Fabrication of Mesh Patterns Using a Selective Laser-Melting Process

Abstract

:1. Introduction

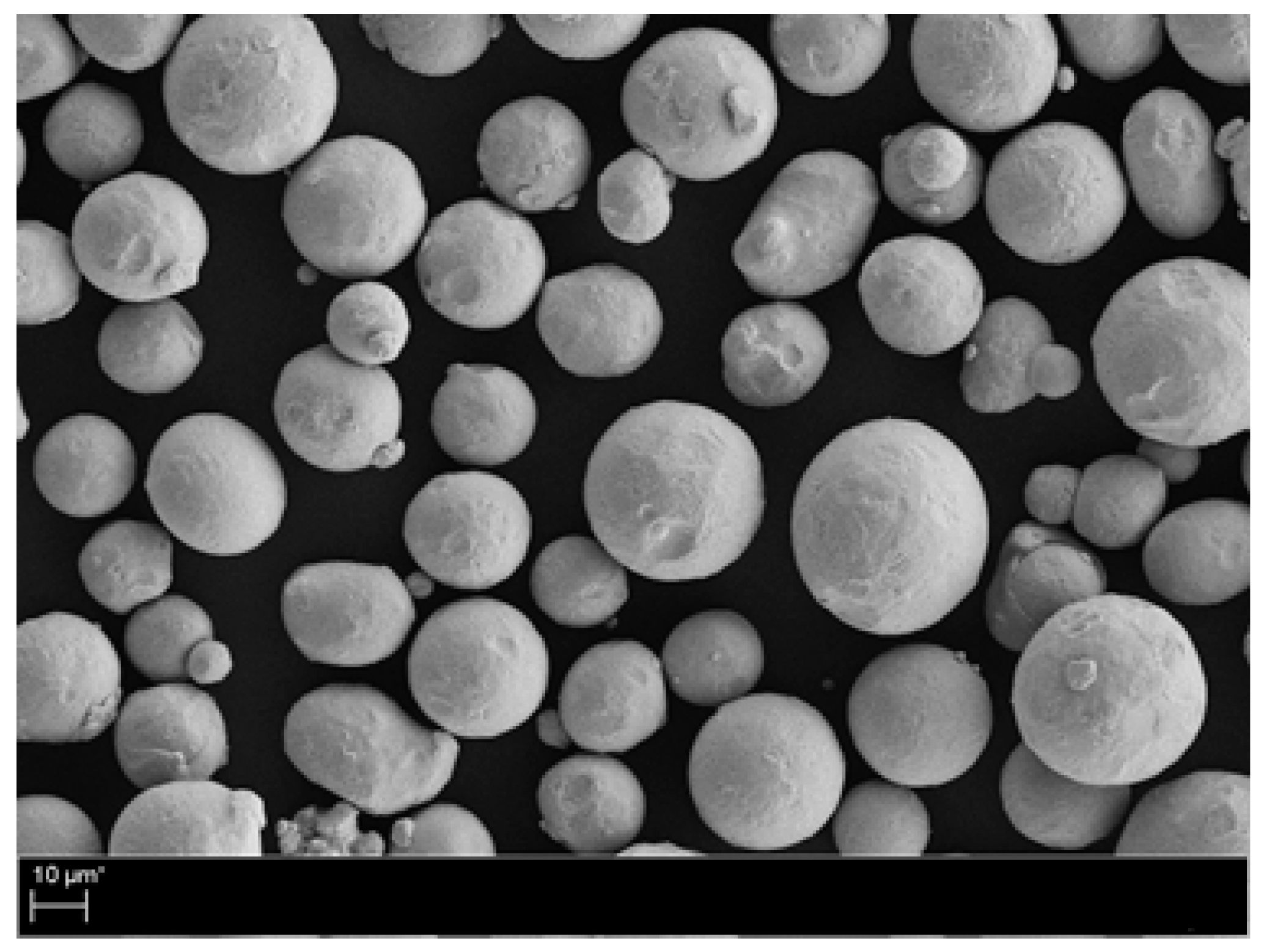

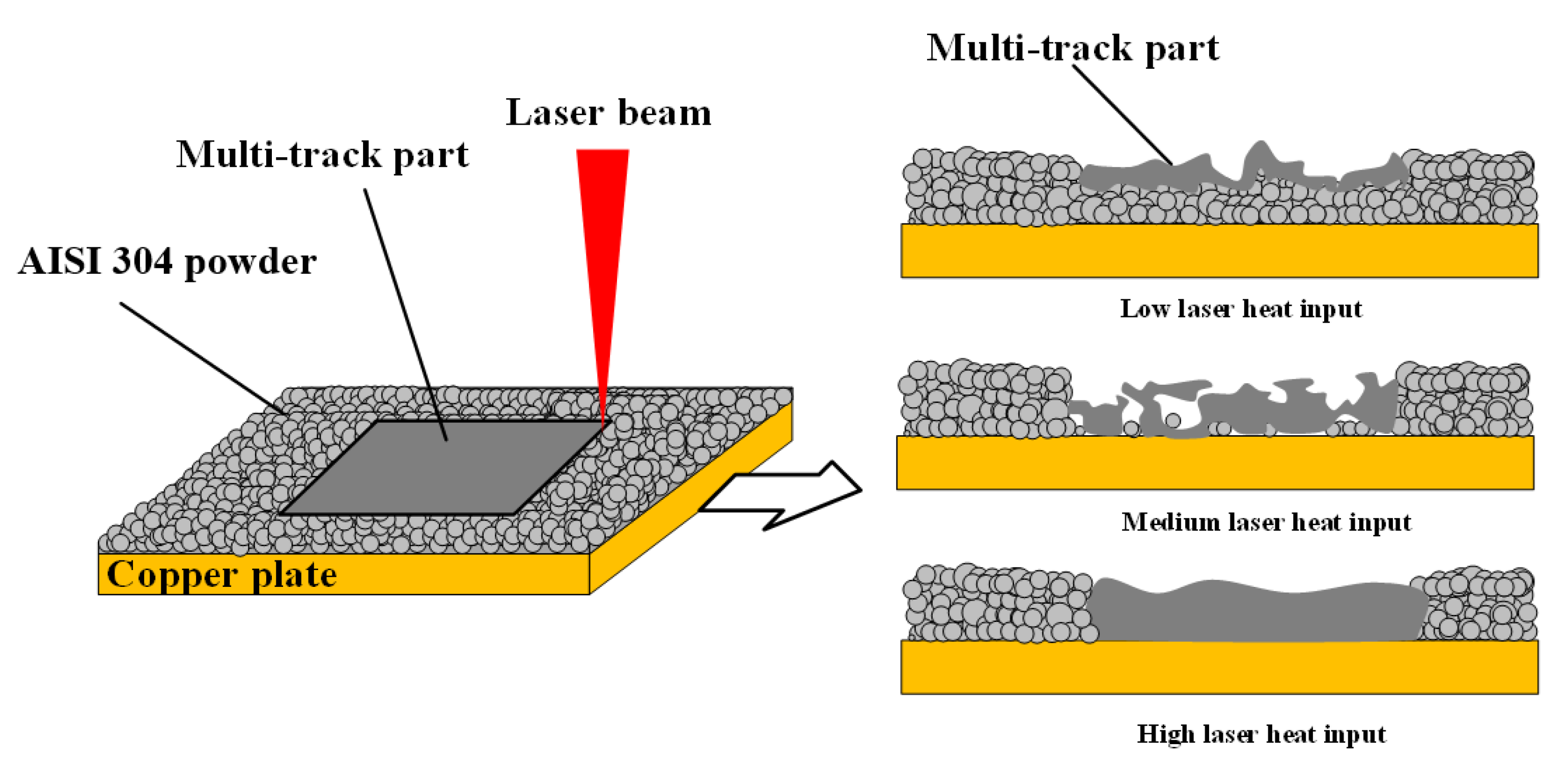

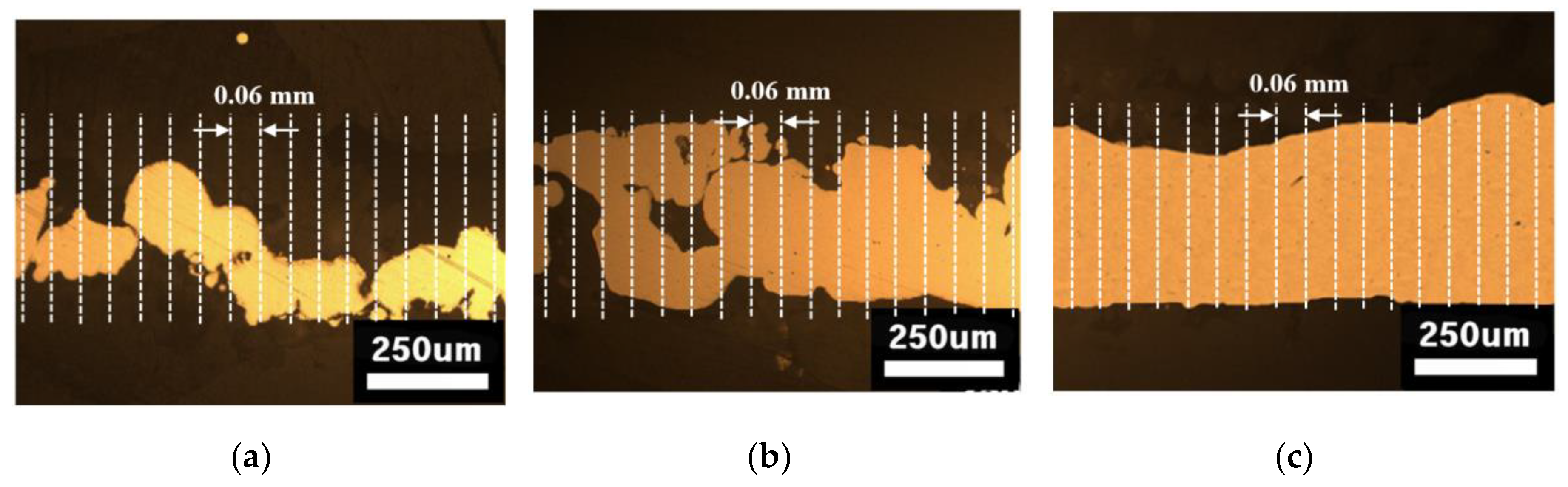

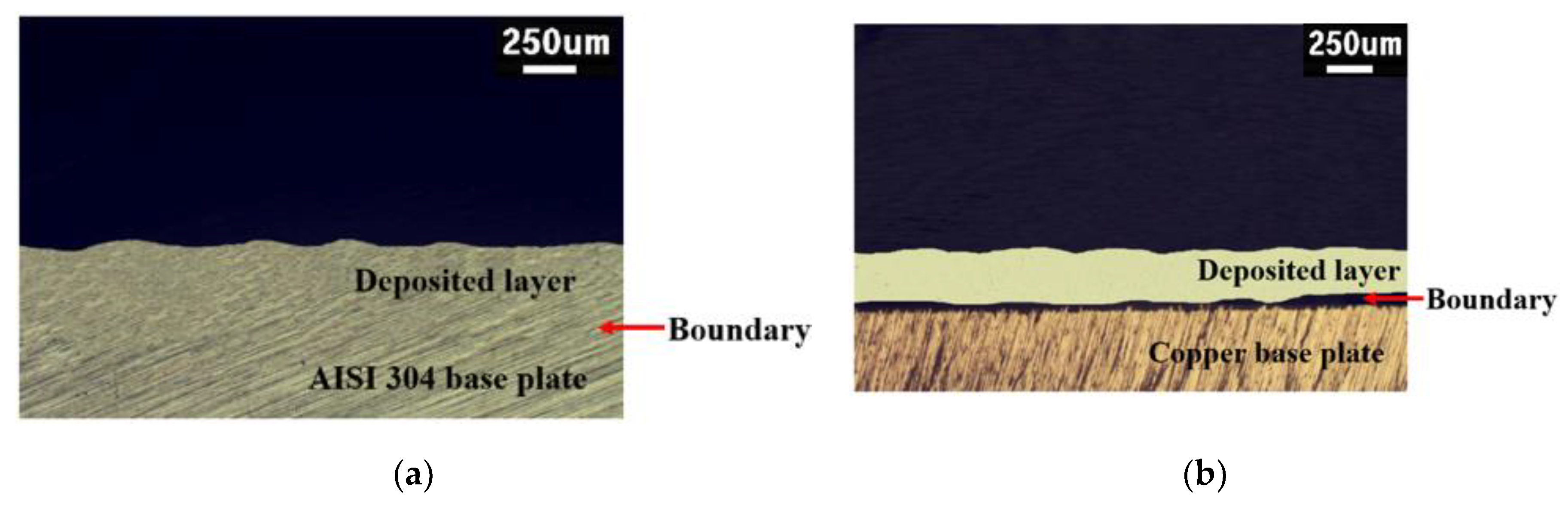

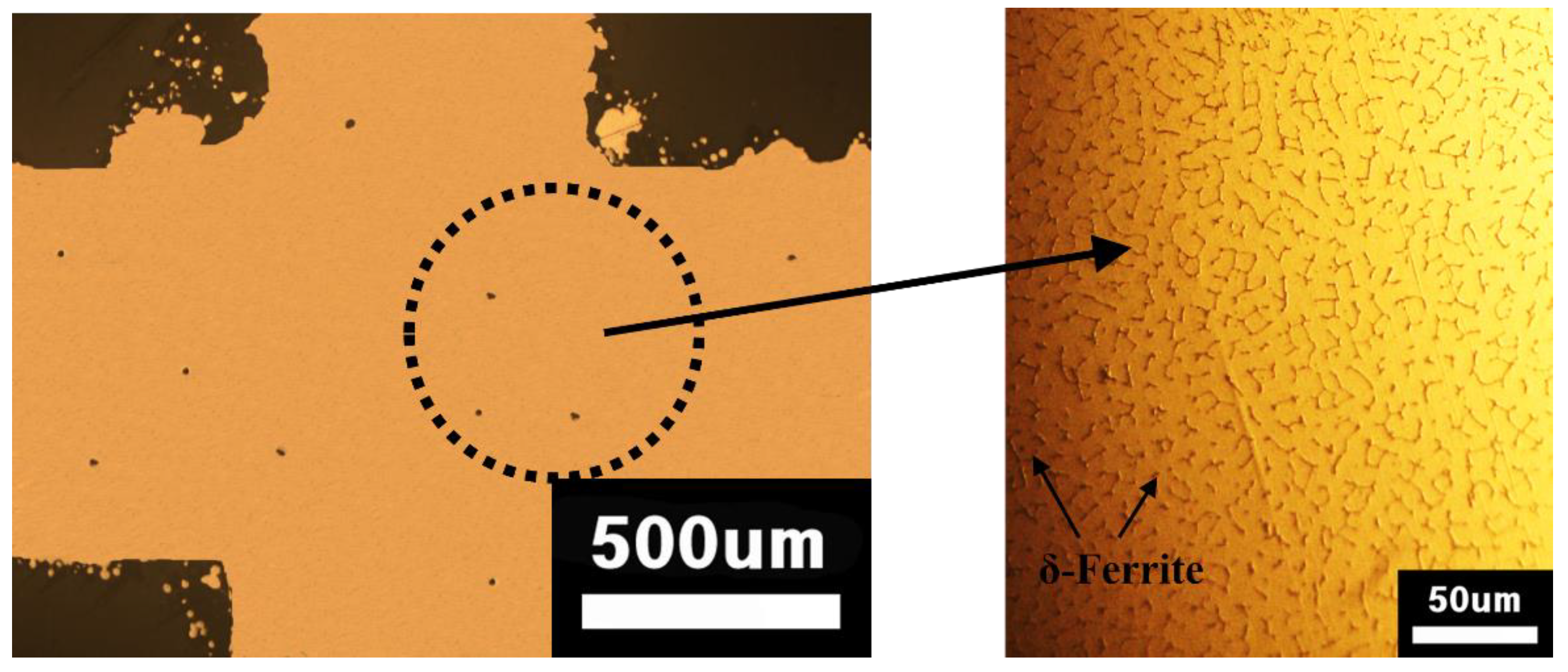

2. Material and Process Characterization

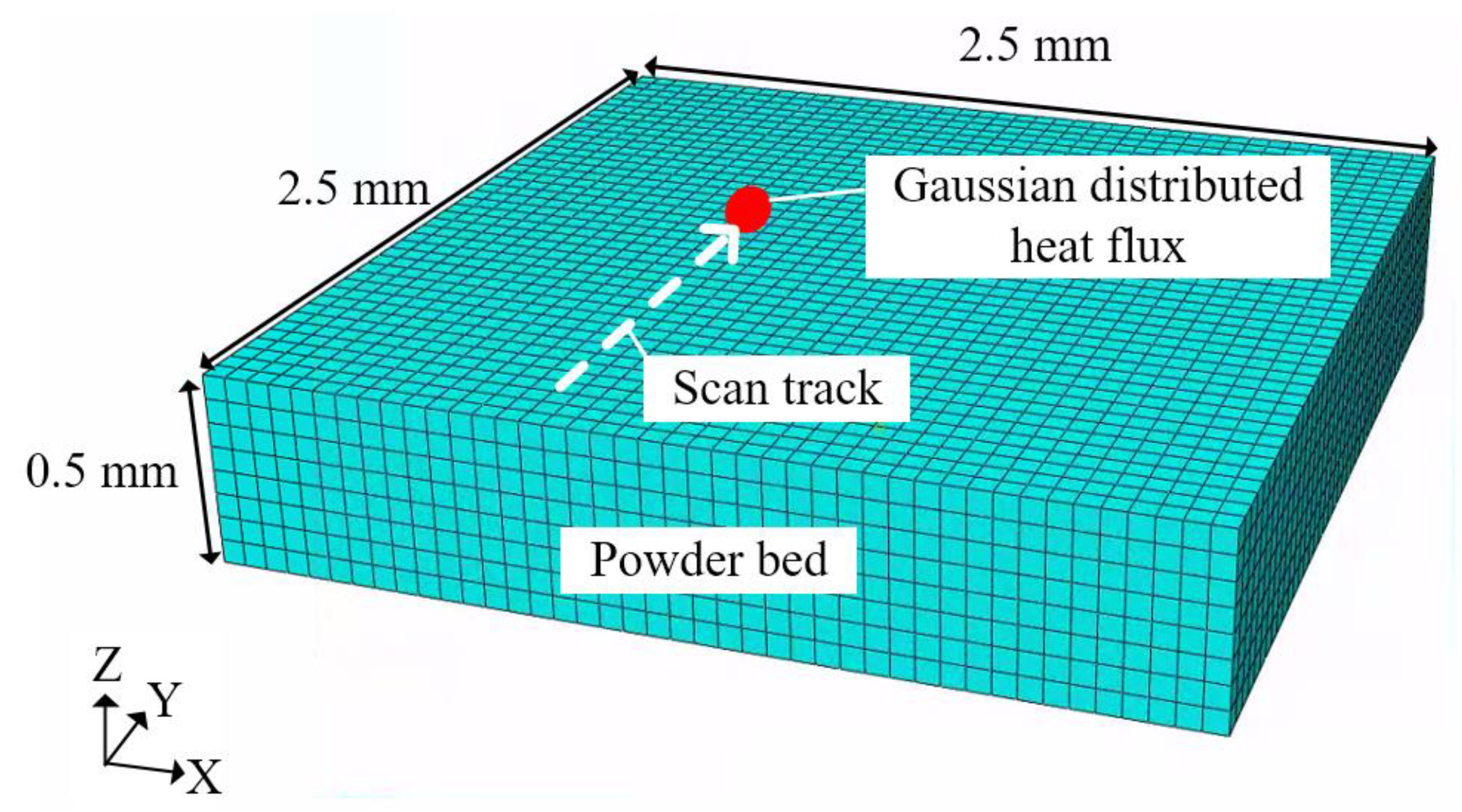

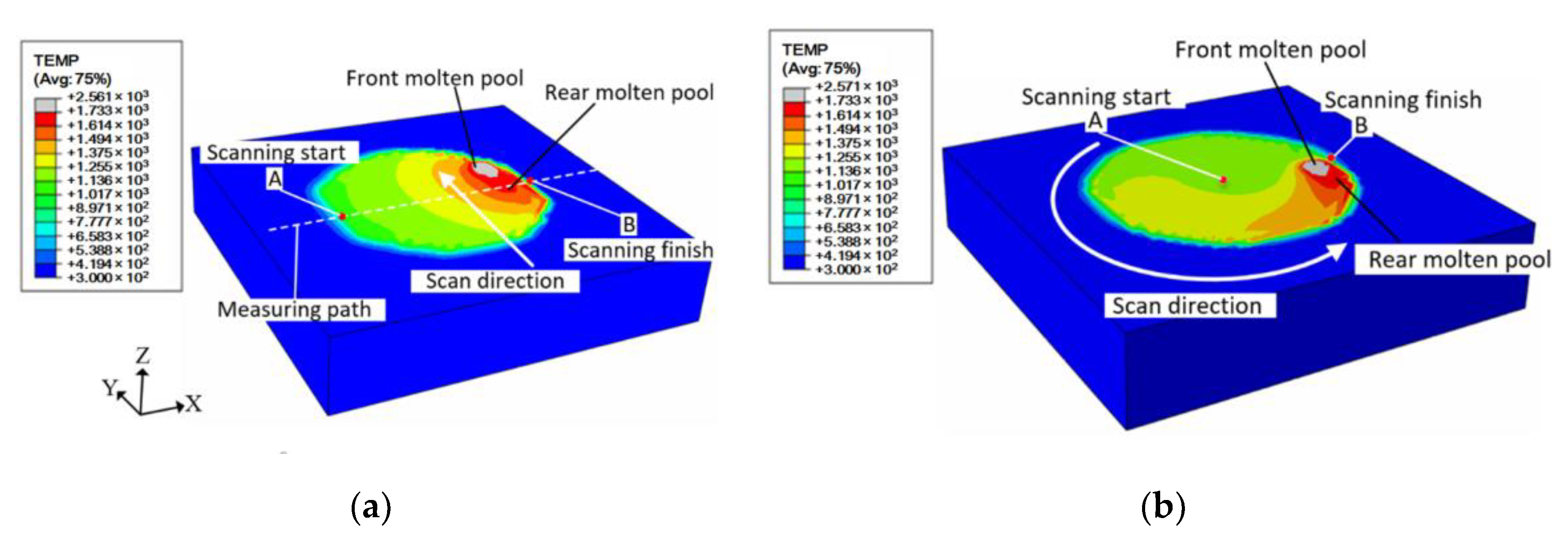

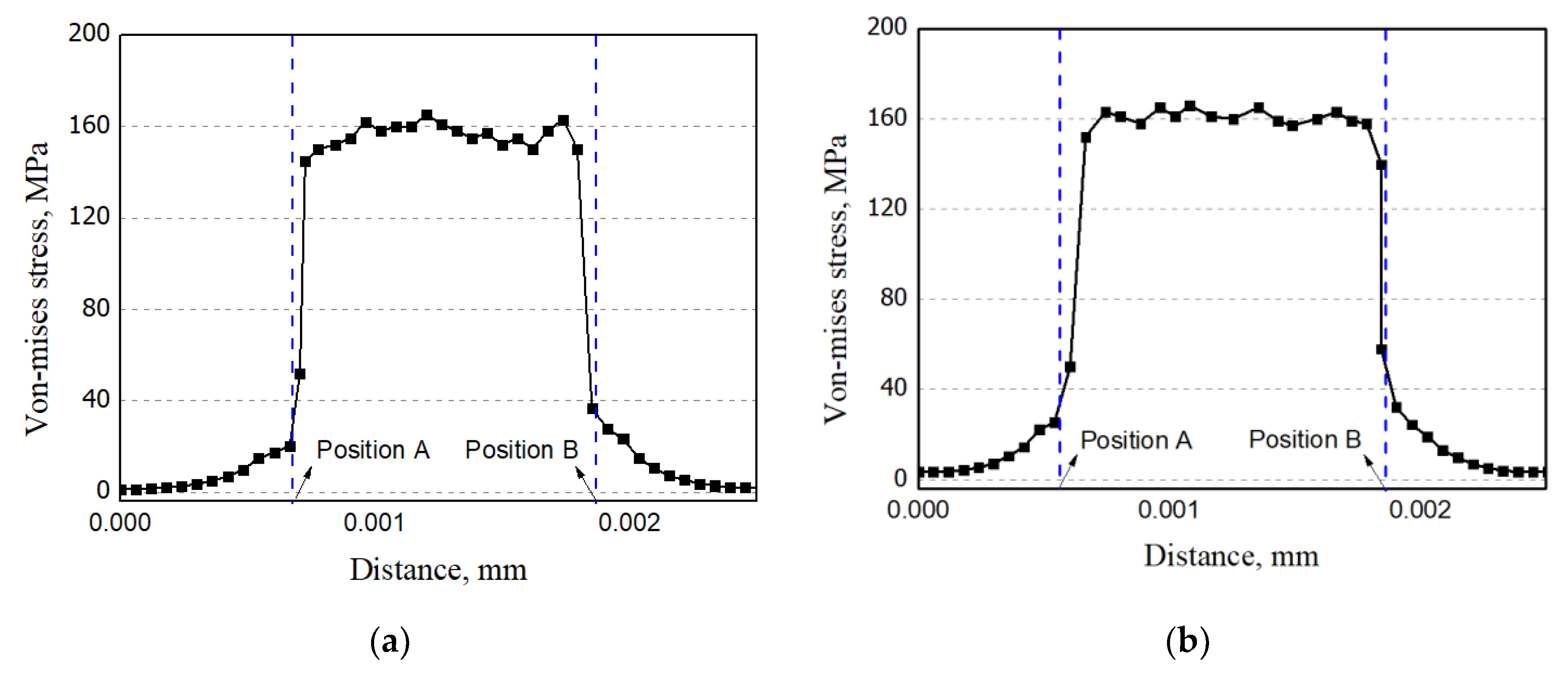

3. Finite Element Analysis

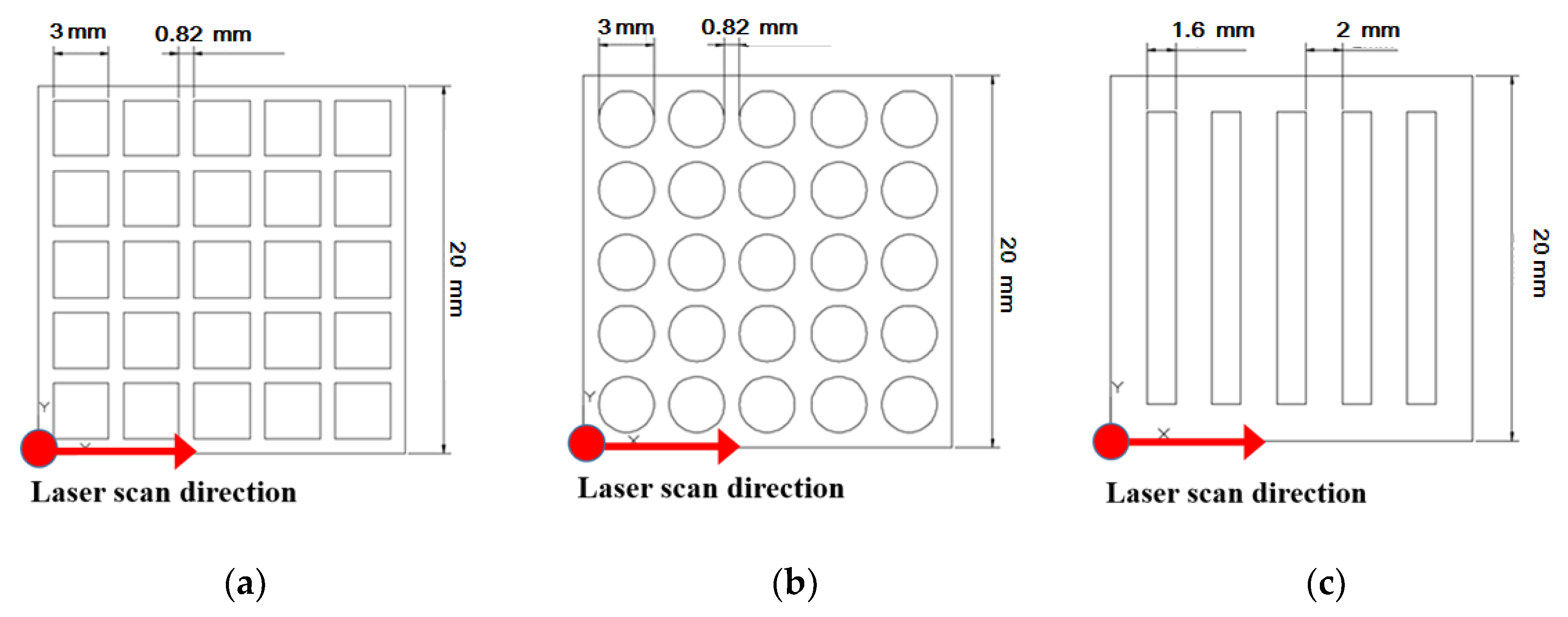

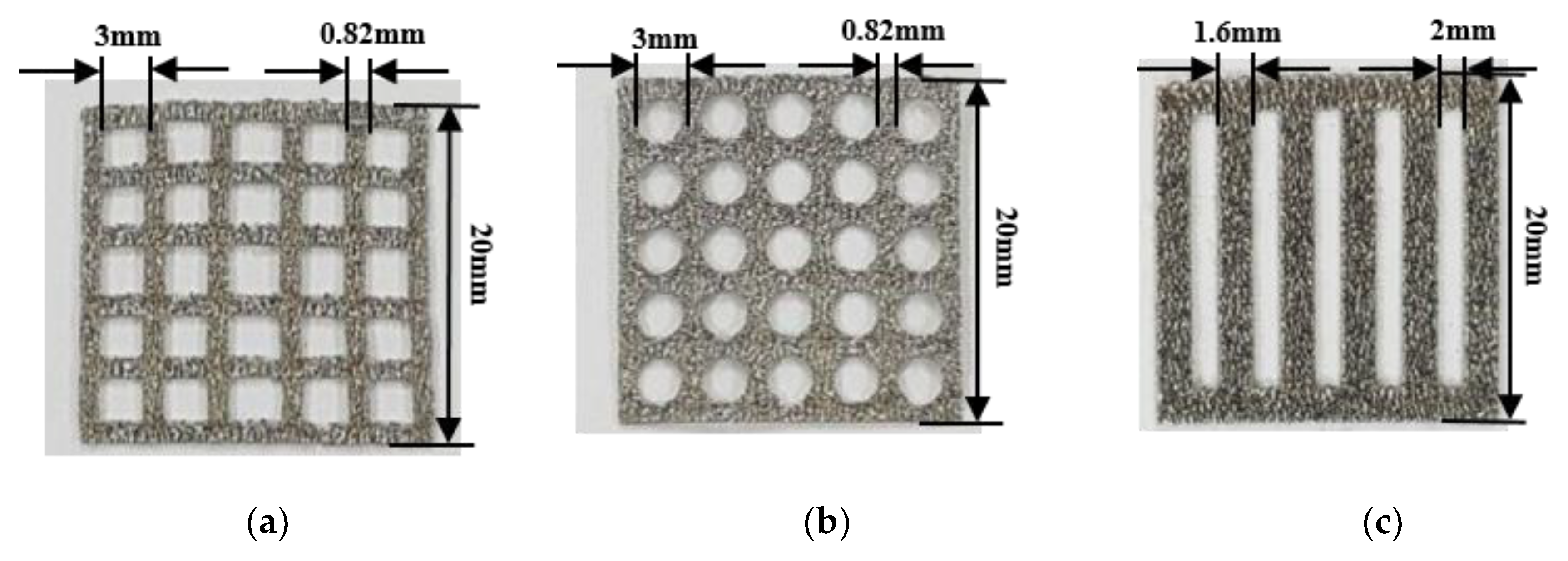

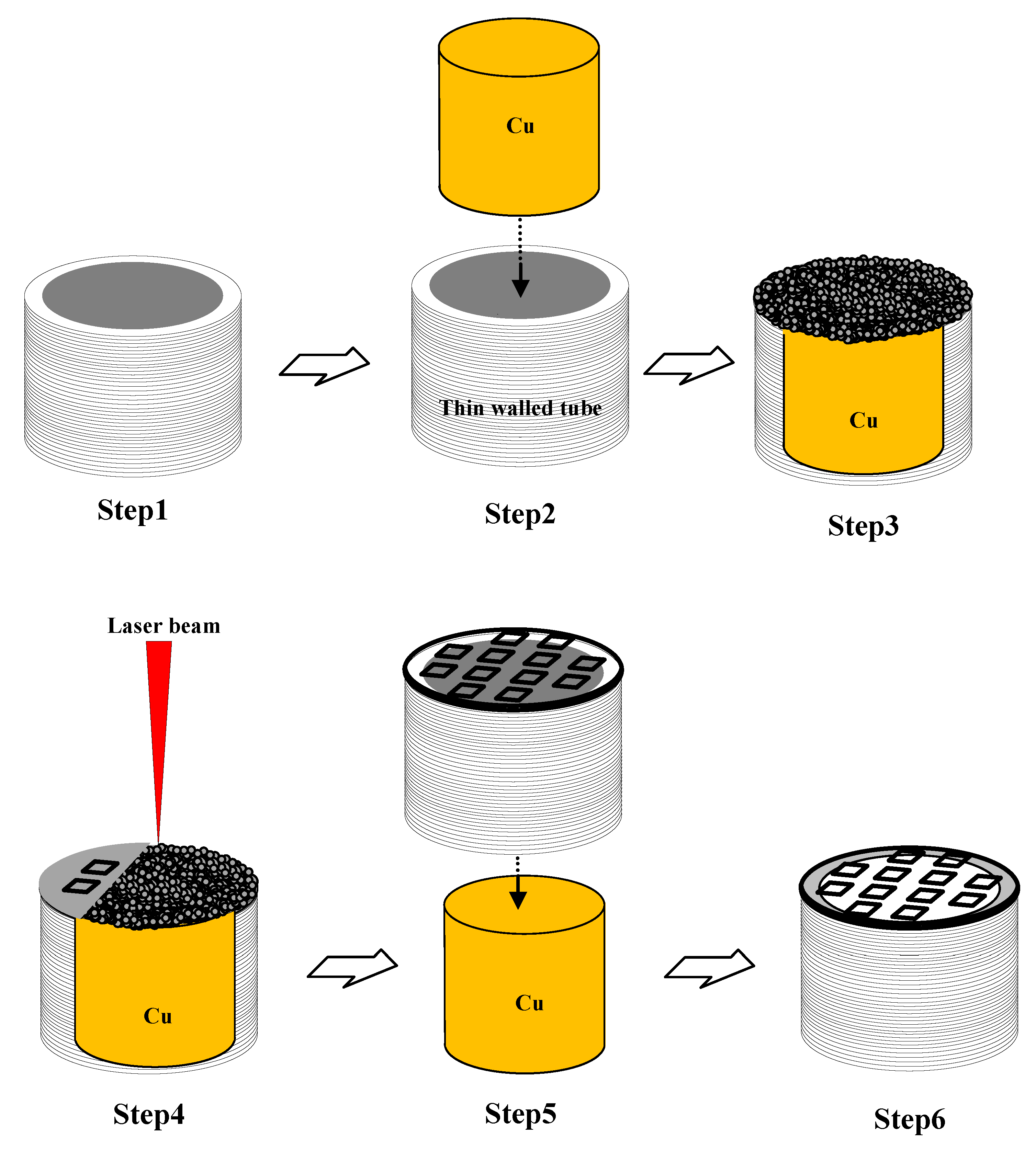

4. Selective Laser Melting (SLM) of Thin Mesh Patterns

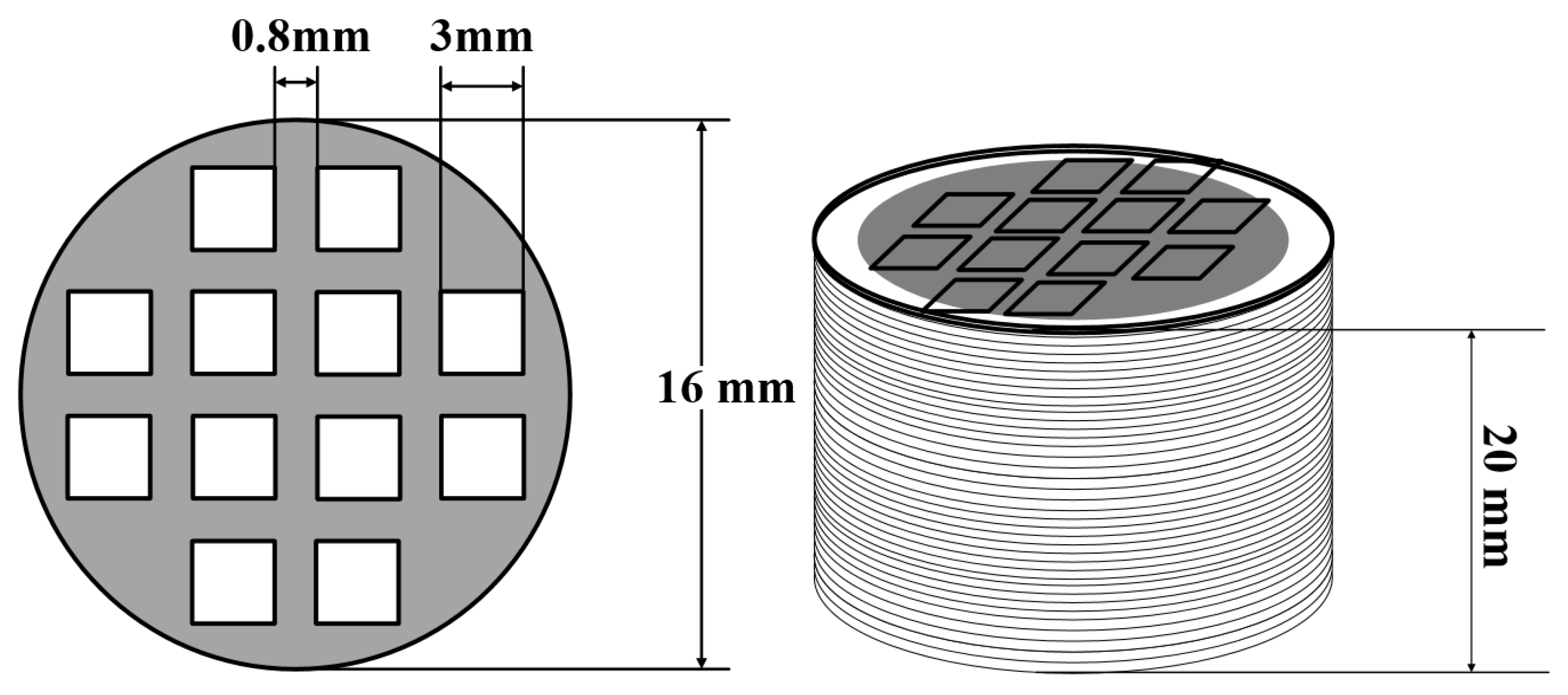

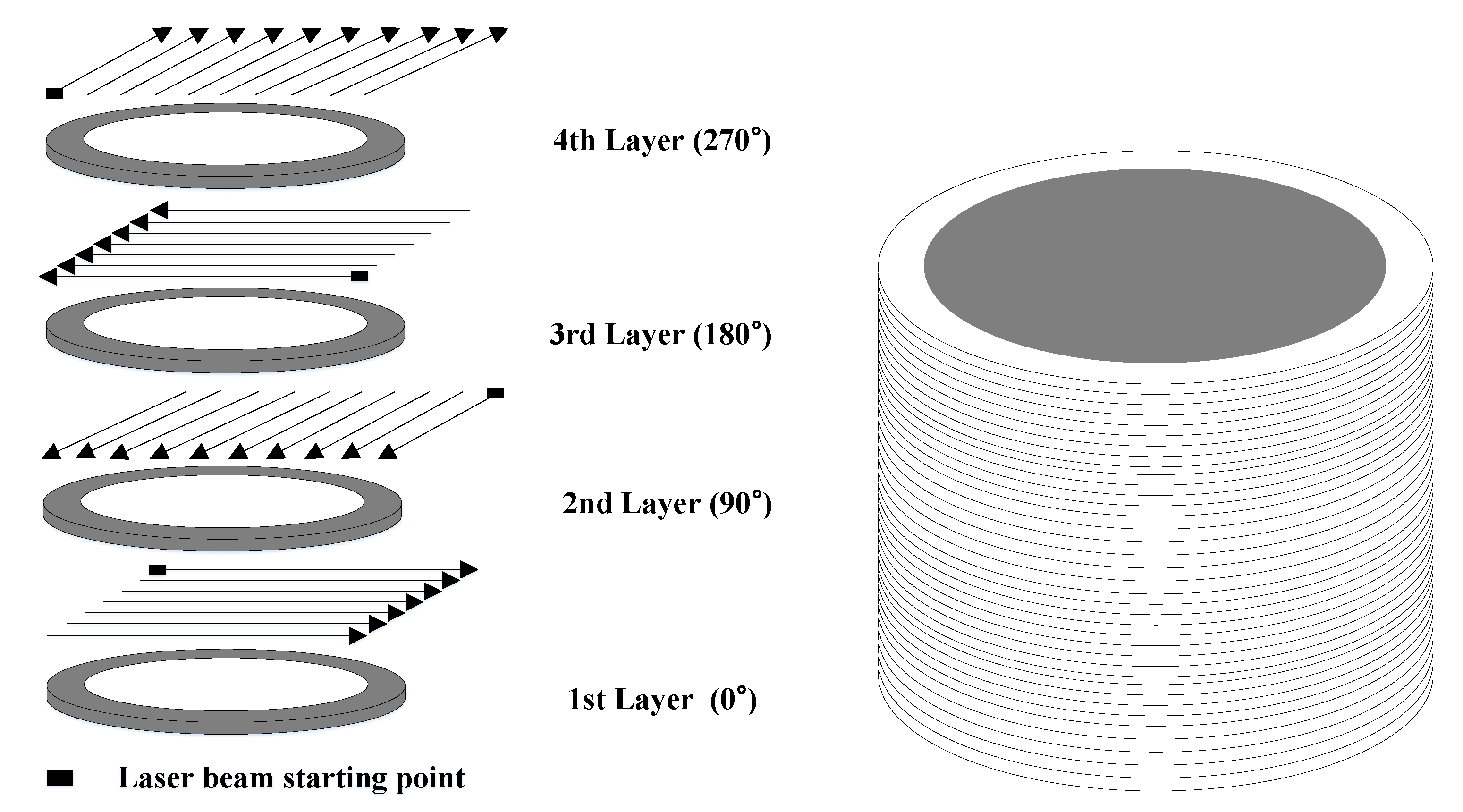

5. Fabrication of Part with Mesh Pattern

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Levy, G.N.; Schindel, R.; Kruth, J.P. Rapid manufacturing and rapid tooling with layer manufacturing (LM) technologies, state of the art and future perspectives. CIRP Ann. Manuf. Technol. 2003, 52, 589–609. [Google Scholar] [CrossRef]

- Hwang, T.W.; Woo, Y.Y.; Han, S.W.; Moon, Y.H. Functionally graded properties in directed-energy-deposition titanium parts. Opt. Laser Technol. 2018, 105, 80–88. [Google Scholar] [CrossRef]

- Kruth, J.P.; Leu, M.C.; Nakagawa, T. Progress in additive manufacturing and rapid prototyping. CIRP Ann. 1998, 47, 525–540. [Google Scholar] [CrossRef]

- Zhang, L.C.; Liu, Y.; Li, S.; Hao, Y. Additive manufacturing of titanium alloys by electron beam melting: A review. Adv. Eng. Mater. 2018, 20, 1700842. [Google Scholar] [CrossRef]

- Lee, J.H.; Jang, J.H.; Joo, B.D.; Son, Y.M.; Moon, Y.H. Laser surface hardening of AISI H13 tool steel. T. Nonferr. Metal. Soc. 2009, 19, 917–920. [Google Scholar] [CrossRef]

- Razavi, S.M.J.; Bordonaro, G.G.; Ferro, P.; Torgersen, J.; Berto, F. Fatigue Behavior of Porous Ti-6Al-4V Made by Laser-Engineered Net Shaping. Materials 2018, 11, 284. [Google Scholar] [CrossRef]

- Song, M.C.; Moon, Y.H. Coupled electromagnetic and thermal analysis of induction heating for the forging of marine crankshafts. Appl. Therm. Eng. 2016, 98, 98–109. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Gusarov, A.; Yadroitsava, I.; Smurov, I. Single track formation in selective laser melting of metal powders. J. Mater. Process. Technol. 2010, 12, 1624–1631. [Google Scholar] [CrossRef]

- Altan, T.; Lilly, B.; Yen, Y.C. Manufacturing of dies and molds. CIRP Ann. Manuf. Technol. 2001, 50, 404–422. [Google Scholar] [CrossRef]

- Park, K.S.; VanTyne, C.J.; Moon, Y.H. Process analysis of multistage forging by using finite element method. J. Mater. Process. Technol. 2007, 187–188, 586–590. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Zhang, W. Additive manufacturing of metallic components–process, structure and properties. Prog. Mater. Sci. 2017, 92, 112–224. [Google Scholar] [CrossRef]

- Moon, Y.H.; Kim, D.W.; Van Tyne, C.J. Analytical model for prediction of sidewall curl during stretch-bend sheet metal forming. Int. J. Mech. Sci. 2008, 50, 666–675. [Google Scholar] [CrossRef]

- Yi, H.K.; Kim, D.W.; VanTyne, C.J.; Moon, Y.H. Analytical prediction of springback based on residual differential strain during sheet metal bending. P. I. Mech. Eng. C. J. Mec. 2008, 222, 117–129. [Google Scholar] [CrossRef]

- Kim, P.H.; Chun, M.S.; Yi, J.J.; Moon, Y.H. Pass schedule algorithms for hot open die forging. J. Mater. Process. Technol. 2002, 130–131, 516–523. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Flynn, J.M.; Shokrani, A.; Newman, S.T.; Dhokia, V. Hybrid additive and subtractive machine tools–Research and industrial developments. Int. J. Mach. Tools Manuf. 2016, 101, 79–101. [Google Scholar] [CrossRef]

- Patel, R.; Hirsch, M.; Dryburgh, P.; Pieris, D.; Achamfuo-Yeboah, S.; Smith, R.; Light, R.; Sharples, S.; Clare, A.; Clark, M. Imaging material texture of as-deposited selective laser melted parts using spatially resolved acoustic spectroscopy. Appl. Sci. 2018, 8, 1991. [Google Scholar] [CrossRef]

- Joo, B.D.; Jang, J.H.; Lee, J.H.; Son, Y.M.; Moon, Y.H. Selective laser melting of Fe-Ni-Cr layer on AISI H13 tool steel. T. Nonferr. Metal. Soc. 2009, 19, 921–924. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Bertrand, P.; Antonenkova, G.; Grigoriev, S.; Smurov, I. Use of track/layer morphology to develop functional parts by selective laser melting. J. Laser. Appl. 2013, 25, 052003. [Google Scholar] [CrossRef]

- Bönninghoff, N.; Chu, J.P.; Chang, C.W.; Mehretie, M.; Lai, B.Z. Preparation and characterization of micron-scale molybdenum metal mesh electrodes. Surf. Coat. Technol. 2018, 349, 224–232. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, J.; Oh, J.H. Fabrication of fine metal patterns using an additive material extrusion process with a molten metal. Microelectron. Eng. 2018, 191, 10–15. [Google Scholar] [CrossRef]

- Huang, H.; Wang, J.; Liu, W. Mechanical properties and reinforced mechanism of the stainless steel wire mesh–reinforced Al-matrix composite plate fabricated by twin-roll casting. Adv. Mech. Eng. 2017, 9, 1–9. [Google Scholar] [CrossRef]

- Lu, C.; Qi, Z.; Guo, W.; Cui, Y. A new fold-cross metal mesh filter for suppressing side lobe leakage in terahertz region. Opt. Commun. 2018, 413, 190–195. [Google Scholar] [CrossRef]

- Carrillo, J.; Rico, A.; Alcocer, S. Experimental study on the mechanical properties of welded-wire meshes for concrete reinforcement in Mexico City. Constr. Build. Mater. 2016, 127, 663–672. [Google Scholar] [CrossRef]

- Ayyub, B.M.; Chang, P.C.; Al-Mutairi, N.A. Welded wire fabric for bridges. I: Ultimate strength and ductility. J. Struct. Eng. 1994, 120, 866–1881. [Google Scholar] [CrossRef]

- Xu, G.; Liu, Y.; Luo, X.; Ma, J.; Li, H. Experimental investigation of transpiration cooling for sintered woven wire mesh structures. Int. J. Heat Mass Transf. 2015, 91, 898–907. [Google Scholar] [CrossRef]

- Ma, J.; Lv, P.; Luo, X.; Liu, Y.; Li, H.; Wen, J. Experimental investigation of flow and heat transfer characteristics in double-laminated sintered woven wire mesh. Appl. Therm. Eng. 2016, 95, 53–61. [Google Scholar] [CrossRef]

- Naderzadeh, M.; Monazzam, M.R.; Nassiri, P.; Fard, S.M.B. Application of perforated sheets to improve the efficiency of reactive profiled noise barriers. Appl. Acoust. 2011, 72, 393–398. [Google Scholar] [CrossRef]

- Liu, B.; Wen, Y.; Liu, C.; Sun, B.; Yuan, X. Multiscale calculation on perforated sheet structured packing to predict the liquid distribution based on computational fluid dynamics simulation. Ind. Eng. Chem. Res. 2016, 55, 7810–7818. [Google Scholar] [CrossRef]

- Mallick, R.K.; Thombre, S.B. Performance of passive DMFC with expanded metal mesh current collectors. Electrochim. Acta. 2017, 243, 299–309. [Google Scholar] [CrossRef]

- Wang, A.; Yuan, W.; Huang, S.; Tang, Y.; Chen, Y. Structural effects of expanded metal mesh used as a flow field for a passive direct methanol fuel cell. Appl. Energy 2017, 208, 184–194. [Google Scholar] [CrossRef]

- Yi, H.K.; Pavlina, E.J.; VanTyne, C.J.; Moon, Y.H. Application of a combined heating system for the warm hydroforming of lightweight alloy tubes. J. Mater. Process. Technol. 2008, 203, 532–536. [Google Scholar] [CrossRef]

- Gordon, W.A.; VanTyne, C.J.; Moon, Y.H. Axisymmetric extrusion through adaptable dies-Part 1: Flexible velocity fields and power terms. Int. J. Mech. Sci. 2007, 49, 86–95. [Google Scholar] [CrossRef]

- Kim, E.S.; Lee, K.H.; Moon, Y.H. A feasibility study of the partial squeeze and vacuum die casting process. J. Mater. Process. Technol. 2000, 105, 42–48. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Shishkovsky, I.; Bertrand, P.; Smurov, I. Manufacturing of fine-structured 3D porous filter elements by selective laser melting. Appl. Surf. Sci. 2009, 255, 5523–5527. [Google Scholar] [CrossRef]

- Fukuda, A.; Takemoto, M.; Saito, T.; Fujibayashi, S.; Neo, M.; Pattanayak, D.K.; Matsushita, T.; Sasaki, K.; Nishida, N.; Kokubo, T.; Nakamura, T. Osteoinduction of porous Ti implants with a channel structure fabricated by selective laser melting. Acta Biomater. 2011, 7, 2327–2336. [Google Scholar] [CrossRef]

- Sercombe, T.B.; Xu, X.; Challis, V.J.; Green, R.; Yue, S.; Zhang, Z.; Lee, P.D. Failure modes in high strength and stiffness to weight scaffolds produced by Selective Laser Melting. Mater. Des. 2015, 67, 501–508. [Google Scholar] [CrossRef] [Green Version]

- Murr, L.E.; Amato, K.N.; Li, S.J.; Tian, Y.X.; Cheng, X.Y.; Gaytan, S.M.; Martinez, E.; Shindo, P.W.; Medina, F.; Wicker, R.B. Microstructure and mechanical properties of open-cellular biomaterials prototypes for total knee replacement implants fabricated by electron beam melting. J. Mech. Behav. Biomed. Mater. 2011, 4, 1396–1411. [Google Scholar] [CrossRef]

- Cansizoglu, O.; Harrysson, O.; Cormier, D.; West, H.; Mahale, T. Properties of Ti–6Al–4V non-stochastic lattice structures fabricated via electron beam melting. Mat. Sci. Eng. A 2008, 492, 468–474. [Google Scholar] [CrossRef]

- Liu, Y.J.; Li, S.J.; Wang, H.L.; Hou, W.T.; Hao, Y.L.; Yang, R.; Sercombe, T.B.; Zhang, L.C. Microstructure, defects and mechanical behavior of beta-type titanium porous structures manufactured by electron beam melting and selective laser melting. Acta Mater. 2016, 113, 56–67. [Google Scholar] [CrossRef]

- Santos, L.M.S.; de Jesus, J.; Ferreira, J.M.; Costa, J.D.; Capela, C. Fracture toughness of hybrid components with selective laser melting 18Ni300 steel parts. Appl. Sci. 2018, 8, 1879. [Google Scholar] [CrossRef]

- Liu, H.; Sparks, T.; Liou, F.; Dietrich, D.M. Residual stress and deformation modelling for metal additive manufacturing processes. In Proceedings of the World Congress on Mechanical, Chemical, and Material Engineering (MCM 2015), Barcelona, Spain, 20–21 July 2015. Paper No. 245. [Google Scholar]

- Chew, Y.; Pang, J.H.L.; Bi, G.; Song, B. Thermo-mechanical model for simulating laser cladding induced residual stresses with single and multiple clad beads. J. Mater. Process. Technol. 2015, 224, 89–101. [Google Scholar] [CrossRef]

- Liu, H.; Sparks, T.E.; Lious, F.W.; Dietrich, D.M. Numerical analysis of thermal stress and deformation in multi-layer laser metal deposition process. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, Spring 2014; pp. 577–591. [Google Scholar]

- Hussein, A.; Hao, L.; Yan, C.; Everson, R. Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting. Mater. Des. 2013, 52, 638–647. [Google Scholar] [CrossRef]

- D’Oliveira, A.S.C.M.; Paredes, R.S.C.; Weber, F.P.; Vilar, R. Microstructural changes due to laser surface melting of an AISI 304 stainless steel. Mater. Res. 2001, 4, 93–96. [Google Scholar] [CrossRef]

- Akgun, O.V.; Inal, O.T. Desensitization of sensitized 304 stainless steel by laser surface melting. J. Mater. Sci. 1992, 27, 2147–2153. [Google Scholar] [CrossRef]

- Pan, Q.Y.; Huang, W.D.; Song, R.G.; Zhou, Y.H.; Zhang, G.L. The improvement of localized corrosion resistance in sensitized stainless steel by laser surface remelting. Surf. Coat. Technol. 1998, 102, 245–255. [Google Scholar] [CrossRef]

- Yasa, E.; Kruth, J.P. Microstructural investigation of Selective Laser Melting 316L stainless steel parts exposed to laser re-melting. Procedia Eng. 2011, 19, 389–395. [Google Scholar] [CrossRef] [Green Version]

| Element | Fe | Cr | Ni | Mo | Mn | Si |

|---|---|---|---|---|---|---|

| wt. % | Bal. | 18.00 | 9.00 | 2.25 | 1.00 | 0.20 |

| Laser Power (W) | 200 |

| Scan rate (mm/s) | 110 |

| Fill-spacing (mm) | 0.06 |

| Powder layering thickness (mm) | 0.2–0.6 |

| Fabricated shape type | square, circle, rectangle |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, T.W.; Woo, Y.Y.; Han, S.W.; Moon, Y.H. Fabrication of Mesh Patterns Using a Selective Laser-Melting Process. Appl. Sci. 2019, 9, 1922. https://doi.org/10.3390/app9091922

Hwang TW, Woo YY, Han SW, Moon YH. Fabrication of Mesh Patterns Using a Selective Laser-Melting Process. Applied Sciences. 2019; 9(9):1922. https://doi.org/10.3390/app9091922

Chicago/Turabian StyleHwang, Tae Woo, Young Yun Woo, Sang Wook Han, and Young Hoon Moon. 2019. "Fabrication of Mesh Patterns Using a Selective Laser-Melting Process" Applied Sciences 9, no. 9: 1922. https://doi.org/10.3390/app9091922

APA StyleHwang, T. W., Woo, Y. Y., Han, S. W., & Moon, Y. H. (2019). Fabrication of Mesh Patterns Using a Selective Laser-Melting Process. Applied Sciences, 9(9), 1922. https://doi.org/10.3390/app9091922