An Inductive Debris Sensor for a Large-Diameter Lubricating Oil Circuit Based on a High-Gradient Magnetic Field

Abstract

:1. Introduction

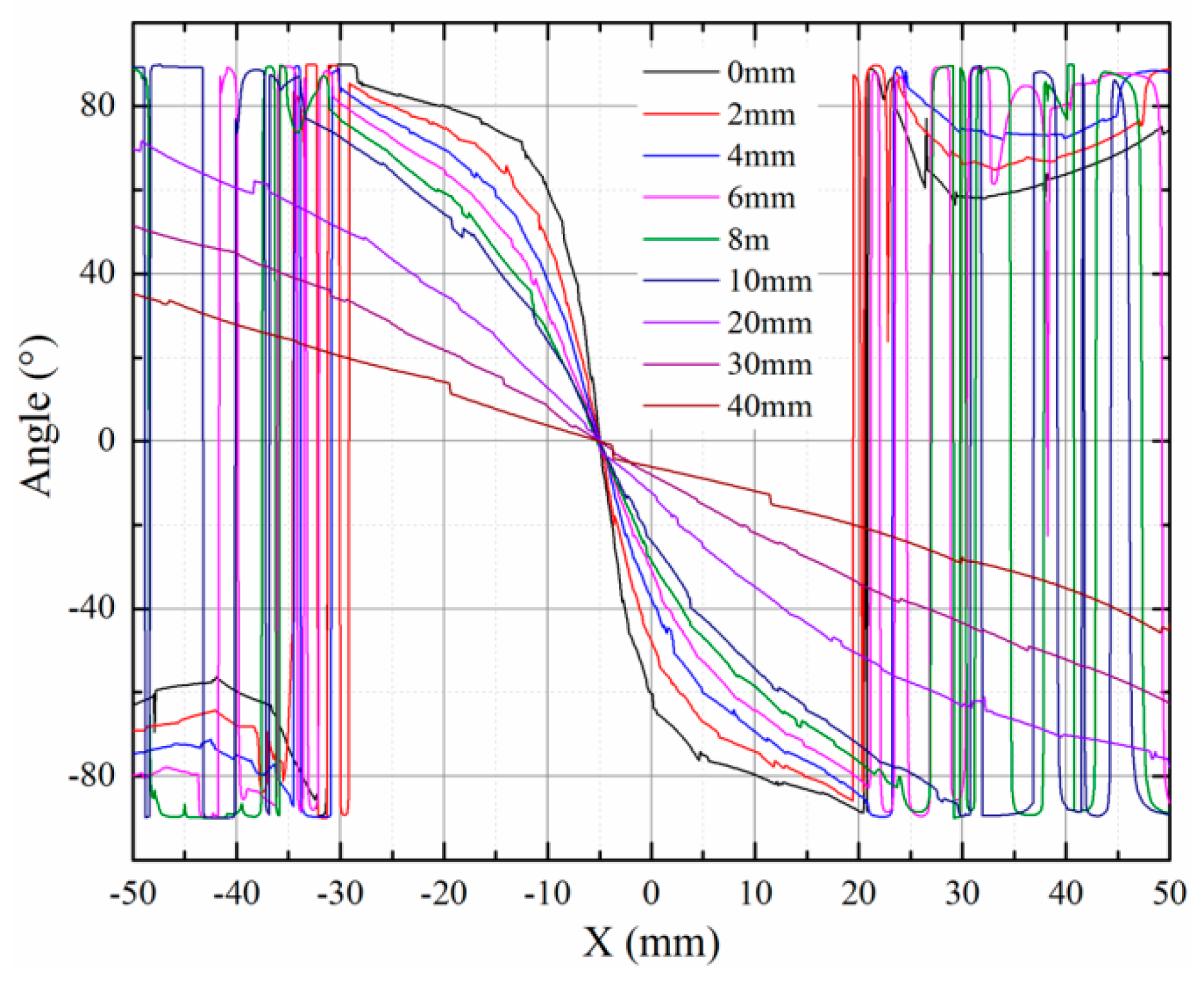

2. Sensor Structure and Mathematical Model

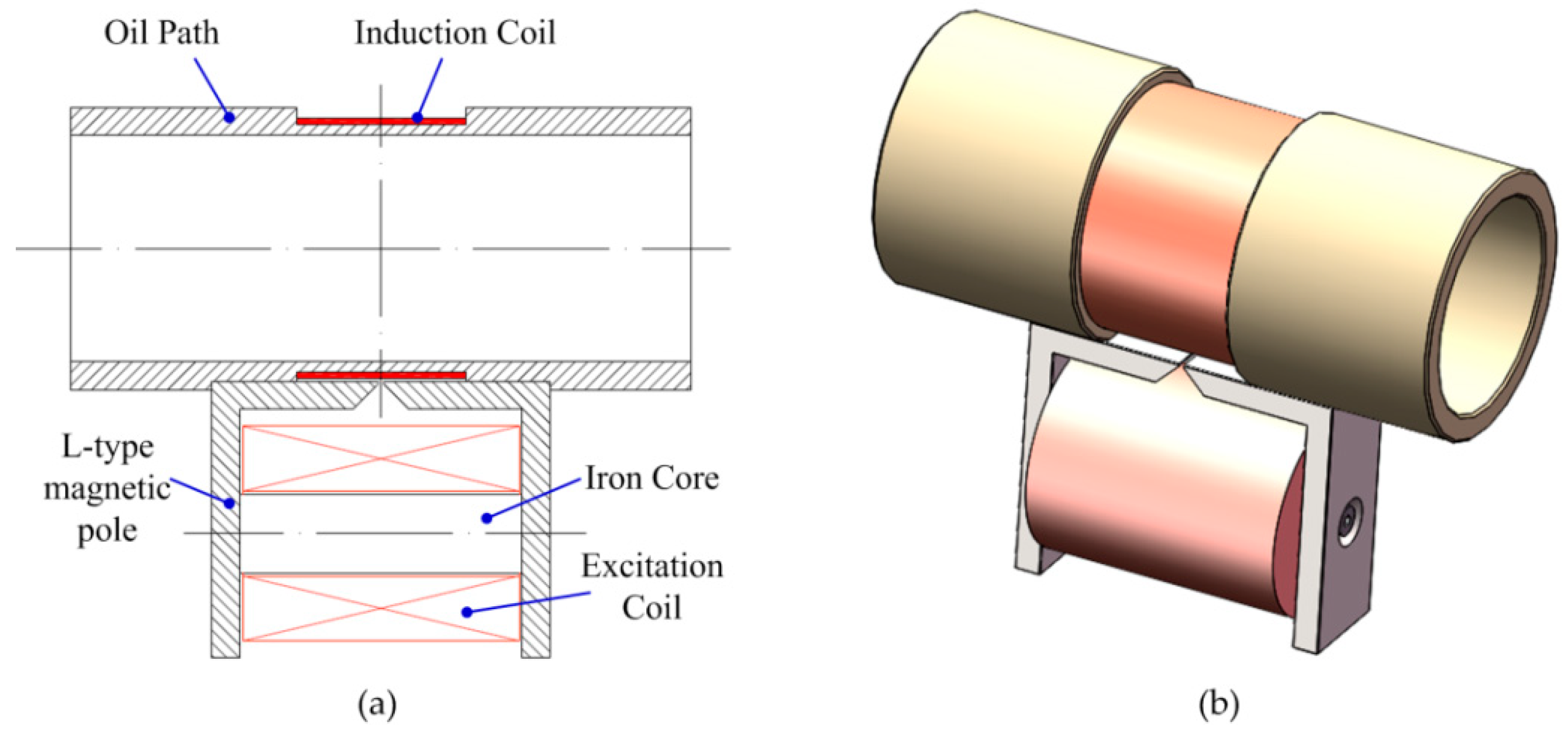

2.1. Sensor Structure

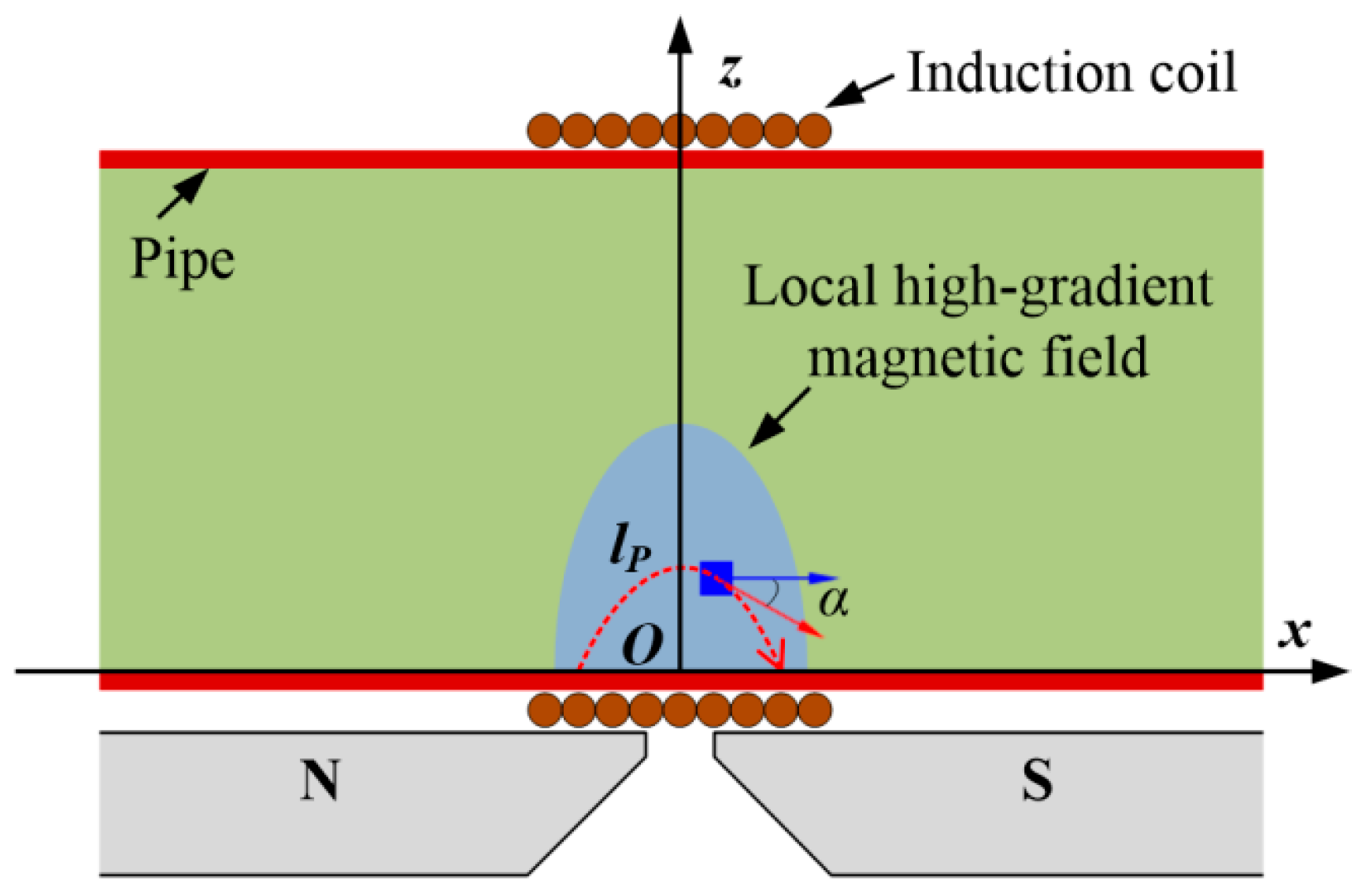

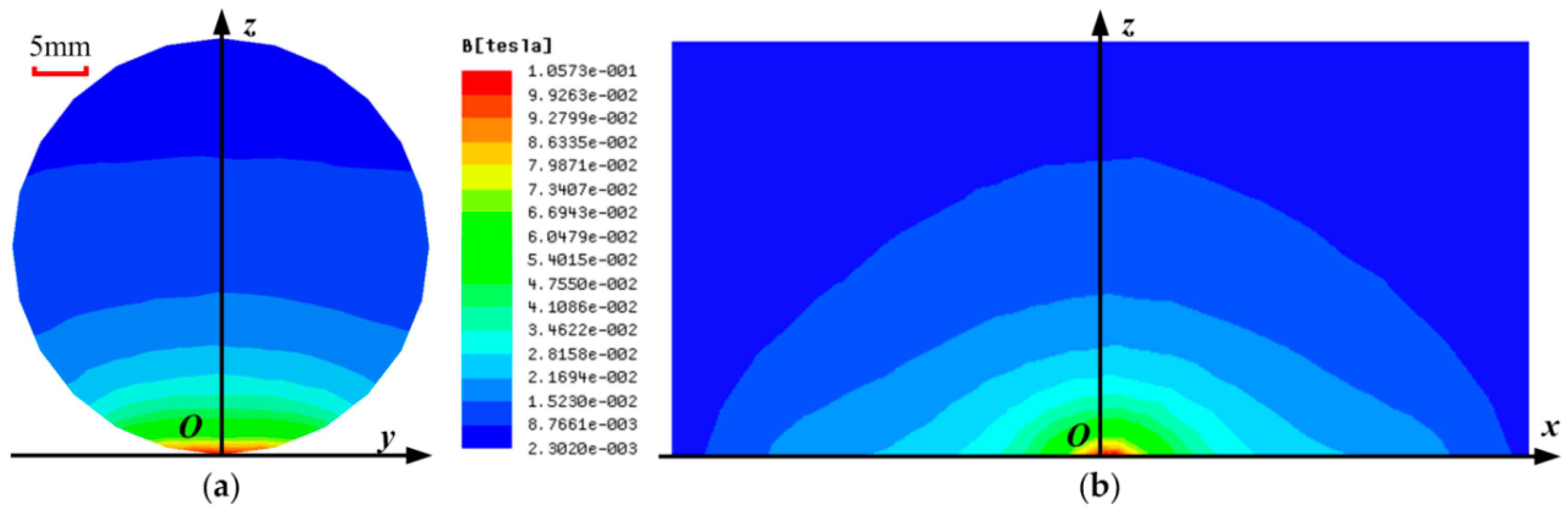

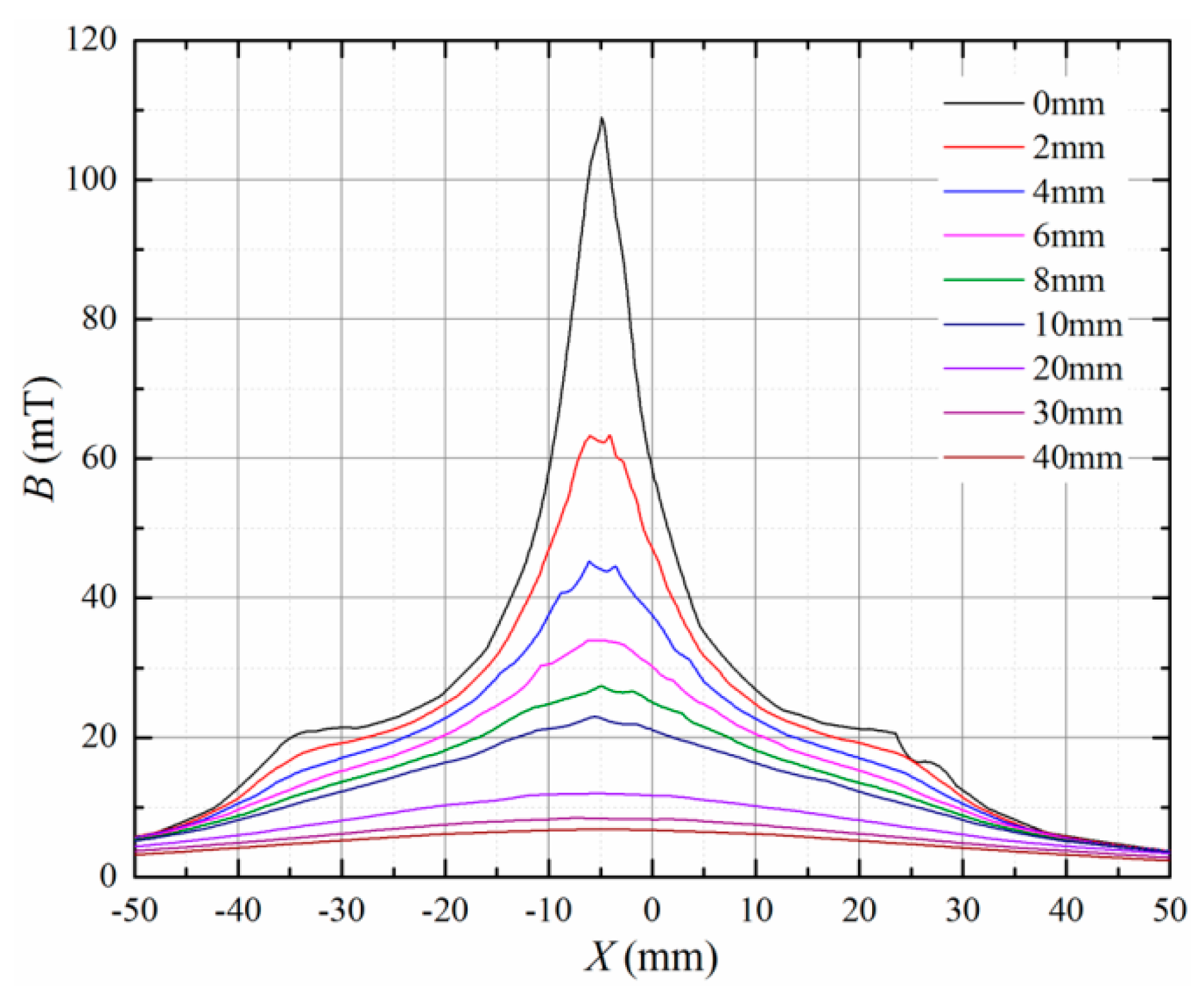

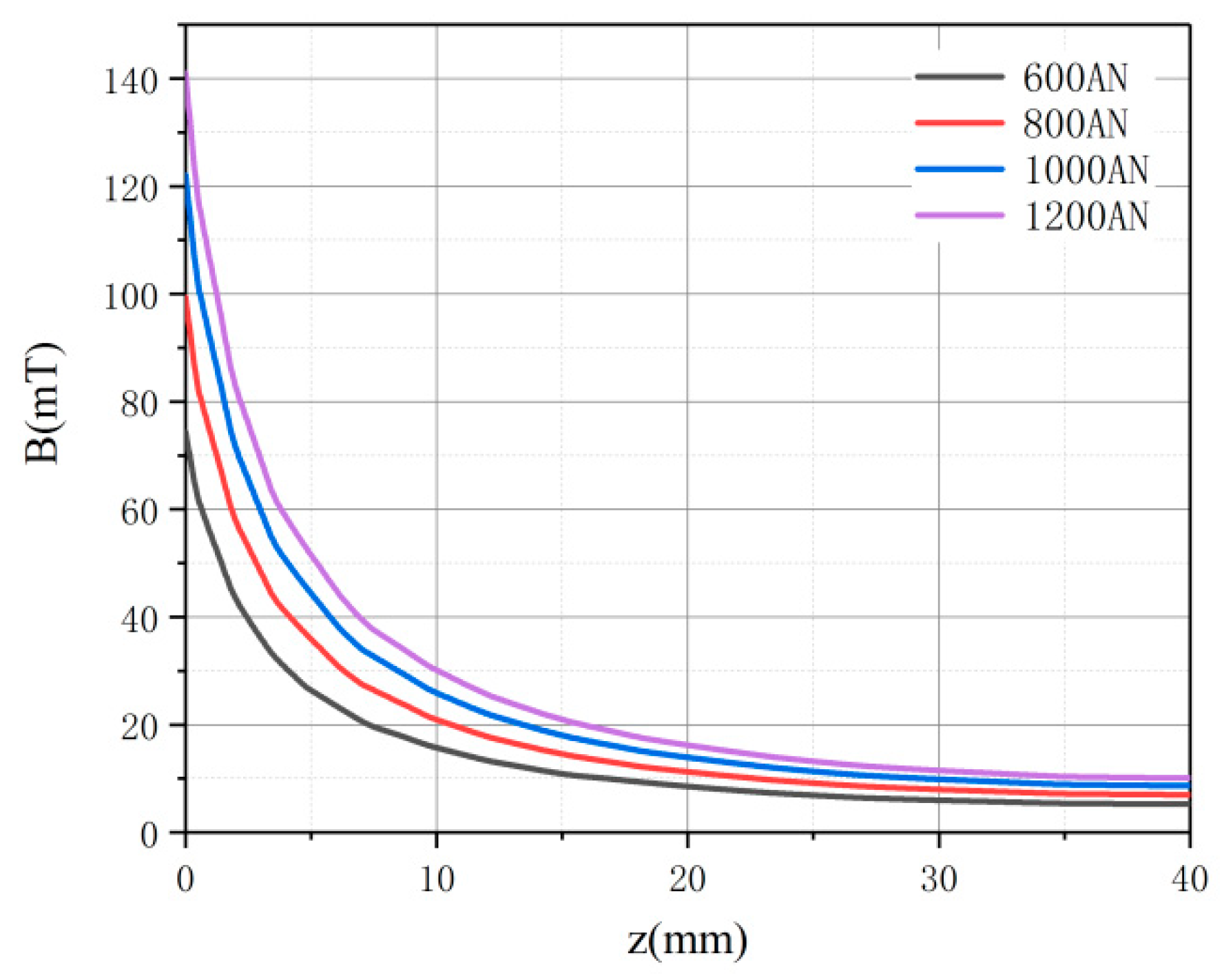

2.2. Mathematical Model of the Sensor

2.3. Transient Simulation of the Induced Voltage

3. Experimental Results and Discussion

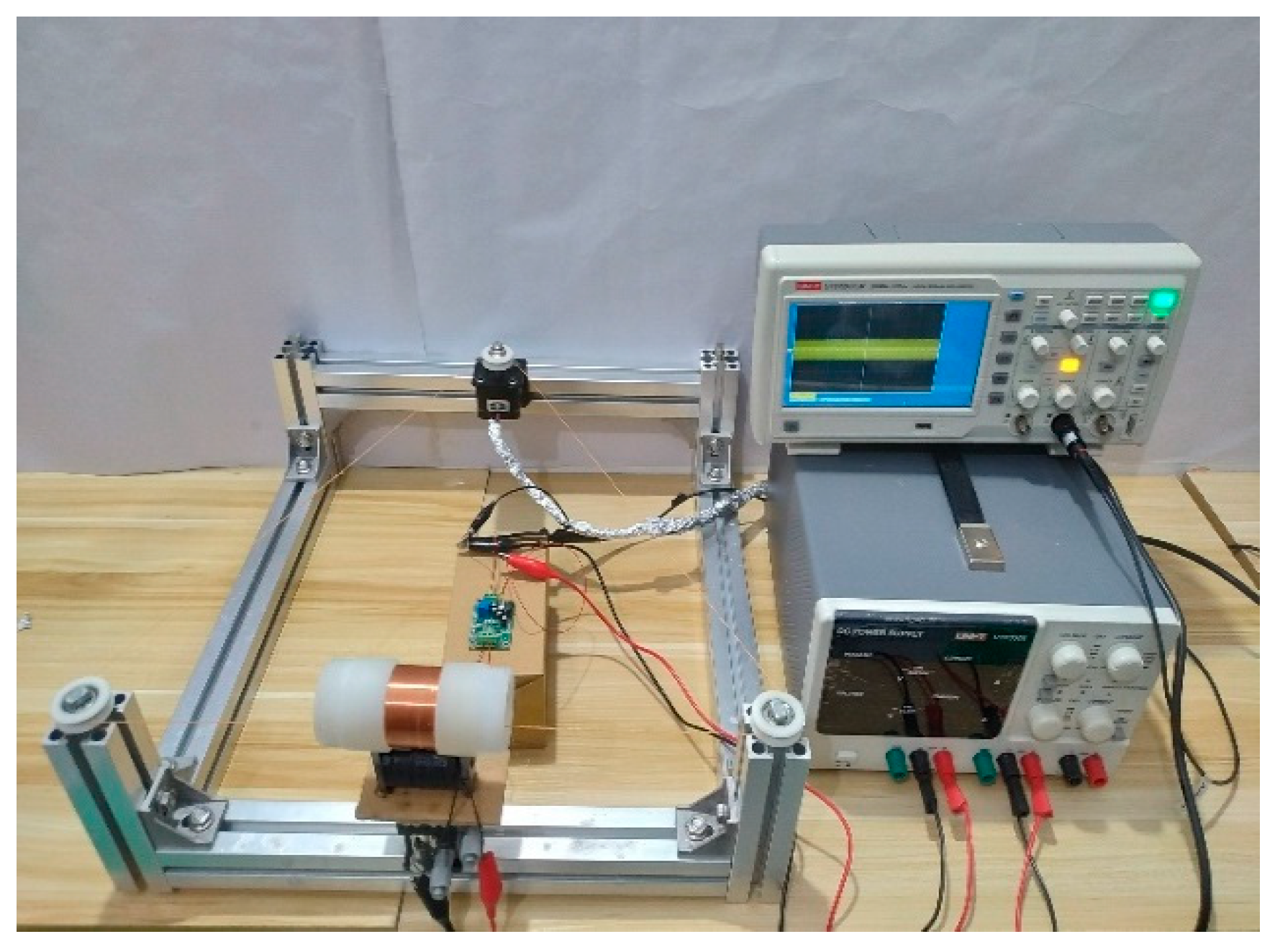

3.1. Experimental Rig

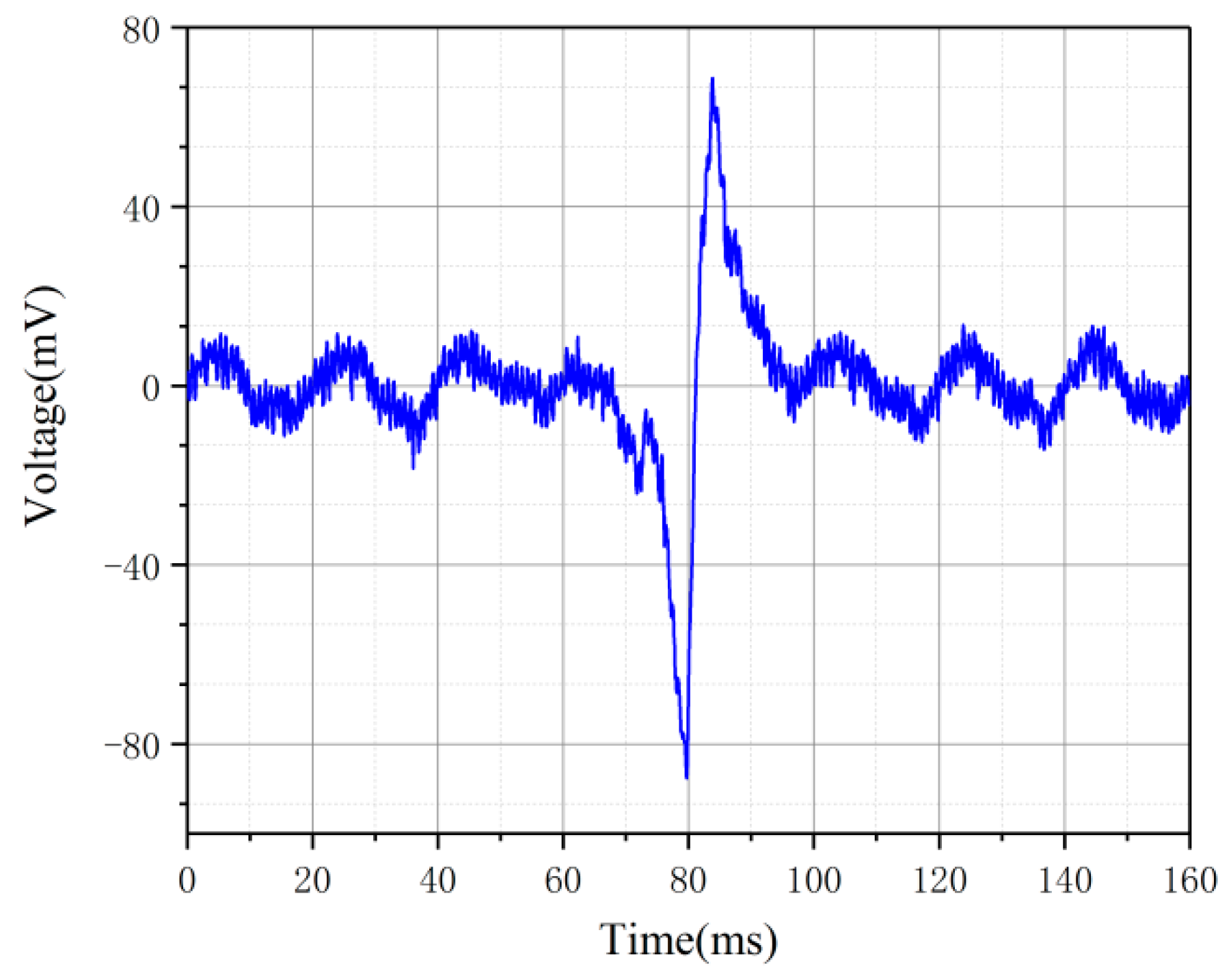

3.2. Experimental Result

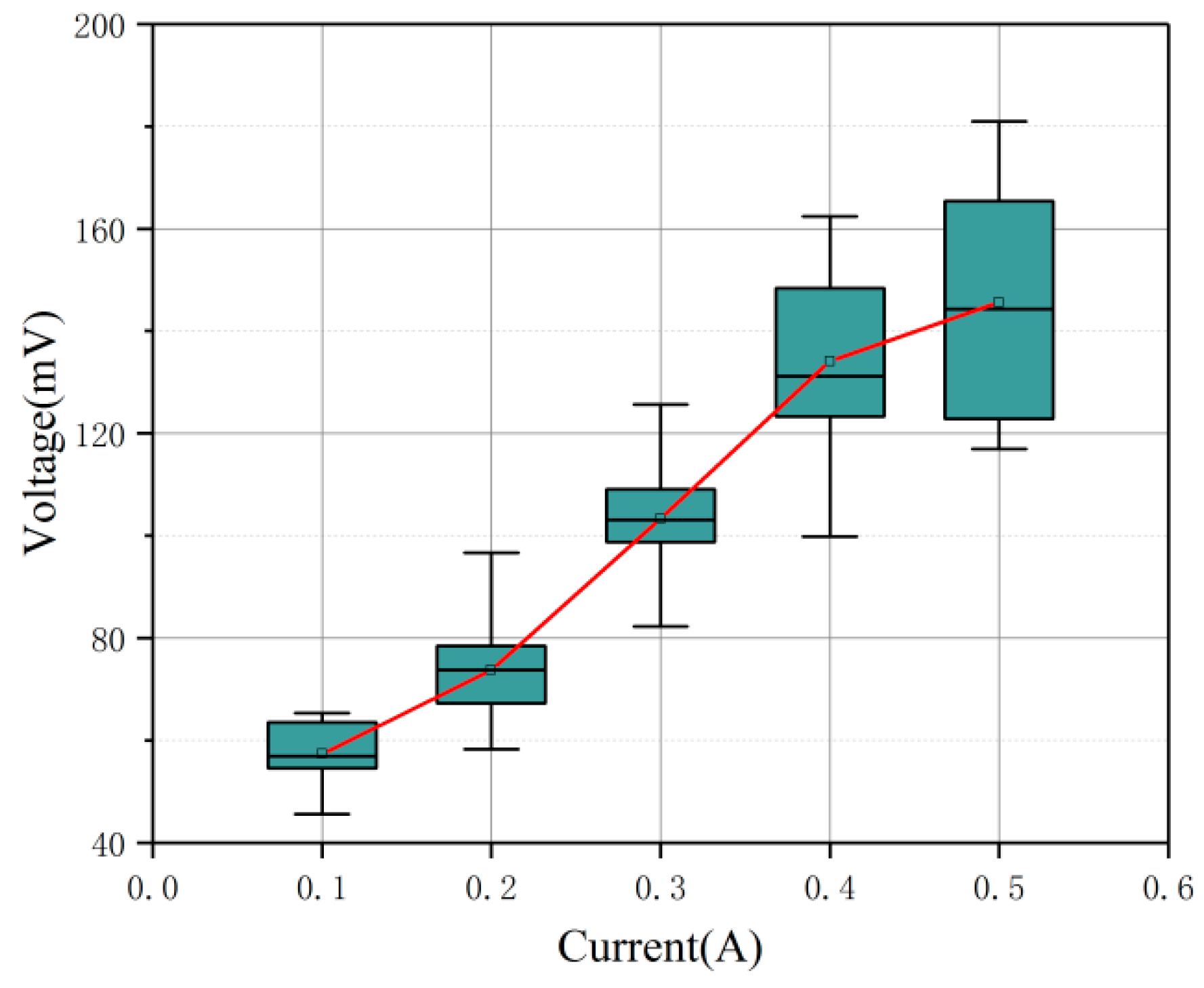

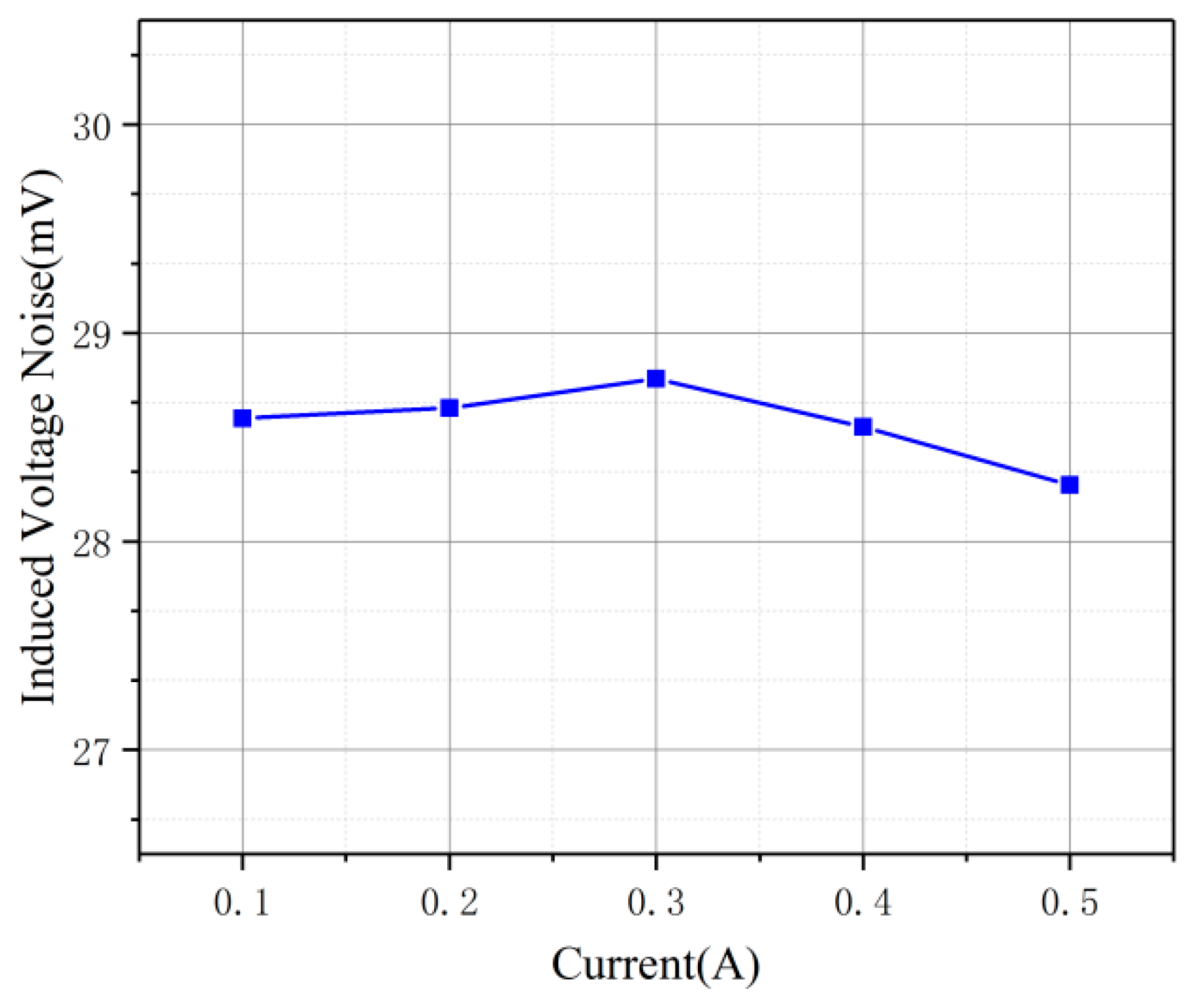

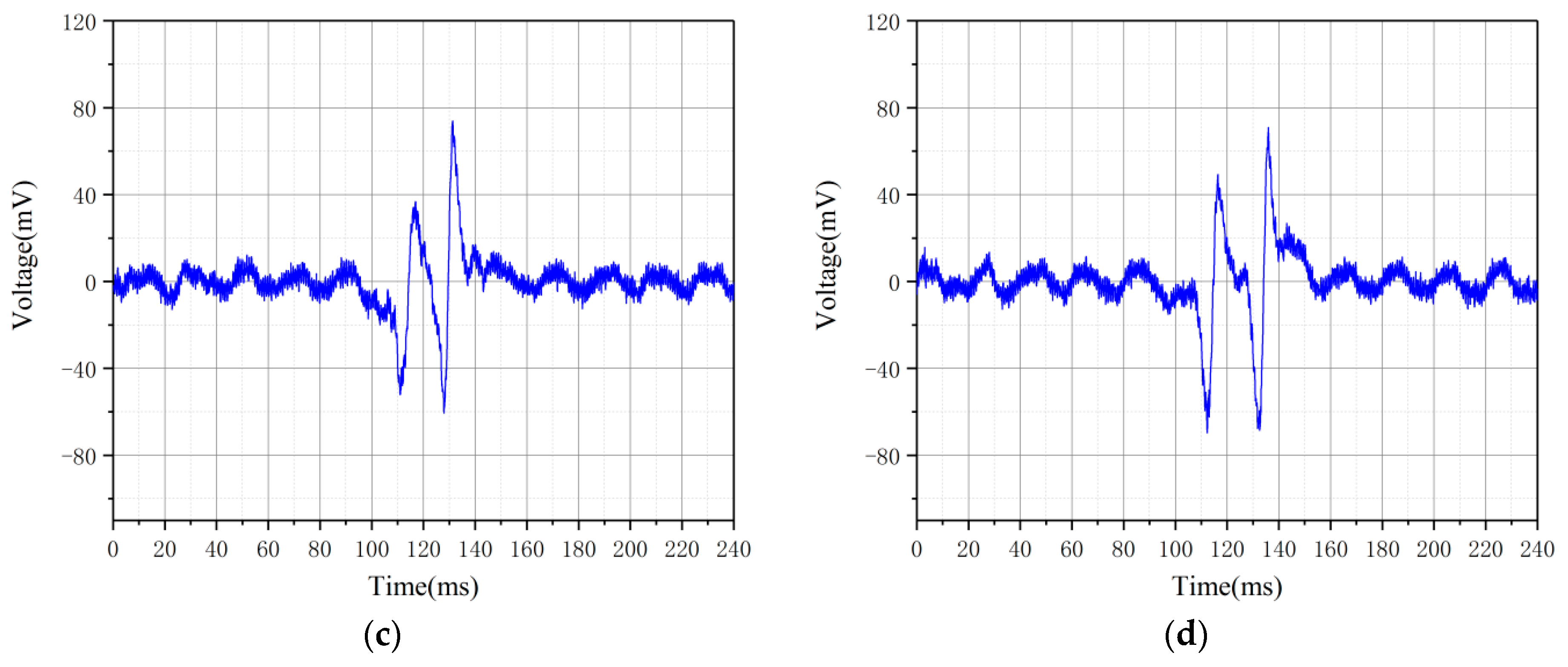

3.2.1. The Relation between the Current and Induced Voltage

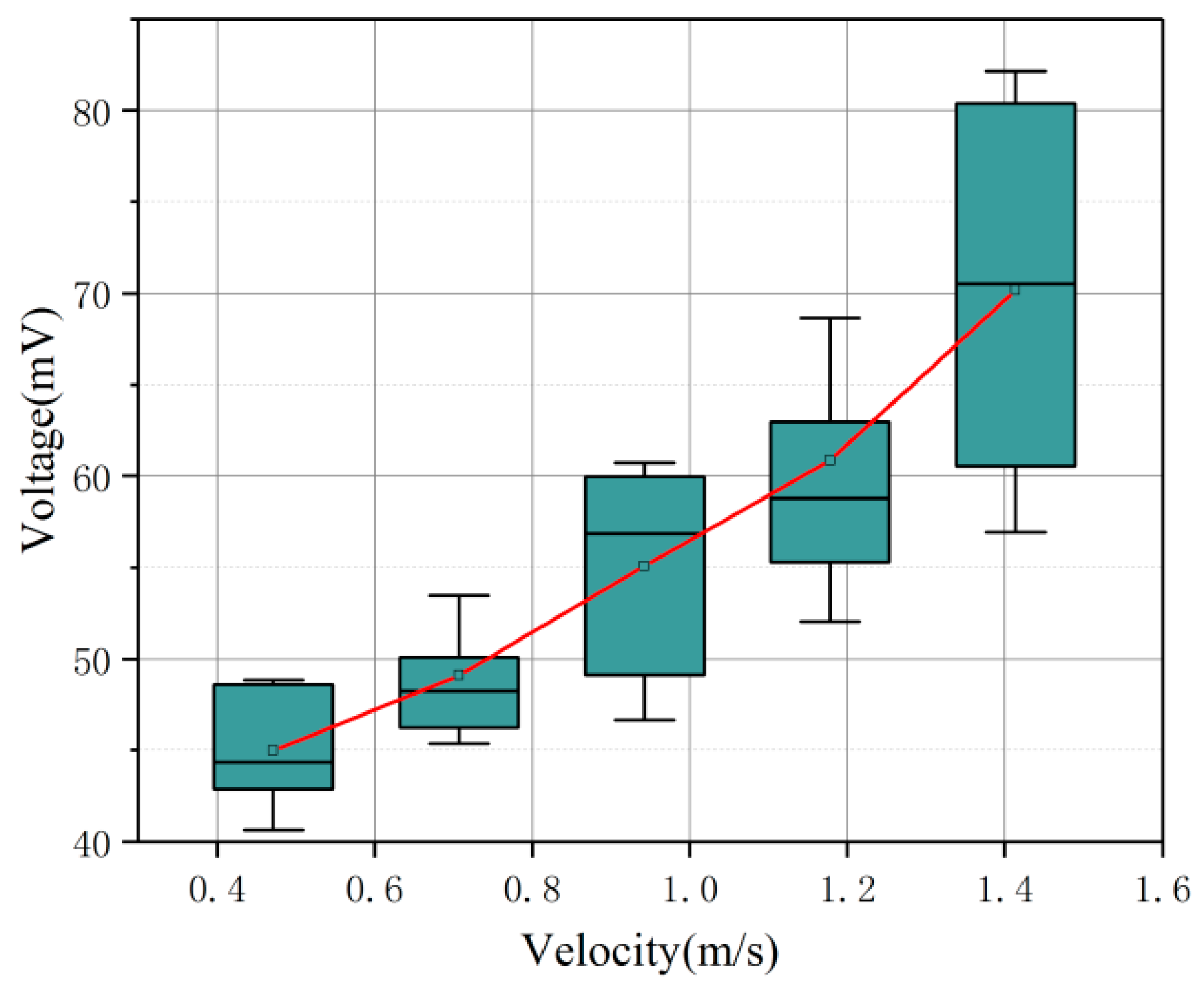

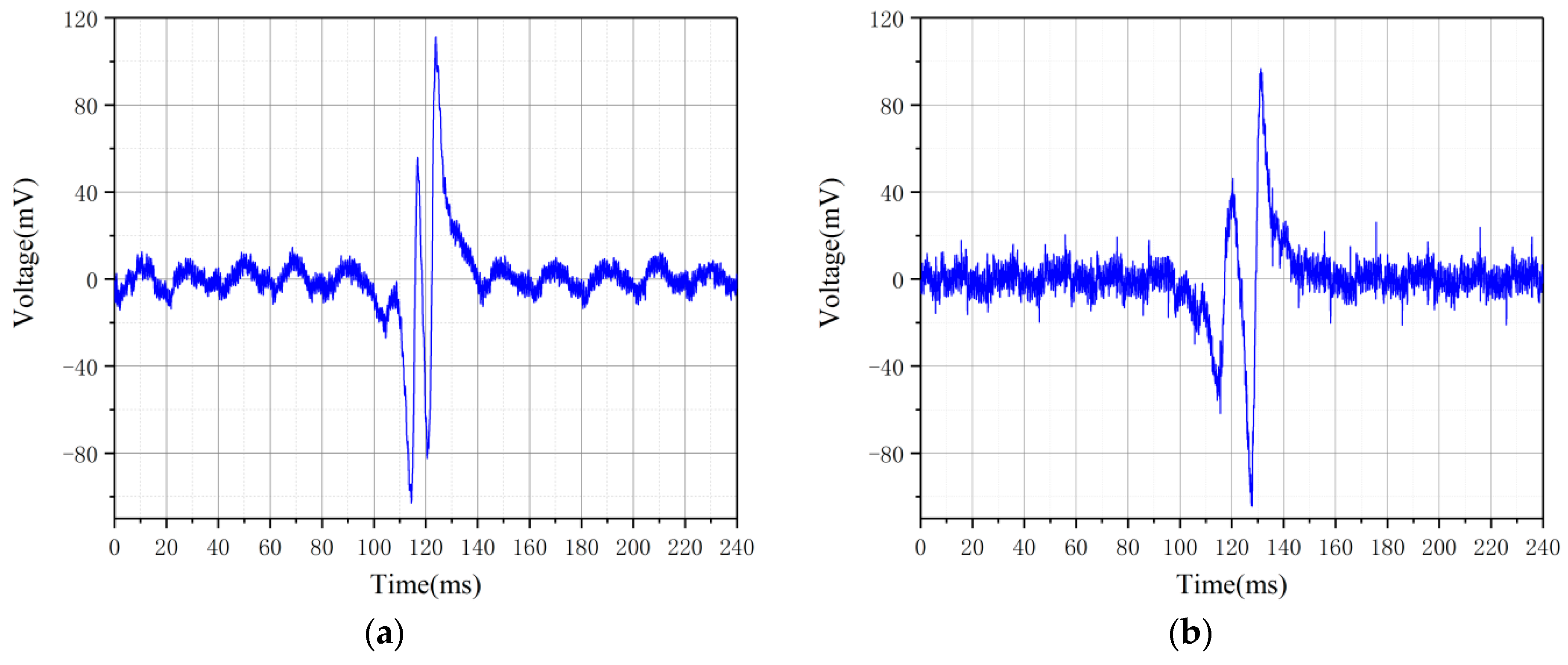

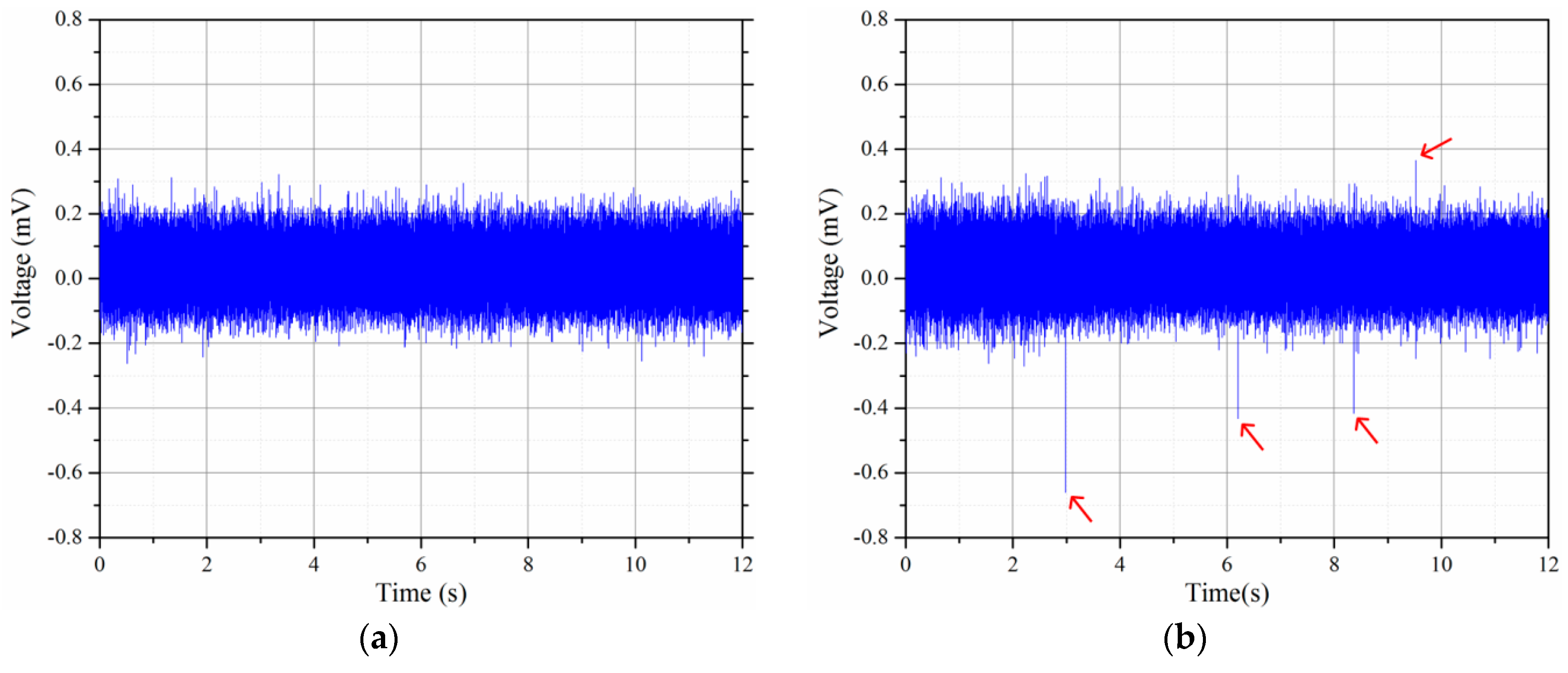

3.2.2. The Relation between the Debris Velocity and Induced Voltage

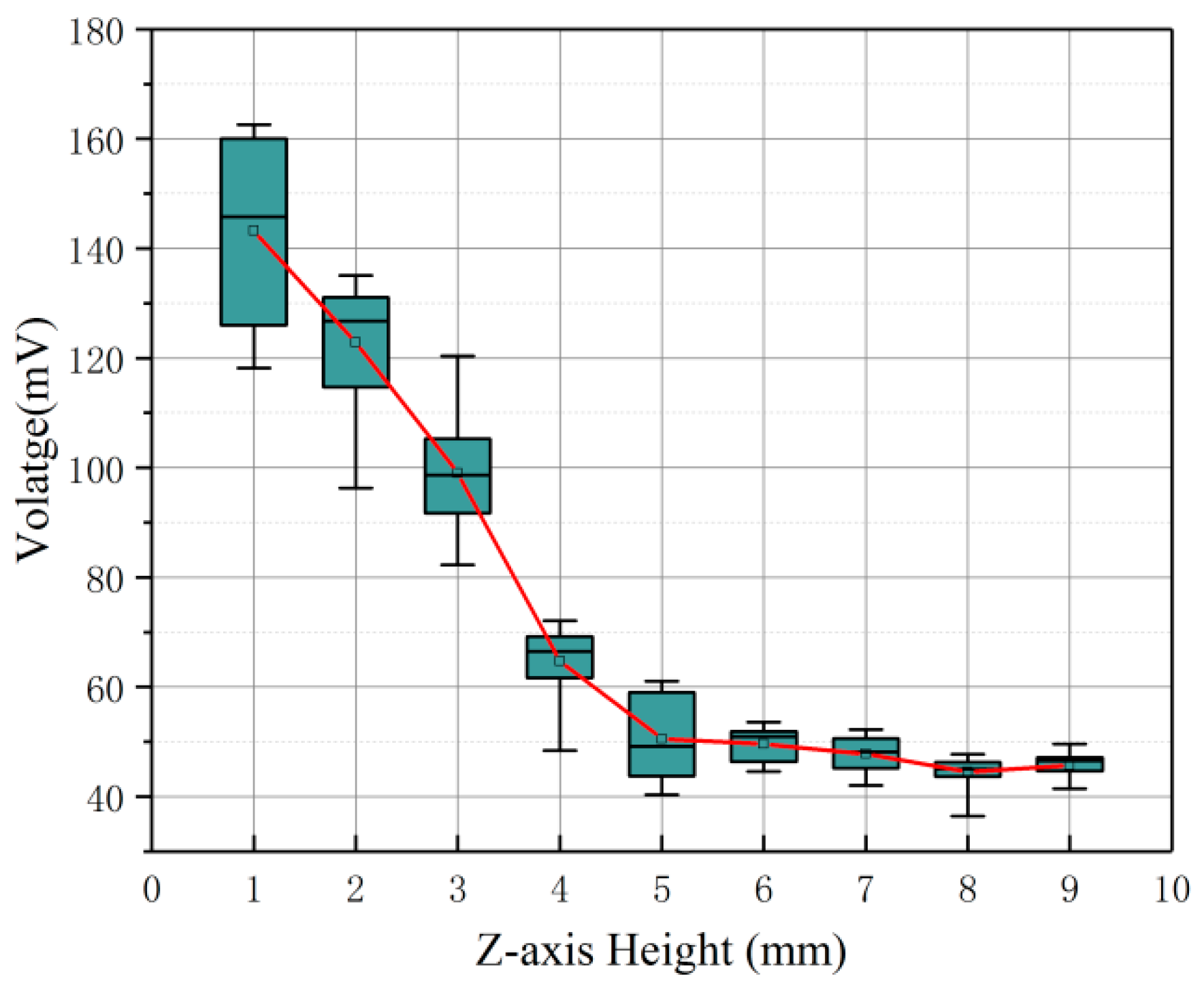

3.2.3. The Relation between the Z-Axis Height and the Induced Voltage

3.2.4. The Relation between the Debris Axial Distribution and the Induced Voltage

3.2.5. Comparative Analysis

4. Conclusions

5. Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Dupuis, R. Application of oil debris monitoring for wind turbine gearbox prognostics and health management. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, Portland, OR, USA, 10–14 October 2010; pp. 10–16. [Google Scholar]

- Liu, Y.; Wen, S.; Xie, Y.; Zhao, F. Advances in research on a multi-channel on-line ferrograph. Tribol. Int. 1997, 30, 279–282. [Google Scholar]

- Rheims, J.; Wriedt, T.; Bauckhage, K. Sizing of inhomogeneous particles by a differential laser Doppler anemometer. Meas. Sci. Technol. 1999, 10, 68. [Google Scholar] [CrossRef]

- Hamilton, A.; Cleary, A.; Quail, F. Development of a novel wear detection system for wind turbine gearboxes. IEEE Sens. J. 2014, 14, 465–473. [Google Scholar] [CrossRef]

- Wu, T.; Wu, H.; Du, Y.; Kwok, N.; Peng, Z. Imaged wear debris separation for on-line monitoring using gray level and integrated morphological features. Wear 2014, 316, 19–29. [Google Scholar] [CrossRef]

- Nemarich, C.P.; Whitesel, H.K.; Sarkady, A. On-Line Wear Particle Monitoring Based on Ultrasonic Detection and Discrimination; David Taylor Research Center Bethesda Md Propulsion and Auxiliary Systems: Anaheim, CA, USA, 1988. [Google Scholar]

- Du, L.; Zhe, J. An integrated ultrasonic–inductive pulse sensor for wear debris detection. Smart Mater. Struct. 2012, 22, 025003. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, P.; Wang, H.; Li, Y.; Lv, C. Ultrasonic echo waveshape features extraction based on QPSO-matching pursuit for online wear debris discrimination. Mech. Syst. Signal Process. 2015, 60–61, 301–315. [Google Scholar] [CrossRef]

- Zhe, J.; Choy, F.K.; Murali, S.V.; Sarangi, M.A.; Wilfong, R. Oil debris detection using capacitance and ultrasonic measurements. In Proceedings of the ASME/STLE 2007 International Joint Tribology Conference, San Diego, CA, USA, 22–24 October 2007; pp. 113–115. [Google Scholar]

- Wen, Z.; Yin, X.; Jiang, Z. Applications of Electrostatic Sensor for Wear Debris Detecting in the Lubricating Oil. J. Inst. Eng. 2013, 94, 281–286. [Google Scholar] [CrossRef]

- Keller, M.; Saba, C. Monitoring of ester base lubricants by dielectric constant. Lubr. Eng. 1989, 45, 347–351. [Google Scholar]

- Murali, S.; Xia, X.; Jagtiani, A.V.; Carletta, J.; Zhe, J. Capacitive Coulter counting: Detection of metal wear particles in lubricant using a microfluidic device. Smart Mater. Struct. 2009, 18, 037001. [Google Scholar] [CrossRef]

- Zhu, X.; Zhong, C.; Zhe, J. Lubricating oil conditioning sensors for online machine health monitoring—A review. Tribol. Int. 2017, 109, 473–484. [Google Scholar] [CrossRef]

- Miller, J.L.; Kitaljevich, D. In-line oil debris monitor for aircraft engine condition assessment. In Proceedings of the 2000 IEEE Aerospace Conference. Proceedings (Cat. No. 00TH8484), Big Sky, MT, USA, 25 March 2000; Volume 6, pp. 49–56. [Google Scholar]

- Becker, A.; Abanteriba, S.; Forrester, D. Determining inductive sensor wear debris limits for rolling contact fatigue of bearings. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 698–711. [Google Scholar] [CrossRef]

- Sheng, S. Monitoring of wind turbine gearbox condition through oil and wear debris analysis: A full-scale testing perspective. Tribol. Trans. 2016, 59, 149–162. [Google Scholar] [CrossRef]

- Tucker, J.E.; Galie, T.R.; Schultz, A.; Reintjes, J.; Lu, C.; Sebok, T.; Holloway, C.; Tankersley, L.L.; McClelland, T.; Howard, P.L.; et al. LASERNET fines optical wear debris monitor: A Navy shipboard evaluation of a CBM enabling technology. In Proceedings of the 3rd Intelligent Ships Symposium, Philadelphia, PA, USA; 1999; pp. 137–150. [Google Scholar]

- Du, L.; Zhe, J.; Carletta, J.E.; Veillette, R.J. Inductive Coulter counting: Detection and differentiation of metal wear particles in lubricant. Smart Mater. Struct. 2010, 19, 057001. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J. A high throughput inductive pulse sensor for online oil debris monitoring. Tribol. Int. 2011, 44, 175–179. [Google Scholar] [CrossRef]

- Du, L.; Zhe, J. Parallel sensing of metallic wear debris in lubricants using undersampling data processing. Tribol. Int. 2012, 53, 28–34. [Google Scholar] [CrossRef]

- Du, L.; Zhu, X.; Han, Y.; Zhao, L.; Zhe, J. Improving sensitivity of an inductive pulse sensor for detection of metallic wear debris in lubricants using parallel LC resonance method. Meas. Sci. Technol. 2013, 24, 075106. [Google Scholar] [CrossRef]

- Ren, Y.J.; Li, W.; Zhao, G.F.; Feng, Z.H. Inductive debris sensor using one energizing coil with multiple sensing coils for sensitivity improvement and high throughput. Tribol. Int. 2018, 128, 96–103. [Google Scholar] [CrossRef]

- Hong, W.; Wang, S.; Tomovic, M.; Han, L.; Shi, J. Radial inductive debris detection sensor and performance analysis. Meas. Sci. Technol. 2013, 24, 125103. [Google Scholar] [CrossRef]

- Hong, W.; Wang, S.; Tomovic, M.M.; Liu, H.; Wang, X. A new debris sensor based on dual excitation sources for online debris monitoring. Meas. Sci. Technol. 2015, 26, 095101. [Google Scholar] [CrossRef]

- Feng, S.; Yang, L.; Qiu, G.; Luo, J.; Li, R.; Mao, J. An Inductive Debris Sensor Based on a High-Gradient Magnetic Field. IEEE Sens. J. 2019, 19, 2879–2886. [Google Scholar] [CrossRef]

- Myshkin, N.K.; Markova, L.V. Wear prediction for tribosystems based on debris analysis, On-Line Cond. Monit. Ind. Lubr. Tribol 2017, 131–201. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, H.; Wang, X.; Li, H.; Luo, J.; Feng, S. An Inductive Debris Sensor for a Large-Diameter Lubricating Oil Circuit Based on a High-Gradient Magnetic Field. Appl. Sci. 2019, 9, 1546. https://doi.org/10.3390/app9081546

Xiao H, Wang X, Li H, Luo J, Feng S. An Inductive Debris Sensor for a Large-Diameter Lubricating Oil Circuit Based on a High-Gradient Magnetic Field. Applied Sciences. 2019; 9(8):1546. https://doi.org/10.3390/app9081546

Chicago/Turabian StyleXiao, Hong, Xinyu Wang, Hongcheng Li, Jiufei Luo, and Song Feng. 2019. "An Inductive Debris Sensor for a Large-Diameter Lubricating Oil Circuit Based on a High-Gradient Magnetic Field" Applied Sciences 9, no. 8: 1546. https://doi.org/10.3390/app9081546

APA StyleXiao, H., Wang, X., Li, H., Luo, J., & Feng, S. (2019). An Inductive Debris Sensor for a Large-Diameter Lubricating Oil Circuit Based on a High-Gradient Magnetic Field. Applied Sciences, 9(8), 1546. https://doi.org/10.3390/app9081546