Evaluation of Chicken Feather and Styrene-Butadiene/Chicken Feather Composites as Modifier for Asphalts Binder

Abstract

:1. Introduction

2. Materials and Methods

2.1. Composite Preparation

2.2. Preparation of Modified Asphalt Mixtures

2.3. Physical Properties

2.4. Thermal Analysis

2.5. Rheological Analysis

3. Results

3.1. Physical Properties

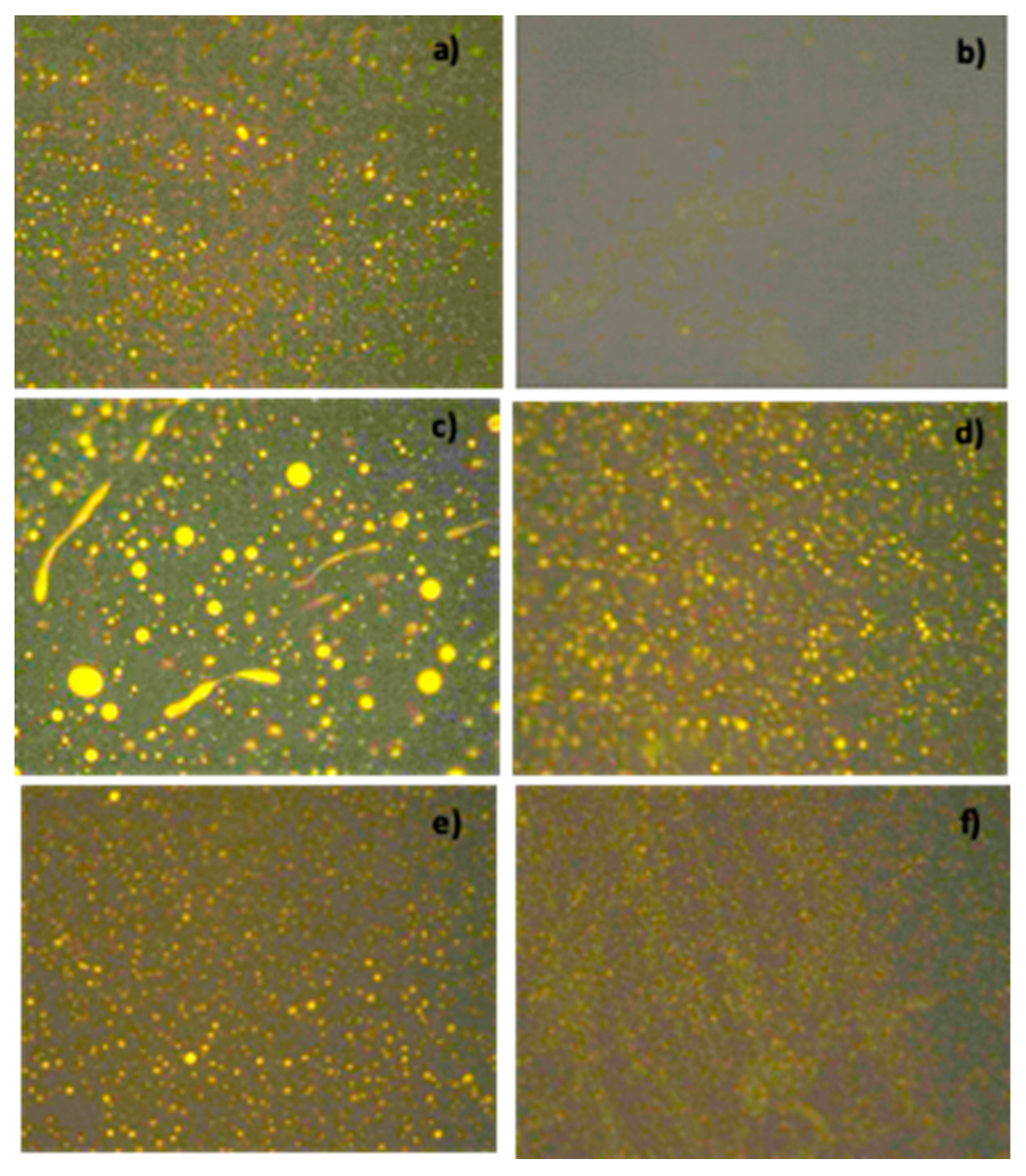

3.2. Fluorescent Microscopy

3.3. Thermogravimetric Analysis (TGA)

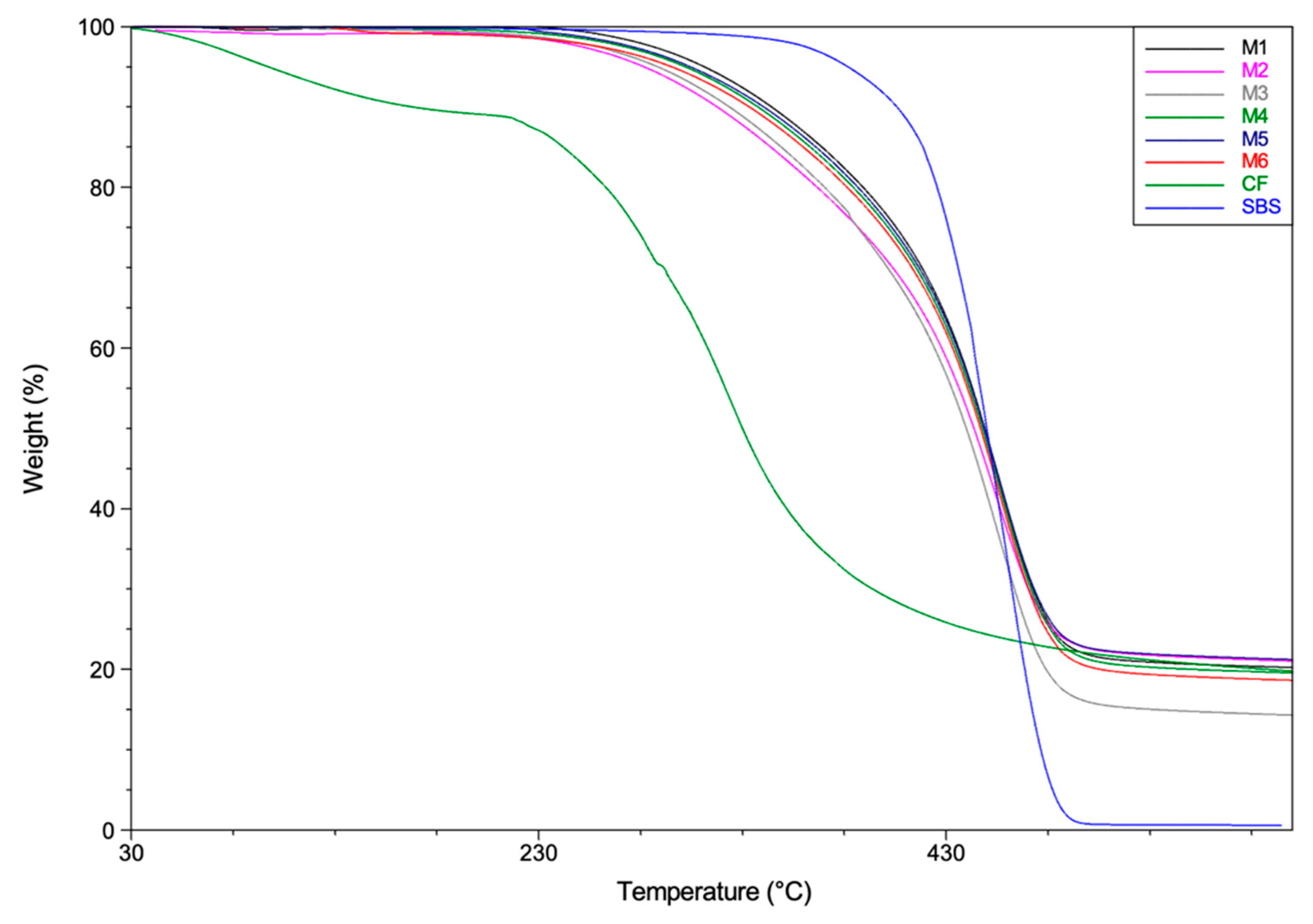

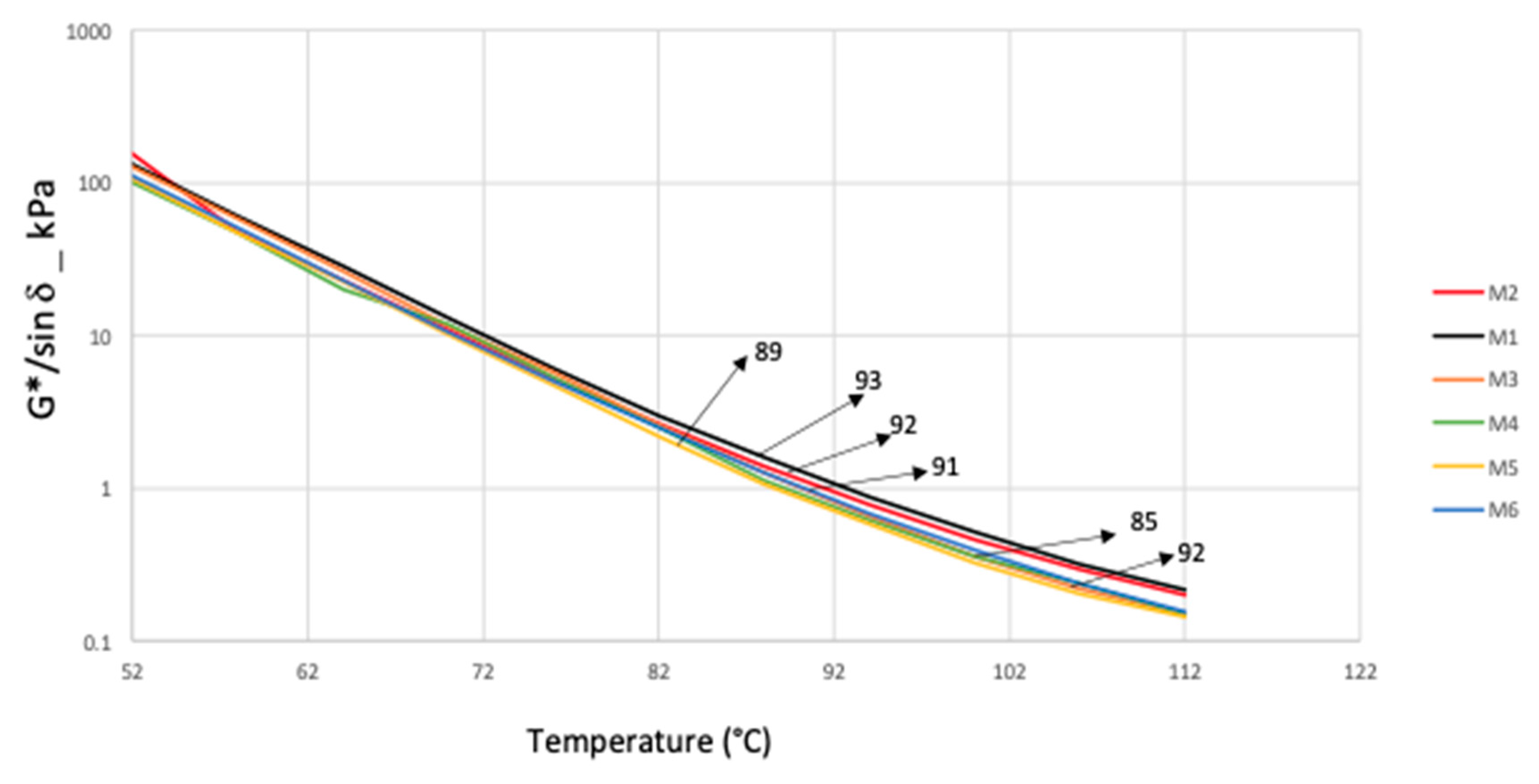

3.4. Rheology

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Su, N.; Xiao, F.; Wang, J.; Cong, L.; Amirkhanian, S. Productions and applications of bio-asphalts—A review. Constr. Build. Mater. 2018, 183, 578–591. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, H.; Gao, J.; You, Z.; Tang, X. High temperature performance of SBS modified bio-asphalt. Constr. Build. Mater. 2017, 144, 99–105. [Google Scholar] [CrossRef]

- Bao, D.X.; Yu, Y.Y.; Zhao, Q.M. Evaluation of the chemical composition and rheological properties of bio-asphalt from different biomass sources. Road Mater. Pavement Des. 2019, 1–16. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.; Dai, Q.; Mills-Beale, J. Mechanical performance of asphalt mixtures modified by bio-oils derived from waste wood resources. Constr. Build. Mater. 2014, 51, 424–431. [Google Scholar] [CrossRef]

- Tang, S.; Williams, R.C. Antioxidant effect of bio-oil additive ESP on asphalt binder. In Proceedings of the 2009 Mid-Continent Transportation Research Symposium, Ames, IA, USA, 20–21 August 2009; p. 14. [Google Scholar]

- Merusi, F.; Giuliani, F.; Polacco, G. Linear viscoelasticbehavior of asphalt binders modified with polymer/clay nanocomposites. Proc.-Soc. Behav. Sci. 2012, 53, 335–345. [Google Scholar] [CrossRef]

- Mothè, M.G.; Leite, L.F.M.; Mothè, C.G. Thermal characterization of asphalt mixtures by TG/DTG, DTA and FTIR. J. Therm. Anal. Calorim. 2008, 93, 105–109. [Google Scholar] [CrossRef]

- Nciri, N.; Shin, T.; Lee, H.; Cho, N. Potential of waste oyster shells as novel biofiller for hot-mix asphalt. Appl. Sci. 2018, 8, 415. [Google Scholar] [CrossRef]

- Razzaq, A.K.; Yousif, R.A.; Tay, S.A. Characterization of hot mix asphalt modified by egg shell powder. Int. J. Eng. Res. Tech. 2018, 11, 481–492. [Google Scholar]

- Sundstrom, D.W.; Kiel, H.E.; Daubenspeck, T.H. Use of byproduct lignins as extenders in asphalt. Ind. Eng. Chem. Prod. Res. Dev. 1983, 22, 496–500. [Google Scholar] [CrossRef]

- Arabani, M.; Tahami, S.A. Assessment of mechanical properties of rice husk ash modified asphalt mixture. Constr. Build. Mater. 2017, 149, 350–358. [Google Scholar] [CrossRef]

- Caro, S.; Vega, N.; Husserl, J.; Alvarez, A.E. Studying the impact of biomodifiers produced from agroindustrial wastes on asphalt binders. Constr. Build. Mater. 2016, 126, 369–380. [Google Scholar] [CrossRef]

- Abo-Sanab, Z.L.; Ragab, A.A.; Naguib, H.M. Improved dynamic mechanical properties of sustainable bio-modified asphalt using agriculture waste. Int. J. Pavement Eng. 2019, 1–7. [Google Scholar] [CrossRef]

- Chen, C.; Podolsky, J.H.; Williams, R.C.; Cochran, E.W. Laboratory investigation of using acrylated epoxidized soybean oil (ESO) for asphalt modification. Constr. Build. Mater. 2018, 187, 267–279. [Google Scholar] [CrossRef]

- Jahromi, S.G.; Khodaii, A. Effects of nanoclay on rheological properties of bitumen binder. Constr. Build. Mater. 2009, 23, 2894–2904. [Google Scholar] [CrossRef]

- Zapién-Castillo, S.; Rivera-Armenta, J.L.; Chávez-Cinco, M.Y.; Salazar-Cruz, B.A.; Mendoza-Martínez, A.M. Physical and rheological properties of asphalt modified with SEBS/montmorillonite nanocomposite. Constr. Build. Mater. 2016, 106, 349–356. [Google Scholar] [CrossRef]

- Fang, C.; Yu, R.; Liu, S.; Li, Y. Nanomaterials applied in asphalt modification: A review. J. Mater. Sci. Technol. 2013, 29, 589–594. [Google Scholar] [CrossRef]

- Ahmed, K.; Nizami, S.S.; Raza, N.Z.; Kamaludin, S.; Mohmood, K. An assessment of rice husk ash modified, marble sludge loaded natural rubber hybrid composites. J. Mater. Environ. Sci. 2013, 4, 205–216. [Google Scholar]

- Huang, Y.; Bird, R.N.; Heidrich, O. A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Méndez-Hernández, M.L.; Salazar-Cruz, B.A.; Rivera-Armenta, J.L.; Estrada-Moreno, I.A.; Chávez-Cinco, M.Y. Preparation and characterization of composites from copolymer styrene-butadiene and chicken feathers. Polimeros 2018, 28, 368–372. [Google Scholar] [CrossRef]

- Castillo-Castillo, C.; Salazar-Cruz, B.A.; Rivera-Armenta, J.L.; Chávez-Cinco, M.Y.; Méndez-Hernández, M.L.; Estrada-Moreno, I.A.; Singh, S.; Singh, P.; Zitoune, R.; Yazdani, M. Futuristic Composites: Behavior, Characterization and Manufacturing; Springer: Berlin, Germany, 2018; pp. 297–318. [Google Scholar]

- Schoff, C.K.; Kamarchik, P.J.; Herman, M.F. Encyclopedia of Polymer Science and Technology; John Wiley & Sons Inc.: New York, NY, USA, 2014; pp. 1041–1049. [Google Scholar]

- Senoz, E.; Wool, R.P.; McChalicher, C.W.J.; Hong, C.K. Physical and chemical changes in feather keratin during pyrolysis. Polym. Degrad. Stab. 2012, 97, 297–307. [Google Scholar] [CrossRef]

- Golestani, B.; Moghaddas, F.; Sadeghpour, S. Performance evaluation of linear and non linear nanocomposite modified bitumens. Constr. Build. Mater. 2012, 35, 197–203. [Google Scholar] [CrossRef]

- Conceicao, M.; Lucena, C.; Aguiar Soares, S. Characterization ad thermal behavior of polymer-modified asphalt. Mater. Res. 2004, 7, 529–534. [Google Scholar]

- Prochon, M.; Janowska, G.; Przepiorkowska, A. Thermal properties and combustibility of elastomer-protein composites, Part I. Composites SBR-keratin. J. Therm. Anal. Calorim. 2012, 109, 1563–1570. [Google Scholar] [CrossRef]

- Bonati, F.; Merusi, G.; Polacco, S.; Filippi Giuliani, F. Ignitability and thermal stability of sphalt binders and mastics for flexible pavements in highway tunnels. Constr. Build. Mater. 2012, 37, 660–668. [Google Scholar] [CrossRef]

- Naskar, M.; Chaki, T.K.; Reddy, K.S. Effect of waste plastic as modifier on thermal stability and degradation kinetics of bitumen/waste plastics blends. Thermochim. Acta 2010, 509, 128–134. [Google Scholar] [CrossRef]

- Munteanu, S.B.; Brebu, M.; Vasile, C. Thermal and thermo-oxidative behavior of butadiene-styrene copolymers with ifferent architectures. Polym. Degrad. Stab. 2005, 89, 501–512. [Google Scholar] [CrossRef]

- Ouyang, C.; Wang, S.; Zhang, Y.; Zhang, Y. Preparation and properties of styrene–butadiene–styrene copolymer/kaolinite clay compound and asphalt modified with the compound. Polym. Degrad. Stab. 2005, 87, 309–317. [Google Scholar] [CrossRef]

- Martínez-Anzures, J.D.; Zapién-Castillo, S.; Salazar-Cruz, B.A.; Rivera-Armenta, J.L.; Antonio-Cruz, R.C.; Hernández-Zamora, G. Preparation and properties of modified asphalt using branch SBS/nanoclay nanocomposites as a modifier. Road Mater. Pavement Des. 2019, 20, 1275–1290. [Google Scholar] [CrossRef]

| Sample | Asphalt with SBS (Control) | Asphalt with CF | Asphalt with SBS + CF | Asphalt with CF + SBS | Asphalt with SBS/CF Composite 50 rpm | Asphalt with SBS/CF Composite 70 rpm |

|---|---|---|---|---|---|---|

| Code | M1 | M2 | M3 | M4 | M5 | M6 |

| Code | Softening Point, R&B (°C) | Phase Separation R&B (°C) | Penetration (dmm) | Rotational Viscosity, 135 °C (Pa.s) |

|---|---|---|---|---|

| Asphalt | 52 | 0 | 44 | 0.545 |

| M1 | 63 | 2.3 | 39.6 | 1.46 |

| M2 | 64 | 0.5 | 28.0 | 1.533 |

| M3 | 54.2 | 10 | 41.1 | 1.275 |

| M4 | 60 | 7.5 | 36.5 | 1.430 |

| M5 | 60 | 2.5 | 39.8 | 1.290 |

| M6 | 60 | 4.5 | 41.6 | 1.202 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colunga-Sánchez, L.M.; Salazar-Cruz, B.A.; Rivera-Armenta, J.L.; Morales-Cepeda, A.B.; Ramos-Gálvan, C.E.; Chávez-Cinco, M.Y. Evaluation of Chicken Feather and Styrene-Butadiene/Chicken Feather Composites as Modifier for Asphalts Binder. Appl. Sci. 2019, 9, 5188. https://doi.org/10.3390/app9235188

Colunga-Sánchez LM, Salazar-Cruz BA, Rivera-Armenta JL, Morales-Cepeda AB, Ramos-Gálvan CE, Chávez-Cinco MY. Evaluation of Chicken Feather and Styrene-Butadiene/Chicken Feather Composites as Modifier for Asphalts Binder. Applied Sciences. 2019; 9(23):5188. https://doi.org/10.3390/app9235188

Chicago/Turabian StyleColunga-Sánchez, Leslie Mariella, Beatriz Adriana Salazar-Cruz, José Luis Rivera-Armenta, Ana Beatriz Morales-Cepeda, Claudia Esmeralda Ramos-Gálvan, and María Yolanda Chávez-Cinco. 2019. "Evaluation of Chicken Feather and Styrene-Butadiene/Chicken Feather Composites as Modifier for Asphalts Binder" Applied Sciences 9, no. 23: 5188. https://doi.org/10.3390/app9235188

APA StyleColunga-Sánchez, L. M., Salazar-Cruz, B. A., Rivera-Armenta, J. L., Morales-Cepeda, A. B., Ramos-Gálvan, C. E., & Chávez-Cinco, M. Y. (2019). Evaluation of Chicken Feather and Styrene-Butadiene/Chicken Feather Composites as Modifier for Asphalts Binder. Applied Sciences, 9(23), 5188. https://doi.org/10.3390/app9235188