Modal Planning for Cooperative Non-Prehensile Manipulation by Mobile Robots

Abstract

:1. Introduction

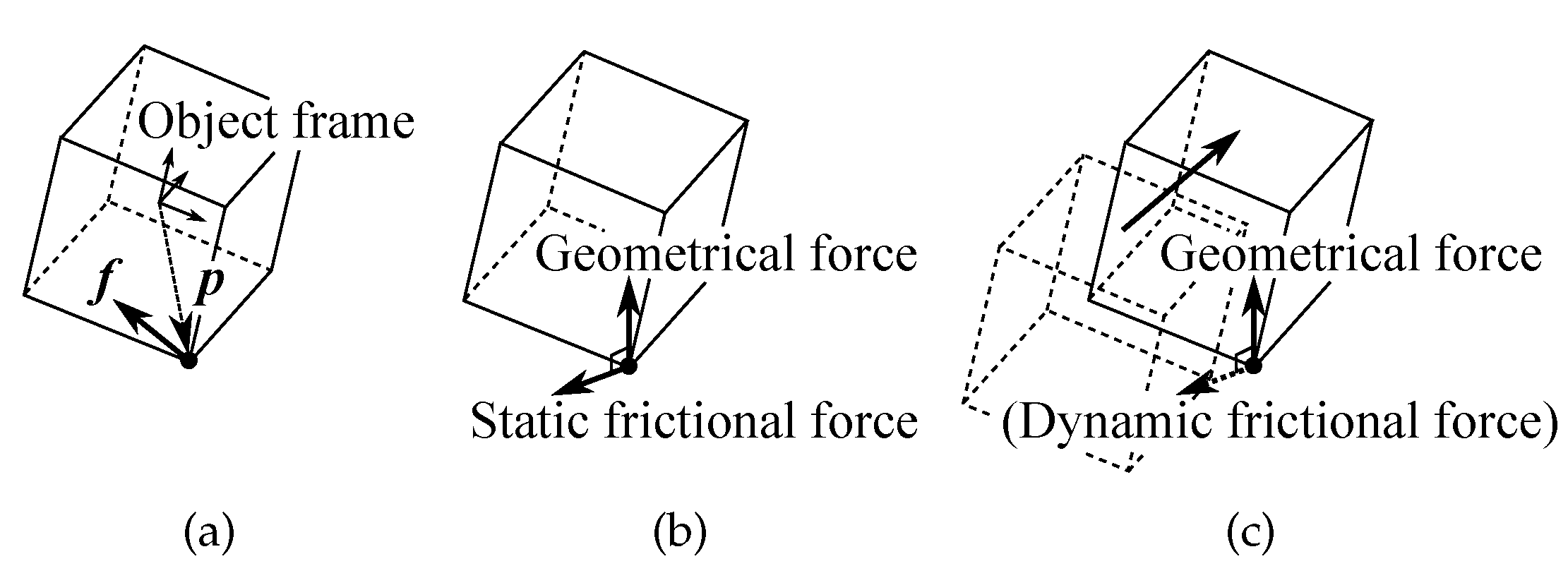

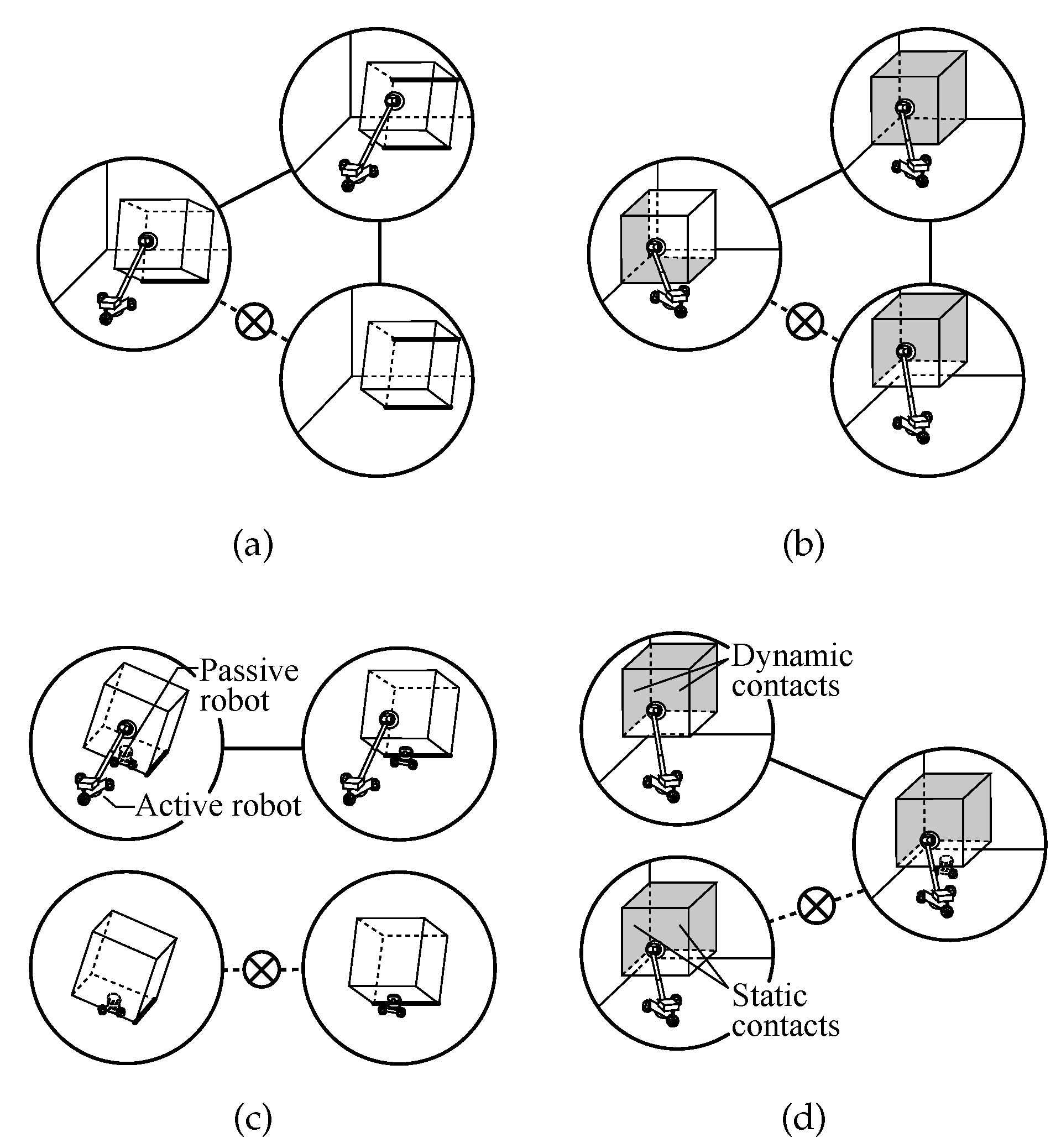

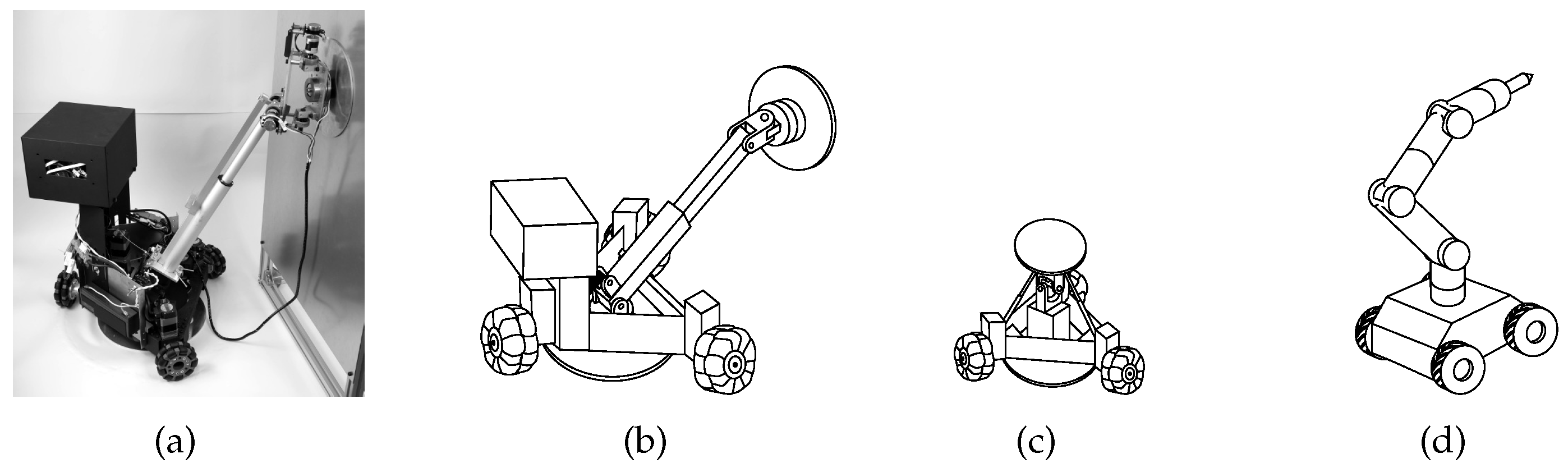

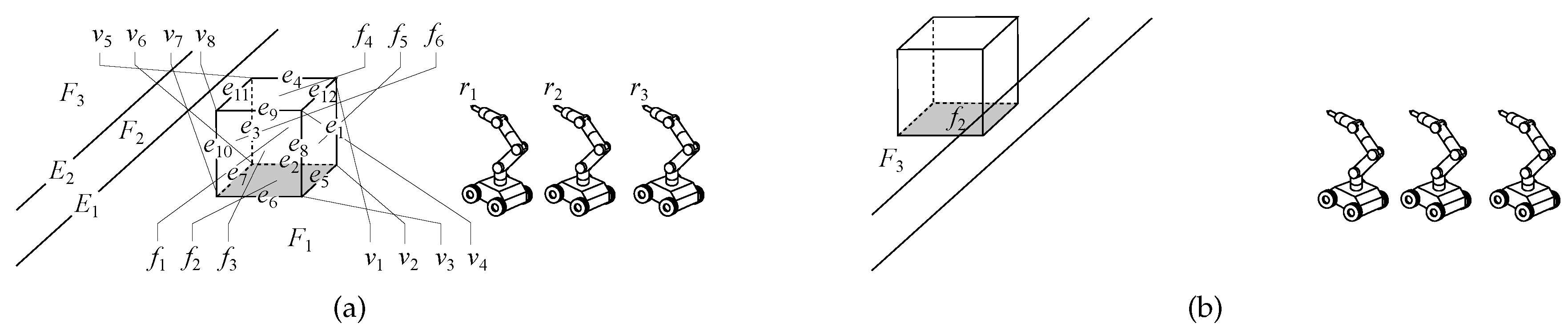

2. Problem Statement

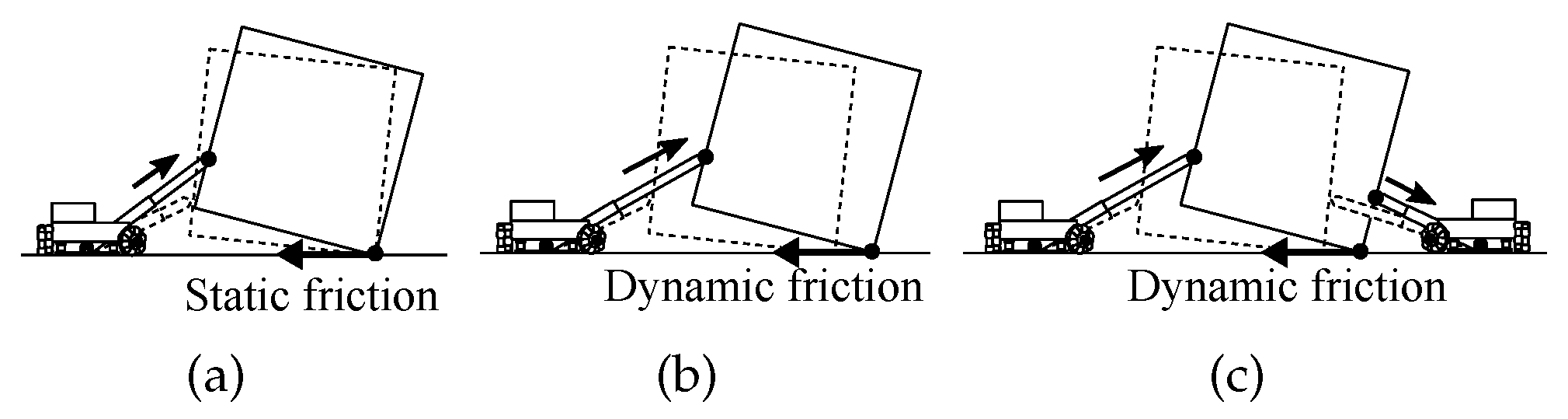

3. Generation of Modes

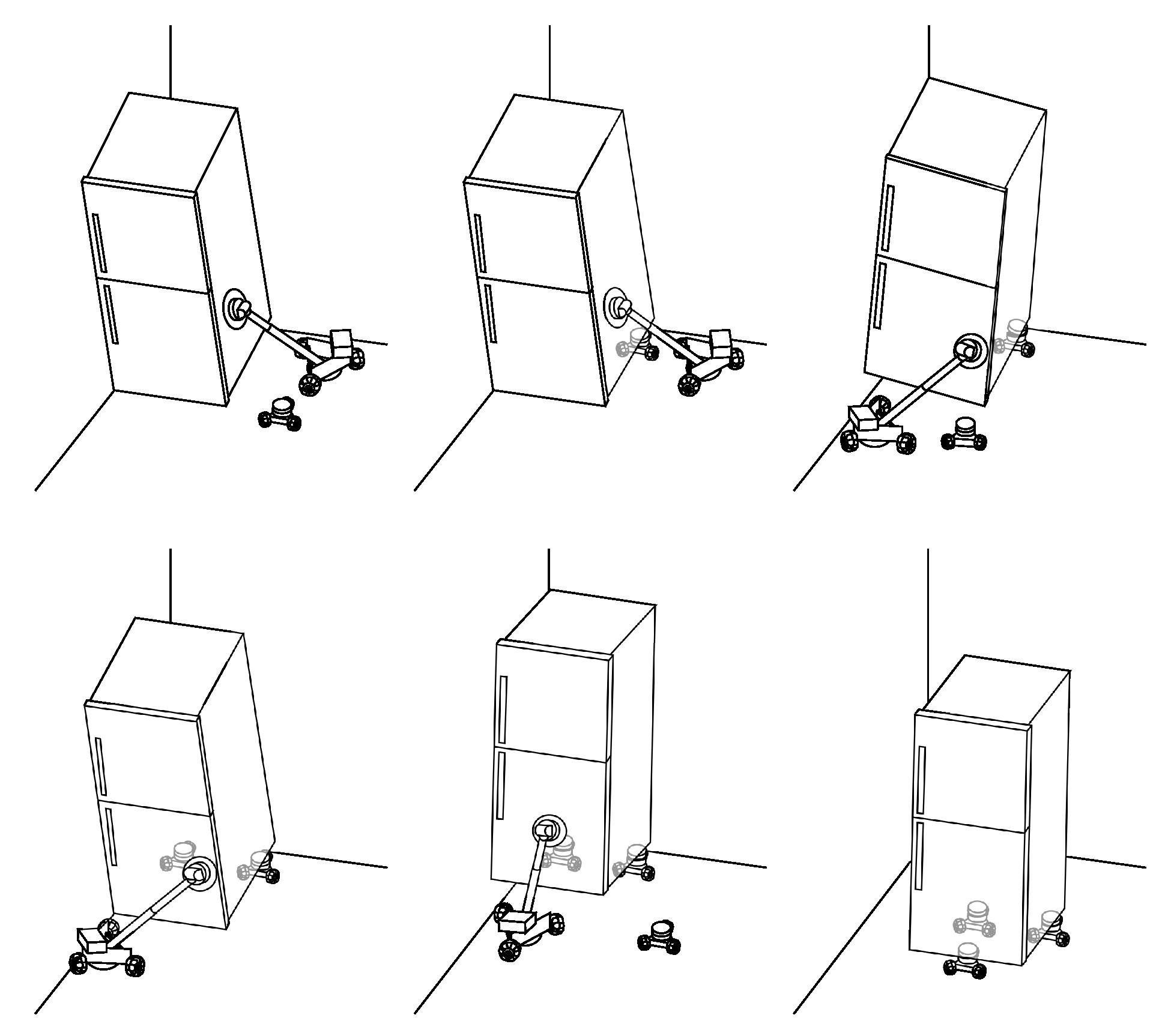

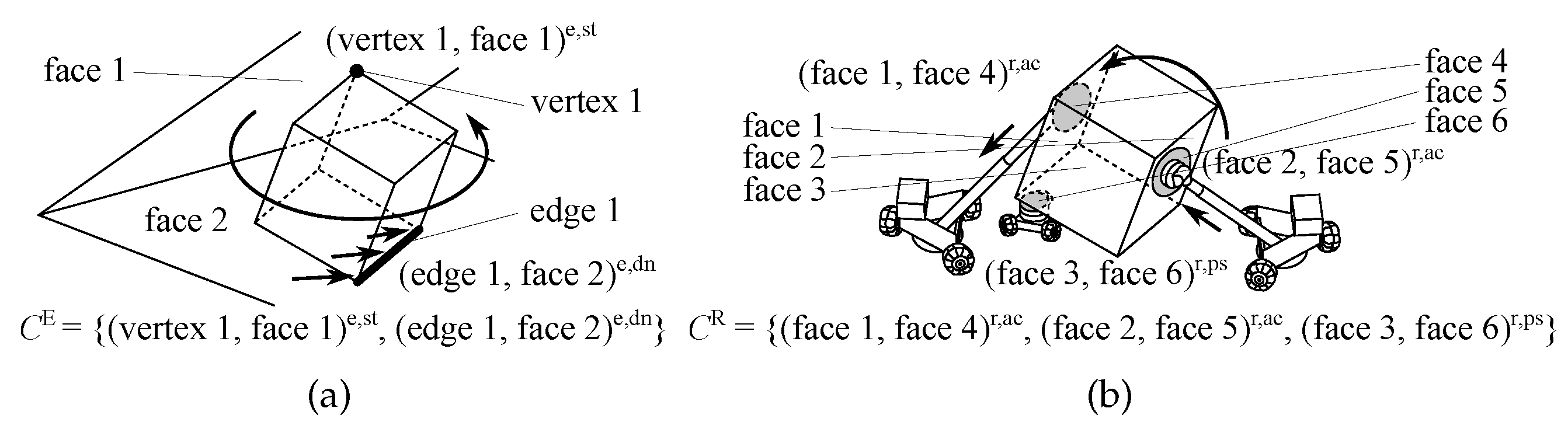

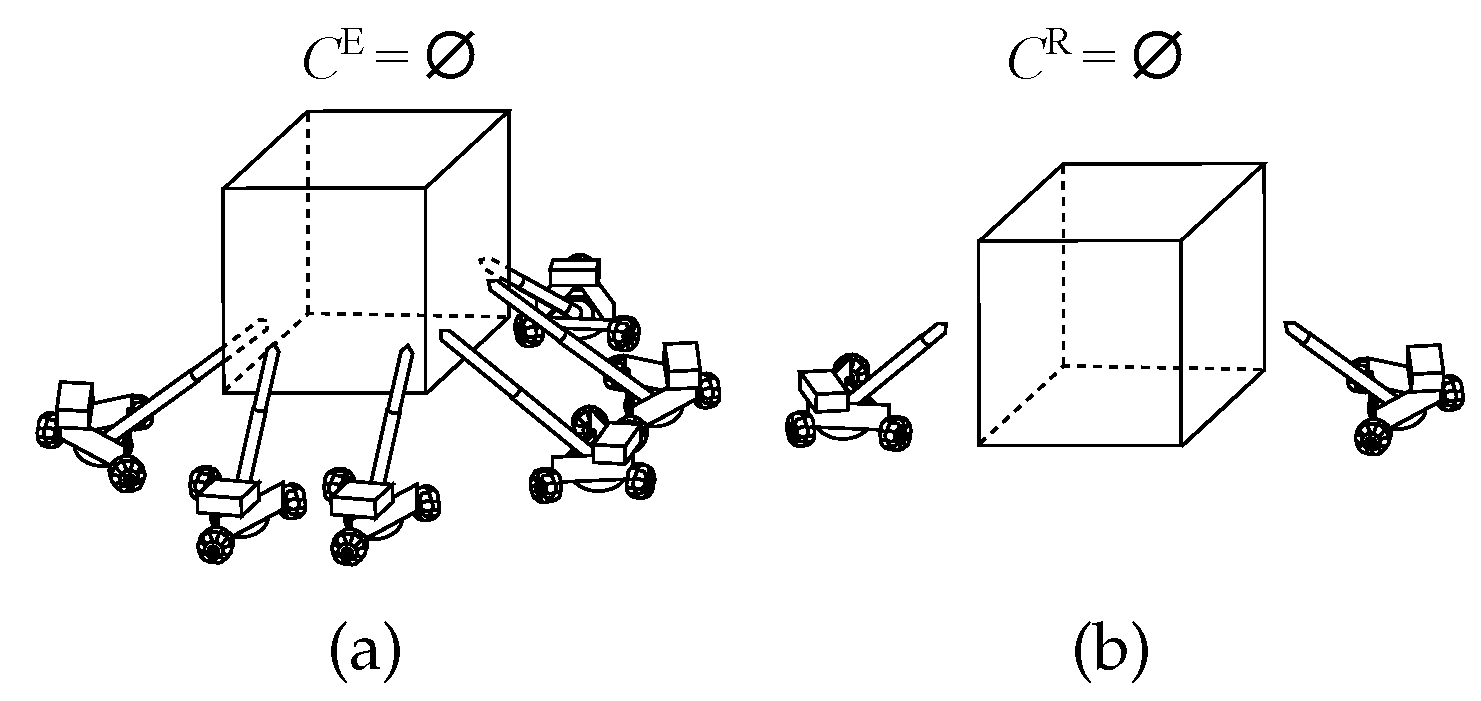

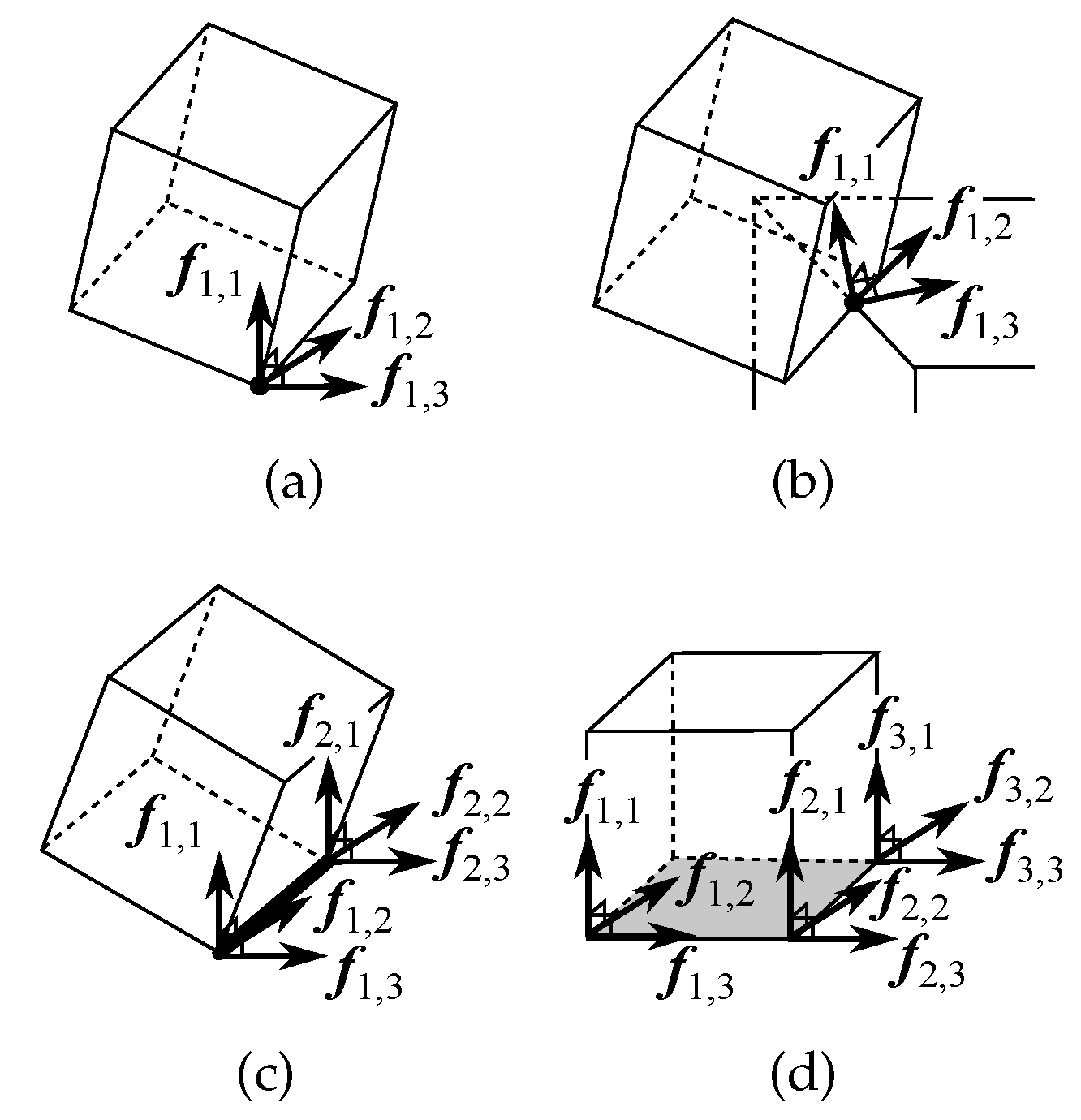

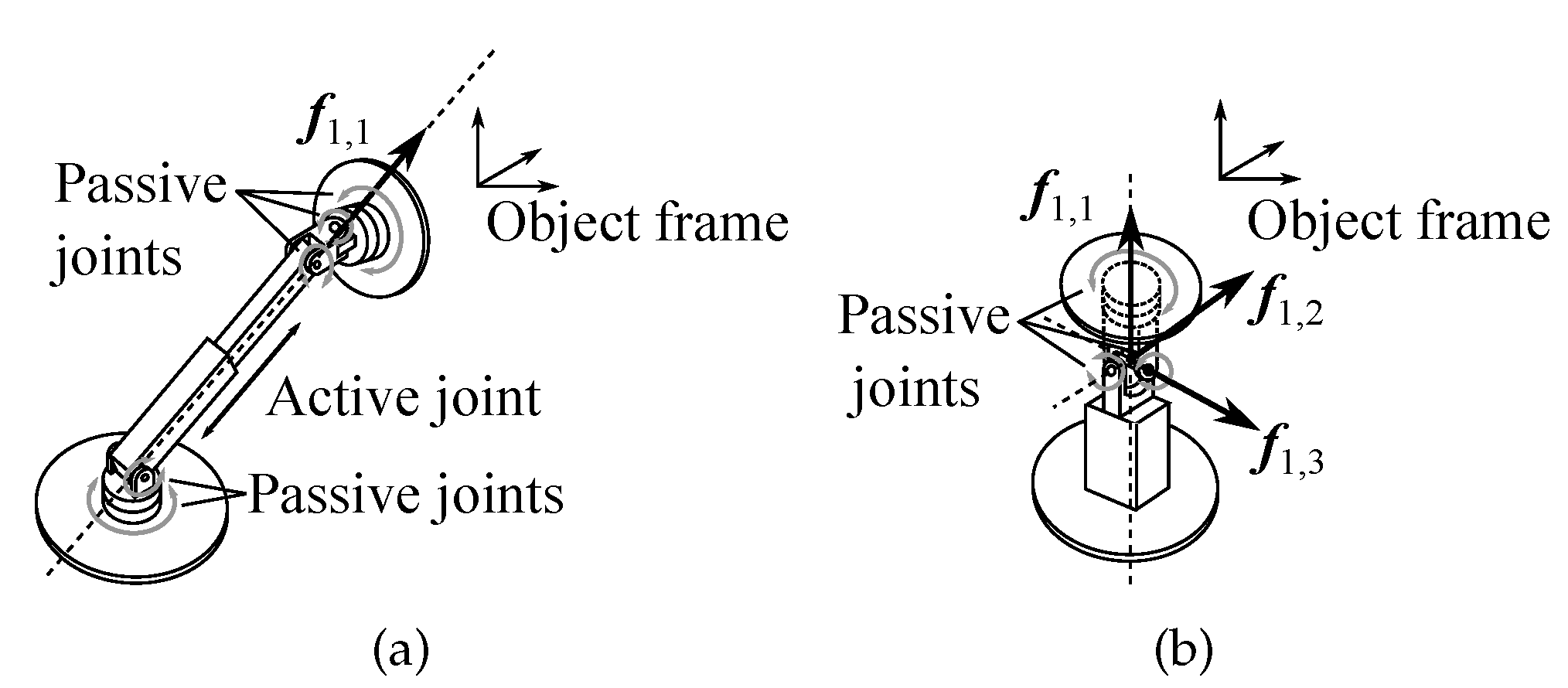

3.1. Generation of ECFs

3.2. Generation of RCFs

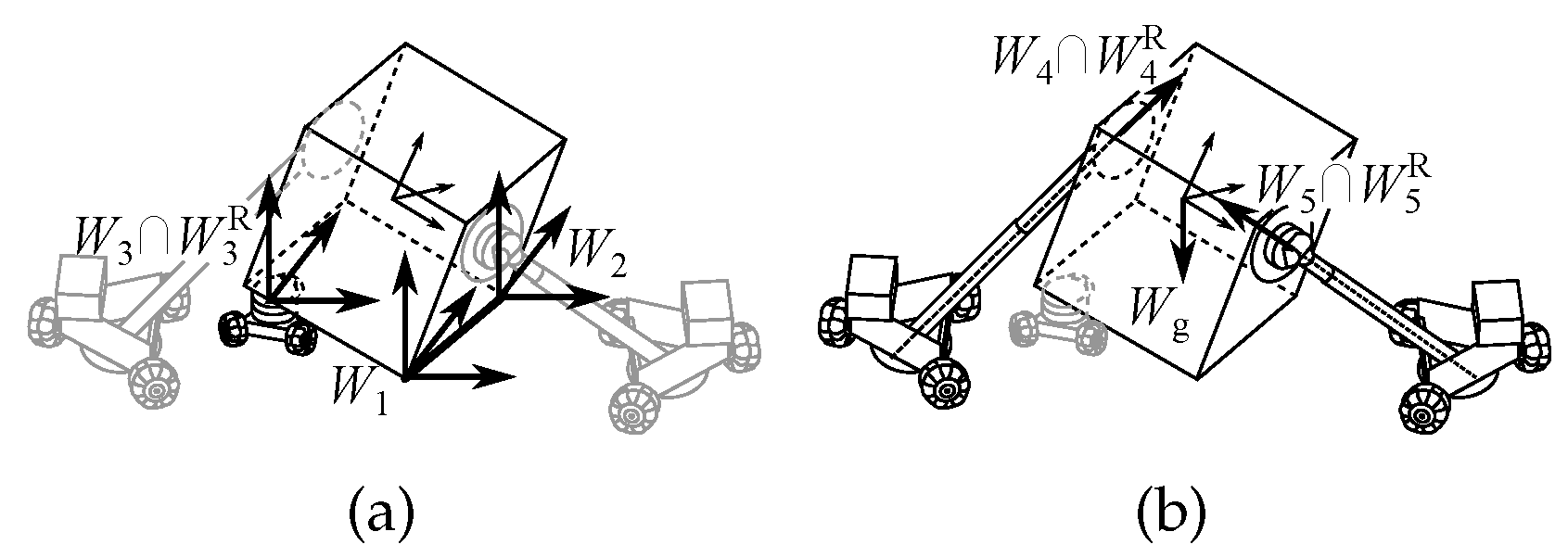

3.3. ECF-RCF Combination

4. Generation of Transitions Among Modes

4.1. Mode Graph

- ECF is changed: and :

- (a)

- ECFs with their primitive CFs connected in are transitable under the motion of the non-fully-constrained object caused by the active robots:, and include active PC, besides gravity, and in either or both and .

- (b)

- Change in isogenous contacts:

- RCF is changed: and .

- (a)

- The active robot is added or removed:comprises only an active PC.

- (b)

- The passive robot is added or removed under the motion of a non-fully-constrained object caused by the active robots:that comprise only a passive PC; and include an active PC, and in either or both and .

- (c)

- Change in isogenous contacts:

4.2. Cost for Transition between Modes

5. Simulations

5.1. Example 1 and Result Discussion

5.2. Example 2 and Result Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| PC | principal contact |

| CF | contact formation |

| ECF | environmental contact formation |

| RCF | robot contact formation |

| GCR | goal-contact-relaxation |

References

- Stilwell, D.J.; Bay, J.S. Toward the development of a material transport system using swarms of ant-like robots. In Proceedings of the IEEE International Conference on Robotics and Automation, Atlanta, GA, USA, 2–6 May 1993; pp. 766–771. [Google Scholar]

- Mason, M.T. Mechanics of Robotic Manipulation; MIT Press: Cambridge, MA, USA, 2001. [Google Scholar]

- Ruggiero, F.; Lippiello, V.; Siciliano, B. Nonprehensile Dynamic Manipulation: A Survey. IEEE Robot. Autom. Lett. 2018, 3, 1711–1718. [Google Scholar] [CrossRef]

- Arai, T.; Ota, J. Let us work together-Task planning of multiple mobile robots. In Proceedings of the 1996 IEEE/RSJ International Conference on Intelligent Robots and Systems’ 96, Osaka, Japan, 8 November 1996; Volume 1, pp. 298–303. [Google Scholar]

- Latombe, J.C. Robot Motion Planning; Springer US: Boston, MA, USA, 1991; Volume 124. [Google Scholar]

- LaValle, S.M. Rapidly-Exploring Random Trees: A New Tool for Path Planning; Technical Report TR98-11; Computer Science Department, Iowa State University: Ames, IA, USA, 1998. [Google Scholar]

- Kavraki, L.; Svestka, P.; Latombe, J.; Overmars, M.H. Probabilistic Roadmaps for Path Planning in High-Dimensional Configuration Spaces. IEEE Trans. Robot. Autom. 1996, 12, 566–588. [Google Scholar] [CrossRef]

- Hauser, K.; Latombe, J.C. Multi-modal motion planning in non-expansive spaces. Int. J. Robot. Res. 2010, 29, 897–915. [Google Scholar] [CrossRef]

- Hsu, D.; Kavraki, L.E.; Latombe, J.C.; Motwani, R.; Sorkin, S. On finding narrow passages with probabilistic roadmap planners. In Proceedings of the Workshop on the Algorithmic Foundations of Robotics, Robotics: The Algorithmic Perspective; A. K. Peters, Ltd.: Natick, MA, USA, 1998; pp. 141–154. [Google Scholar]

- Maeda, Y.; Arai, T. Planning of graspless manipulation by a multifingered robot hand. Adv. Robot. 2005, 19, 501–521. [Google Scholar] [CrossRef]

- Miyazawa, K.; Maeda, Y.; Arai, T. Planning of graspless manipulation based on rapidly-exploring random trees. In Proceedings of the 6th IEEE International Symposium on Assembly and Task Planning: From Nano to Macro Assembly and Manufacturing, Montreal, QC, Canada, 19–21 July 2005; pp. 7–12. [Google Scholar]

- Barry, J.; Kaelbling, L.P.; Lozano-Pérez, T. A hierarchical approach to manipulation with diverse actions. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 1799–1806. [Google Scholar]

- Lee, G.; Lozano-Pérez, T.; Kaelbling, L.P. Hierarchical planning for multi-contact non-prehensile manipulation. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; pp. 264–271. [Google Scholar]

- Schmitt, P.S.; Neubauer, W.; Feiten, W.; Wurm, K.M.; Wichert, G.V.; Burgard, W. Optimal, sampling-based manipulation planning. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; pp. 3426–3432. [Google Scholar]

- Xiao, J. Goal-contact relaxation graphs for contact-based fine motion planning. In Proceedings of the 1997 IEEE International Symposium on Assembly and Task Planning, Marina del Rey, CA, USA, 7–9 August 1997; pp. 25–30. [Google Scholar]

- Xiao, J.; Ji, X. Automatic generation of high-level contact state space. Int. J. Robot. Res. 2001, 20, 584–606. [Google Scholar] [CrossRef]

- Fan, C.; Shirafuji, S.; Ota, J. Least Action Sequence Determination in the Planning of Non-Prehensile Manipulation with Multiple Mobile Robots. In the 15th International Conference on Intelligent Autonomous Systems (IAS–15); Springer: Cham, Switzerland, 2018; pp. 174–185. [Google Scholar]

- Xiao, J.; Zhang, L. A General Strategy to Determine Geometrically Valid Contact Formations from Possible Contact Primitives. In Proceedings of the IEEE International Conference on Robotics And Automation, Atlanta, GA, USA, 2–6 May 1993; Volume 1, p. 2728. [Google Scholar]

- Maeda, Y.; Aiyama, Y.; Arai, T.; Ozawa, T. Analysis of object-stability and internal force in robotic contact tasks. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Osaka, Japan, 8 November 1996; Volume 2, pp. 751–756. [Google Scholar]

- Aiyama, Y.; Arai, T.; Ota, J. Dexterous assembly manipulation of a compact array of objects. CIRP Ann. 1998, 47, 13–16. [Google Scholar] [CrossRef]

- LaValle, S.M. Planning Algorithms; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Ji, X.; Xiao, J. Planning motions compliant to complex contact states. Int. J. Robot. Res. 2001, 20, 446–465. [Google Scholar] [CrossRef]

- Ponce, J.; Faverjon, B. On computing three-finger force-closure grasps of polygonal objects. IEEE Trans. Robot. Autom. 1995, 11, 868–881. [Google Scholar] [CrossRef]

- Murray, R.M.; Li, Z.; Sastry, S.S. A Mathematical Introduction to Robotic Manipulation; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Shirafuji, S.; Terada, Y.; Ota, J. Mechanism Allowing a Mobile Robot to Apply a Large Force to the Environment. In The 14th International Conference on Intelligent Autonomous Systems (IAS–14); Springer: Cham, Switzerland, 2016; pp. 795–808. [Google Scholar]

- Shirafuji, S.; Terada, Y.; Ito, T.; Ota, J. Mechanism allowing large-force application by a mobile robot, and development of ARODA. Robot. Auton. Syst. 2018, 110, 92–101. [Google Scholar] [CrossRef]

- Ito, T.; Shirafuji, S.; Ota, J. Development of a Mobile Robot Capable of Tilting Heavy Objects and its Safe Placement with Respect to Target Objects. In Proceedings of the 2018 IEEE International Conference on Roboics and Biomimetics (ROBIO2018), Kuala Lumpur, Malaysia, 12–15 December 2018; pp. 716–722. [Google Scholar]

| Before Adopting Our Method | After Adopting Our Method | |

|---|---|---|

| Generated modes | 167,180,587 | 166,553,714 |

| Number of mode transitions |

| Image | ECF and RCF in the Mode |

|---|---|

| |

| |

| |

| |

| |

| |

| |

| |

|

| Before Adopting Our Method | After Adopting Our Method | |

|---|---|---|

| Generated modes | 299,967 | 292,415 |

| Number of mode transitions |

| Path 1 | Path 2 | ||

|---|---|---|---|

| Image | ECF and RCF in the Mode | Image | ECF and RCF in the Mode |

|  | ||

|  | ||

|  | ||

|  | ||

|  | ||

|  | ||

|  | ||

|  | ||

|  | ||

|  |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, C.; Shirafuji, S.; Ota, J. Modal Planning for Cooperative Non-Prehensile Manipulation by Mobile Robots. Appl. Sci. 2019, 9, 462. https://doi.org/10.3390/app9030462

Fan C, Shirafuji S, Ota J. Modal Planning for Cooperative Non-Prehensile Manipulation by Mobile Robots. Applied Sciences. 2019; 9(3):462. https://doi.org/10.3390/app9030462

Chicago/Turabian StyleFan, Changxiang, Shouhei Shirafuji, and Jun Ota. 2019. "Modal Planning for Cooperative Non-Prehensile Manipulation by Mobile Robots" Applied Sciences 9, no. 3: 462. https://doi.org/10.3390/app9030462

APA StyleFan, C., Shirafuji, S., & Ota, J. (2019). Modal Planning for Cooperative Non-Prehensile Manipulation by Mobile Robots. Applied Sciences, 9(3), 462. https://doi.org/10.3390/app9030462