An Artificial Bee Colony Algorithm Based on a Multi-Objective Framework for Supplier Integration

Abstract

Featured Application

Abstract

1. Introduction

2. Methodologies Used

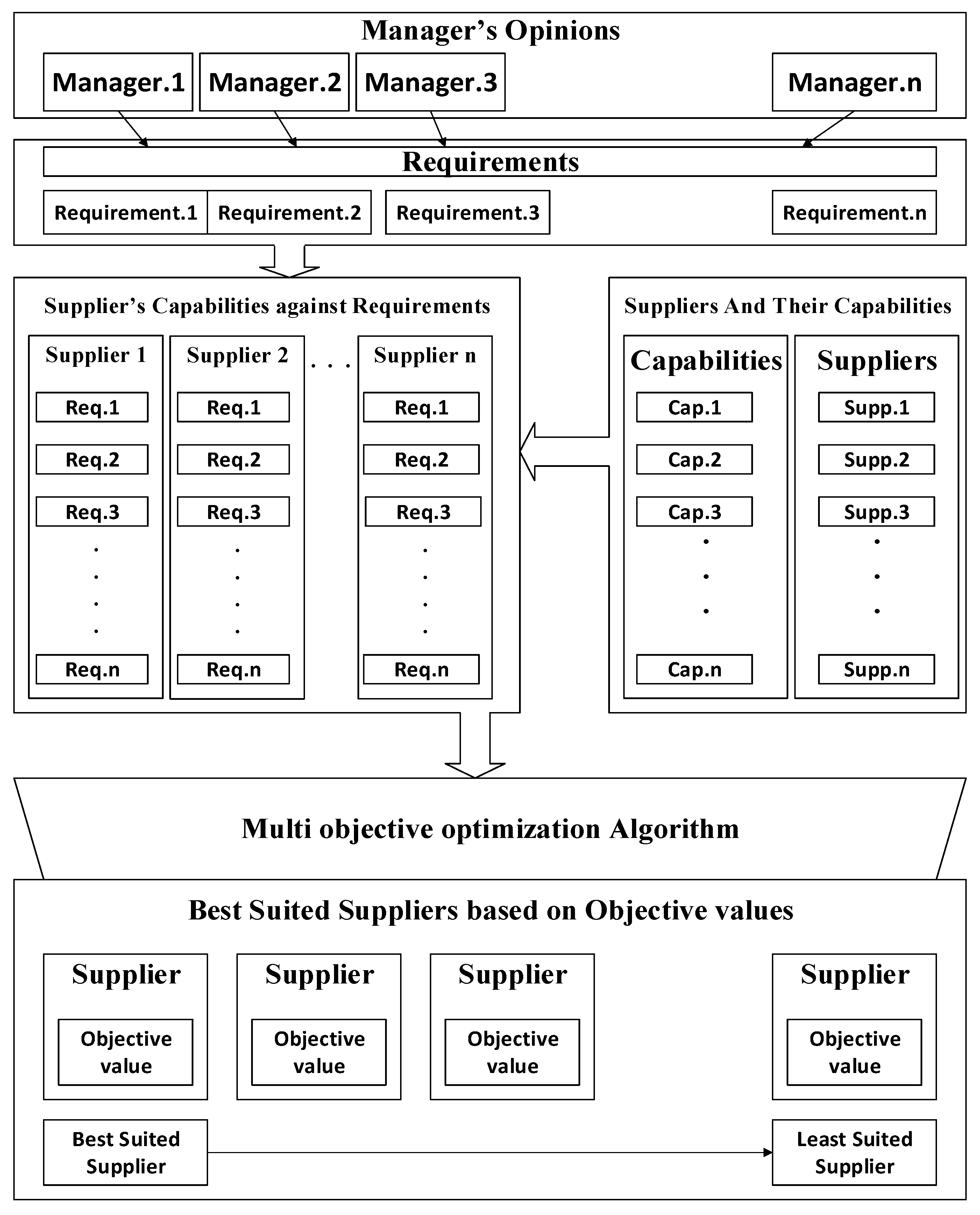

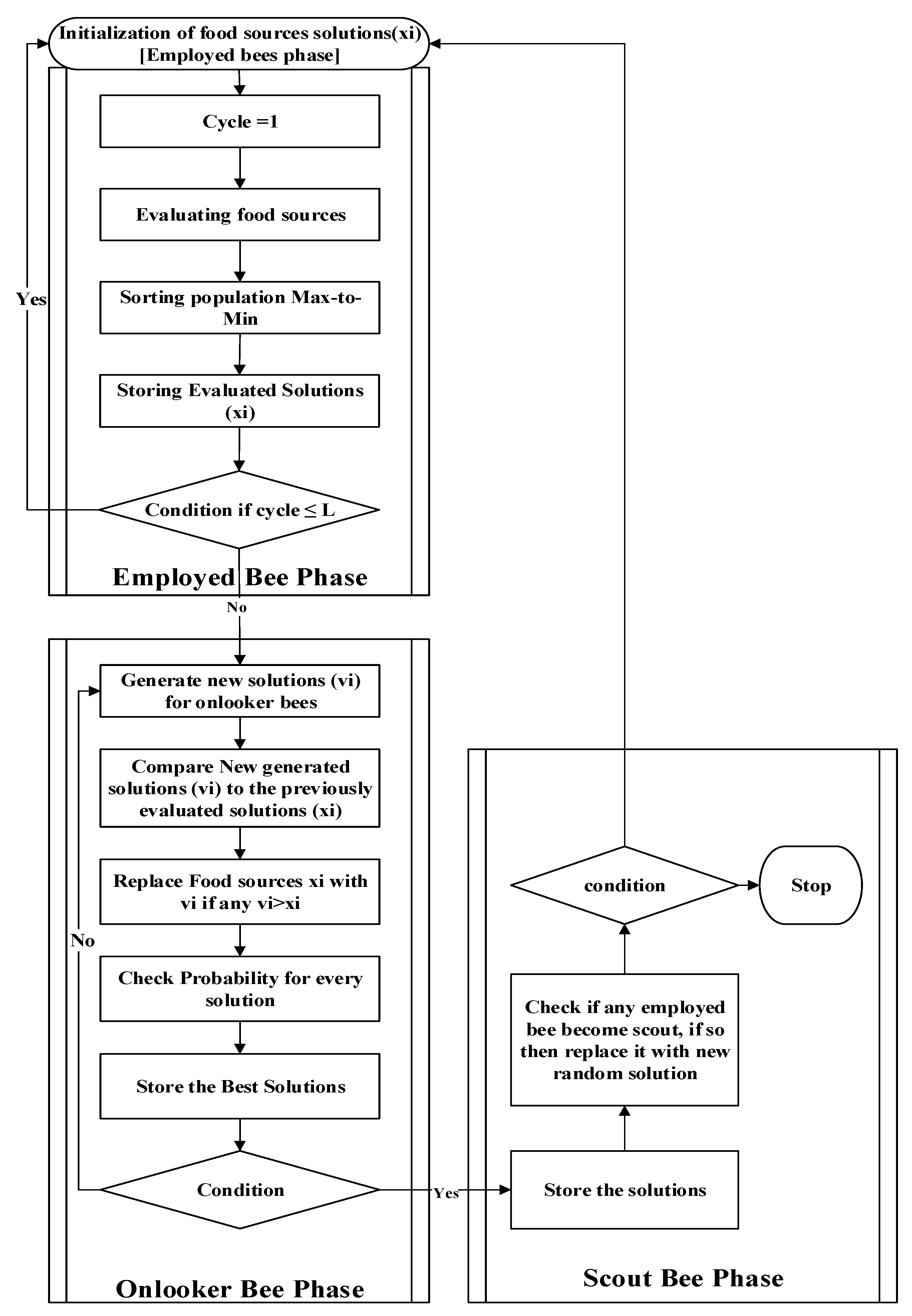

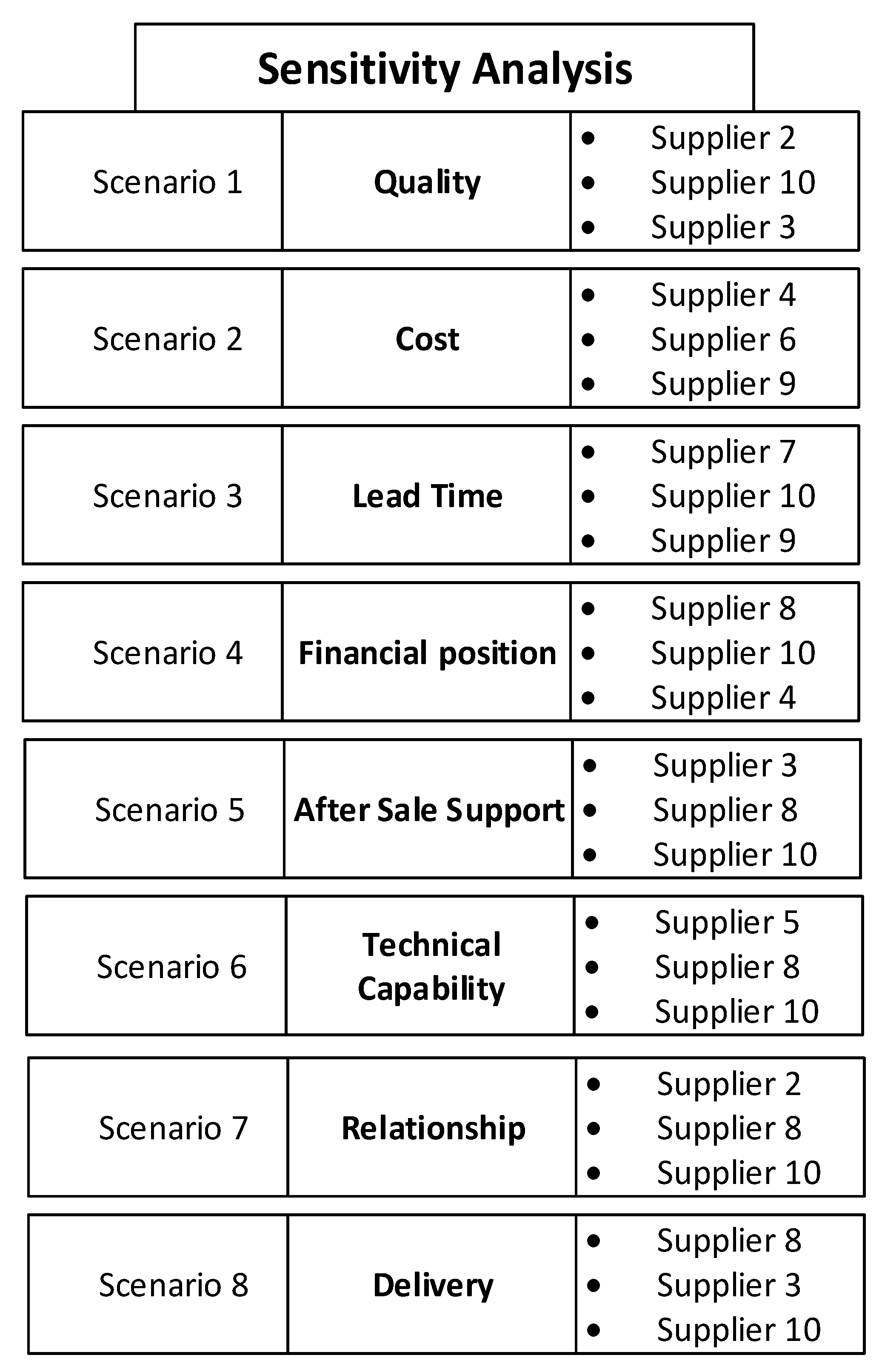

3. Background of ABC

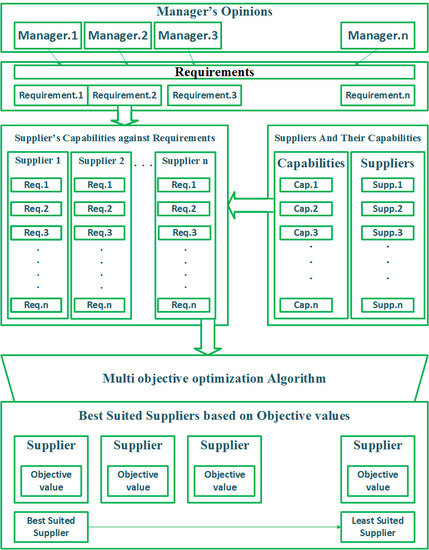

4. Proposed Framework

4.1. Layer 1: Manager Opinions

4.2. Layer 2: Supplier Capabilities

4.3. Layer 3: Multi Objective Optimization

5. Data-Specific Solutions of the Framework

6. Results and Discussion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ghodsypour, S.H.; O’Brien, C. A decision support system for supplier selection using an integrated analytic hierarchy process and linear programming. Int. J. Prod. Econ. 1998, 1, 199–212. [Google Scholar] [CrossRef]

- Locatelli, G.; Mancini, M.; Ishimwe, A. How can system engineering improve supplier management in megaprojects? Procedia Soc. Behav. Sci. 2014, 119, 510–518. [Google Scholar] [CrossRef]

- So, S.; Sun, H. Supplier integration strategy for lean manufacturing adoption in electronic-enabled supply chains. Supply Chain Manag. Int. J. 2010, 15, 474–487. [Google Scholar] [CrossRef]

- Petersen, K.J.; Handfield, R.B.; Ragatz, G.L. A model of supplier integration into new product development. J. Prod. Innov. Manag. 2003, 20, 284–299. [Google Scholar] [CrossRef]

- Ylimäki, J. A dynamic model of supplier–customer product development collaboration strategies. Ind. Mark. Manag. 2014, 43, 996–1004. [Google Scholar] [CrossRef]

- Huikkola, T.; Ylimäki, J.; Kohtamäki, M. Joint learning in R&D collaborations and the facilitating relational practices. Ind. Mark. Manag. 2013, 42, 1167–1180. [Google Scholar]

- Distel, S.; Klaus, P.; Prockl, G.; Baresel, A.; Zimmermann, R. Integrated Supplier—ECR is Also for Suppliers of Ingredients, Raw Materials and Packaging; Efficient Consumer Response Europe: Munich, Germany, 2000. [Google Scholar]

- Lockström, M.; Schadel, J.; Harrison, N.; Moser, R.; Malhotra, M.K. Antecedents to supplier integration in the automotive industry: A multiple-case study of foreign subsidiaries in China. J. Oper. Manag. 2010, 28, 240–256. [Google Scholar] [CrossRef]

- Bercz, C. Supplier Integration Systems: Understanding Adoption Process and Structure. Master’s Thesis, University of Twente, Enschede, The Netherlands, 2008. [Google Scholar]

- Danese, P.; Romano, P.; Vinelli, A. Managing business processes across supply networks: The role of coordination mechanisms. J. Purch. Supply Manag. 2004, 10, 165–177. [Google Scholar] [CrossRef]

- Dou, Y.; Zhu, Q.; Sarkis, J. Evaluating green supplier development programs with a grey-analytical network process-based methodology. Eur. J. Oper. Res. 2014, 233, 420–431. [Google Scholar] [CrossRef]

- Talluri, S.; Sarkis, J. A model for performance monitoring of suppliers. Int. J. Prod. Res. 2002, 40, 4257–4269. [Google Scholar] [CrossRef]

- Huang, S.H.; Keskar, H. Comprehensive and configurable metrics for supplier selection. Int. J. Prod. Econ. 2007, 105, 510–523. [Google Scholar] [CrossRef]

- Liker, J.K.; Choi, T.Y. Building deep supplier relationships. Harv. Bus. Rev. 2004, 82, 104–113. [Google Scholar]

- Hartley, J.L.; Choi, T.Y. Supplier development: Customers as a catalyst of process change. Bus. Horiz. 1996, 39, 37–44. [Google Scholar] [CrossRef]

- Verma, R.; Pullman, M.E. An analysis of the supplier selection process. Omega 1998, 26, 739–750. [Google Scholar] [CrossRef]

- Goh, S.H.; Eldridge, S. New product introduction and supplier integration in sales and operations planning: Evidence from the Asia Pacific region. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 861–886. [Google Scholar] [CrossRef]

- Kotula, M.; Ho, W.; Dey, P.K.; Lee, C.K.M. Strategic sourcing supplier selection misalignment with critical success factors: Findings from multiple case studies in Germany and the United Kingdom. Int. J. Prod. Econ. 2015, 166, 238–247. [Google Scholar] [CrossRef]

- Banaeian, N.; Mobli, H.; Fahimnia, B.; Nielsen, I.E.; Omid, M. Green supplier selection using fuzzy group decision making methods: A case study from the agri-food industry. Comput. Oper. Res. 2018, 89, 337–347. [Google Scholar] [CrossRef]

- Memon, M.S.; Mari, S.I.; Shaikh, F.; Shaikh, S.A. A grey-fuzzy multiobjective model for supplier selection and production-distribution planning considering consumer safety. Math. Probl. Eng. 2018, 2018, 17. [Google Scholar] [CrossRef]

- Alkahtani, M. Automobile tire assessment: A multi-criteria approach. Eng. Technol. Appl. Sci. Res. 2016, 7, 1363–1368. [Google Scholar]

- Humphreys, P.K.; Li, W.; Chan, L. The impact of supplier development on buyer–supplier performance. Omega 2004, 32, 131–143. [Google Scholar] [CrossRef]

- Dai, J.; Blackhurst, J. A four-phase AHP–QFD approach for supplier assessment: A sustainability perspective. Int. J. Prod. Res. 2012, 50, 5474–5490. [Google Scholar] [CrossRef]

- Ağan, Y.; Kuzey, C.; Acar, M.F.; Açıkgöz, A. The relationships between corporate social responsibility, environmental supplier development, and firm performance. J. Clean. Prod. 2014, 112, 1872–1881. [Google Scholar] [CrossRef]

- Shad, Z.; Roghanian, E.; Mojibian, F. Integration of QFD, AHP, and LPP methods in supplier development problems under uncertainty. J. Ind. Eng. Int. 2014, 10, 1–9. [Google Scholar] [CrossRef]

- Sancha, C.; Longoni, A.; Giménez, C. Sustainable supplier development practices: Drivers and enablers in a global context. J. Purch. Supply Manag. 2015, 21, 95–102. [Google Scholar] [CrossRef]

- Ekhtiari, M.; Poursafary, S. Multiobjective stochastic programming for mixed integer vendor selection problem using artificial bee colony algorithm. ISRN Artif. Intell. 2013, 2013, 13. [Google Scholar] [CrossRef]

- Karaboga, D.; Akay, B. A comparative study of artificial bee colony algorithm. Appl. Math. Comput. 2009, 214, 108–132. [Google Scholar] [CrossRef]

- Ilgin, M.A.; Gupta, S.M. Environmentally manufacturing and product recovery (ECMPRO): A review of the state of the art. J. Environ. Manag. 2010, 91, 563–591. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.M.; Gungor, A. Product recovery using a disassembly line: Challenges and solution. In Proceedings of the 2001 IEEE International Symposium on Electronics and the Environment, Denver, CO, USA, 9 May 2001; pp. 36–40. [Google Scholar]

- Koc, A.; Sabuncuoglu, I.; Erel, E. Two exact formulations for disassembly line balancing problems with task precedence diagram construction using an AND/OR graph. IIE Trans. 2009, 41, 866–881. [Google Scholar] [CrossRef]

- Altekin, F.T.; Akkan, C. Task-failure-driven rebalancing of disassembly lines. Int. J. Prod. Res. 2012, 50, 4955–4976. [Google Scholar] [CrossRef]

- Bentaha, M.L.; Battaia, O.; Dolgui, A. A sample average approximation method for disassembly line balancing problem under uncertainty. Comput. Oper. Res. 2014, 51, 111–122. [Google Scholar] [CrossRef]

- Altekin, F.T.; Kandiller, L.; Ozdemirel, N.E. Profit-oriented disassembly-line balancing. Int. J. Prod. Res. 2008, 46, 2675–2693. [Google Scholar] [CrossRef]

- Mcgovern, S.M.; Gupta, S.M. Combinatorial optimization analysis of the unary NP-complete disassembly line balancing problem. Int. J. Prod. Res. 2007, 45, 4485–4511. [Google Scholar] [CrossRef]

- Mcgovern, S.M.; Gupta, S.M. A balancing method and genetic algorithm for disassembly line balancing. Eur. J. Oper. Res. 2007, 179, 692–708. [Google Scholar] [CrossRef]

- Yang, H.; Zeqiang, Z.; Wang Kaipu, W.; Lili, M. Pareto bacterial foraging algorithm for multi-objective disassembly line balance problem. J. Comput. Appl. 2016, 33, 3265–3269. [Google Scholar]

- Ding, L.-P.; Feng, Y.-X.; Tan, J.-R.; Gao, Y.-C. A new multi-objective ant colony algorithm for solving the disassembly line balancing problem. Int. J. Adv. Manuf. Technol. 2010, 48, 761–771. [Google Scholar] [CrossRef]

- Ming, L.; Zeqiang, Z.; Yang, H. Research on disassembly line balance problem and its solving algorithm for U-shaped layout. Mod. Manuf. Eng. 2015, 7, 7–12. [Google Scholar]

- Kalayci, C.B.; Hancilar, A.; Gungor, A.; Gupta, S.M. Multi-objective fuzzy disassembly line balancing using a hybrid discrete artificial bee colony algorithm. J. Manuf. Syst. 2015, 37, 672–682. [Google Scholar] [CrossRef]

- Scholl, A.; Boysen, N.; Fliedner, M. The sequence-dependent assembly line balancing problem. OR Spectr. 2008, 30, 579–609. [Google Scholar] [CrossRef]

- Andrés, C.; Miralles, C.; Pastor, R. Balancing and scheduling tasks in assembly lines with sequence-dependent setup times. Eur. J. Oper. Res. 2008, 187, 1212–1223. [Google Scholar] [CrossRef]

- Yolmeh, A.; Kianfar, F. An efficient hybrid genetic algorithm to solve assembly line balancing problem with sequence-dependent setup times. Comput. Ind. Eng. 2012, 62, 936–945. [Google Scholar] [CrossRef]

- Hamta, N.; Ghomi, S.M.T.F.; Jolai, F.; Shirazi, M.A. A hybrid PSO algorithm for a multi-objective assembly line balancing problem with flexible operation times, sequence-dependent setup times and learning effect. Int. J. Prod. Econ. 2013, 141, 99–111. [Google Scholar] [CrossRef]

- Akpinar, S.; Bayhan, G.M.; Baykasoglu, A. Hybridizing ant colony optimization via genetic algorithm for mixed-model assembly line balancing problem with sequence dependent setup times between tasks. Appl. Soft Comput. 2013, 13, 574–589. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Gupta, S.M. Ant colony optimization for sequence-dependent disassembly line balancing problem. J. Manuf. Technol. Manag. 2013, 24, 413–427. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Polat, O.; Gupta, S.M. A hybrid genetic algorithm for sequence-dependent disassembly line balancing problem. Ann. Oper. Res. 2016, 242, 321–354. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Gupta, S.M. A tabu search algorithm for balancing a sequence-dependent disassembly line. Prod. Plan. Control 2014, 25, 149–160. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Polat, O.; Gupta, S.M. A variable neighbourhood search algorithm for disassembly lines. J. Manuf. Technol. Manag. 2015, 26, 182–194. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Gupta, S.M. Artificial bee colony algorithm for solving sequence-dependent disassembly line balancing problem. Expert Syst. Appl. 2013, 40, 7231–7241. [Google Scholar] [CrossRef]

- Özbakir, L.; Baykasoğlu, A.; Tapkan, P. Bees algorithm for generalized assignment problem. Appl. Math. Comput. 2010, 215, 3782–3795. [Google Scholar] [CrossRef]

- Fahmy, A. Using the Bees Algorithm to select the optimal speed parameters for wind turbine generators. J. King Saud Univ. Comput. Inf. Sci. 2012, 24, 17–26. [Google Scholar] [CrossRef]

- Yuce, B.; Packianather, M.S.; Mastrocinque, E.; Pham, D.T.; Lambiase, A. Honey bees inspired optimization method: The Bees Algorithm. Insects 2013, 4, 646–662. [Google Scholar] [CrossRef] [PubMed]

- Delgado-Osuna, J.A.; Lozano, M.; García-Martínez, C. An alternative artificial bee colony algorithm with destructive–constructive neighbourhood operator for the problem of composing medical crews. Inf. Sci. 2016, 326, 215–226. [Google Scholar] [CrossRef]

- Pham, D.; Ghanbarzadeh, A. Multi-objective optimisation using the Bees Algorithm. In Proceedings of the 3rd IPROMS Conference, Cardiff, UK, 2–13 July 2007. [Google Scholar]

- Karaboga, D.; Ozturk, C. A novel clustering approach: Artificial Bee Colony (ABC) algorithm. Appl. Soft Comput. 2011, 11, 652–657. [Google Scholar] [CrossRef]

- Bouaziz, A.; Draa, A.; Chikhi, S. Artificial bees for multilevel thresholding of iris images. Swarm Evolut. Comput. 2015, 21, 32–40. [Google Scholar] [CrossRef]

| ABC Comparison | |||

|---|---|---|---|

| Reference | Comparison of Algorithms | Selected Algorithm | Application |

| Özbakir [51] | Bees Algorithm (BA), Genetic Algorithm (GA) | BA | Continuous Optimization |

| Fahmy [22] | Particle Swarm Optimization (PSO), BA | BA | Speed parameters for wind turbine generators |

| Yuce [53] | Swarm Optimization Algorithms (SOAs), Bee Colonial Optimization (BCO), GA, ABC | ABC | Honey bees-inspired optimization method |

| Delgado-Osuna [54] | GA, state-of-the-art algorithm, ABC | ABC | Problem of composing medical crews |

| Karaboga [28] | Differential Evolution (DE), GA, PSO, ABC, Evolution Strategy (ES) | ABC | Comparative study of Bees Algorithm |

| Pham [55] | GA, K-means, BA | BA | Data clustering |

| Karaboga [28] | ABC, PSO | ABC | Clustering Approach |

| Bouaziz [57] | ABC, PSO, | ABC | Iris Image optimization |

| Karaboga [56] | ABC, PSO. | ABC | Multi Objective Optimization |

| Factors | Quality | Delivery | Cost | Technical Capability |

| Weightage | 4.78 | 4.51 | 4.33 | 4.24 |

| Past Data of 10 Main Suppliers | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Factors (Recommended Range in %) | Ranges of the Factors Against Vendors | |||||||||

| Quality | 80–90 | 90–95 | 85–90 | 85–90 | 80–90 | 60–75 | 60–70 | 80–90 | 85–90 | 85–95 |

| Cost | 40–48 | 60–70 | 30–40 | 40–45 | 55–60 | 25–30 | 30–35 | 45–50 | 25–35 | 35–45 |

| Lead Time | 80–85 | 85–95 | 60–65 | 65–70 | 65–70 | 90–95 | 80–85 | 85–90 | 75–80 | 85–90 |

| Financial Position | 70–85 | 65–70 | 80–85 | 90–95 | 95–100 | 60–70 | 60–70 | 80–90 | 80–95 | 90–95 |

| Technical Capability | 60–75 | 25–35 | 30–40 | 15–20 | 30–35 | 35–40 | 20–25 | 30–40 | 20–30 | 30–35 |

| After Sale Support | 80–85 | 60–65 | 80–90 | 70–85 | 60–70 | 60–65 | 70–80 | 90–95 | 65–70 | 90–95 |

| Relationships | 85–90 | 90–95 | 85–90 | 80–85 | 85–90 | 85–90 | 85–90 | 90–95 | 70–75 | 90–95 |

| Delivery | 90–95 | 85–90 | 85–90 | 90–95 | 80–85 | 85–90 | 75–85 | 90–95 | 80–90 | 95–100 |

| Supplier number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Capacity of Supplier (Units/month) | 50 | 63 | 75 | 55 | 50 | 43 | 38 | 56 | 65 | 72 |

| Parameter | Value |

|---|---|

| Maximum number of cycles | 50 |

| Number of food sources | 10 |

| Demand limit | 200 |

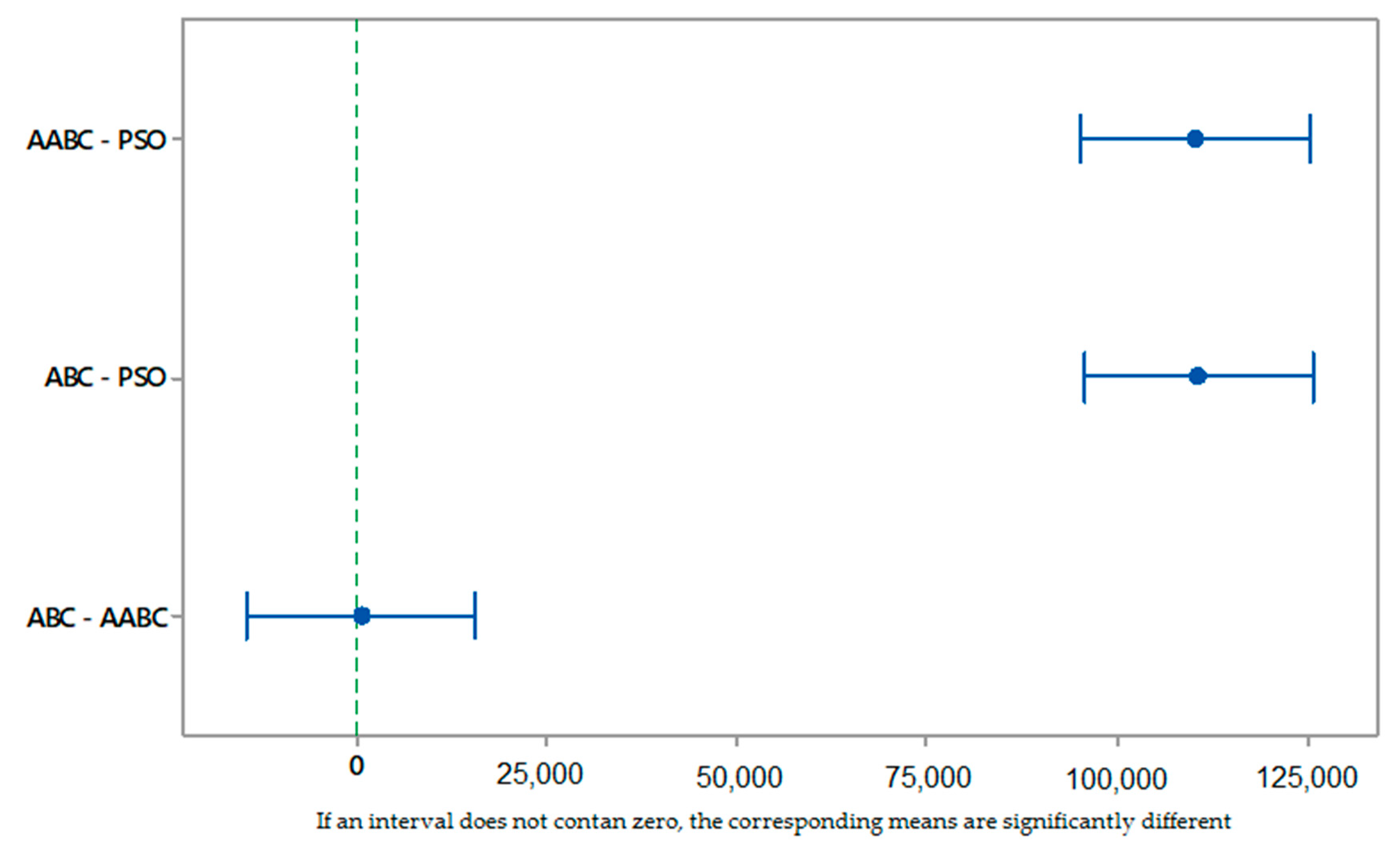

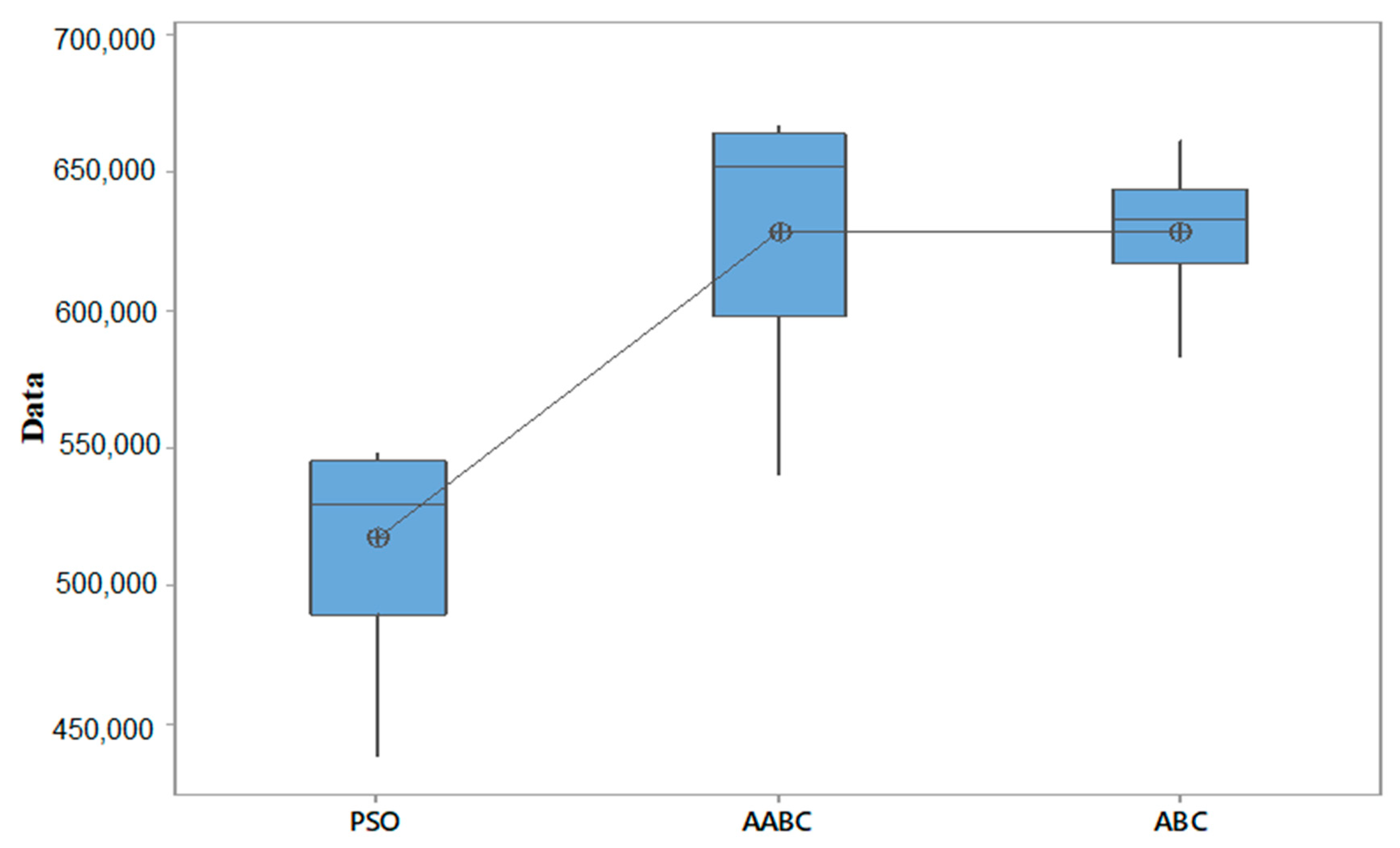

| Source | Degree of Freedom (DF) | Adj SS | Adj MS | F-Value | P-Value |

|---|---|---|---|---|---|

| Factor | 2 | 4.06532 1011 | 2.03266 1011 | 201.93 | 0.000 |

| Error | 147 | 1.47973 1011 | 10 106 | ||

| Total | 149 | 5.54505 1011 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farooq, M.U.; Salman, Q.; Arshad, M.; Khan, I.; Akhtar, R.; Kim, S. An Artificial Bee Colony Algorithm Based on a Multi-Objective Framework for Supplier Integration. Appl. Sci. 2019, 9, 588. https://doi.org/10.3390/app9030588

Farooq MU, Salman Q, Arshad M, Khan I, Akhtar R, Kim S. An Artificial Bee Colony Algorithm Based on a Multi-Objective Framework for Supplier Integration. Applied Sciences. 2019; 9(3):588. https://doi.org/10.3390/app9030588

Chicago/Turabian StyleFarooq, Muhammad Umer, Qazi Salman, Muhammad Arshad, Imran Khan, Rehman Akhtar, and Sunghwan Kim. 2019. "An Artificial Bee Colony Algorithm Based on a Multi-Objective Framework for Supplier Integration" Applied Sciences 9, no. 3: 588. https://doi.org/10.3390/app9030588

APA StyleFarooq, M. U., Salman, Q., Arshad, M., Khan, I., Akhtar, R., & Kim, S. (2019). An Artificial Bee Colony Algorithm Based on a Multi-Objective Framework for Supplier Integration. Applied Sciences, 9(3), 588. https://doi.org/10.3390/app9030588