Timely and Durable Polymer Modified Patching Materials for Pothole Repairs in Low Temperature and Wet Conditions

Abstract

:1. Introduction

2. Materials and Methods

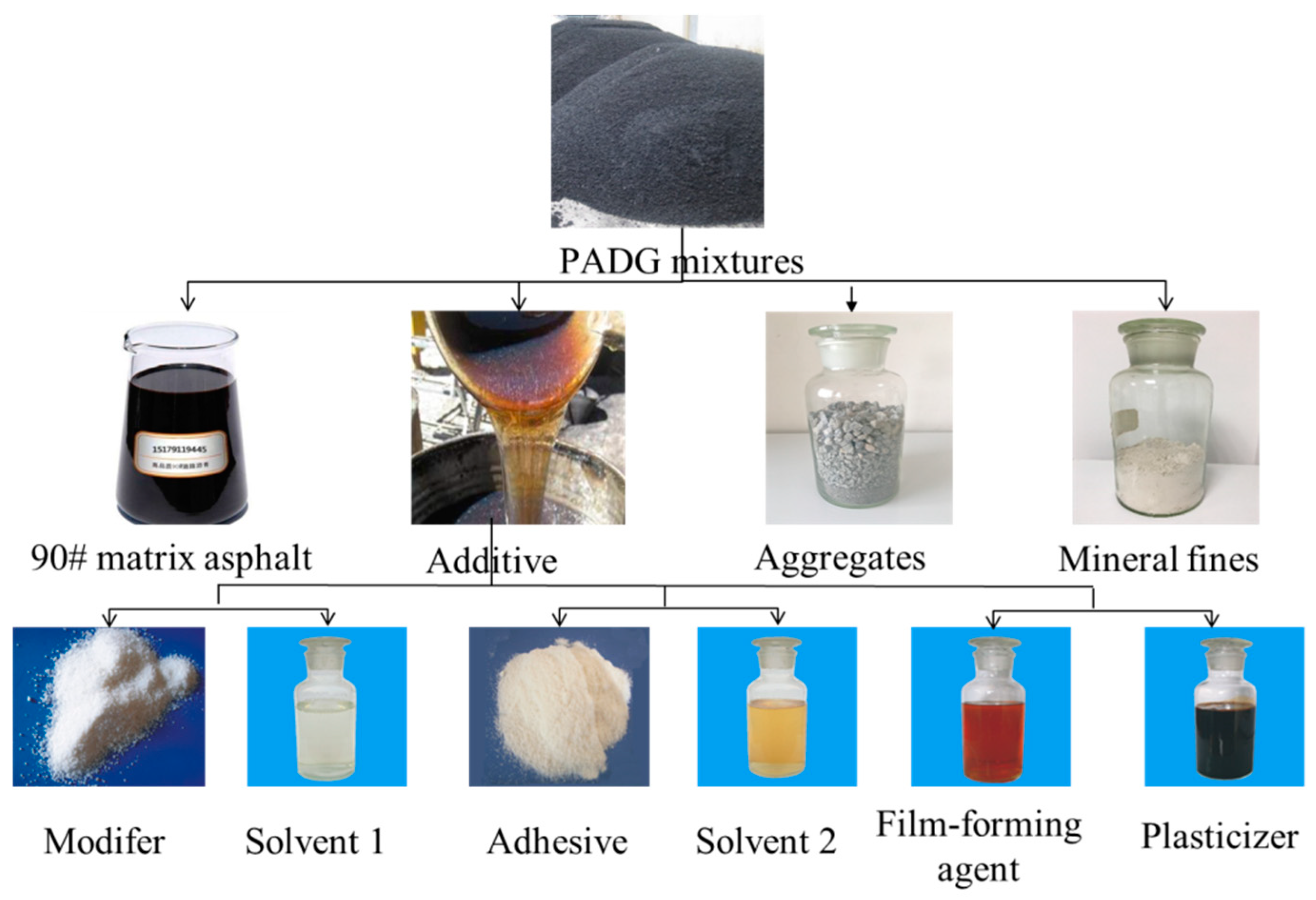

2.1. Materials

2.2. Methods

2.2.1. Workability and Storability Tests

2.2.2. Cohesion Tests

2.2.3. Marshall Tests

- Initial stability: Three standard Marshall samples per mixture were stored in a ventilated room for 2 h at 25 °C.

- Molded stability: Three standard Marshall samples per mixture together with mold were compacted 25 times again on both sides, after being side upright placed in an oven at 100 °C for 48 h. Subsequently, samples with mold were placed into a ventilated room of 25 °C for 48 h. Then the molds were removed and samples were placed in ventilated room for 2 h.

- Stability forming speed: Three standard Marshall samples per mixture were placed in a 5 °C ventilated room for 3, 7, 15, 30, 45, and 90 days.

- Low temperature stability: Three standard Marshall samples per mixture were placed in a refrigerator at −10 ℃ for 72 h.

- Immersed stability: For this process there were multiple groups of samples. In the first group, three Marshall samples of per mixture were immersed in a 10 °C water bath for 30 min and then placed in 25 °C ventilated room for 72 h, to determine the dry stability (S1). As for the second group, the remaining three Marshall samples of each mixture were laid into a 25 °C ventilated room for 24 h after being soaked in a 10 °C water bath for 48 h. Marshall stability of immersed samples was tested and recorded as S2. The percentage rate of S1 and S2 was calculated to assess the ability of resistance to water damage.

2.2.4. Freeze-Thaw Tensile Strength Tests

2.2.5. Accelerated Loaded Test

3. Results and Discussion

3.1. Workability Analysis

3.2. Storability Analysis

3.3. Cohesion Analysis

3.4. Stability Analysis

3.5. Durability Analysis

3.5.1. Freeze-Thaw Tensile Strength Test Results Analysis

3.5.2. Accelerated Loaded Test Results Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Dong, Q.; Huang, B.; Zhao, S. Field and laboratory evaluation of winter season pavement pothole patching materials. Int. J. Pavement Eng. 2014, 15, 279–289. [Google Scholar] [CrossRef]

- Wilson, T.P.; Romine, A.R. Materials and Procedures for Repair of Potholes in Asphalt-Surfaced Pavements—Manual of Practice; Federal Highway Administration: Washington, DC, USA, 2001. [Google Scholar]

- Chatterjee, S.; White, R.P.; Smit, A.; Prozzi, J.; Prozzi, J.A. Development of Mix Design and Testing Procedures for Cold Patching Mixtures; National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2006. [Google Scholar]

- García, A. A Fast Pothole Repair Method Using Asphalt Tiles and Induction Heating. Constr. Build. Mater. 2017, 131, 592–599. [Google Scholar]

- Wilson, T.P.; Romine, A.R. Innovative Materials Development and Testing. Volume 2: Pothole Repair; Publication SHRP-H-353; National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 1993. [Google Scholar]

- Dong, Q.; Yuan, J.; Chen, X.; Ma, X. Reduction of Moisture Susceptibility of Cold Asphalt Mixture with Portland Cement and Bentonite Nanoclay Additives. J. Clean. Prod. 2018, 176, 320–328. [Google Scholar] [CrossRef]

- Kandhal, P.S.; Mellott, D.B. A Rational Approach to the Design of Bituminous Stockpile Mixtures. J. Transp. Res. Rec. 1981, 821, 16–21. [Google Scholar]

- Prowell, B.; Franklin, A. Evaluation of Cold Mixes for Winter Pothole Repair. J. Transp. Res. Rec. 1996, 1529, 76–85. [Google Scholar] [CrossRef]

- Anderson, D.A.; Siddiqui, Z.; Krivohlavek, D.D. More Effective Cold, Wet-Weather Patching Materials for Asphalt Pavements: Final Report; Federal Highway Administration: Washington, DC, USA, 1988. [Google Scholar]

- Leonelli, F.; Di Mascio, P.; Germinario, A.; Picarella, F.; Moretti, L.; Cassata, M.; De Rubeis, A. Laboratory and On-Site Tests for Rapid Runway Repair. Appl. Sci. 2017, 7, 1192. [Google Scholar] [CrossRef]

- Maher, A.; Gucunski, N.; Yanko, W.; Petsi, F. Evaluation of Pothole Patching Materials; Laboratory Tests; National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2001. [Google Scholar]

- Copas, T.L.; Pennock, H.A. Bituminous Patching Mixtures, National Highway Research Program 64. Presented at the 58th Annual Meeting of the Transportation Research Board, Washington, DC, USA, 15–19 January 1979. [Google Scholar]

- María, J.; Pimentel, F. Accelerated Testing Methodology for Evaluating Pavement Patching Materials. Presented at the 86th Annual Meeting of the Transportation Research Board, Washington, DC, USA, 21–25 January 2007. [Google Scholar]

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794. [Google Scholar] [CrossRef] [PubMed]

- Mozaffari, S.; Tchoukov, P.; Atias, J.; Czarnecki, J.; Nazemifard, N. Effect of Asphaltene Aggregation on Rheological Properties of Diluted Athabasca Bitumen. Energy Fuels 2015, 29, 5595–5599. [Google Scholar] [CrossRef]

- Mozaffari, S.; Tchoukov, P.; Mozaffari, A.; Atias, J.; Czarnecki, J.; Nazemifard, N. Capillary driven flow in nanochannels—Application to heavy oil rheology studies. Colloids Surf. A Physicochem. Eng. Asp. 2016, 513, 178–187. [Google Scholar] [CrossRef]

- Darjani, S.; Koplik, J.; Pauchard, V. Extracting the equation of state of lattice gases from random sequential adsorption simulations by means of the Gibbs adsorption isotherm. Phys. Rev. E 2017, 96, 052803. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Zhou, Q.; Ye, H.-M. Optimizing the Preparation of Semi-Crystalline Paraffin/Poly(Urea-Formaldehyde) Microcapsules for Thermal Energy Storage. Appl. Sci. 2019, 9, 599. [Google Scholar] [CrossRef]

- Tabakovic, A.; Schuyffel, L.; Karac, A.; Schlangen, E. An Evaluation of the Efficiency of Compartmented Alginate Fibres Encapsulating a Rejuvenator as an Asphalt Pavement Healing System. Appl. Sci. 2017, 7, 647. [Google Scholar] [Green Version]

- Aaron, A.; Brenna, T.; Veronika, K. Encapsulation and Ultrasound-Triggered Release of G-Quadruplex DNA in Multilayer Hydrogel Microcapsules. Polymers 2018, 10, 1342. [Google Scholar]

- Choi, Y.C.; Cho, Y.K.; Shin, K.J.; Kwon, S.J. Development and application of microcapsule for cement hydration control. KSCE J. Civ. Eng. 2016, 20, 282–292. [Google Scholar] [CrossRef]

- Perez, G.; Gaitero, J.J.; Erkizia, E.; Jimenez, I.; Guerrero, A. Characterisation of cement pastes with innovative self-healing system based in epoxy-amine adhesive. Cem. Concr. Compos. 2015, 60, 55–64. [Google Scholar] [CrossRef]

- Du, W.; Yu, J.; Gu, Y.; Li, Y.; Han, X.; Liu, Q. Preparation and application of microcapsules containing toluene-di-isocyanate for self-healing of concrete. Constr. Build. Mater. 2019, 202, 762–769. [Google Scholar] [CrossRef]

- Sun, D.; Pang, Q.; Zhu, X.; Tian, Y.; Lu, T.; Yang, Y. Enhanced Self-healing Process of Sustainable Asphalt Materials Containing Microcapsules. ACS Sustain. Chem. Eng. 2017, 5, 9881–9893. [Google Scholar] [CrossRef]

- Zhao, Y.; Gu, F.; Xu, J.; Jin, J. Analysis of aging mechanism of SBS polymer modified asphalt based on Fourier transform infrared spectrum. J. Wuhan Univ. Technol. 2010, 25, 1047–1052. [Google Scholar] [CrossRef]

- Larsen, D.O.; Alessandrini, J.L.; Bosch, A.; Cortizo, M.S. Micro-structural and rheological characteristics of SBS-asphalt blends during their manufacturing. Constr. Build. Mater. 2009, 23, 2769–2774. [Google Scholar] [CrossRef]

- ASTM. Test Method for Resistance of Plastic Flow of Bituminous Mixtures Using Marshall Apparatus; ASTM D1559; ASTM: West Conshohocken, PA, USA, 1998. [Google Scholar]

- AASHTO. Standard Method of Test for Resistance of Compacted Hot Mix Asphalt (HMA) to Moisture-Induced Damage; AASHTO Guide, T283; AASHTO: Washington, DC, USA, 2007. [Google Scholar]

- Liu, F.; Darjani, S.; Akhmetkhanova, N.; Maldarelli, C.; Banerjee, S.; Pauchard, V. Mixture Effect on the Dilatation Rheology of Asphaltenes-Laden Interfaces. Langmuir 2017, 33, 1927–1942. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.-H. Unified Strength Theory and Its Applications; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Estakhri, C.K.; Jimenez, L.M.; Button, J.W. Guidelines for Improving the Performance of Txdot Item 334, Hot-Mix, Cold-Laid Asphalt Concrete Paving Mixtures; National Technical Information Service: Springfield, VA, USA, 1999. [Google Scholar]

| Properties | Values | Specifications |

|---|---|---|

| Penetration (25 °C,100 g, 5 s) (0.1 mm) | 88.5 | 80~100 |

| Softening point (°C) | 48.2 | ≥44 |

| Ductility (15 °C) (mm) | 138 | ≥100 |

| Density (g/cm3) | 1.022 | - |

| Wax content (%) | 1.6 | ≤2.2 |

| Mixtures Type | Losing Mass (g) | Residual Ratio (%) |

|---|---|---|

| DG mixtures | 12.3 | 98.46 |

| OG mixtures | 34.8 | 95.65 |

| PADG mixtures | 25.4 | 96.83 |

| Mixtures Type | Stability in Different Conditions (kN) | ||||

|---|---|---|---|---|---|

| Initial | Modeled | Low Temperature | Dry | Immersed | |

| DG mixtures | 0.30 | 5.54 | 4.40 | 5.32 | 3.80 |

| OG mixtures | 0.55 | 3.03 | 5.05 | 4.52 | 2.79 |

| PADG mixtures | 3.44 | 6.03 | 5.46 | 6.00 | 4.98 |

| Mixtures Type | Dry Tensile Strength (MPa) | Freezing-Thawing Tensile Strength (MPa) | Tensile Strength Ratio (TSR) (%) |

|---|---|---|---|

| DG mixtures | 0.59 | 0.37 | 62.71 |

| OG mixtures | 0.43 | 0.25 | 58.14 |

| PADG mixtures | 0.62 | 0.50 | 80.65 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, S.; Liu, M.; Shang, W.; Qi, X.; Zhang, Z.; Dong, S. Timely and Durable Polymer Modified Patching Materials for Pothole Repairs in Low Temperature and Wet Conditions. Appl. Sci. 2019, 9, 1949. https://doi.org/10.3390/app9091949

Han S, Liu M, Shang W, Qi X, Zhang Z, Dong S. Timely and Durable Polymer Modified Patching Materials for Pothole Repairs in Low Temperature and Wet Conditions. Applied Sciences. 2019; 9(9):1949. https://doi.org/10.3390/app9091949

Chicago/Turabian StyleHan, Sen, Mengmei Liu, Weigong Shang, Xiang Qi, Zhuang Zhang, and Shihao Dong. 2019. "Timely and Durable Polymer Modified Patching Materials for Pothole Repairs in Low Temperature and Wet Conditions" Applied Sciences 9, no. 9: 1949. https://doi.org/10.3390/app9091949

APA StyleHan, S., Liu, M., Shang, W., Qi, X., Zhang, Z., & Dong, S. (2019). Timely and Durable Polymer Modified Patching Materials for Pothole Repairs in Low Temperature and Wet Conditions. Applied Sciences, 9(9), 1949. https://doi.org/10.3390/app9091949