Enhancing Properties of Aerospace Alloy Elektron 21 Using Boron Carbide Nanoparticles as Reinforcement

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Primary Processing

2.2. Secondary Processing

2.3. Testing and Characterization

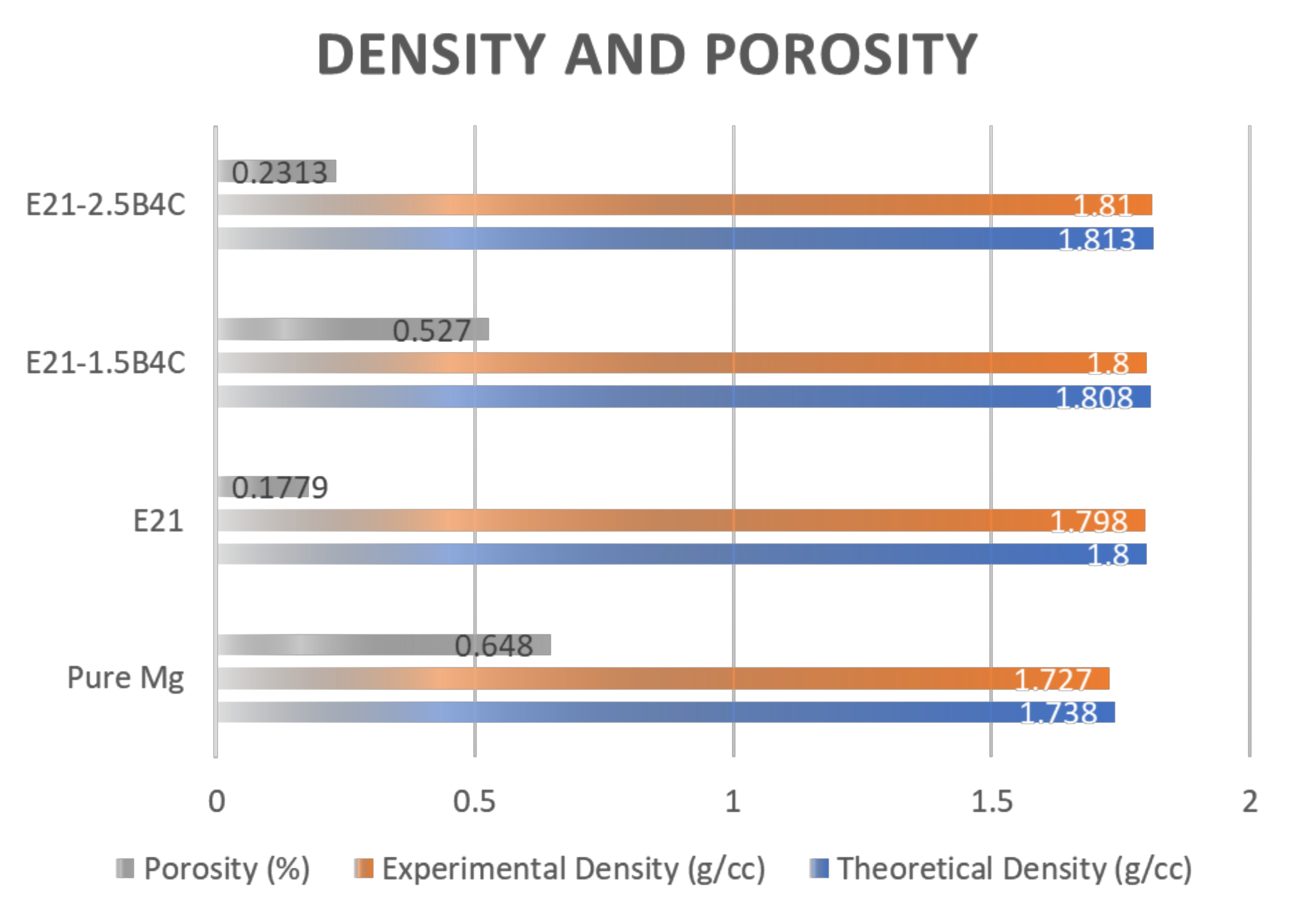

2.3.1. Density and Porosity Measurements

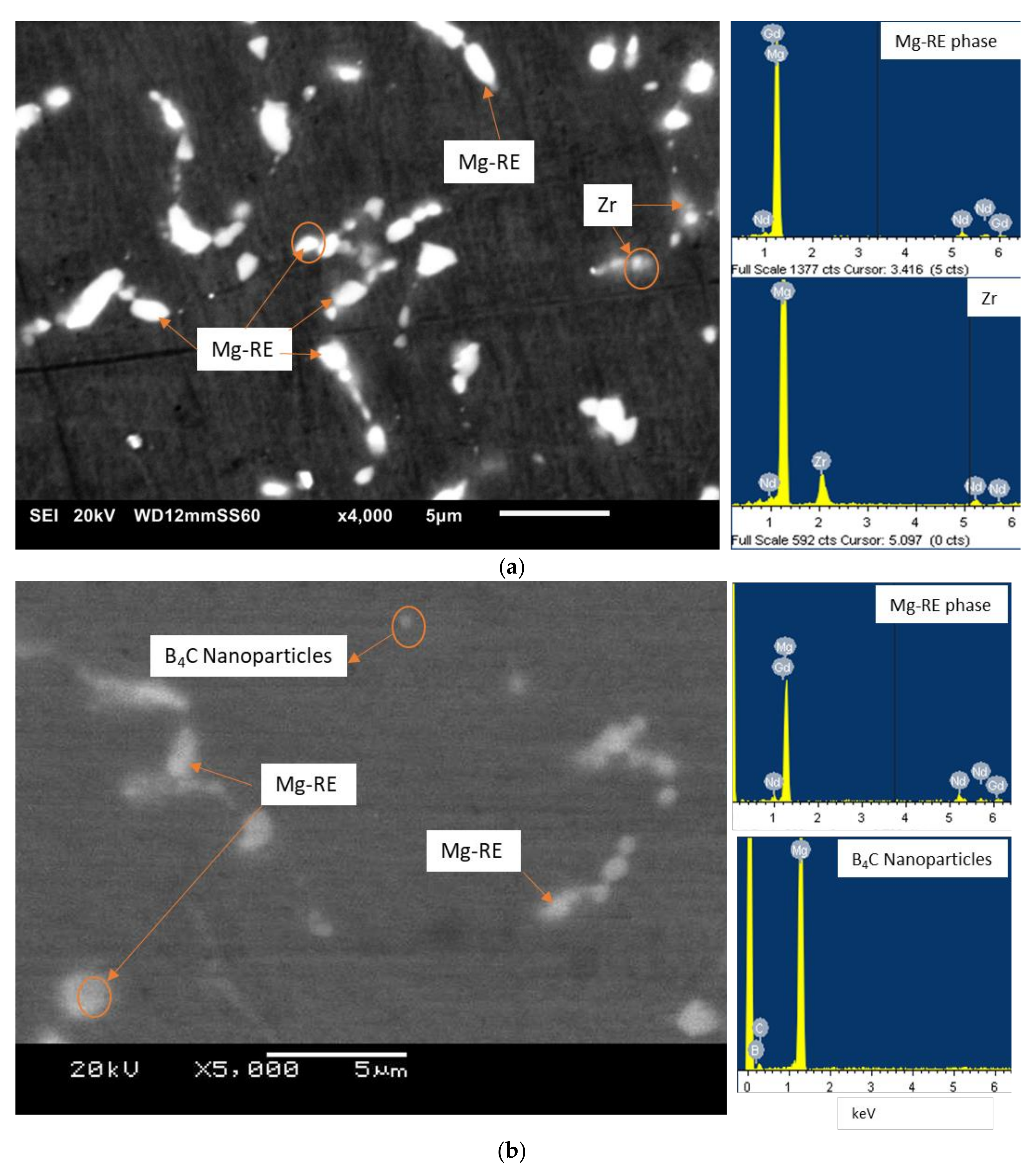

2.3.2. Microstructural Characterization

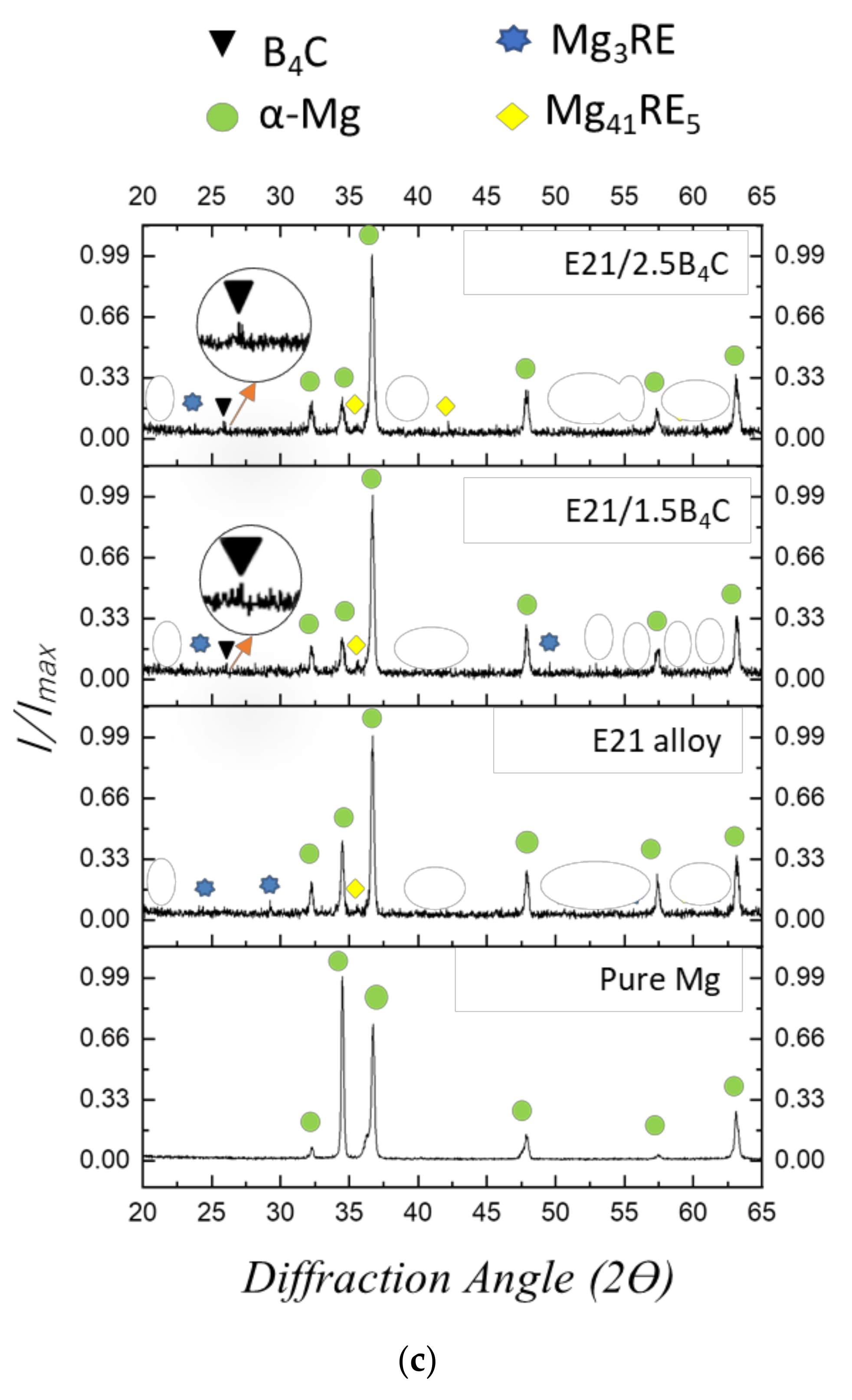

2.3.3. X-Ray Diffraction Studies

2.3.4. Damping Capacity and Young’s Modulus

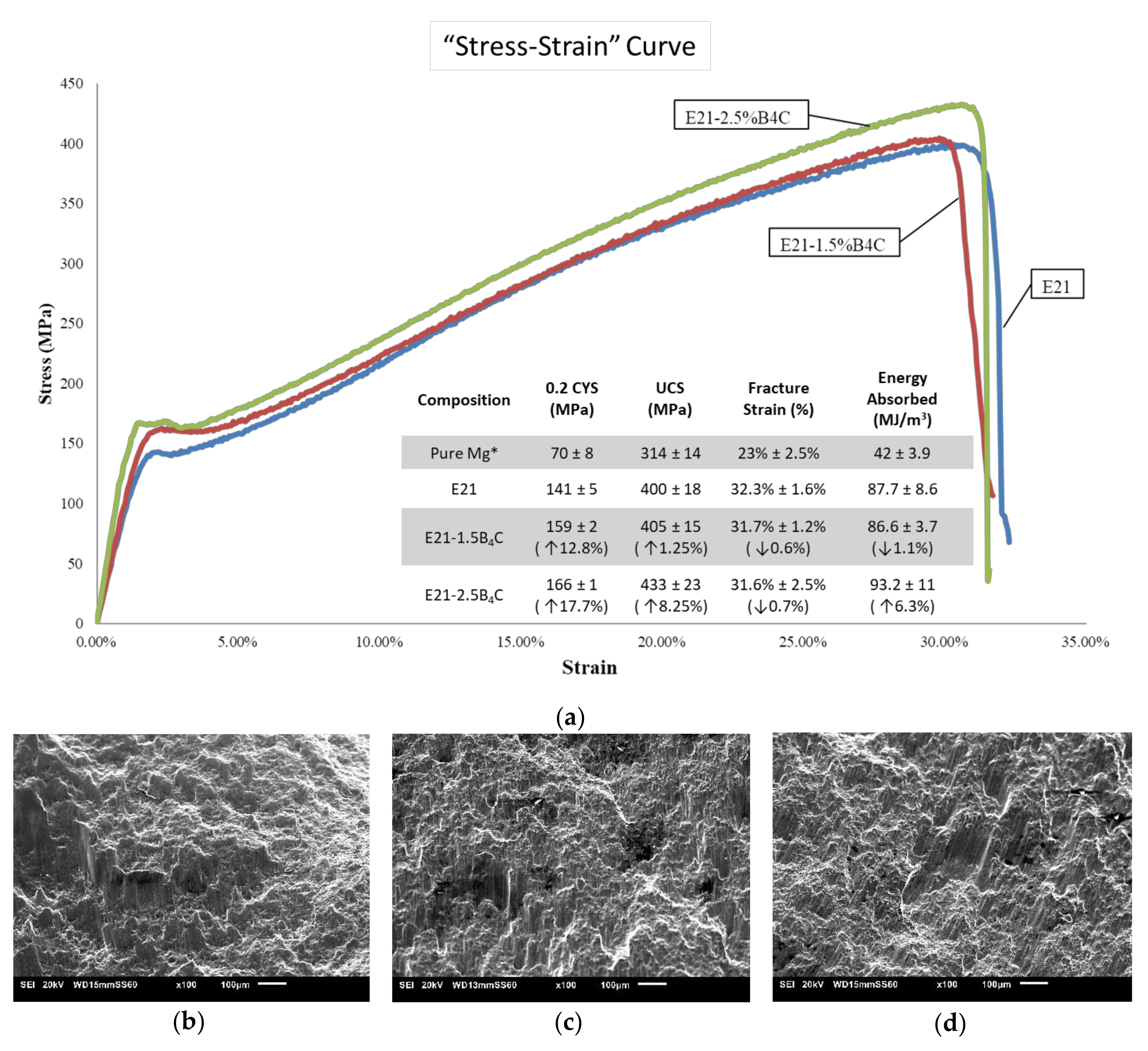

2.3.5. Compression Testing

2.3.6. Ignition Temperature Determination

3. Results and Discussion

3.1. Structural Characterization

3.2. Property Profile

3.2.1. Mechanical Properties

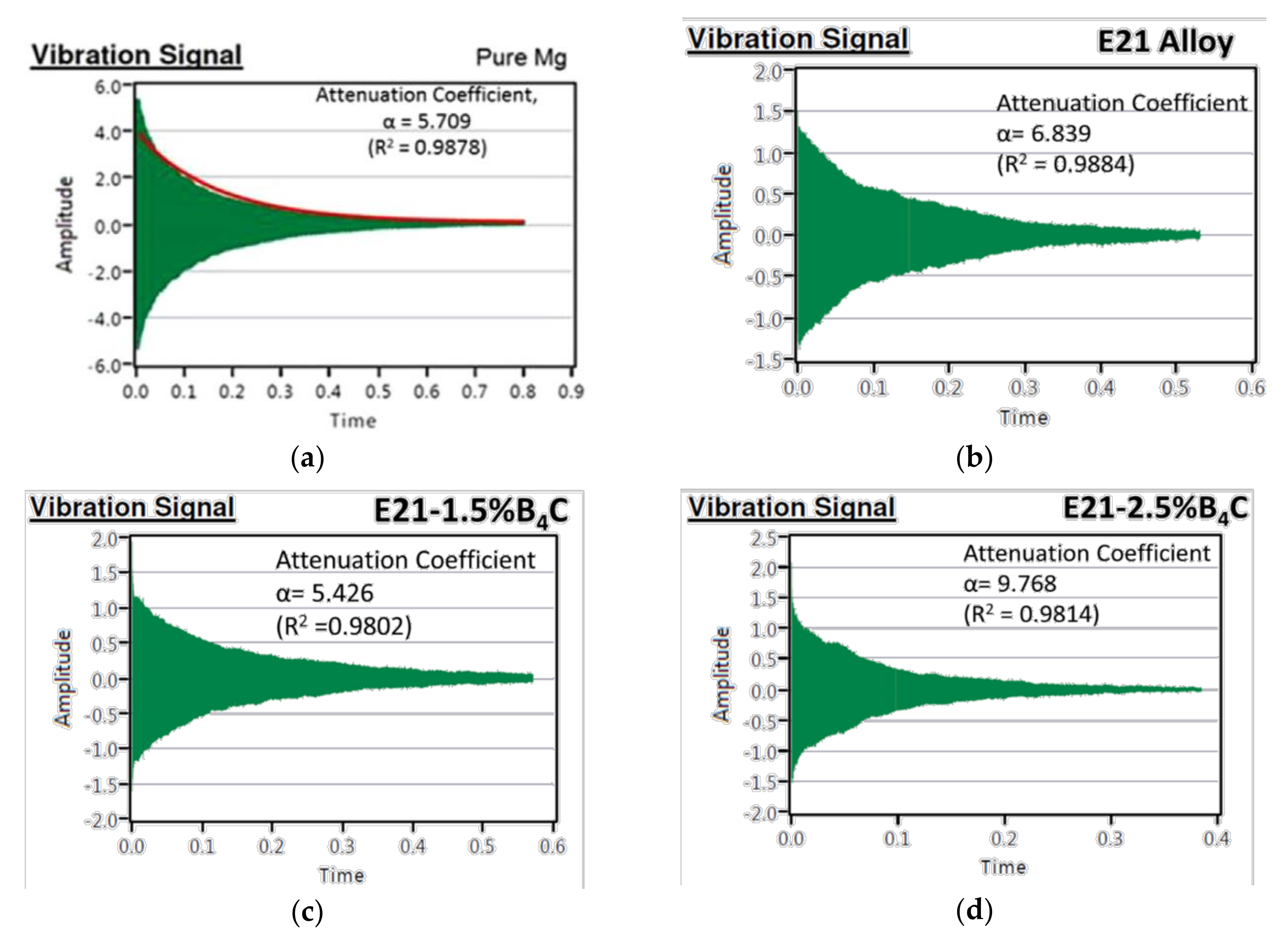

3.2.2. Damping Capacity and Young’s Modulus

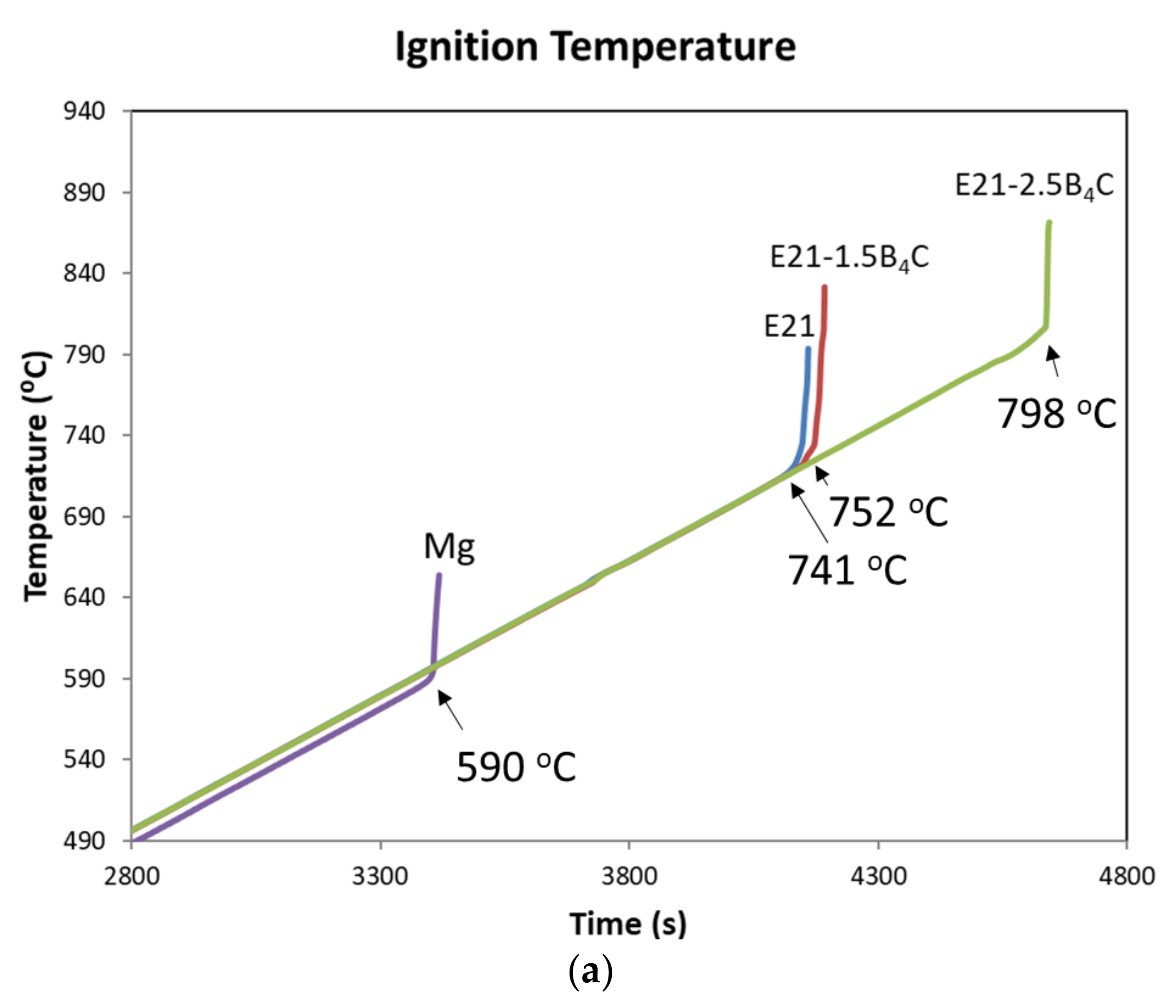

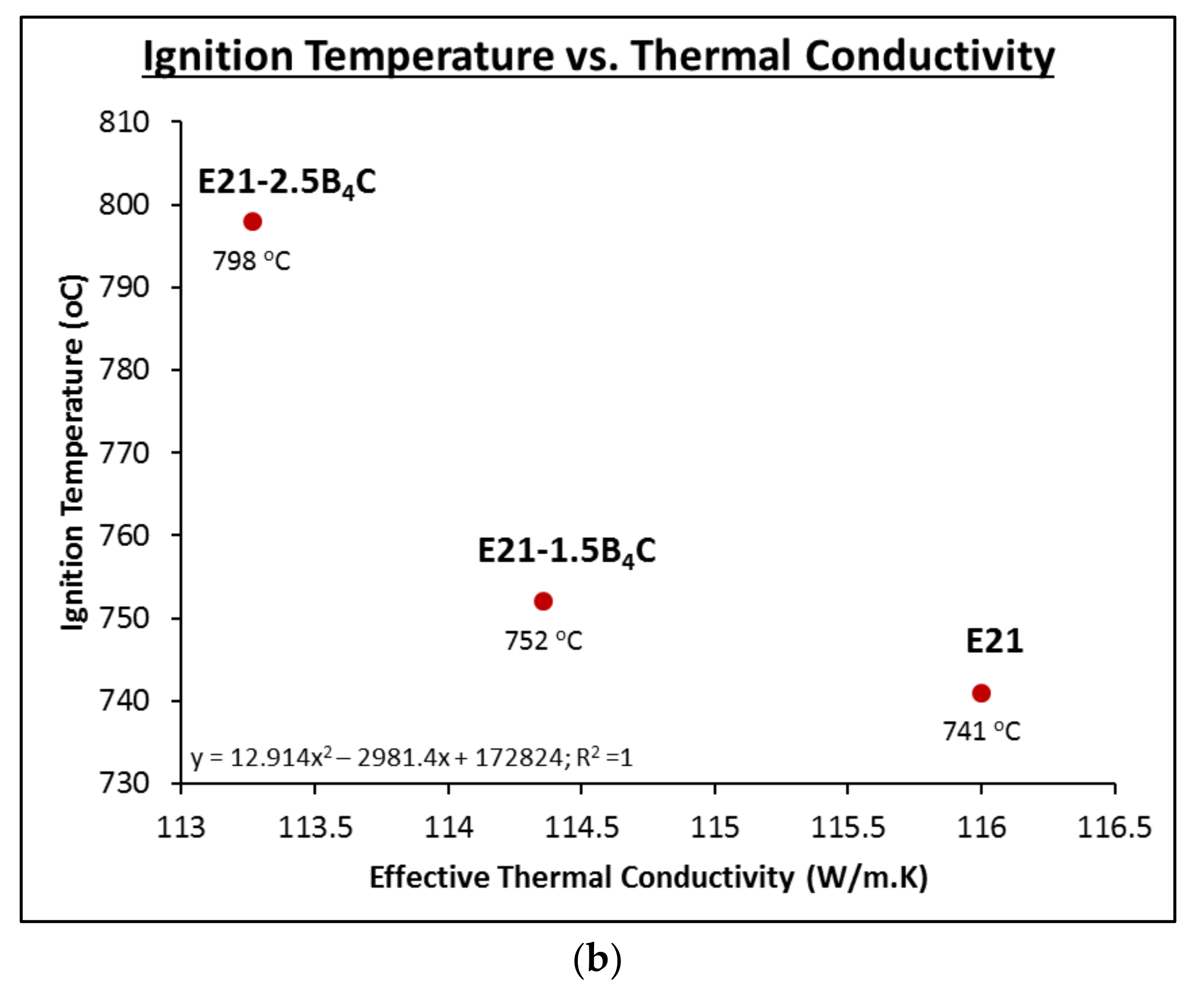

3.2.3. Ignition Properties

4. Conclusions

- (1)

- The presence of B4C nanoparticles in E21 alloy did not significantly increase the density of nanocomposites but reduced the grain sizes of E21 alloy by 29%.

- (2)

- The mechanical strength (i.e., compressive yield strength and ultimate strength of the nanocomposites, particularly E21-2.5B4C) increased significantly without compromising on ductility.

- (3)

- The damping capacity of E21-2.5B4C is the highest, with the fastest time taken to stop the vibration. This makes E21-2.5B4C a promising material to be used in the aerospace sector without the need for any special energy absorbers.

- (4)

- The addition of B4C nanoparticles in E21 alloys also led to the promising behavior of E21 alloy in terms of their ignition response. E21-2.5B4C demonstrated the highest ignition temperature of 798 °C, which is about 57 °C higher than the E21 alloy, showcasing the positive role of boron carbide nanoparticles.

- (5)

- Thus, E21-2.5B4C nanocomposites with boron carbide nanoparticles areca desirable and suitable material for the aerospace industry to be used in in-cabin applications, as well as for gearbox housing applications.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Safehaven.com. New Tech Could Transform the $2 Trillion Auto Industry. Available online: https://www.prnewswire.com/news-releases/new-tech-could-transform-the-2-trillion-auto-industry-673561583.html (accessed on 19 August 2019).

- Arnaldo Valdés, R.M.; Burmaoglu, S.; Tucci, V.; Braga da Costa Campos, L.M.; Mattera, L.; Gomez Comendador, V.F. Flight path 2050 and acare goals for maintaining and extending industrial leadership in aviation: A map of the aviation technology space. Sustainability 2019, 11, 2065. [Google Scholar] [CrossRef]

- Perera, F. Pollution from fossil-fuel combustion is the leading environmental threat to global pediatric health and equity: Solutions exist. Int. J. Environ. Res. Public Health 2017, 15, 16. [Google Scholar] [CrossRef] [PubMed]

- Czerwinski, F. Controlling the ignition and flammability of magnesium for aerospace applications. Corros. Sci. 2014, 86, 1–16. [Google Scholar] [CrossRef]

- Marker, T.R. Development of a Laboratory Scale Flammability Test for Magnesium Alloys used in Aircraft Seat Construction; Federal Aviation Administration Technical Center: New Jersey, NJ, USA, 2014.

- Lu, Y.; Bradshaw, A.R.; Chiu, Y.L.; Jones, I.P. Effects of secondary phase and grain size on the corrosion of biodegradable mg–zn–ca alloys. Mater. Sci. Eng. C 2015, 48, 480–486. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Tekumalla, S.; Gupta, M. Cumulative effect of strength enhancer—Lanthanum and ductility enhancer—Cerium on mechanical response of magnesium. Metals 2017, 7, 241. [Google Scholar] [CrossRef]

- Saboori, A.; Padovano, E.; Pavese, M.; Badini, C. Novel magnesium elektron21-aln nanocomposites produced by ultrasound-assisted casting; microstructure, thermal and electrical conductivity. Materials (Basel) 2017, 11, 27. [Google Scholar] [CrossRef] [PubMed]

- Tekumalla, S.; Seetharaman, S.; Almajid, A.; Gupta, M. Mechanical properties of magnesium-rare earth alloy systems: A review. Metals 2015, 5, 1–39. [Google Scholar] [CrossRef]

- Tekumalla, S.; Gupta, M. An insight into ignition factors and mechanisms of magnesium based materials: A review. Mater. Des. 2017, 113, 84–98. [Google Scholar] [CrossRef]

- Tekumalla, S.; Nandigam, Y.; Bibhanshu, N.; Rajashekara, S.; Yang, C.; Suwas, S.; Gupta, M. A strong and deformable in-situ magnesium nanocomposite igniting above 1000 °C. Sci. Rep. 2018, 8, 7038. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Tekumalla, S.; Guo, Y.B.; Gupta, M. Introducing mg-4zn-3gd-1ca/zno nanocomposite with compressive strengths matching/exceeding that of mild steel. Sci. Rep. 2016, 6, 32395. [Google Scholar] [CrossRef] [PubMed]

- Sankaranarayanan, S.; Sabat, R.K.; Jayalakshmi, S.; Suwas, S.; Gupta, M. Effect of nanoscale boron carbide particle addition on the microstructural evolution and mechanical response of pure magnesium. Mater. Des. (1980–2015) 2014, 56, 428–436. [Google Scholar] [CrossRef]

- Tekumalla, S.; Bibhanshu, N.; Suwas, S.; Gupta, M. Superior ductility in magnesium alloy-based nanocomposites: The crucial role of texture induced by nanoparticles. J. Mater. Sci. 2019, 54, 8711–8718. [Google Scholar] [CrossRef]

- Gupta, M.; Wong, W.L.E. Magnesium-based nanocomposites: Lightweight materials of the future. Mater. Charact. 2015, 105, 30–46. [Google Scholar] [CrossRef]

- Chawla, K.K. Composite Materials: Science and Engineering; Springer: New York, NY, USA, 2012. [Google Scholar]

- Berlin, J. Analysis of boron with energy dispersive x-ray spectrometry. Imaging Microsc. 2011, 13, 19–21. [Google Scholar]

- Chen, Y.; Tekumalla, S.; Guo, Y.B.; Shabadi, R.; Shim, V.P.W.; Gupta, M. The dynamic compressive response of a high-strength magnesium alloy and its nanocomposite. Mater. Sci. Eng. A 2017, 702, 65–72. [Google Scholar] [CrossRef]

- Cullity, B.D. Elements of X Ray Diffraction-Scholar’s Choice Edition; Scholar’s Choice: Wolcott, NY, USA, 2015. [Google Scholar]

- Kiełbus, A.; Rzychoń, T.; Lityńska-Dobrzyńska, L.; Dercz, G. Characterization of β and mg41nd5 equilibrium phases in elektron 21 magnesium alloy after long-term annealing. Solid State Phenom. 2010, 163, 106–109. [Google Scholar] [CrossRef]

- Tekumalla, S.; Farhan, N.; Srivatsan, T.S.; Gupta, M. Nano-zno particles’ effect in improving the mechanical response of mg-3al-0.4ce alloy. Metals 2016, 6, 276. [Google Scholar] [CrossRef]

- Nie, K.; Zhu, Z.; Deng, K.; Wang, T.; Han, J. Hot deformation behavior and processing maps of sic nanoparticles and second phase synergistically reinforced magnesium matrix composites. Nanomaterials (Basel) 2019, 9, 57. [Google Scholar] [CrossRef] [PubMed]

- Tekumalla, S.; Shabadi, R.; Yang, C.; Seetharaman, S.; Gupta, M. Strengthening due to the in-situ evolution of ß1’ mg-zn rich phase in a zno nanoparticles introduced mg-y alloy. Scr. Mater. 2017, 133, 29–32. [Google Scholar] [CrossRef]

- Li, B.; Lavernia, E.J. 3.23-spray forming of mmcs. In Comprehensive Composite Materials; Kelly, A., Zweben, C., Eds.; Pergamon: Oxford, UK, 2000; pp. 617–653. [Google Scholar]

- Bai, J.; Wang, C.; Wan, F.; Yan, G. Review of aircraft vibration environment prediction methods. Procedia Environ. Sci. 2011, 10, 831–836. [Google Scholar] [CrossRef]

| Material (wt.) | Nd | Gd | Zn | Zr | B4C | Mg |

|---|---|---|---|---|---|---|

| E21 Alloy | 2.8 | 1.4 | 0.3 | 0.5 | − | Bal. |

| E21-1.5B4C Nanocomposite | 2.8 | 1.4 | 0.3 | 0.5 | 1.5 | Bal. |

| E21-2.5B4C Nanocomposite | 2.8 | 1.4 | 0.3 | 0.5 | 2.5 | Bal. |

| Composition | Frequency (Hz) | Loss Rate (%) | Damping Capacity | Young’s Modulus (GPa) |

|---|---|---|---|---|

| E21 Alloy | 8760.58 | 6.2 | 0.000225 | 48.14 |

| E21-1.5B4C Nanocomposite | 8332.76 | 5.6 | 0.000213 | 47.18 |

| E21-2.5B4C Nanocomposite | 8361.67 | 10.8 | 0.000413 | 52.02 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tekumalla, S.; Joo Yuan, N.; Haghshenas, M.; Gupta, M. Enhancing Properties of Aerospace Alloy Elektron 21 Using Boron Carbide Nanoparticles as Reinforcement. Appl. Sci. 2019, 9, 5470. https://doi.org/10.3390/app9245470

Tekumalla S, Joo Yuan N, Haghshenas M, Gupta M. Enhancing Properties of Aerospace Alloy Elektron 21 Using Boron Carbide Nanoparticles as Reinforcement. Applied Sciences. 2019; 9(24):5470. https://doi.org/10.3390/app9245470

Chicago/Turabian StyleTekumalla, Sravya, Ng Joo Yuan, Meysam Haghshenas, and Manoj Gupta. 2019. "Enhancing Properties of Aerospace Alloy Elektron 21 Using Boron Carbide Nanoparticles as Reinforcement" Applied Sciences 9, no. 24: 5470. https://doi.org/10.3390/app9245470

APA StyleTekumalla, S., Joo Yuan, N., Haghshenas, M., & Gupta, M. (2019). Enhancing Properties of Aerospace Alloy Elektron 21 Using Boron Carbide Nanoparticles as Reinforcement. Applied Sciences, 9(24), 5470. https://doi.org/10.3390/app9245470