Mechanical Properties of Desert Sand-Based Fiber Reinforced Concrete (DS-FRC)

Abstract

:Featured Application

Abstract

1. Introduction

2. Experimental Program

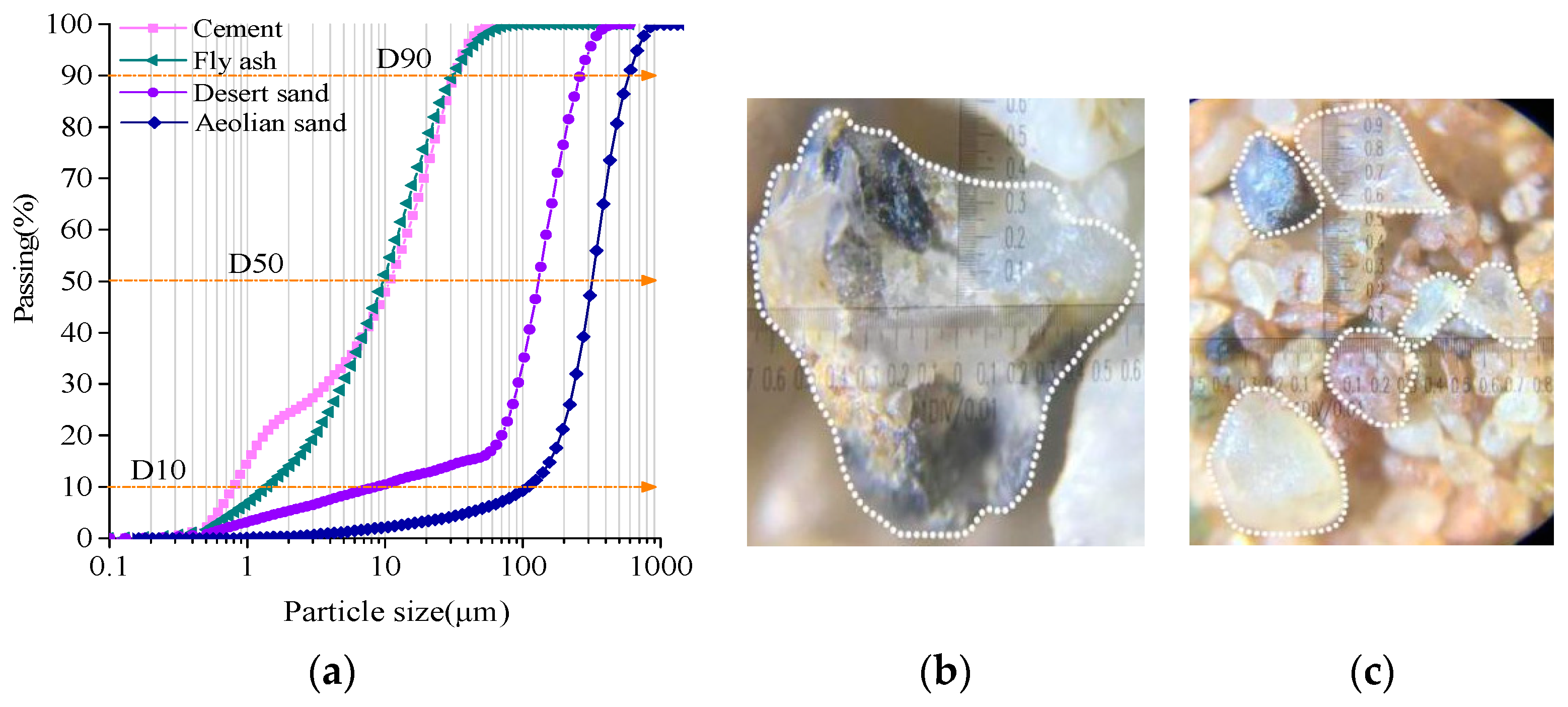

2.1. Mix Proportions and Material Properties

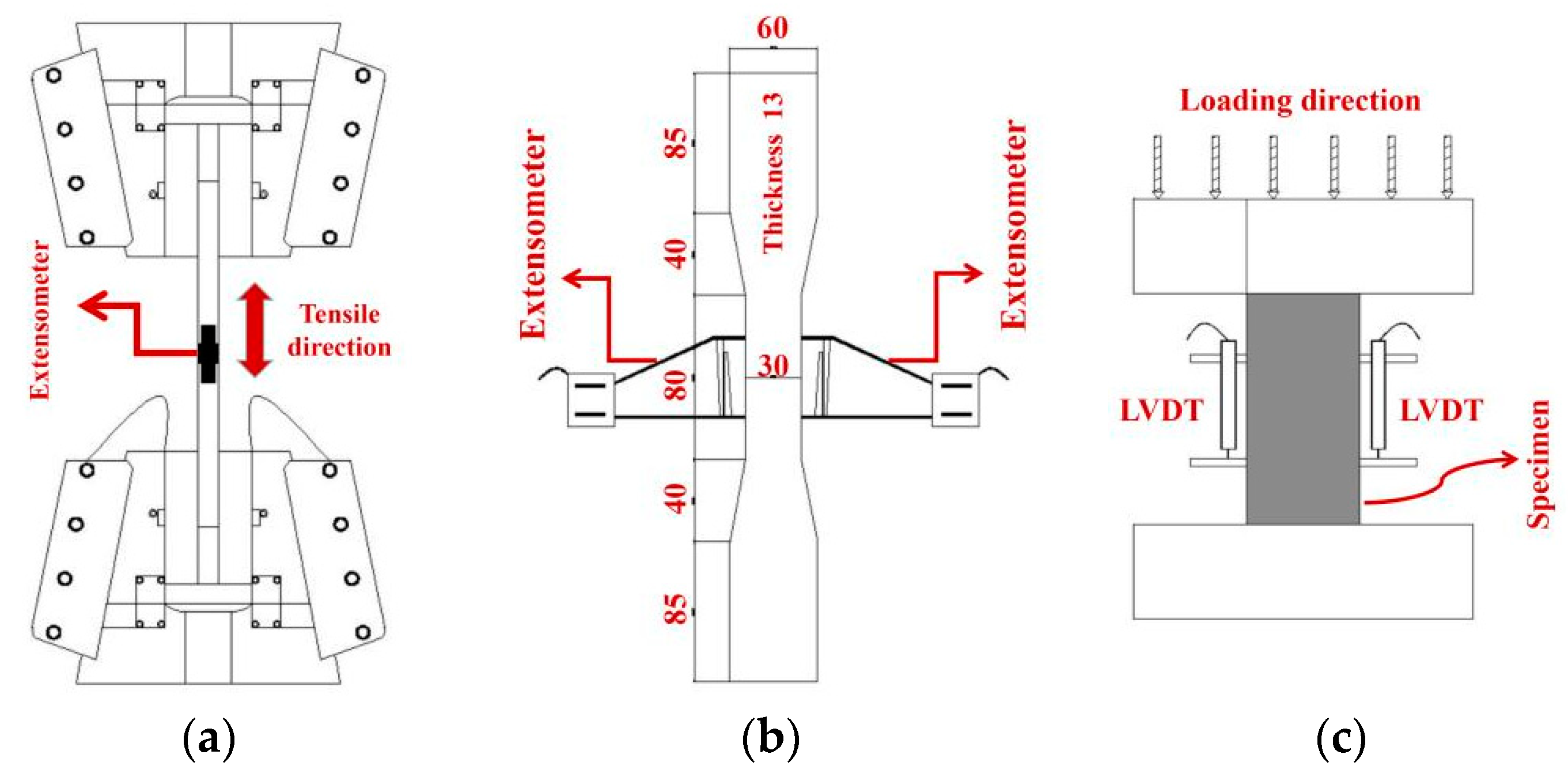

2.2. Test Setup and Loading Procedure

2.2.1. Consistency and Density Test

2.2.2. Uniaxial Tensile and Compression Test

3. Results and Discussion

3.1. Workability

3.2. Elastic Modulus

3.3. Uniaxial Tensile Properties of DS-FRC

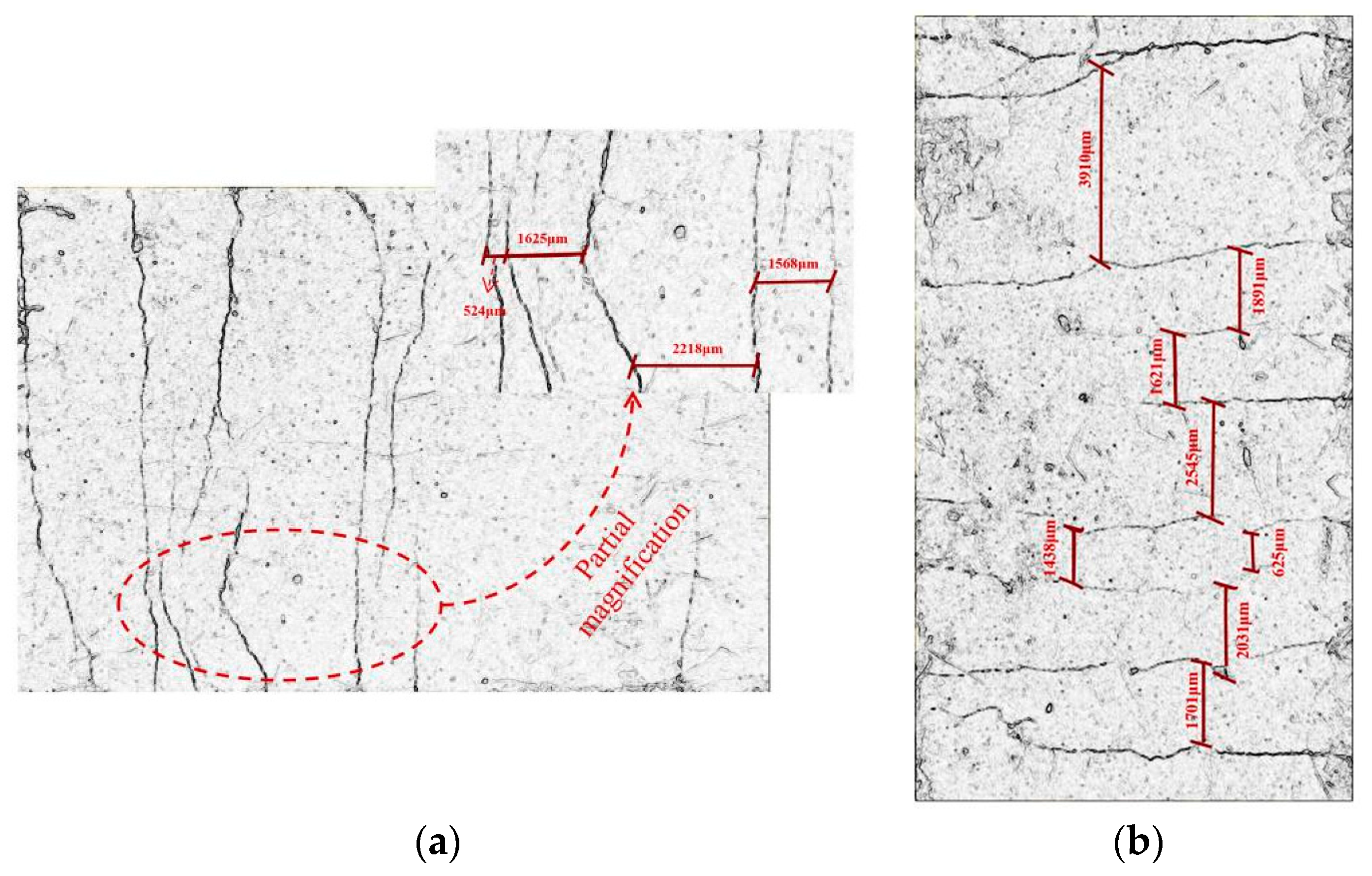

3.3.1. The Failure Mode of Specimens

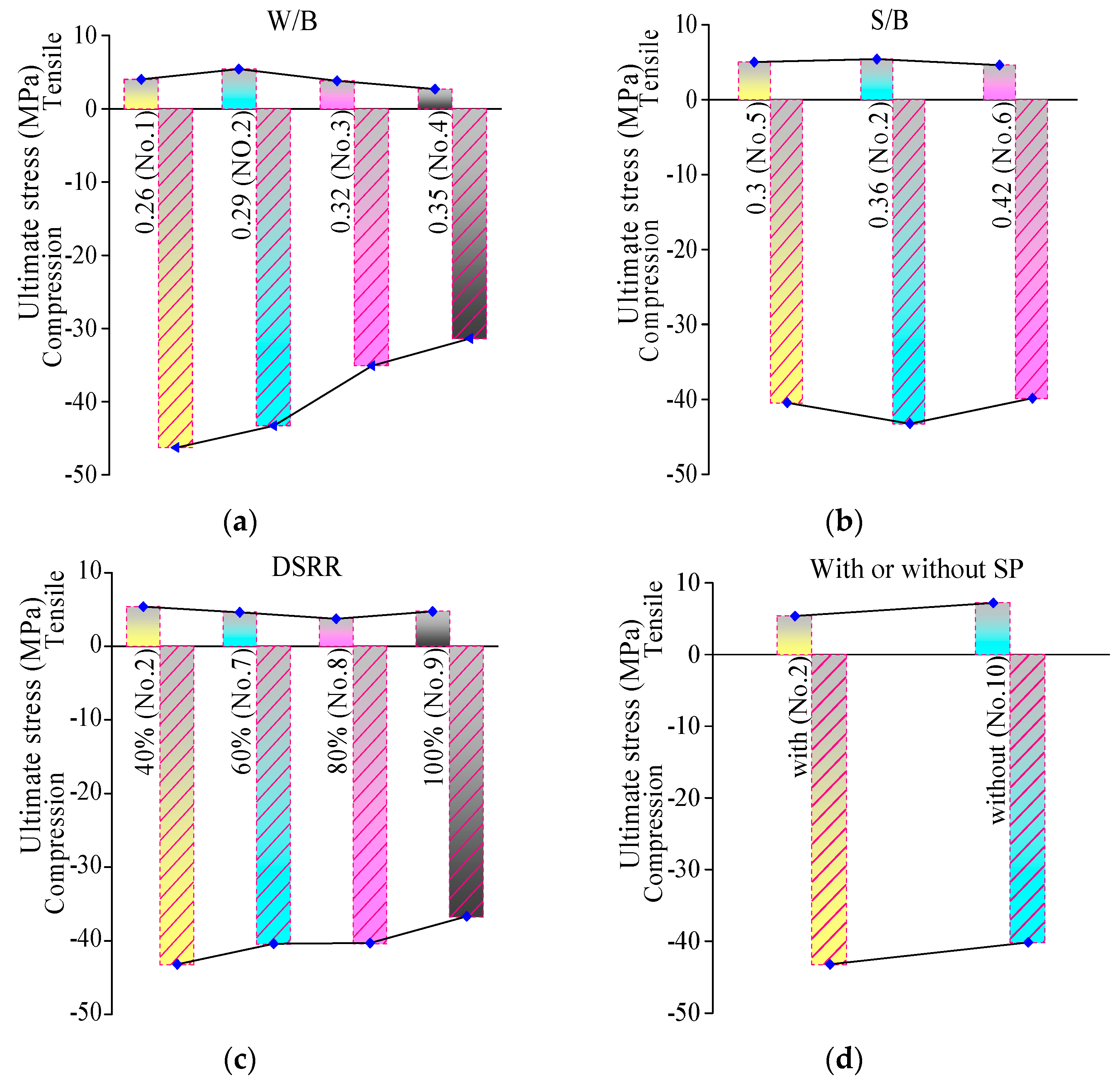

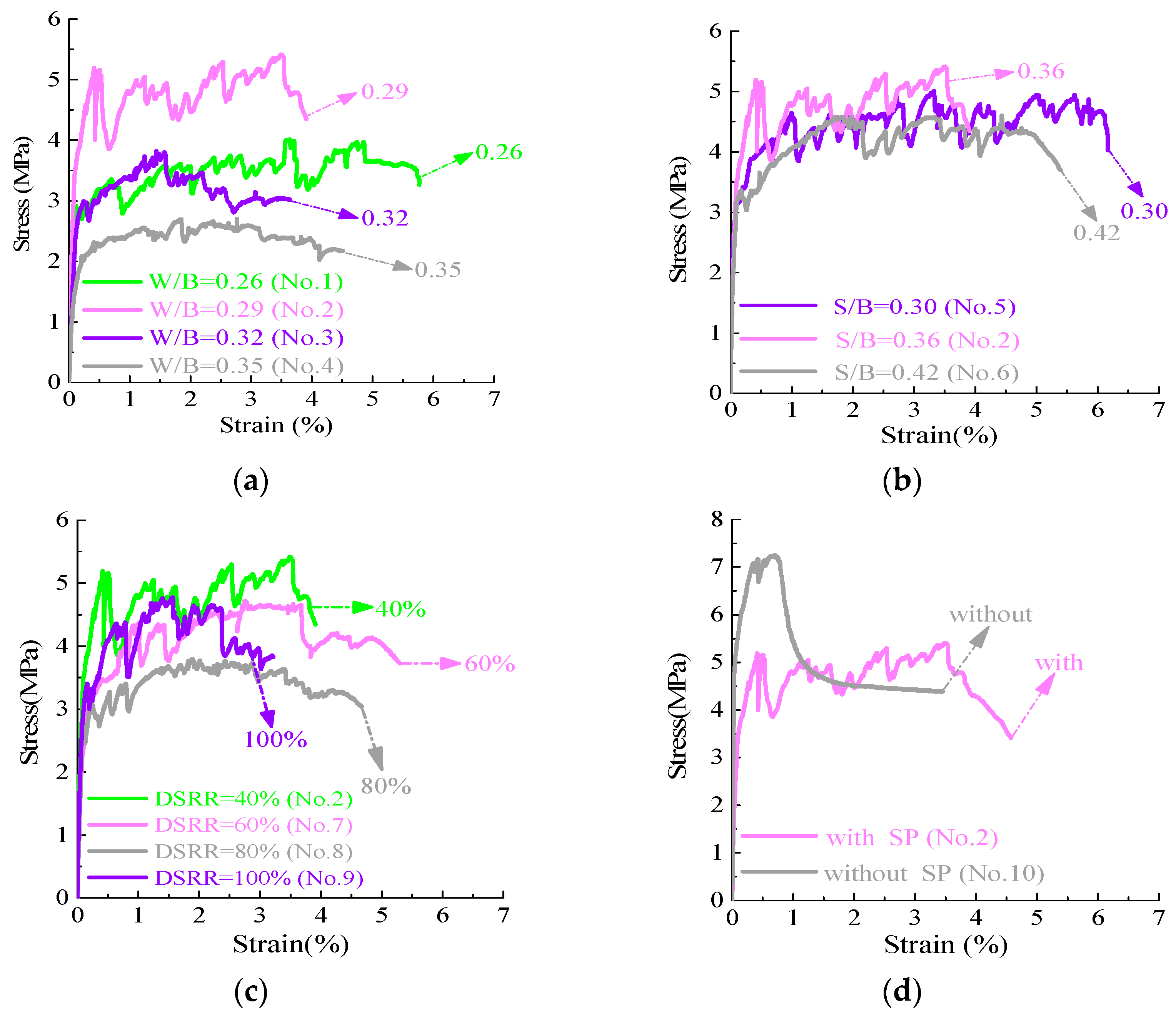

3.3.2. The Strength Development and Stress–Strain Curves

3.4. Uniaxial Compression Properties of DS-FRC

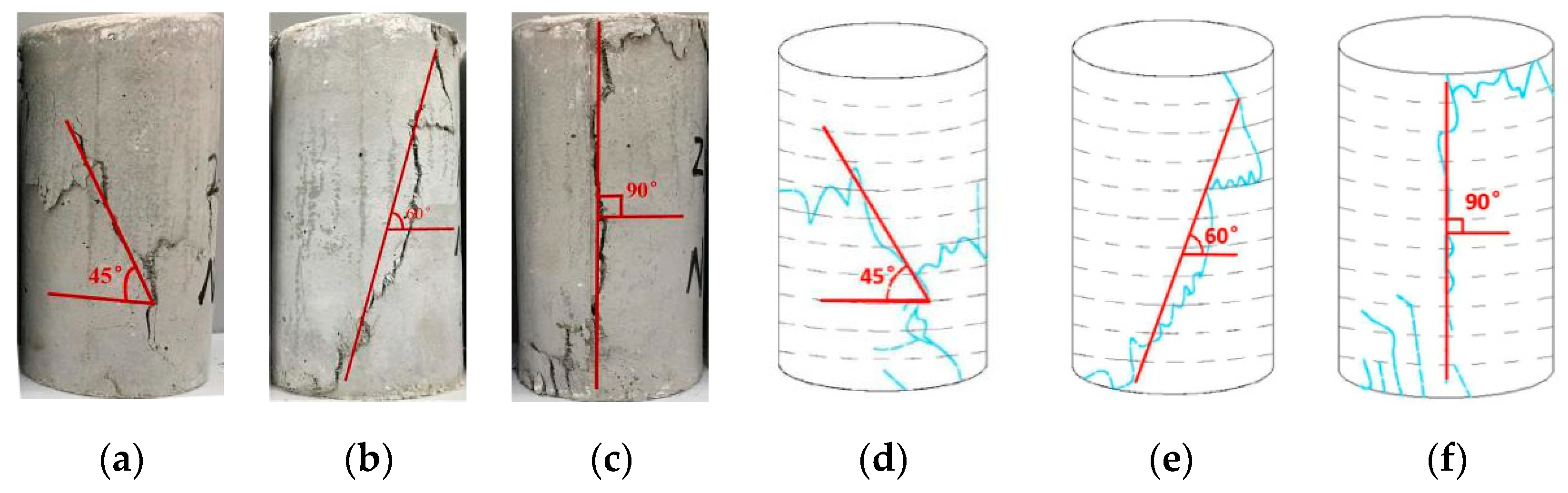

3.4.1. The Failure Mode of Specimens

3.4.2. The Strength Development and Stress–Strain Curves

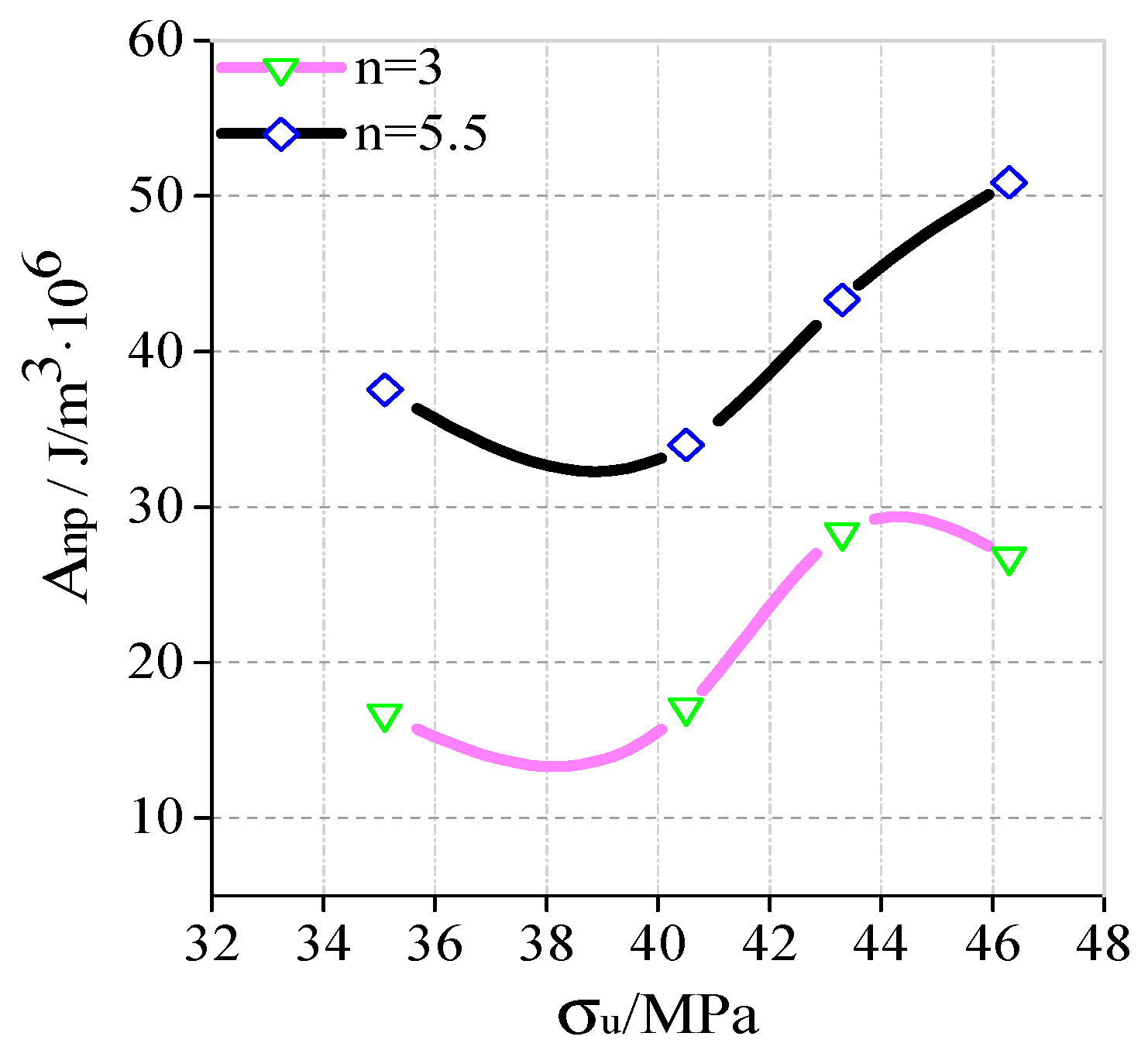

3.4.3. The Uniaxial Compression Toughness

3.5. Microstructure

4. Conclusions

- (1)

- The close consistency values of approximately 60–70 are observed in most DS-FRC, except for the critical W/B, such as the highest and lowest. The W/B and the content of desert sand are main factors affecting the workability of DS-FRC. At the highest W/B, the phenomenon of clumping (balling) or floating of fibers is observed. The high content of desert sand is bad for the fluidity of DS-FRC. Besides, the densities of DS-FRC maintain a comparable level, approximately 1900 kg/m3, which are 10% lower than that of ordinary concrete, resulting from the lack of coarse aggregates and the porosity caused by the addition of fibers.

- (2)

- The Elastic Modulus of DS-FRC are about 13–20 GPa which are lower than that of the ordinary concrete due to the lack of coarse aggregate and increased porosity caused by the addition of fiber. The high content of desert sand has a negative effect on the Elastic Modulus of DS-FRC. It will decrease with the increase of DSRR. When the DSRR was low, the comparable Elastic Modulus are observed with the increase of S/B. The Poisson’s ratio of DS-FRC is smaller than that of the ordinary concrete, approximately 0.18–0.25. That is because the lateral deformation of DS-FRC is limited by the bridging effect of fibers.

- (3)

- The uniaxial tension and compression properties of DS-FRC are mainly affected by the W/B and S/B. The optimum uniaxial mechanical performances are obtained at the W/B of 0.29 and the S/B of 0.36, respectively. The ultimate tensile stresses and corresponding strains are up to 4–5 MPa and 3%, respectively. However, for the uniaxial compression performance, all specimens maintain a high level more than 40 MPa and 1.0%, respectively.

- (4)

- In terms of the DSRR, it is observed that slightly improved ultimate tensile stresses due to improved matrix compactness and reduced corresponding strains are obtained. However, for the uniaxial compression performance, slightly reduced ultimate compression stresses and comparable strains approximately 1% are observed. It has few effects on the mechanical properties of DS-FRC, even for the DSRR of 100%, which reveals the feasibility of desert sand as the replacement of fine aggregates.

- (5)

- Compression toughness indexes are calculated to evaluate the compression deformation performance of DS-FRC, such as the initial cracking strain, the cracking strain energy density, the equivalent compression strength and post-peak fiber toughening index. The results show that the ratio of the cracking stress and the ultimate stress is at the range of 0.39–0.49, while the ratio of the equivalent compression strength and the ultimate compression strength is about 0.5 to 0.8. The cracking strain energy density is closely related with the ultimate compression stress. Besides, all specimens have the characteristics of the multiple cracking before the compression destruction. It reveals that DS-FRC can be determined as a ductile material.

- (6)

- As far as the microstructural of DS-FRC, the excellent crack controlling performance with micro-crack widths of about 40–60 μm is observed. The phenomenon of fiber debonding and pulling out is obvious, which promotes the development of tensile strain hardening. Besides, good compactness of the matrix is obtained due to the filling effect of fine undisturbed desert sand.

Author Contributions

Funding

Conflicts of Interest

References

- Şahmaran, M.; Li, V.C. Durability of mechanically loaded engineered cementitious composites under highly alkaline environments. Cem. Concr. Compos. 2008, 30, 72–81. [Google Scholar] [CrossRef]

- Sun, L.; Hao, Q.; Zhao, J.; Wu, D.; Yang, F. Stress strain behavior of hybrid steel-PVA fiber reinforced cementitious composites under uniaxial compression. Constr. Build. Mater. 2018, 188, 349–360. [Google Scholar] [CrossRef]

- Li, V.C.; Leung, C.K.Y. Steady-State and Multiple Cracking of Short Random Fiber Composites. J. Eng. Mech. 1992, 118, 2246–2264. [Google Scholar] [CrossRef]

- Li, V.C.; Stang, H.; Krenchel, H. Micromechanics of crack bridging in fiber-reinforced concrete. Mater. Struct. 1993, 26, 486–494. [Google Scholar] [CrossRef]

- Kang, S.T.; Kim, J.K. The relation between fiber orientation and tensile behavior in an Ultra High-Performance Fiber Reinforced Cementitious Composites (UHPFRCC). Cem. Concr. Res. 2011, 41, 1001–1014. [Google Scholar] [CrossRef]

- Kwon, S.H.; Kang, S.T.; Bang, Y.L.; Kim, J.K. The variation of flow-dependent tensile behavior in radial flow dominant placing of Ultra High-Performance Fiber Reinforced Cementitious Composites (UHPFRCC). Constr. Build. Mater. 2009, 33, 109–121. [Google Scholar] [CrossRef]

- Cong, L.; Leung, C.K.Y. A new model for the cracking process and tensile ductility of Strain Hardening Cementitious Composites (SHCC). Cem. Concr. Res. 2016, 79, 353–365. [Google Scholar]

- Curosu, I.; Mechtcherine, V.; Forni, D.; Cadoni, E. Performance of various strain-hardening cement-based composites (SHCC) subject to uniaxial impact tensile loading. Cem. Concr. Res. 2017, 102, 16–28. [Google Scholar] [CrossRef]

- Arain, M.F.; Wang, M.; Chen, J.; Zhang, H. Study on PVA fiber surface modification for strain-hardening cementitious composites (PVA-SHCC). Constr. Build. Mater. 2019, 197, 107–116. [Google Scholar] [CrossRef]

- Cai, X.R.; Xu, S.L.; Fu, B.Q. A statistical micromechanical model of multiple cracking for ultra-high toughness cementitious composites. Eng. Fract. Mech. 2011, 78, 1091–1100. [Google Scholar] [CrossRef]

- Cai, X.R.; Fu, B.Q. An analytical study on the complete strain hardening process of ultra-high toughness cementitious composites under direct tension load. Eng. Fract. Mech. 2013, 102, 249–256. [Google Scholar] [CrossRef]

- Huang, B.T.; Li, Q.H.; Xu, S.L.; Liu, W.; Wang, H.T. Fatigue deformation behavior and fiber failure mechanism of ultra-high toughness cementitious composites in compression. Mater. Des. 2018, 157, 457–468. [Google Scholar] [CrossRef]

- Deng, M.; Han, J.; Liu, H.; Qin, M.; Liang, X. Analysis of Compressive Toughness and Deformability of High Ductile Fiber Reinforced Concrete. Adv. Mater. Sci. Eng. 2015, 2015, 384902. [Google Scholar] [CrossRef]

- Deng, M.; Pan, J.; Liang, X. Uniaxial Compressive Test of High Ductile Fiber-Reinforced Concrete and Damage Constitutive Model. Adv. Civ. Eng. 2018, 2018, 4308084. [Google Scholar] [CrossRef]

- Li, V.C. On Engineered Cementitious Composites(ECC) A Review of the Material and Its Application. J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Rokugo, K.; Kanda, T.; Yokota, H.; Sakata, N. Applications and recommendations of high performance fiber reinforced cement composites with multiple fine cracking (HPFRCC) in Japan. Mater. Struct. 2009, 42, 1197–1208. [Google Scholar] [CrossRef]

- Zhang, J.; Gong, C.; Ju, X. Characteristics of high ductility and low shrinkage engineered cementitious composite and its applications. J. Hydraul. Eng. 2011, 42, 1452–1461. [Google Scholar]

- Yucel, H.E.; Jashami, H.; Sahmaran, M.; Guler, M.; Sahmaran, M. Thin ECC overlay systems for rehabilitation of rigid concrete pavements. Mag. Concr. Res. 2013, 65, 108–120. [Google Scholar] [CrossRef]

- Li, Q.; Gao, X.; Xu, S. Study on the permanent template of nano-modified UHTCC for the thermal insulation and seepage prevention. J. Civ. Eng. 2015, 6, 12–20. [Google Scholar]

- Huang, X.; Ranade, R.; Zhang, Q.; Ni, W.; Li, V.C. Mechanical and thermal properties of green lightweight engineered cementitious composites. Constr. Build. Mater. 2013, 48, 954–960. [Google Scholar] [CrossRef]

- Aslani, F. Effects of specimen size and shape on compressive and tensile strengths of self-compacting concrete with or without fibers. Mag. Concr. Res. 2013, 65, 914–929. [Google Scholar] [CrossRef]

- Chi, Y.; Xu, L.; Zhang, Y. Experimental Study on Hybrid Fiber–Reinforced Concrete Subjected to Uniaxial Compression. J. Mater. Civ. Eng. 2014, 26, 211–218. [Google Scholar] [CrossRef]

- Lin, Y.; Wotherspoon, L.; Ingham, J. Tensile Properties of an Engineered Cementitious Composite Shotcrete Mix. J. Mater. Civ. Eng. 2015, 27, 04014205. [Google Scholar] [CrossRef]

- Saidani, M.; Saraireh, D.; Gerges, M. Behaviour of different types of fibre reinforced concrete without admixture. Eng. Struct. 2016, 113, 328–334. [Google Scholar] [CrossRef]

- Deb, S.; Mitra, N.; Majumder, S.B.; Maitra, S. Improvement in tensile and flexural ductility with the addition of different types of polypropylene fibers in cementitious composites. Constr. Build. Mater. 2018, 180, 405–411. [Google Scholar] [CrossRef]

- Ding, X.; Li, C.; Li, Y.; Lu, Y.; Song, C.; Zhao, S. Experimental and numerical study on stress–strain behavior of self-compacting SFRC under uniaxial compression. Constr. Build. Mater. 2018, 185, 30–38. [Google Scholar] [CrossRef]

- Guan, X.; Li, Y.; Liu, T.; Zhang, C.; Li, H.; Ou, J. An economical ultra-high ductile engineered cementitious composite with large amount of coarse river sand. Constr. Build. Mater. 2019, 201, 461–472. [Google Scholar] [CrossRef]

- Li, V.C.; Wu, C.; Wang, S.X.; Ogawa, A.; Saito, T. Interface tailoring for strain-hardening polyvinyl alcohol engineered cementitious composite (PVA-ECC). Mater. J. 2002, 99, 463–472. [Google Scholar]

- Li, V.C.; Wang, S.X.; Wu, C. Tensile strain-hardening behavior of polyvinyl alcohol engineered cementitious composite (PVA-ECC). Mater. J. 2001, 98, 483–492. [Google Scholar]

- Sahmaran, M.; Yucel, H.E.; Demirhan, S.; Ank, M.T.; Li, V.C. Combined Effect of Aggregate and Mineral Admixtures on Tensile Ductility of Engineered Cementitious Composites. Mater. J. 2012, 109, 627–637. [Google Scholar]

- Alhozaimy, A.; Jaafar, M.S.; Al-Negheimish, A.; Abdullah, A.; Taufiq-Yap, Y.H.; Noorzaei, J.; Alawad, O.A. Properties of high strength concrete using white and dune sands under normal and autoclaved curing. Constr. Build. Mater. 2012, 27, 218–222. [Google Scholar] [CrossRef]

- Luo, F.J.; He, L.; Pan, Z.; Duan, W.H.; Zhao, X.L.; Collins, F. Effect of very fine particles on workability and strength of concrete made with dune sand. Constr. Build. Mater. 2013, 47, 131–137. [Google Scholar] [CrossRef]

- Duxson, P.; Lukey, G.C.; van Deventer, J.S.J. The thermal evolution of metakaolin geopolymers: Part 2—Phase stability and structural development. J. Non-Cryst. Solids 2007, 353, 2186–2200. [Google Scholar] [CrossRef]

- Yang, E.H.; Yang, Y.; Li, V.C. Use of high volumes of fly ash to improve ECC mechanical properties and material greeniness. Mater. J. 2007, 104, 620–628. [Google Scholar]

- Li, X.; Luo, M.; Yan, Q. Influence of Specimen Shape and Mix Proportion on Tensile Property of Green High-Performance Fiber Reinforced Cementitious Composites (GHPFRCC). J. Coast. Res. 2015, 73, 516–520. [Google Scholar] [CrossRef]

- Iqbal Khan, M.; Fares, G.; Mourad, S. Optimized Fresh and Hardened Properties of Strain Hardening Cementitious Composites: Effect of Mineral Admixtures, Cementitious Composition, Size, and Type of Aggregates. J. Mater. Civ. Eng. 2017, 29, 04017178. [Google Scholar] [CrossRef]

- Huang, X.; Ranade, R.; Ni, W.; Li, V.C. Development of green engineered cementitious composites using iron ore tailings as aggregates. Constr. Build. Mater. 2013, 44, 757–764. [Google Scholar] [CrossRef]

- Xu, W.; Wen, X.; Wei, J.; Xu, P.; Zhang, B.; Yu, Q.; Ma, H. Feasibility of kaolin tailing sand to be as an environmentally friendly alternative to river sand in construction applications. J. Clean. Prod. 2018, 205, 1114–1126. [Google Scholar] [CrossRef]

- Hasdemir, S.; Tugrul, A.; Yilmaz, M. The effect of natural sand composition on concrete strength. Constr. Build. Mater. 2016, 112, 940–948. [Google Scholar] [CrossRef]

- Huang, Y.; He, X.; Wang, Q.; Sun, Y. Mechanical properties of sea sand recycled aggregate concrete under axial compression. Constr. Build. Mater. 2018, 175, 55–63. [Google Scholar] [CrossRef]

- Chuah, S.; Duan, W.H.; Pan, Z.; Hunter, E.; Korayem, A.H.; Zhao, X.L.; Collins, F.; Sanjayan, J.G. The properties of fly ash based geopolymer mortars made with dune sand. Mater. Des. 2016, 92, 571–578. [Google Scholar] [CrossRef]

- Yang, W.W.; Chen, Y.L.; Ma, J.R.; Liu, H.F.; Song, J.X.; Yang, D. Influence of desert sand replacement ratio on the compressive strength of high strength concrete. Sci. Technol. Eng. 2014, 2, 205–215. [Google Scholar]

- Liu, H.; Ma, J.; Wang, Y.; Ning, J. Influence of desert sand on the mechanical properties of concrete subjected to impact loading. Acta Mech. Solida Sin. 2017, 30, 583–595. [Google Scholar]

- Amel, C.L.; Kadri, E.H.; Sebaibi, Y.; Soualhi, H. Dune sand and pumice impact on mechanical and thermal lightweight concrete properties. Constr. Build. Mater. 2017, 133, 209–218. [Google Scholar] [CrossRef]

- Wang, W.H.; Han, L.H.; Li, W.; Jia, Y.H. Behavior of concrete-filled steel tubular stub columns and beams using dune sand as part of fine aggregate. Constr. Build. Mater. 2014, 51, 352–363. [Google Scholar] [CrossRef]

- Che, J.; Li, Q.; Lee, M.; Wang, D. Experimental research on mechanical properties of desert sand steel-PVA fiber engineered cementitious composites. Funct. Mater. 2017, 24, 584–592. [Google Scholar]

- Han, G.; Che, J.; Li, Q.; Ma, C.; Liu, H. Experimental study on mechanical properties of desert sand PVA-ECC. Constr. Technol. 2018, 47, 27–31. [Google Scholar]

- JSCE. Recommendations for Design and Construction of High Performance Fiber Reinforced Cement Composites with Multiple Fine Cracks; Japan Society of Civil Engineers: Tokyo, Japan, 2008. [Google Scholar]

- Li, V.C.; Wu, H.C.; Maalej, M.; Mishra, D.K.; Hashida, T. Tensile behavior of cement-based composites with random discontinuous steel fibers. J. Am. Ceram. Soc. 1996, 79, 74–78. [Google Scholar] [CrossRef]

- JGJ/T70-2009. National Standard of the People’s Republic of China, the Test Standard of Basic Performance of Building Mortar; Ministry of Construction of People’s Republic: Beijing, China, 2009.

- Wille, K.; El-Tawil, S.; Naaman, A.E. Properties of strain hardening ultra-high-performance fiber reinforced concrete (UHP-FRC) under direct tensile loading. Cem. Concr. Compos. 2014, 48, 53–66. [Google Scholar] [CrossRef]

- ASTM C39. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM: West Conshohocken, PA, USA, 2001. [Google Scholar]

- Zhang, G.; Song, J.; Yang, J.; Liu, X. Performance of mortar and concrete made with a fine aggregate of desert sand. Build. Environ. 2006, 41, 1478–1481. [Google Scholar] [CrossRef]

- Xu, S.; Cai, X.; Zhang, Y. Experimental Research and Analysis of Full Stress–strain Curves of UHTCC under Uniaxial Compressive Test. China Civ. Eng. J. 2009, 42, 79–85. [Google Scholar]

- Li, Y.; Liu, Z. Mechanical Properties and Constitutive Relation of High Toughness PVA-FRCC under the Uniaxial Compression Test. J. Build. Mater. 2014, 1, 606–612. [Google Scholar]

- Kanda, T.; Li, V. New micromechanics design theory for pseudo-strain hardening cementitious composite. Eng. Mech. 1999, 125, 373–381. [Google Scholar] [CrossRef]

- Liang, X.; Che, J.; Deng, M. Experimental research on seismic behavior of diagonally reinforced FRC coupling beams with small span-to-depth ratio. J. Build. Struct. 2013, 34, 135–141. [Google Scholar]

- Deng, M.; Zhang, H.; Liang, X.; Bu, X. Experimental study on seismic behavior of high ductile fiber reinforced concrete short column. J. Build. Struct. 2015, 36, 62–69. [Google Scholar]

- Che, J. Finite Element Analysis for Improvement of FRC Diagonally Reinforced Coupling Beams with the Small Span-depth Ratio. Special Structures 2016, 33, 92–96. [Google Scholar]

- Che, J.L.; Han, G.S.; Liang, X.W.; Xing, P.T.; Chen, Z.Y. Study on Restoring Force Model of Fiber Reinforced Concrete Diagonally Reinforced Coupling Beams with Small Span-to-depth Ratio. Earthq. Resist. Eng. Retrofit. 2017, 39, 41–46. [Google Scholar]

- Deng, M.; Ma, F.; Wang, Y.; Liang, X. Investigation of the shear strength of HDC deep beams based on a modified direct strut-and-tie model. Constr. Build. Mater. 2018, 172, 340–348. [Google Scholar] [CrossRef]

- Guettala, S.; Mezghiche, B. Compressive strength and hydration with age of cement pastes containing dune sand powder. Constr. Build. Mater. 2011, 25, 1263–1269. [Google Scholar] [CrossRef]

- Han, M.C.; Han, C.G.; Lee, G.C. Mixture and Material Factors Affecting the Strength and Shrinkage of High Performance Concrete. J. Asian Archit. Build. Eng. 2006, 5, 145–151. [Google Scholar] [CrossRef] [Green Version]

- Cai, X.; Xu, S. Experimental study and evaluation index of the uniaxial compression toughness of the UHTCC. Eng. Mech. 2010, 27, 218–224. [Google Scholar]

- Jian, C.; Peng, L.; Song, G.; Zhang, R. Piezo-based wireless sensor network for early-age concrete strength monitoring. Opt. Int. J. Light Electron Opt. 2016, 127, 2983–2987. [Google Scholar]

- Li, W.; Kong, Q.; Ho, S.C.M.; Lim, I.; Mo, Y.L.; Song, G. Feasibility study of using smart aggregates as embedded acoustic emission sensors for health monitoring of concrete structures. Smart Mater. Struct. 2016, 25, 115031. [Google Scholar] [CrossRef]

- Li, W.; Xu, C.; Ho, S.C.; Wang, B.; Song, G. Monitoring Concrete Deterioration Due to Reinforcement Corrosion by Integrating Acoustic Emission and FBG Strain Measurements. Sensors 2017, 17, 657. [Google Scholar] [CrossRef]

- Li, P.; Gu, H.; Song, G.; Zheng, R.; Mo, Y.L. Concrete structural health monitoring using piezoceramic-based wireless sensor networks. Smart Struct. Syst. 2010, 6, 731–748. [Google Scholar] [CrossRef]

- Liao, W.I.; Wang, J.X.; Song, G.; Gu, H.; Olmi, C.; Mo, Y.L.; Chang, K.C.; Loh, C.H. Structural health monitoring of concrete columns subjected to seismic excitations using piezoceramic-based sensors. Smart Mater. Struct. 2011, 20, 125015. [Google Scholar] [CrossRef]

- Jiang, T.; Zheng, J.; Huo, L.; Song, G. Finite Element Analysis of Grouting Compactness Monitoring in a Post-Tensioning Tendon Duct Using Piezoceramic Transducers. Sensors 2017, 17, 2239. [Google Scholar] [CrossRef]

- Du, G.; Huo, L.; Kong, Q.; Song, G. Damage detection of pipeline multiple cracks using piezoceramic transducers. J. Vibroeng. 2016, 18, 2828–2838. [Google Scholar] [CrossRef]

- Xu, B.; Li, B.; Song, G. Active Debonding Detection for Large Rectangular CFSTs Based on Wavelet Packet Energy Spectrum with Piezoceramics. ASCE J. Struct. Eng. 2013, 139, 1435–1443. [Google Scholar] [CrossRef]

- Jiang, T.; Kong, Q.; Patil, D.; Luo, Z.; Huo, L.; Song, G. Detection of Debonding Between Fiber Reinforced Polymer Bar and Concrete Structure Using Piezoceramic Transducers and Wavelet Packet Analysis. IEEE Sens. J. 2017, 17, 1992–1998. [Google Scholar] [CrossRef]

| Description | Al2O3 | Na2O | CaO | SiO2 | P2O5 | SO3 | Fe2O3 | K2O | TiO2 | Cl | MgO |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 5.05 | 0.73 | 60.24 | 21.22 | / | 2.67 | 3.26 | 0.50 | / | / | 0.97 |

| Fly ash | 23.6 | 13.2 | 6.12 | 38.5 | 1.06 | 2.13 | 7.49 | 1.84 | / | 0.26 | 3.66 |

| River sand | 11.8 | 16.0 | 6.87 | 45.2 | 1.01 | 0.58 | 6.33 | 4.65 | 0.86 | 0.33 | / |

| Desert sand | 12.3 | / | 4.83 | 74.2 | 0.80 | 0.50 | 3.69 | 2.62 | 0.49 | 0.41 | / |

| Description | Length (mm) | Diameter (μm) | Specific Gravity (kg/m3) | Ultimate Tensile Strength (MPa) | Young’s Modulus cN/dtex |

|---|---|---|---|---|---|

| PVA | 12 | 40 | 1300 | 1600 | ≥380 |

| Mix NO. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| W/B | 0.26 | 0.29 | 0.32 | 0.35 | 0.29 | 0.29 | 0.29 | 0.29 | 0.29 | 0.29 |

| S/B | 0.36 | 0.36 | 0.36 | 0.36 | 0.30 | 0.42 | 0.36 | 0.36 | 0.36 | 0.36 |

| DSRR | 40% | 40% | 40% | 40% | 40% | 40% | 60% | 80% | 100% | 40% |

| Cement kg/m3 | 550.22 | 541.35 | 532.47 | 514.72 | 559.10 | 514.73 | 541.35 | 541.35 | 541.35 | 541.35 |

| Fly ash kg/m3 | 825.33 | 812.02 | 798.71 | 772.09 | 838.64 | 772.08 | 812.02 | 812.02 | 812.02 | 812.02 |

| Water kg/m3 | 357.64 | 392.48 | 421.54 | 450.38 | 399.35 | 377.17 | 392.48 | 392.48 | 392.48 | 392.48 |

| River sand kg/m3 | 292.86 | 292.33 | 287.53 | 277.95 | 252.92 | 332.80 | 194.88 | 97.44 | 0 | 292.33 |

| Desert sand kg/m3 | 195.24 | 194.88 | 191.68 | 185.30 | 168.61 | 221.86 | 292.33 | 389.77 | 487.21 | 194.88 |

| PVA fiber kg/m3 | 26 | 26 | 26 | 26 | 26 | 26 | 26 | 26 | 26 | 26 |

| Superplasticizer kg/m3 | 0.78 | 0.77 | 0.75 | 0.73 | 0.79 | 0.73 | 0.77 | 0.77 | 0.77 | 0 |

| Density kg/m3 | 1949.5 | 1949.2 | 1874.0 | 1815.8 | 1910.5 | 1918.8 | 1859.5 | 1853.4 | 1861.9 | / |

| Consistency mm | 35 | 74 | 78 | 133 | 74 | 70 | 59 | 67 | 63 | 66 |

| Elastic Modulus GPa | / | 19.16 | / | / | 18.31 | 18.39 | 19.28 | 17.31 | 13.13 | / |

| Mix NO. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Tensile Initial Cracking Stress (MPa) | 2.20 | 2.95 | 1.85 | 0.99 | 2.04 | 2.00 | 1.96 | 2.08 | 2.04 | 4.20 |

| Tensile Initial Cracking Strain (%) | 0.07 | 0.07 | 0.07 | 0.04 | 0.03 | 0.04 | 0.06 | 0.06 | 0.05 | 0.03 |

| Ultimate Tensile Stress (MPa) | 4.01 | 5.42 | 3.83 | 2.71 | 5.01 | 4.61 | 4.65 | 3.79 | 4.78 | 7.25 |

| Ultimate Tensile Strain (%) | 3.63 | 3.50 | 1.44 | 2.77 | 3.32 | 4.43 | 3.68 | 1.87 | 1.57 | 0.7 |

| Ultimate Compression Stress (MPa) | 46.3 | 43.3 | 35.1 | 31.4 | 40.5 | 39.9 | 40.5 | 40.4 | 36.8 | 40.2 |

| Ultimate Compression Strain (%) | 1.17 | 1.08 | 1.26 | 1.06 | 1.13 | 1.36 | 1.00 | 1.37 | 1.19 | 0.97 |

| Mix NO. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 20.95 | 20.32 | 13.83 | 15.61 | 18.76 | 16.69 | 15.67 | 16.46 | 15.12 | 19.00 | ||

| 0.39 | 0.42 | 0.34 | 0.33 | 0.37 | 0.51 | 0.30 | 0.33 | 0.44 | 0.39 | ||

| n = 3 | 26.78 | 28.36 | 16.76 | 16.69 | 23.15 | 30.73 | 17.09 | 17.23 | 25.47 | 25.24 | |

| n = 5.5 | 50.84 | 43.32 | 37.54 | 35.04 | 37.82 | 43.17 | 33.97 | 41.97 | 41.72 | 39.46 | |

| n = 3 | 34.33 | 33.76 | 24.65 | 25.29 | 31.28 | 30.13 | 28.48 | 26.11 | 28.94 | 32.36 | |

| n = 5.5 | 28.97 | 22.92 | 24.54 | 23.60 | 22.71 | 18.81 | 25.16 | 28.26 | 21.07 | 22.48 | |

| 1.5 | 1.2 | 1.0 | 1.7 | 0.5 | 0.6 | 1.1 | 0.7 | 1.0 | 1.3 | ||

| 0.45 | 0.47 | 0.39 | 0.49 | 0.46 | 0.42 | 0.39 | 0.41 | 0.41 | 0.47 | ||

| n = 3 | 0.74 | 0.80 | 0.70 | 0.81 | 0.77 | 0.76 | 0.70 | 0.65 | 0.79 | 0.81 | |

| n = 5.5 | 0.63 | 0.53 | 0.70 | 0.75 | 0.56 | 0.47 | 0.62 | 0.70 | 0.57 | 0.60 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Che, J.; Wang, D.; Liu, H.; Zhang, Y. Mechanical Properties of Desert Sand-Based Fiber Reinforced Concrete (DS-FRC). Appl. Sci. 2019, 9, 1857. https://doi.org/10.3390/app9091857

Che J, Wang D, Liu H, Zhang Y. Mechanical Properties of Desert Sand-Based Fiber Reinforced Concrete (DS-FRC). Applied Sciences. 2019; 9(9):1857. https://doi.org/10.3390/app9091857

Chicago/Turabian StyleChe, Jialing, Dan Wang, Haifeng Liu, and Yixin Zhang. 2019. "Mechanical Properties of Desert Sand-Based Fiber Reinforced Concrete (DS-FRC)" Applied Sciences 9, no. 9: 1857. https://doi.org/10.3390/app9091857

APA StyleChe, J., Wang, D., Liu, H., & Zhang, Y. (2019). Mechanical Properties of Desert Sand-Based Fiber Reinforced Concrete (DS-FRC). Applied Sciences, 9(9), 1857. https://doi.org/10.3390/app9091857