The Effects of Selective Laser Melting Process Parameters on Relative Density of the AlSi10Mg Parts and Suitable Procedures of the Archimedes Method

Abstract

1. Introduction

2. Materials and Experimental Procedures

2.1. Materials

2.2. Doehlert Design for Optimization of Parameters

2.3. Experimental Procedures

3. Results and Discussion

3.1. Relative Density

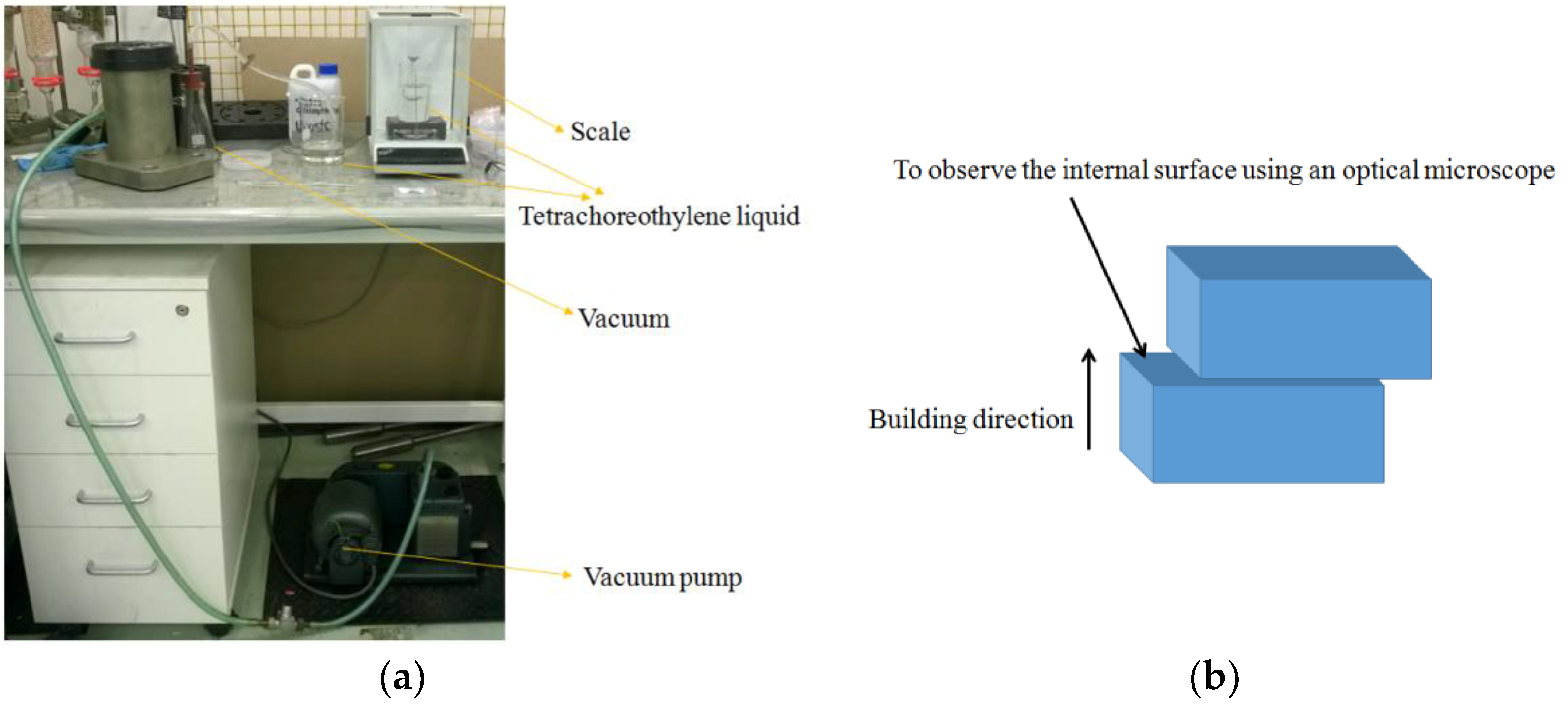

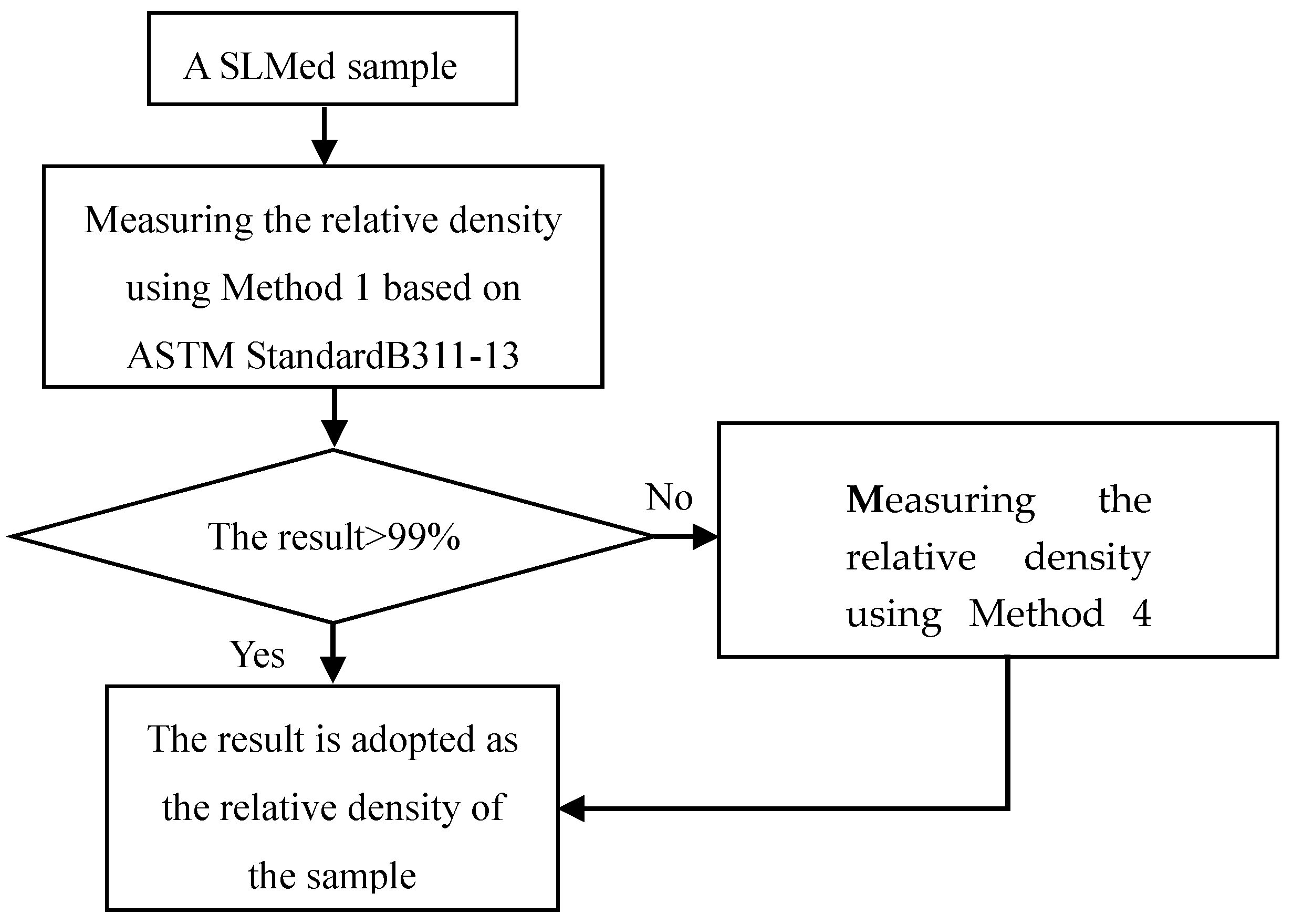

3.1.1. Archimedes Method

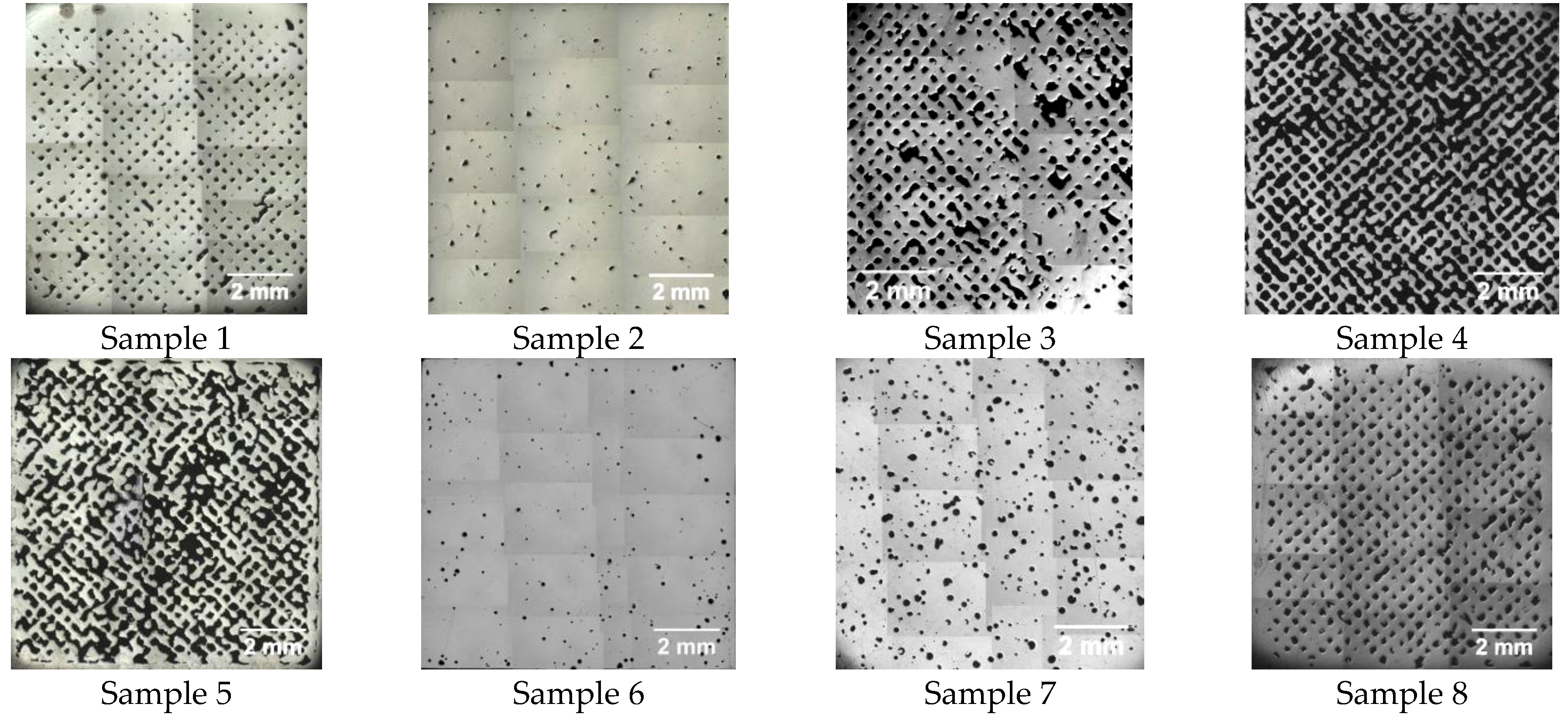

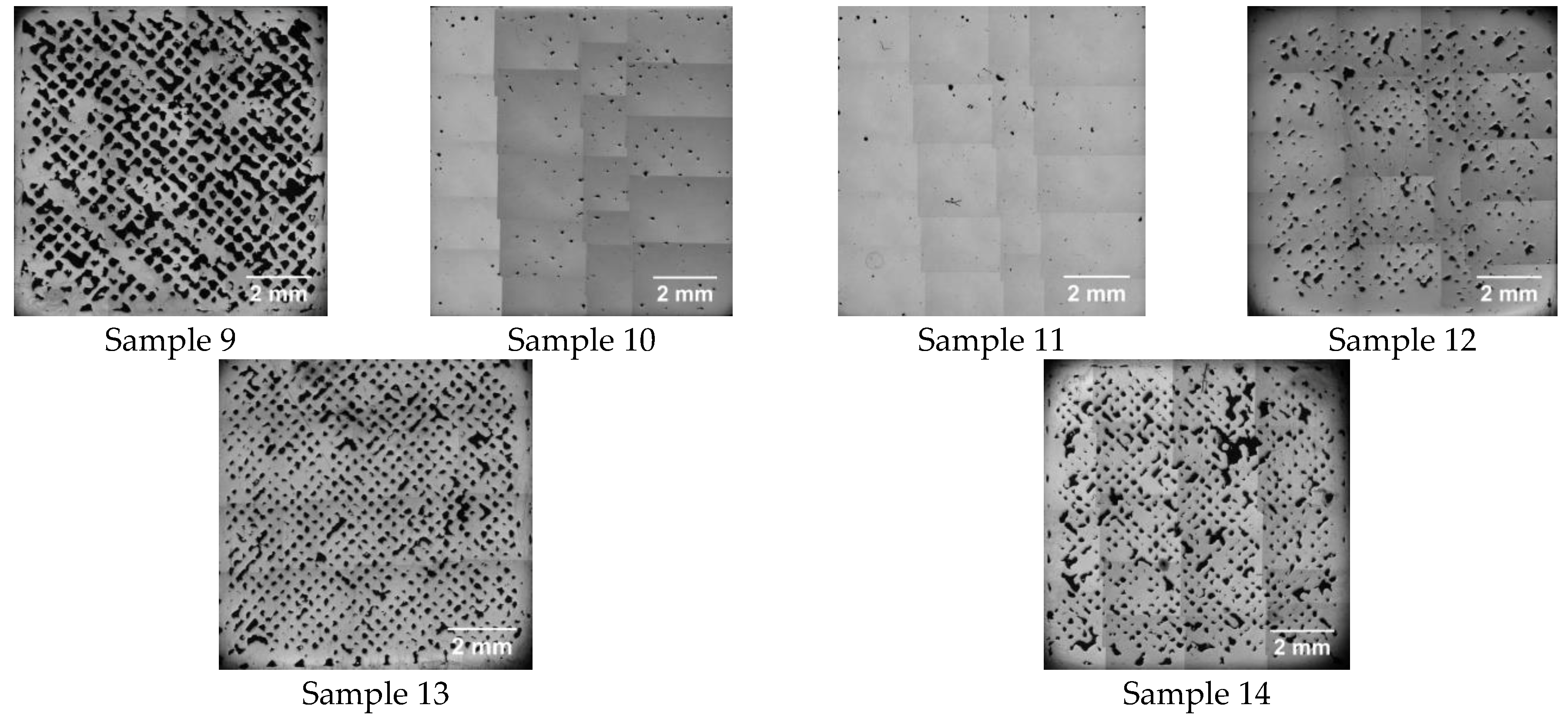

3.1.2. Image Analysis

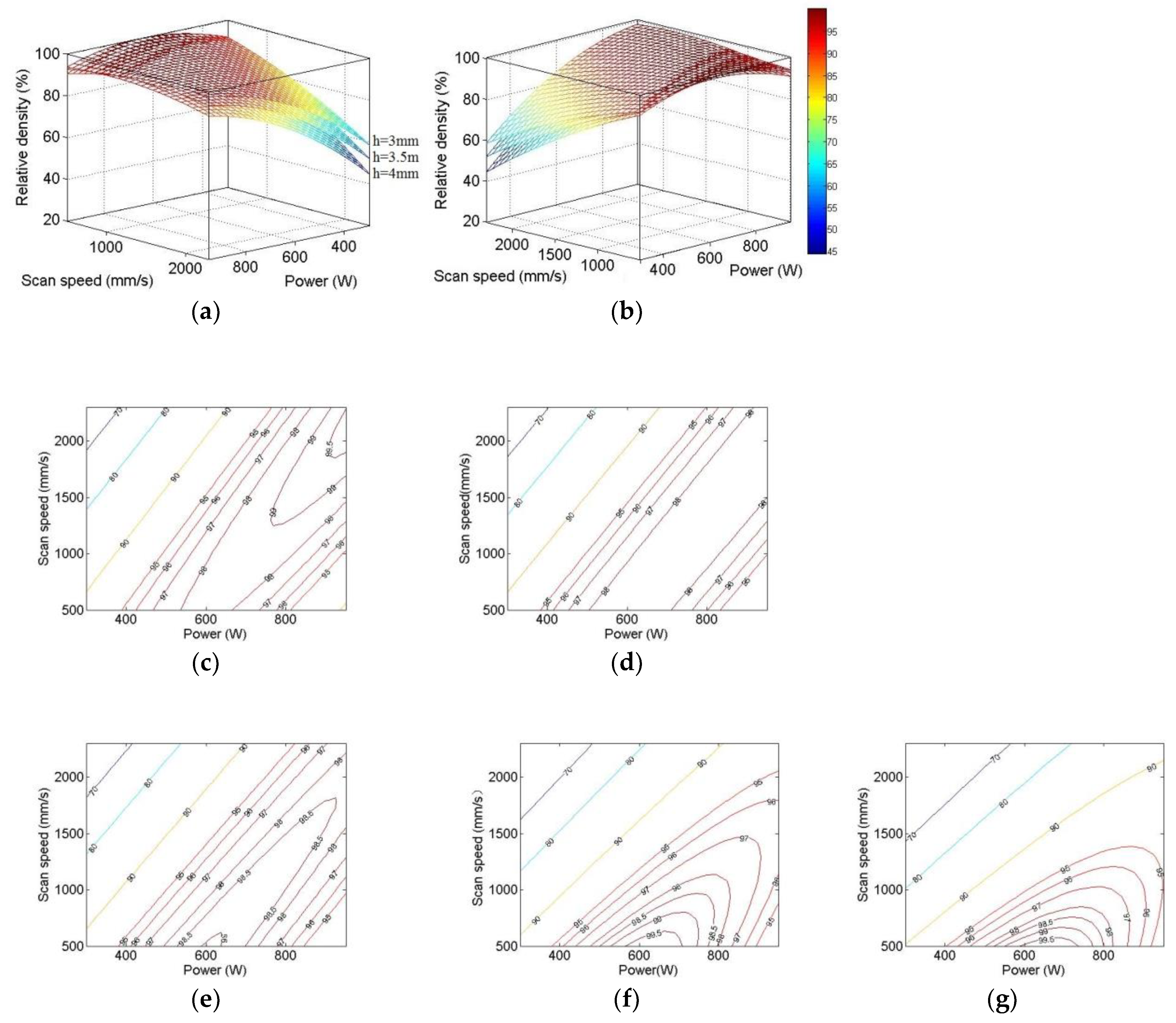

3.2. Optimization of the SLM Processing Parameters

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Muktinutalapati, N.R. Materials for Gas Turbines—An over view. In Advance in Gas Turbine Technology; Benini, E., Ed.; IntechOpen: London, UK, 2011; pp. 293–314. [Google Scholar]

- Kelbassa, I.; Albus, P.; Dietrich, J.; Wilkes, J. Manufacture and repair of Aeroengine components using laser technology. In Proceedings of the 3rd Pacific International Conference on Application of Laser and Optics, Beijing, China, 16–18 April 2008; pp. 208–212. [Google Scholar]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimization and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef]

- Li, B.; Wang, H.W.; Jie, J.C.; Wei, Z.J. Effects of yttrium and heat treatment on the microstructure and tensile properties of Al-7.5Si-0.5Mg alloy. Mater. Des. 2011, 32, 1617–1622. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; van Humbeeck, J.; Kruth, J.-P. Processing AlSi10Mg by selective laser melting: Parameter optimisation and material characterization. Mater. Sci. Technol. 2015, 31, 917–923. [Google Scholar] [CrossRef]

- Weingarten, C.; Buchbinder, D.; Pirch, N. Formation and reduction of hydrogen porosity during selective laser melting of AlSi10Mg. J. Mater. Process. Technol. 2015, 221, 112–120. [Google Scholar] [CrossRef]

- Atwood, R.C.; Sridhar, S.; Zhang, W.; Lee, P.D. Diffusion-controlled growth of hydrogen pores in aluminium-silicon castings: On situ observation and modelling. Acta Mater. 2000, 48, 405–417. [Google Scholar] [CrossRef]

- Buchbinder, D.; Schleifenbaum, H.; Heidrich, S.; Meiners, W.; Büttmann, J. High power selective laser melting (HPSLM) of aluminium parts. Phys. Procedia 2011, 12, 271–278. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef]

- Yang, K.V.; Rometsch, P.; Jarvis, T.; Rao, J.; Cao, S.; Davies, C.; Wu, X. Porosity formation mechanisms and fatigue response in Al-Si-Mg alloys made by selective laser melting. Mater. Sci. Eng. A 2018, 712, 166–174. [Google Scholar] [CrossRef]

- Olakanmi, E.O.T.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, andproperties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Tang, M.; Pistorius, P.C. Oxides, porosity and fatigue performance of AlSi10Mg parts produced by selective laser melting. Int. J. Fatigue 2017, 94, 192–201. [Google Scholar] [CrossRef]

- Spierings, A.B.; Schneider, M. Comparison of density measurement techniques for additive manufactured metallicparts. Rapid Prototyp. J. 2011, 17, 380–386. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Shahabi, S.H.; Attar, H.; Srivastava, V.C.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J.; Scudino, S. Production of high strength Al85Gd8Ni5Co2 alloy by selective laser melting. Addit. Manuf. 2015, 6, 1–5. [Google Scholar] [CrossRef]

- Schwab, H.; Prashanth, K.G.; Löber, L.; Kühn, U.; Eckert, J. Selective laser melting of Ti-45Nb alloy. Metals 2015, 5, 686–694. [Google Scholar] [CrossRef]

- Carter, L.N.; Wang, X.; Read, N.; Khan, R.; Aristizabal, M.; Essa, K.; Attallah, M.M. Process optimization of selective laser melting using energy density model for nickel based super alloys. Mater. Sci. Technol. 2016, 32, 657–661. [Google Scholar]

- Maamoun, A.H.; Xue, Y.F.; Elbestawi, M.A.; Veldhuis, S.C. Effect of Selective Laser Melting Process Parameters on the Quality of Al Alloy Parts: Powder Characterization, Density, Surface Roughness, and Dimensional Accuracy. Materials 2018, 11, 2343. [Google Scholar] [CrossRef] [PubMed]

- Maamoun, A.H.; Xue, Y.F.; Elbestawi, M.A.; Veldhuis, S.C. The Effect of Selective Laser Melting Process Parameters on the Microstructure and Mechanical Properties of Al6061 and AlSi10Mg Alloys. Materials 2019, 12, 12. [Google Scholar] [CrossRef] [PubMed]

- Suryawanshi, J.; Prashanth, K.G.; Scudino, S.; Eckert, J.; Prakash, O.; Ramamurty, U. Simultaneous enhancements of strength and toughness in an Al-12Si alloy synthesized using selective laser melting. Acta Mater. 2016, 115, 285–294. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Maity, T.; Dasd, J.; Eckert, J. Is the energy density are liable parameter for materials synthesis by selective laser melting. Mater. Res. Lett. 2017, 5, 386–390. [Google Scholar] [CrossRef]

- Fotovvati, B.; Wayne, S.F.; Lewis, G.; Asadi, E. A Review on Melt-Pool Characteristicsin Laser Welding of Metals. Adv. Mater. Sci. Eng. 2018, 2018, 4920718. [Google Scholar]

- Perevoshchikova, N.; Rigaud, J.; Sha, Y.; Heilmaier, M. Optimisation of selective laser melting parameters for the Ni-based super alloy IN-738LC using Doehlert’s design. Rapid Prototyp. J. 2017, 23, 881–892. [Google Scholar] [CrossRef]

- Standard Test Method for Density of Powder Metallurgy (PM) Materials Containing Less Than Two Percent Porosity; Standard B311-13; ASTM: New York, NY, USA, 2014.

- Standard Test Method for Density of Compacted or Sintered Powder Metallurgy (PM) Products Using Archimedes’ Principle; Standard B962-13; ASTM: New York, NY, USA, 2014.

- Casalino, G.; Campanelli, S.L.; Contuzzi, N.; Ludovico, A.D. Experimental investigation and statistical optimisation of the selective laser melting process of a maraging steel. Opt. Laser Technol. 2015, 65, 151–158. [Google Scholar] [CrossRef]

- Quignon, F.; Huyard, A.; Schwartzbrod, L.; Thomas, F. Use of Doehlert matrices for study of poliovirus-1adsorption. J. Virol. Methods 1997, 68, 33–44. [Google Scholar] [CrossRef]

- Taragano, V.M.; Pilosof, A.M.M. Application of Doehlert designs for water activity, pH and fermentation time optimization for Aspergillus niger pectinolytic activities production in solid-state and submerged fermentation. Enzym. Microb. Technol. 1999, 25, 411–419. [Google Scholar] [CrossRef]

- Doehlert, D.H. Uniform shell designs. Appl. Stat. 1970, 19, 231–239. [Google Scholar] [CrossRef]

- Ferreira, S.L.C.; dos Santos, W.N.L.; Quintella, C.M.; Neto, B.B.; Bosque-Sendra, J.M. Doehlert matrix: A chemometric tool for analytical chemistry—Review. Talanta 2004, 63, 1061–1067. [Google Scholar] [CrossRef] [PubMed]

- Laakso, P.; Riipinen, T.; Laukkanen, A.; Andersson, T.; Jokinen, A.; Revuelta, A.; Ruusuvuori, K. Optimization and Simulation of SLM Process for High Density H13 Tool Steel Parts. Phys. Procedia 2016, 83, 26–35. [Google Scholar] [CrossRef]

- Schneider, C.A.; Raband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Levy, G.; Herres, N.; Spierings, A.B.; Bourell, D. Influence of the particle size distribution on surface quality and mechanical properties in am steel parts. Rapid Prototyp. J. 2010, 17, 195–202. [Google Scholar]

| Si | Mg | Cu | Fe | Zn | Al |

|---|---|---|---|---|---|

| wt.% | wt.% | wt.% | wt.% | wt.% | wt.% |

| 10.6 | 0.45 | 0.02 | 0.19 | <0.01 | Bal. |

| Sample | P (W) | v (mm/s) | h (mm) | Energy Density (J/mm2) |

|---|---|---|---|---|

| 1 | 625 | 1400 | 0.35 | 1.28 |

| 2 | 950 | 1400 | 0.35 | 1.94 |

| 3 | 788 | 2300 | 0.35 | 0.98 |

| 4 | 463 | 2300 | 0.35 | 0.58 |

| 5 | 300 | 1400 | 0.35 | 0.61 |

| 6 | 463 | 500 | 0.35 | 2.65 |

| 7 | 788 | 500 | 0.35 | 4.50 |

| 8 | 788 | 1700 | 0.4 | 1.16 |

| 9 | 463 | 1700 | 0.4 | 0.68 |

| 10 | 625 | 800 | 0.4 | 1.95 |

| 11 | 788 | 1099 | 0.3 | 2.39 |

| 12 | 463 | 1099 | 0.3 | 1.40 |

| 13 | 625 | 2000 | 0.3 | 1.04 |

| 14 | 300 | 800 | 0.3 | 1.25 |

| Method | Liquid for Liquid-Impregnation | Liquid for Providing Buoyancy | Using Vacuum Pump (Yes/No) | Impregnation Time (min) | Surface |

|---|---|---|---|---|---|

| 1 | N/A | Ethanol | No | 30 | SLMed |

| 2-1 | Ethanol | Ethanol | No | 30 | SLMed |

| 2-2 | Ethanol | Ethanol | No | 30 | Ground |

| 3-1 | Tetrachloroethylene | Tetrachloroethylene | Yes | 5 | Ground |

| 3-2 | Tetrachloroethylene | Tetrachloroethylene | Yes | 30 | Ground |

| 4 | Pure Silicone Fluid | Ethanol | Yes | 30 | Ground |

| Liquid | Density (g/cm3) | Viscosity (10−6m2/s) | Surface Tension (10−3N/m) |

|---|---|---|---|

| 96% Ethanol | 0.8075 | 0.740 | 22.39 |

| Tetrachloroethylene(C2Cl4) | 1.622 | 0.549 | 31.74 |

| Pure Silicone Fluid | 0.97 | 50 | 20.8 |

| Sample | P (W) | v (mm/s) | h (mm) | Energy Density (J/mm2) | ρrelative (%) | |||

|---|---|---|---|---|---|---|---|---|

| Archimedes Methods | Image Analysis | |||||||

| 1 | 4 | 4* | ||||||

| 1 | 625 | 1400 | 0.35 | 1.28 | 95.67 | 93.82 | 93.82 | 90.9 |

| 2 | 950 | 1400 | 0.35 | 1.94 | 99.15 | 97.72 | 99.15 | 98.68 |

| 3 | 788 | 2300 | 0.35 | 0.98 | 94.33 | 86.96 | 86.96 | 80.21 |

| 4 | 463 | 2300 | 0.35 | 0.58 | 93.2 | 71.98 | 71.98 | 52.06 |

| 5 | 300 | 1400 | 0.35 | 0.61 | 93.94 | 72.13 | 72.13 | 60.51 |

| 6 | 463 | 500 | 0.35 | 2.65 | 99.57 | 97.58 | 99.57 | 98.6 |

| 7 | 788 | 500 | 0.35 | 4.50 | 96.29 | 94.48 | 94.48 | 93.86 |

| 8 | 788 | 1700 | 0.4 | 1.16 | 94.67 | 90.67 | 90.67 | 85.02 |

| 9 | 463 | 1700 | 0.4 | 0.68 | 94.25 | 75.27 | 75.27 | 71.78 |

| 10 | 625 | 800 | 0.4 | 1.95 | 99.16 | 97.41 | 99.16 | 98.93 |

| 11 | 788 | 1099 | 0.3 | 2.39 | 99.77 | 98.62 | 99.77 | 99.51 |

| 12 | 463 | 1099 | 0.3 | 1.40 | 95.78 | 92.92 | 92.92 | 94.72 |

| 13 | 625 | 2000 | 0.3 | 1.04 | 94.83 | 88.3 | 88.3 | 85.58 |

| 14 | 300 | 800 | 0.3 | 1.25 | 94.68 | 88.37 | 88.37 | 87.24 |

| Regression Constants | Coefficient a | Results |

| a0 | 60.1737 | |

| a1 | 0.0518 | |

| a2 | 0.0032 | |

| a3 | 123.5745 | |

| a11 | −7.42 × 10−5 | |

| a22 | −4.11 × 10−6 | |

| a33 | −180.9538 | |

| a12 | 3.47 × 10−5 | |

| a13 | 0.0726 | |

| a23 | −0.0688 | |

| f test | F | 8.9160 |

| Correlation Coefficient | R2 | 0.95 |

| Optimum Combination | Po (W) | 651 |

| vo (mm/s) | 500 | |

| ho (mm) | 0.378 | |

| Calculated Results Using the Optimum Combination | ρrelative,max (%) | 100.01 |

| Energy density (J/mm2) | 3.44 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, S.; Perevoshchikova, N.; Sha, Y.; Wu, X. The Effects of Selective Laser Melting Process Parameters on Relative Density of the AlSi10Mg Parts and Suitable Procedures of the Archimedes Method. Appl. Sci. 2019, 9, 583. https://doi.org/10.3390/app9030583

Bai S, Perevoshchikova N, Sha Y, Wu X. The Effects of Selective Laser Melting Process Parameters on Relative Density of the AlSi10Mg Parts and Suitable Procedures of the Archimedes Method. Applied Sciences. 2019; 9(3):583. https://doi.org/10.3390/app9030583

Chicago/Turabian StyleBai, Shigang, Nataliya Perevoshchikova, Yu Sha, and Xinhua Wu. 2019. "The Effects of Selective Laser Melting Process Parameters on Relative Density of the AlSi10Mg Parts and Suitable Procedures of the Archimedes Method" Applied Sciences 9, no. 3: 583. https://doi.org/10.3390/app9030583

APA StyleBai, S., Perevoshchikova, N., Sha, Y., & Wu, X. (2019). The Effects of Selective Laser Melting Process Parameters on Relative Density of the AlSi10Mg Parts and Suitable Procedures of the Archimedes Method. Applied Sciences, 9(3), 583. https://doi.org/10.3390/app9030583