Single-Crystalline Si1−xGex (x = 0.5~1) Thin Films on Si (001) with Low Threading Dislocation Density Prepared by Low Temperature Molecular Beam Epitaxy

Abstract

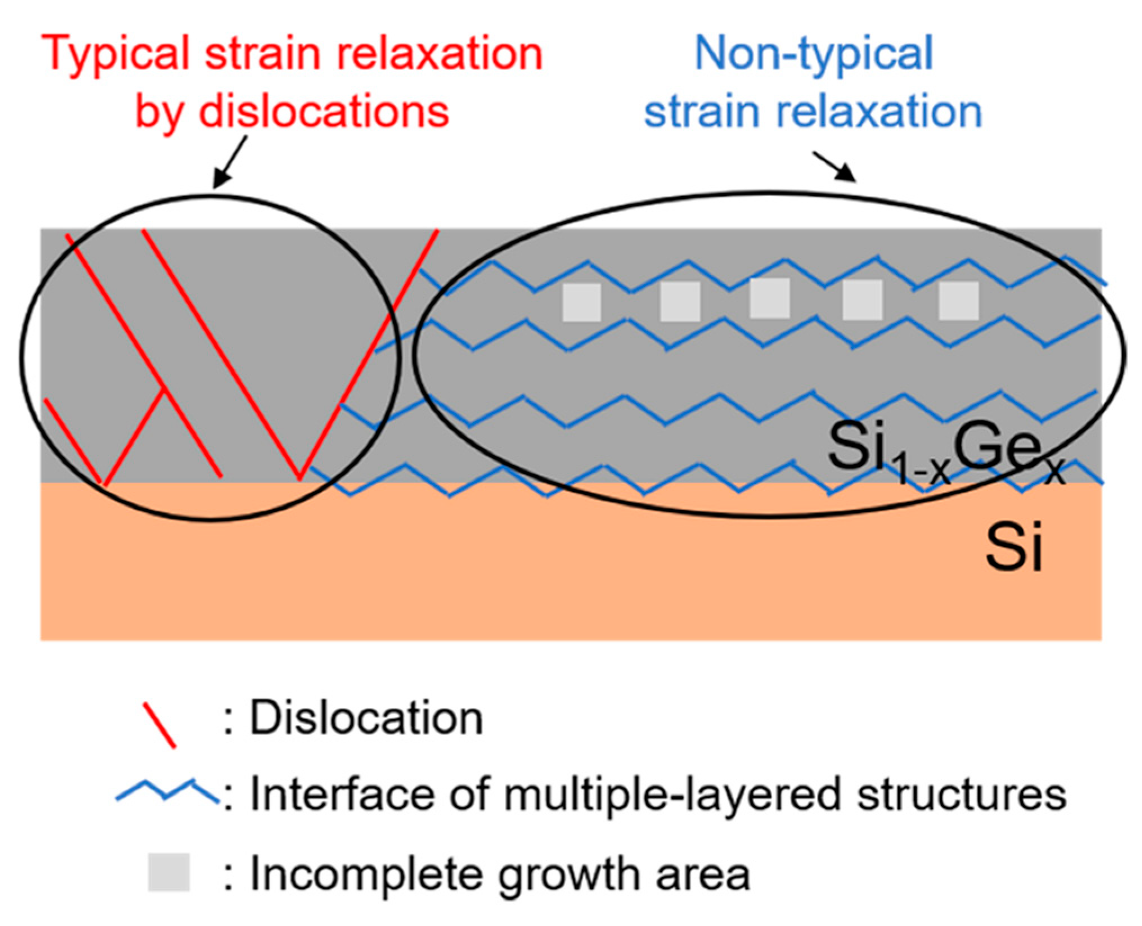

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bakkers, E.P.; van Dam, J.A.; De Franceschi, S.; Kouwenhoven, L.P.; Kaiser, M.; Verheijen, M.; Wondergem, H.; van der Sluis, P. Epitaxial growth of InP nanowires on germanium. Nat. Mater. 2004, 3, 769–773. [Google Scholar] [CrossRef]

- Liu, H.; Wang, T.; Jiang, Q.; Hogg, R.; Tutu, F.; Pozzi, F.; Seeds, A. Long-wavelength InAs/GaAs quantum-dot laser diode monolithically grown on Ge substrate. Nat. Photonics 2011, 5, 416–419. [Google Scholar] [CrossRef]

- Lu Low, K.; Yang, Y.; Han, G.; Fan, W.; Yeo, Y.-C. Electronic band structure and effective mass parameters of Ge1-xSnx alloys. J. Appl. Phys. 2012, 112, 103715. [Google Scholar] [CrossRef]

- Gupta, S.; Magyari-Köpe, B.; Nishi, Y.; Saraswat, K.C. Achieving direct band gap in germanium through integration of Sn alloying and external strain. J. Appl. Phys. 2013, 113, 073707. [Google Scholar] [CrossRef]

- Wirths, S.; Geiger, R.; von den Driesch, N.; Mussler, G.; Stoica, T.; Mantl, S.; Ikonic, Z.; Luysberg, M.; Chiussi, S.; Hartmann, J.M.; et al. Lasing in direct-bandgap GeSn alloy grown on Si. Nat. Photonics 2015, 9, 88–92. [Google Scholar] [CrossRef]

- Bhargava, N.; Coppinger, M.; Prakash Gupta, J.; Wielunski, L.; Kolodzey, J. Lattice constant and substitutional composition of GeSn alloys grown by molecular beam epitaxy. Appl. Phys. Lett. 2013, 103, 041908. [Google Scholar] [CrossRef]

- Oehme, M.; Buca, D.; Kostecki, K.; Wirths, S.; Holländer, B.; Kasper, E.; Schulze, J. Epitaxial growth of highly compressively strained GeSn alloys up to 12.5% Sn. J. Cryst. Growth 2013, 384, 71–76. [Google Scholar] [CrossRef]

- Brunner, K. Si/Ge nanostructures. Rep. Prog. Phys. 2001, 65, 27–72. [Google Scholar] [CrossRef]

- Gao, H. Surface roughening of heteroepitaxial thin films. Annu. Rev. Mater. Sci. 1999, 29, 173–209. [Google Scholar] [CrossRef]

- Ye, H.; Yu, J. Germanium epitaxy on silicon. Sci. Technol. Adv. Mater. 2014, 15, 024601. [Google Scholar] [CrossRef] [PubMed]

- Tatsumi, T.; Hirayama, H.; Aizaki, N. Si/Ge0.3Si0.7/Si heterojunction bipolar transistor made with Si molecular beam epitaxy. Appl. Phys. Lett. 1988, 52, 895–897. [Google Scholar] [CrossRef]

- Liu, Z. The Key Technologies in Silicon Based Microwave and RF MEMS Device Fabrication. In Proceedings of the 2004 4th International Conference on Microwave and Millimeter Wave Technology, Nanjing, China, 18–21 August 2004. [Google Scholar]

- Giovane, L.M.; Luan, H.-C.; Agarwal, A.M.; Kimerling, L.C. Correlation between leakage current density and threading dislocation density in SiGe p-i-n diodes grown on relaxed graded buffer layers. Appl. Phys. Lett. 2001, 78, 541–543. [Google Scholar] [CrossRef]

- Liu, Z.; Hao, X.; Huang, J.; Ho-Baillie, A.; Green, M.A. Reduction of Threading Dislocation Density in Sputtered Ge/Si(100) Epitaxial Films by Continuous-Wave Diode Laser-Induced Recrystallization. ACS Appl. Energy Mater. 2018, 1, 1893–1897. [Google Scholar] [CrossRef]

- Choi, D.; Ge, Y.; Harris, J.S.; Cagnon, J.; Stemmer, S. Low surface roughness and threading dislocation density Ge growth on Si (001). J. Cryst. Growth 2008, 310, 4273–4279. [Google Scholar] [CrossRef]

- Chen, D.; Xue, Z.; Wei, X.; Wang, G.; Ye, L.; Zhang, M.; Wang, D.; Liu, S. Ultralow temperature ramping rate of LT to HT for the growth of high quality Ge epilayer on Si (100) by RPCVD. Appl. Surf. Sci. 2014, 299, 1–5. [Google Scholar] [CrossRef]

- Tan, Y.H.; Tan, C.S. Growth and characterization of germanium epitaxial film on silicon (001) using reduced pressure chemical vapor deposition. Thin Solid Films 2012, 520, 2711–2716. [Google Scholar] [CrossRef]

- Convertino, C.; Zota, C.; Schmid, H.; Caimi, D.; Sousa, M.; Moselund, K.; Czornomaz, L. InGaAs FinFETs Directly Integrated on Silicon by Selective Growth in Oxide Cavities. Materials 2018, 12, 87. [Google Scholar] [CrossRef]

- Borg, M.; Schmid, H.; Moselund, K.E.; Signorello, G.; Gignac, L.; Bruley, J.; Breslin, C.; Das Kanungo, P.; Werner, P.; Riel, H. Vertical III-V nanowire device integration on Si(100). Nano Lett. 2014, 14, 1914–1920. [Google Scholar] [CrossRef]

- Ren, D.; Meng, X.; Rong, Z.; Cao, M.; Farrell, A.C.; Somasundaram, S.; Azizur-Rahman, K.M.; Williams, B.S.; Huffaker, D.L. Uncooled Photodetector at Short-Wavelength Infrared Using InAs Nanowire Photoabsorbers on InP with p-n Heterojunctions. Nano Lett. 2018, 18, 7901–7908. [Google Scholar] [CrossRef] [PubMed]

- Ren, D.; Farrell, A.C.; Williams, B.S.; Huffaker, D.L. Seeding layer assisted selective-area growth of As-rich InAsP nanowires on InP substrates. Nanoscale 2017, 9, 8220–8228. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Ren, D.; Farrell, A.C.; Huffaker, D.L. Catalyst-free selective-area epitaxy of GaAs nanowires by metal-organic chemical vapor deposition using triethylgallium. Nanotecnology 2018, 29, 085601. [Google Scholar] [CrossRef]

- Li, Q.; Ng, K.W.; Tang, C.W.; Lau, K.M.; Hill, R. Defect reduction in epitaxial InP on nanostructured Si (001) substrates with position-controlled seed arrays. J. Cryst. Growth 2014, 405, 81–86. [Google Scholar] [CrossRef]

- Bean, J.C.; Sheng, T.T.; Feldman, L.C.; Fiory, A.T.; Lynch, R.T. Pseudomorphic growth of GexSi1−xon silicon by molecular beam epitaxy. Appl. Phys. Lett. 1984, 44, 102–104. [Google Scholar] [CrossRef]

- Halbwax, M.; Bouchier, D.; Yam, V.; Débarre, D.; Nguyen, L.H.; Zheng, Y.; Rosner, P.; Benamara, M.; Strunk, H.P.; Clerc, C. Kinetics of Ge growth at low temperature on Si(001) by ultrahigh vacuum chemical vapor deposition. J. Appl. Phys. 2005, 97, 064907. [Google Scholar] [CrossRef]

- Mooney, P.M. Strain relaxation and dislocations in SiGe/Si structures. Mater. Sci. Eng. 1996, 17, 105–146. [Google Scholar] [CrossRef]

- LeGoues, F.K.; Mooney, P.M.; Tersoff, J. Measurement of the activation barrier to nucleation of dislocations in thin films. Phys. Rev. Lett. 1993, 71, 396–399. [Google Scholar] [CrossRef]

- Faleev, N.; Sustersic, N.; Bhargava, N.; Kolodzey, J.; Magonov, S.; Smith, D.J.; Honsberg, C. Structural investigations of SiGe epitaxial layers grown by molecular beam epitaxy on Si(001) and Ge(001) substrates: II—Transmission electron microscopy and atomic force microscopy. J. Cryst. Growth 2013, 365, 35–43. [Google Scholar] [CrossRef]

- Chen, X.; Zuo, D.; Kim, S.; Mabon, J.; Sardela, M.; Wen, J.; Zuo, J.-M. Large Area and Depth-Profiling Dislocation Imaging and Strain Analysis in Si/SiGe/Si Heterostructures. Microsc. Microanal. 2014, 20, 1521–1527. [Google Scholar] [CrossRef]

- Bolkhovityanov, Y.B.; Deryabin, A.S.; Gutakovskii, A.K.; Revenko, M.A.; Sokolov, L.V. Strain relaxation of GeSi/Si(001) heterostructures grown by low-temperature molecular-beam epitaxy. J. Appl. Phys. 2004, 96, 7665–7674. [Google Scholar] [CrossRef]

- Eaglesham, D.J.; Cerullo, M. Low-temperature growth of Ge on Si(100). Appl. Phys. Lett. 1991, 58, 2276–2278. [Google Scholar] [CrossRef]

- Bauer, M.; Lyutovich, K.; Oehme, M.; Kasper, E.; Herzog, H.J.; Ernst, F. Relaxed SiGe buffers with thicknesses below 0.1 mm. Thin Solid Films 2000, 369, 152–156. [Google Scholar] [CrossRef]

- d’Aragona, F.S. Dislocation Etch for (100) Planes in Silicon. J. Electrochem. Soc. 1972, 119, 948–951. [Google Scholar]

- Narayan, J. Recent progress in thin film epitaxy across the misfit scale (2011 Acta Gold Medal Paper). Acta Mater. 2013, 61, 2703–2724. [Google Scholar] [CrossRef]

- Marée, P.M.J.; Barbour, J.C.; van der Veen, J.F.; Kavanagh, K.L.; Bulle-Lieuwma, C.W.T.; Viegers, M.P.A. Generation of misfit dislocations in semiconductors. J. Appl. Phys. 1987, 62, 4413–4420. [Google Scholar] [CrossRef]

- Matt Law, J.G.; Yang, P. Semiconductor nanowires and nanotubes. Annu. Rev. Mater. Res. 2004, 34, 83–122. [Google Scholar]

- Wu, Y.; Fan, R.; Yang, P. Block-by-Block Growth of Single-Crystalline Si/SiGe Superlattice Nanowires. Nano Lett. 2002, 2, 283–286. [Google Scholar] [CrossRef]

- Wu, Y.; Yang, P. Direct Observation of Vapor-Liquid-Solid Nanowire Growth. J. Am. Chem. Soc. 2001, 123, 3165–3166. [Google Scholar] [CrossRef]

- Chen, K.; Kapadia, R.; Harker, A.; Desai, S.; Seuk Kang, J.; Chuang, S.; Tosun, M.; Sutter-Fella, C.M.; Tsang, M.; Zeng, Y.; et al. Direct growth of single-crystalline III-V semiconductors on amorphous substrates. Nat. Commun. 2016, 7, 10502. [Google Scholar] [CrossRef]

- Zheng, M.; Horowitz, K.; Woodhouse, M.; Battaglia, C.; Kapadia, R.; Javey, A. III-Vs at scale: A PV manufacturing cost analysis of the thin film vapor-liquid-solid growth mode. Prog. Photovolt. Res. Appl. 2016, 24, 871–878. [Google Scholar] [CrossRef]

- Hettick, M.; Zheng, M.; Lin, Y.; Sutter-Fella, C.M.; Ager, J.W.; Javey, A. Nonepitaxial Thin-Film InP for Scalable and Efficient Photocathodes. J. Phys. Chem. Lett. 2015, 6, 2177–2182. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, Y.; Zhao, Y.; Ye, J.; Deng, Y.; Lu, H. Single-Crystalline Si1−xGex (x = 0.5~1) Thin Films on Si (001) with Low Threading Dislocation Density Prepared by Low Temperature Molecular Beam Epitaxy. Appl. Sci. 2019, 9, 1772. https://doi.org/10.3390/app9091772

Gu Y, Zhao Y, Ye J, Deng Y, Lu H. Single-Crystalline Si1−xGex (x = 0.5~1) Thin Films on Si (001) with Low Threading Dislocation Density Prepared by Low Temperature Molecular Beam Epitaxy. Applied Sciences. 2019; 9(9):1772. https://doi.org/10.3390/app9091772

Chicago/Turabian StyleGu, Yu, Yunlei Zhao, Jiajia Ye, Yu Deng, and Hong Lu. 2019. "Single-Crystalline Si1−xGex (x = 0.5~1) Thin Films on Si (001) with Low Threading Dislocation Density Prepared by Low Temperature Molecular Beam Epitaxy" Applied Sciences 9, no. 9: 1772. https://doi.org/10.3390/app9091772

APA StyleGu, Y., Zhao, Y., Ye, J., Deng, Y., & Lu, H. (2019). Single-Crystalline Si1−xGex (x = 0.5~1) Thin Films on Si (001) with Low Threading Dislocation Density Prepared by Low Temperature Molecular Beam Epitaxy. Applied Sciences, 9(9), 1772. https://doi.org/10.3390/app9091772