Abstract

The effect of borosilicate glass on the thermal neutron shielding performance and the compressive strength of cement mortar was investigated. The borosilicate glass was used as a replacement material for fine aggregate in this study. The cement mortars were mixed by four different replacement ratios of borosilicate glass. The following tests were conducted with the cement mortar: (1) Compressive strength, (2) TG/DSC and (3) neutron shielding rate using 241Am–Be neutron source. Results indicated that the cement mortar with borosilicate glass showed higher compressive strength and higher thermal neutron shielding rate as the replacement ratio of borosilicate glass increased. The increase of the compressive strength and the thermal neutron shielding rate was associated with the pozzolanic reaction of borosilicate glass and the increase of boron content in cement mortar, respectively.

1. Introduction

Concrete is one of most widely used materials for neutron shielding because in addition to having the proper structural properties, there are a variety of choices for the materials used to build it, leading to the manufacture of concrete with different densities and different combinations [1]. However, when the concrete absorbs neutrons, the concrete releases secondary gamma rays that should be considered in shielding design [2].

Boron carbide (B4C) absorbs neutrons without the radiation of secondary gamma ray and is generally used in the neutron shielding application [3]. However, the increase of boron carbide content in a concrete mixture leads to the significant decrease of the compressive strength of concrete [4,5].

This study investigated the effect of borosilicate glass on the thermal neutron shielding performance and the compressive strength gain of cement mortar. The compressive strength, the amount of calcium hydroxide and the thermal neutron shielding rate of cement mortar with borosilicate glass were measured for the investigation.

2. Experiments

2.1. Material and Specimen Preparation

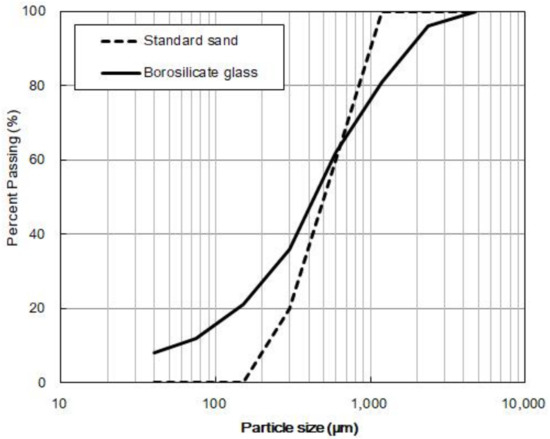

To investigate the effect of borosilicate glass on the thermal neutron shielding performance and the compressive strength gain of cement mortar, the borosilicate glass (boron content of 13% by mass, DURAN-Borosilicate glass 3.3, SCHOTT) crushed by the jaw crusher was used in this study. Table 1 shows the chemical composition of borosilicate glass. Figure 1 and Figure 2 show the crushed glass and the particle size distribution of crushed glass, respectively.

Table 1.

The chemical composition of borosilicate glass.

Figure 1.

Borosilicate glass used in this study.

Figure 2.

Particle size distributions of standard sand and borosilicate glass.

For the preparation of cement mortar specimens, ordinary Portland cement (OPC) equivalent to ASTM C 150 type I Portland cement and the standard sand equivalent to ASTM C 778 were used [6,7]. The cement mortar mixture was prepared at a water to cement ratio of 0.475 and a cement to fine aggregate ratio of 1:2.25. The borosilicate glass was used as a replacement material for fine aggregate. The cement mortars were mixed by four different replacement ratios of borosilicate glass (25%, 50%, 70% and 100% by mass of standard sand). For each mixture, a total of 27 cement mortar cubes (50 × 50 × 50 mm3) were cast. The specimens were demolded in 24 h and cured in the lime water until the day of testing.

2.2. Testing Procedures

The flow test was conducted according to KS L 5105 to evaluate the fluidity of the fresh mortar. The compressive strength test was conducted for cement mortar mixtures at the age of 3, 7 and 28 days. A total of nine specimens were tested for each mixture at each age. The specimens were loaded using a universal testing machine with a loading rate of 10 kN/min and the load value was recorded until the failure of the specimens occurred. The strength of the cement mortar was calculated using the peak load value divided by the loading area of the specimens. The calcium hydroxides in cement mortar were quantitatively evaluated by TG/DSC analysis at the age of 3, 7 and 28 days. The temperature was raised up to 1000 °C at heating rate of 10 °C/min using TG/DSC (SDT Q600, TA Instrument). The amount of calcium hydroxide in the cement mortar was calculated using the weight loss and endothermic DSC peak at about 450 °C.

The test of thermal neutron shielding rate of cement mortar specimens was performed using 241Am–Be neutron source. Figure 3 shows 241Am–Be neutron source and the experimental setup for the thermal neutron shielding rate. 241Am–Be neutron source (neutron emission rate of 2.334 × 105 s−1) was surrounded by a thick polyethylene neutron moderator which reduced the speed of fast neutrons producing thermal neutrons. Each side of the polyethylene was covered with a lead block to prevent leakage of thermal neutrons. Produced thermal neutrons passed through the 50 mm thick cement mortar specimen and the thermal neutron counter measured the amount of passed thermal neutrons using an SP9 3He proportional counter (sensitivity of 3.163 cm2)

Figure 3.

Experimental setup for thermal neutron shielding performance.

3. Test Results and Discussion

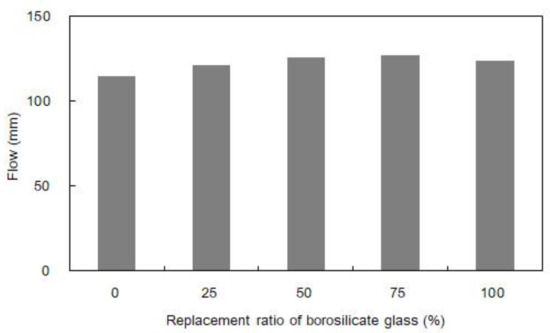

Figure 4 shows the flow of fresh cement mortars. The flow value of plain cement mortar was 108 mm. The flow values of all the cement mortars with borosilicate glass were slightly higher than that of plain cement mortar. However, the replacement of borosilicate glass showed no significant influence on the fluidity of the cement mortar.

Figure 4.

Flow of fresh cement mortar with borosilicate glass.

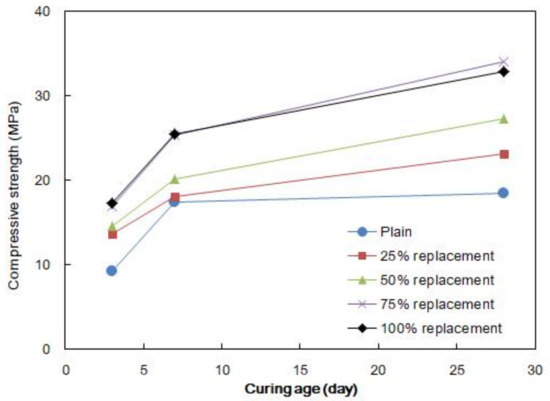

Figure 5 shows the compressive strength of cement mortar at the age of 3, 7 and 28 days. All the cement mortars with borosilicate glass showed higher compressive strength compared to the plain cement mortar, regardless of the age of cement mortar. The compressive strength of cement mortar with borosilicate glass increased as the replacement ratio of borosilicate glass increased. However, when the level of replacement ratio exceeded 75%, the compressive strength of cement mortar did not significantly increase.

Figure 5.

Compressive strength of cement mortar with borosilicate glass.

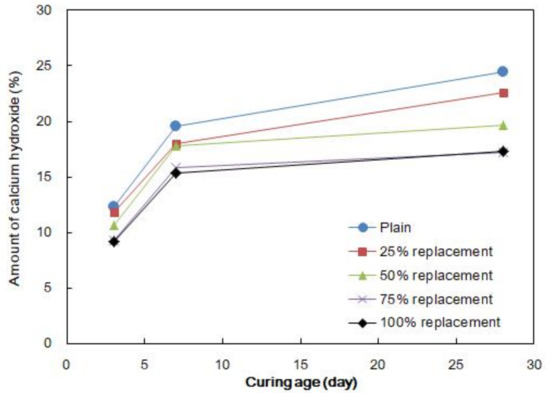

Figure 6 shows the amount of calcium hydroxide in the cement mortar at the age of 3, 7 and 28 days. The amount of calcium hydroxide in the cement mortar with borosilicate glass decreased as the replacement ratio of borosilicate glass increased up to 75%. However, when the level of replacement ration exceeded 75% (reached 100%), the amount of calcium hydroxide in the cement mortar did not decrease.

Figure 6.

Amount of calcium hydroxide in cement mortar with borosilicate glass.

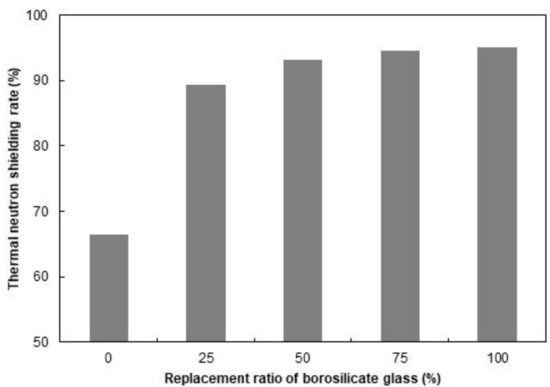

Figure 7 shows the thermal neutron shielding rate of cement mortar at the age of 28 days. The thermal neutron shielding rates were 66%, 89%, 93%, 94% and 95% for the cement mortar with replacement ratios of 0%, 25%, 50%, 75% and 100%, respectively. All the cement mortar showed higher thermal neutron shielding rates compared to plain cement mortar. The thermal neutron shielding rate of cement mortar with borosilicate glass increased as the replacement ratio of borosilicate glass increased. The thermal neutron shielding rate of cement mortar with a replacement ratio of 100% showed the largest increase (approximately 43%) from that of plain cement mortar.

Figure 7.

Thermal neutron shielding performance of cement mortar with borosilicate glass.

It is known that borosilicate glass is a pozzolan material [8]. The pozzolans, like borosilicate glass, are silicate-based materials that consume the calcium hydroxide during the period of the hydration process of cement to produce the calcium silicate hydrates (C-S-H). The strength of cement mortar is governed by the quantity of C-S-H gel. Thus the incorporation of pozzolans in a cement mixture can increase the strength of the cement mortar because of the additional C-S-H gel produced by pozzolanic reaction [9]. However, it is difficult to quantify C-S-H in cementitious materials. Since the amount of calcium hydroxide is proportional to the amount of C-S-H, it can be used to deduce the amount of C-S-H in the hydrated cement paste. From the experimental results, the cement mortar with borosilicate glass showed higher compressive strength gain in all ages. The results from TG/DSC showed that the calcium hydroxide of cement mortar with borosilicate glass decreased as the replacement ratio of borosilicate glass increased. The results of the compressive strength and the amount of calcium hydroxide tests suggest that the strength development in cement mortar with borosilicate glass is associated with the increase of C-S-H gel produced by the pozzolanic reaction.

It is known that the thermal neutron shielding rate of concrete increases as the boron content in concrete increases [4,5]. From the results of testing for the neutron shielding performance, the cement mortar with borosilicate glass showed higher thermal neutron shielding rates as the replacement ratio of borosilicate glass in the cement mortar increased. The increase of thermal neutron shielding rate of cement mortar with borosilicate glass is associated with the increase of boron content in the cement mortar.

4. Conclusions

This study investigated the effect of borosilicate glass on the thermal neutron shielding performance and the compressive strength gain of cement mortar. The cement mortar with borosilicate glass replacing fine aggregate showed higher compressive strength and higher thermal neutron shielding rate in all ages. The compressive strength and thermal neutron shielding rate of cement mortar increased as the replacement ratio of borosilicate glass increased. Through TG/DSC results, the cause of increase in compressive strength of cement mortar with borosilicate glass was associated with the pozzolanic activity of borosilicate glass in cement mortar. Also, the cause of increase of thermal neutron shielding rate of cement mortar with borosilicate glass was associated with the increase of boron content in the cement mortar. Based on the results and discussion, cement mortar with borosilicate glass can be effectively used as thermal neutron shielding material without decrease of strength.

Author Contributions

Conceptualization, J.C.L.; Experimentation, J.C.L.; Data interpretation, H.G.C.; Writing, J.C.L and H.G.C.

Funding

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. NRF-2018R1A5A1025137).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Thomas, R.H.; Casey, W.R.; Cossairt, J.D.; O’Brien, K.; Rohrig, N.; Slaback, L.A., Jr.; Stapleton, G.B.; Swanson, W.P.; Moritz, L.E.; Vylet, V.; et al. Radiation Protection for Particle Accelerator Facilities; NCRP Report 144; National Council on Radiation Protection and Measurement: Bethesda, MA, USA, 2006. [Google Scholar]

- Kaplan, M.F. Concrete Radiation Shielding; Longman Scientific & Technical: Harlow, United Kingdom, 1989. [Google Scholar]

- Kharita, M.H.; Yousef, S.; Alnassar, M. Review on the addition of boron compounds to radiation shielding concrete. Prog. Nucl. Energy 2011, 53, 207–211. [Google Scholar] [CrossRef]

- Abdullah, Y.; Yusof, A.; Muhamad, A.; Samsu, Z.; Abdullah, N.E. Cement-boron carbide concrete as radiation shielding material. J. Nucl. Related Technol. 2010, 7, 74–79. [Google Scholar]

- Abdullah, Y.; Nabilah, F.; Ariffin, T.; Hamid, R.; Moad, R.; Yusof, A.; Nurazila, M.; Zali, M.; Harun, A.; Rashid, M.; et al. Preliminary study of neutron absorption by concrete with boron carbide addition. AIP Conference Proc. 2014, 1584, 101–104. [Google Scholar]

- ASTM C150/C150M-16e1. Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM C778-13. Standard Specification for Standard Sand; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Shi, C.; Zheng, K. A review on the use of waste glasses in the production of cement and concrete. Resour. Conserv. Recycl. 2007, 52, 234–247. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete, 4th ed.; Wiley: New Jersey, NJ, USA, 1996; pp. 83–85. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).