Effects of BIM-Based Construction of Prefabricated Steel Framework from the Perspective of SMEs

Abstract

:1. Introduction

2. Literature Review

2.1. Characteristics of SMEs in Construction Management

- micro-sized companies as those having fewer than 10 employees,

- small-sized companies as those having fewer than 50 employees,

- medium-sized companies as those having between 50 and 249 employees, and

- large-sized companies as those having 250 employees or above.

2.2. Limitations of BIM Adoption

2.3. BIM for Prefabricated Steel Frame Construction

2.4. Evaluation of Information System

3. Research Method

3.1. BIM-Based Construction Management System Framework

3.2. Main Function Derivation for the System

3.3. Definition of System Database

3.3.1. Building Objects of Prefabricated Steel Frame

3.3.2. Connecting Building Objects to Create a Prefabricated Steel Frame

4. Effects of BIM-Based Construction Management System for SMEs

4.1. Case Study

4.1.1. Project Description

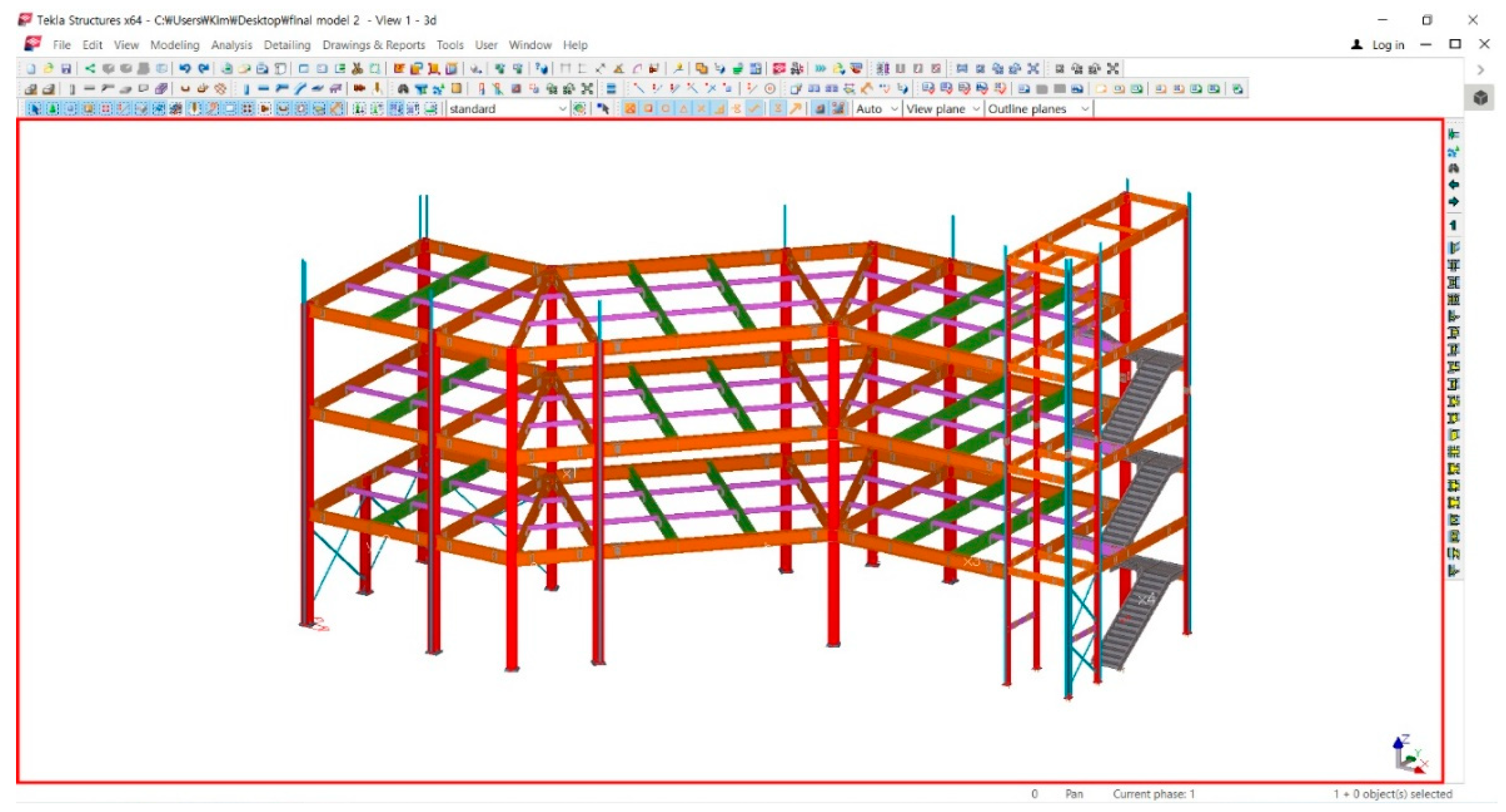

4.1.2. Description of the BIM Model of a Prefabricated Steel Frame

4.2. Effects of BIM-Based Construction Management System for SMEs in the Preconstruction Phase

4.2.1. Extraction of Fabrication Drawing

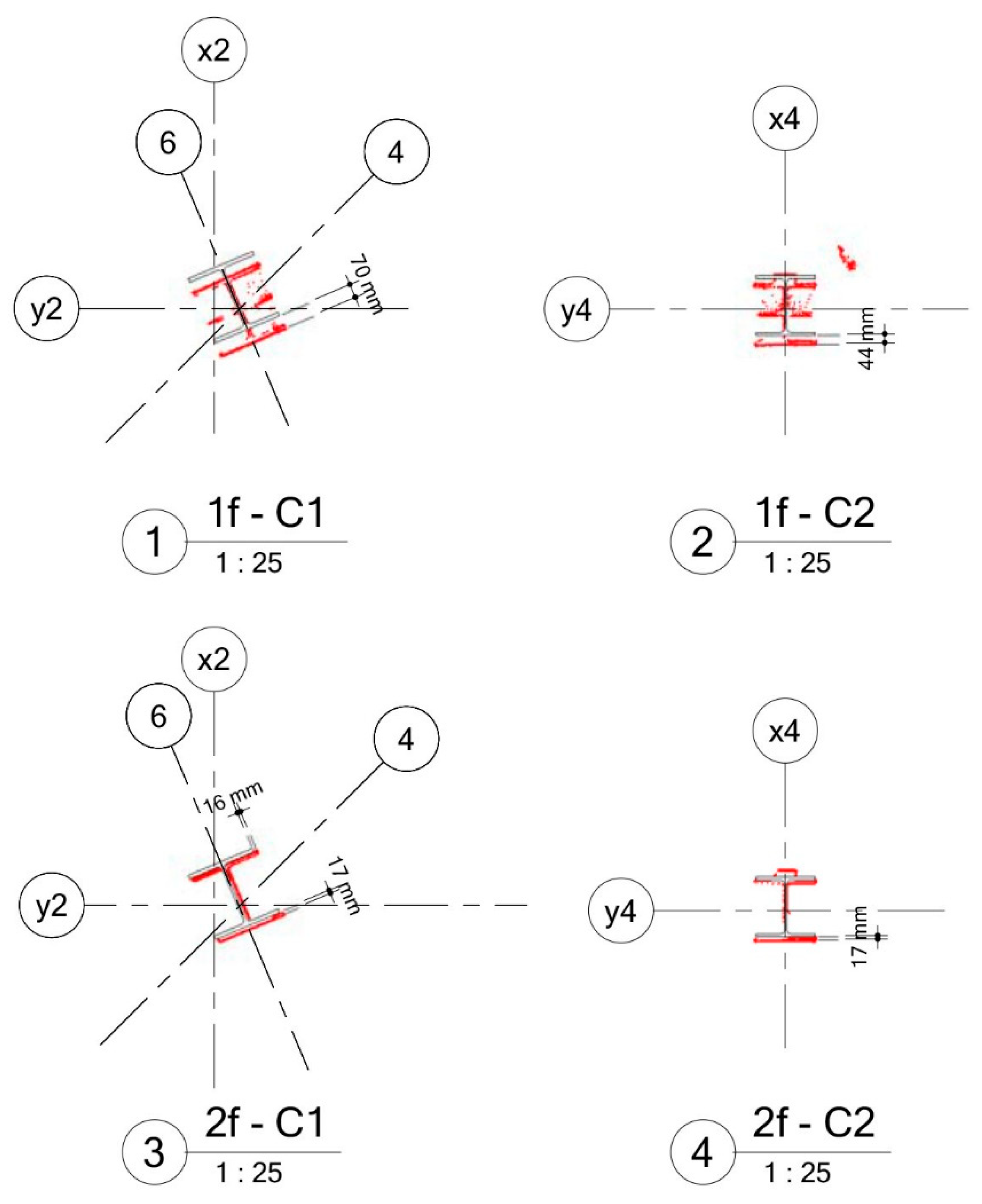

4.2.2. Review of Shop Drawing

- when steel frame members were crossed or penetrated,

- between the bolts and bolted plates, and

- between a steel part member and a steel plate member.

4.3. Effects of BIM-Based Construction Management System for SMEs in the Fabrication Phase

4.3.1. Prefabrication Review

- confirm whether it is easy to fabricate, transfer, lift, and field-install;

- confirm whether it contains additional steel frames for building the steel frames;

- check the welding position, welding method, and dimensions; and,

- check the size and shape of the steel frames.

4.3.2. Carrying Steel Frame Members from Off-Site to On-Site

4.4. Effects of BIM-Based Construction Management System for SMEs in the Construction Phase

4.4.1. Integrated Management of Cost and Schedule

4.4.2. Quality Management Using BIM and Laser Scanning

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Data Availability

References

- Cheng, J.C.P.; Won, J.; Das, M. Construction and demolition waste management using BIM technology. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction, Perth, Australia, 29–31 July 2015. [Google Scholar]

- Sacks, R.; Eastman, C.; Lee, G.; Teicholz, P. BIM Handbook: A Guide to Building Information Modeling for Owners, Designers, Engineers, Contractors, and Facility Managers, 3rd ed.; Wiley: Hoboken, NJ, USA, 2018. [Google Scholar]

- Rajendran, P.; Gomez, C.P. Implementing BIM for waste minimisation in the construction industry: A literature review. In Proceedings of the 2nd International Conference on Management, Langkawi Kedah, Malaysia, 11–12 June 2012. [Google Scholar]

- Ahankoob, A.; Khoshnava, S.M.; Rostami, R.; Preece, C. BIM perspectives on construction waste reduction. In Proceedings of the Management in Construction Research Association (MiCRA), Langkawi Kedah, Malaysia, 5–6 December 2012. [Google Scholar]

- Anumba, C.; Dubler, C.; Goodman, S.; Kasprzak, C.; Kreider, R.; Messner, J.; Saluja, C.; Zikic, N. The BIM project execution planning guide and templates—Version 2.0. CIC Research Group, Department of Architectural Engineering, the Pennsylvania State University, University Park, PA, USA. 2010. Available online: https://www.bim.psu.edu/ (accessed on 12 January 2019).

- Williams, M. Building-information Modeling Improves Efficiency, Reduces Need for Changes. Bus. J. 2011. Available online: http://www.bizjournals.com/louisville/print-edition/2011/07/08/building-information-modeling-improves.html (accessed on 17 March 2017).

- Ham, N.; Lee, S. Project benefits of digital fabrication in irregular-shaped buildings. Adv. Civil Eng. 2019, 2019, 1–14. [Google Scholar] [CrossRef]

- Hamid, M.; Tolba, O.; El Antably, A. BIM semantics for digital fabrication: A knowledge-based approach. Autom. Constr. 2018, 91, 62–82. [Google Scholar] [CrossRef]

- Zhang, J.P.; Hu, Z.Z. BIM- and 4D-based integrated solution of analysis and management for conflicts and structural safety problems during construction: 1. Principles and methodologies. Autom. Constr. 2011, 20, 155–166. [Google Scholar] [CrossRef]

- Bryde, D.; Broquetas, M.; Volm, J.M. The project benefits of building information modelling (BIM). Int. J. Project Manag. 2013, 31, 971–980. [Google Scholar] [CrossRef]

- Lee, G.; Park, K.H.; Won, J. D3 city project—Economic impact of BIM-assisted design validation. Autom. Constr. 2012, 22, 577–586. [Google Scholar] [CrossRef]

- Kim, S.; Chin, S.; Han, J.; Choi, C.H. Measurement of construction BIM value based on a case study of a large-scale building project. J. Manag. Eng. 2017, 33, 05017005. [Google Scholar] [CrossRef]

- Ham, N.; Moon, S.; Kim, J.H.; Kim, J.J. Economic analysis of design errors in BIM-based high-rise construction projects: Case study of Haeundae L Project. J. Constr. Eng. Manag. 2018, 144, 05018006. [Google Scholar] [CrossRef]

- Hong, Y.; Hammad, A.W.A.; Sepasgozar, S.; Akbarnezhad, A. BIM adoption model for small and medium construction organisations in Australia. Eng. Constr. Archit. Manag. 2018, 26, 154–183. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Banihashemi, S.; Chileshe, N.; Namzadi, M.O.; Udeaja, C.E.; Rameezdeen, R.; McCuen, T. BIM adoption within Australian small and medium sized enterprises (SMEs): An innovation diffusion model. Constr. Econ. Build. 2016, 16, 71–86. [Google Scholar] [CrossRef]

- Dainty, A.R.J.; Leiringer, R.; Fernie, S.; Harty, C. BIM and the small construction firm: A critical perspective. Build. Res. Inf. 2017, 45, 696–709. [Google Scholar] [CrossRef]

- Lam, T.T.; Mahdjoubi, L.; Mason, J. A framework to assist in the analysis of risks and rewards of adopting BIM for SMEs in the UK. J. Civ. Eng. Manag. 2017, 23, 740–752. [Google Scholar] [CrossRef]

- Ghaffarianhoseini, A.; Doan, D.T.; Zhang, T.; Ur Rehman, A.; Amirhosein, G.; Nicola, N.; John, T. A BIM readiness & implementation strategy for SME construction companies in the UK. In Proceedings of the 33rd CIB W78 Conference 2016, Brisbane, Australia, 31 October–2 November 2016. [Google Scholar]

- Jernigan, F.E. BIG BIM Little BIM: The Practical Approach to Building Information Modeling-Integrated Practice Done the Right Way! 4Site Press: Salisbury, MD, USA, 2008. [Google Scholar]

- Erin, R.H. Achieving strategic ROI, measuring the value of BIM, in: Is it time for BIM? Achieving strategic ROI in your firm, Autodesk. 2016. Available online: https://damassets.autodesk.net/content/dam/autodesk/www/solutions/pdf/Is-it-Time-for-BIM-Achieving-Strategic-ROI-in-Your-Firm%20_ebook_BIM_fin al_200.pdf (accessed on 5 March 2017).

- Mark, R. SMEs: The key to the construction sector’s future. Latest News, Scape Group. 2017. Available online: https://www.scapegroup.co.uk/news/2017/smes-the-key-to-the-construction-sectors-future (accessed on 2 September 2017).

- National Statistics. Business Population Estimates 2017: Annual Business Population Estimates for the UK and Regions in 2017. Includes Revised Totals for 2013 to 2016, Taking Account of Updated Source Data; Department for Business, Energy & Industrial Strategy: London, UK, 2017.

- Department for Business, Enterprise and Regulatory Reform (BERR) (2006), SME STATISTICS 2006, BERR: Enterprise Directorate Analytical Unit. Available online: http://stats.berr.gov.uk/ed/sme/ (accessed on 22 January 2019).

- Lu, S.L.; Sexton, M.G.; Abbot, C. Key characteristics of small construction firms: A United Kingdom perspective. In Proceedings of the CIB W065/055 Commissions: Transformation through Construction, Dubai, UAE, 15–17 November 2008; Available online: https://www.irbnet.de/daten/iconda/CIB17619.pdf (accessed on 17 February 2019).

- Curran, J.; Blackburn, R.A. Researching the Small Enterprise, 1st ed.; Sage Publications: London, UK, 2001. [Google Scholar]

- Robinson, R.B., Jr.; Pearce, J.A. Research thrusts in small firm strategic planning. Acad. Manag. Rev. 1984, 9, 128–137. [Google Scholar] [CrossRef]

- Lu, S.; Sexton, M. Innovation in small construction knowledge-intensive professional service firms: A case study of an architectural practice. Constr. Manag. Econ. 2006, 24, 1269–1282. [Google Scholar] [CrossRef]

- Sexton, M.; Barrett, P. Appropriate innovation in small construction firms. J. Constr. Manag. Econ. 2003, 21, 623–633. [Google Scholar] [CrossRef]

- Yoo, M.; Choi, C.; Yoo, S.; Park, S. Communication performance of BLE-based IoT devices and routers for tracking indoor construction resources. IJIBC 2019, 11, 27–38. [Google Scholar] [CrossRef]

- Alsafouri, S.; Ayer, S.K. Review of ICT implementations for facilitating information flow between virtual models and construction project sites. Automat. Constr. 2018, 86, 176–189. [Google Scholar] [CrossRef]

- Singh, V.; Gu, N.; Wang, X. A theoretical framework of a BIM-based multi-disciplinary collaboration platform. Automat. Constr. 2011, 20, 134–144. [Google Scholar] [CrossRef]

- Suh, S.W.; Yoon, Y.S.; Kim, S.K. The Development of Schedule Risk Management Tools at the Preconstruction Phase in Building Construction-Focused on the Steel Work. J. Constr. Eng. Manag. 2005, 6, 177–185. [Google Scholar]

- Lim, C.H. Application of 3D information to reduce rework in a steel structure construction. Master’s Thesis, Hanyang University, Seoul, Korea, 2017. [Google Scholar]

- Jung, S.J. Building Construction - Construction of Steel Structure; Kimoondang: Seoul, Korea, 2013; ISBN 9788962255331. [Google Scholar]

- Kim, Y.H.; Lee, J.S.; Oh, J.K.; Kim, J.J. A study for derivation of participant’s information flow at framework construction based on BIM. Korea J. Constr. Eng. Manag. 2013, 14, 22–34. [Google Scholar] [CrossRef]

- Park, C.S.; Park, H.T. Improving contractibility analysis tasks by applying BIM technology. Korea J. Constr. Eng. Manag. 2010, 11, 137–146. [Google Scholar] [CrossRef]

- Eom, J.U.; Shin, T.S. A study on the automation of the connection modeling for steel structures based on BIM. J. Korean Soc. Steel Constr. 2010, 22, 99–108. [Google Scholar]

- Ko, A.R.; Lee, S.I.; Cho, Y.S. Development of automatic design system for steel connection based on S-BIM. Korea J. Constr. Eng. Manag. 2013, 29, 21–28. [Google Scholar]

- Eom, J.U.; Shin, T.S. A development of interface module between structural design and detail design based on BIM. J. Korean Soc. Steel Constr. 2011, 23, 113–124. [Google Scholar]

- Li, K.; Gan, Y.; Ke, G.; Chen, Z. The Analysis and Application of BIM Technology in Design of Steel Structure Joints. In Proceedings of the 4th International Conference on Sensors, Measurement and Intelligent Materials (ICSMIM 2015), Shenzhen, China, 27–28 December 2015; pp. 1166–1171. [Google Scholar]

- Oti, A.H.; Tizani, W. BIM extension for the sustainability appraisal of conceptual steel design. Adv. Eng. Inform. 2015, 29, 28–46. [Google Scholar] [CrossRef] [Green Version]

- Ryu, J.S.; Kim, K.H. A study of 4D simulation system using automatic scheduling process-The focus on steel structural construction. J. Architectural Inst. Korea 2009, 25, 173–180. [Google Scholar]

- Yun, S.H.; Park, C.W.; Lee, G.; Bongkeun, K. A study on a method for tracking lifting paths of a tower crane using GPS in the BIM environment. J. Architectural Inst. Korea 2008, 24, 163–170. [Google Scholar]

- Shin, T.S.; Yang, J. A proposal for the automation process of creating shop drawings in steel constructions. J. Architectural Inst. Korea 2009, 11, 267–274. [Google Scholar]

- Kim, K.T. A study on the application of RTLS technology for the automation of spray-applied fire resistive covering work. J. Korea Inst. Build. Constr. 2009, 9, 79–86. [Google Scholar] [CrossRef]

- Xie, H.; Shi, W.; Issa, R.R.A. Using RFID and real-time virtual reality simulation for optimization in steel construction. J. Inf. Technol. Constr. 2011, 16, 291–308. [Google Scholar]

- Liu, W.; Guo, H.; Li, H.; Li, Y. Using BIM to improve the design and construction of bridge projects: A case study of a long-span steel-box arch bridge project. Int. J. Adv. Robot. Syst. 2014, 11, 125. [Google Scholar] [CrossRef]

- Ginzberg, M.J.; Zmud, R.W. Evolving Criteria for Information Systems Assessment. In Proceedings of the IFIP WG 8.2 Working Conference, San Francisco State University, San Francisco, CA, USA, 11–12 December 1987. [Google Scholar]

- Will, P.; Olson, M.H. Managing investment in information technology: Mini case examples and implication. MIS Q. 1989, 13, 3–17. [Google Scholar] [CrossRef]

- Benjamin, R.I.; Rockart, J.F.; Wyman, S.M.J. Information technology: A strategic opportunity. Sloan Manag. Rev. 1984, 25, 3–14. [Google Scholar]

- Joan, S. IT Performance Measurement: A Discussion Paper on Measurement Practices. Available online: www.gsa.itpolicy.gov (accessed on 14 December 2018).

- Shannon, C.E.; Weaver, W. The Mathematical Theory of Communication; University of Illinois Press: Urbana, IL, USA, 1949. [Google Scholar]

- Mason, R.O. Measuring information output: A communication systems approach. Inform. Manag. 1978, 1, 219–234. [Google Scholar] [CrossRef]

- Delone, W.H.; Mclean, E.R. Information systems success: The quest for the dependent variable. Inf. Syst. Res. 1992, 3, 66–95. [Google Scholar] [CrossRef]

- Lucas, H.C., Jr.; Henry, C. Evolution of An Information System: From Keyman to Every Person. Sloan Manag. Rev. 1978, 19, 39–55. [Google Scholar]

- Hamilton, S.; Chervany, N.L. Evaluating information system effectiveness—Part I: Comparing evaluation approaches. MIS Q. 1981, 5, 55–69. [Google Scholar] [CrossRef]

- Saarineen, T. An expanded instrument for evaluating information system success. Inform. Manag. 1996, 31, 103–118. [Google Scholar] [CrossRef]

- Bailey, J.; Pearson, S. Development of a tool for measuring and analyzing computer user satisfaction. Manag. Sci. 1983, 29, 530–545. [Google Scholar] [CrossRef]

- Miller, J.; Doyle, B.A. Measuring the effectiveness of computer-based information systems in the financial services sector. MIS Q. 1987, 11, 107–124. [Google Scholar] [CrossRef]

- Kim, J.S.; Cho, Y.B.; Kim, Y.I. A study on factor analysis for successful informatization of SMEs. KMIS 1994, 1994, 129–163. [Google Scholar]

- Jung, K.E.; Lee, D.M. Reciprocal effect of the factors influencing the satisfaction of IS users. Asia Pac. J. Inf. Syst. 1995, 5, 199–226. [Google Scholar]

- Suh, K.S. A study on the factors affecting the success of end-user computing. APJIS 1995, 5, 259–288. [Google Scholar]

- Lves, B.; Olson, M.H.; Baroudi, J.J. The measurement of user information satisfaction. Commun. ACM 1983, 26, 785–793. [Google Scholar] [Green Version]

- Doll, W.J.; Torkzadeh, G. The management of end-user computing satisfaction. MIS Q. 1988, 12, 259–274. [Google Scholar] [CrossRef]

- Doll, W.J.; Xia, W. Confirmatory factor analysis of the end-user computing satisfaction instrument: A replication. JUEC. 1994, 9, 24–31. [Google Scholar] [CrossRef]

- Kim, S.; McHaney, R. Validation of the end-user computing satisfaction instrument in case tool environments. J. Comput. Inform. Syst. 2000, 41, 49–55. [Google Scholar]

- Hendrickson, A.R.; Glorfeld, K. On the repeated test-retest reliability of the end-user computing satisfaction instrument. Decis. Sci. 1994, 25, 655–667. [Google Scholar]

- AEC Magazine. Tekla Structure 19. 2013. Available online: http://www.aecmag. com/software-mainmenu-32/563-tekla-structures-19 (accessed on 2 February 2019).

- Kim, J.; Yoo, M.; Ham, N.; Kim, J.; Choi, C. Process of Using BIM for Small-Scale Construction Projects - Focusing on the Steel-frame Work. KIBIM Mag. 2018, 8, 41–50. [Google Scholar]

- Robinson, C. Structural BIM: Discussion, case studies and latest developments. Struct. Des. Tall Spec. Build. 2007, 16, 519–533. [Google Scholar] [CrossRef]

| BIM Function | Effect of BIM | Phase |

|---|---|---|

| 3D BIM conversion design | - Create object information through 3D modeling - Improved drawing consistency | Design/Construction |

| Visualization | - Improved understanding of work scope and tasks through improved communication - Design suitability review and VE enhancement function | Design/Construction |

| Linking through object base | - Automation of design changes - Prevention of drawing errors and notation omissions | Design/Construction |

| Clash check | - Enabling advance production of members through accurate drawings - Reduced field work and construction period and increased productivity | Design/Construction |

| 2D drawing creation | - Design, construction, and automatic extraction of tender drawings - Reduced field work and construction period and increased productivity | Design/Construction |

| Quantity calculation and estimation | - Quantity calculation and utilization depending on the part type, construction type, and phase - 4D + Cost = 5D (Estimate analysis) | Design/Construction |

| 4D simulation | - Creation of schedule, material, and allocation plans for personnel - 3D + Time = 4D (Process analysis) | Design/Construction |

| Temporary work and construction management | - Transfer of equipment, material transfer and loading path, operator working path planning, and pre-work coordination with equipment operator(s) | Construction |

| Combination with various analyses | - Analysis of energy efficiency, structural analysis, and Leadership in Energy and Environmental Design (LEED) analysis | Design |

| Category | Researcher/s (Year) | Research Content |

|---|---|---|

| Design | Eom and Shin [37] | Development of an automation module for modeling steel frame joints that can be used in structural detail design and modeling stages |

| Ko et al. [38] | Development of an automatic design system for steel connections based on set-based Design with structural building information modeling (S-BIM) | |

| Eom and Shin [39] | Development of an interface module that can exchange information between structural analysis software supporting structural design work and BIM software supporting detailed modeling and drawing work | |

| Li et al. [40] | Description of a modeling system for steel structure joints based of BIM at the design stage | |

| Oti and Tizani [41] | Introduction of a BIM-based structural sustainability appraisal system | |

| Construction | Ryu and Kim [42] | Development of a 4D simulation system prototype through automatic-process production |

| Yun et al. [43] | Development of a tracking method for lifting paths of a steel frame tower crane using global positioning system (GPS) in the BIM environment | |

| Shin and Yang [44] | Development of a smart creation process for shop drawings depending on drawing types | |

| Kim [45] | Application of real-time locating system (RTLS) technology for automating spray-applied fire-resistive covering work | |

| Xie et al. [46] | Using radio-frequency identification and real-time virtual reality simulation for optimization in steel construction | |

| Liu et al. [47] | Using BIM to improve the design and construction of bridge projects |

| Category | Evaluation Index | Contents of Evaluation Index |

|---|---|---|

| Content | C1 | Does the system provide the precise information you need? |

| C2 | Does the information content meet your need? | |

| C3 | Does the system provide reports that seem to be just about exactly what you need? | |

| C4 | Does the system provide sufficient information? | |

| Accuracy | A1 | Is the system accurate? |

| A2 | Are you satisfied with the accuracy of the system? | |

| Format | F1 | Do you think the output is presented in a useful format? |

| F2 | Is the information clear? | |

| Ease of Use | E1 | Is the system user friendly? |

| E2 | Is the system easy to use? | |

| Timeliness | T1 | Do you get the information you need in time? |

| T2 | Does the system provide up-to-date information? |

| Phase | Task | Authority | Location | BIM Use |

|---|---|---|---|---|

| Preconstruction | - Drawing and specification review | GC/SC * | On-site | - |

| - Construction planning | GC/SC | On-site | Visualization, 4D simulation | |

| - Shop drawing | GC/SC | On-site | Creation of 2D shop drawings | |

| - Cross check | GC/SC | On-site | Visualization, clash check | |

| Prefabrication | - Bringing steel framing members and reviewing the quantity | GC/SC | Off-site | Quantity calculation |

| - Steel frame cutting | GC/SC | Off-site | Creation of 2D drawings (cutting plan) | |

| - Steel frame mounting | GC/SC | Off-site | - | |

| - Steel frame assembly and welding | GC/SC | Off-site | Quantity calculation | |

| - Painting steel frame members | GC/SC | Off-site | Quantity calculation | |

| - Marking | GC/SC | Off-site | 3D BIM authoring | |

| - Precision inspection | GC/SC | Off-site | Visualization (e.g., laser scanning) | |

| - Carrying steel frame on and off the site | GC/SC | Off-site | Quantity calculation | |

| Construction | - Review of quantity brought to a laydown area | GC/SC | On-site | Quantity calculation |

| - Building and installing steel frame columns | GC/SC | On-site | Visualization, temporary works, and construction management | |

| - Steel girder, beam lifting, and installation | GC/SC | On-site | Temporary works and construction management | |

| - Vertical and horizontal inspection of the steel | GC/SC | On-site | Visualization (e.g., laser scanning) | |

| - Bolting and welding of the steel | GC/SC | On-site | Quantity calculation | |

| - Fireproof coating spray on steel | GC/SC | On-site | Quantity calculation | |

| - Steel frame installation finish (fastening) | GC/SC | On-site | Quantity calculation |

| Figure | Input | Attribute | Value | Type | |

|---|---|---|---|---|---|

| End plate (a) | Material | mat | S275JR | string |

| Thickness | tpl1 | 10 | double | ||

| Depth | hpl1 | 200 | double | ||

| Width | bpl1 | 180 | double | ||

| Bolt (c) | Diameter | diameter | 20 | double | |

| Grade | screw | 7990 | string | ||

| lbd | 60 | string | |||

| lwd | 67.1 | string | |||

| lba | 66 | double | |||

| nb | 3 | int | |||

| nw | 2 | int | |||

| rb1 | 40 | double | |||

| rb2 | 40 | double | |||

| rw1 | 40 | double | |||

| rw2 | 40 | double | |||

| lbtyp | 1 | int | |||

| Weld (b) | w3_size | 6 | double | ||

| Notch (d) | t_cut_length | 82 | double | ||

| t_cope_length | 26 | double | |||

| b_cut_length | 82 | double | |||

| b_cope_length | 26 | double | |||

| cope_fitting_type | 3 | int | |||

| Item | Description |

|---|---|

| Project name | Neighborhood residence facilities construction |

| Location | Gyeonggi-do Namyangju-si Sampae-dong 153-7 |

| Main structure | Steel structure |

| Construction duration | 04/12/2017–10/31/2017 |

| Total Cost (₩) | 761,406,020 |

| Quantity of prefabricated steel frame | 91.78 t |

| Building coverage | 294.00 m2 |

| Item of Comparison | GC/Specialty Contractor 1 (Selected) | GC/Specialty Contractor 2 | GC/Specialty Contractor 3 |

|---|---|---|---|

| Total construction cost (₩) | 761,406,020 (VAT included) | 818,840,000 (VAT included) | 1,017,514,000 (VAT included) |

| Prefabricated steel frame construction (₩) | 161,406,202 | 155,700,000 | 253,658,750 |

| Quantity of prefabricated steel frame (t) | 91.78 | - (No information on quantity) | 105.13 (Lack of information on the quantity calculation) |

| Material, labor, and overhead costs | Constructed based on steel billets | Missing information | Missing information |

| Whether BIM was applied | Yes | No | No |

| BIM Software | TEKLA | - | - |

| Drawing | Name | Quantity (Unit, EA) |

|---|---|---|

| General arrangement drawings | Block plan drawing, ground plan drawing, elevation drawing, cross-sectional drawing, and window and door drawing | 24 |

| Shop drawing | General arrangement drawing | 13 |

| Single part drawing | 20 | |

| Assembly drawing | 71 | |

| Others (anchor detail and 3D) | 3 |

| Girder Detail (2-Girders G24) | ||||

|---|---|---|---|---|

| ||||

| Bill of Material | ||||

| Mark | Description | Quantity | Length | Remark |

| MG19 | H250 × 125 × 6 × 9 | 2 | 1580 | SS400 |

| 250A2 | PL16 × 121 | 8 | 530 | SS400 |

| 250C2 | PL6 × 170 | 8 | 200 | SS400 |

| GP8 | PL9 × 149.5 | 2 | 232 | SS400 |

| SF15 | PL9 × 59.5 | 2 | 232 | SS400 |

| Field Bolts | Grid Location | |||

| 24–M16 T.S.B × 45, F10T | G23 | x4-x5/y3, EL+17.566 | ||

| 128–M16 T.S.B × 50, F10T | G23 | x4-x5/y3-y4, EL+17.566 | ||

| Main progress | Building steel frame columns and non-shrink grouting | Main progress | Installation of plates on the first and second floors, and installation of steel beams on the first floor. | ||||

|  | ||||||

| Date | 8/5/2017 | Quantity | 31.4 t | Date | 8/6/2017 | Daily construction quantity | 15.36 t |

| Manpower | 5 people | Rate of daily progress | 34.19% | Manpower | 5 people | Rate of daily progress | 50.89% |

| Equipment | Crane 1 EA | Payment of daily progress | ₩35,340,239 | Equipment | Crane 1 EA | Payment of daily progress | ₩22,999,953 |

| Main progress | Carrying steel frame members to the laydown area, installation of steel beams on the first, second, and third floors, and installation of plates on the third floor | Main progress | Installation of steel beams on the second and third floors | ||||

|  | ||||||

| Date | 8/7/2017 | Daily construction quantity | 19.48 t | Date | 8/8/2017 | Daily construction quantity | 20.12 t |

| Manpower | 5 people | Rate of daily progress | 72.06% | Manpower | 5 people | Rate of daily progress | 93.93% |

| Equipment | Crane 1 EA | Payment of daily progress | ₩24,196,437 | Equipment | Crane 1 EA | Payment of daily progress | ₩24,713,486 |

| Perspective | BIM Effects |

|---|---|

| Client |

|

| GC (SME) |

|

| SC (SME) |

|

| Category | Content | Accuracy | Format | Ease of Use | Timeliness | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | 3.81 | 3.79 | 3.58 | 3.00 | 3.37 | |||||||

| Index | C1 | C2 | C3 | C4 | A1 | A2 | F1 | F2 | E1 | E2 | T1 | T2 |

| Mean | 3.69 | 3.77 | 3.92 | 3.85 | 3.81 | 3.77 | 3.73 | 3.42 | 2.65 | 3.35 | 3.38 | 3.35 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoo, M.; Kim, J.; Choi, C. Effects of BIM-Based Construction of Prefabricated Steel Framework from the Perspective of SMEs. Appl. Sci. 2019, 9, 1732. https://doi.org/10.3390/app9091732

Yoo M, Kim J, Choi C. Effects of BIM-Based Construction of Prefabricated Steel Framework from the Perspective of SMEs. Applied Sciences. 2019; 9(9):1732. https://doi.org/10.3390/app9091732

Chicago/Turabian StyleYoo, Mooyoung, Jaejun Kim, and Changsik Choi. 2019. "Effects of BIM-Based Construction of Prefabricated Steel Framework from the Perspective of SMEs" Applied Sciences 9, no. 9: 1732. https://doi.org/10.3390/app9091732

APA StyleYoo, M., Kim, J., & Choi, C. (2019). Effects of BIM-Based Construction of Prefabricated Steel Framework from the Perspective of SMEs. Applied Sciences, 9(9), 1732. https://doi.org/10.3390/app9091732