The Use of a Special Stereoscopic Microscope Attachment for the Sieve Analysis of Aggregate in Concrete

Abstract

:Featured Application

Abstract

1. Introduction

2. Experimental

3. Results and Discussion

3.1. Analysis of Sand Particle Size Distribution

3.2. Determination of the Cement Paste Volume in the Air Entrained Concrete

4. Conclusions

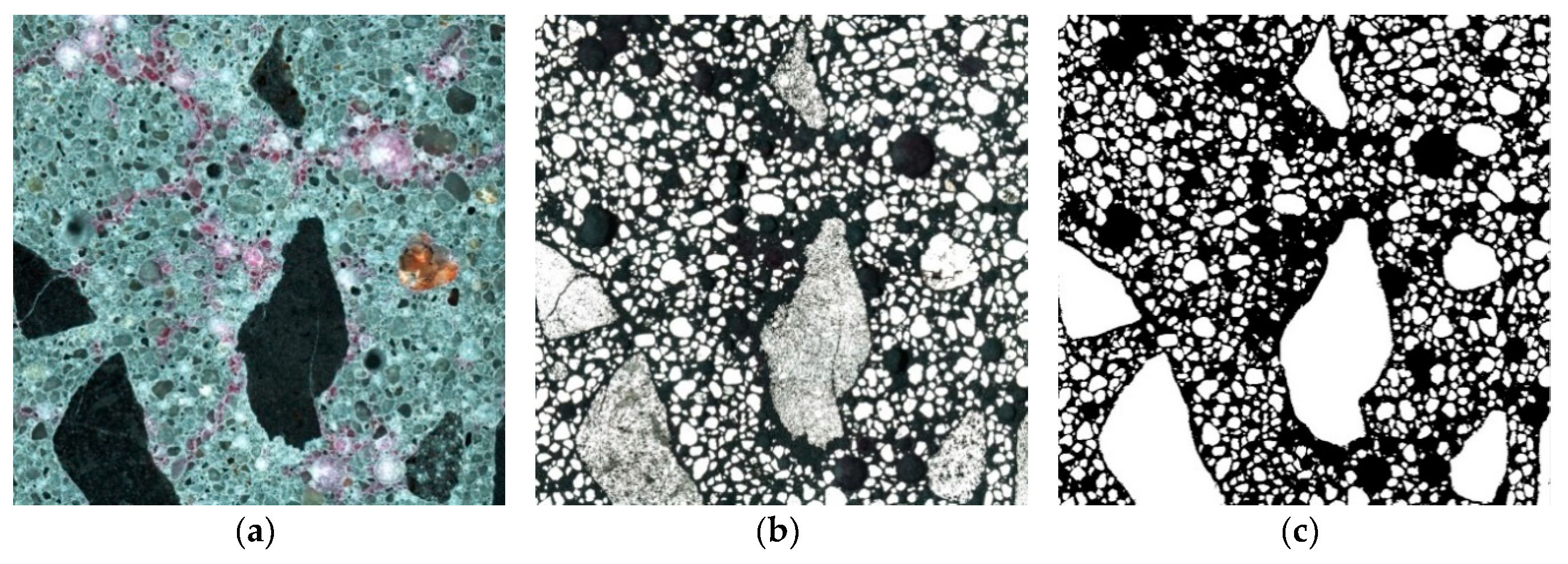

- The attachment mounted on the lens of a stereoscopic microscope significantly extended the potential of a regular stereoscopic microscope in the analysis of hardened concrete composition. The attachment was equipped with a focused light source. Light rays falling almost vertically reflected off the surface of the specimen, which resulted in the image visible in the right part of the field of view in the lens. This image was transmitted to a computer by means of a camera. The rays reflected much better on the particles of sand and aggregate than on the porous cement paste. Many characteristics of the extracted aggregate particles can be evaluated on the basis of the obtained large image subjected to morphological operations. The contents of the paste and concrete components will be determined using known air content tests.

- The professional microscopic set with the attachment allowed for recording and analysing much larger areas of concrete samples (e.g., 50 cm2) compared with other methods which are capable of examining an area of only several square centimetres.

- The proposed method is not universal, because it is not always possible to automate it. In the case of coarse aggregate, which is porous or cracked, the luminous flux was significantly dispersed without giving a clear reflection. This required additional work in order to manually correct the imperfections in the binary image. Manual correction consists of manually drawing particle outlines in the graphic editor, filling them and then separating the connected objects (the automatic separation function available in the computer program was unsatisfactory).

- The results obtained from the analyses were very promising and provided a method with the potential to be applied in practice to analyse the composition of hardened concrete extracted from the structure, determine the paste volume as the basic parameter necessary to calculate the air void spacing factor L to EN 480-11, establish the sand particle size, necessary for the design of renovation mortar compositions (restoration of historic buildings) and, in the case of concrete mix segregation, to determine the volume concentration of sand and coarse aggregate in different layers of hardened concrete.

- The proposed method was simple and inexpensive.

Author Contributions

Funding

Conflicts of Interest

References

- Sahu, S.; Badger, S.; Thaulow, N.; Lee, R.J. Determination of water–cement ratio of hardened concrete by scanning electron microscopy. Cem. Concr. Compos. 2004, 26, 987–992. [Google Scholar] [CrossRef]

- Edwin, R.S.; Mushthofa, M.; Gruyaert, E.; De Belie, N. Quantitative analysis on porosity of reactive powder concrete based on automated analysis of back-scattered-electron images. Cem. Concr. Compos. 2019, 96, 1–10. [Google Scholar] [CrossRef]

- Lu, H.; Alymov, E.; Shah, S.; Peterson, K. Measurement of air void system in lightweight concrete by X-ray computed tomography. Constr. Build. Mater. 2017, 152, 467–483. [Google Scholar] [CrossRef]

- Yuan, J.; Wu, Y.; Zhang, J. Characterization of air voids and frost resistance of concrete based on industrial computerized tomographical technology. Constr. Build. Mater. 2018, 168, 975–983. [Google Scholar] [CrossRef]

- Deboodt, T.; Wildenschild, D.; Ideker, J.H.; Isgor, O.B. Use of iodine for improving phase quantification using X-ray tomography. Cem. Concr. Res. 2019, 116, 102–112. [Google Scholar] [CrossRef]

- Wong, R.C.K.; Chau, K.T. Estimation of air void and aggregate spatial distributions in concrete under uniaxial compression using computer tomography scanning. Cem. Concr. Res. 2005, 35, 1566–1576. [Google Scholar] [CrossRef]

- Wan, K.; Chen, L.; Xu, Q. Calibration of grayscale values of cement constituents using industrial X-ray tomography. Sci. China Technol. Sci. 2015, 58, 485–492. [Google Scholar] [CrossRef]

- Garboczi, E.J. Three-dimensional mathematical analysis of particle shape using X-ray tomography and spherical harmonics: Application to aggregates used in concrete. Cem. Concr. Res. 2002, 32, 1621–1638. [Google Scholar] [CrossRef]

- Balázs, G.L.; Lublóy, E.; Földes, T. Evaluation of concrete elements with X-ray computed tomography. J. Mater. Civ. Eng. 2018, 30, 1–9. [Google Scholar] [CrossRef]

- Diamond, S. The microstructure of cement paste and concrete—A visual primer. Cem. Concr. Compos. 2004, 26, 919–933. [Google Scholar] [CrossRef]

- Elsen, J.; Lens, N.; Aarre, T.; Quenard, D.; Smolej, V. Determination of the w/c ratio of hardened cement paste and concrete samples on thin sections using automated image analysis techniques. Cem. Concr. Res. 1995, 25, 827–834. [Google Scholar] [CrossRef]

- Marinoni, N.; Pavese, A.; Foi, M.; Trombino, L. Characterisation of mortar morphology in thin sections by digital image processing. Cem. Concr. Res. 2005, 35, 1613–1619. [Google Scholar] [CrossRef]

- Jakobsen, U.H.; Brown, D.R. Reproducibility of w/c ratio determination from fluorescent impregnated thin sections. Cem. Concr. Res. 2006, 36, 1567–1573. [Google Scholar] [CrossRef]

- NT BUILD 361. Concrete, Hardened: Water-Cement Ratio, 2nd ed.; Nordtest: Espoo, Finland, 1999. [Google Scholar]

- Head, M.K.; Wong, H.S.; Buenfeld, N.R. Characterizing aggregate surface geometry in thin-sections of mortar and concrete. Cem. Concr. Res. 2008, 38, 1227–1231. [Google Scholar] [CrossRef]

- Mertens, G.; Elsen, J. Use of computer assisted image analysis for the determination of the particle-size distribution of sands used in mortars. Cem. Concr. Res. 2006, 36, 1453–1459. [Google Scholar] [CrossRef]

- European Standard EN 480-11. Admixtures for Concrete, Mortar and Grout—Test Methods—Part 11: Determination of Air Void Characteristics in Hardened Concrete; CEN: Brussels, Belgium, 2005. [Google Scholar]

- Chinchón, S.; García, J.; López-Atalaya, M.; Linares, A.; Vera, R. Cement paste colouring in concretes. Cem. Concr. Res. 2004, 34, 1987–1991. [Google Scholar] [CrossRef]

- Załocha, D.; Kasperkiewicz, J. Estimation of the structure of air entrained concrete using a flatbed scanner. Cem. Concr. Res. 2005, 35, 2041–2046. [Google Scholar] [CrossRef]

- Murotani, T.; Igarashi, S.; Koto, H. Distribution analysis and modeling of air voids in concrete as spatial point processes. Cem. Concr. Res. 2019, 115, 124–132. [Google Scholar] [CrossRef]

- Peterson, K. Air Void Analysis of Hardened Concrete via Flatbed Scanner. Master’s Thesis, Michigan Technological University, Houghton, MI, USA, 2001. [Google Scholar]

- Chatterji, S.; Gudmundsson, H. Characterization of entrained air bubble systems in concretes by means on an image analyzing microscope. Cem. Concr. Res. 1977, 7, 423–428. [Google Scholar] [CrossRef]

- Gudmundsson, H.; Chatterji, S.; Jensen, A.D.; Thaulow, N.; Christensen, P. The measurement of paste content in hardened concrete using automatic image analyzing technique. Cem. Concr. Res. 1979, 9, 607–612. [Google Scholar] [CrossRef]

- Brzezicki, J. Use of computer assisted image analysis for the analysing the structure of concrete. In Proceedings of the 39th Scientific Conference KILiW i KN PZITB, Warszawa-Krynica-Rzeszów, Poland, 1993; pp. 21–28. [Google Scholar]

- Pleau, R.; Plante, P.; Gagne, R.; Pigeon, M. Practical considerations pertaining to the microscopical determination of air void characteristics of hardened concrete (ASTM standard). Cem. Concr. Aggreg. 1990, 12, 3–11. [Google Scholar] [CrossRef]

- ASTM C457. Standard Test Method for Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete; ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Saltykov, S.A. Stereometric Metallography, 2nd ed.; Metallurgizdat: Moscow, Russia, 1976. [Google Scholar]

- Underwood, E.E. Quantitative Stereology; Addison-Wiley Publishing Company: Boston, MA, USA, 1970. [Google Scholar]

- Xu, Y.-H.; Pitot, H.C. An improved stereologic method for three-dimensional estimation of particle size distribution from observations in two dimensions and its application. Comput. Methods Programs Biomed. 2003, 72, 1–20. [Google Scholar] [CrossRef]

| Class | Diameter µm | Na(i), 1/mm2 | Nv(i) | |||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | Average | 1/mm3 | ||

| 1 | 0–39 | 0.007 | 0.002 | 0.040 | 0.0212 | 1.3895 |

| 2 | 40–49 | 0.003 | 0.003 | 0.087 | 0.0452 | 2.3745 |

| 3 | 50–62 | 0.044 | 0.010 | 0.175 | 0.0925 | 3.8560 |

| 4 | 63–79 | 0.185 | 0.142 | 0.253 | 0.1976 | 6.4840 |

| 5 | 80–99 | 0.312 | 0.291 | 0.321 | 0.3058 | 8.0286 |

| 6 | 100–124 | 0.395 | 0.363 | 0.376 | 0.3695 | 7.7585 |

| 7 | 125–157 | 0.459 | 0.406 | 0.436 | 0.4212 | 6.9931 |

| 8 | 158–199 | 0.514 | 0.446 | 0.509 | 0.4780 | 6.2614 |

| 9 | 200–250 | 0.571 | 0.478 | 0.578 | 0.5281 | 5.5014 |

| 10 | 251–315 | 0.537 | 0.472 | 0.585 | 0.5285 | 4.3598 |

| 11 | 316–397 | 0.423 | 0.417 | 0.470 | 0.4436 | 2.8914 |

| 12 | 398–500 | 0.276 | 0.283 | 0.329 | 0.3059 | 1.5718 |

| 13 | 501–630 | 0.140 | 0.165 | 0.164 | 0.1645 | 0.6626 |

| 14 | 631–793 | 0.060 | 0.075 | 0.077 | 0.0759 | 0.2381 |

| 15 | 794–999 | 0.022 | 0.026 | 0.027 | 0.0266 | 0.0640 |

| 16 | 1000–1259 | 0.009 | 0.009 | 0.011 | 0.0098 | 0.0177 |

| 17 | 1260–1584 | 0.005 | 0.002 | 0.004 | 0.0030 | 0.0038 |

| 18 | 1585–1995 | 0.000 | 0.000 | 0.000 | 0.0002 | 0.0002 |

| Constituent | kg/m3 | Constituent Density kg/dm3 | Volume Fraction % | |

|---|---|---|---|---|

| W | 151 | 1.0 | 15.1 | P = 26.9 |

| C | 338 | 3.1 | 10.9 | |

| SF | 18 | 2.2 | 0.8 | |

| S | 615 | 2.63 | 23.4 | BS = 67.3 |

| B2-8 | 588 | 2.97 | 19.7 | |

| B8-16 | 718 | 2.97 | 24.1 | |

| Air content | - | - | 5.8 | A = 5.8 |

| Concrete density | 2437 | - | - | - |

| Area of Measurement AOM | Aggregate BS2D % | Air Content A2D % | Cement Paste P2D % |

|---|---|---|---|

| 1 | 69.30 | 4.71 | 26.0 |

| 2 | 65.96 | 6.03 | 28.0 |

| 3 | 70.09 | 3.76 | 26.2 |

| Mean | 68.45 | 4.83 | 26.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wawrzeńczyk, J.; Molendowska, A. The Use of a Special Stereoscopic Microscope Attachment for the Sieve Analysis of Aggregate in Concrete. Appl. Sci. 2019, 9, 1853. https://doi.org/10.3390/app9091853

Wawrzeńczyk J, Molendowska A. The Use of a Special Stereoscopic Microscope Attachment for the Sieve Analysis of Aggregate in Concrete. Applied Sciences. 2019; 9(9):1853. https://doi.org/10.3390/app9091853

Chicago/Turabian StyleWawrzeńczyk, Jerzy, and Agnieszka Molendowska. 2019. "The Use of a Special Stereoscopic Microscope Attachment for the Sieve Analysis of Aggregate in Concrete" Applied Sciences 9, no. 9: 1853. https://doi.org/10.3390/app9091853

APA StyleWawrzeńczyk, J., & Molendowska, A. (2019). The Use of a Special Stereoscopic Microscope Attachment for the Sieve Analysis of Aggregate in Concrete. Applied Sciences, 9(9), 1853. https://doi.org/10.3390/app9091853