Selection of Diagnostic Symptoms and Injection Subsystems of Marine Reciprocating Internal Combustion Engines

Abstract

:1. Introduction

- formulation of a research problem

- definition of restrictions based on preliminary information about the test object

- the proposal of a mathematical model

- choosing a research plan based on the mathematical theory of experiment planning

- test plan execution

- analysis of the obtained results and implementation of the mathematical model by determining unknown parameters

- verification of the mathematical model or a new model proposal

- using the model to further study the object’s properties, including the optimal conditions for its functioning

2. Planning Diagnostic Experiments

2.1. Criteria for the Selection of the Research Object

- the research object

- type of experiment

- locations of measuring sensors

- measured quantities and observation sites

- measurement methods and devices

- test conditions

- diagnostic symptoms

- frequency of measurements

- inference methods

- the responsibility of the assembly (element) in realising a task chain

- functionality on the ship

- the object’s impact on safety (people, goods and the environment)

- unreliability

- maintenance costs in upstate

- ensuring the safety of people, cargo and the environment

- implementation of tasks

- effective (optimal according to economic criteria) operation of a sea-going ship

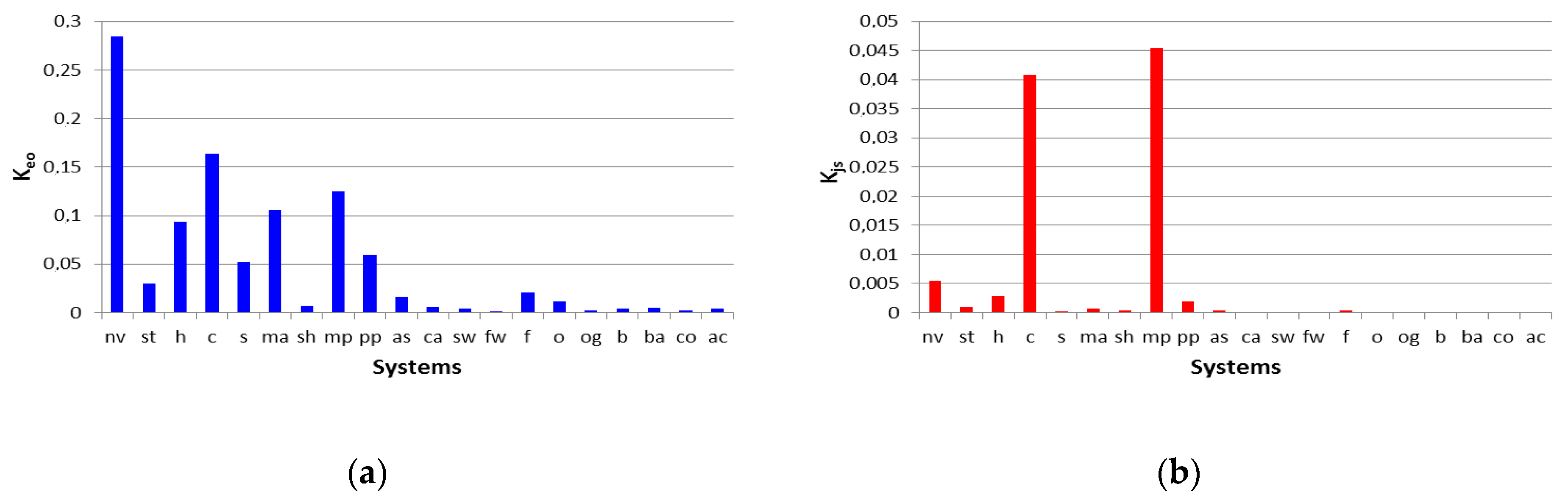

2.2. Research Object Selection Methods

2.3. Selection of the Location of Measurement Places

- about the highest level of noise signal generated

- about the highest level of vibration signal generated

- about the highest number of harmonics in the frequency spectrum

- about the expected location of the damage signal generation

- of places independent of each other

- of reliability analysis

- of preliminary test results

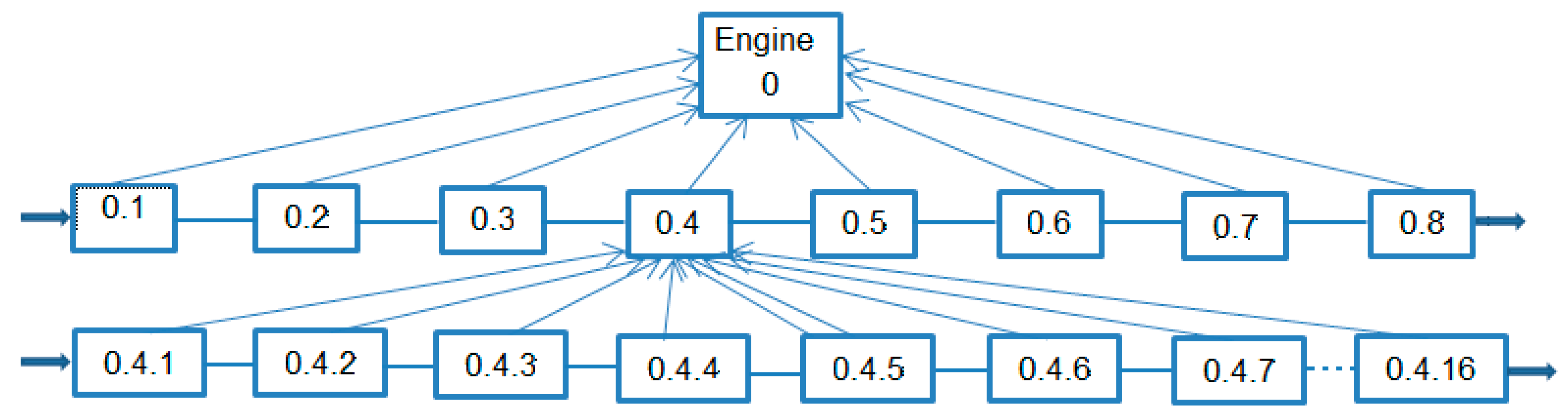

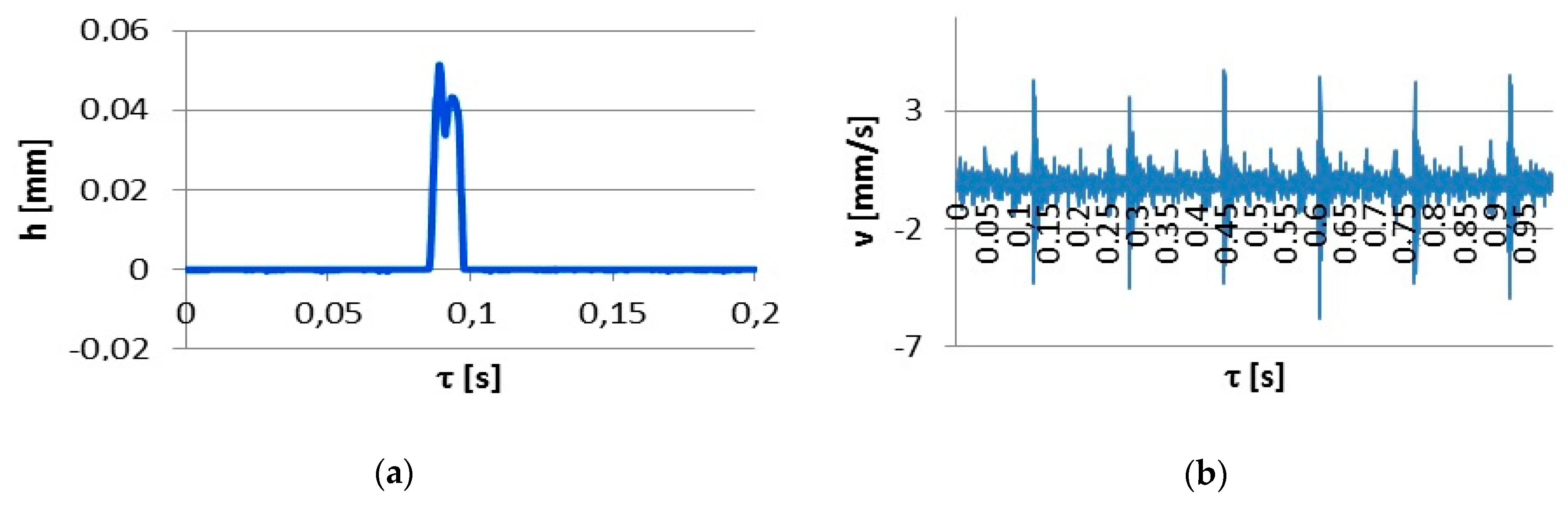

3. Results of Diagnostic Tests

3.1. Selection of the Type of Experiment

3.2. Quantities Initially Included in the Studies

3.3. Determination of Test Conditions

- pressure, temperature and relative humidity of the environment

- operating conditions associated with increasing the resistance of the air filter, the temperature of oil and cooling water

- total barometric pressure 100 kPa

- air temperature 25 °C

- relative humidity 30%

- charge air coolant temperature 25 °C

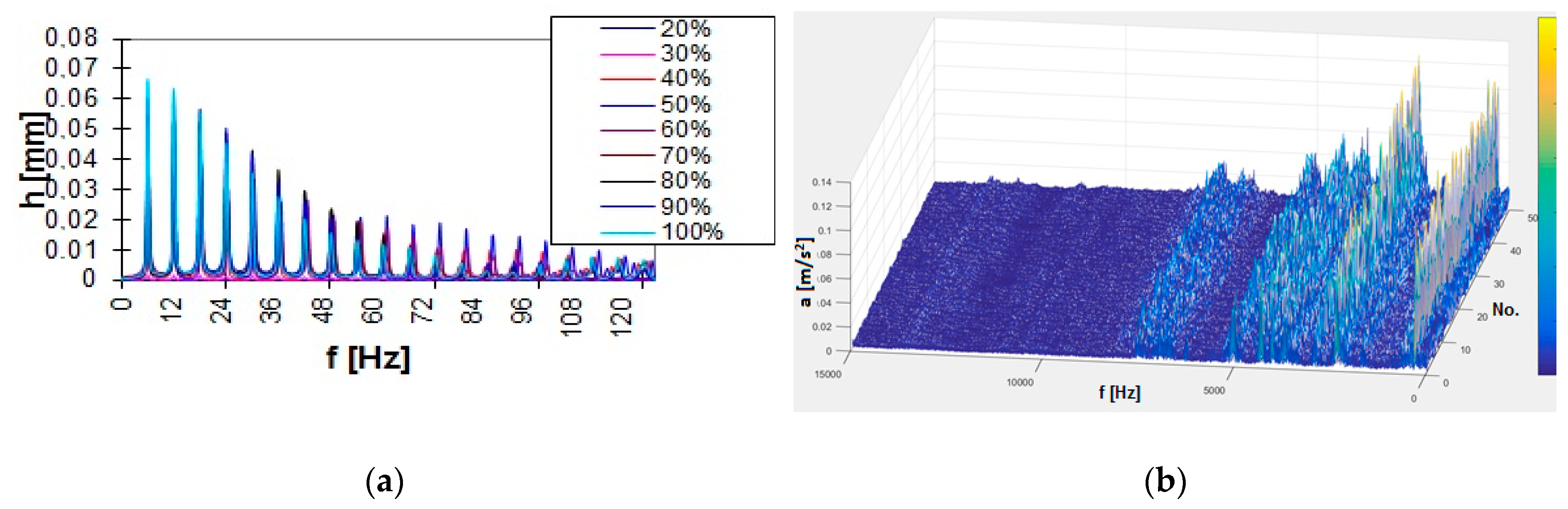

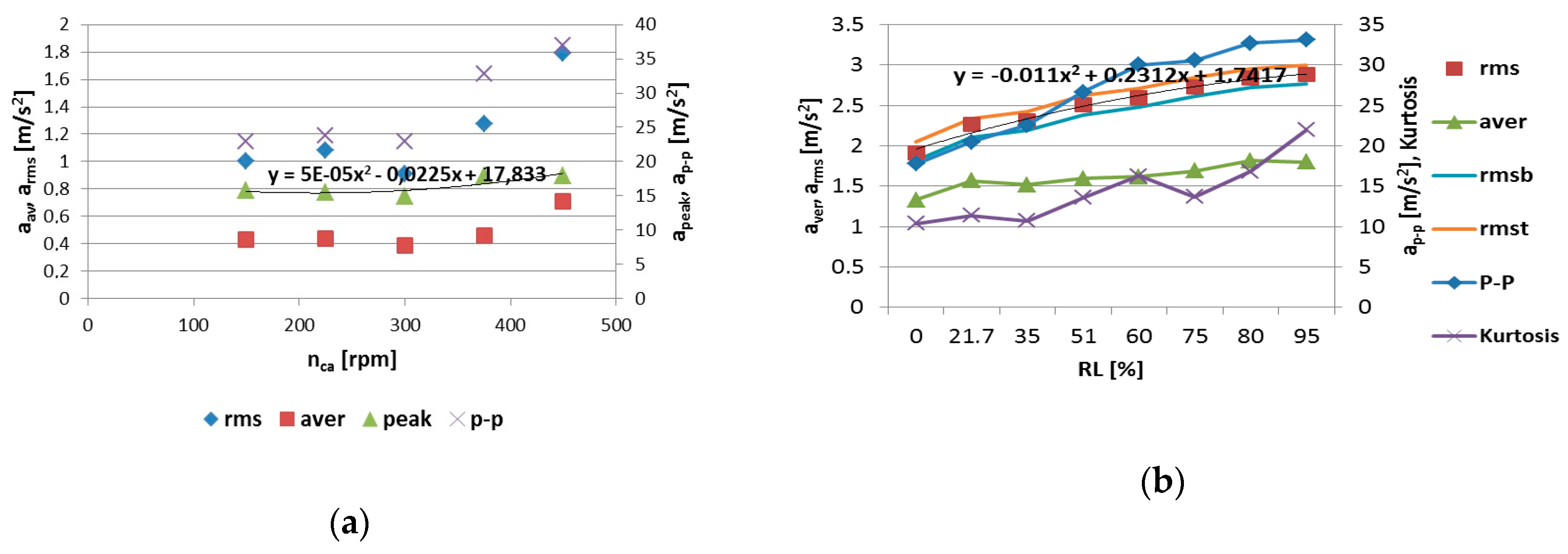

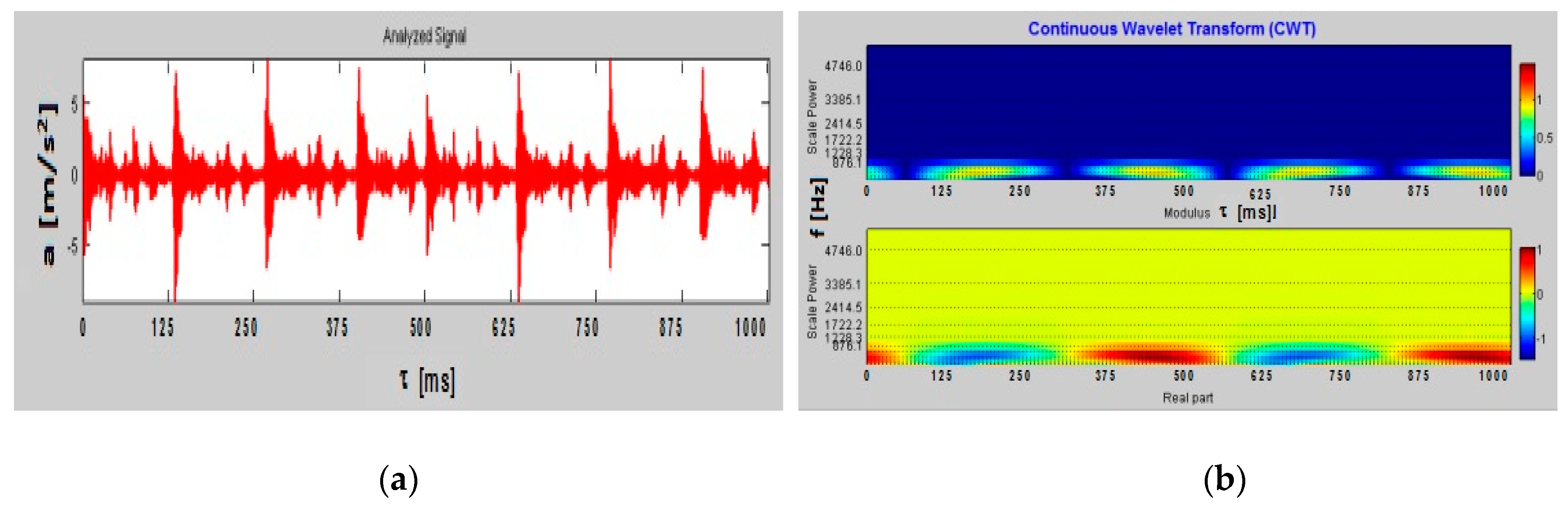

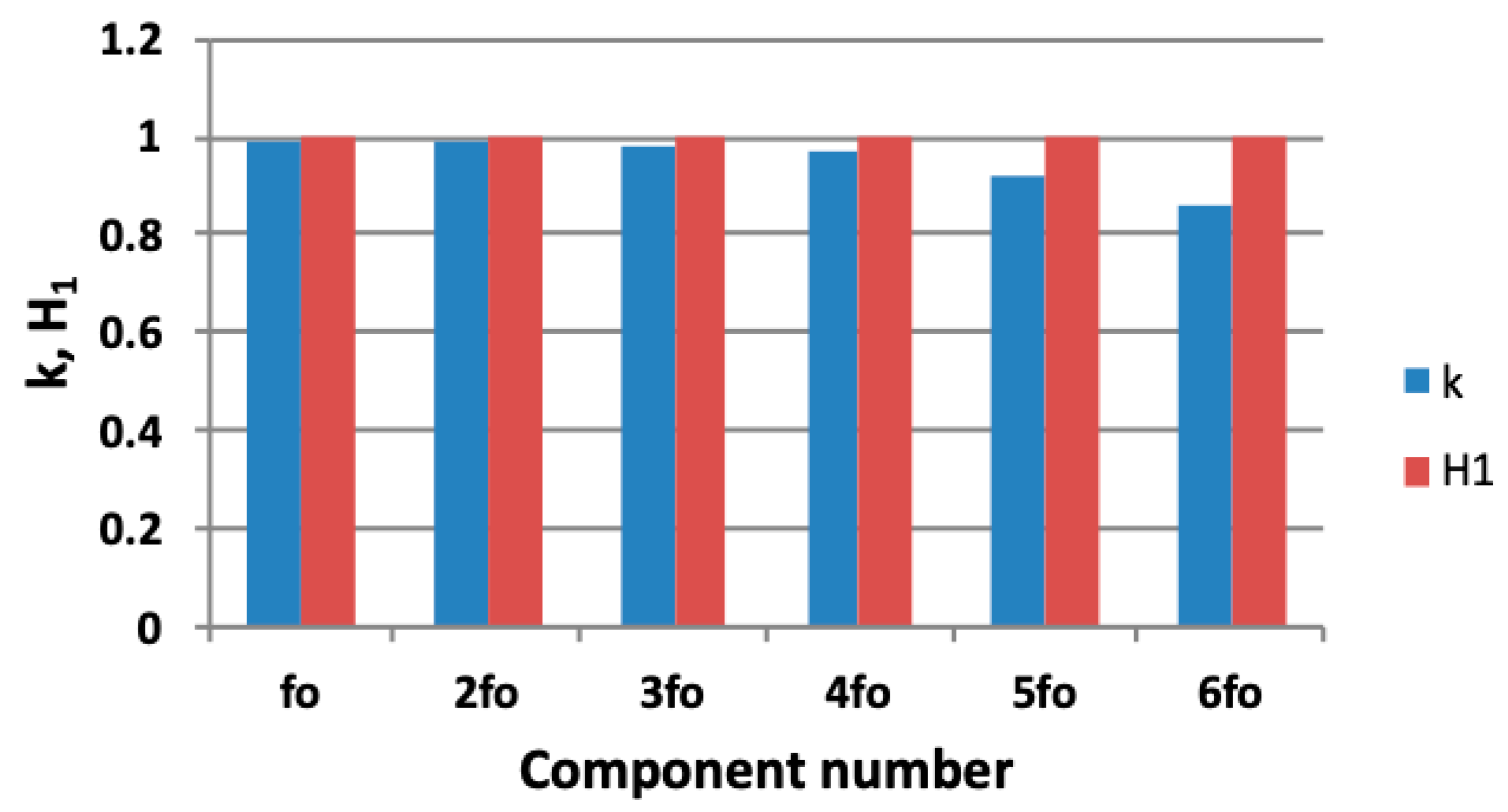

3.4. Selection of Signals and Diagnostic Parameters

4. Conclusions

5. Patents

Funding

Acknowledgments

Conflicts of Interest

References

- Żółtowski, B.; Cempel, C. Elements of the theory of technical diagnostics. In Engineering of Diagnostics Machines; Society of Technical Diagnostics: Bydgoszcz, Poland, 2004; pp. 17–525. [Google Scholar]

- Migdalski, J. Planning experiments in reliability. In Reliability Engineering; University of Technology and Agriculture in Bydgoszcz, ZETOM Warsaw: Bydgoszcz, Poland, 1992; pp. 123–157. [Google Scholar]

- Monieta, J. Preliminary diagnostic investigation of injectors of marine diesel engines. Expl. Prob. Mach. 2003, 1, 169–185. [Google Scholar]

- Tomaszewski, F. Problems of Determination of a Complex Mechanical Structure’s Technical Condition Using Vibroaccoustic Signal. Habilitation Dissertation, Poznan University of Technology, Poznan, Poland, 1998. no. 337. [Google Scholar]

- Korzyński, M. Experiment Methodology; WNT: Warsaw, Poland, 2013. [Google Scholar]

- Polanski, Z. Planning Experience in Creating Quality; Statsoft: Kraków, Poland, 1999; pp. 37–46. [Google Scholar]

- Woropay, M. Method of Building Multilevel Systems for Testing Reliability Made of Elements with Established a Priori Significance. Habilitation Dissertation, no. 18. University of Technology and Agriculture in Bydgoszcz, Bydgoszcz, Poland, 1983. [Google Scholar]

- Czajgucki, J.Z. The Method of Implementation of the Postulate of the Required Reliability of Marine Engine Power Plants in the Process of Their Design; WSM: Gdynia, Poland, 1991. [Google Scholar]

- Revised Guidelines for Formal Safety Assessment (FSA) for Use in The Imo Rule-Making Process; London Se1 7sr, MSC-MEPC.2/Circ.12/Rev.2; International Maritime Organization: London, UK, 2018; pp. 1–71.

- Tarełko, W. Methodology of Designing Exploitation Properties of Complex Technical Objects; Library of Problems of Exploitation, Gdynia: Radom, Poland, 2011. [Google Scholar]

- Girtler, J.; Kuszmider, S.; Plewiński, L. Selected Issues of the Operation of Ships in the Safety Aspect of the Navigation; Maritime University of Szczecin: Szczecin, Poland, 2003. [Google Scholar]

- Banks, J.; Hines, J.; Lebold, M.; Campbell, R.; Begg, C.; Byington, C. Failure modes and predictive diagnostics considerations for diesel engines. Report: New Frontiers in Integrated Diagnostics and Prognostics. In Proceedings of the 55th Meeting of the Society for Machinery Failure Prevention Technology, Virginia Beach, VA, USA, 2–5 April 2001; pp. 93–102. [Google Scholar]

- Witkowski, K. The correct selection of diagnostic parameters of marine diesel engine and their minimization of as a necessary action in the formation of diagnostic algorithm. J. KONES Power Trans. 2017, 24, 287–292. [Google Scholar] [CrossRef]

- Kontovas, C.A.; Psaraftis, H.N. Formal safety assessment: A critical review. Mar. Technol. USA 2009, 46, 45–59. [Google Scholar]

- Dong, C.; Yuan, C.; Liu, Z.; Yan, X. Marine propulsion system reliability research based on fault tree analysis. Adv. Shipp. Ocean 2013, 2, 27–33. [Google Scholar]

- Grzywaczewski, Z. Reliability of Ships; WEMA Machine Industry Publishers: Warsaw, Poland, 1988. [Google Scholar]

- Adamkiewicz, W.; Hempel, L.; Posiadło, A.; Sliwinski, R. Research and Evaluation of Machine Reliability in the Transport System; WKiŁ: Warsaw, Poland, 1983. [Google Scholar]

- Monieta, J. Experiment designing in operating investigations of sub-assembly of the marine energy systems. Environment, Energy & Earth Sciences. E3S Web of Conferences. In Proceedings of the 3rd Internal Conference on Energy and Environmental Protection, Krakow, Poland, 13–14 September 2018; pp. 19–25. [Google Scholar] [CrossRef]

- Monieta, J. Control diagnosis of marine diesel engines injectors with utilization of the parameters of the working and concomitant process. Ex Probe Mach. 2001, 4, 167–179. [Google Scholar]

- Pietak, A. Operation of the Engine with SI Conditions of Dynamically Changing Loads. Diagnosis of CI Engines Based on Transient Processes. Habilitaion Dissertation, Poznan University of Technology, Poznan, Poland, 1999; pp. 21–34. [Google Scholar]

- Chłopek, Z. Some remarks on engines testing in dynamic states. Com. Eng. Pol. 2001, 143, 60–71. [Google Scholar]

| Measure | Engine Relative Load [%] | ||||

|---|---|---|---|---|---|

| 0 | 25 | 50 | 75 | 100 | |

| Hca | 0.0215031 | 0.025128 | 0.029725 | 0.033432 | 0.037543 |

| σ2 | 0.0014999 | 0.002139 | 0.003058 | 0.004442 | 0.005621 |

| σ | 0.0387283 | 0.046247 | 0.055296 | 0.066648 | 0.074976 |

| Hcrms | 0.4957277 | 0.588987 | 0.702516 | 0.834318 | 0.938233 |

| m4 | −0.61845 | −0.61837 | −0.61838 | −0.61837 | −0.61837 |

| Ran | 0.1945914 | 0.232522 | 0.28155 | 0.344197 | 0.387929 |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monieta, J. Selection of Diagnostic Symptoms and Injection Subsystems of Marine Reciprocating Internal Combustion Engines. Appl. Sci. 2019, 9, 1540. https://doi.org/10.3390/app9081540

Monieta J. Selection of Diagnostic Symptoms and Injection Subsystems of Marine Reciprocating Internal Combustion Engines. Applied Sciences. 2019; 9(8):1540. https://doi.org/10.3390/app9081540

Chicago/Turabian StyleMonieta, Jan. 2019. "Selection of Diagnostic Symptoms and Injection Subsystems of Marine Reciprocating Internal Combustion Engines" Applied Sciences 9, no. 8: 1540. https://doi.org/10.3390/app9081540

APA StyleMonieta, J. (2019). Selection of Diagnostic Symptoms and Injection Subsystems of Marine Reciprocating Internal Combustion Engines. Applied Sciences, 9(8), 1540. https://doi.org/10.3390/app9081540