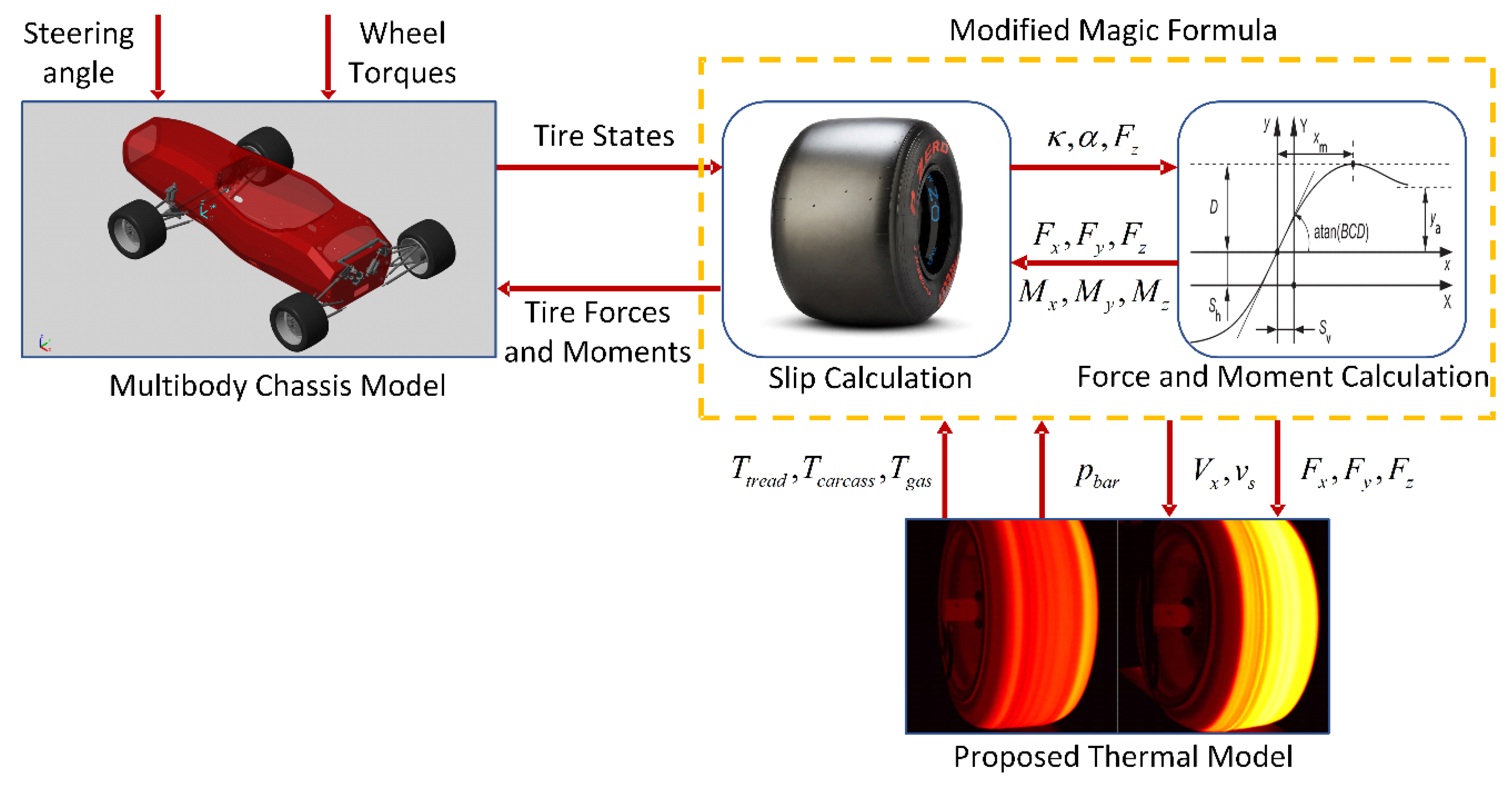

3.1. Proposed Thermal Model

A lumped parameter approach is used according to [

18] and the thermal model consists of three bodies such as the tread with temperature

Ttread, the carcass with temperature

Tcarcass, and the inflation gas with temperature

Tgas. The road surface with ambient air provides the boundary conditions with fixed temperatures

Troad and

Tamb. In contrast to the study [

19], a single value of tread temperature was calculated without the need to define a complex temperature distribution across the contact patch area. The temperature change of tread, carcass, and gas is described as:

where

Qsliding is the heat flow due to sliding;

is the heat flow between tread and road;

is the heat flow between carcass and tread;

is the heat flow between tread and ambient air;

Qdamp is the heat flow due to carcass deflection;

is the heat flow between carcass and ambient air;

is the heat flow between carcass and inflation gas;

Stread is the specific heat capacity of carcass;

Scarcass is the specific heat capacity of carcass;

Sgas is the specific heat capacity of inflation gas;

Mtread is the tread mass;

Mcarcass is the carcass mass;

Mgas is the inflation gas mass.

According to [

18], two heat generation processes should be considered:

• Due to carcass deflection

where

Ex, Ey, and

Ez are the carcass longitudinal, lateral, and vertical force efficiency factors;

Fx,

Fy, and

Fz are the longitudinal, lateral, and normal forces;

Vx is the longitudinal velocity.

• Due to sliding friction in the contact patch

where

µd is the dynamic friction coefficient;

vs is the sliding velocity.

To define the shift along the

µ axis with compound temperature, the dynamic friction model [

18] was modified. Based on the friction model [

20], Equation (4) is proposed incorporating the shift along the

µ axis due to temperature using the parameters

µ and

h as temperature dependent. The idea was taken from research [

21] where the parameters of the friction models from [

20] and [

22] were made temperature-dependent. The final equation for the dynamic friction model is described:

The temperature-dependent peak friction coefficient

µpeak is defined:

where

a1,

a2, and

a3 are the tuning parameters for a second order polynomial function.

Dimensionless parameter

h is related to the width of the speed range in which the friction coefficient varies significantly [

23]. The following temperature-dependent adjustment is made similar to the adaptation of the compound shear modulus in [

18]:

where

b1 and

b2 are the tuning parameters.

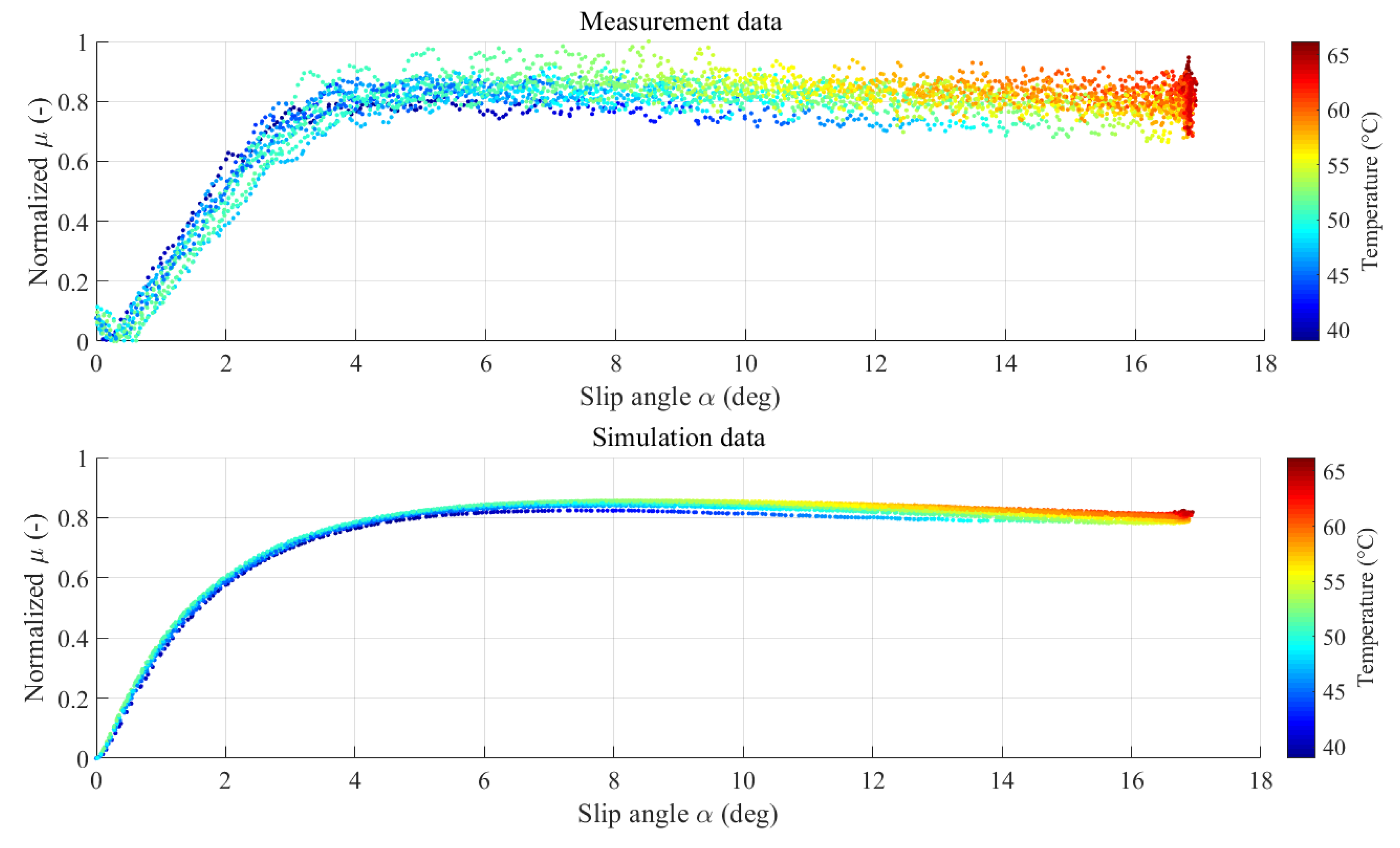

The proposed modifications cover both sliding and non-sliding friction components. Temperature-dependent peak friction coefficient

µpeak corresponds to the peak friction properties of the tire compound. The parameter

h affects the curve slope and results in the change of the shear modulus of the tire compound. The peak friction coefficient

µpeak, the lower limit of friction coefficient

µbase, and the parameter

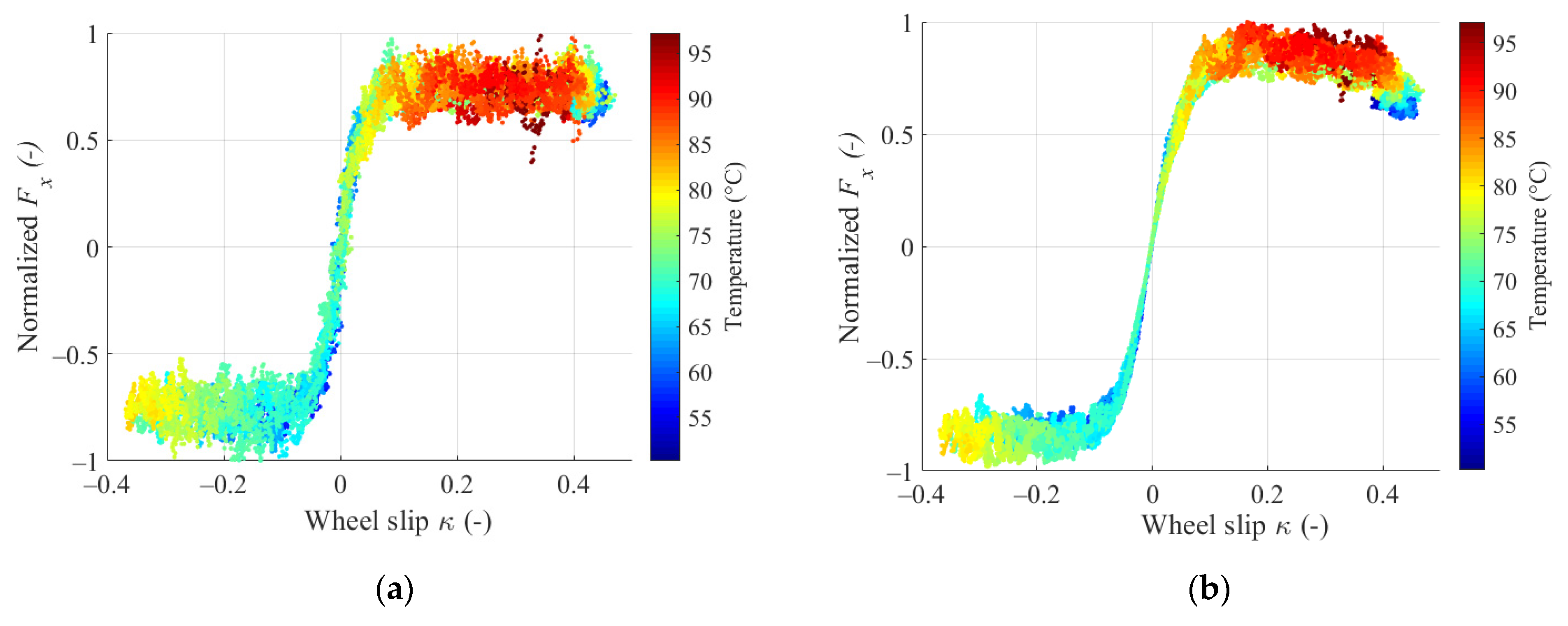

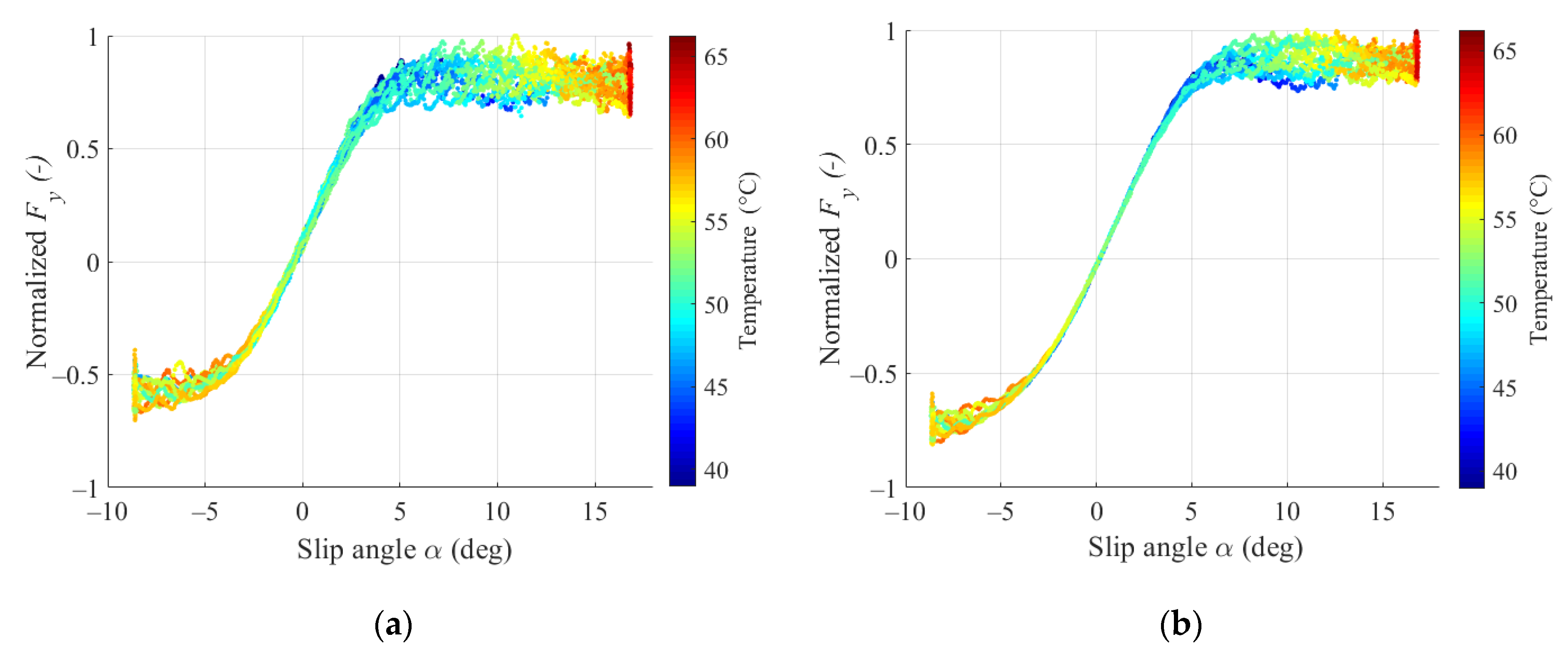

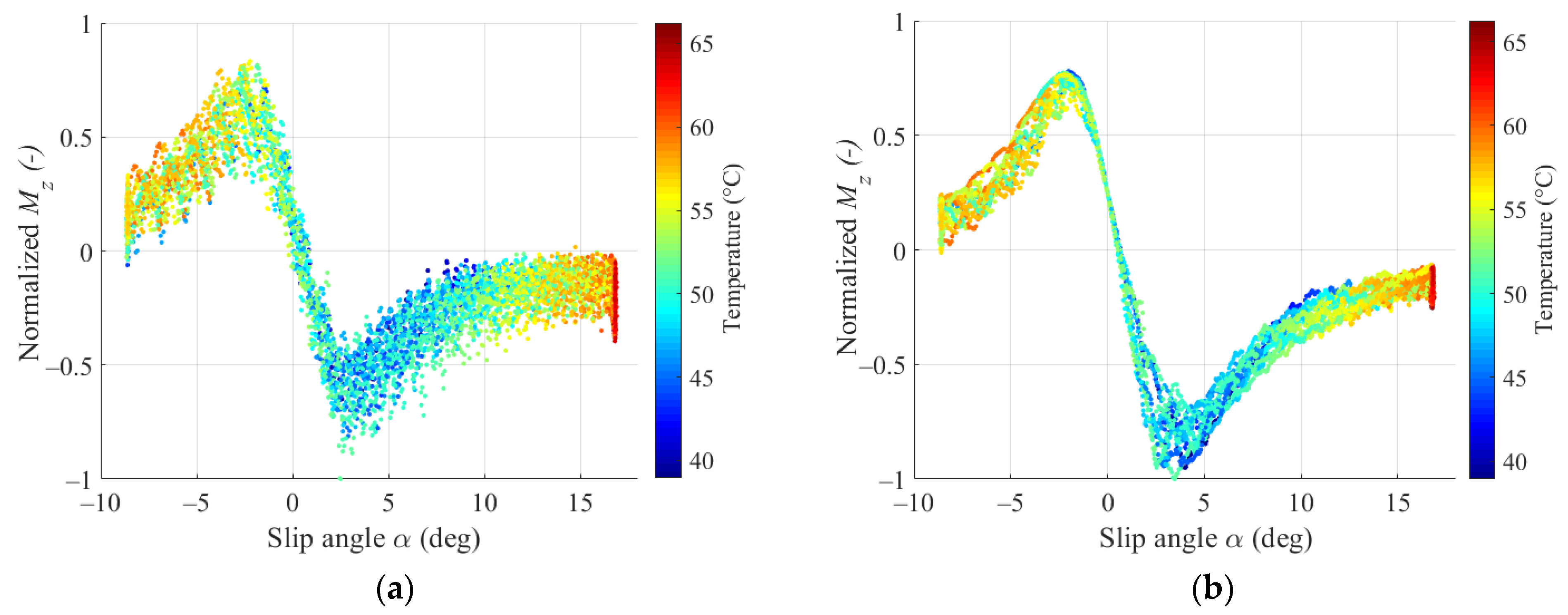

h are identified from measurement data. The simulation and experimental results for the obtained normalized lateral friction coefficient are shown in

Figure 6. The model shows similar qualitative behavior observed in the experimental data at the slip angle above 4°.

Four types of heat flows are considered: (i) heat flow between tread and ambient air; (ii) heat flow between carcass and ambient air; (iii) heat flow between tread and carcass; (iv) heat flow between carcass and inflation gas.

Heat flow with the ambient air

and

is defined as:

The heat flow coefficient

Hcarcass−amb is constant and the heat flow coefficient

Htread-amb is assumed to be a function of the longitudinal vehicle speed

Vx and taken as a linear function [

18]:

Heat flow between the tread and carcass

is calculated as:

Heat flow between the carcass and inflation gas

is defined as:

Using heat flow coefficient

Htread−road, heat flow between tread and road

can be found as:

The contact patch area,

Acp, is calculated assuming a constant width of the contact patch

b and the variable contact patch length

a which was adjusted compared to [

18] to better match the data of the FSAE tires:

Since the volume of the gas is constant, the pressure is directly proportional to the Kelvin temperature and thus the inflation pressure

pbar can be calculated as:

where

pcold is the pressure of the tire at ambient temperature.

3.2. Comparison with the Established Models

The Sorniotti model [

12] describes an empirical model to estimate tire temperature as the function of the actual working conditions of the component. To evaluate the temperature effect on tire forces, a combination of the estimated temperature with a tire brush model [

24] was used. The model was empirically tuned using experimental data to demonstrate the variation of tire performance as temperature function. The thermal model considers distinct thermal capacities related to the tread and carcass. The tread thermal capacity is related to the heat flux caused by the tire–road forces and carcass thermal capacity is affected by rolling resistance and exchanges heat with the external ambient. Other heat fluxes corresponded to the ambient and exchange between the two capacities. The original model [

12] did not consider the heat flow between the road and tread. Therefore, the heat flow term

Ptread,road was introduced to the original model to improve the accuracy according to [

25].

The model is described as:

Power fluxes corresponding to the cooling flux due to the temperature difference between carcass and ambient

Pambient,carcass, and tire tread and ambient

Pambient,tread are defined as:

Power fluxes related to conduction between tread and carcass

Pconduction and between tread and road

Ptread,road are calculated as:

Compared to the Sorniotti model, the proposed thermal model due to a higher differential order should capture more dynamics related to heat flow and potentially produce better results.

The Kelly and Sharp model [

18] states that in racing applications, the temperature of the tread significantly affects both the tire stiffness and the contact patch friction. It should be noted that the effect on the friction is higher. Since the rubber viscoelastic properties depend on temperature, the maximum performance on the racetrack is only available in a specific temperature range.

The tire model is also based on the brush model. Using the bristle stiffness

cp the adhesion part can be presented:

where

wcp is the contact patch width;

htread is the tread height.

The shear modulus of the tread

Gtread is defined as:

where

GTA is the reference shear modulus at temperature A;

GTB is the reference shear modulus at temperature B;

Glimit is the limit shear modulus value at a high temperature;

TGA is the reference temperature A;

TGB is the reference temperature B.

The sliding part of the contact patch is described using the dynamic friction coefficient. The master curve of the friction coefficient

μmc for the tread compound is assumed to have a Gaussian shape and it describes a friction curve with a Gaussian shape on a log frequency axis:

where

μbase and

μpeak are the lower and upper limits of the dynamic friction coefficient;

Kshape is the master curve shape factor;

vs is the sliding velocity;

Kshift is the master curve temperature shift factor;

Ttread is the tread temperature;

Tref is the master curve reference temperature.

In addition, the model takes into account the influence of contact patch pressure on friction coefficient. It is assumed that friction coefficients are reduced linearly with contact patch pressure. The static and dynamic friction coefficients are defined as:

where

pcp is the contact patch pressure;

Kcpp is the parameter of friction reduction rate;

Kpcpp is the friction roll-off factor with contact patch pressure;

Krefcpp is the reference contact patch pressure;

μ0 is the static friction coefficient;

μd is the dynamic friction coefficient;

μref is the reference static friction coefficient.

Compared to the Kelly and Sharp model, the peak friction coefficient μpeak is temperature-dependent in the proposed model, which could result in better accuracy.

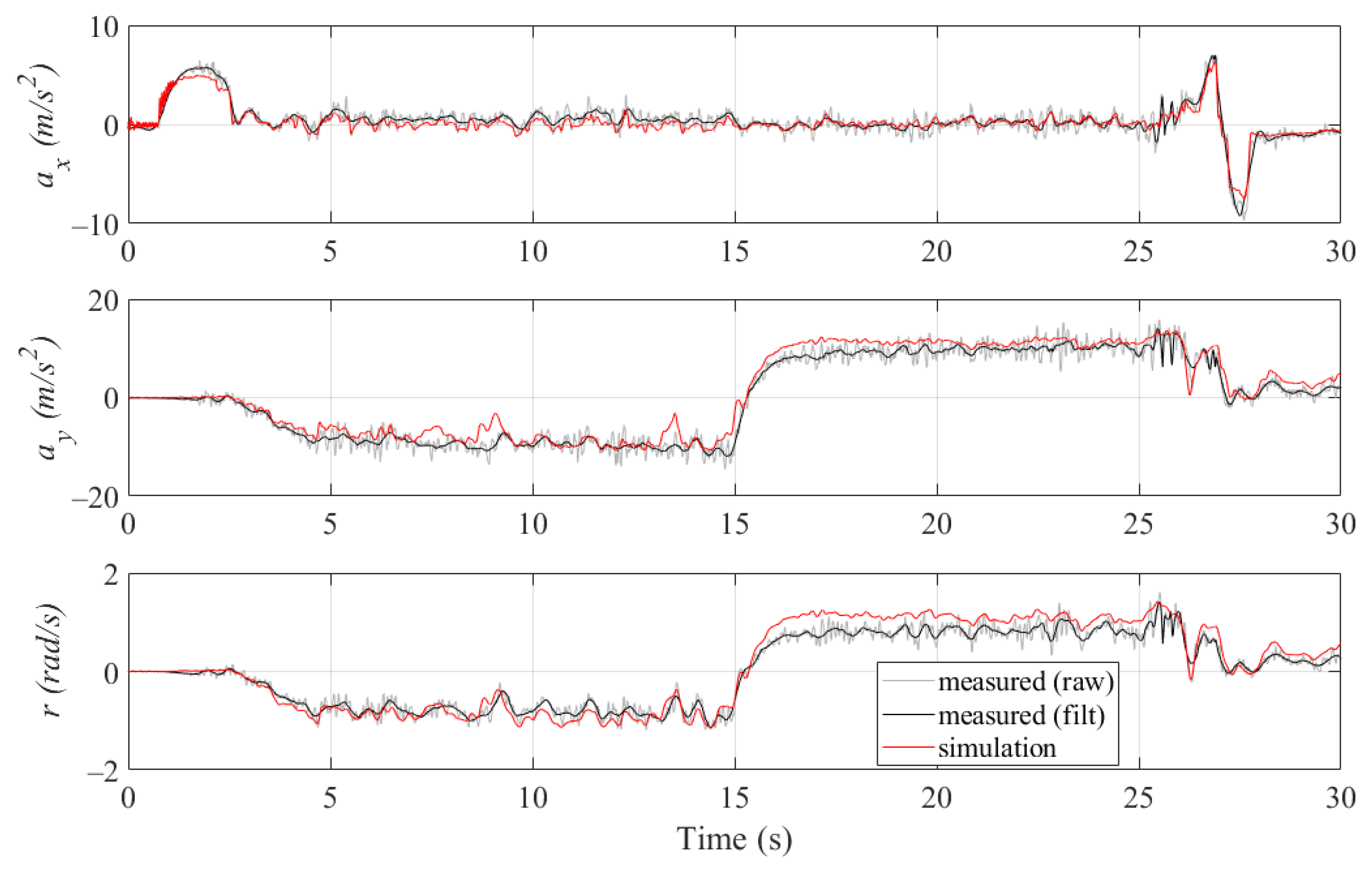

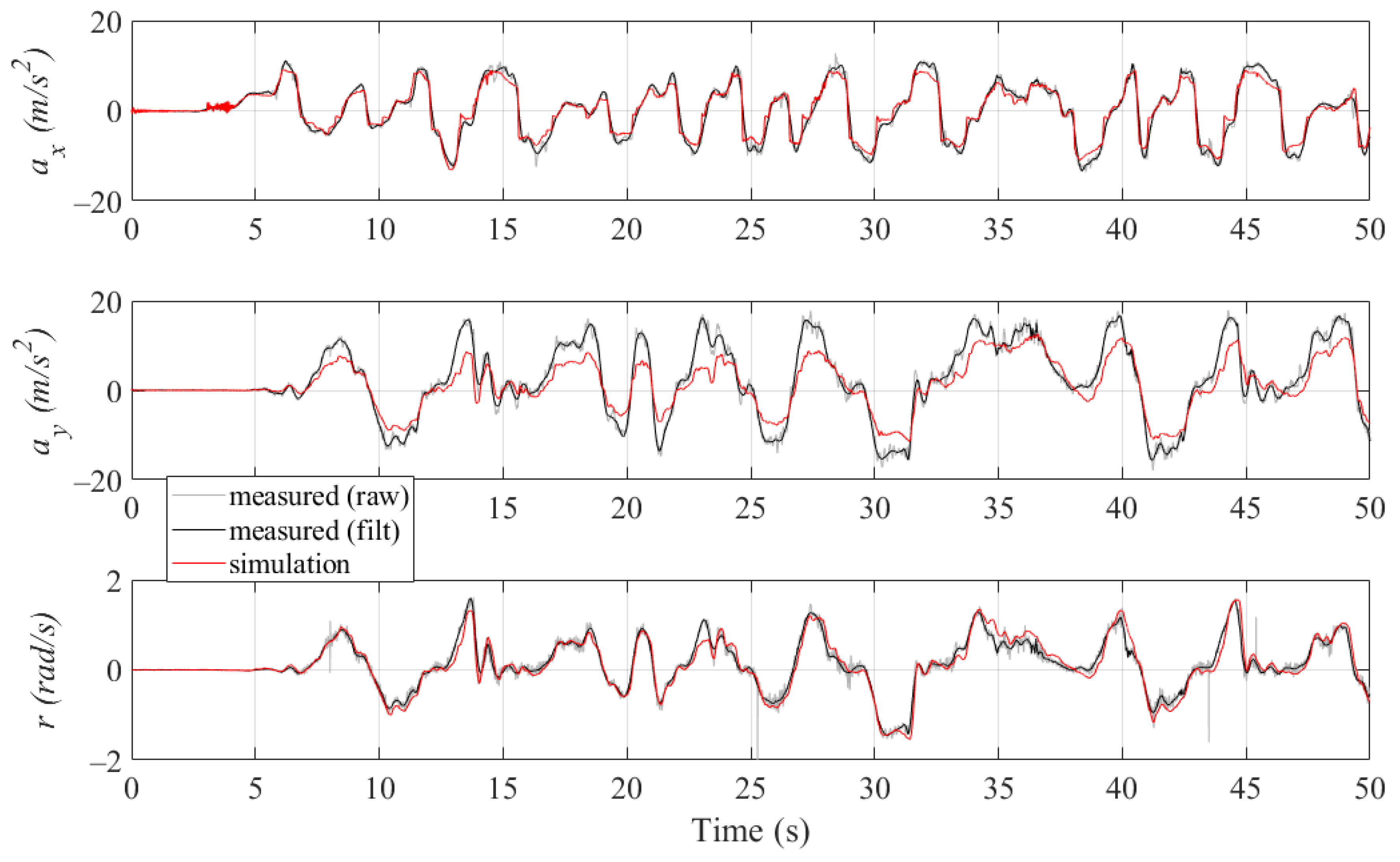

3.3. Comparison Results

The simulation results obtained from the considered thermal models were compared with measurement data for various maneuvers. The initial values of coefficients were taken from [

18,

25] and further tuned using constrained parameter optimization.

To tune parameters, a non-linear least square method was applied to obtain a suitable approximation of temperature effect and was based on the error from the measurement defined as:

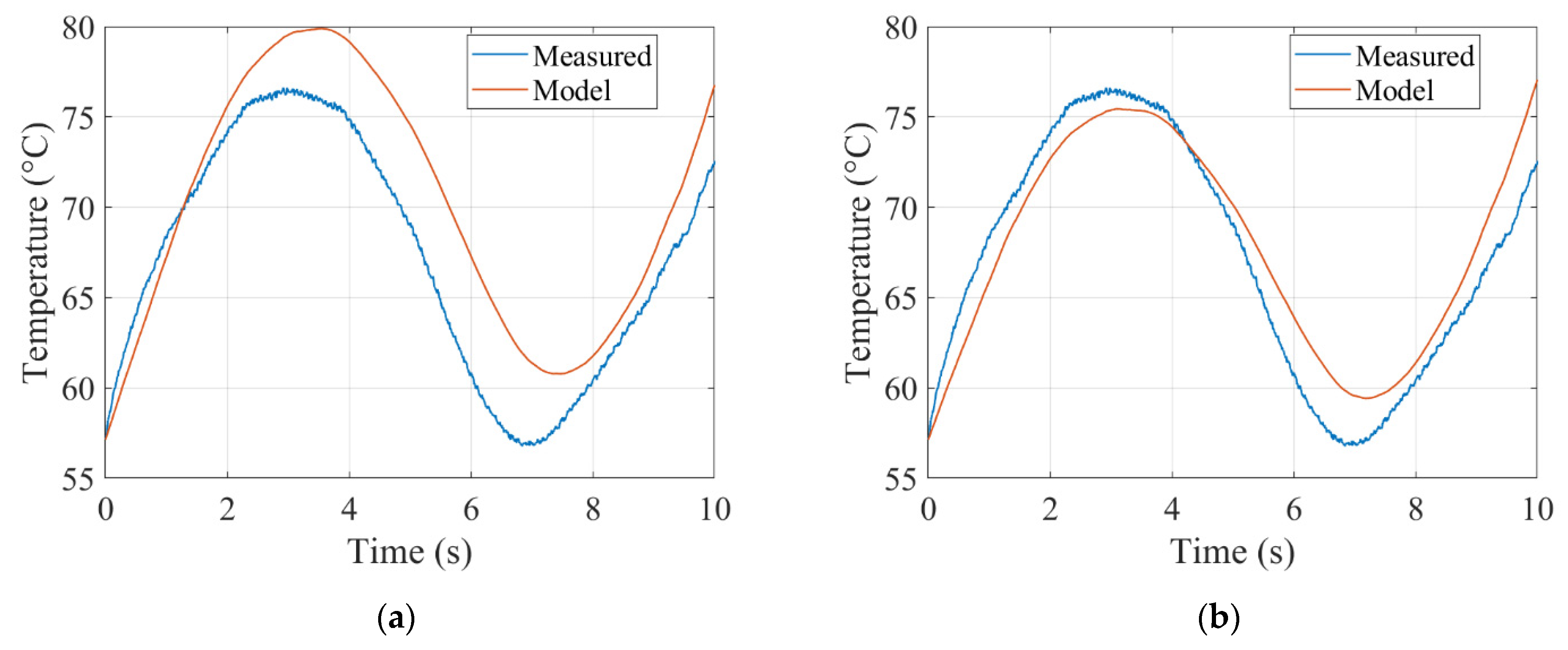

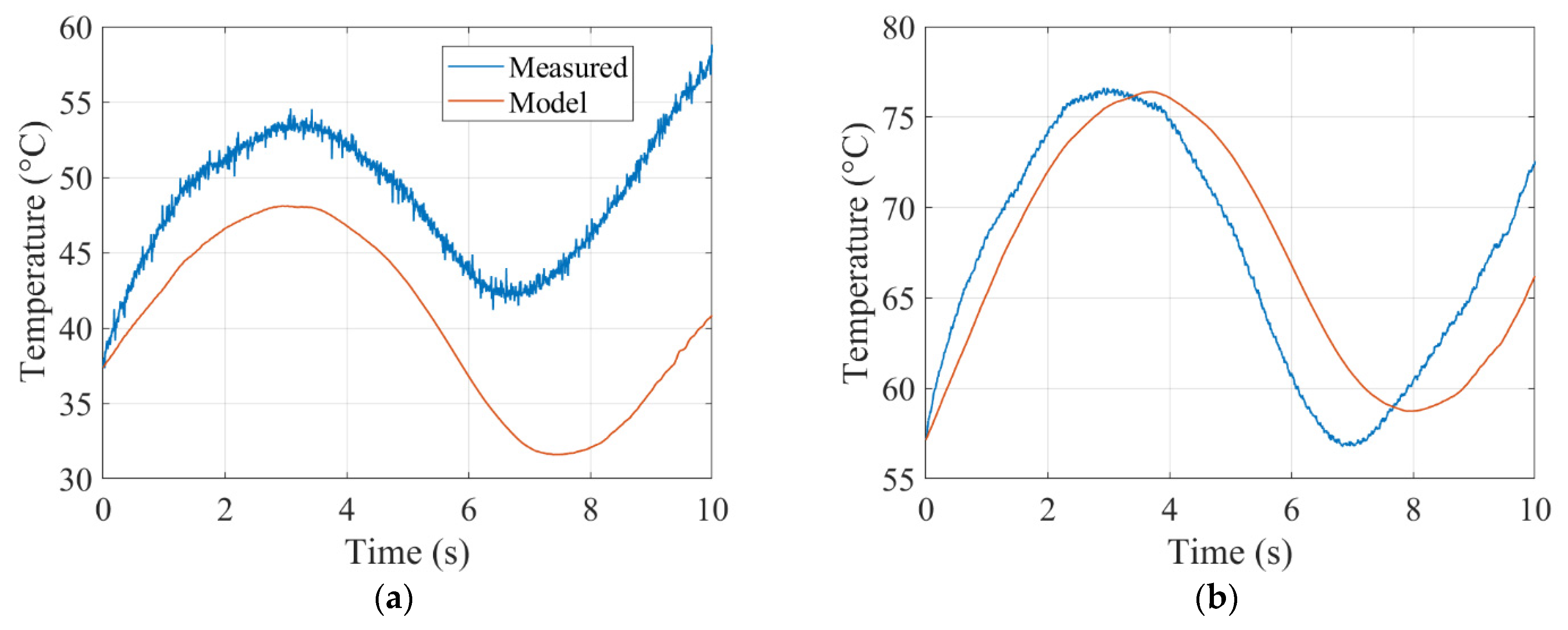

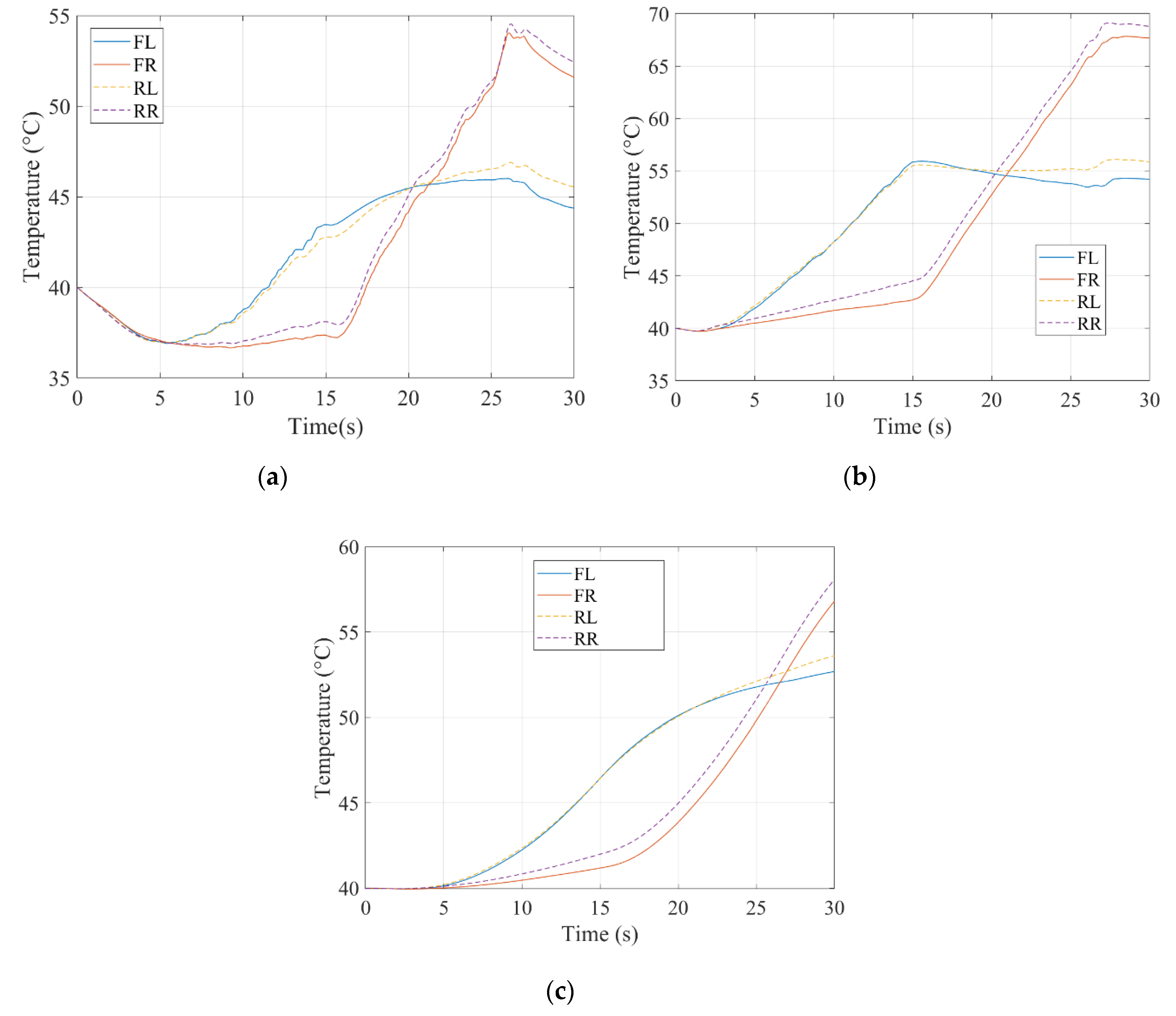

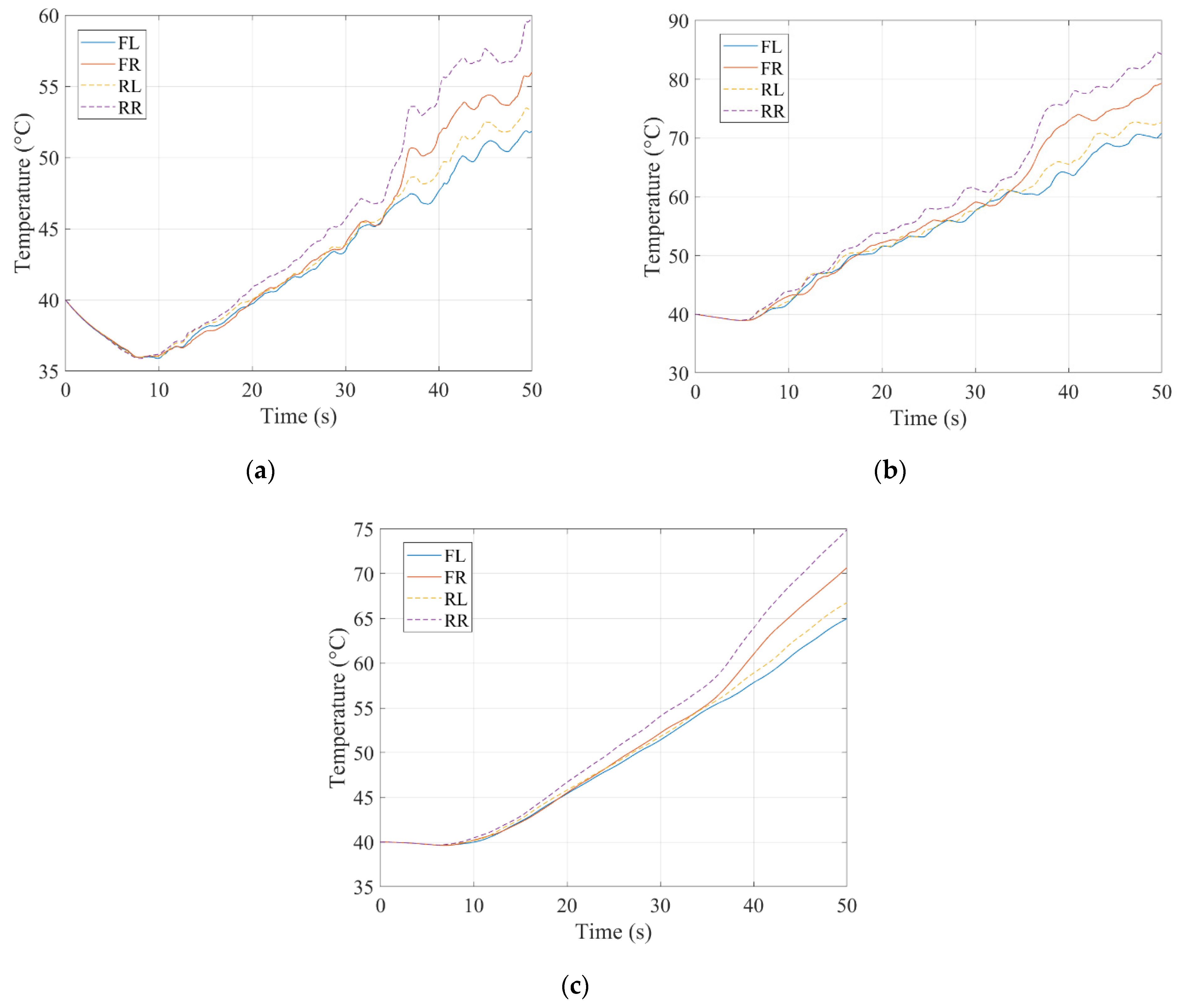

It was checked that the fitting parameters provide a good estimation for different maneuvers. For example, the parameters were first optimized for lateral tests and later checked again for acceleration/braking tests. Then an average was taken for the tuning parameters to cover all the experimental tests and represent the whole driving envelope. The comparisons between the measured temperature, the temperature obtained from the Kelly and Sharp model, and the proposed thermal model are shown in

Figure 7.

The accumulated error for the compared thermal models is summarized in

Table 2.

The results of the proposed thermal model and the compared models are close to the measurement data for all conducted tests. The proposed thermal model provides the smallest error for pure cornering. For pure braking the Sorniotti model shows the best performance and for pure acceleration the smallest error can be achieved using the Kelly and Sharp model. However, the conclusions regarding adaptability of the models to different normal loads cannot be extracted from

Table 2. Since the Kelly and Sharp model considers the contact patch area depending on the normal load and air pressure, the model can adapt to different normal loads and the maximum error is limited to ~6%. Therefore, the models were also checked using measurement data for different load conditions. It was found that although the Sorniotti model has a good fit to the measured data, the error increases when the load condition is changed (

Figure 8).