 | 120 | 611.9 | ||||

| 38 | 90 | 114 | 376.5 | ||||

| Optimal conditions at average time | 38 | 90 | 116 | 205.2 | 119.5 | 604.8 | 377.1 |

| Proposed conditions | 38 | 75 | 30 | 189.3 | 108.5 | 535.6 | 320.7 |

| Response | Cultivar | with UAE | without UAE |

|---|---|---|---|

| TPC (mg GA/g dw) | Lovely Red | 159.3 a ± 1.4 | 160.5 a ± 6.0 |

| Malu | 100.4 a ± 1.9 | 100.6 a ± 2.4 | |

| Lovely Red | 527.4 a ± 6.9 | 481.3 b ± 10.9 | |

| AA (mg Trolox/g dw) | Malu | 291.9 a ± 7.7 | 279.5 b ± 6.9 |

| N° | Rt. (min) | Formula | Compound | [M-H]− (m/z) | MS/MS |

|---|---|---|---|---|---|

| 1 | 2.5 | C7H12O6 | Quinic acid | 191.0558 | 171, 155, 137, 127 |

| 2 | 10.2 | C15H14O6 | Catechin | 289.0709 | 179, 145 |

| 3 | 10.8 | C41H26O26 | Unknown ellagitannin | 466.0303 * | 301, 451 |

| 4 | 11.2 | C17H20O14 | Galloyl hexose malic acid | 447.0785 | 331, 169, 133 |

| 5 | 11.8 | C27H30O18 | Myricetin 3,5-di-O-glucoside | 641.1350 | 541, 479, 410, 355, 317 |

| 6 | 12.2 | C34H24O22 | Bis-HHDP-hexose | 391.0316 * | 301 |

| 7 | 12.2 | C41H28O26 | Galloyl-bis-HHDP-hexose | 935.0772 | 451 |

| 8 | 12.5 | C41H26O26 | Unknown ellagitannin | 466.0291 * | 301, 451 |

| 9 | 17.8 | C20H18O11 | Quercetin-O-pentoside | 433.0762 | 410, 300 |

| 10 | 18.1 | C21H20O12 | Quercetin-O-hexoside | 463.0899 | 410, 300 |

| 11 | 18.6 | C14H6O8 | Ellagic acid | 300.9995 | 283, 257, 245, 229, 210, 201, 185, 173 |

| 12 | 19.3 | C27H30O16 | Rutin | 609.1462 | 410, 343, 301 |

| 13 | 19.5 | C21H20O11 | Quercetin-O-rhamnoside | 447.0930 | 410, 300, 271, 178, 151 |

| 14 | 19.7 | C28H24O15 | Quercetin-O-galloylrhamnoside | 599.1042 | 447, 410, 313, 285, 226, 169 |

| 15 | 20.2 | C20H18O10 | Kaempferol-O-pentoside | 417.0814 | 284, 255, 227 |

| 16 | 20.7 | C27H30O15 | Kaempferol-O-hexosyl-deoxyhexoside | 593.1507 | 410, 285 |

| 17 | 21.1 | C21H20O10 | Kaempferol-O-deoxyhexoside | 431.1003 | 410, 284, 255, 227 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baibuch, S.; Zema, P.; Bonifazi, E.; Cabrera, G.; Mondragón Portocarrero, A.d.C.; Campos, C.; Malec, L. Effect of the Drying Method and Optimization of Extraction on Antioxidant Activity and Phenolic of Rose Petals. Antioxidants 2023, 12, 681. https://doi.org/10.3390/antiox12030681

Baibuch S, Zema P, Bonifazi E, Cabrera G, Mondragón Portocarrero AdC, Campos C, Malec L. Effect of the Drying Method and Optimization of Extraction on Antioxidant Activity and Phenolic of Rose Petals. Antioxidants. 2023; 12(3):681. https://doi.org/10.3390/antiox12030681

Chicago/Turabian StyleBaibuch, Sabrina, Paula Zema, Evelyn Bonifazi, Gabriela Cabrera, Alicia del Carmen Mondragón Portocarrero, Carmen Campos, and Laura Malec. 2023. "Effect of the Drying Method and Optimization of Extraction on Antioxidant Activity and Phenolic of Rose Petals" Antioxidants 12, no. 3: 681. https://doi.org/10.3390/antiox12030681

APA StyleBaibuch, S., Zema, P., Bonifazi, E., Cabrera, G., Mondragón Portocarrero, A. d. C., Campos, C., & Malec, L. (2023). Effect of the Drying Method and Optimization of Extraction on Antioxidant Activity and Phenolic of Rose Petals. Antioxidants, 12(3), 681. https://doi.org/10.3390/antiox12030681