Smart Cyber-Physical Manufacturing: Extended and Real-Time Optimization of Logistics Resources in Matrix Production

Abstract

:1. Introduction

2. Literature Review

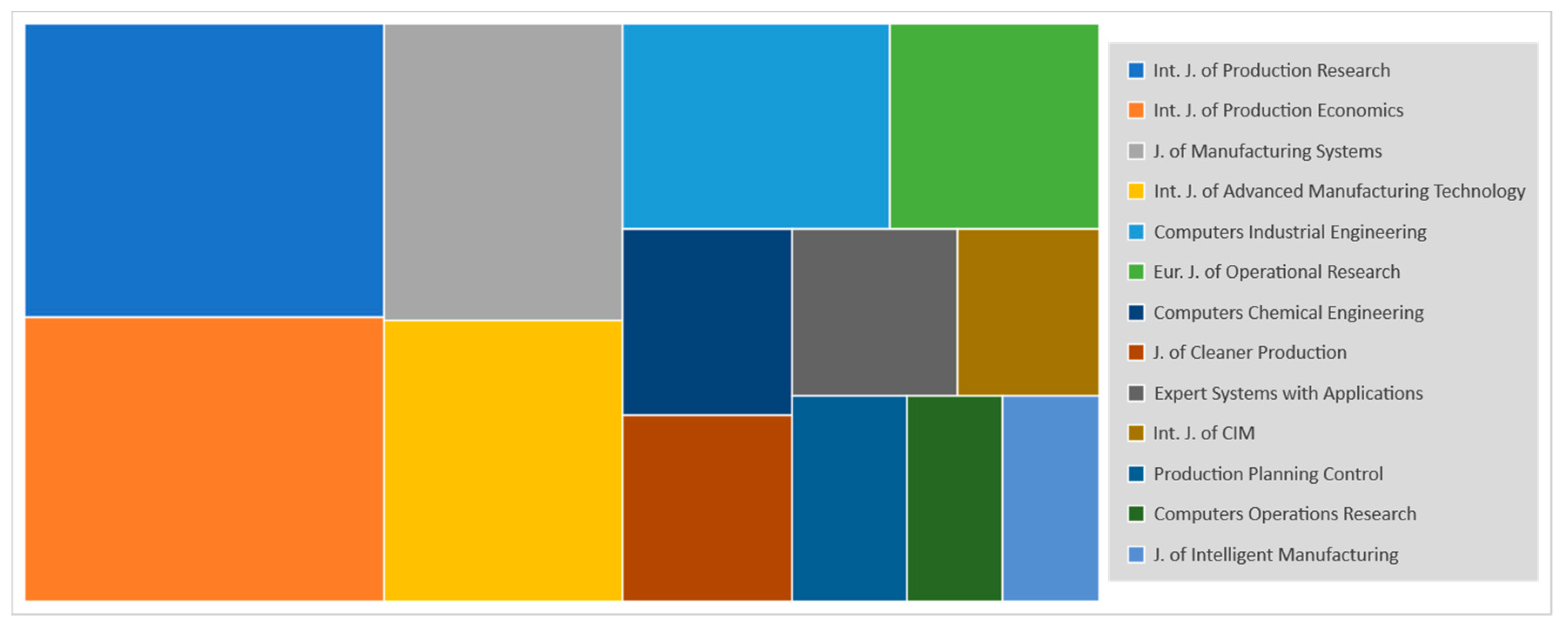

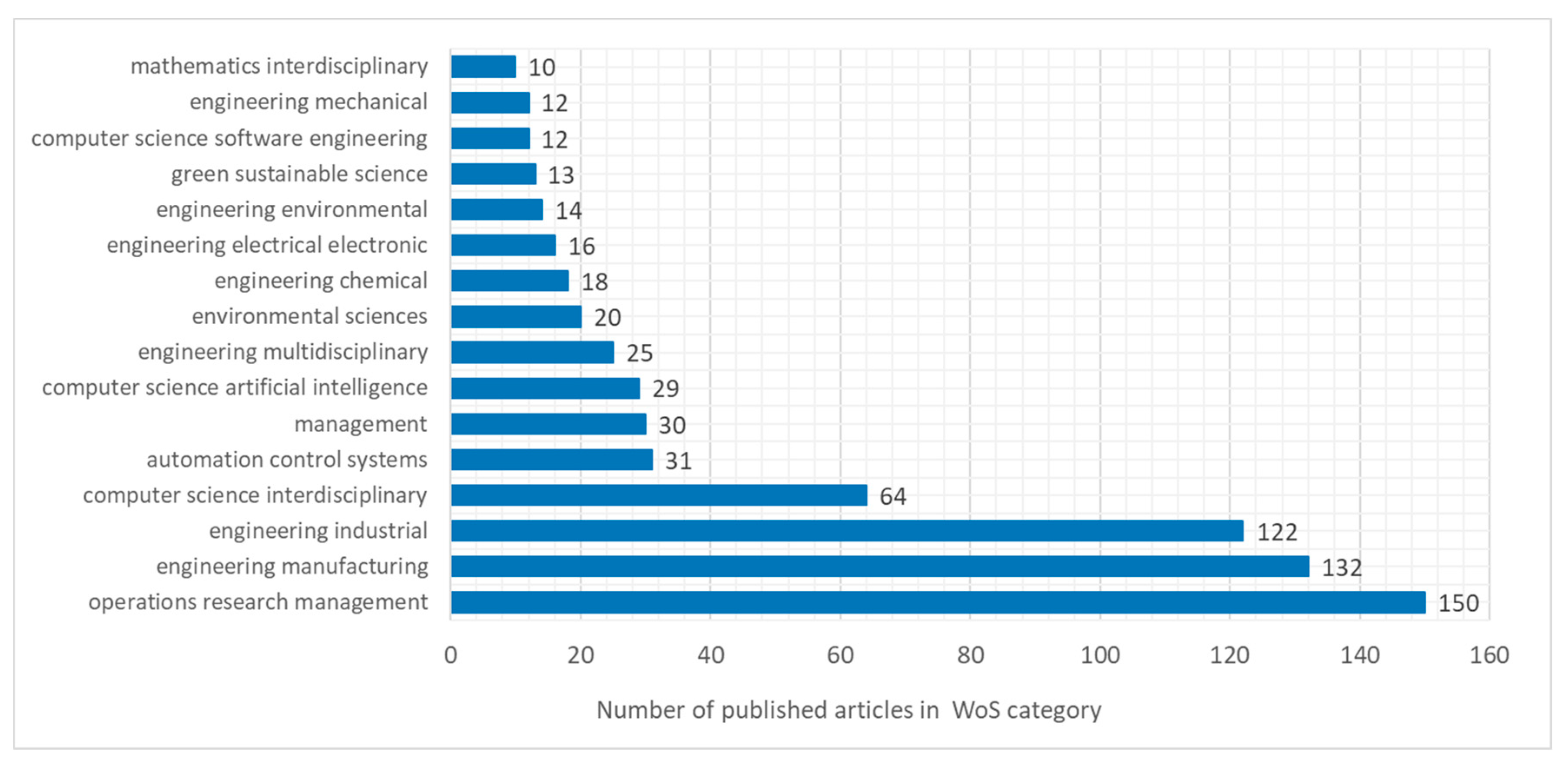

2.1. Descriptive Analysis

2.2. Content Analysis

A Holonic Manufacturing System (HMS) is a manufacturing system where key elements, such as machines, cells, factories, parts, products, operators, teams, etc., are modeled as ‘holons’ having autonomous and cooperative properties. The decentralized information structure, the distributed decision-making authority, the integration of physical and informational aspects, and the cooperative relationship among holons, make the HMS a new paradigm, with great potential for meeting today’s agile manufacturing challenges.[19]

- data transmission: get data to communicate from robot to machine to person,

- connection: get this data to a large capacity IoT server,

- big data processing: make the data visible and actionable to people for analysis.

2.3. Consequences of Literature Review

3. Methodology—Mathematical Modelling and Heuristic Optimization Method

- mathematical modelling of the cyber-physical matrix production system from an extended and real-time optimization point of view,

- performance analysis of available heuristic solution algorithm and selection of the suitable algorithms,

- application of suitable algorithms to solve the extended and real-time clustering, routing, and assignment problems,

- validation of the model and the algorithm with scenario analysis.

3.1. Mathematical Modelling of Extended and Real-Time Resource Optimization in Cyber-Physical Matrix Production

3.1.1. Extended Logistics Resource Optimization

Clustering of Supply-Demand

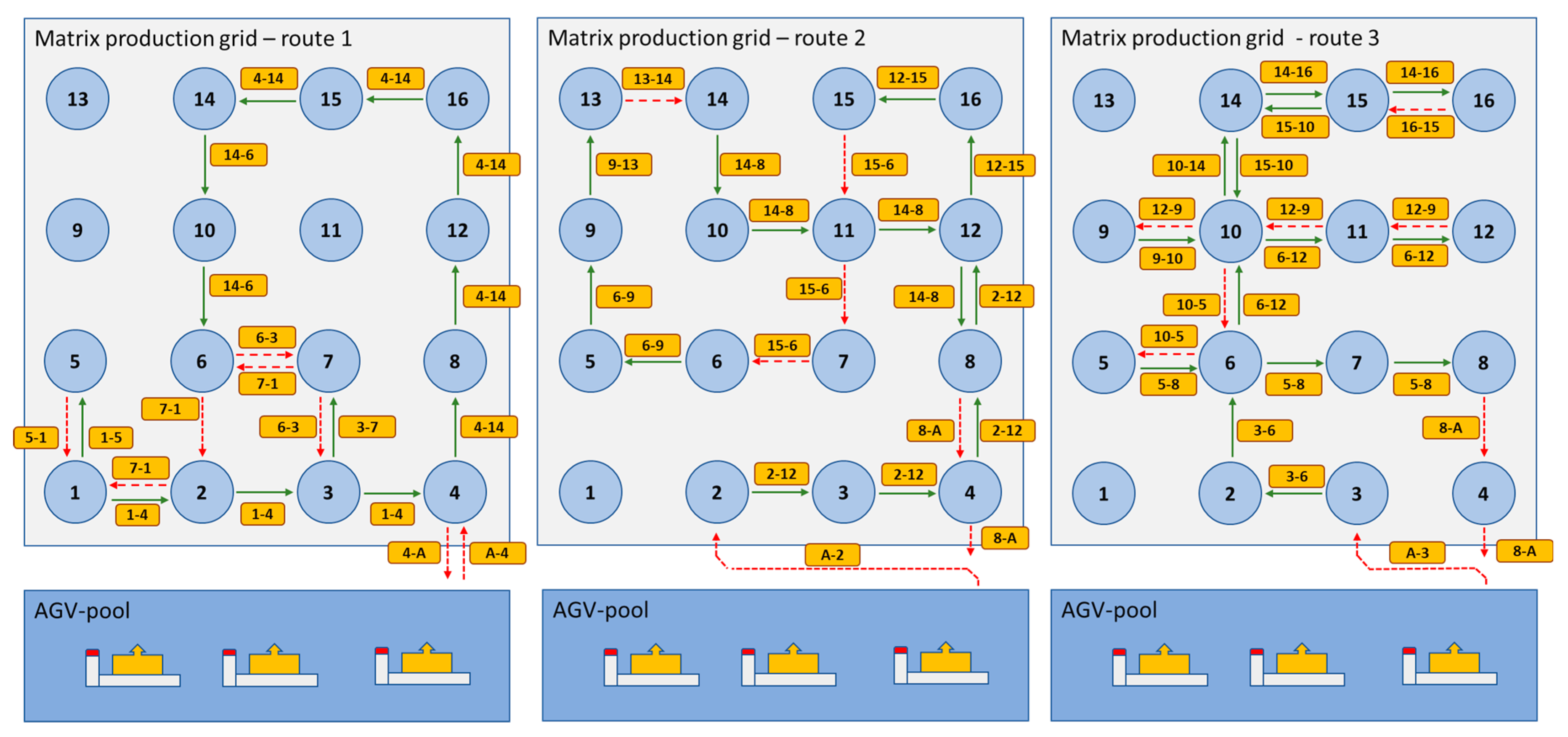

Routing and Scheduling of Supply-Demand

- Matrix cell–matrix cell relations are simply added to the virtual demand matrix:

- Component warehouse–matrix cell relation is transformed into a matrix cell–matrix cell relation. The component amount will be added as initial loading to the AGVs loading and a virtual matrix cell–matrix cell relation is added to the virtual supply-demand matrix:

- Tool storage–matrix cell relation is transformed into a matrix cell–matrix cell relation. The tool amount will be added as initial loading to the AGVs loading and a virtual matrix cell–matrix cell relation is added to the virtual supply-demand matrix:

3.1.2. Real-Time Logistics Resource Optimization

- is the x and y coordinate of the scheduled matrix cell of scheduled route r,

- and is the x and y coordinate of the pickup matrix cell of the new supply-demand ,

- and is the x and y coordinate of the destination matrix cell of the new supply-demand .

3.2. Heuristic Optimization for Extended and Real-Time Logistics Resource Optimization Based on Black Hole Algorithm

3.2.1. Black Hole Optimization-Based Clustering

- big-bang phase: this phase is the initialization of the position and velocity of stars in the multidimensional search space. The stars represent potential solutions of the optimization problem, where the coordinates of the stars in the search space are the values of the decision variables. Stars can be initialized only inside the search space.

- evaluation phase: this phase includes the calculation of the objective function based on the parameters represented by the coordinates of the star.

- selection of black hole: within the frame of this phase a new black hole is defined as having the highest value of objective function. This star has the highest weight (represented by the value of objective function) and therefore it has the highest force of gravity and it is the center of movement of stars in the next movement phase.

- moving of stars: in this phase of the algorithm, a new position of stars is calculated. The movement of the stars can be influenced only by the black hole, but it is also possible to take into consideration the gravity force of the other stars.

- decreasing the event horizon and the photon sphere: in this phase, the size of the event horizon and the photon sphere is decreased based on the Hawking radiation, which describes the lost weight process of black holes. This phase makes it possible to prevent the absorption of stars representing solutions of the optimization problem near the optimum:where is the number of the current iteration step.

- shift the position of the black hole: in this phase of the optimization we use the idea of Hawking radiation. Particles can escape and the black hole’s mass reduces because if a particle–antiparticle pair is created beyond the event horizon, it is possible to have one drawn into the black hole itself while the other is ejected [105]. The position of the black hole is shifted using the following calculation:where is the shift-factor.

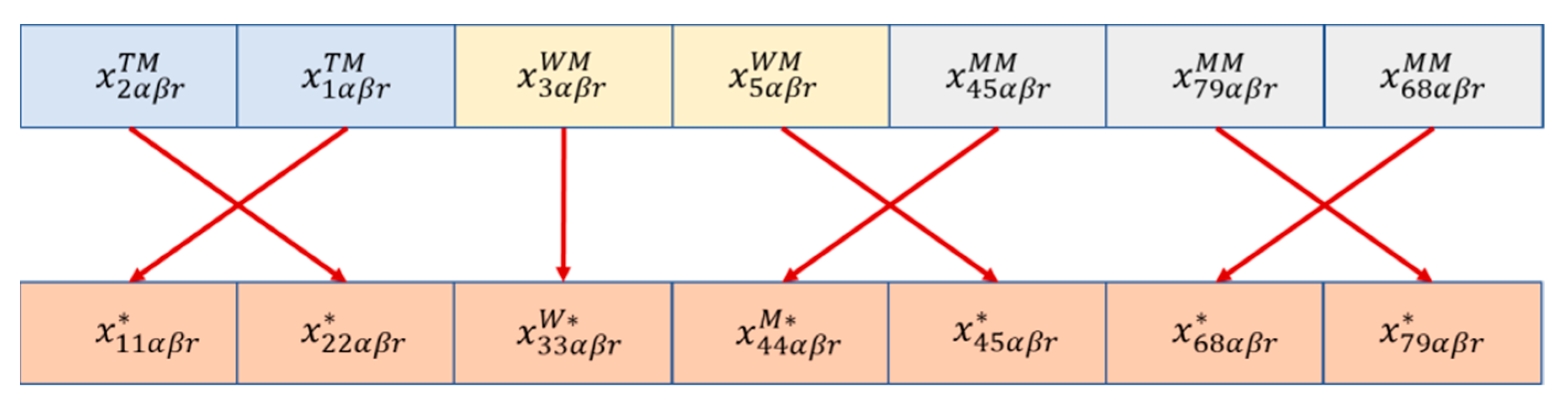

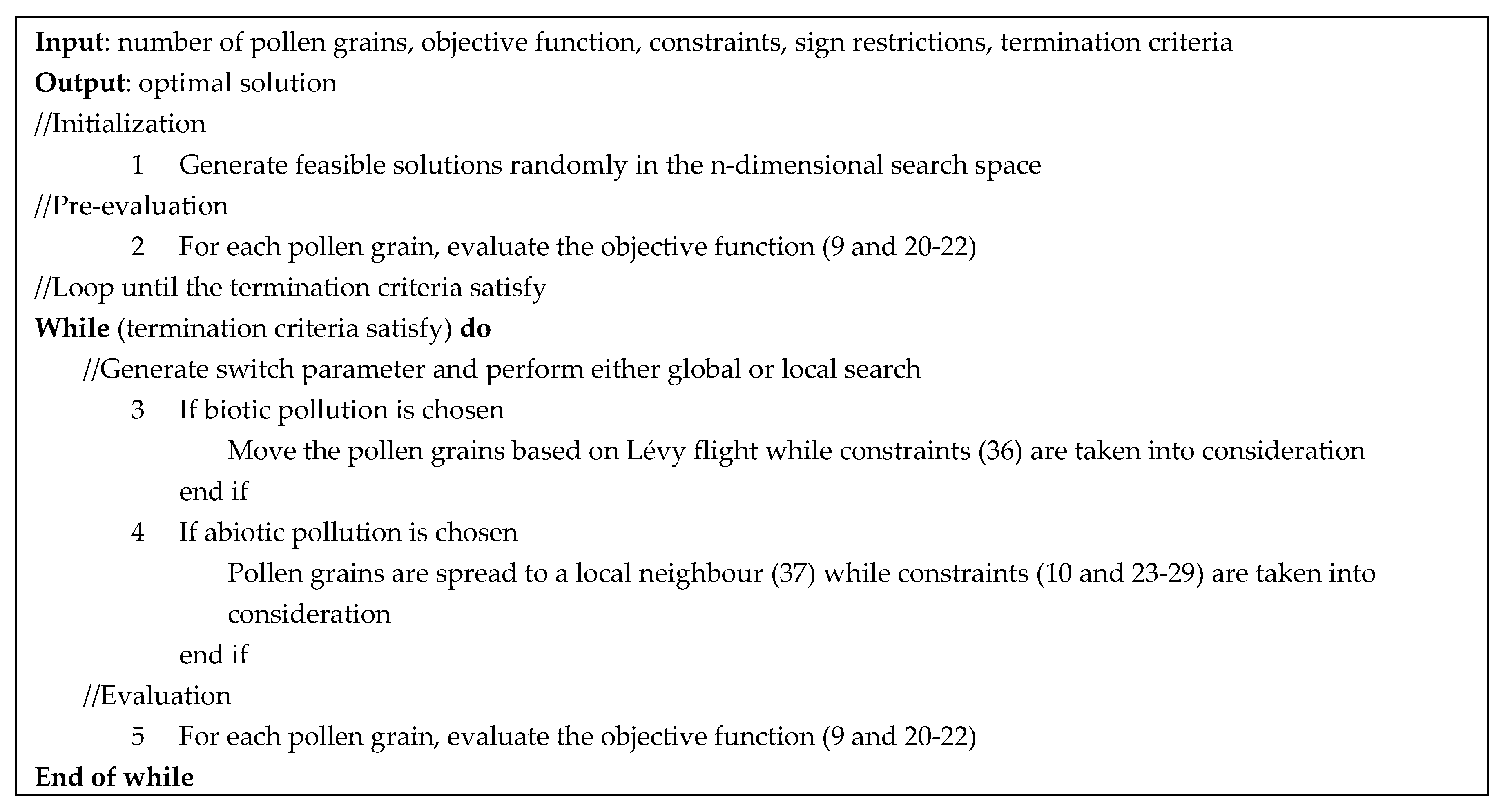

3.2.2. Discretized Flower Pollination-Based Routing and Scheduling for Extended and Real-Time Optimization

- initialization of parameters: in this phase both problem-specific and algorithm-specific parameters are initialized. Problem-specific parameters are the parameters of search space (dimensions and size) and the constraints-defined parameters. Algorithm-specific parameters are the following: switch parameter between local and global search, distribution function parameters for Lévy flight, termination criteria, and the number of pollen grains.

- calculation of the initial solutions: in this phase, the initial potential solutions of the optimization problem are defined.

- evaluation of pollen grains: within the frame of this phase, pollen grains are evaluated based on the objective function of the optimization problem.

- initialization of iteration phase: in this phase, a random number is generated to switch between global and local search option. If then global pollination (biotic pollination) takes place otherwise local pollination (abiotic pollination) takes place.

- biotic pollination phase: this phase represents the global search in the search space. The operator is based on Lévy flight and can be defined as follows:where is the value of variable i at iteration step t, is the value of variable i at iteration step t in the case of the global best solution and is the Levy distribution.

- abiotic pollination: this phase represents a local search, in which pollen grains are spread to a local neighbor:where and are random selected pollen grains about the neighborhood of the currently processed pollen grain and is a random number.

- transformation of the continuous representation into permutation-based representation: within the frame of this phase the continuous variables are transformed into discrete numbers describing a permutation-based problem. We are using the smallest position value rule and the largest order value rule [112] for this transformation (Table 4).

- checking the termination criteria: in this phase, the following termination criteria’s can be checked: computational time, iteration steps, the value of the best solution, lower limit of convergence speed.

4. Results from the Scenario Analysis of Extended and Real-Time Logistics Resource Optimization in Matrix Production

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Watson, R. Jump Starting Digital Transformation in Manufacturing. Available online: https://www.manufacturingglobal.com/technology/jump-starting-digital-transformation-manufacturing (accessed on 8 February 2019).

- Matrix Production: An Example for Industrie 4.0. Available online: https://www.kuka.com/en-de/industries/solutions-database/2016/10/matrix-production (accessed on 20 January 2019).

- Aderohunmu, R.; Mobolurin, A.; Bryson, N. Joint vendor buyer policy in JIT manufacturing. J. Oper. Res. Soc. 1995, 46, 375–385. [Google Scholar] [CrossRef]

- Rittershaus, E.; Weinhold, F.; Tonshoff, H.K. Process-related simulation applied to manufacturing optimization. Int. J. Comp. Integr. Manuf. 1995, 8, 79–91. [Google Scholar] [CrossRef]

- Gupta, A.; Maranas, C.D. Managing demand uncertainty in supply chain planning. Comput. Chem Eng. 2001, 27, 1219–1227. [Google Scholar] [CrossRef]

- Pishvaee, M.S.; Jolai, F.; Razmi, J. A stochastic optimization model for integrated forward/reverse logistics network design. J. Manuf. Syst. 2009, 28, 107–114. [Google Scholar] [CrossRef]

- Pan, F.; Nagi, R. Robust supply chain design under uncertain demand in agile manufacturing. Comput. Oper. Res. 2010, 37, 668–683. [Google Scholar] [CrossRef]

- McMullen, P.R. An ant colony optimization approach to addressing a JIT sequencing problem with multiple objectives. Artif. Intell. Eng. 2001, 15, 309–317. [Google Scholar] [CrossRef]

- Kannan, D.; Diabat, A.; Alrefaei, M.; Govindan, K.; Yong, G. A carbon footprint based reverse logistics network design model. Resour. Conserv. Recycl. 2012, 67, 75–79. [Google Scholar] [CrossRef]

- Ertogral, K.; Wu, S.D. Auction-theoretic coordination of production planning in the supply chain. IIE Trans. 2000, 32, 931–940. [Google Scholar] [CrossRef]

- Kannan, G.; Haq, A.N.; Devika, M. Analysis of closed loop supply chain using genetic algorithm and particle swarm optimisation. Int. J. Prod. Res. 2009, 47, 1175–1200. [Google Scholar] [CrossRef]

- Vorasayan, J.; Ryan, S.M. Optimal price and quantity of refurbished products. Prod. Oper. Manag. 2006, 15, 369–383. [Google Scholar] [CrossRef]

- Bilgen, B.; Ozkarahan, I. Strategic tactical and operational production-distribution models: A review. Int. J. Technol. Manag. 2004, 28, 151–171. [Google Scholar] [CrossRef]

- Lee, J. Machine performance monitoring and proactive maintenance in computer-integrated manufacturing—Review and perspective. Int. J. CIM 1995, 8, 370–380. [Google Scholar] [CrossRef]

- Goldhar, J.D.; Lei, D. Organizing and managing the cim/fms firm for maximum competitive advantage. Int. J. Technol. Manag. 1994, 9, 709–732. [Google Scholar]

- Ovacik, I.M.; Uzsoy, R. Rolling horizon algorithms for a single-machine dynamic scheduling problem with sequence-dependent setup times. Int. J. Prod. Res. 1994, 32, 1243–1263. [Google Scholar] [CrossRef]

- Rickards, H.D.; Dudenhausen, H.M.; Makatsoris, C.; de Ridder, L. Flow of orders through a virtual enterprise - their proactive planning and scheduling, and reactive control. Comput. Control Eng. J. 1997, 8, 173–179. [Google Scholar] [CrossRef]

- Van Brussel, H.; Wyns, J.; Valckenaers, P.; Bongaerts, L.; Peeters, P. Reference architecture for holonic manufacturing systems: PROSA. Comput. Ind. 1998, 37, 255–274. [Google Scholar] [CrossRef]

- Gou, L.; Luh, P.B.; Kyoya, Y. Holonic manufacturing scheduling: Architecture, cooperation mechanism, and implementation. Comput. Ind. 1998, 37, 213–231. [Google Scholar] [CrossRef]

- Zhou, Q.; Souben, P.; Besant, C.B. An information management system for production planning in virtual enterprises. Comput. Ind. Eng. 1998, 5, 153–156. [Google Scholar] [CrossRef]

- Sanchez, J.A.; López de Lacalle, L.N.; Lamikiz, A. A computer-aided system for the optimization of the accuracy of the wire electro-discharge machining process. Int. J. CIM 2004, 17, 413–420. [Google Scholar] [CrossRef]

- López de Lacalle, L.N.; Lamikiz, A.; Muñoa, J.; Sánchez, J.A. The CAM as the centre of gravity of the five-axis high speed milling of complex parts. Int. J. Prod. Res. 2005, 43, 1983–1999. [Google Scholar] [CrossRef]

- Internet of Everything: The Next Manufacturing Revolution: Powering Lean Production with the Vision of a Smart Factory. Available online: http://www.toyoda.com/automation-solutions/smartmanufacturing. (accessed on 19 March 2019).

- Jiang, J.-R. An improved cyber-physical systems architecture for Industry 4.0 smart factories. Adv. Mech. Eng. 2018, 10, 1–15. [Google Scholar] [CrossRef]

- 5G for Manufacturing—A Robust Opportunity for Operators. Available online: https://www.ericsson.com/en/networks/trending/insights-and-reports/5g-for-manufacturing (accessed on 19 March 2019).

- Huang, S.H.; Guo, Y.; Zha, S.S.; Wang, Y.C. An internet-of-things-based production logistics optimisation method for discrete manufacturing. Int. J. Comp. Integr. Manuf. 2019, 32, 13–26. [Google Scholar] [CrossRef]

- Westerweel, B.; Basten, R.J.I.; van Houtum, G.J. Traditional or Additive Manufacturing? Assessing Component Design Options through Lifecycle Cost Analysis. Eur. J. Oper. Res. 2018, 270, 570–585. [Google Scholar] [CrossRef]

- Zhou, L.F.; Zhang, L.; Laili, Y.J.; Zhao, C.; Xiao, Y.Y. Multi-task scheduling of distributed 3D printing services in cloud manufacturing. Int. J. Adv. Manuf. Technol. 2018, 96, 3003–3017. [Google Scholar] [CrossRef]

- Liu, Y.K.; Xu, X.; Zhang, L.; Tao, F. An Extensible Model for Multitask-Oriented Service Composition and Scheduling in Cloud Manufacturing. J. Comput. Inf. Sci. Eng. 2016, 16, 041009. [Google Scholar] [CrossRef]

- Baldea, M.; Edgar, T.F.; Stanley, B.L.; Kiss, A.A. Modular manufacturing processes: Status, challenges, and opportunities. Aiche J. 2017, 63, 4262–4272. [Google Scholar] [CrossRef]

- Fang, C.C.; Lai, M.H.; Huang, Y.S. Production planning of new and remanufacturing products in hybrid production systems. Comput. Ind. Eng. 2017, 108, 88–99. [Google Scholar] [CrossRef]

- Berthaut, F.; Gharbi, A.; Pellerin, R. Joint hybrid repair and remanufacturing systems and supply 4control. Int. J. Prod. Res. 2010, 48, 4101–4121. [Google Scholar] [CrossRef]

- Aras, N.; Verter, V.; Boyaci, T. Coordination and priority decisions in hybrid manufacturing/remanufacturing systems. Prod. Oper. Manag. 2006, 15, 528–543. [Google Scholar] [CrossRef]

- Sadic, S.; de Sousa, J.P.; Crispim, J.A. A two-phase MILP approach to integrate order, customer and manufacturer characteristics into Dynamic Manufacturing Network formation and operational planning. Expert Syst. Appl. 2018, 96, 462–478. [Google Scholar] [CrossRef]

- Tari, F.G.; Hashemi, Z. Prioritized K-mean clustering hybrid GA for discounted fixed charge transportation problems. Comput. Ind. Eng. 2018, 126, 63–74. [Google Scholar] [CrossRef]

- Slak, A.; Tavcar, J.; Duhovnik, J. Application of Genetic Algorithm into Multicriteria Batch Manufacturing Scheduling. Strojn. Vestn. J. Mech. Eng. 2011, 57, 110–124. [Google Scholar] [CrossRef]

- Gubán, M.; Gubaá, Á. Production scheduling with genetic algorithm. Adv. Log. Syst. 2012, 1, 33–44. [Google Scholar]

- Strak, L.; Skinderowicz, R.; Boryczka, U. Adjustability of a discrete particle swarm optimization for the dynamic. Soft Comput. 2018, 22, 7633–7648. [Google Scholar] [CrossRef]

- Mokhtari, H.; Noroozi, A. An efficient chaotic based PSO for earliness/tardiness optimization in a batch processing flow shop scheduling problem. J. Intell. Manuf. 2018, 29, 1063–1081. [Google Scholar] [CrossRef]

- Santuka, R.; Mahapatra, S.S.; Dhal, P.R.; Mishra, A. An Improved Particle Swarm Optimization Approach for Solving Machine Loading Problem in Flexible Manufacturing System. J. Adv. Manuf. Syst. 2015, 14, 167–187. [Google Scholar] [CrossRef]

- Li, S.B.; Zhang, C.L.; Qu, J.L. Location Optimization of Wireless Sensor Network in Intelligent Workshop Based on the Three-Dimensional Adaptive Fruit Fly Optimization Algorithm. Int. J. Online Eng. 2018, 14, 202–211. [Google Scholar] [CrossRef]

- Leung, C.S.K.; Lau, H.Y.K. A hybrid multi-objective AIS-based algorithm applied to simulation-based optimization of material handling system. Appl. Soft Comput. 2018, 71, 553–567. [Google Scholar] [CrossRef]

- Zhang, X.D.; Zhou, H.L.; Zhao, D.F. Layout Optimization of Flexible Manufacturing Cells Based on Fuzzy Demand and Machine Flexibility. Math. Probl. Eng. 2018, 4018628. [Google Scholar] [CrossRef]

- Sevastjanov, P.V.; Rog, P. Fuzzy modeling of manufacturing and logistic systems. Math. Comput. Simul. 2003, 63, 569–585. [Google Scholar] [CrossRef]

- Safarzadeh, S.; Koosha, H. Solving an extended multi-row facility layout problem with fuzzy clearances using GA. Appl. Soft. Comput. 2017, 61, 819–831. [Google Scholar] [CrossRef]

- Wiebe, J.; Cecilia, I.; Misener, R. Data-Driven Optimization of Processes with Degrading Equipment. Ind. Eng. Chem. Res. 2018, 57, 17177–17191. [Google Scholar] [CrossRef]

- Gonzalez-Resendiz, J.; Arredondo-Soto, K.C.; Realyvasquez-Vargas, A.; Hijar-Rivera, H.; Carrillo-Gutierrez, T. Integrating Simulation-Based Optimization for Lean Logistics: A Case Study. Appl. Sci. Basel 2018, 8, 2448. [Google Scholar] [CrossRef]

- Wang, Y.R.; Chen, A.N. Production logistics simulation and optimization on industrial enterprise based on FlexSim. Int. J. Simul. Model. 2016, 15, 732–741. [Google Scholar] [CrossRef]

- Petropoulakis, L.; Giacomini, L. Development of a hybrid simulator for manufacturing processes. Comput. Ind. 1998, 36, 117–124. [Google Scholar] [CrossRef]

- Guo, Z.G.; Zhang, Y.F.; Zhao, X.B.; Song, X.Y. A Timed Colored Petri Net Simulation-Based Self-Adaptive Collaboration Method for Production-Logistics Systems. Appl. Sci. Basel 2017, 7, 235. [Google Scholar] [CrossRef]

- Piera, M.A.; Narciso, M.; Riera, D. Optimization of logistic and manufacturing systems through simulation: A colored Petri net-based methodology. Simulation 2004, 80, 121–129. [Google Scholar] [CrossRef]

- Dotoli, M.; Fanti, M.P.; Iacobellis, G.; Rotunno, G. An integrated technique for the internal logistics analysis and management in discrete manufacturing systems. Int. J. Comp. Integr. Manuf. 2014, 27, 165–180. [Google Scholar] [CrossRef]

- Scholz-Reiter, B.; Windt, K.; Liu, H.X. A multiple-logistic-objective-optimized manufacturing planning and control system. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 599–610. [Google Scholar] [CrossRef]

- Vitayasak, S.; Pongcharoen, P. Performance improvement of Teaching-Learning-Based Optimisation for robust machine layout design. Expert Syst. Appl. 2018, 98, 129–152. [Google Scholar] [CrossRef]

- Kanduc, T.; Rodic, B. Optimisation of machine layout using a force generated graph algorithm and simulated annealing. Int. J. Simul. Model 2016, 15, 275–287. [Google Scholar] [CrossRef]

- Karageorgos, A.; Mehandjiev, N.; Weichhart, G.; Hammerle, A. Agent-based optimisation of logistics and production planning. Eng. Appl. Artif. Intell. 2003, 16, 335–348. [Google Scholar] [CrossRef]

- Stopka, O.; Luptak, V. Optimization of Warehouse Management in the Specific Assembly and Distribution Company: A Case Study. Nase More 2018, 65, 266–269. [Google Scholar] [CrossRef]

- Colledani, M.; Coupek, D.; Verl, A.; Aichele, J.; Yemane, A. A cyber-physical system for quality-oriented assembly of automotive electric motors. CIRP J. Manuf. Sci. Technol. 2018, 20, 12–22. [Google Scholar] [CrossRef]

- Correcher, J.F.; Alonso, M.T.; Parreno, F.; Alvarez-Valdes, R. Solving a large multicontainer loading problem in the car manufacturing industry. Comput. Oper. Res. 2017, 82, 139–152. [Google Scholar] [CrossRef]

- Gomez, A.; Rios, J.; Mas, F.; Vizan, A. Method and software application to assist in the conceptual design of aircraft final assembly lines. J. Manuf. Syst. 2016, 40, 37–53. [Google Scholar] [CrossRef]

- Hsieh, L.Y.; Chang, K.H. Yield improvement on in-mold decoration manufacturing through parameter optimization. Int. J. Precis. Eng. Manuf. 2013, 14, 1823–1828. [Google Scholar] [CrossRef]

- Yanez, F.C.; Frayret, J.M.; Leger, F.; Rousseau, A. Agent-based simulation and analysis of demand-driven production strategies in the timber industry. Int. J. Prod. Res. 2009, 47, 6295–6319. [Google Scholar] [CrossRef]

- Stray, J.; Fowler, J.W.; Carlyle, W.M.; Rastogi, A.P. Enterprise-wide semiconductor manufacturing resource planning. IEEE Trans. Semicond. Manuf. 2006, 19, 259–268. [Google Scholar] [CrossRef]

- Gupta, A.K.; Sivakumar, A.I. Single machine scheduling with multiple objectives in semiconductor manufacturing. Int. J. Adv. Manuf. Technol. 2005, 26, 950–958. [Google Scholar] [CrossRef]

- Bruzzone, A.G.; Longo, F. An Advanced Modeling & Simulation Tool for Investigating the Behavior of a Manufacturing System in the Hazelnuts Industry Sector. Int. J. Food Eng. 2013, 9, 241–257. [Google Scholar] [CrossRef]

- Andres, B.; Sanchis, R.; Poler, R.; Diaz-Madronedoa, M.; Mula, J. A MILP for multi-machine injection moulding sequencing in the scope of C2NET Project. Int. J. Prod. Manag. Eng. 2018, 6, 29–36. [Google Scholar] [CrossRef]

- Turki, S.; Sauvey, C.; Rezg, N. Modelling and optimization of a manufacturing/remanufacturing system with storage facility under carbon cap and trade policy. J. Clean. Prod. 2018, 193, 441–458. [Google Scholar] [CrossRef]

- Bhattacharya, R.; Kaur, A.; Amit, R.K. Price optimization of multi-stage remanufacturing in a closed loop supply chain. J. Clean. Prod. 2018, 186, 943–962. [Google Scholar] [CrossRef]

- Chakravarty, A.K. Global plant capacity and product allocation with pricing decisions—Production, manufacturing and logistics. Eur. J. Oper. Res. 2005, 165, 157–181. [Google Scholar] [CrossRef]

- Jiang, W.W.; Sha, E.H.M.; Zhuge, Q.F.; Wu, L. Efficient assignment algorithms to minimize operation cost for supply chain networks in agile manufacturing. Comput. Ind. Eng. 2017, 108, 225–239. [Google Scholar] [CrossRef]

- Kapur, P.K.; Sachdeva, N.; Singh, O. Optimal profit for manufacturers in product remanufacturing diffusion dynamics. J. Ind. Prod. Eng. 2017, 34, 568–579. [Google Scholar] [CrossRef]

- Kristianto, Y.; Gunasekaran, A.; Helo, P. Building the "Triple R" in global manufacturing. Int. J. Prod. Econ. 2017, 183, 607–619. [Google Scholar] [CrossRef]

- Sivaramkumar, V.; Thansekhar, M.R.; Saravanan, R.; Amali, S.M.J. Multi-objective vehicle routing problem with time windows: Improving customer satisfaction by considering gap time. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 1248–1263. [Google Scholar] [CrossRef]

- Srinivasan, S.; Khan, S.H. Multi-stage manufacturing/re-manufacturing facility location and allocation model under uncertain demand and return. Int. J. Adv. Manuf. Technol. 2018, 94, 2847–2860. [Google Scholar] [CrossRef]

- Arbib, C.; Rossi, F. Optimal resource assignment through negotiation in a multi-agent manufacturing system. IIE Trans. 2000, 32, 963–974. [Google Scholar] [CrossRef]

- Panagiotidou, S.; Nenes, G.; Zikopoulos, C.; Tagaras, G. Joint optimization of manufacturing/remanufacturing lot sizes under imperfect information on returns quality. Eur. J. Oper. Res. 2017, 258, 537–551. [Google Scholar] [CrossRef]

- Zikopoulos, C. Remanufacturing lotsizing with stochastic lead- time resulting from stochastic quality of returns. Int. J. Prod. Res. 2017, 55, 1565–1587. [Google Scholar] [CrossRef]

- Macedo, P.B.; Alem, D.; Santos, M.; Lage, M.; Moreno, A. Hybrid manufacturing and remanufacturing lot-sizing problem with stochastic demand, return, and setup costs. Int. J. Adv. Manuf. Technol. 2016, 82, 1241–1257. [Google Scholar] [CrossRef]

- Alemany, M.M.E.; Grillo, H.; Ortiz, A.; Fuertes-Miquel, V.S. A fuzzy model for shortage planning under uncertainty due to lack of homogeneity in planned production lots. Appl. Math. Model. 2015, 39, 4463–4481. [Google Scholar] [CrossRef]

- Li, K.P.; Sivakumar, A.I.; Ganesan, V.K. Analysis and algorithms for coordinated scheduling of parallel machine manufacturing and 3PL transportation. Int. J. Prod. Econ. 2008, 115, 482–491. [Google Scholar] [CrossRef]

- Zhang, F.; Guan, Z.L.; Zhang, L.; Cui, Y.Y.; Yi, P.X.; Ullah, S. Inventory management for a remanufacture-to-order production with multi-components (parts). J. Intell. Manuf. 2019, 30, 59–78. [Google Scholar] [CrossRef]

- Vilas, D.D.; Longo, F.; Monteil, N.R. A general framework for the manufacturing workstation design optimization: A combined ergonomic and operational approach. Simulation 2013, 89, 306–329. [Google Scholar] [CrossRef]

- Polotski, V.; Kenne, J.P.; Gharbi, A. Production and setup policy optimization for hybrid manufacturing-remanufacturing systems. Int. J. Prod. Econ. 2017, 183, 322–333. [Google Scholar] [CrossRef]

- Jain, A.K. Data clustering: 50 years beyond K-means. Pattern Recogn. Lett. 2009, 31, 651–666. [Google Scholar] [CrossRef]

- Cheng, Y.Z. Mean shift, mode seeking and clustering. IEEE T. Pattern Anal. 1995, 17, 790–799. [Google Scholar] [CrossRef]

- Duan, L.; Xu, L.; Guo, F.; Lee, J.; Yan, B.P. A local-density based spatial clustering algorithm with noise. Inform. Syst. 2007, 32, 978–986. [Google Scholar] [CrossRef]

- Murtagh, F.; Legendre, P. Ward’s Hierarchical Agglomerative Clustering Method: Which Algorithms Implement Ward’s Criterion? J. Classif. 2014, 31, 274–295. [Google Scholar] [CrossRef]

- Zhou, Y.; He, F.Z.; Qiu, Y.M. Dynamic strategy based parallel ant colony optimization on GPUs for TSPs. Sci. China Inform. Sci. 2017, 60, 068102. [Google Scholar] [CrossRef]

- Karaboga, D.; Basturk, B. A powerful and efficient algorithm for numerical function optimization: Artificial bee colony (ABC) algorithm. J. Glob. Optim. 2007, 39, 459–471. [Google Scholar] [CrossRef]

- Jiang, H.M.; Xie, K.; Wang, Y.F. Optimization of pump parameters for gain flattened Raman fiber amplifiers based on artificial fish school algorithm. Opt. Commun. 2011, 284, 5480–5483. [Google Scholar] [CrossRef]

- Chakri, A.; Khelif, R.; Benouaret, M.; Yang, X.S. New directional bat algorithm for continuous optimization problems. Expert Syst. Appl. 2017, 69, 159–175. [Google Scholar] [CrossRef]

- Wang, G.G.; Guo, L.H.; Wang, H.Q.; Duan, H.; Liu, L.; Li, J. Incorporating mutation scheme into krill herd algorithm for global numerical optimization. Neural Comput. Appl. 2014, 24, 853–871. [Google Scholar] [CrossRef]

- Yang, X.S. Firefly algorithm, stochastic test functions and design optimization. Int. J. Bio-Inspir. Comput. 2010, 2, 78–84. [Google Scholar] [CrossRef]

- Li, H.Z.; Guo, S.; Li, C.J.; Sun, J.Q. A hybrid annual power load forecasting model based on generalized regression neural network with fruit fly optimization algorithm. Knowl.-Based Syst. 2013, 37, 378–387. [Google Scholar] [CrossRef]

- Mo, H.W.; Liu, L.L.; Xu, L.F. A power spectrum optimization algorithm inspired by magnetotactic bacteria. Neural Comput. Appl. 2014, 25, 1823–1844. [Google Scholar] [CrossRef]

- Huang, K.W.; Chen, J.L.; Yang, C.S.; Tsai, C.W. PSGO: Particle Swarm Gravitation Optimization Algorithm. J. Intell. Fuzzy Syst. 2015, 28, 2655–2665. [Google Scholar] [CrossRef]

- Alatas, B. Uniform Big Bang-Chaotic Big Crunch optimization. Commun. Nonliear Sci. 2011, 16, 3696–3703. [Google Scholar] [CrossRef]

- Dariane, A.B.; Sarani, S. Application of Intelligent Water Drops Algorithm in Reservoir Operation. Water Resour. Manag. 2013, 27, 4827–4843. [Google Scholar] [CrossRef]

- Gao, W. Investigating the critical slip surface of soil slope based on an improved black hole algorithm. Soils Found. 2017, 57, 988–1001. [Google Scholar] [CrossRef]

- Soto, R.; Crawford, B.; Olivares, R.; Barraza, J.; Figueroa, I.; Johnson, F.; Paredes, F.; Olguin, E. Solving the non-unicost set covering problem by using cuckoo search and black hole optimization. Nat. Comput. 2017, 16, 213–229. [Google Scholar] [CrossRef]

- Banyai, A.; Banyai, T.; Illes, B. Optimization of Consignment-Store-Based Supply Chain with Black Hole Algorithm. Complexity 2017, 6038973. [Google Scholar] [CrossRef]

- Bravetti, A.; Gruber, C.; Lopez-Monsalvo, C.S. Thermodynamic optimization of a Penrose process: An engineers’ approach to black hole thermodynamics. Phys. Rev. D 2016, 93, 064070. [Google Scholar] [CrossRef]

- Bouchekara, H.R.E.H. Optimal power flow using black-hole-based optimization approach. Appl. Soft Comput. 2014, 24, 879–888. [Google Scholar] [CrossRef]

- Bouchekara, H.R.E.H. Optimal Design of Electromagnetic Devices Using a Black-Hole-Based Optimization Technique. IEEE Trans. Magn. 2013, 49, 5709–5714. [Google Scholar] [CrossRef]

- Black Holes: Facts, Theory & Definition. Available online: https://www.space.com/15421-black-holes-facts-formation-discovery-sdcmp.html (accessed on 18 January 2019).

- Binh, H.T.T.; Hanh, N.T.; Van Quan, L.; Dey, N. Improved Cuckoo Search and Chaotic Flower Pollination optimization algorithm for maximizing area coverage in Wireless Sensor Networks. Neural Comput. Appl. 2018, 30, 2305–2317. [Google Scholar] [CrossRef]

- Bekdaş, G.; Nigdeli, S.M.; Yang, X.-S. Sizing optimization of truss structures using flower pollination algorithm. App. Soft Comput. J. 2015, 37, 322–331. [Google Scholar] [CrossRef]

- Dubey, H.M.; Pandit, M.; Panigrahi, B.K. A Biologically Inspired Modified Flower Pollination Algorithm for Solving Economic Dispatch Problems in Modern Power Systems. Cogn. Comput. 2015, 7, 594–608. [Google Scholar] [CrossRef]

- Sreenivasa Rao, M.; Venkata Naresh Babu, A.; Venkaiah, N. Modified Flower Pollination Algorithm to Optimize WEDM parameters while Machining Inconel-690 alloy. Mater. Today 2018, 5, 7864–7872. [Google Scholar] [CrossRef]

- Wang, C.; Sun, H.X.; Yang, J.S.; Zhang, H.; Zong, Y.; Liang, H.P. Calculation of maximum permitted capacity of photovoltaic based on flower pollination algorithm combined with genetic algorithm (GA-FPA) in distribution network. IOP Conf. Ser. Earth Environ. 2018, 188, 012081. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Shawky, L.A. Flower pollination algorithm: A comprehensive review. Artif. Intell. Rev. 2018, 1–25. [Google Scholar] [CrossRef]

- Kongkaew, W. Bat algorithm in discrete optimization: A review of recent applications. Songklanakarin J. Sci. Technol. 2017, 39, 641–650. [Google Scholar] [CrossRef]

- World Nuclear Association. Comparison of Lifecycle Greenhouse Gas Emissions of Various Electricity Generation Sources; World Nuclear Association: London, UK, 2011; pp. 1–12. [Google Scholar]

- Larsen, A.W.; Vrgoc, M.; Christensen, T.H. Diesel consumption in waste collection and transport and its environmental significance. Waste. Manag. Res. 2009, 27, 652–659. [Google Scholar] [CrossRef]

- Qiu, L.; Wang, J.; Chen, W.; Wang, H. Heterogeneous AGV routing problem considering energy consumption. In Proceedings of the IEEE International Conference on Robotics and Biomimetics, Zhuhai, China, 6–9 December 2015; pp. 1894–1899. [Google Scholar] [CrossRef]

| Evaluation Function | Black Hole Optimization | Genetic Algorithm | Harmony Search | Flower Pollination |

|---|---|---|---|---|

| Ackley | 3.66 × 10−7 | 4.67 × 10−6 | 1.28 × 10−7 | 3.45 × 10−7 |

| Bukin | 2.45 × 10−6 | 5.45 × 10−7 | 9.08 × 10−7 | 5.61 × 10−8 |

| Cross-in-tray | 8.55 × 10−9 | 7.32 × 10−9 | 6.98 × 10−8 | 6.12 × 10−7 |

| Easom | 1.18 × 10−5 | 2.09 × 10−4 | 8.18 × 10−9 | 4.02 × 10−8 |

| Eggholder | 5.50 × 10−7 | 3.12 × 10−7 | 1.98 × 10−8 | 1.39 × 10−8 |

| Three hump camel back | 1.51 × 10−6 | 4.17 × 10−8 | 7.79 × 10−10 | 6.60 × 10−9 |

| Tasks | Relation | Time Frame Limit | Loading 2 | ||

|---|---|---|---|---|---|

| From | To | Lower | Upper | ||

| 1 | 7 | 14 | 10:10 | 10:50 | 2 |

| 2 | 8 | 12 | 10:00 | 11:00 | 4 |

| 3 | 9 | 11 | 10:15 | 11:10 | 6 |

| 4 | 16 | 20 | 10:35 | 11:20 | 8 |

| 5 | 32 | 36 | 11:15 | 11:35 | 1 |

| 6 | 2 | 5 | 10:05 | 10:35 | 3 |

| 7 | 8 | 1 | 10:32 | 11:00 | 5 |

| 8 | 22 | 33 | 10:40 | 11:25 | 7 |

| 9 | 5 | 9 | 10:45 | 11:30 | 8 |

| 10 | 14 | 22 | 10:20 | 10:55 | 5 |

| 11 | 8 | 13 | 10:55 | 11:30 | 3 |

| 12 | 3 | 11 | 10:12 | 10:45 | 9 |

| Tasks | Relation | Loading | Tasks | Relation | Loading | ||

|---|---|---|---|---|---|---|---|

| From | To | From | To | ||||

| 7 | 8 | 1 | 5 | 12 | 3 | 11 | 9 |

| 10 | 14 | 22 | 5 | 4 | 16 | 20 | 8 |

| 2 | 8 | 12 | 4 | 9 | 5 | 9 | 8 |

| 3 | 9 | 11 | 6 | 11 | 8 | 13 | 3 |

| 6 | 2 | 5 | 3 | 8 | 22 | 33 | 7 |

| 1 | 7 | 14 | 2 | 5 | 32 | 36 | 1 |

| Pollen Grain Value | Index Number | Permutation Rule SPV |

|---|---|---|

| 12.31 | 1 | 6 |

| 8.24 | 2 | 4 |

| −24.51 | 3 | 1 |

| 9.25 | 4 | 5 |

| 0.15 | 5 | 3 |

| −1.35 | 6 | 2 |

| Tasks | Relation | Time Frame Limit | Loading | ||

|---|---|---|---|---|---|

| From | To | Lower | Upper | ||

| 1 | 6 | 11 | 9:10 | 9:50 | 4 |

| 2 | 31 | 35 | 9:00 | 10:00 | 8 |

| 3 | 28 | 29 | 9:15 | 10:10 | 2 |

| 4 | 16 | 20 | 9:35 | 10:20 | 3 |

| 5 | 32 | 36 | 10:15 | 10:35 | 9 |

| 6 | 1 | 4 | 9:05 | 9:35 | 3 |

| 7 | 3 | 8 | 9:32 | 10:00 | 2 |

| 8 | 22 | 33 | 9:40 | 10:25 | 8 |

| 9 | 2 | 4 | 9:45 | 10:30 | 5 |

| 10 | 14 | 20 | 9:20 | 9:55 | 9 |

| 11 | 7 | 14 | 9:55 | 10:30 | 7 |

| 12 | 23 | 27 | 9:12 | 9:45 | 9 |

| Tasks | Relation | Loading | Tasks | Relation | Loading | ||

|---|---|---|---|---|---|---|---|

| From | To | From | To | ||||

| 6 | 1 | 4 | 3 | 4 | 16 | 20 | 3 |

| 2 | 31 | 35 | 8 | 11 | 7 | 14 | 7 |

| 10 | 14 | 20 | 9 | 12 | 23 | 27 | 9 |

| 3 | 28 | 29 | 2 | 9 | 2 | 4 | 5 |

| 8 | 22 | 33 | 8 | 5 | 32 | 36 | 9 |

| 1 | 6 | 11 | 4 | 7 | 3 | 8 | 2 |

| Tasks | Relation | Time Frame Limit | Loading | ||

|---|---|---|---|---|---|

| From | To | Lower | Upper | ||

| 1 | 12 | 15 | 10:10 | 10:30 | 12 |

| 2 | 1 | 4 | 10:20 | 10:50 | 9 |

| 3 | 9 | 10 | 10:30 | 11:15 | 15 |

| 4 | 5 | 8 | 10:40 | 11:05 | 8 |

| 5 | 3 | 7 | 10:50 | 11:10 | 24 |

| 6 | 14 | 8 | 10:10 | 10:40 | 7 |

| 7 | 9 | 13 | 10:05 | 10:35 | 44 |

| 8 | 6 | 9 | 10:12 | 10:38 | 7 |

| 9 | 5 | 8 | 10:55 | 11:28 | 31 |

| 10 | 15 | 10 | 11:25 | 11:40 | 21 |

| 11 | 14 | 6 | 11:30 | 12:00 | 17 |

| 12 | 1 | 5 | 11:05 | 11:30 | 56 |

| 13 | 3 | 6 | 10:35 | 11:05 | 22 |

| 14 | 6 | 12 | 10:25 | 10:55 | 11 |

| 15 | 4 | 14 | 10:45 | 11:05 | 8 |

| 16 | 14 | 16 | 10:50 | 12:00 | 9 |

| Tasks | Relation | Loading | Tasks | Relation | Loading | Tasks | Relation | Loading | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| From | To | From | To | From | To | ||||||

| 4 | 5 | 8 | 8 | 7 | 9 | 13 | 44 | 9 | 5 | 8 | 31 |

| 16 | 14 | 16 | 9 | 6 | 14 | 8 | 7 | 14 | 6 | 12 | 11 |

| 3 | 9 | 10 | 15 | 8 | 6 | 9 | 7 | 5 | 3 | 7 | 24 |

| 12 | 1 | 5 | 56 | 1 | 12 | 15 | 12 | 13 | 3 | 6 | 22 |

| 10 | 15 | 10 | 21 | 2 | 1 | 4 | 9 | 15 | 4 | 14 | 8 |

| - | - | - | - | - | - | - | - | 11 | 14 | 6 | 17 |

| Tasks | Relation | Loading | Tasks | Relation | Loading | Tasks | Relation | Loading | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| From | To | From | To | From | To | ||||||

| 11 | 14 | 6 | 17 | 17 | 2 | 12 | 21 | 9 | 5 | 8 | 31 |

| 5 | 3 | 7 | 24 | 7 | 9 | 13 | 44 | 16 | 14 | 16 | 9 |

| 12 | 1 | 5 | 56 | 6 | 14 | 8 | 7 | 10 | 15 | 10 | 21 |

| 2 | 1 | 4 | 9 | 8 | 6 | 9 | 7 | 4 | 5 | 8 | 8 |

| 15 | 4 | 14 | 8 | 1 | 12 | 15 | 12 | 13 | 3 | 6 | 22 |

| - | - | - | - | - | - | - | - | 3 | 9 | 10 | 15 |

| - | - | - | - | - | - | - | - | 14 | 6 | 12 | 11 |

| Routes | EGS 1 | Emission | |||||

|---|---|---|---|---|---|---|---|

| CO2 | SO2 | CO | HC | NOX | PM | ||

| Specific emissions in g/liter fuel consumption [114] | - | 2629 | 0.08 | 2.2 | 1.2 | 11.9 | 0.1 |

| Specific GHG emission 2 [113] | Lignite | 1054 | 0.032 | 0.880 | 0.480 | 4.760 | 0.040 |

| Coal | 888 | 0.028 | 0.733 | 0.400 | 3.960 | 0.030 | |

| Oil | 733 | 0.022 | 0.615 | 0.335 | 3.324 | 0.028 | |

| Natural gas | 499 | 0.016 | 0.418 | 0.228 | 2.226 | 0.019 | |

| Photovoltaic | 85 | 0.002 | 0.073 | 0.040 | 0.396 | 0.003 | |

| Biomass | 45 | 0.001 | 0.038 | 0.021 | 0.205 | 0.002 | |

| Nuclear | 29 | <10−3 | 0.024 | 0.013 | 0.132 | 0.001 | |

| Water | 26 | <10−3 | 0.022 | 0.012 | 0.119 | 0.001 | |

| Wind | 26 | <10−3 | 0.022 | 0.012 | 0.119 | 0.001 | |

| Scenario 1 | Emission | |||||

|---|---|---|---|---|---|---|

| CO2 | SO2 | CO | HC | NOX | PM | |

| Extended scheduling of known supply-demands | 8600 | 0.26 | 7.1808 | 3.9168 | 38.841 | 0.3264 |

| Real-time scheduling with added new supply-demand | 9106 | 0.27 | 7.6032 | 4.1472 | 41.126 | 0.3456 |

| Separated route for new supply-demand | 1264 | 0.04 | 1.056 | 0.5760 | 5.7120 | 0.0480 |

| Emission reduction with real-time scheduling | 843.2 | 0.03 | 0.7004 | 0.3840 | 3.808. | 0.0320 |

| Scenario 1 | Emission | |||||

|---|---|---|---|---|---|---|

| CO2 | SO2 | CO | HC | NOX | PM | |

| Extended scheduling of known supply-demands | 5981.2 | 0.1795 | 5.0184 | 2.7336 | 27.123 | 0.2285 |

| Real-time scheduling with added new supply-demand | 6333.1 | 0.1901 | 5.3136 | 2.8944 | 28.719 | 0.2419 |

| Separated route for new supply-demand | 879.6 | 0.0264 | 0.7380 | 0.4020 | 3.9888 | 0.0336 |

| Emission reduction with real-time scheduling | 586.4 | 0.0176 | 0.4920 | 0.2680 | 2.6592 | 0.0022 |

| Scenario 1 | Emission | |||||

|---|---|---|---|---|---|---|

| CO2 | SO2 | CO | HC | NOX | PM | |

| Extended scheduling of known supply-demands | 693.6 | 0.0163 | 0.5957 | 0.3264 | 3.2314 | 0.0245 |

| Real-time scheduling with added new supply-demand | 734.4 | 0.0173 | 0.6307 | 0.3456 | 3.4214 | 0.0259 |

| Separated route for new supply-demand | 102.0 | 0.0024 | 0.0876 | 0.0480 | 0.4752 | 0.0036 |

| Emission reduction with real-time scheduling | 68.0 | 0.0016 | 0.0584 | 0.0320 | 0.3168 | 0.0024 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bányai, Á.; Illés, B.; Glistau, E.; Machado, N.I.C.; Tamás, P.; Manzoor, F.; Bányai, T. Smart Cyber-Physical Manufacturing: Extended and Real-Time Optimization of Logistics Resources in Matrix Production. Appl. Sci. 2019, 9, 1287. https://doi.org/10.3390/app9071287

Bányai Á, Illés B, Glistau E, Machado NIC, Tamás P, Manzoor F, Bányai T. Smart Cyber-Physical Manufacturing: Extended and Real-Time Optimization of Logistics Resources in Matrix Production. Applied Sciences. 2019; 9(7):1287. https://doi.org/10.3390/app9071287

Chicago/Turabian StyleBányai, Ágota, Béla Illés, Elke Glistau, Norge Isaias Coello Machado, Péter Tamás, Faiza Manzoor, and Tamás Bányai. 2019. "Smart Cyber-Physical Manufacturing: Extended and Real-Time Optimization of Logistics Resources in Matrix Production" Applied Sciences 9, no. 7: 1287. https://doi.org/10.3390/app9071287

APA StyleBányai, Á., Illés, B., Glistau, E., Machado, N. I. C., Tamás, P., Manzoor, F., & Bányai, T. (2019). Smart Cyber-Physical Manufacturing: Extended and Real-Time Optimization of Logistics Resources in Matrix Production. Applied Sciences, 9(7), 1287. https://doi.org/10.3390/app9071287