1. Introduction

Granular materials are useful in a number of engineering applications, for example, to increase the gas diffusion layer in a proton exchange membrane fuel cell [

1], including the capillary pressure effect based on a fractal structure [

2]. On the other hand, porous materials are widely used in practice, particularly in fibrous porous media made up of fibers and solid particles [

3], as well as for ensuring the effective diffusion through charged porous media [

4].

A classifier as a device for the separation of bulk polydispersed mixtures is one of the most commonly used pieces of equipment in any production. A variety of requirements and material properties determine a variety of designs and operating processes of this equipment. Increasing the efficiency of chemical, heat, and mass exchange, as well as thermal and heterogeneous processes in most cases, is achieved using solid materials in a powder-like condition and in a certain granulometric composition. Therefore, classifiers are installed in technological lines aimed at separating granular mixtures into two or more phases. This process is predominantly realized for fine and coarse particles. For this purpose, a pneumatic classification is widely used, and pneumatic classifiers are installed in devices of different designs.

The complexity of interactions between gas, solid particles, and functional elements of the apparatus determines the difficulty to describe them, and there is so far an insufficient number of studies on the operating process. Therefore, the development of new designs (more efficient in terms of productivity) with a fundamentally new organization of the operating process should be based on experimental studies and a mathematical synthesis of the obtained results. This fact determines the relevance of this work.

Granular materials are separated into fine and coarse fractions mainly under the influence of gravitational and inertial forces in the ascending gas flow in gravitational pneumatic classifiers or centrifugal-type devices [

5]. The development and use of pneumatic classifiers in an industry are complicated due to the absence of general approaches for calculation of their parameters, which should be based on reliable mathematical models of the operating process. Consequently, one of the main objectives of recent research is developing a comprehensive approach for modeling the suspended layer when it is transferred from the polydispersed fraction in the apparatus and separated by the turbulent gas flow.

Most designs of pneumatic classifiers operate quite efficiently as separators for the removal of fine fractions from granular mixtures with a content of fine fraction in the starting material in a range of 15–20%. When separating binary granular mixtures with an equal content of fine and coarse fractions, the typical pneumatic classifiers provide purity of the obtained fractions of 70–75% maximum. However, technologies requiring a clean separation product are needed for ensuring the efficiency of at least 95%. Therefore, it is necessary to develop new designs of related devices with a fundamentally different organization of pneumatic classification processes and pneumatic enrichment of granular mixtures in order to obtain sufficiently clean separation products.

An important objective in the study of pneumatic classification is the development of the mathematical model, which allows determining the concentration of fine particles in a suspended layer of granular material and, consequently, the entrainment of fine particles from this layer [

6]. It should be noted that there is a sufficient number of empirical equations to determine the entrainment of a fine fraction from the polydisperse mixture by the gas flow. However, these equations contain empirical constants, the determination of which is highly complicated. Moreover, these constants can be evaluated for a certain design of apparatus only.

Thus, an urgent problem is present in developing theoretical foundations of the pneumatic classification process in order to obtain generalized solutions that can be used for further research in practice.

2. Literature Review

The simplest pneumatic classifiers with vertical channels are not widely used since they do not provide the required separation efficiency [

7]. In such devices, a raw material is loaded into the working volume, causing an increase in gas-dispersed flow density. Consequently, the mixture has poor contact with the gas flow. Therefore, the coarse fraction entrains the fine fraction, which decreases the efficiency of fractional separation.

Further development of such devices was presented by zigzag pneumatic classifiers [

8,

9], wherein centrifugal forces arise due to the gas flow turns, causing particle circulation. This effect reduces flow density and, consequently, increases the efficiency of the classification process. However, this type of pneumatic classifier was modernized, and the new design has a vertical channel with a rectangular cross-section, in which blind shelves are installed at two angles to the gas flow [

10,

11]. However, blind shelves significantly increase the hydraulic resistance of the device and turbulize the flow, which increases entrainment of a coarse fraction into the cyclone.

The device with inclined perforated shelves allows implementing an active aerodynamic mode of suspending the granular layer. Consequently, entrainment of the coarse fraction and energy costs of the pneumatic classification process are reduced. The apparatus of this design enables effectively removing the fine fraction of less than 1 mm from the polydisperse mixture of granular mineral fertilizers [

12].

Pneumatic classifiers with a fluidized bed of the granular layer and perforated grate [

13,

14] are mainly intended for separation of the bulk product in order to separate particles less than 0.5 mm from the layer. This allows extending the separation possibility to significantly increase the gas flow rate, which leads to increased energy costs.

Pneumatic classifiers based on the action of centrifugal forces are mainly used for separation of fine materials with a particle size less than 0.04–0.05 mm [

15,

16]. Their main disadvantage is the content of a significant amount (about 20–25%) of fine particles and the presence of a coarse fraction in the final product. Moreover, centrifugal turbo-air classifiers are highly complicated [

17,

18].

Thus, a rhomb-shaped pneumatic classifier is a relatively new device, which is applied in the technology of producing organic mineral fertilizers [

19]. Due to the absence of internal contact elements, the rhomb-shaped pneumatic classifiers have a minimized hydraulic resistance. Moreover, a relatively high degree of product separation in such an apparatus is achieved by cyclic loading of raw material into the apparatus, thereby creating a rotating vortex layer; accordingly, prolongation of the contact of particles with the gas flow is efficiently provided.

Complicated nonlinear dependencies describing the mass transfer process can be numerically calculated using the artificial intelligence systems based on the generalized approach presented in Reference [

20]. Additionally, research work [

21] was devoted to decreasing the complexity of the practical use of empirical constants and their applicability to specific conditions. However, the mechanism of particle transportation in a fluidized bed depends on a number of hydrodynamic effects, including collisions of particles, and on the characteristics of both solid particles and suspended layer. Moreover, the use of a graphical method for calculating the process of pneumatic classification using separation curves is proposed in Reference [

22]. Unfortunately, in this case, computer realization is not possible.

Due to the abovementioned issues, the aim of this article is to develop a reliable mathematical model of the pneumatic classification process for polydisperse mixtures of granular material in a rhomb-shaped apparatus.

To achieve this aim, the following objectives are formulated for significantly improving the previous research in the field of the pneumatic classification and increasing the efficiency of the operating process:

Development of the physical model of the hydrodynamic structure of a layer suspended in the working volume of the rhomb-shaped apparatus;

Experimental studying of the pneumatic classification and ensuring the reliability of the operating process;

Development of the mathematical model based on solving differential equations describing the non-stationary mass transfer process;

Analytical determination of the fine fraction concentration distribution at the height of the apparatus; theoretical substantiation of the geometrical parameters, a wide range of variations of which are proposed in previous research;

Obtaining regression dependencies for estimating the operating parameters of the pneumatic classification process (e.g., a period of granular material supply to provide the required separation efficiency).

The relevance of this research is proven by the obtained results within the research projects of Sumy State University and Technical University of Kosice with the support of the governments of Ukraine and Slovakia.

3. Research Methodology

3.1. Simplified Model of the Pneumatic Classification Process

A large number of scientific publications were devoted to determining entrainment of a fine fraction from a polydisperse layer suspended in the working volume of gravitational pneumatic classifiers. The analysis of existing dependencies shows that they have special peculiarities due to a large number of assumptions. The previous studies considered the equations most used in research practice, which are reduced to the dependencies for the entrainment rate that have the following form [

12]:

where

C is concentration of fine particles in a layer (kg/kg),

t is time of the process (s),

Ge is the entrainment rate (kg/s),

Gl is the mass of particles in the layer (kg), and

k is entrainment rate as an empirical separation constant (s

−1).

However, the obvious simplicity of Equation (1) is negated by the ambiguous definition of the entrainment rate constant k as a function of the following parameters: gas flow rate, averaged over the cross-section of the apparatus; velocity of a rotating solid particle; internal diameter of the apparatus; average diameter of solid particles; height of the suspended layer; density of the gas flow and solid particles; porosity of the suspended layer; Froude and Reynolds numbers.

In Reference [

11], the correlation for determining the average value of the coefficient

k is presented in the following form:

where

Cmax is maximum concentration, and

T is the time of the separation process.

Due to the complexity of parameter identification, there were no practical applications of Equations (1) and (2) in practice.

3.2. The Physical Model of the Hydrodynamic Structure of a Suspended Layer

Physical and theoretical fundamentals of developing a pneumatic classification method for granular materials are aimed at the efficient use of the operating area of the classifier. This allows obtaining an effective impact of the air flow on a granular material for ensuring a significant increase of the separation quality. Consequently, the design of a device for pneumatic classification of granular materials by changing the form of the apparatus working volume as rhomb-shaped cross-sections is proposed. In this case, the increase of separation quality and the decrease of the hydraulic resistance, as well as specific productivity and efficiency of the pneumatic classification process, can be highly improved.

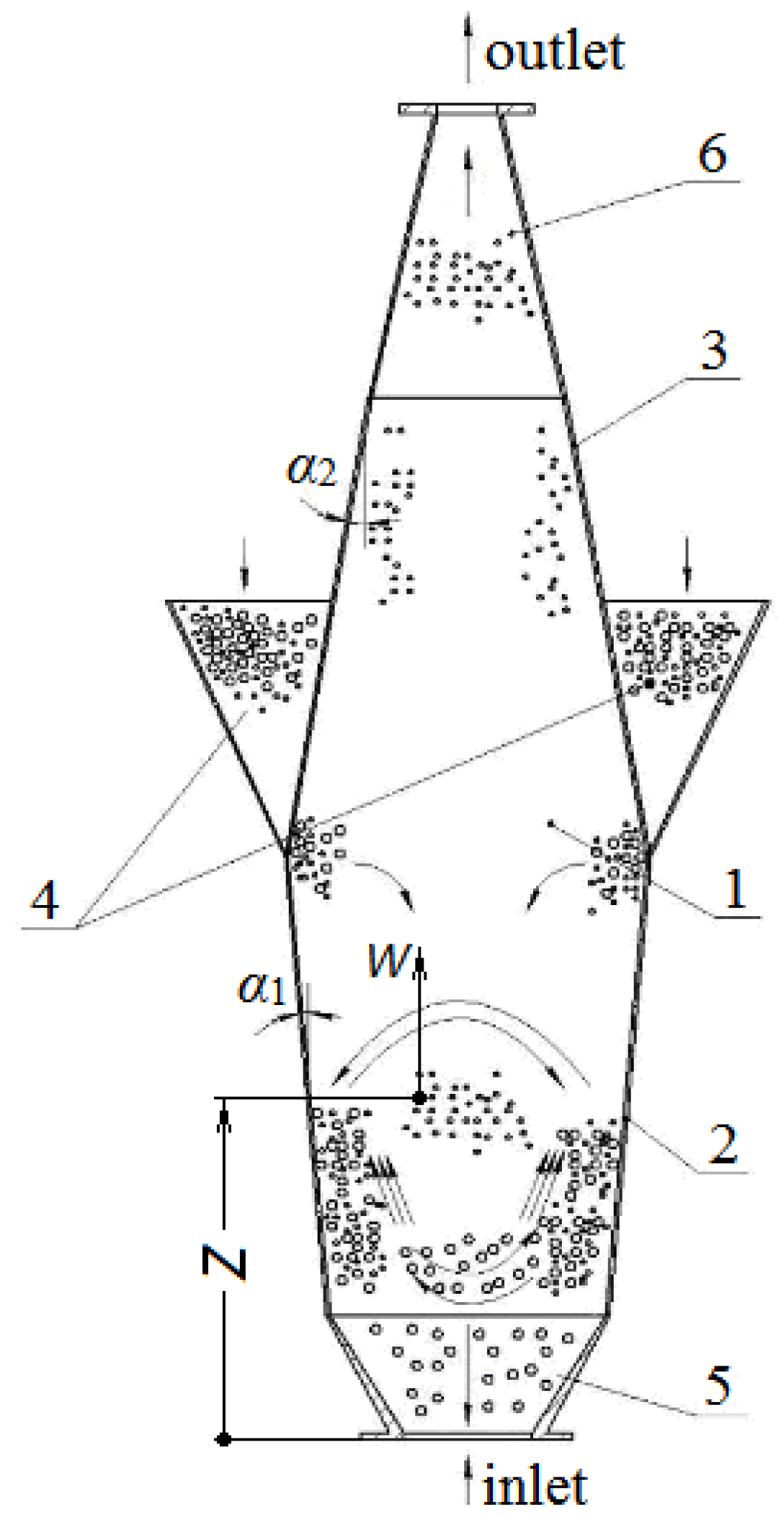

To realize the abovementioned design, a new method of pneumatic classification of granular materials is proposed (

Figure 1).

The rhomb-shaped body 1 has an angle

α1 of separation

Section 2, which is equal to 8–9°.

Section 3 of fine fraction removal has an angle

α2 in a range of 10–11°. The loading areas 4 are located in the middle of the body symmetrically to its vertical axis.

Feedings of the raw material and the air flow are carried out into the body of the apparatus, and raw material is also periodically fed into the middle part of the body through its two-way input. The distribution of fractions is realized in the bottom part of the apparatus. The coarse fraction falling down to the bottom is withdrawn through the pipe 5. The fine fraction carried out into the upper part of the apparatus by the flow is accelerated and withdrawn from the apparatus body through the pipe 6.

The periodical two-way feeding of material into the middle part of the rhomb-shaped apparatus enables creating the conditions under which a layer of material starts rotating, and the flow presses itself from one wall to another. This layer is created by feeding the initial amount of material into the apparatus in at least three steps and it partially closes the inlet of the air flow into the pneumatic classifier. Due to the sharp increase in flow velocity, a turbulent motion is created, and the material layer is pressed and moved from one wall to another by the acceleration of the flow. It allows providing additional material sifting at the bottom of the device, as well as improving the efficiency of the separation process.

3.3. The Mathematical Model of the Pneumatic Classification Process

The concentration of a fine fraction in space and time is described by the following first-order partial differential equation [

23]:

where

= {

U,

V,

W} is a vector of particle velocity with components

U,

V, and

W (m/s),

C* is the limiting concentration of a fine fraction in the suspended layer (kg/kg), and

K is the entrainment rate (s

−1).

For a relatively small width of the cross-section in comparison with the apparatus height, it can be considered that ∂/∂

X = 0, and ∂/∂

Y = 0, where

X and

Y are coordinates of the cross-section. In this case, Equation (3) can be rewritten in the following form:

where

W is a vertical component of the velocity in the

Z-direction (

Figure 1).

Equation (4) determines the kinetic removal of fine particles from a suspended layer for the case of small rotating velocity in comparison with the gas flow rate.

The consequent use of the direct and inverse Laplace transforms allows obtaining the general solution of the first-order partial differential Equation (4) describing the non-stationary problem for determining the concentration of particles by the apparatus height in time [

24].

where

Cin and

C0 are the inlet and initial concentrations as the boundary and initial conditions, respectively (kg/kg).

Particularly, in the case of

Cin =

C0, Equation (5) can be rewritten in the following form:

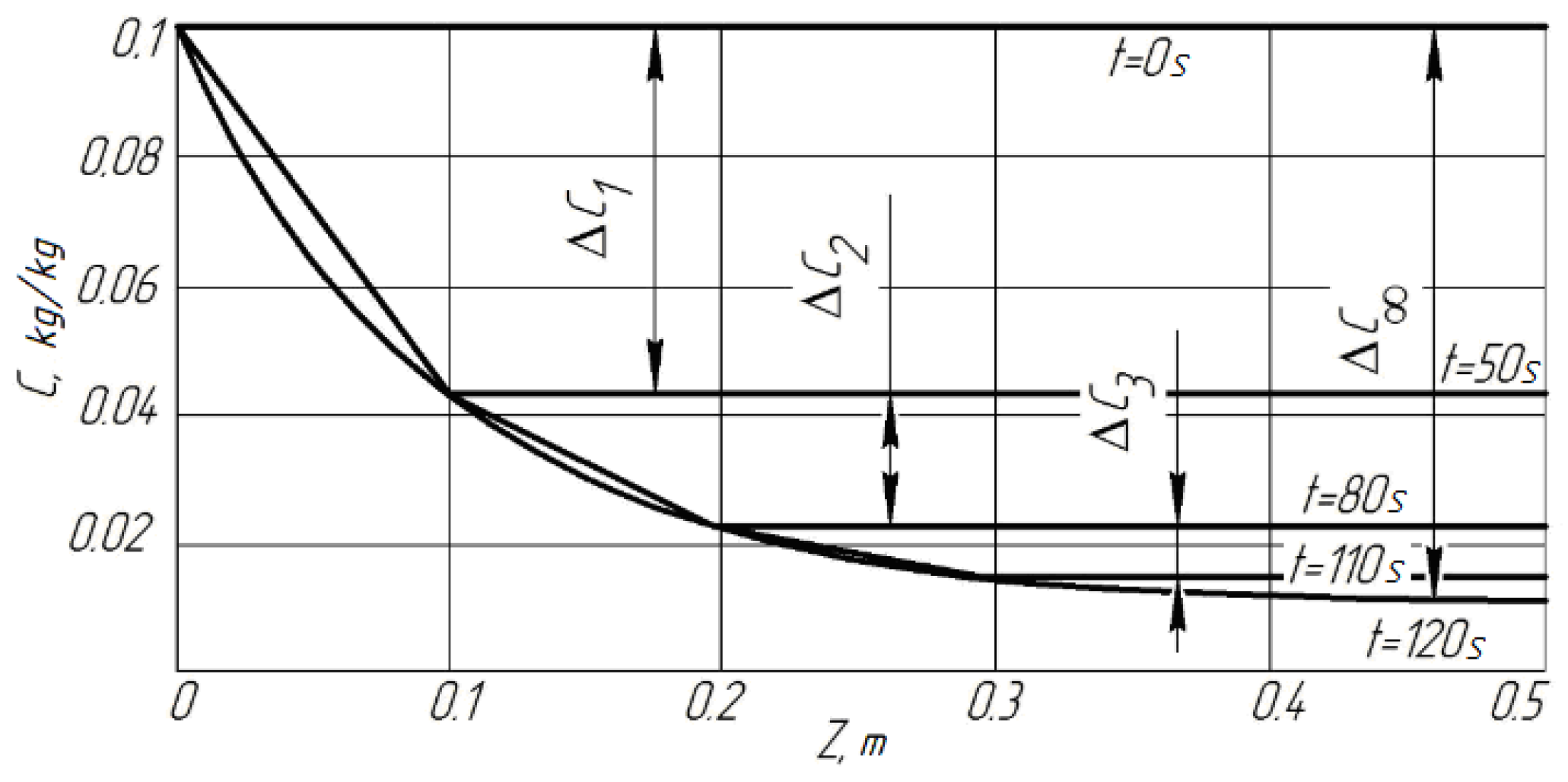

The mathematical model described by the general solution (Equation (6)) of Equation (4) allows graphically representing the dependence between the concentration of fine particles and vertical coordinate in time (

Figure 2).

The obtained results prove the fact that the concentration of fine particles is reduced by the apparatus height in time. This fact allows ensuring the separation efficiency. However, a small number of fine particles are removed from the apparatus with the gas flow.

4. Results and Discussion

4.1. Experimental Research of the Pneumatic Classification Process for Granular Materials

The experimental stand was based on a pneumatic classification device for granular materials with the changed shape of the operating volume. The proposed geometry allowed increasing the separation quality and reducing hydraulic resistance for the consequent increase in the specific volume rate and efficiency of the pneumatic classification process.

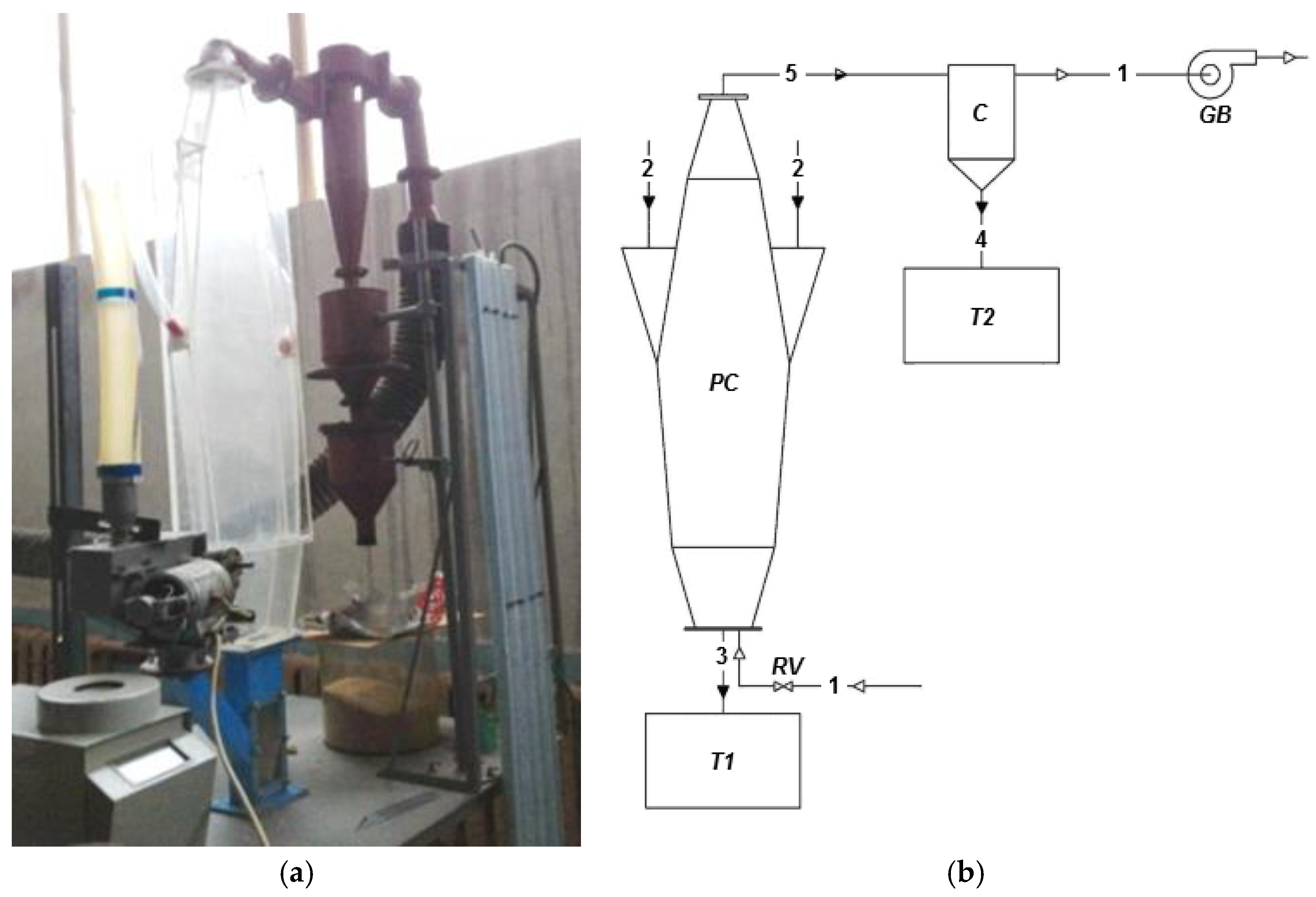

Experimental research of granular materials was carried out in the laboratory model of the pneumatic classifier. The related experimental stand and its technological scheme are presented in

Figure 3.

The initial mixture of a bulk material entered the loading tank of the apparatus. After that, the mixture moved into the middle part of the pneumatic classifier (PC). Air flow entered the lower part of the apparatus. The flow rate was regulated by a calibrated collector with the regulating valve (RV). A fine fraction was removed by the air flow to a cyclone (C). As a result, fine particles were deposited in the tank T2, and the air flow was removed from the apparatus. Coarse particles fell down into the lower part of the apparatus and they were removed into the tank T1 through the switchgear. A suction air flow was created using the gas blower (GB).

The separation occurred directly in the apparatus body with the two following operating areas:

Lower part—separation area with rotating and mixing material. In this part, fine and coarse fractions were removed from a rotating layer.

Upper part—area in which the small fraction was dispersed and removed from the apparatus.

The fine fraction removed from the apparatus passed through the cyclone and deposited into the tank. The coarse one fell down and moved into another tank.

It should be noted that, in previous work [

24], the factors influencing the hydrodynamics of the device were substantiated. In particular, the shape of the body is rhombic with a diffuser angle of about 8–9°, and a diffuser angle of 10–11°. Moreover, since continuous product loading has a negative impact on the separation quality, periodic loading should be used. As a result, using periodic loading allows ensuring the appearance of rolling swirls in the separation section since these swirls prevent removal of the gas-dispersed mixture from a suspended layer.

The research methodology of studying the efficiency of the pneumatic classification process was as follows:

As a model material, a binary mixture of quartz sand was selected. The river sand was dried in a muffle furnace.

The use of a set of sieves (0.63, 0.4, 0.32, 0.20, and 0.16 mm) allowed obtaining the different charges of sand.

After the charge was weighed by an electronic scale “Momert-6000” with an accuracy of 0.1 g, the material was loaded into the hopper for the consequent raw material feeding.

The gas blower was switched on, and the air flow was controlled by the clamp pressurizing the air flow.

The pressure in the apparatus body was measured by the “U-shaped” liquid pressure gauges. Air velocity was measured using the Pitot–Prandtl tubes inserted at different cross-sections of the body. The tubes were connected to the micromanometer with a sloping tube “MMN-240(5)-0.1”, which measured the pressure difference at the cross-sections of the apparatus body. The pressure values were recalculated into the velocity. The material charges were periodically loaded into the device. To start a process, a triple amount of material was firstly fed to create a rotating layer in the body. Then, the loading hopper cover was opened every 1 min, and the next amount of material (50–60 g) was fed into the body for 15 s. This created a specific load rate in a range of 18–65 kg/(m2·s). The rotating layer was saturated again, and the suspended layer was stabilized.

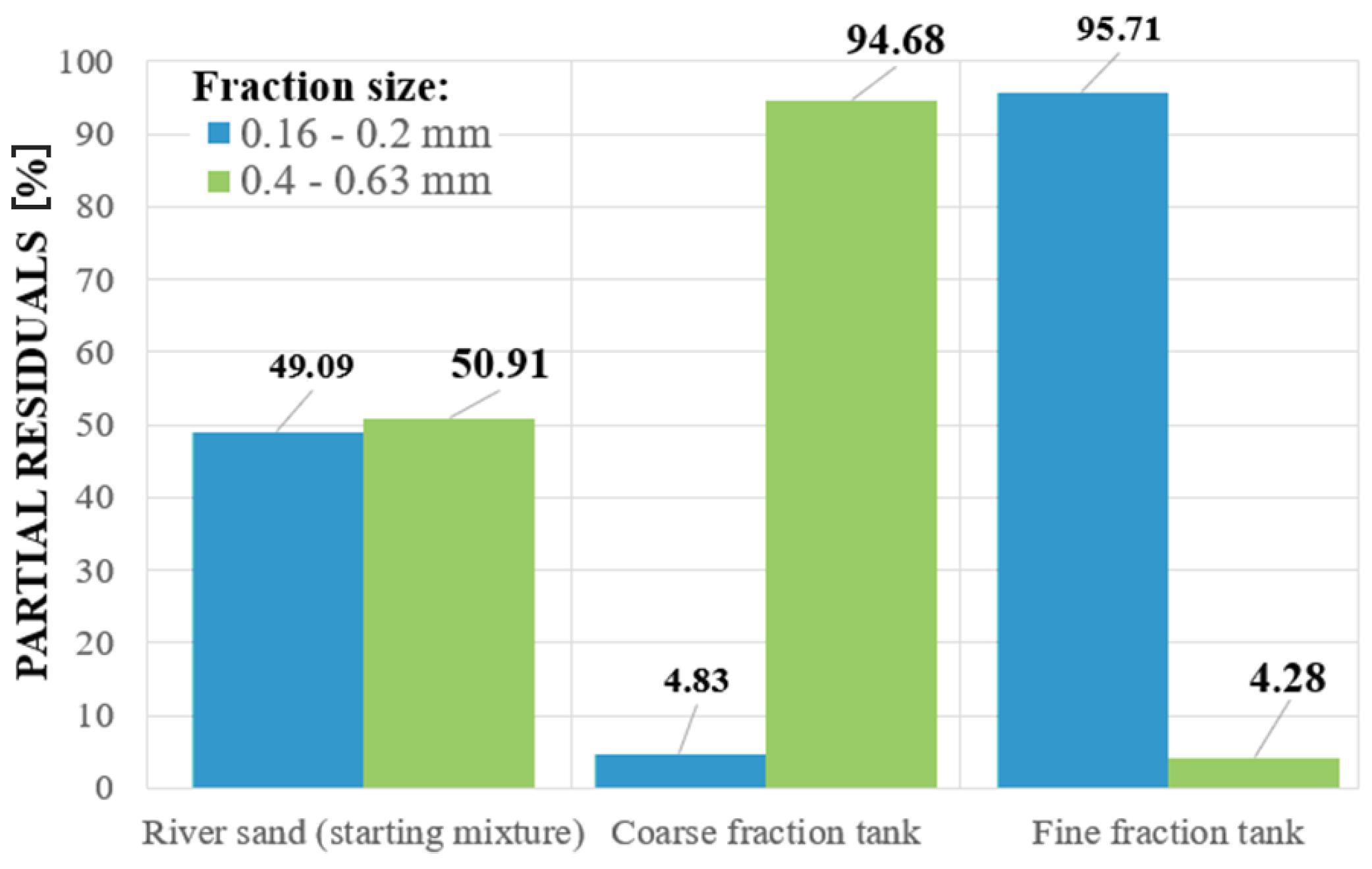

As a result, the optimal parameters of the process were selected. The obtained results are presented in

Figure 4 and summarized in

Table 1.

The data summarized in

Table 1 and shown in

Figure 4 reflect the possibility of efficient separation of mixtures for various bulk materials in rhomb-shape pneumatic classifiers. Since the device is able to separate a gas-sand mixture, the fractions of which have relatively equal velocities, the separation efficiency should be increased significantly for the case of larger granules of different shapes and different speeds. Contamination of the coarse fraction by a fine one is not less than 5% for the sand mixture. Consequently, for the case of other materials, this value should be reduced. As a result, the developed apparatus can provide a highly efficient separation process of polydisperse mixtures for various bulk materials.

4.2. Parameter Identification of the Pneumatic Classification Process

This section describes the analysis of the impact of the loading and unloading time for material in a layer on the quality of pneumatic classification. The presented pneumatic classification process is cyclic and divided into two main stages (2 and 3 in

Figure 5). At stage 2, the material is fed into the body by a dosing device. At stage 3, the gradual unloading of granular material accumulated in a suspended layer occurs. In the process of feeding, the operating time of the dosing device significantly impacts the separation efficiency.

At the initial stage 1 (continuous loading), the material is continuously fed into the pneumatic classificator. This mode reduces the total time of the process, but the separation efficiency does not exceed 60%. Consequently, the loss of the main fraction reaches 40%. At the first stage (operating area), there is a decrease in the losses of the main fraction before loading the material layer. Reducing the loss occurs until 20 s before reloading, and then the process proceeds to the next stage (flow fracture area). At this stage, losses of the main fraction increase. The loading time additionally affects the total time of the process.

To optimize the time

T for additional loading of various materials, the following dependence is proposed based on the obtained experimental data:

where

Dc and

Df are particle sizes of a coarse and fine fraction (mm), and

a and

n are experimental constants.

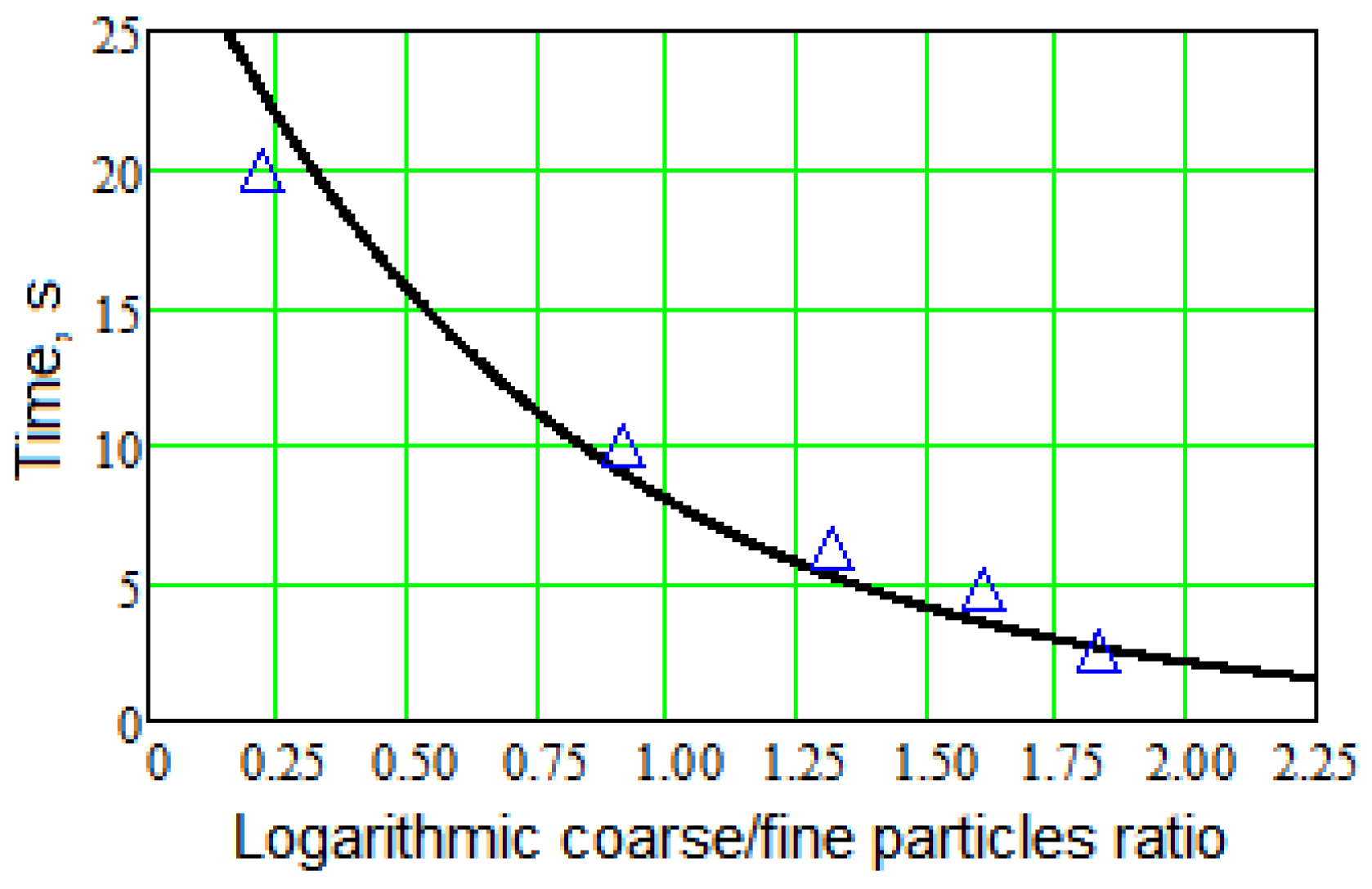

This dependence (

Figure 6) shows that the greater the ratio of coarse and fine fractions is, the lower the time it takes to reload the rotating layer is. Additionally, the closer the boundary of the separated fractions is, the more time is required to reload the material.

Increasing the feeding time reduces the total time of the process, but negatively impacts the separation efficiency since it increases the loss of the main fraction and its contamination by the fine fraction. Additionally, an oversaturating mixture in the rotating layer gradually falls down. This fact leads to the overlap of gas flow at the inlet. As a result, the gas flow removes coarse and fine fractions.

Based on the obtained data, optimal time limits should be selected for each cycle of loading that affects energy loss and the efficiency of the process. Thus, a mathematical model for evaluating the parameters of Equation (7) is proposed. This model is based on using quasi-linear regression analysis [

25]. As a result, the following dependencies are obtained:

where

ψ = ln(

Dc/

Df) is the logarithmic ratio of coarse to fine particles,

i is an experimental point number, and

N is the total number of experimental data points.

As a result of quasi-linear regression analysis based on Equations (8) and (9) for the obtained experimental data presented in

Figure 6, the following values of the experimental parameters

a and

n were evaluated:

a = 30.74,

n = 1.35.

The comparison of the approximating curve based on the regression Equations (8) and (9) with the corresponding experimental results (

Figure 6), resulting in the Pearson product–moment correlation coefficient 0.992, confirms the reliability of the proposed mathematical model.

It should be noted that the obtained results significantly complement previous studies. In particular, in previous work [

23,

24], recommendations were made for the geometrical parameters of pneumatic classifiers. The mathematical model proposed in this article allows analytically estimating the operating parameters of the process, particularly the period of supply for granulated material to the apparatus for ensuring the efficient separation. Additionally, based on analytically solving the differential Equation (4) describing the process of mass transfer, the analytical dependences in Equations (5) and (6) for the non-stationary concentration of a fine fraction on apparatus height are obtained. This approach allows theoretically substantiating the choice of geometric parameters of the pneumatic classifier in order to attain the required permissible concentration.

Despite the abovementioned factors, studying the coupled hydroaerodynamics and mass transfer problem for gas-dispersed mixtures still remains an unresolved problem. Furthermore, the procedure of parameter identification of the developed mathematical model using computational intelligence is an outstanding question.

5. Conclusions

The proposed physical model of granular mixture separation in rhomb-shaped pneumatic classifiers allows explaining the hydrodynamic features of separation into fractions. The related mathematical model of the classification processes of granular mixtures was developed to obtain the generalized equation for determining the concentration of a fine fraction in a suspended layer. A cyclic method of carrying out the process of pneumatic separation is proposed. The initial cycle consists of loading a suspended layer with the outlet mixture for 15–20 s. The next cycle involves gradual unloading of the material accumulated in the layer.

The experimental research on the separation efficiency for granulated material also showed the presence of two different areas. In the first area, loss of the coarse fraction decreased, contamination of a coarse fraction by the fine particles was observed, and the flow rate increased. In the second area, flow fracture occurred, and flow rate and loss of the coarse fraction increased.

The obtained experimental results allowed evaluating the rational geometrical parameters of the working space in pneumatic granulators, as well as verifying the proposed mathematical model based on the implementation of the quasi-linear regression procedure. As a result, it was shown that the rhomb-shaped pneumatic classifier provides an effective separation of granular material with the purity of the target fraction up to 95%. Thus, contamination of a fine fraction by the coarse one does not exceed 5%.

A pneumatic classification method for granular materials using the rhomb-shaped apparatus was developed, and the reliability of the operating process was ensured based on the influence of the flow on the granular material concentrations. The abovementioned approach can be used to optimize geometrical designs of pneumatic classifiers, as well as to evaluate technological parameters of the operating process. Finally, the reliability of the proposed mathematical model was justified by the relatively high value of the correlation coefficient (0.992).

The practical significance of the research was proven by the application of the developed methodology to improve the level of automation and the quality of granular materials obtained using the pneumatic classification at “Sumyfitofarmacia” Ltd., (Sumy, Ukraine) specialized in producing raw materials for pharmaceutical and food-processing industries in Eastern Europe (agreement No. 51.18-02.15 SP).

Further research will be aimed at the improvement of the recent analytical and experimental approaches for carrying out the coupled analysis of hydroaerodynamics and mass transfer of gas-dispersed mixtures in separators and pneumatic classifiers. The corresponding scientific and methodological approaches based on using artificial neural networks for parameter identification of the proposed mathematical model will be developed.