1. Introduction

With the continuous development of ultrasonic guided wave research, great progress has been made in the basic theory, numerical calculation, and simulation experiments. The application of ultrasonic guided wave technology is more and more extensive in the field of nondestructive testing. Cawley et al. [

1,

2] and Rose et al. [

3,

4] led their research groups to develop a pipeline detection system for non-destructive detection of buried pipelines based on ultrasonic guided wave technology. Loveday et al. [

5,

6] developed a rail detection system. Researchers have carried out non-destructive testing of waveguide mediums, such as flat plates [

7,

8], composite materials, pipes, rods [

9], and rails [

10,

11], by using ultrasonic guided wave technology. The results obtained have greatly promoted the development and application of ultrasonic guided wave technology in petrochemical, aerospace, high-speed railway, and other industries.

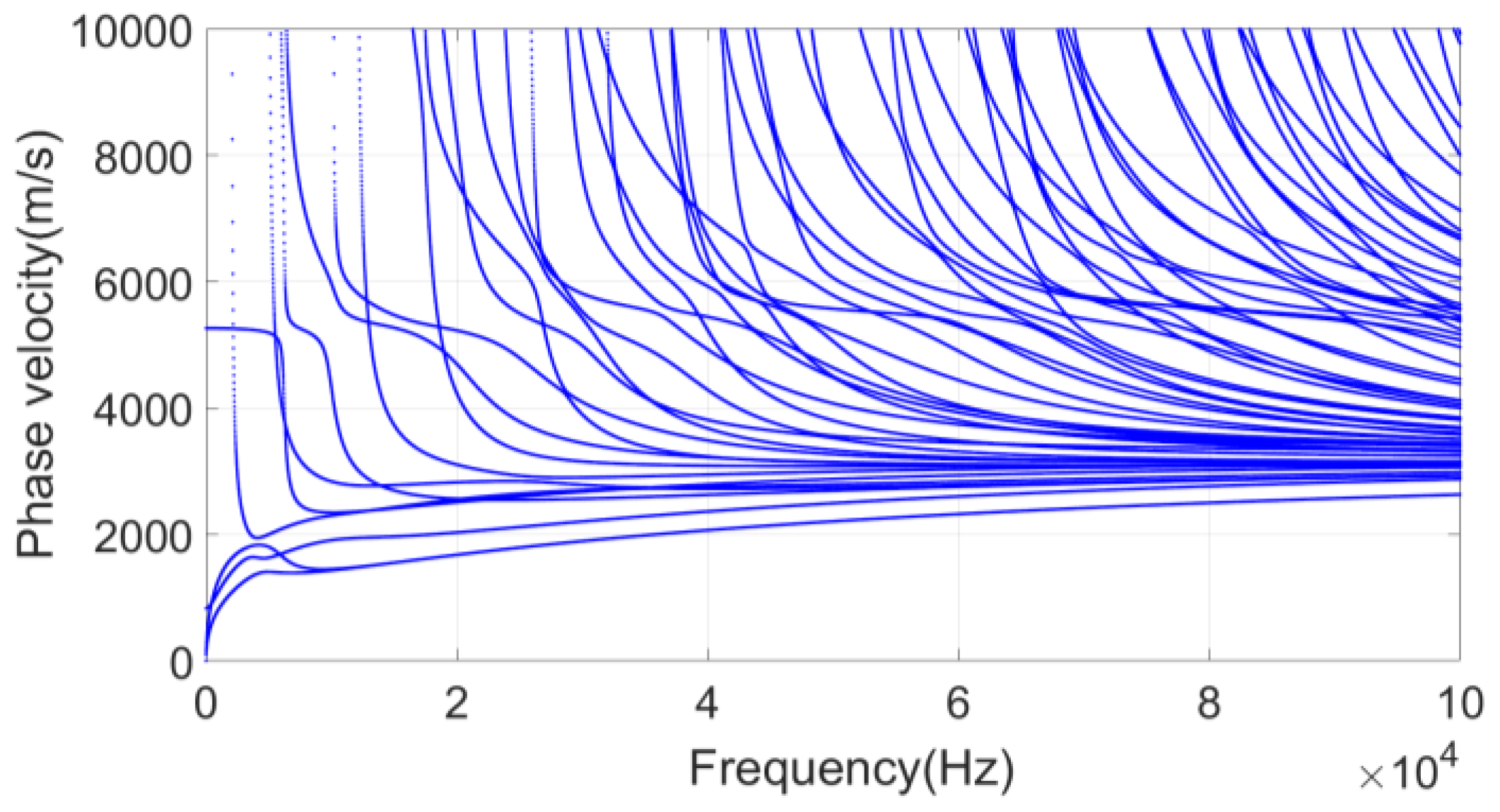

Ultrasonic guided waves can cover the cross-section of the waveguide medium during propagation and have a higher detection efficiency [

12]. However, guided waves have the characteristics of multi-mode and dispersion, which also makes it complicated to use guided wave technology for non-destructive testing. The dispersion curves [

13] describe the guided wave modes that can propagate at a certain frequency in a waveguide medium, and contain information, such as phase velocity, frequency, wavenumber, group velocity, and so on. It is important to develop a theoretical framework for analyzing and designing guided wave detecting equipment. There are many methods for solving the dispersion curves of waveguide media, and the semi-analytical finite elements (SAFE) method [

14,

15] is often used to solve the dispersion curves of guided waves in an arbitrary cross-section waveguide medium. After the finite element discretization on the cross-section of the waveguide medium, the wave process is expressed by the simple harmonic motion along the direction of the wave propagation and the wave equation is established based on the Hamiltonian principle of the variational method. The relationship between the wavenumber and frequency is obtained by solving the eigenvalue problems, and then the dispersion curves can be plotted.

When applying the SAFE method to solve the dispersion curves, the eigenvector is the displacement of each discrete node in the cross-section, and contains the shape of the guided mode. The eigenvector is used to analyze the mode shapes, which is important to study the excitation of the guided wave modes and develop a guided wave transducer. Takahiro Hayashi et al. [

16] analyzed the process of Lamb wave propagation in metallic and resin plates loaded with water on a single surface. The structure of the Lamb wave was analyzed by the SAFE method. Takahiro Hayashi et al. [

17] solved the dispersion curves of the guided waves in a rod, analyzed the mode shapes, and plotted the wave structures for a square bar. Alessandro Marzani [

18] solved the dispersion equation of guided waves in cylinders and plotted a mode diagram of the n-order modes of the guided waves in a pipe. Ivan Bartoli et al. [

19] plotted the mode shapes in a rail at low frequency, and analyzed the vibration characteristics of each mode based on the mode diagram.

In recent years, high-speed railways have developed rapidly [

20]. Rails are important infrastructure components of railways. In order to guarantee the safe operation of high-speed railways, it is necessary to detect rails’ internal defects and prevent potential fracture in advance.

The cross-section of the rail is complex. In the discrete cross-section, there are more nodes and elements, and the modes of vibration are complicated [

21]. When analyzing the guided wave mode shapes in the rail, the method of plotting the mode displacement vector diagram is generally adopted [

22]. The displacements of all nodes in the x, y, and z directions are listed in the mode vector matrix. In order to determine the energy distribution and maximum vibration position of each mode shape, it is necessary to design specific algorithms for the corresponding data analysis. This paper develops a graphical analysis method to analyze the vibration mode in the rail, which converts the node displacements into RGB pixel values, and expresses the mode vector diagrams by RGB color images intuitively. In this way, the existing image processing algorithms [

23] can be used, which greatly enriches the analysis method for the mode of vibration. Converting the data processing of mode shapes into image processing simplifies the data analysis process and makes the mode of the vibration analysis more intuitive and simpler.

3. Graphical Analysis Method of the Mode Shape

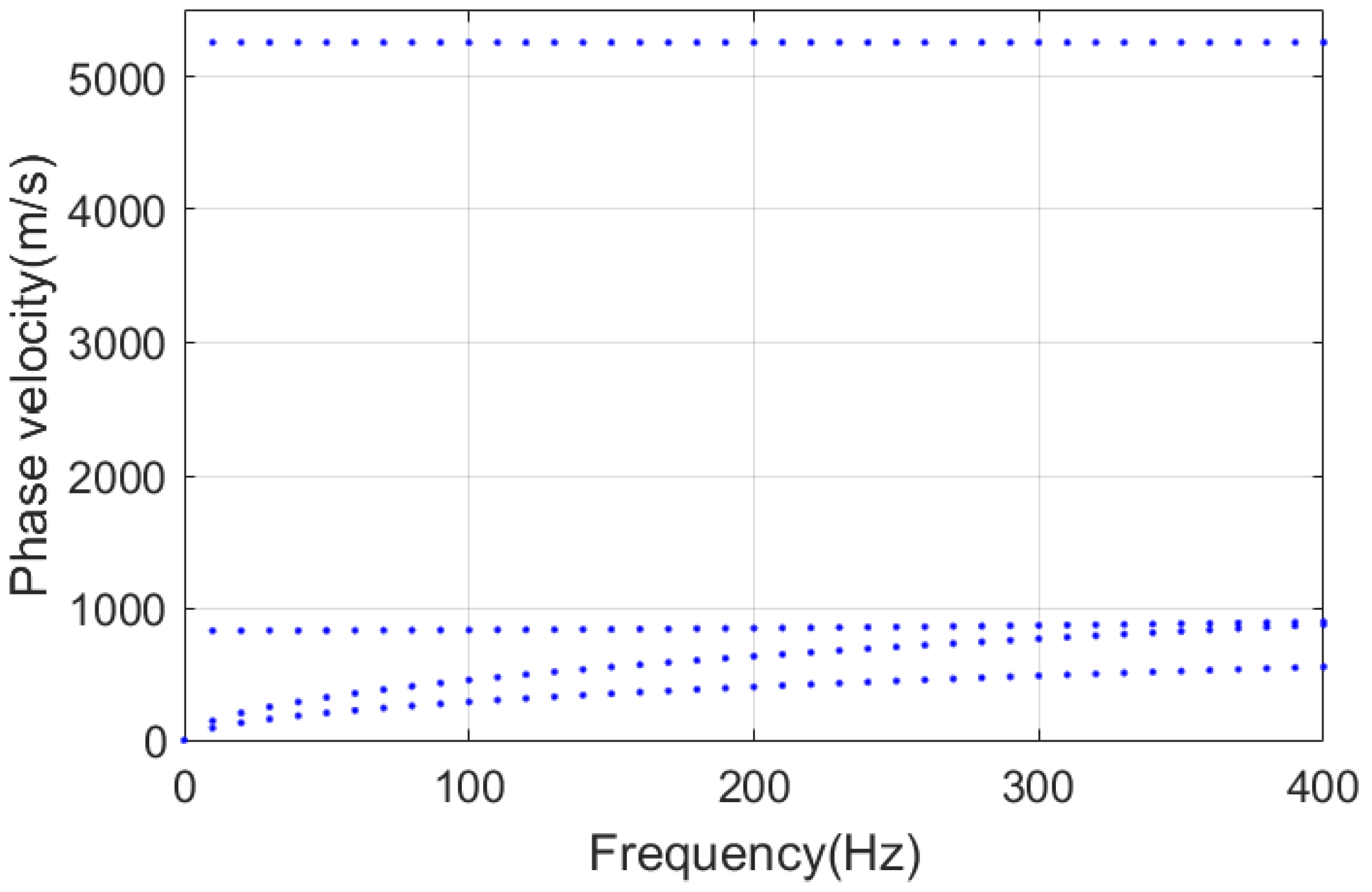

At the low frequency, the number of guided wave modes in the rail is relatively small. With the increase of the frequency, the number increases gradually. Expressing the vector matrix data of the mode shapes in a graphical way can display the vibration characteristics of each mode more intuitively. Furthermore, processing is more efficient with a common image processing method.

Given a frequency,

f, the eigenvector,

U, can be solved as Equation (5). It contains the displacement information of each node of all modes as Equation (6):

The eigenvector,

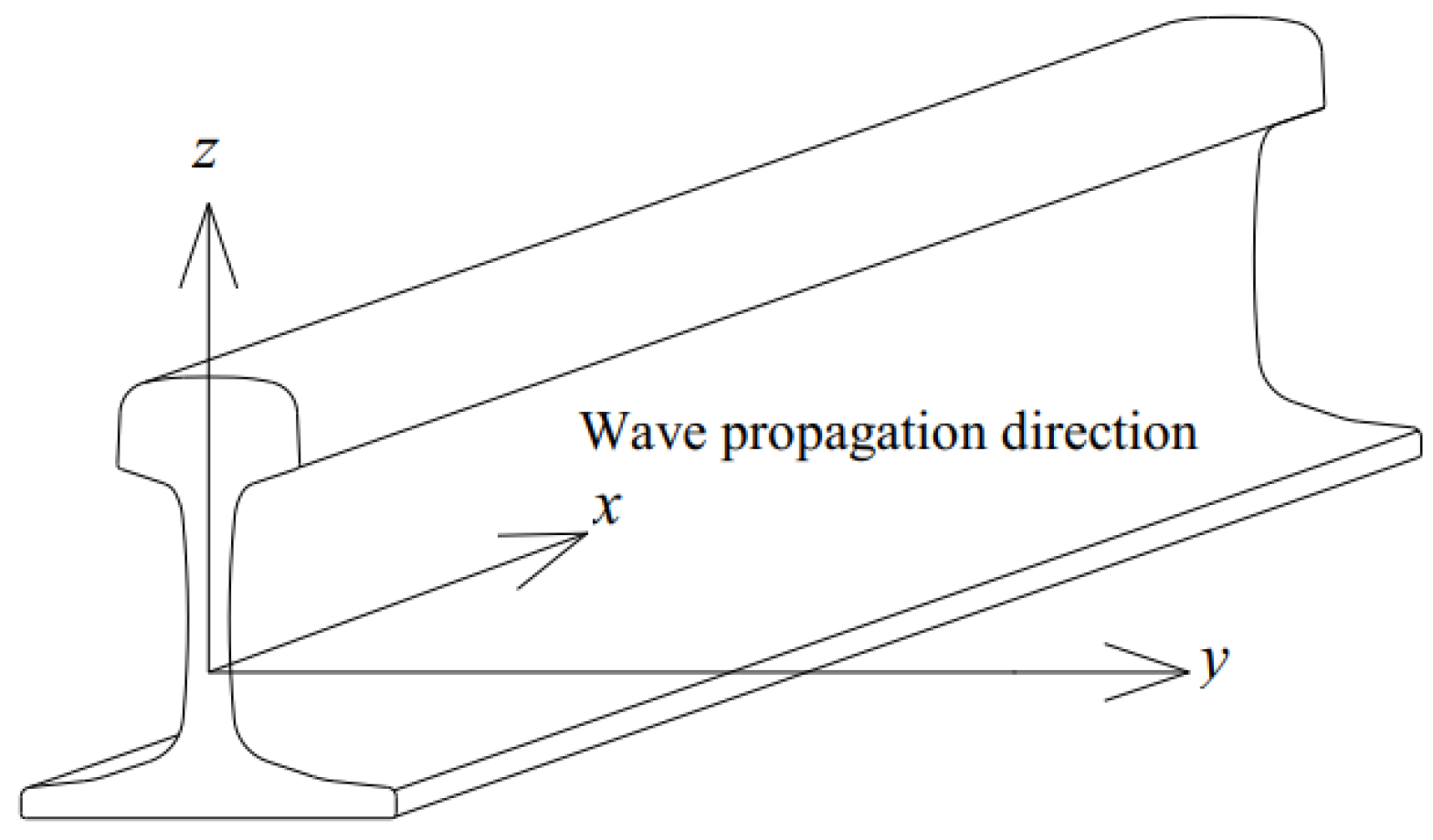

, includes the mode shape information of m modes. There are

n nodes, and each node has displacements in the

x, y, and

z directions in the discrete rail cross-section as shown in

Figure 2. For a specific mode, the eigenvector solves the displacement values of

n discrete nodes of all rail cross-sections. Taking the frequency of 35 kHz as an example, 20 guided wave modes can propagate in the rail, as shown in

Table 1.

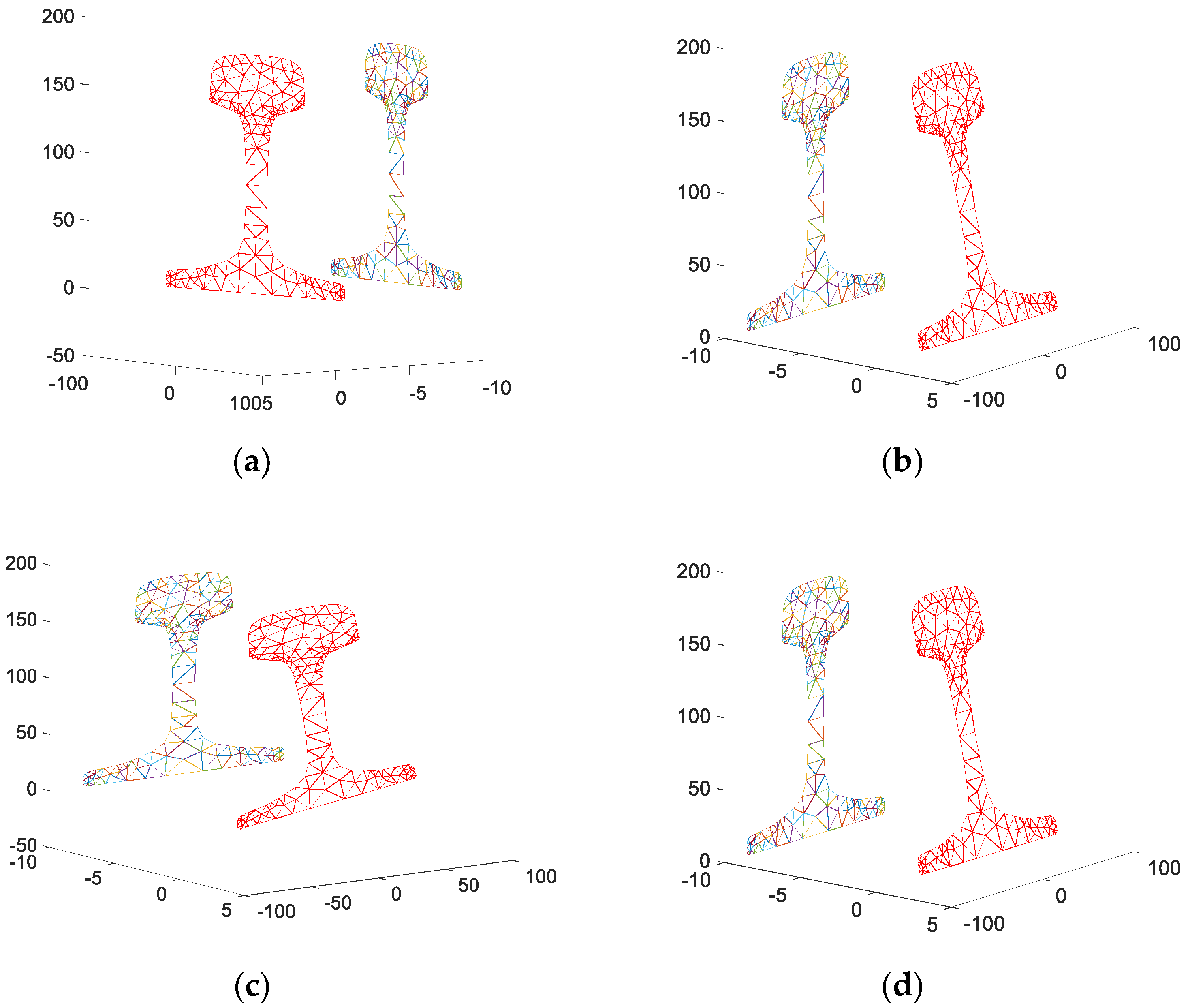

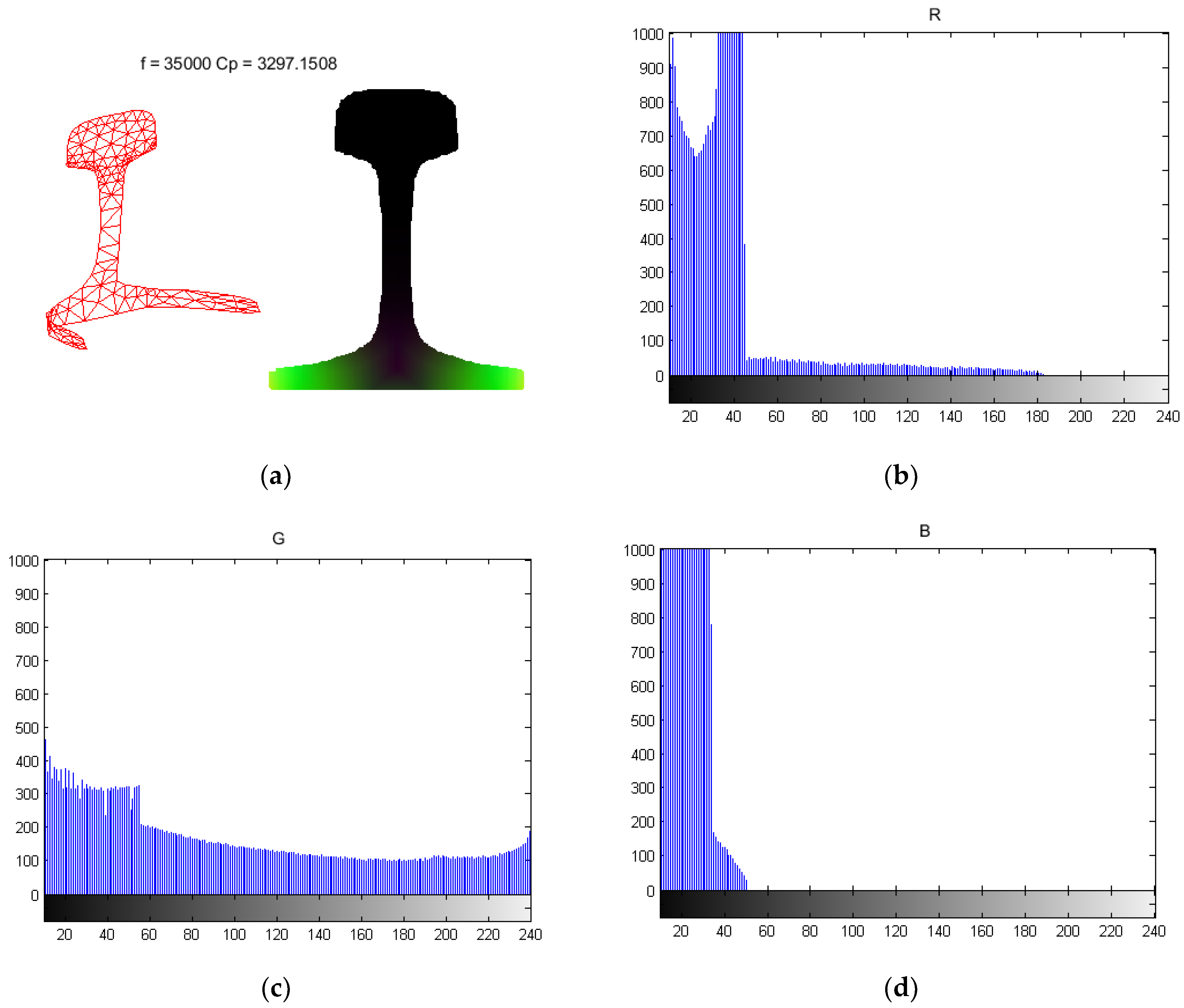

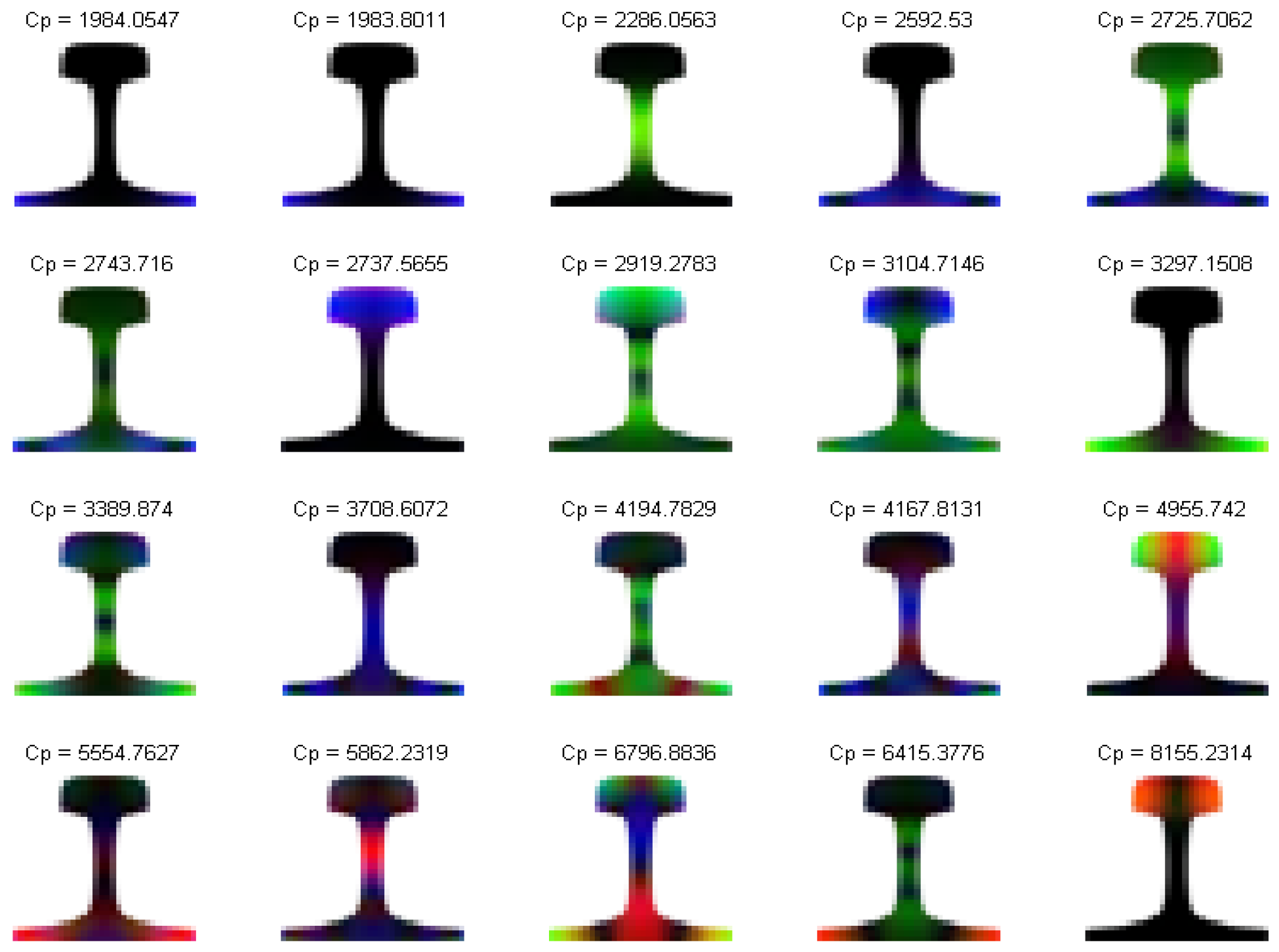

The shapes of mode 2, mode 3, mode 7, and mode 10 with phase velocities of 1983.80 m/s, 2286.06 m/s, 2737.57 m/s, and 3297.15 m/s, respectively, are plotted in

Figure 7.

According to the vibration mode information of the guided wave modes in the rail, the main vibration position and energy concentration point can be analyzed to determine the excitation position and direction of the mode. The orthogonal relationship between the modes can also be analyzed. However, these processing methods require related data processing on the mode matrix data without a fixed algorithm theory, and researchers need to design related algorithms according to the data characteristics.

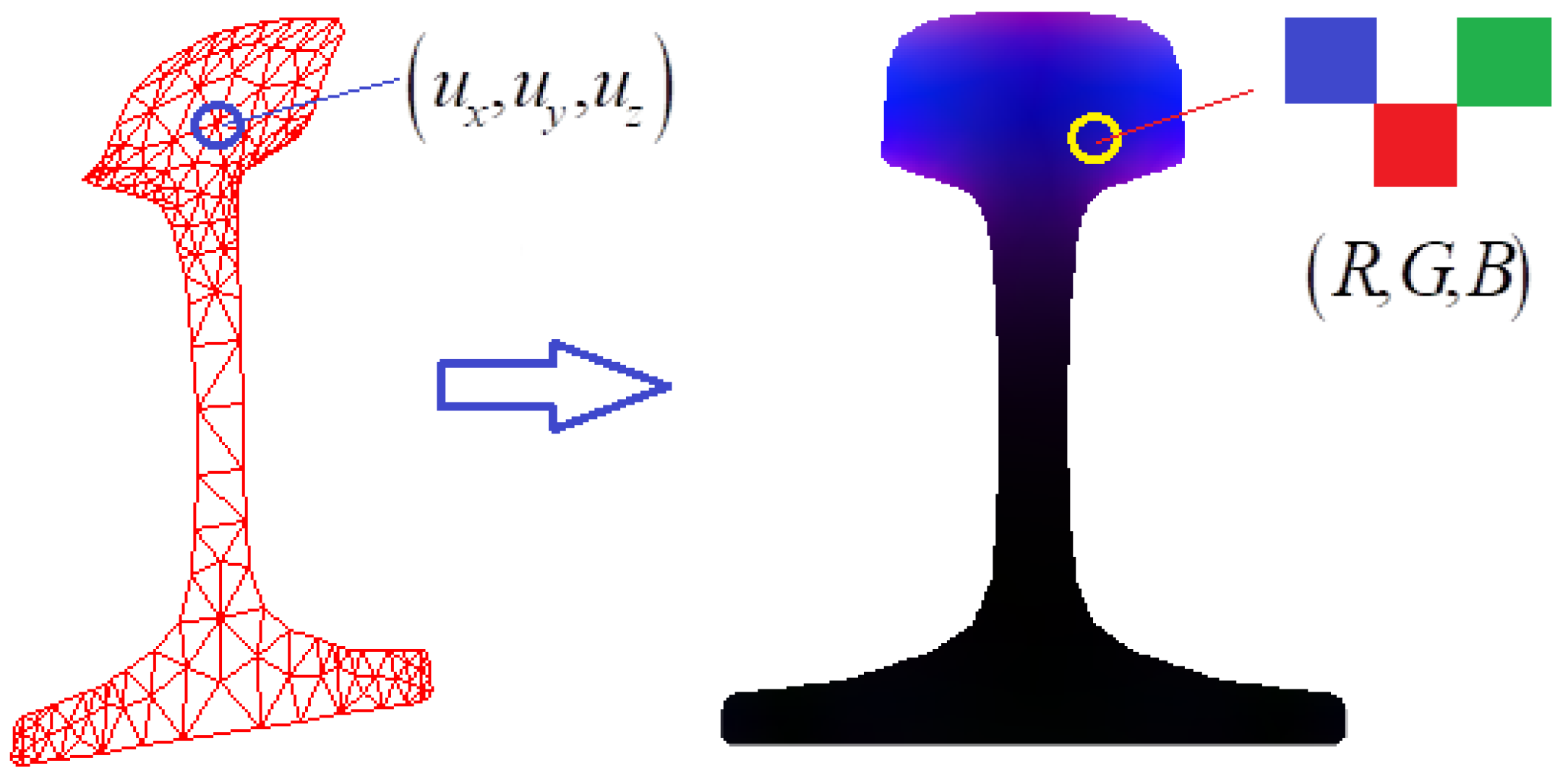

At present, image processing technology has been widely used in various industries. There are many image processing methods, such as the histogram, binarization, gradient method, and so on. If the vibration mode vector data is converted into an image, the guided wave modes in the rail can be analyzed by the image processing method directly. The conversion idea is shown in

Figure 8, which converts the displacement value of any point in the triangle element into RGB pixel values.

The conversion process includes the following steps:

- (1)

According to the rail size, the original image is generated, and the initial RGB pixel value is 0.

- (2)

Set the DPI value to generate the coordinate values of all the pixel points.

- (3)

Find the dot in the triangle elements of all coordinate values.

- (4)

Solve the displacement value of the current pixel point in the triangle elements by the difference equation.

- (5)

The displacement values of all the pixel points are converted into [0, 255] RGB pixel values by normalization.

- (6)

Plot the vibration mode image of the rail, RGB color, or gray image.

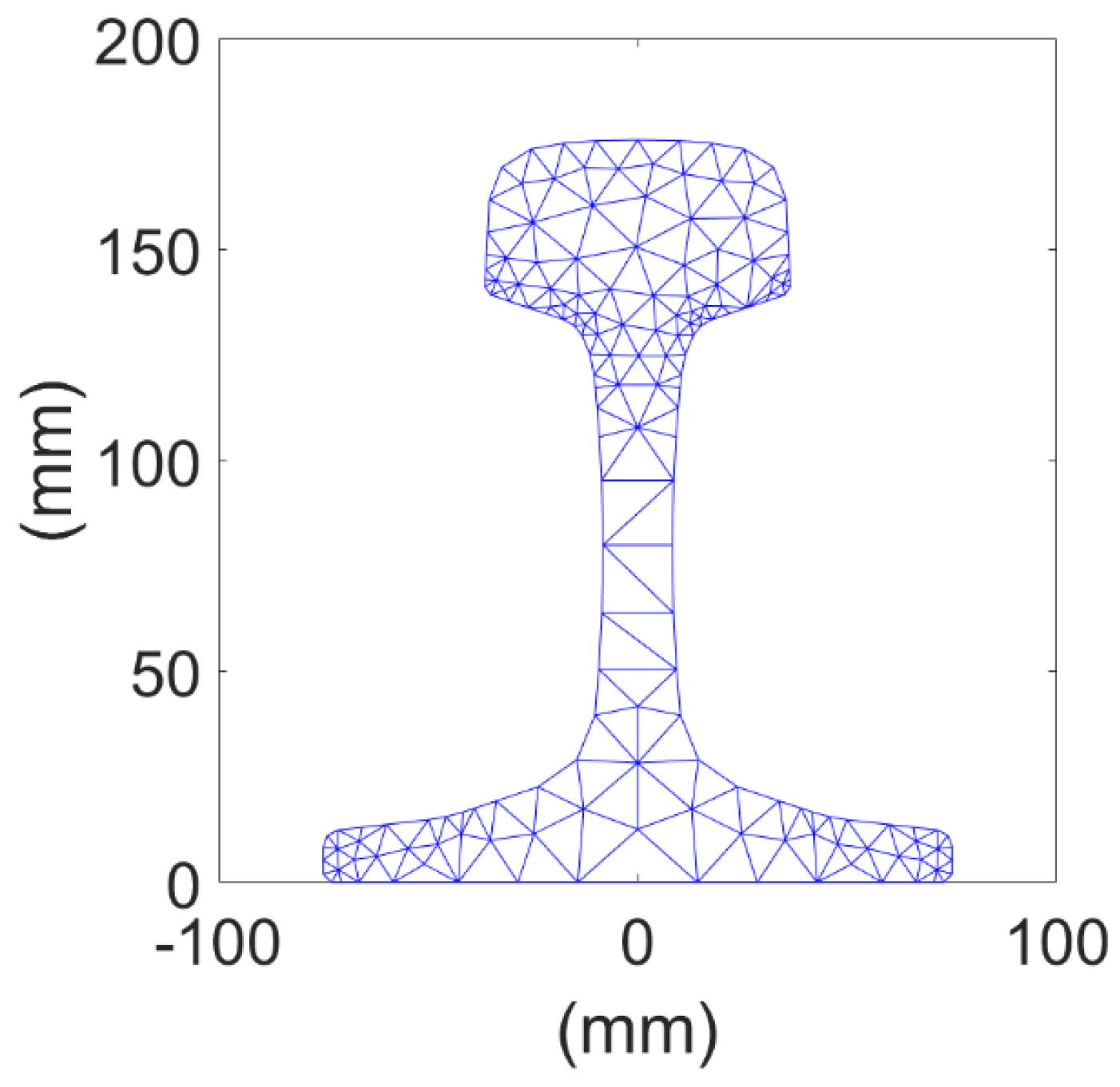

The width of the CHN60 rail base is 150 mm, and the height is 176 mm. The DPI value of the generated vibration image is set to 96. There are about 4 pixel points of 1 mm, and the image resolution is set to 601 × 705. Then, we created an image array I (601, 705, 3) and transformed 423,705 pixels in the image to the coordinate value (

y, z) of the rail cross-section. Based on the coordinate values, the vibration displacement of each pixel is solved by the difference equation of a triangular element. First, we need to know whether the coordinate is located inside the triangle element. This is judged by the method of equal area, as shown in

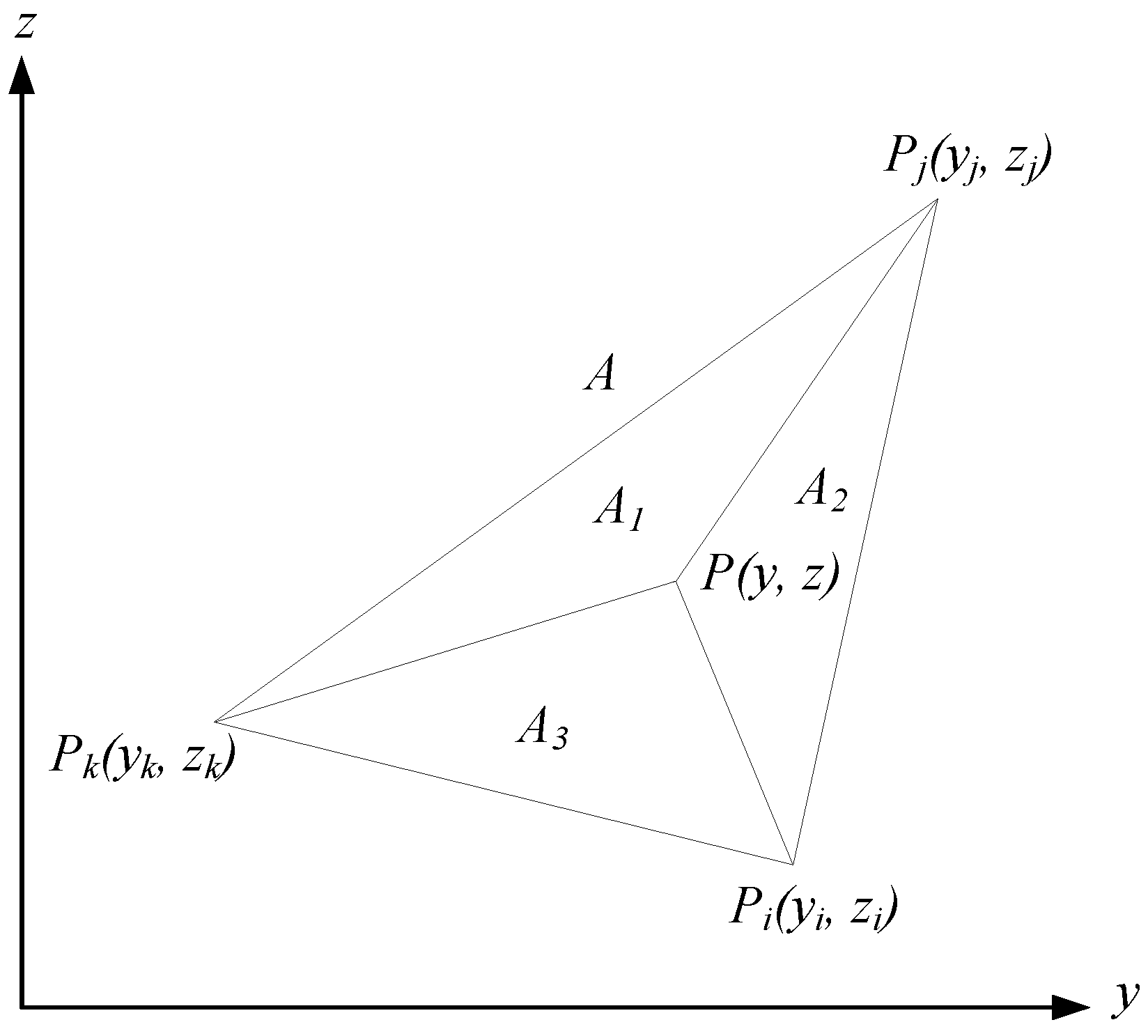

Figure 9.

The three vertices of the triangle element are

Pi, Pj, and

Pk, and its area is

A. The points,

P,

Pi, Pj, and

Pk, form three new triangles, with the areas of

A1,

A2, and

A3, respectively. If the point,

P, is inside the triangle element, it should satisfy

A =

A1 +

A2 +

A3. The coordinates of the three vertices of the triangle element are denoted as

Pi(

yi,

zi),

Pj(

yj,

zj),

Pk(

yk,

zk), and the area of the triangle is calculated using Equation (7):

For any triangular element, the displacement values of each node are solved from Equation (1). If the displacement values of the three nodes are known, the displacement value of any point inside the triangular element is obtained by the difference of Equation (2). For example, in

Figure 9, the displacement values of three vertices (nodes) are, respectively: (

uix,

uiy,

uiz), (

ujx,

ujy,

ujz), (

ukx,

uky,

ukz). The displacement values of point

P in triangular elements (

ux,

uy,

uz) are obtained as Equation (8):

where

Ni,

Nj, and

Nk are triangular element shape functions as Equation (9):

where

A is the area of the triangle element, which is obtained as Equation (7), and

α, β, and

δ are intermediate coefficients as Equation (10):

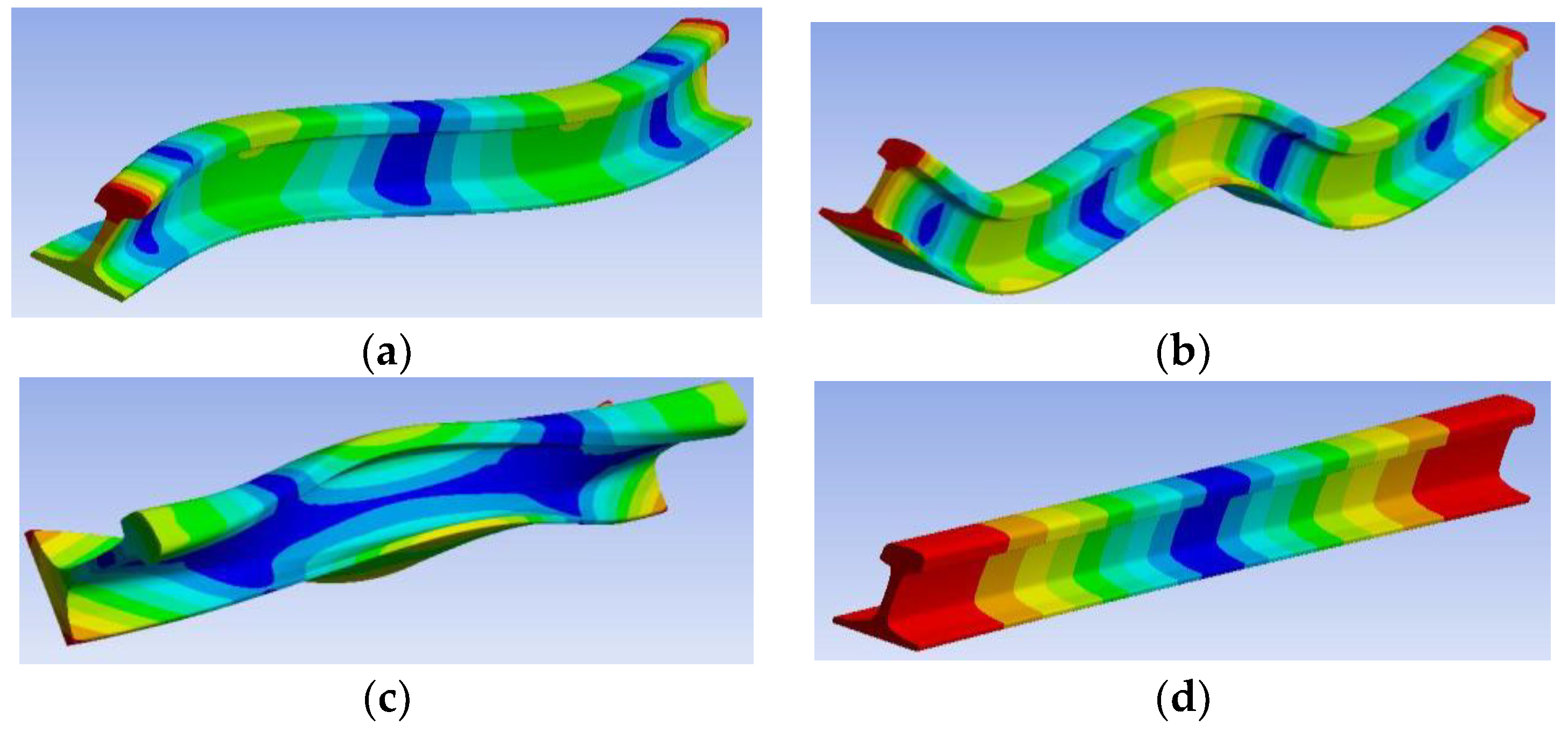

The displacement values of all pixel points are calculated according to Equation (8). They are normalized to obtain the pixel values of the interval [0, 255]. The images of the four mode shapes in

Figure 7 are obtained by calculation, as shown in

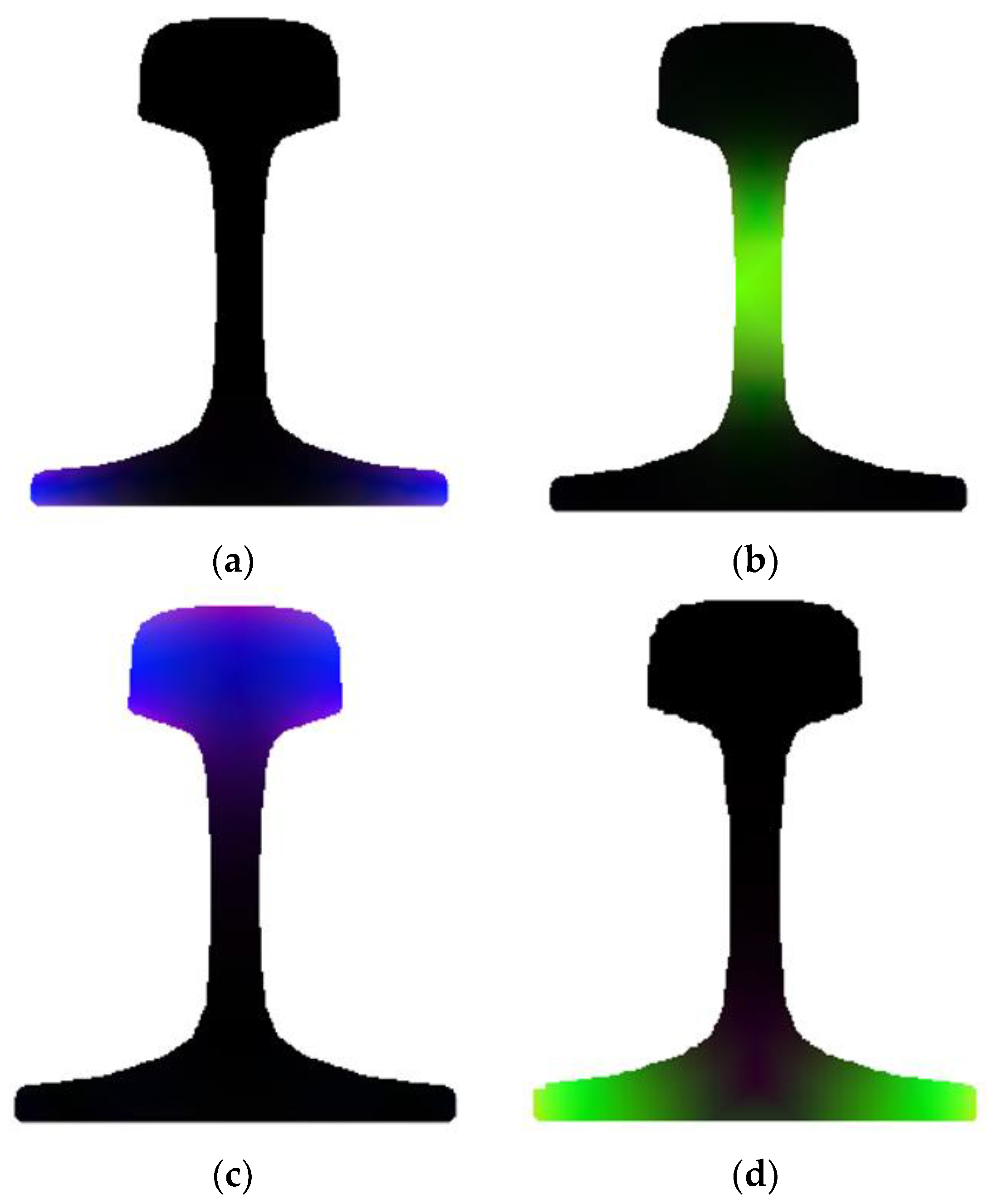

Figure 10.

The main vibration position of the mode is clearly seen from

Figure 10. When there is no vibration, the pixel value is 0, presented as the black image. According to the brightness, the displacement of the vibration is estimated. After generating the RGB image, the vibration mode can be analyzed by using the general image processing algorithm.

4. Image Processing Methods of the Mode Shape

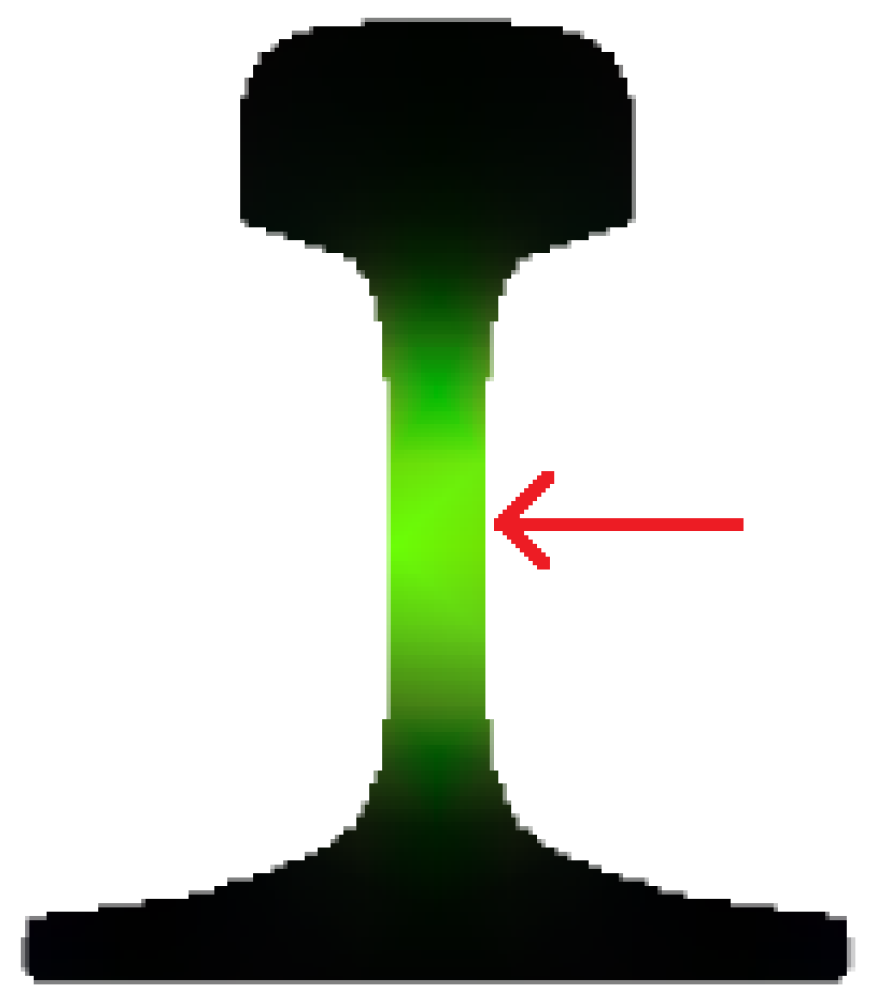

After converting the vibration vector into the RGB image, the energy concentration position of the mode is determined by viewing the RGB image. As shown in

Figure 10, the four modes at 35 kHz are selected.

Figure 10a depicts mode 2 with a phase velocity of 1983.80 m/s, and its energy is concentrated at the base of the rail.

Figure 10b shows mode 3 with a phase velocity of 2286.06 m/s, and its energy is concentrated at the rail web. Its maximum brightness is at the center of the rail web. Therefore, the crack at the rail web can be detected by this mode. The maximum vibrational positions of the other two modes are at the rail head and the rail base, respectively. Through simple image analysis and observation of the brightness distribution, it is possible to determine the location of the vibration energy concentration of each mode, and provide guidance for installation of the transducer when exciting specific modes. In the following, some simple image processing methods are adopted to analyze the mode image to obtain the vibration characteristics of the guided wave modes.

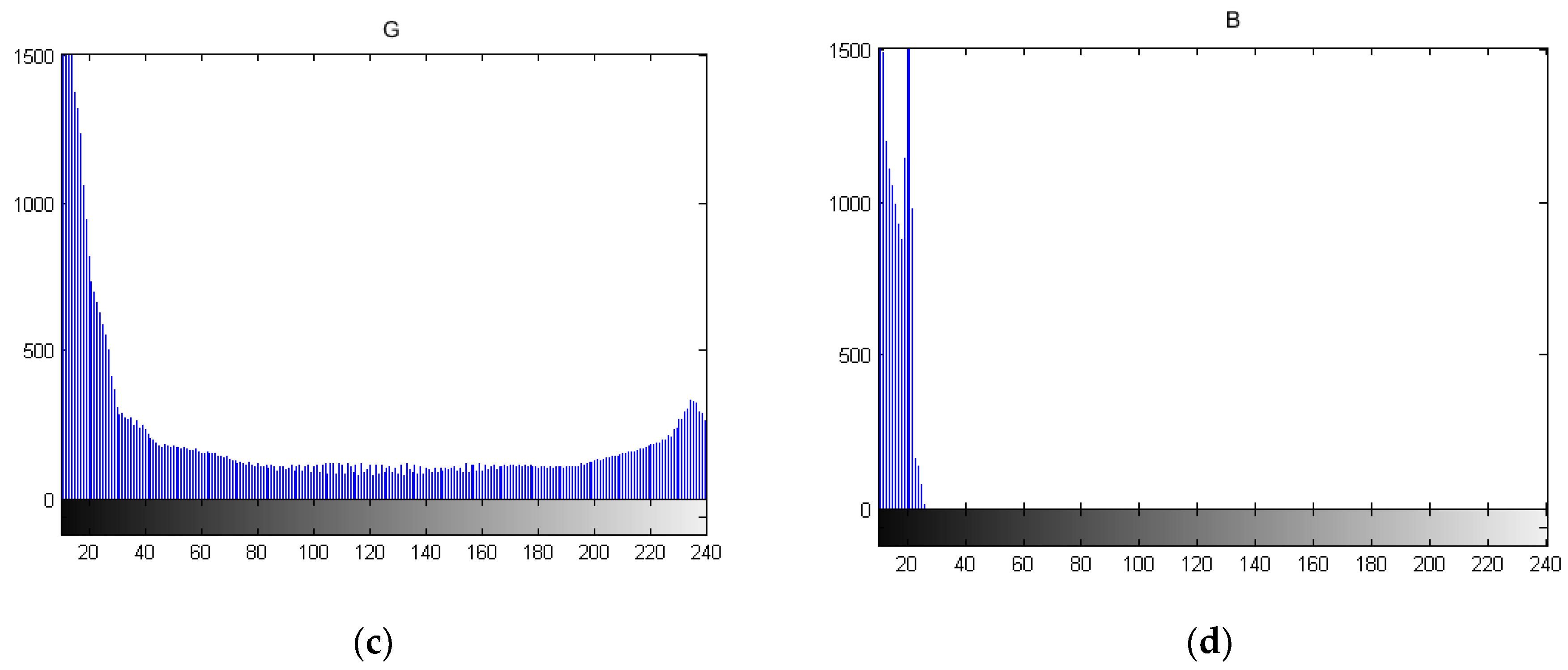

4.1. Histogram Processing

When plotting the vibration mode image of the rail, the displacement values in the x, y, and z directions are converted into the pixel values of the RGB image, respectively. The vibration distribution of the guided wave modes in the x, y, and z directions is analyzed with the histogram method. The histograms of three RGB colors are drawn, respectively. The abscissa represents the pixel value of the color from 0 to 255, and the ordinate represents the distribution of the pixel value. The more the distribution of the pixel values in the image is on the right side, the greater the vibration value of the mode in this direction.

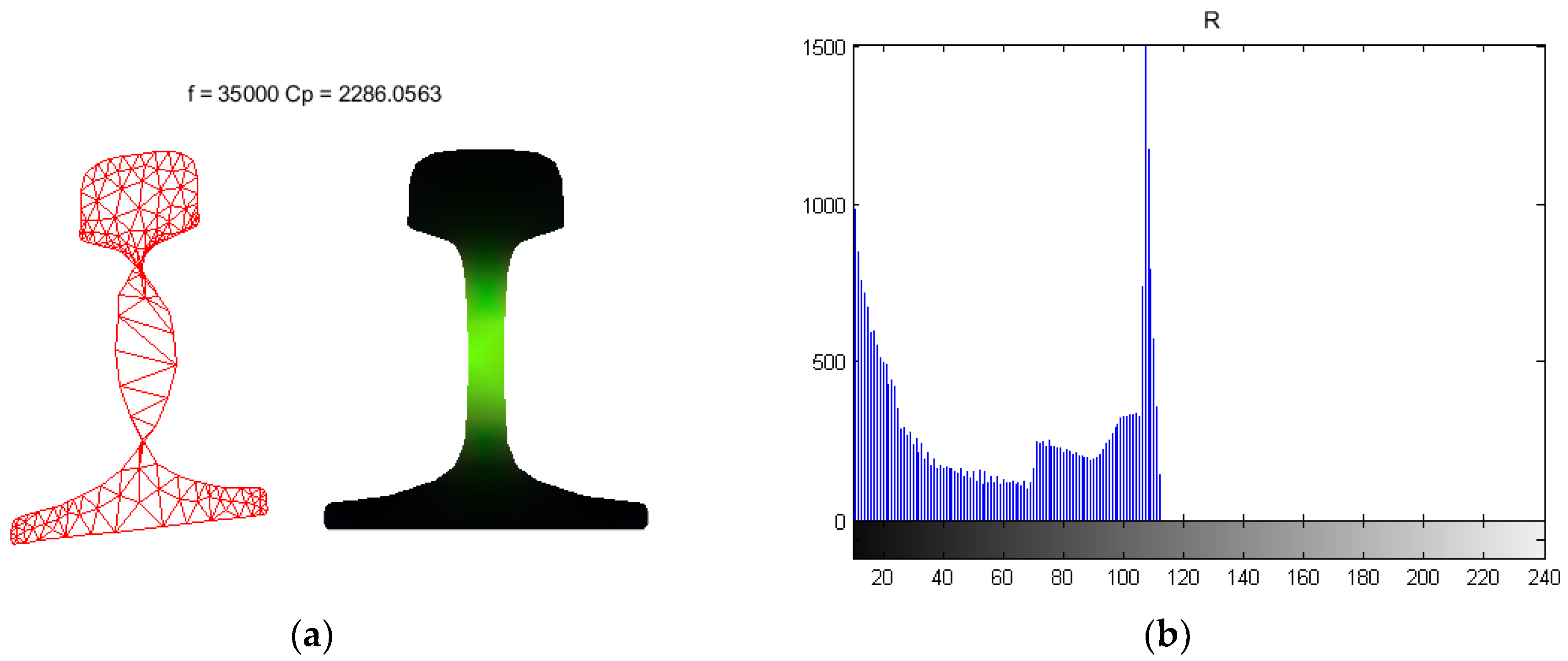

It can be seen from

Figure 11 that when the pixel value is bigger than 120, the blue pixels in the

z direction still has a 20~100 distribution in

Figure 11d. Therefore, for mode 2, the histogram in the

z direction of the blue pixels distributes more in the region of the high pixel value, so the main direction of vibration is the

z direction.

In terms of mode 3, as the pixel value increases, only

Figure 12c has a distribution in the high-pixel region. That is to say, the histogram along the

y direction of the green pixels distributes more in the region of the high pixel value, so the main direction of vibration is the

y direction.

Similarly, in terms of mode 7, only

Figure 13d has a distribution in the high-pixel range of 145 to 240. This is, the histogram of the blue pixels distributes more in the region of the high pixel value, so the main direction of vibration is the

z direction.

In terms of mode 10, when the pixel value is bigger than 180, the green pixels in the

y direction still has the distribution in

Figure 14c. That is to say, the histogram of the green pixels distributes more in the region of the high pixel value, so the main direction of vibration is the

y direction.

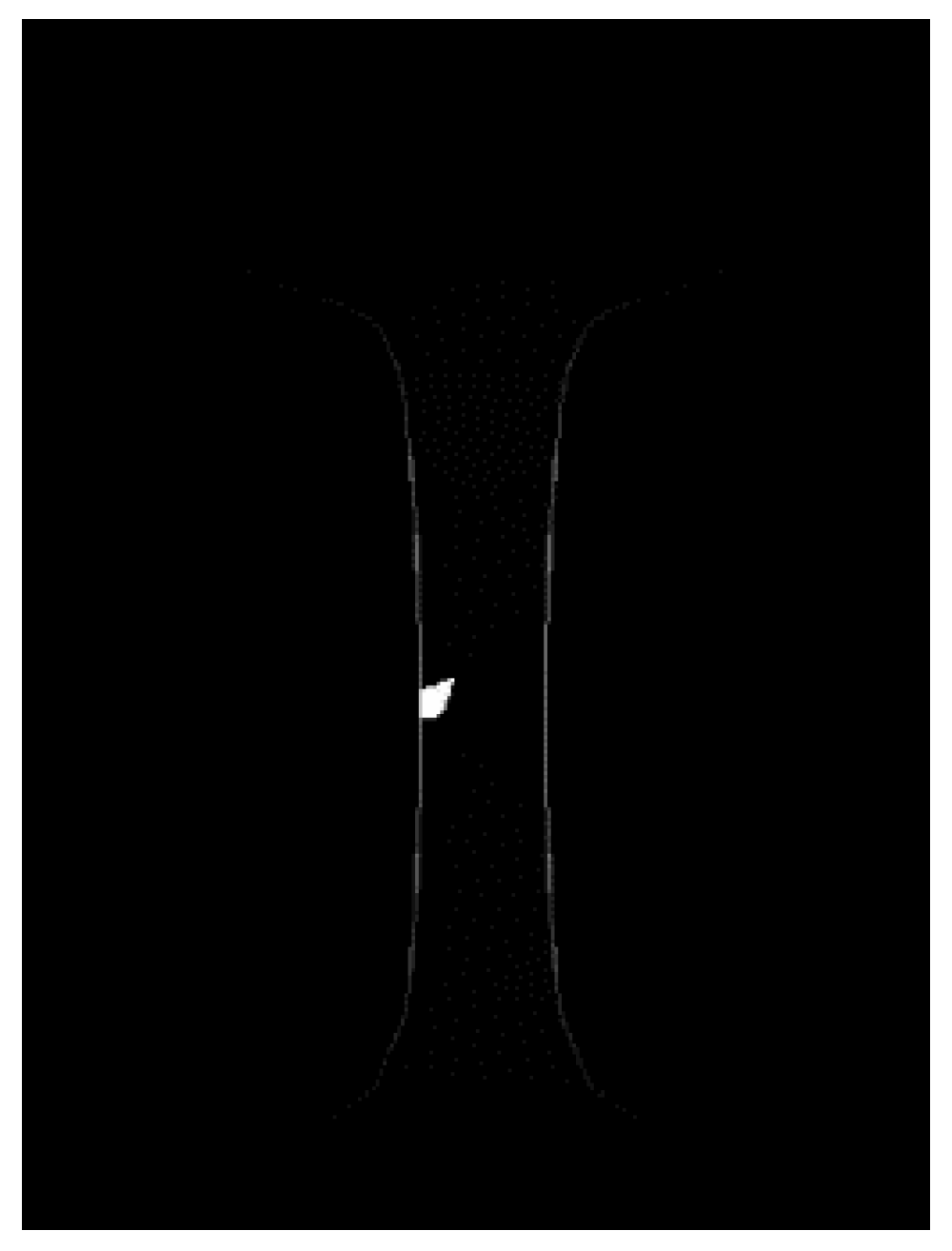

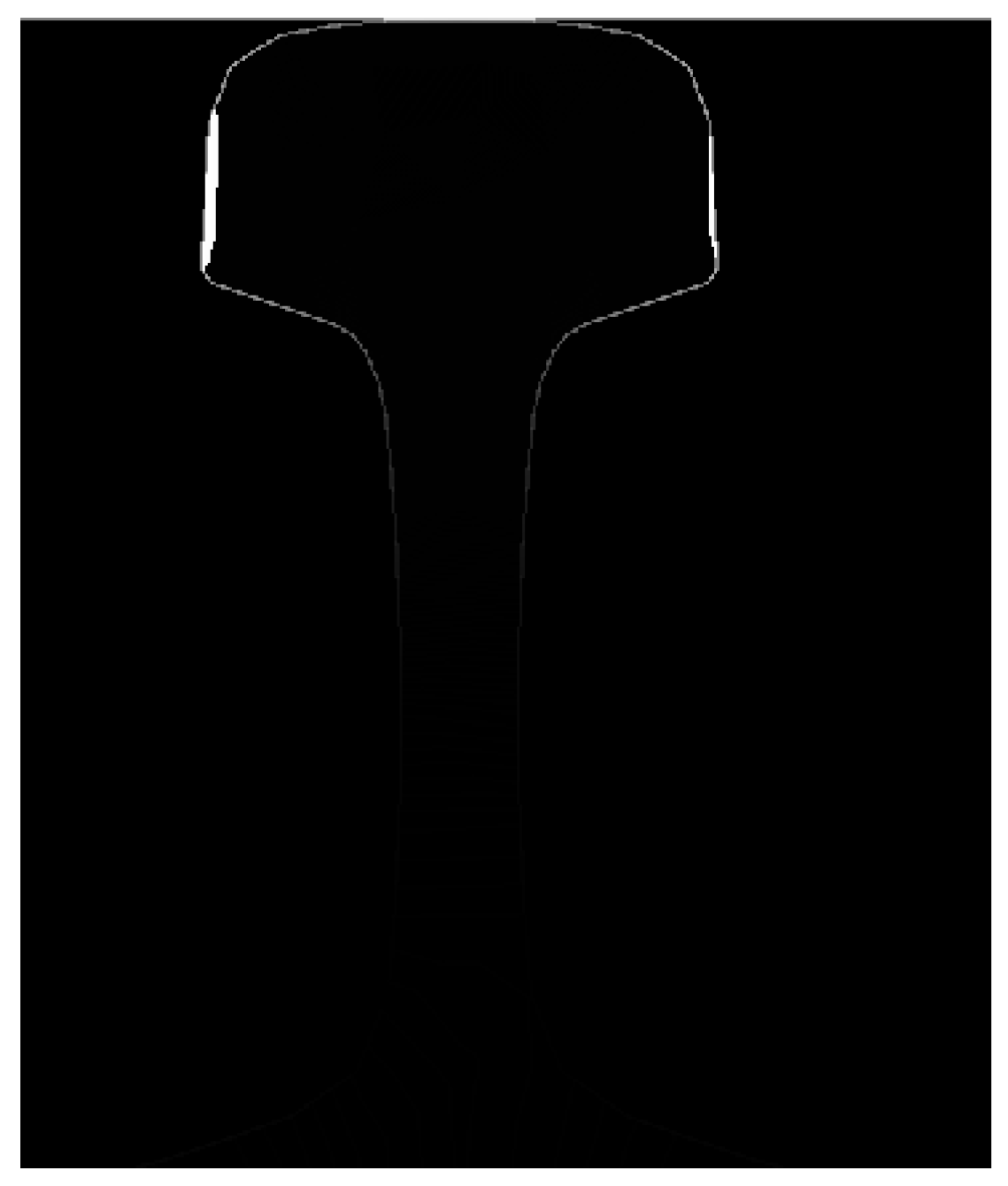

4.2. Image Gradient and Binarization

After obtaining the energy distribution area and the main vibration direction of a mode, it is necessary to estimate the maximum vibration area of this mode in order to determine the installation location of the transducer when exciting this mode. To deal with this issue, the binarization method of the image processing is used by setting a maximum pixel threshold. The pixel value is set to 1 if it is greater than the threshold and 0 if it is less than the threshold. The pixel value of the non-rail area is set to 0 in order to eliminate disturbances. The outline of the rail is plotted by the edge extraction method of the image gradient. The gradient edge extraction and binarization image of mode 3 are shown in

Figure 15.

After binarization, it can be seen that the maximum vibration point of mode 3 is in the rail web center. Therefore, in order to excite mode 3, a transducer is installed in the center of the rail web and excited in the y direction.

In the same way, mode 7 is binarized. As shown in

Figure 16, the maximum vibration point of mode 7 is located on both sides of the rail head in the

z direction.

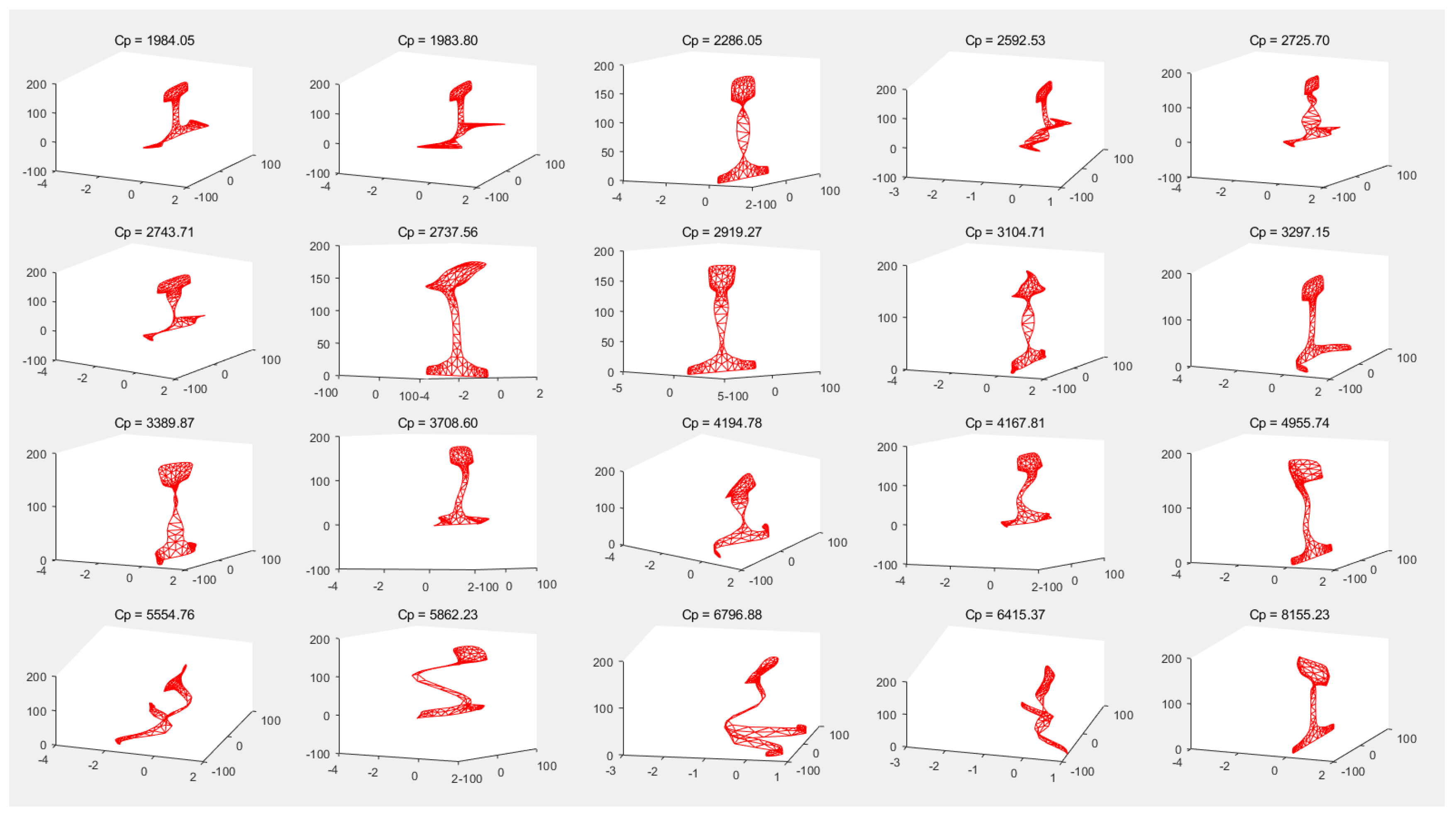

4.3. Mode Classification Based on the K-Means Clustering Algorithm

In the study of guided waves, researchers usually classify guided wave modes according to the mode shapes. Lamb waves in plates are divided into symmetric and antisymmetric modes. The modes in the pipeline are divided into the longitudinal mode, torsional mode, and bending mode. Due to the complexity of the cross-section, the modes in the rail are divided into the longitudinal mode, torsional mode, and bending mode according to the mode shapes at low frequencies. However, the mode is very complicated at high frequencies, e.g., at 35 kHz, there are 20 modes in the rail as shown in

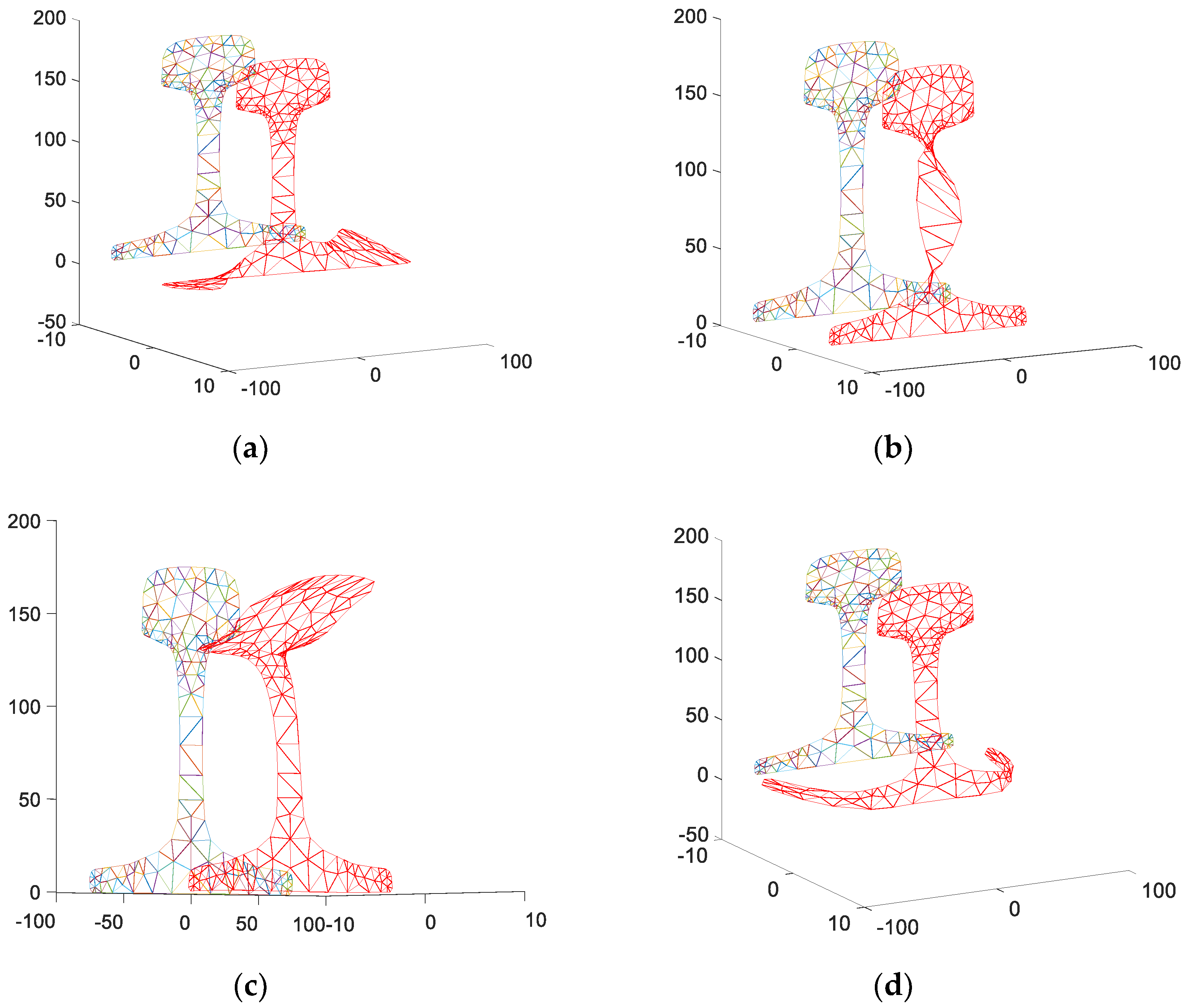

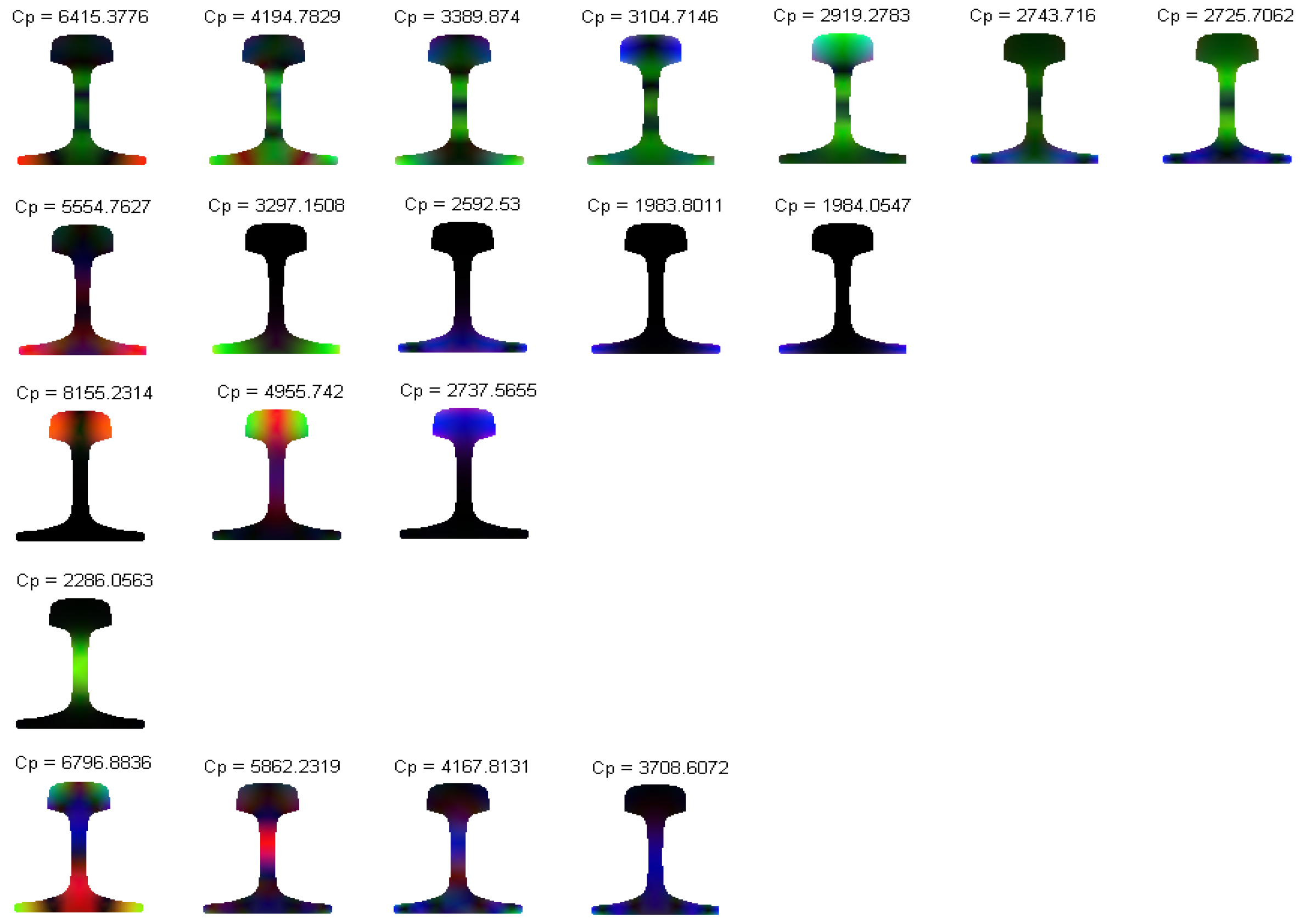

Figure 17.

As clearly shown in the figure, the guided wave modes are complex and cannot be classified intuitively from the mode diagrams. Therefore, we converted the mode shapes in

Figure 17 into RGB images as shown in

Figure 18.

According to the color image of

Figure 18, the common image classification algorithms in image processing, such as the K-means clustering algorithm, can be used to classify the color image of modes. K-means is one of the clustering algorithms [

25], where K represents the number of categories and means represents the mean. The K-means clustering algorithm divides similar data points by a preset K value and the initial centroid of each category. The optimal clustering results are obtained by iterative optimization of means.

Firstly, the RGB images of the guided wave modes in

Figure 18 is compressed to reduce the dimension of image data processing. The original image resolution of the mode shape is 601 × 705, and the color image is compressed to 32 × 32 pixels as shown in

Figure 19.

Each color image of the mode shape is expanded into a one-dimensional array. There are 32 × 32 pixels, each of which contains three RGB values. Then RGB images of 20 modes generate a 20 × 3072 raw data array shown as Equation (11):

where

represent three color pixel values of the nth mode.

The array is classified by the K-means clustering algorithm with K = 5. Since the initial centroid of the K-means clustering algorithm is randomly selected, the results are inconsistent. Therefore, the classification results with the highest frequency are obtained through multiple classifications, as shown in

Figure 20.

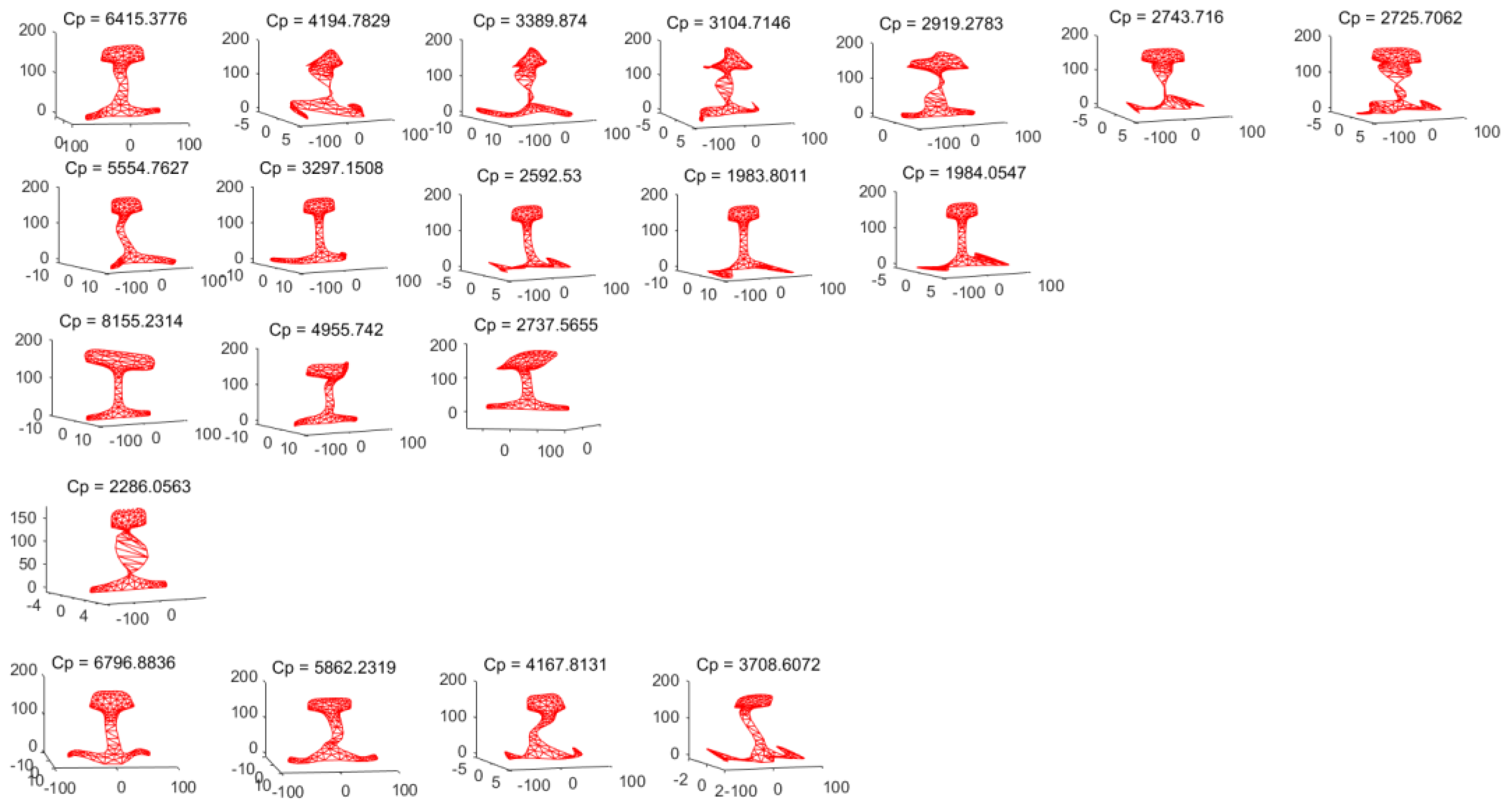

In order to observe the classification results conveniently, the vibration displacement diagrams of each mode are plotted as shown in

Figure 21.

It can be seen from

Figure 21 that the K-means clustering algorithm divides the mode shapes into five categories at the frequency of 35 kHz in the rail. The first type of mode shape has large vibration over the whole rail cross-section. In the second type, the maximum vibration position is located at the rail base. The vibration is mainly located at the rail head in the third type. The fourth type is a torsional vibration. The vibration of the rail head and the rail base is small, and the vibration of the rail web is large. In the fifth type, the vibration position is in the rail web, and its vibration is S-type and non-torsional. By classifying the guided wave modes in rails at specific frequencies, the vibration relations and regularity of each mode are found. It is of certain theoretical guiding significance for the application of guided wave technology to detect internal defects of rails at different locations.

5. Mode Excitation Simulation

Taking mode 3 at frequency of 35 kHz as an example, it can be seen from

Figure 10,

Figure 12, and

Figure 15 that the maximum vibration region of mode 3 is located at the rail web, the main vibration direction is the y direction, and the maximum vibration point is located at the center of the rail web. Therefore, as shown in

Figure 22, the excitation point is applied in the

y direction at the center of the rail web to verify whether mode 3 is excited.

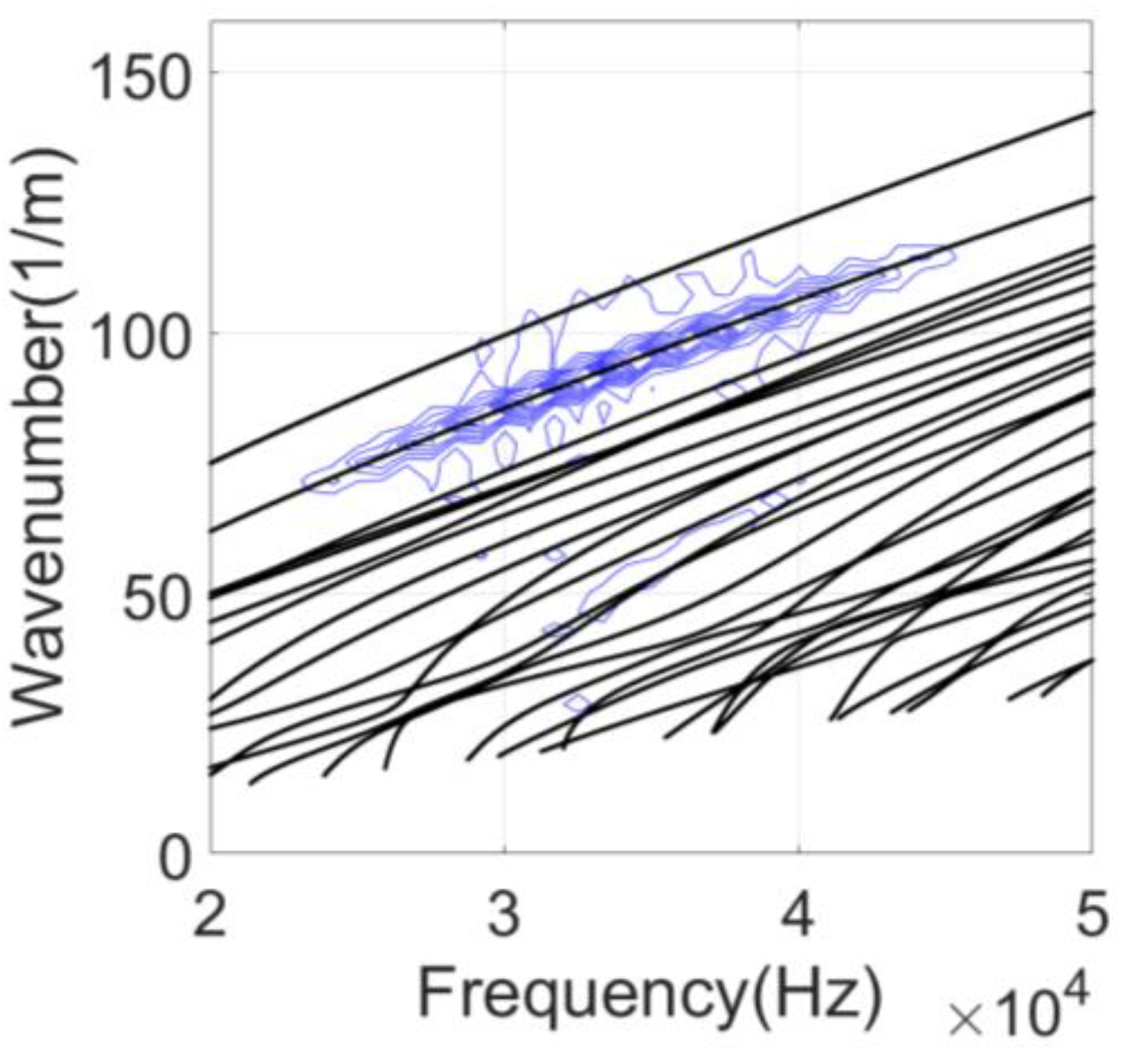

The CHN60 rail model with a length of 10 m was established by using the ANSYS (version 15.0, the ANSYS, Inc., Canonsburg, PA, USA) simulation software. In order to avoid the influence of the rail end echo on the simulation results, the excitation signal was applied to the rail periphery at 4 m from the left end of the rail model, and a data acquisition point was set between 0.8 m and 2.7 m from the excitation position with intervals of 5 mm. There were 380 synchronous acquisition points. The phase velocity of the mode was calculated by the two-dimensional fast Fourier transform(2-D FFT). The simulation results were compared with the frequency-wavenumber dispersion curves solved by the SAFE method as shown in

Figure 23.

We can see from

Figure 23 that the contour map is the 2-D FFT results of mode 3 and the black lines are frequency wavenumber dispersion curves. After merging the two curves, the 2-D FFT results coincide well with the dispersion curve of mode 3. Thus, mode 3 is excited at this point in the

y direction. Therefore, the method of determining the direction and location of the mode excitation proposed in this paper can excite the expected mode.

6. Conclusions

Ultrasonic guided waves can propagate a long distance in the rail. They are usually used for on-line monitoring of rail internal defects, which provides early warning data for rail maintenance. There are many guided wave modes that can propagate in the rail, and their mode shapes are different. The analysis of the vibration regularity of guided wave modes is of great significance for mastering the propagation characteristics of guided waves and the efficient use of guided waves for non-destructive testing.

Based on the SAFE method, the dispersion curves of the guided waves in the rail were solved. The eigenvectors contain the vibration displacements of discrete nodes of the rail cross-section. Since there were no existing algorithms in the literature, it was necessary to design one for the analysis of the vibration mode data while using the traditional matrix data processing method. It requires numerous data computing and is not intuitive. Therefore, this paper proposed a processing method to convert the vibration mode data of the rail into the RGB image. Modes of vibration were visually displayed as an image. At the same time, it is realizable to directly use various existing algorithms of image processing. The mode shapes of the rail can be analyzed by image processing algorithms, such as the histogram, binarization, gradient solution, and image classification. By applying the proposed image processing method in the analysis of vibration mode data, the guided wave modes at a specific frequency were preliminarily classified. The energy concentration position of each mode was further determined. The simulation results proved that this method provides a solid theoretical reference for the design and installation of excitation transducers. When detecting rail cracks based on ultrasonic guided wave technology, this method can also guide the selection of a specific mode to detect a crack in different cross-section positions.