1. Introduction

Fatigue is a well-known behavior due to the iterative loading and unloading at stress levels that are below the ultimate strength of the asphalt pavement. Thus, the fatigue performance of an asphalt mixture is an important criterion for evaluating the asphalt mixture. Some studies [

1,

2,

3,

4] have shown that the fatigue performance of a modified asphalt mixture is obviously better than that of a base asphalt mixture due to the addition of an SBS modifier. Some studies [

2,

3,

4,

5,

6,

7] show that the addition of PE (polyethylene), PA (polyamide), and warm mixing agents will change the fatigue performance of the asphalt mixture. Many scholars [

4,

5,

6,

7,

8,

9,

10,

11,

12] have chosen different fatigue setups to carry out fatigue tests. However, fatigue test methods have different accuracy and pertinence in different test environments and conditions. It is necessary to compare the fatigue performance of different modified asphalt mixtures after analyzing the principles of different fatigue tests to make up for defects of understanding in design and blindness in the choice of asphalt.

In this study, the following three representative fatigue test methods are selected to test the fatigue life of six kinds of modified asphalt mixtures and base asphalt mixtures: the four-point bending beam fatigue test (4PB), which is an ASTM standard test and widely accepted in China [

13]; the two-point trapezoidal beam fatigue test (Trapezoidal Beam), which is widely used in Europe [

14]; and Overlay Tester (OT) tension, which is mainly used in Texas, USA [

15]. Different test methods can provide a more comprehensive reference for fatigue performance evaluation of different kinds of asphalt mixtures from multiple dimensions, avoiding the evaluation deviation caused by defects in a single fatigue test. At the same time, it is easier to find a suitable fatigue method to evaluate the effects of various modifiers, especially for the newly developed ones, on the fatigue performance of asphalt mixtures, and the advantages and disadvantages of the same asphalt mixtures in different test methods can be analyzed.

2. Materials and Experiment Design

2.1. Asphalt and Its Preparation Technology

Six types of asphalts were selected for the experiment, including base asphalt and modified ones, which cover commonly used types in engineering and newly developed ones. The base asphalt is SK70. The modified asphalt used in the test contains two types of SBS-modified asphalt (SBS 4 and SBS 6), warm mixing agent modified asphalt (WA), waxed PE (waxed polyethylene) and SBS composite modified asphalt (WPES), and SBS + nylon fiber 610 (PA610) modified asphalt (4S4P). The modification scheme of modified asphalt is shown in

Table 1, and the asphalt used in the test and its index are shown in

Table 2.

2.2. Aggregate and Gradation

Aggregate, gradation, and mixture designs are as follows: coarse aggregate (particle size >2.36 mm) is made of basalt gravel, fine aggregate (particle size <2.36 mm) is made of manufactured sand, and filler is made of mineral powder. The vast majority of mineral fillers are made of limestone mainly because the limestone powder combines with asphalt strongly [

16]. The aggregate indexes meet the requirements of JTG F40-2004 “Technical Specification for Asphalt Pavement Construction of Highway” [

17]. The asphalt content of the asphalt mixture is 4.8%, and the gradation is AC-13. The design gradation is shown in

Table 3, which contains a group of gravity data of the aggregates in different particle sizes.

2.3. Mix Design

The optimum asphalt content for the different modified asphalt mixtures has been determined by the Marshall mix design. For consistency with the applications and studies in China [

1,

4,

7,

9,

18], we chose the Marshall compaction method, T0702-2011, of Chinese specification [

13]. The design indexes are shown in

Table 4.

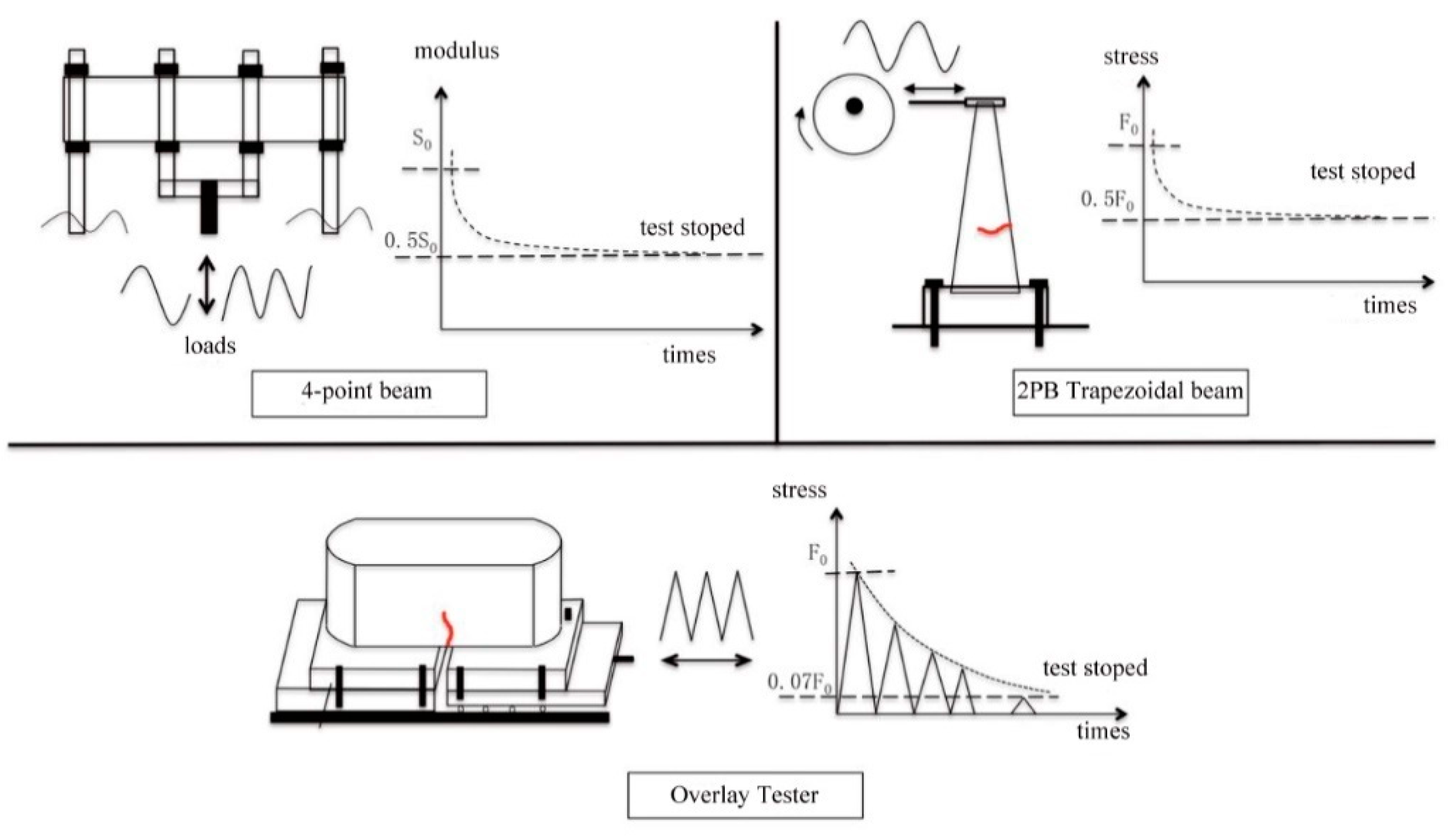

2.4. Three Fatigue Test Methods

The 4PB fatigue test derives from the ASTM D7460 [

19] standard of the United States. The mixture specimens were prepared in a trabecular (380 mm (long) × 63.5 mm (wide) × 50 mm (height)). The loading waveform is a half sinusoidal wave, the standard loading frequency is 10 Hz, the equivalent fatigue temperature of pavement in China is 15 °C, and the 50th loading was used as the initial stiffness modulus. When the normalized stiffness ratio

NM reaches the maximum value, the loading times

M, which cause fatigue failure of the specimens, is considered as the fatigue life of the asphalt mixture, in which

NM is calculated according to the following equation:

where

Si is the modulus of stiffness under the x-th loading,

Ni are loading times,

S0 is the initial loading stiffness modulus (the 50th stiffness modulus is defined as the initial loading modulus), and

N0 are the initial loading times (taken to be 50).

This method was first proposed by Rowe et al. [

11] to form the standard ASTM D7460. Compared with the standard method in which the stiffness modulus changes to 50% of the initial stiffness modulus as the end of the test, the fatigue life variation coefficient is smaller, which can reflect the fatigue life of a modified asphalt mixture better [

20]. The 10 beam shape samples were tested in each of the asphalt mixes, and the variance of 10% are the valid data.

The fatigue test of Trapezoidal Beam was adopted from the European EN 12697-24 [

21] standard. The mixture specimens were prepared to be 25 mm × 25 mm at the top, 25 mm × 56 mm at the bottom, and 250 mm high. The loading waveform is a sinusoidal wave, the standard loading frequency is 25 Hz, and the equivalent fatigue temperature of pavement in China is 15 °C. The initial stiffness modulus is the 100th loading, and when the modulus of stiffness decreases to 50% of the initial value, the number of loading times is taken as the fatigue life. The three beam samples were tested in each of the asphalt mixes, and the variance of 20% are the valid data.

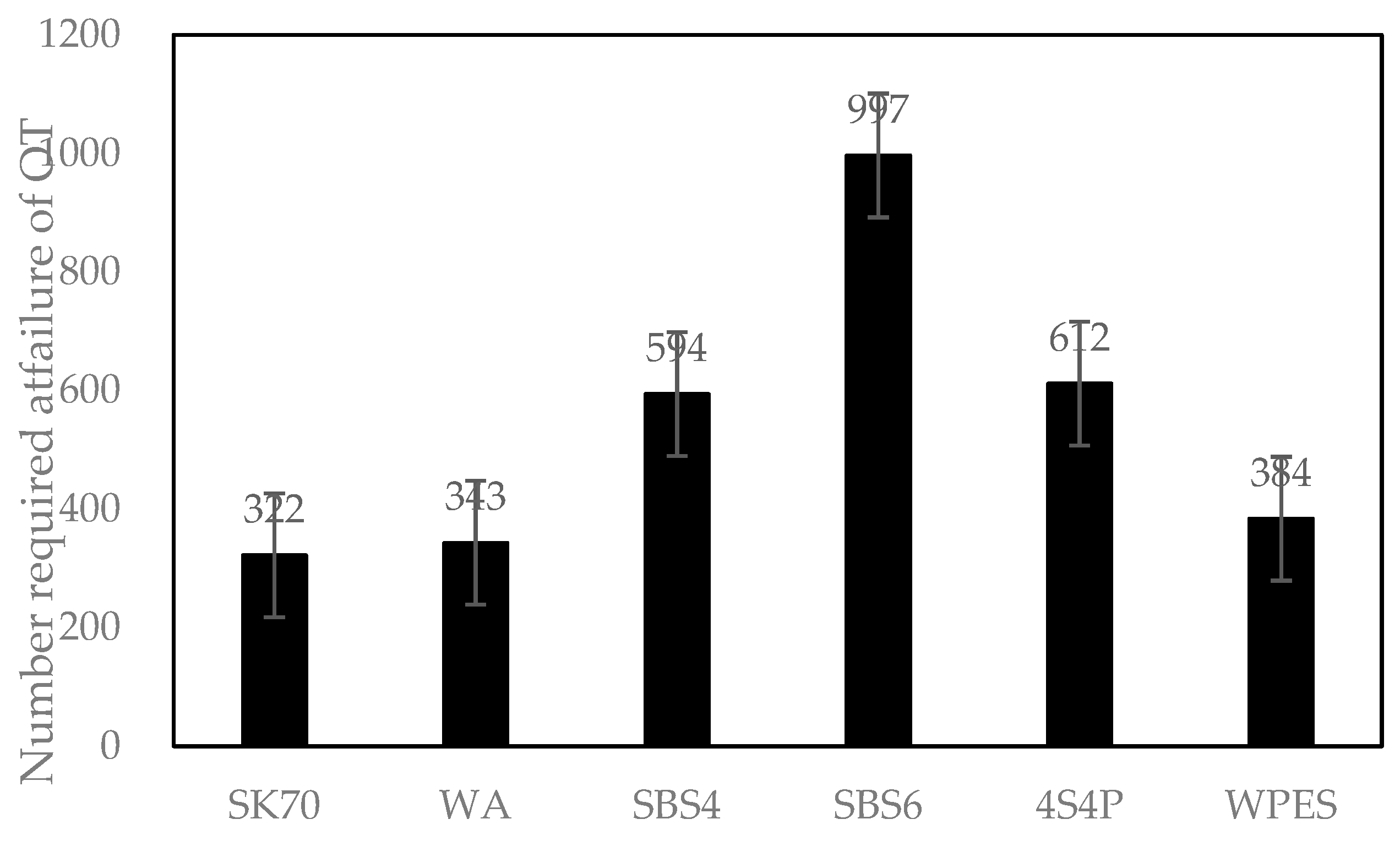

The Overlay Tester fatigue test adopts the TEX-248-F [

15] standard of Texas, USA. The mixture specimen is a cylinder, which is 150 mm in diameter, 38 mm in height, and 76 mm in width. The loading waveform is a triangular wave, the standard loading period is 0.1 Hz, and the test temperature is 25 °C. The judgment for the end of the experiment is that the initial force decreases to 93% of the initial one or the loading times reach 1000. So, the number of loading times taken to reach 93% of the initial force or loading times of 1000 will be taken as the fatigue life of the specimen. The three samples were tested in each of the asphalt mixes, and the final results were averaged and are included in the chart.

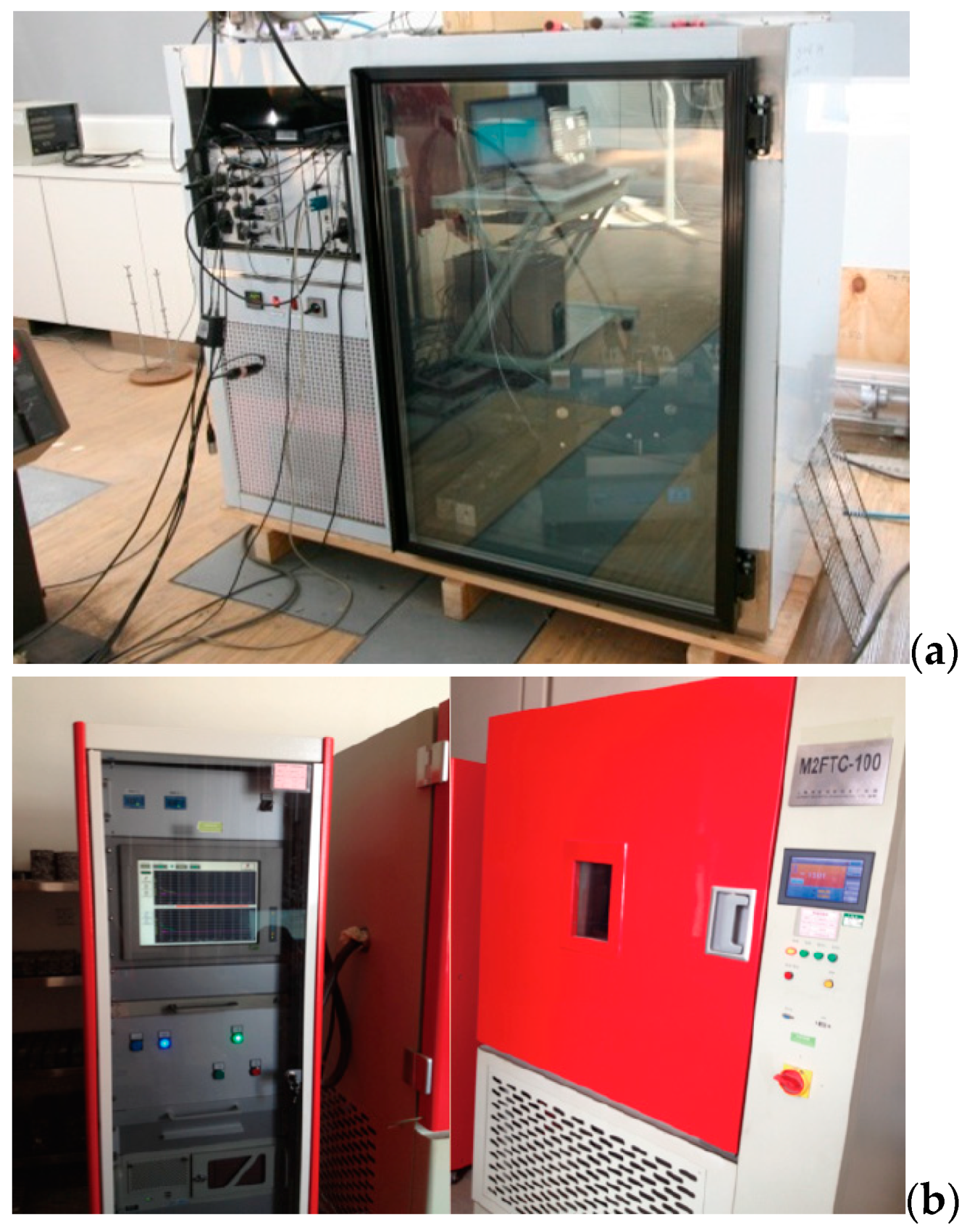

Figure 1 shows the three fatigue testing apparatuses and

Figure 2 shows the principles of the three fatigue test methods.

3. Results and Discussion

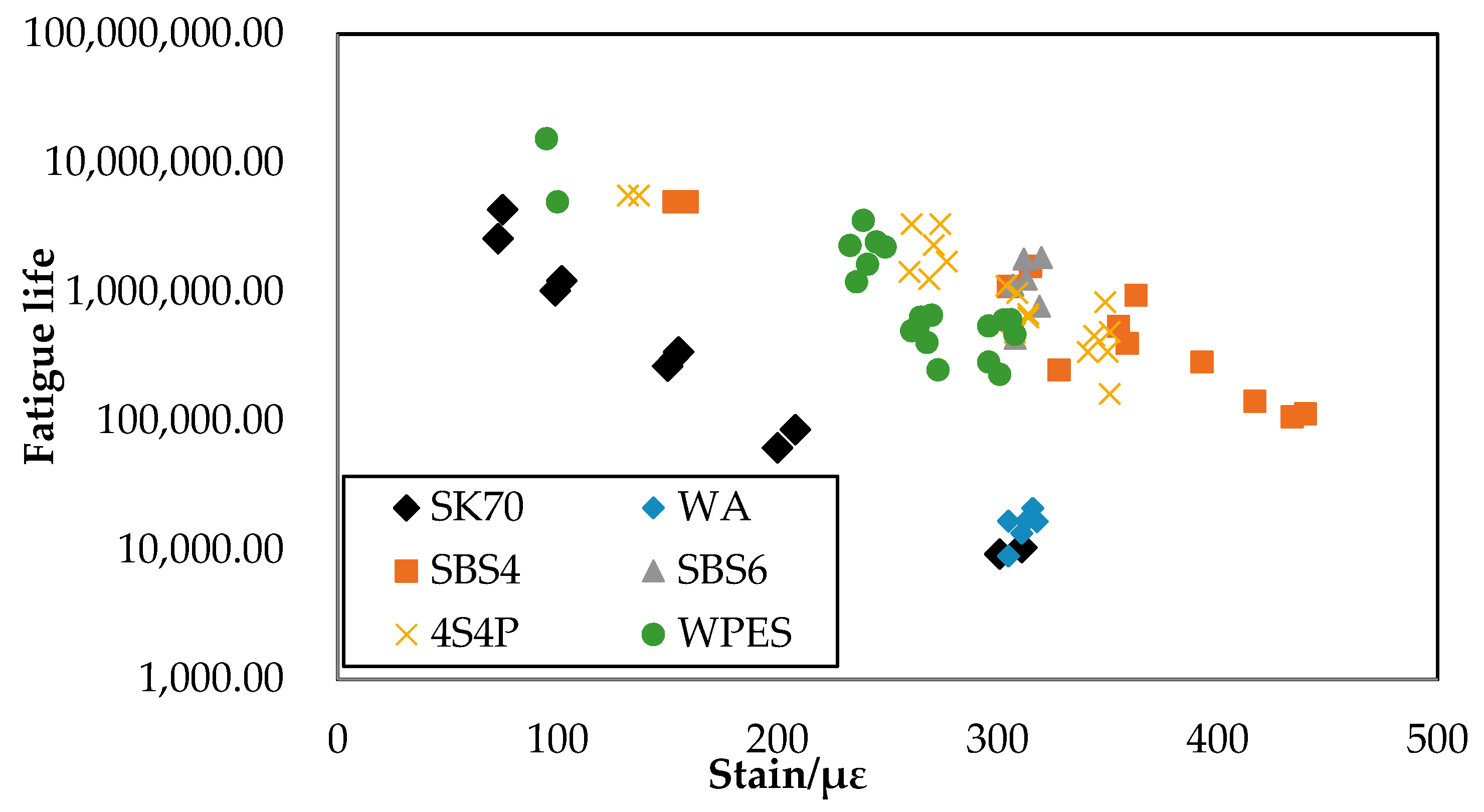

3.1. Fatigue Test Results

The fatigue tests of 4PB and Trapezoidal Beam are under a different strain level, while the OT tests keep the same strain at 300 × 10

−6. All tests should be repeated at least four times, and the average values of the three results with the smallest coefficient of variation should be taken as the test results. The results of all the three fatigue tests are shown in

Figure 3,

Figure 4 and

Figure 5.

3.2. Separate Analysis of the Results

4PB: The strain range used in the 4PB test is very wide, and number of samples used in each group is small, which requires high precision. Therefore, more precise forming and cutting technology is needed. The fatigue life of the six asphalt mixtures decreases gradually with the increase of strain. The fatigue properties of SK70 and WA are obviously poor, SBS4 is in the middle, and 4S4P, WPES, and SBS6 are the best ones. The specific performance order is slightly different with the change of strain, and WPES performs best at high strain. With the increase of SBS content, the fatigue performance of the asphalt mixture increases continuously. The addition of WPE and PA610 improves the fatigue performance of the modified asphalt mixture in varying degrees.

Trapezoidal Beam: The preparation of test samples is complex and the amount of test data is huge. It has high precision and is suitable for scientific research instead of a field laboratory. The strain range of the test is moderate in the three methods. The fatigue life of the six asphalt mixtures decreases gradually with the increase of strain, and the fatigue performance of SK70 and WA are the worst, and 4S4P, SBS4, and SBS6 are the best. The specific performance ranking varies slightly with strain, which is similar to the conclusion for 4PB. The values obtained from the Trapezoidal Beam tests are more concentrated in regions with a smaller strain than 4PB.

Overlay Tester: The strain range of the OT test is the narrowest. The test specimen is relatively simple to prepare and the test process takes less time. It is easier to popularize than the above two test methods. Similarly, the OT test again verified that the fatigue performance of SK70 and WA are poor. The fatigue performance of SBS4, 4S4P, and WPES are in the middle, and SBS6 showed the best fatigue performance. With the increase of SBS content, the fatigue life of the asphalt mixture increased. The fatigue life of 4S4P was better than that of SBS4. This result confirmed the results of the Trapezoidal Beam tests but differed from that of 4PB.

3.3. Comparative Analysis of Three Kinds of Fatigue Tests

In order to analyze the comprehensive evaluation results of different asphalt mixtures in the three fatigue tests, the fatigue tests at or nearby 300 × 10

−6 strain were unified and chosen to compare the fatigue life of different asphalt mixtures under the three different tests. According to the order of fatigue life of different mixtures, the mixture with the best fatigue performance scores 6 points and the worst scores 1 point. The total scores of the three test methods for various asphalt mixtures are given by analogy. The results are shown in

Table 5.

1. In the 4PB fatigue test, WPES has the best fatigue life, which is 19.03 times of the fatigue life of the base asphalt mixture. In the Trapezoidal Beam fatigue test, SBS6 has the best fatigue life, which is 127.48 times of the fatigue life of the base asphalt mixture. In the OT fatigue test, SBS6 has the best fatigue life, which is 3.1 times of the fatigue life of base asphalt mixture.

2. According to the total score, the fatigue performance of the asphalt mixture is ranked: SBS6 > 4S4P > WPES ≈ SBS4 > WA > SK70.

3. In the three fatigue tests, the fatigue lives of SK70 and WA are significantly lower than that of the other four asphalt mixtures, which is also identical to the experience in practical engineering [

22,

23,

24], that is, the fatigue life of the base asphalt mixtures is not significantly improved by a warm mixing agent [

25,

26]. The fatigue performance of the asphalt mixture is improved by adding SBS, and the fatigue performance of the asphalt mixture is improved more obviously with the increase of SBS content. The addition of WPE and PA610 also improves the fatigue performance of the asphalt mixture in varying degrees. Considering fatigue performance and cost saving, these two new modification methods can replace part of the SBS-modified asphalt.

4. In the three fatigue tests, the fatigue performance of the mixture can be roughly distinguished, but the specific rankings are different. The test samples, waveforms, and frequencies are different, so the evaluation results of fatigue life values cannot be directly transformed. However, in the research and development of new materials, the three different fatigue tests can be used simultaneously to obtain a more comprehensive and objective evaluation.

4. Conclusions

In this research program, test schemes are designed for the fatigue performance of several modified asphalt mixtures in three fatigue tests. According to the experimental test results and the statistical analysis findings, the following conclusions can be drawn:

1. In the 4PB fatigue test, the fatigue performance ranking is WPES > SBS6 > 4S4P > SBS4 > SK70 > WA; in the Trapezoidal Beam fatigue test, the fatigue performance ranking is SBS6 > SBS4 > 4S4P > WPE + SBS > WA > SK70; in the OT fatigue test, the fatigue performance ranking is SBS6 > SBS4 > WPE + SBS > 4S4P > SK70.

2. According to the total score, the fatigue performance of the asphalt mixture is ranked: SBS6 > 4S4P > WPES ≈ SBS4 > WA > SK70.

3. In all three fatigue tests, the fatigue lives of SK70 and WA are significantly lower than that of the other four asphalt mixtures, which means that the fatigue life of the base asphalt mixtures is not significantly improved by the warm mixing agent. The fatigue performance of the asphalt mixture is improved by adding SBS, and the fatigue performance of asphalt mixture is improved more obviously with the increase of SBS content. The addition of WPE and PA610 also improves the fatigue performance of the asphalt mixture in varying degrees. Considering fatigue performance and cost saving, these two new modification methods can replace part of SBS-modified asphalt.

4. In all three fatigue tests, the fatigue performance of the mixture can be distinguished, but it differs in specific rankings. Although the evaluation results of the three fatigue life values cannot be directly transformed, the three different fatigue tests can be used simultaneously to obtain a more comprehensive and objective evaluation in the R&D process of a new modified asphalt.

5. More precise forming and cutting technology is needed because the strain range used in the 4PB test is very wide, and number of samples used in each group is small. The preparation of the Trapezoidal Beam test samples is complex; the amount of test data is huge and has high precision, which is suitable for scientific research instead of the field laboratory, and the strain range of the test is moderate in the three methods. The strain range of the OT test is the narrowest; the test specimen is relatively simple to prepare, and fatigue performance of a specific modified asphalt mixture can be obtained quickly in a simple laboratory. It is easier to popularize than the above two test methods.

Author Contributions

Conceptualization, K.L.; methodology, M.H., H.Z. and B.L.; validation, K.L. and B.L.; formal analysis, M.H. and H.Z.; investigation, H.Z. and B.L.; resources, H.Z. and B.L.; data curation, M.H. and B.L.; writing—original draft preparation, H.Z. and B.L.; writing—review and editing, K.L. and M.H.; visualization, B.L.; supervision, M.H..; project administration, K.L. and M.H.; funding acquisition, K.L.

Funding

This research received no external funding.

Acknowledgments

The authors would like to thank Huang Xin from Beihang University for helpful and constructive prophase studies.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yu, J. Research on Fatigue Performance of Asphalt Mixture; South China University of Technology: Guangzhou, China, 2005. [Google Scholar]

- Fontes, L.P.T.L.; Trichês, G.; Pais, J.C.; Pereira, P.A.A. Evaluating permanent deformation in asphalt rubber mixtures. Constr. Build. Mater. 2010, 24, 1193–1200. [Google Scholar] [CrossRef]

- Kim, T.W.; Baek, J.; Lee, H.J.; Choi, J.Y. Fatigue performance evaluation of SBS modified mastic asphalt mixtures. Constr. Build. Mater. 2013, 48, 908–916. [Google Scholar] [CrossRef]

- Li, X.; Clyne, T.; Reinke, G.; Johnson, E.N.; Gibson, N.H.; Kutay, M.E. Laboratory Evaluation of Asphalt Binders and Mixtures Containing Polyphosphoric acid. Transp. Res. Rec. J. Transp. Res. Board. 2011, 2210, 47–56. [Google Scholar] [CrossRef]

- Kristjansdottir, O. Warm Mix Asphalt; University of Washington: Seattle, WA, USA, 2006. [Google Scholar]

- Modarres, A.; Hamedi, H. Developing laboratory fatigue and resilient modulus models for modified asphalt mixes with waste plastic bottles (PET). Constr. Build. Mater. 2014, 68, 259–267. [Google Scholar] [CrossRef]

- Huang, W.; Li, B.; Huang, M. Evaluation of Self-healing of Asphalt Mixture through Four-Point Bending Fatigue Test. J. Build. Mater. 2015, 18, 572–577. [Google Scholar]

- Vaitkus, A.; Čygas, D.; Laurinavičius, A.; Vorobjovas, V.; Perveneckas, Z. Influence of warm mix asphalt technology on asphalt physical and mechanical properties. Constr. Build. Mater. 2016, 112, 800–806. [Google Scholar] [CrossRef]

- Huang, S.C.; Turner, T.F.; Miknis, F.P.; Thomas, K.P. Long-Term Aging Characteristics of Polyphosphoric acid-Modified Asphalts. Transp. Res. Rec. J. Transp. Res. Board. 2008, 2051, 1–7. [Google Scholar] [CrossRef]

- Al-Khateeb, G.; Shenoy, A. A distinctive fatigue failure criterion. J. Assoc. Asphalt Paving Technol. 2004, 73, 585–622. [Google Scholar]

- Rowe, G.M.; Bouldin, M.G. Improved techniques to evaluate the fatigue resistance of asphaltic mixtures. In Proceedings of the 2nd Euro Asphalt and Euro Bitume Congress, Barcelona, Spain, 20–22 September 2000. [Google Scholar]

- Huang, M.; Wen, X.; Huang, W. Fatigue Performance of Asphalt Mixtures with Different Design Goals. J. Tongji Univ. Nat. Sci. 2016, 44, 572–579. [Google Scholar]

- JTG E20-2011—Standard Test Method of Bitumen and Bituminous Mixtures for Highway Engineering; China Communications Press: Beijing, China, 2011.

- British Standards Institution. Bituminous Mixtures—Test Methods for Hot Mix Asphalt—Part 24: Resistance to Fatigue; BSI: London, UK, 2012. [Google Scholar]

- TEX-248-F—Test Procedure for the Overlay Test. TEX-248-F; Texas Department of Transportation: Austin, TX, USA, 2013; pp. 15–37.

- British Standards Institute. Bituminous Mixtures—Test Method for Hot Mix Asphalt—Part 2: Determination of Particle Size Distribution; British Standards Institute: London, UK, 2002. [Google Scholar]

- JTG F40-2004—Technical Specification for Asphalt Pavement Construction of Highway; China Communications Press: Beijing, China, 2004.

- Qi, X.; Shenoy, A.; Al-Khateeb, G.; Arnold, T.; Gibson, N.; Youtcheff, J.; Harman, T. Laboratory Characterization and Full-Scale Accelerated Performance Testing of Crumb Rubber Asphalts and Other Modified Asphalt Systems. In Proceedings of the Asphalt Rubber 2006 Conference, Palm Springs, CA, USA, 25–27 October 2006. [Google Scholar]

- ASTM D7460-10—Standard Test Method for Determining Fatigue Failure of Compacted Asphalt Concrete Subjected to Repeated Flexural Bending; ASTM International: West Conshohocken, PA, USA, 2010.

- Huang, M.; Huang, W. Laboratory Investigation on Fatigue Performance of Modified Asphalt Concretes Considering Healing. Constr. Build. Mater. 2016, 113, 68–76. [Google Scholar] [CrossRef]

- Pérez-Jiménez, F.; Valdés, G.A.; Botella, R.; Miró, R.; Martínez, A. Approach to fatigue performance using Fénix test for asphalt mixtures. Constr. Build. Mater. 2012, 26, 372–380. [Google Scholar] [CrossRef]

- Tsai, B.W.; Jones, D.; Harvey, J.T.; Monismith, C.L. Reflective Cracking Study: First-Level Report on Laboratory Fatigue Testing; Research Report UCPRC-RR-2006-08; Institute of Transportation Studies, University of California: Davis, CA, USA, 2008. [Google Scholar]

- El-Basyouny, M.M.; Witczak, M. Calibration of Alligator Fatigue Cracking Model for 2002 Design Guide; Transportation Research Record No. 1919; Transportation Research Board, National Academies: Washington, DC, USA, 2005; pp. 77–86. [Google Scholar]

- Jones, D.; Harvey, J.; Monismith, C. Reflective Cracking Study: Summary Report; Report UCPRC-SR-2007-01; University of California Pavement Research Center: Davis, CA, USA, 2007. [Google Scholar]

- Safaei, F.; Lee, J.-S.; do Nascimento, L.A.H.; Hintz, C. Implications of warm-mix asphalt on long-term oxidative ageing and fatigue performance of asphalt binders and mixtures. Road Mater. Pavement Des. 2014, 15, 45–61. [Google Scholar] [CrossRef]

- Goh, S.W.; You, Z. Evaluation of Warm Mix Asphalt Produced at Various Temperatures through Dynamic Modulus Testing and Four Point Beam Fatigue Testing; Geotechnical Special Publication No. 212; ASCE: Reston, VA, USA, 2011; pp. 123–129. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).