On the Fault Detection and Diagnosis of Railway Switch and Crossing Systems: An Overview

Abstract

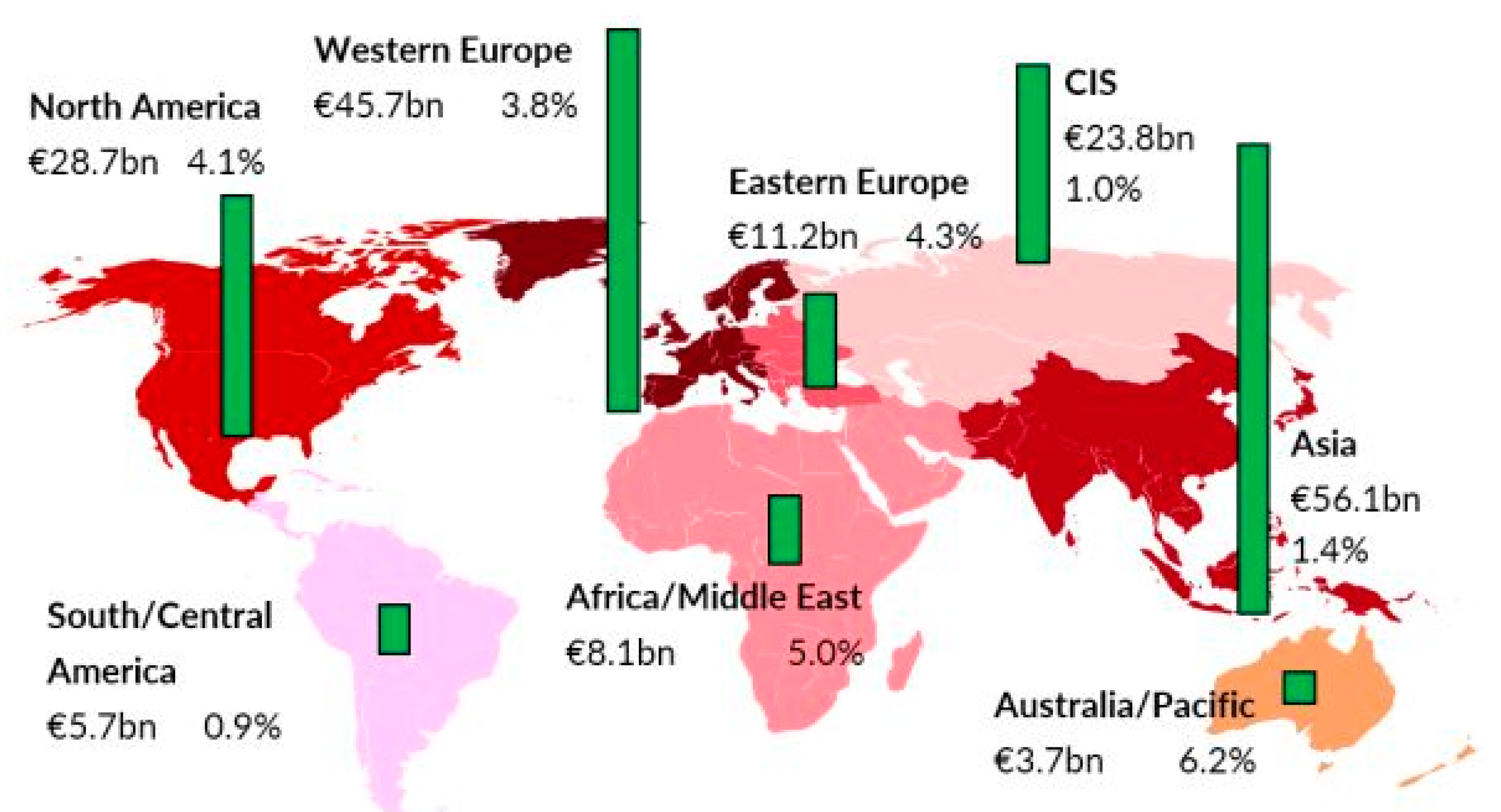

1. Introduction

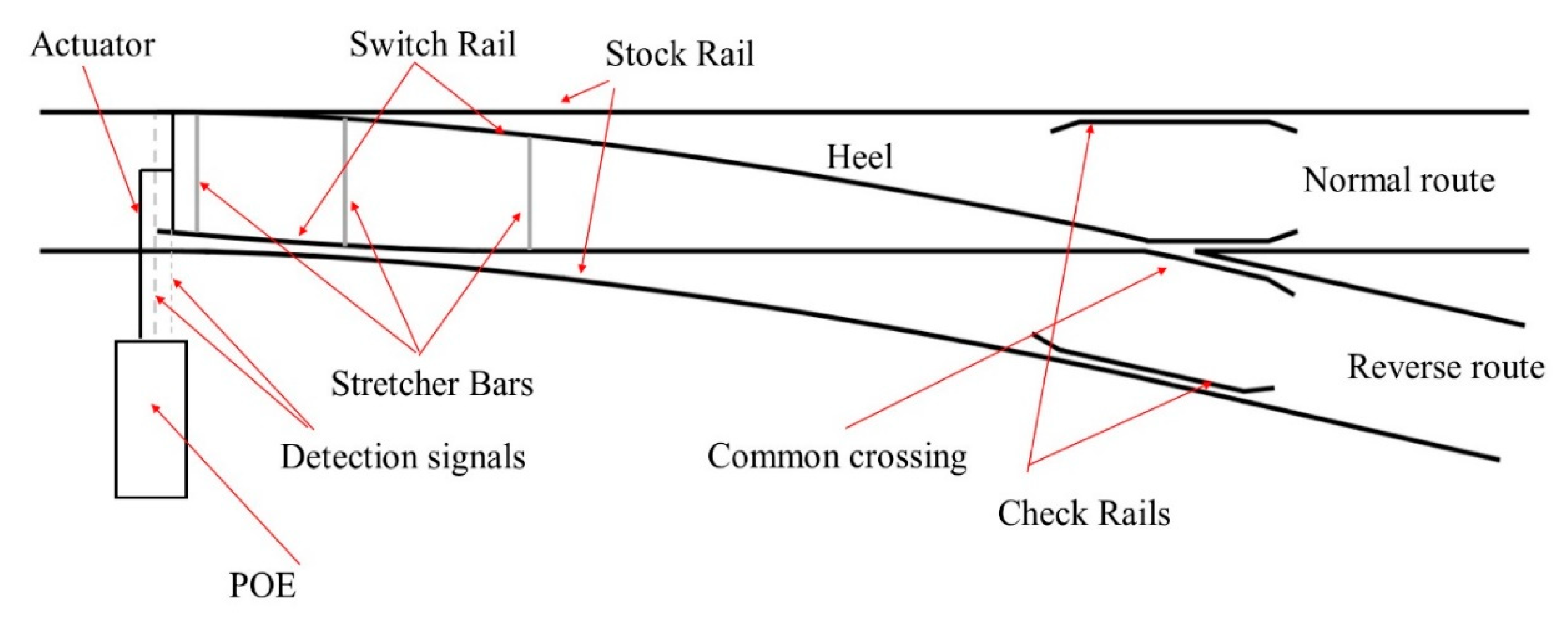

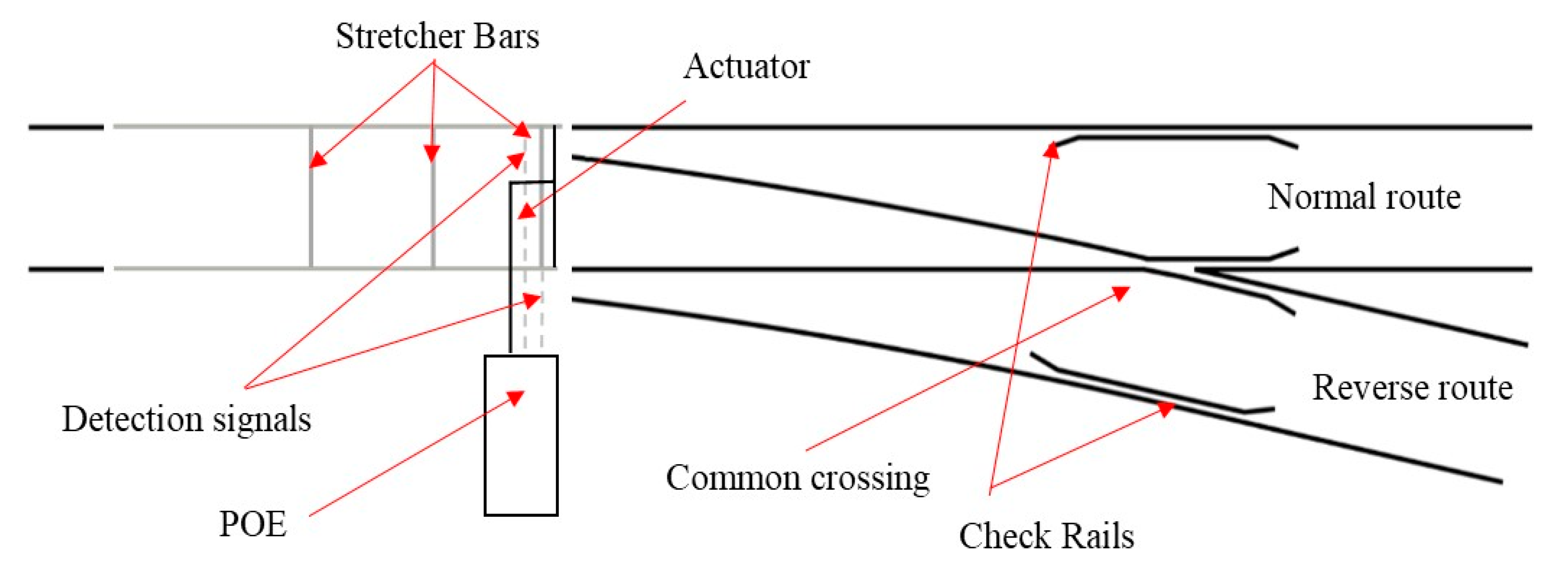

2. Fundamentals of S&C Systems: Actuation Mechanisms, Sensors and Controllers, Locking Systems, and Their Failure Modes

2.1. Actuation Mechanism

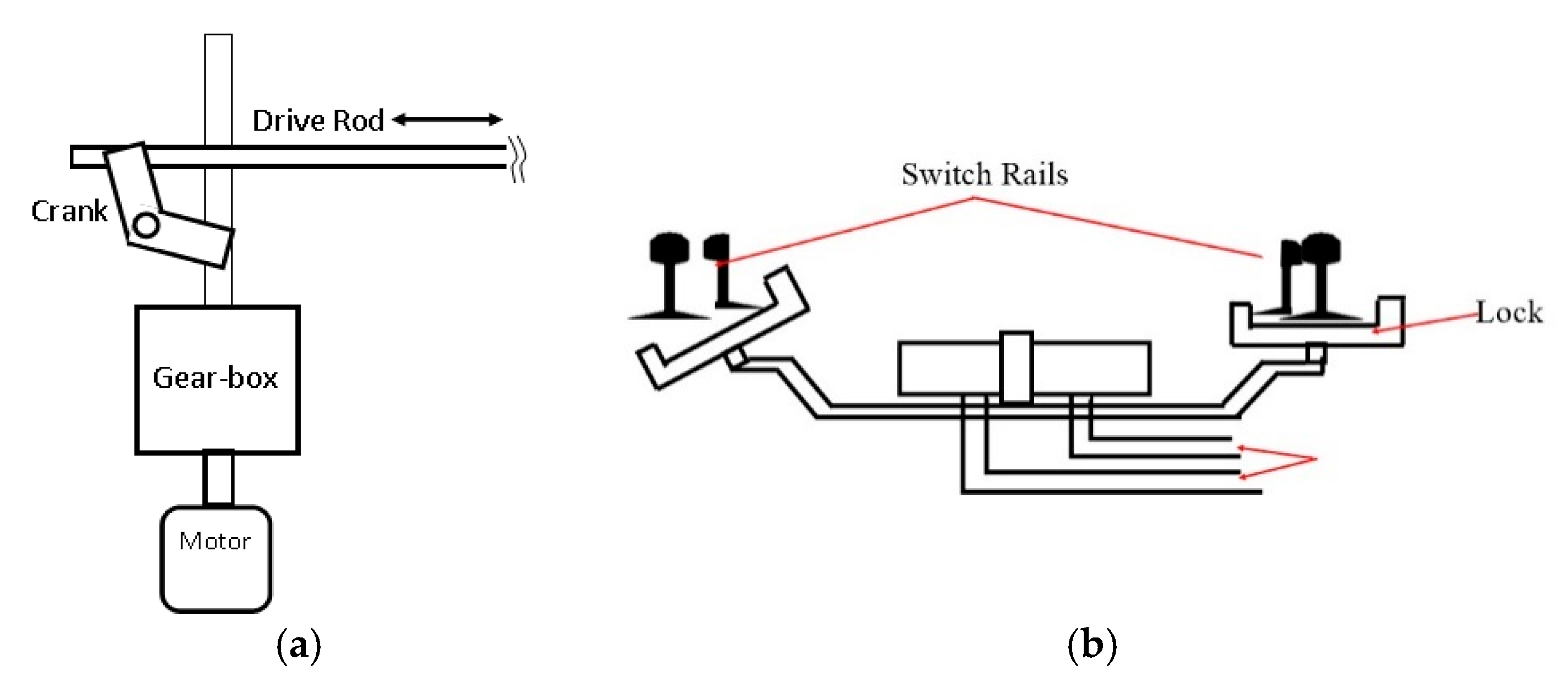

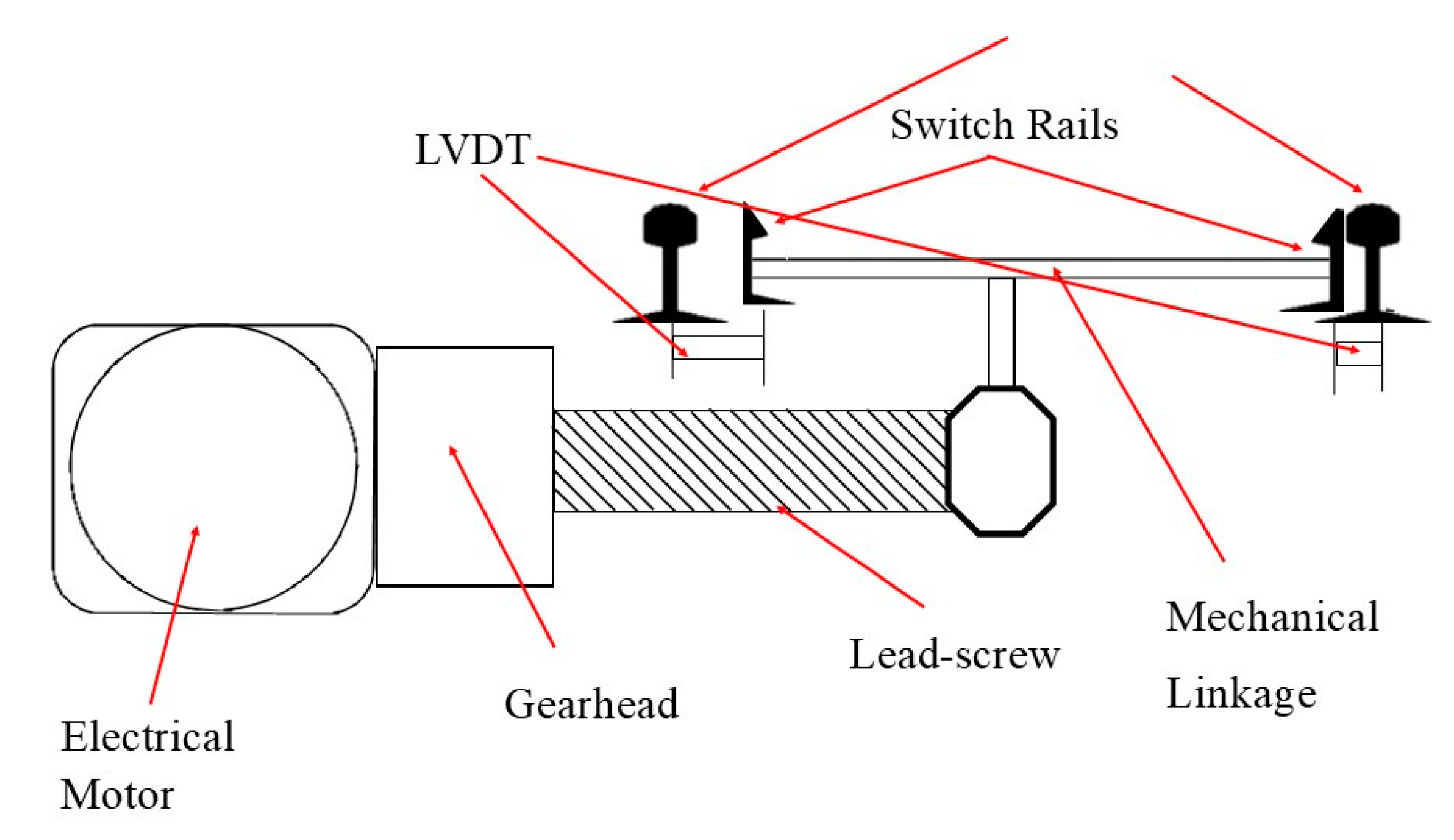

2.1.1. Linear Actuation

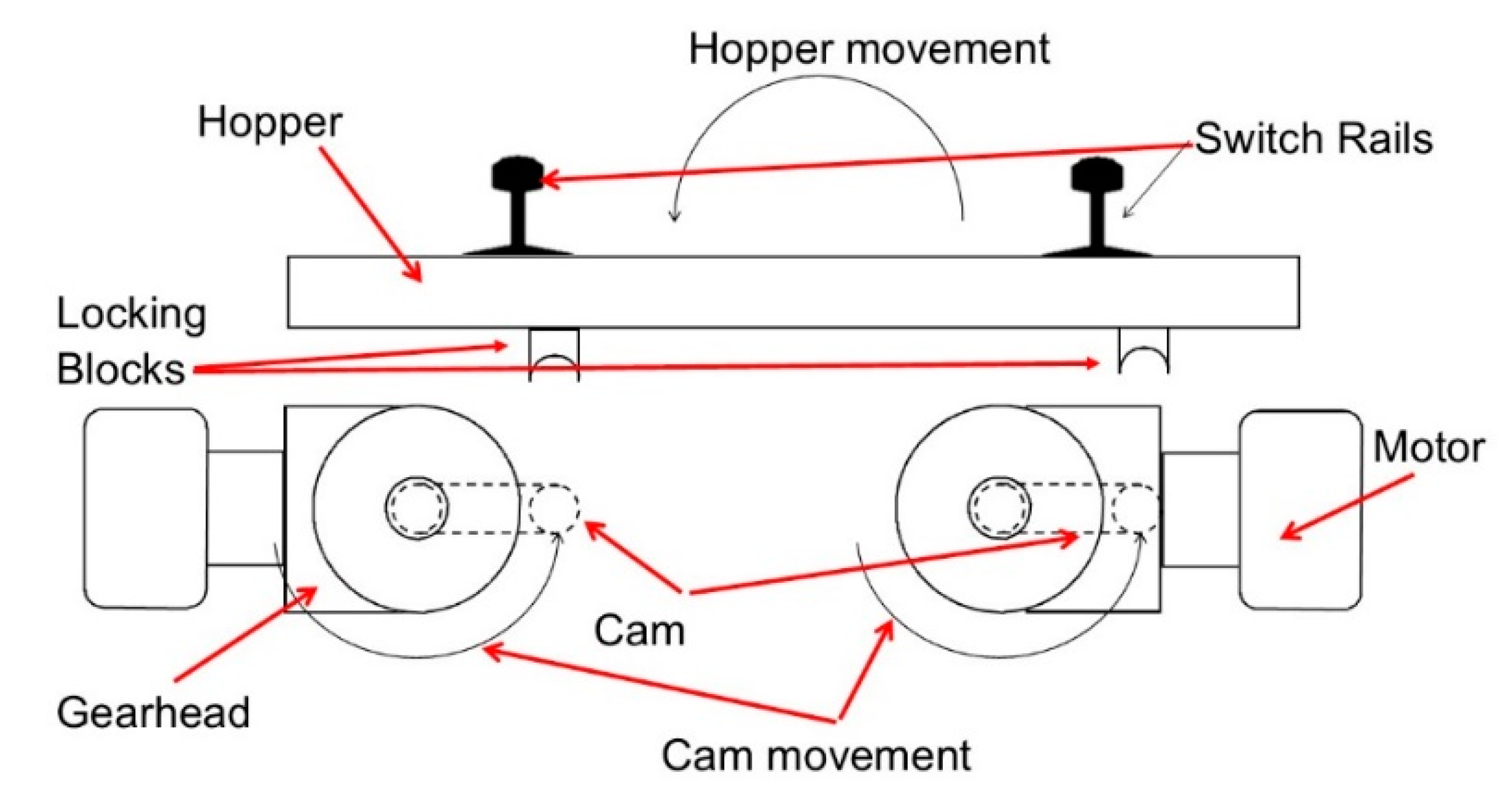

2.1.2. Lift-Hop-Drop Actuation

2.2. Sensors and Controllers

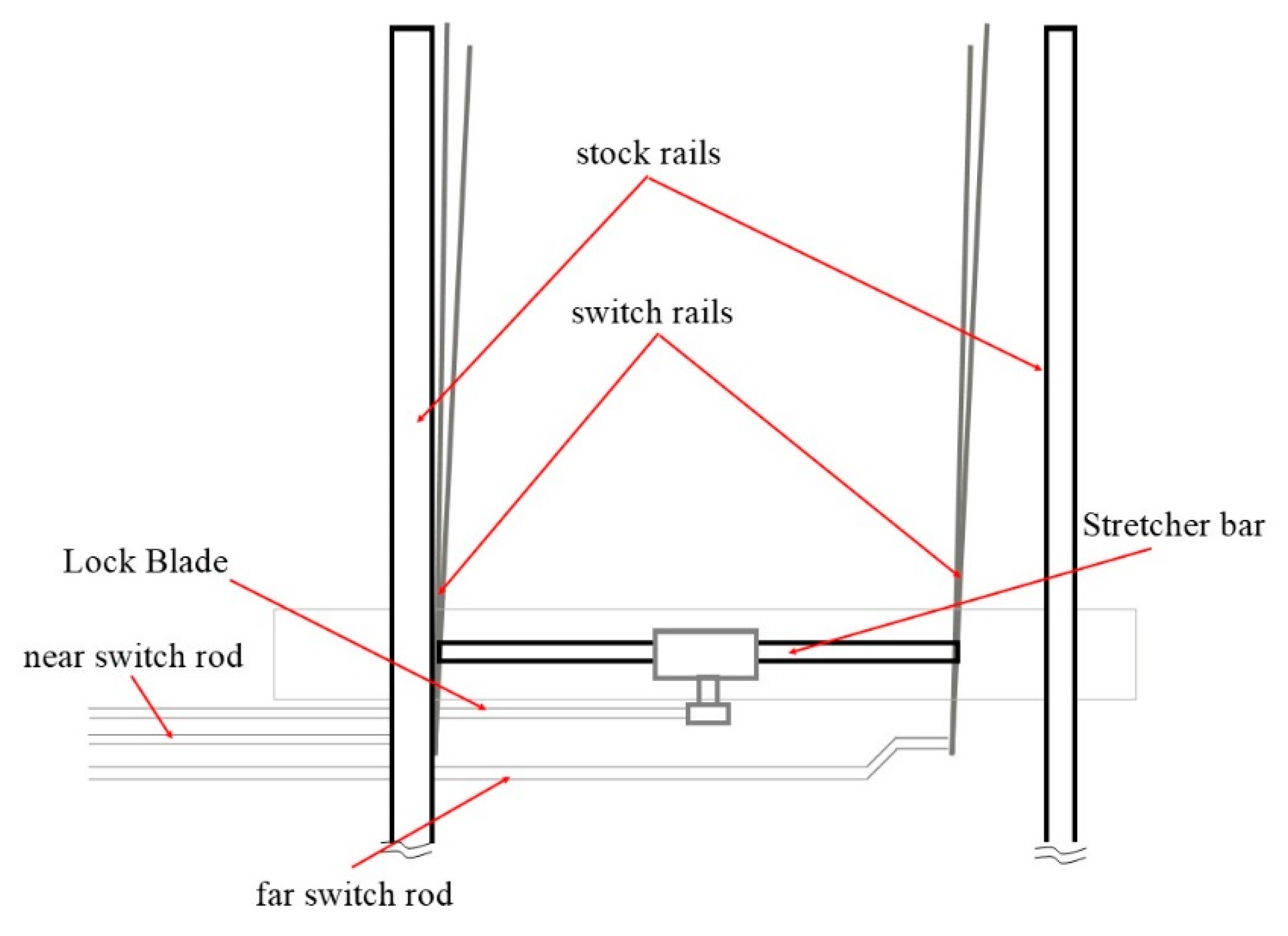

2.3. Detection and Locking

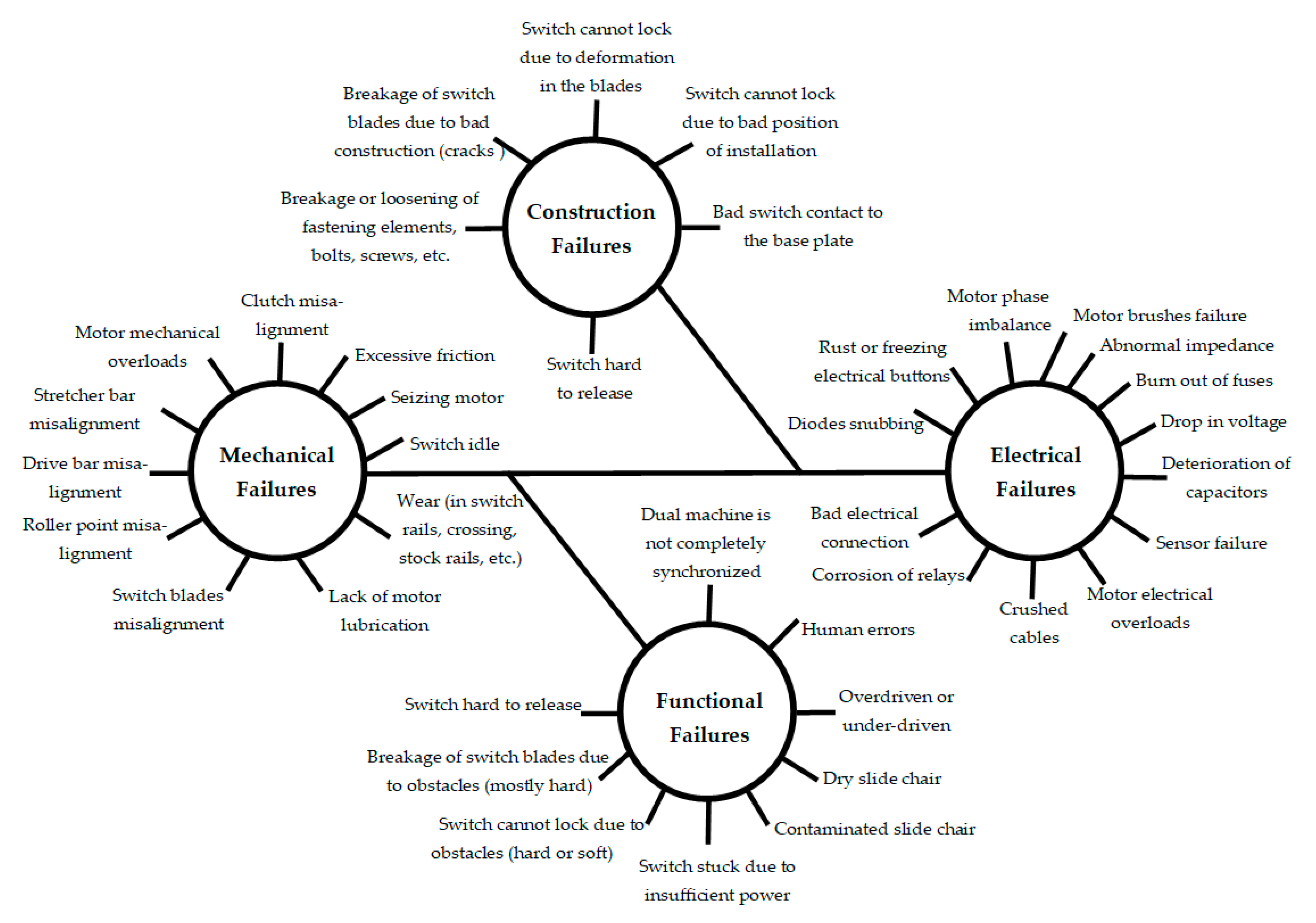

2.4. Failure Modes of Railway S&C Systems

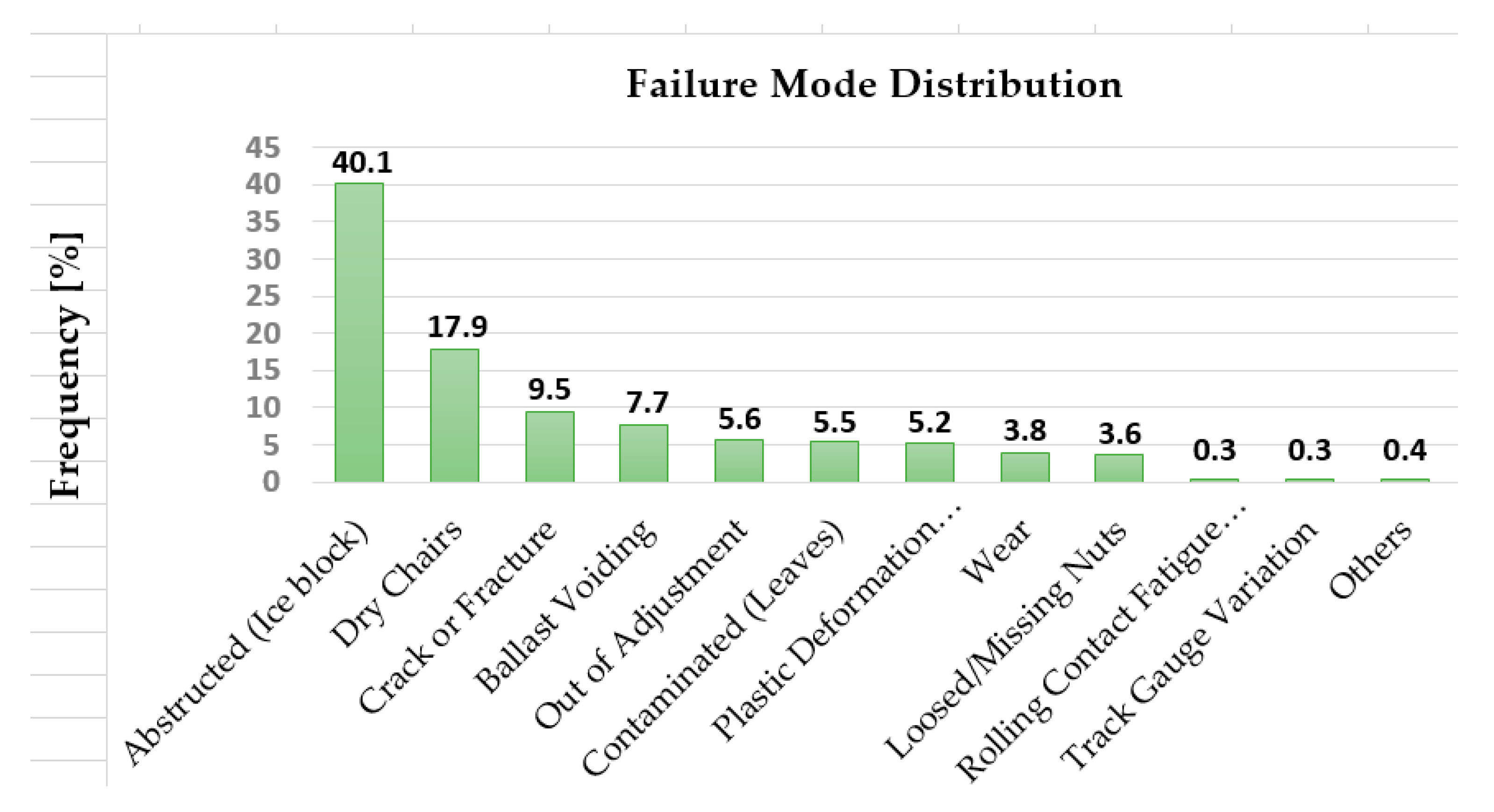

2.4.1. Permanent Way

2.4.2. Actuation Subsystem

2.4.3. Sensor and Control Subsystem

2.4.4. Detection and Locking Subsystem

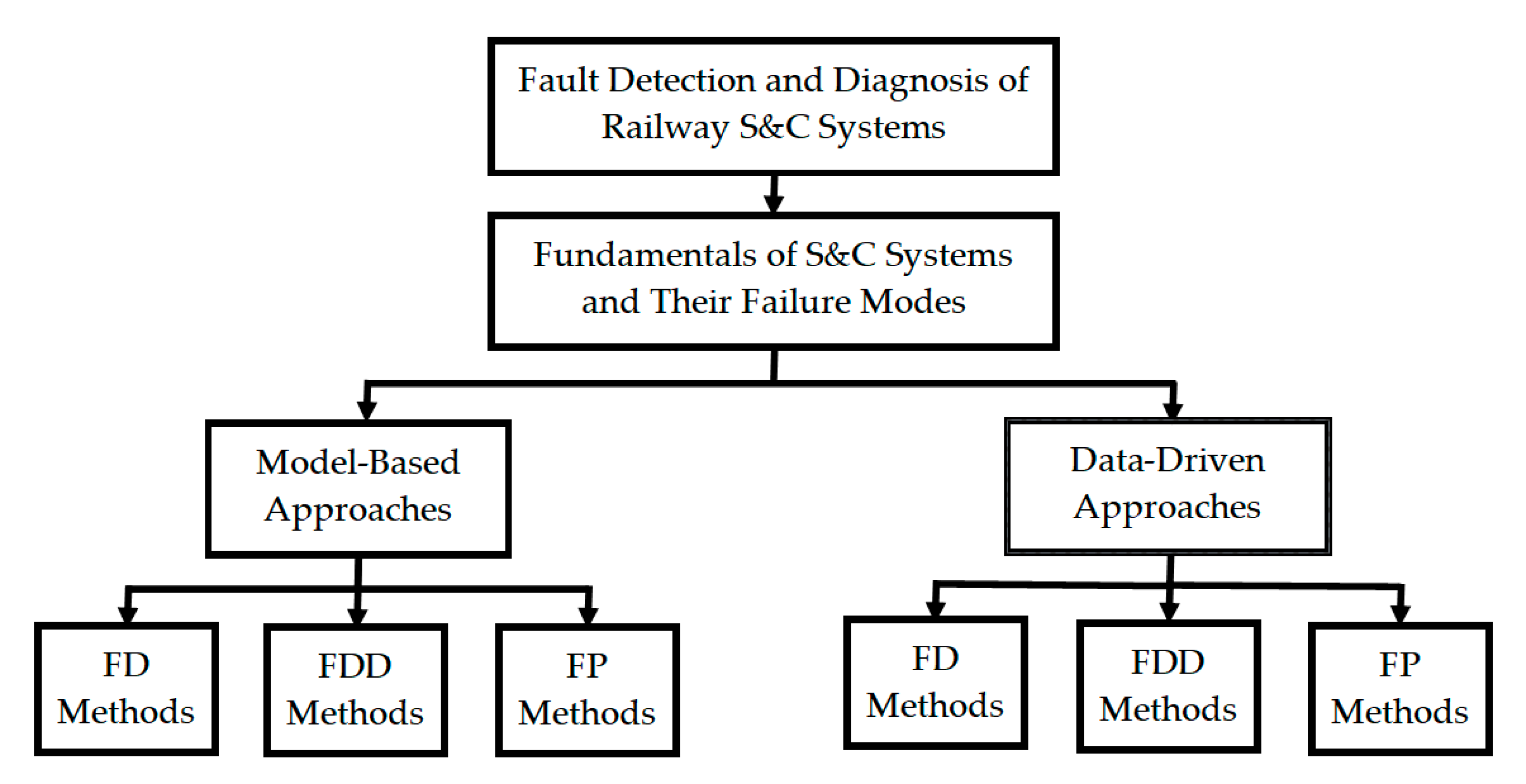

3. FDD of Railway S&C Systems

3.1. Model-Based FDD Methods for Railway S&C Systems

3.1.1. FD Methods

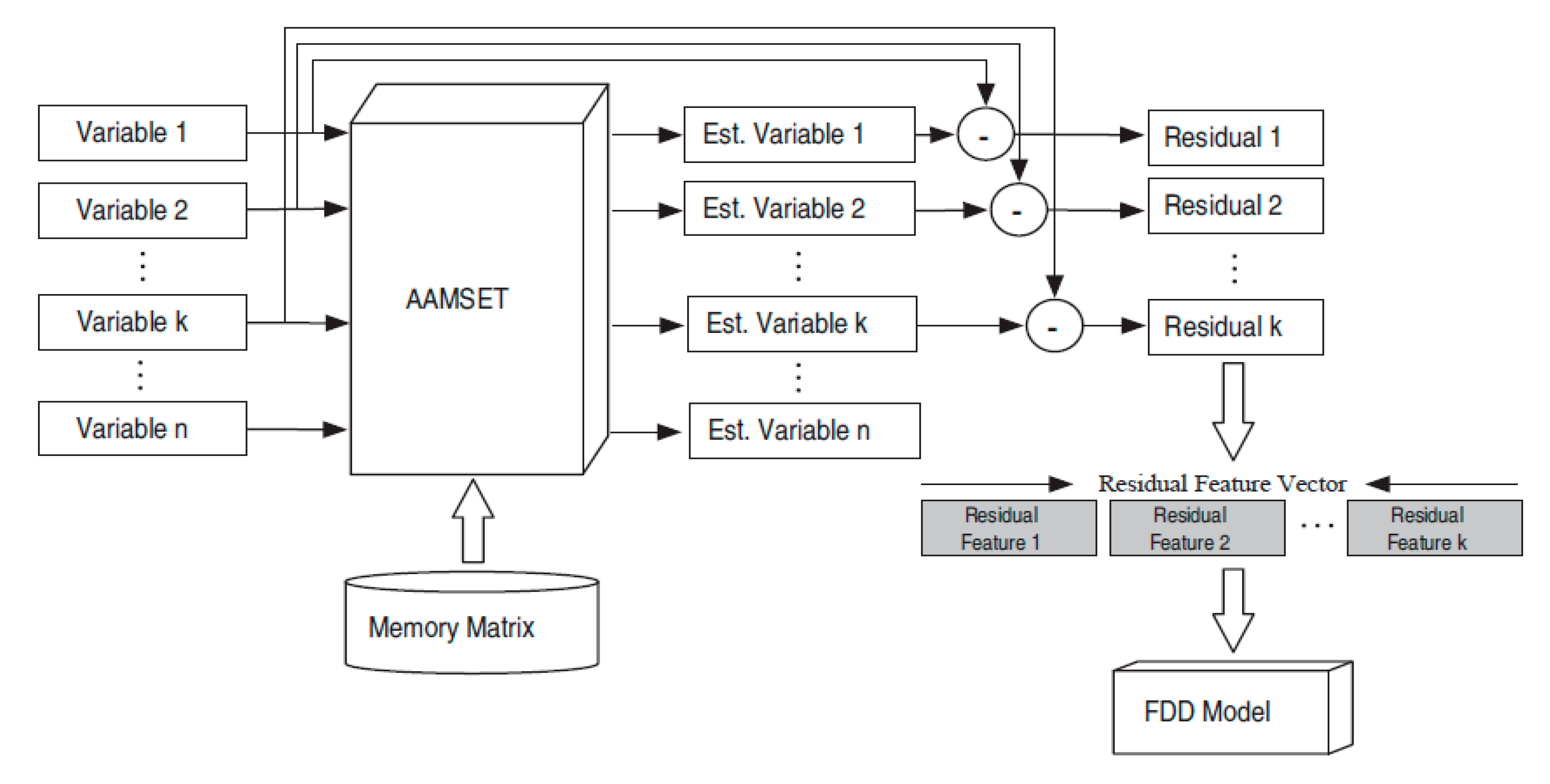

3.1.2. FDD Methods

3.1.3. FP Methods

3.2. Data-Driven FDD Methods for Railway S&C Systems

3.2.1. FD Methods

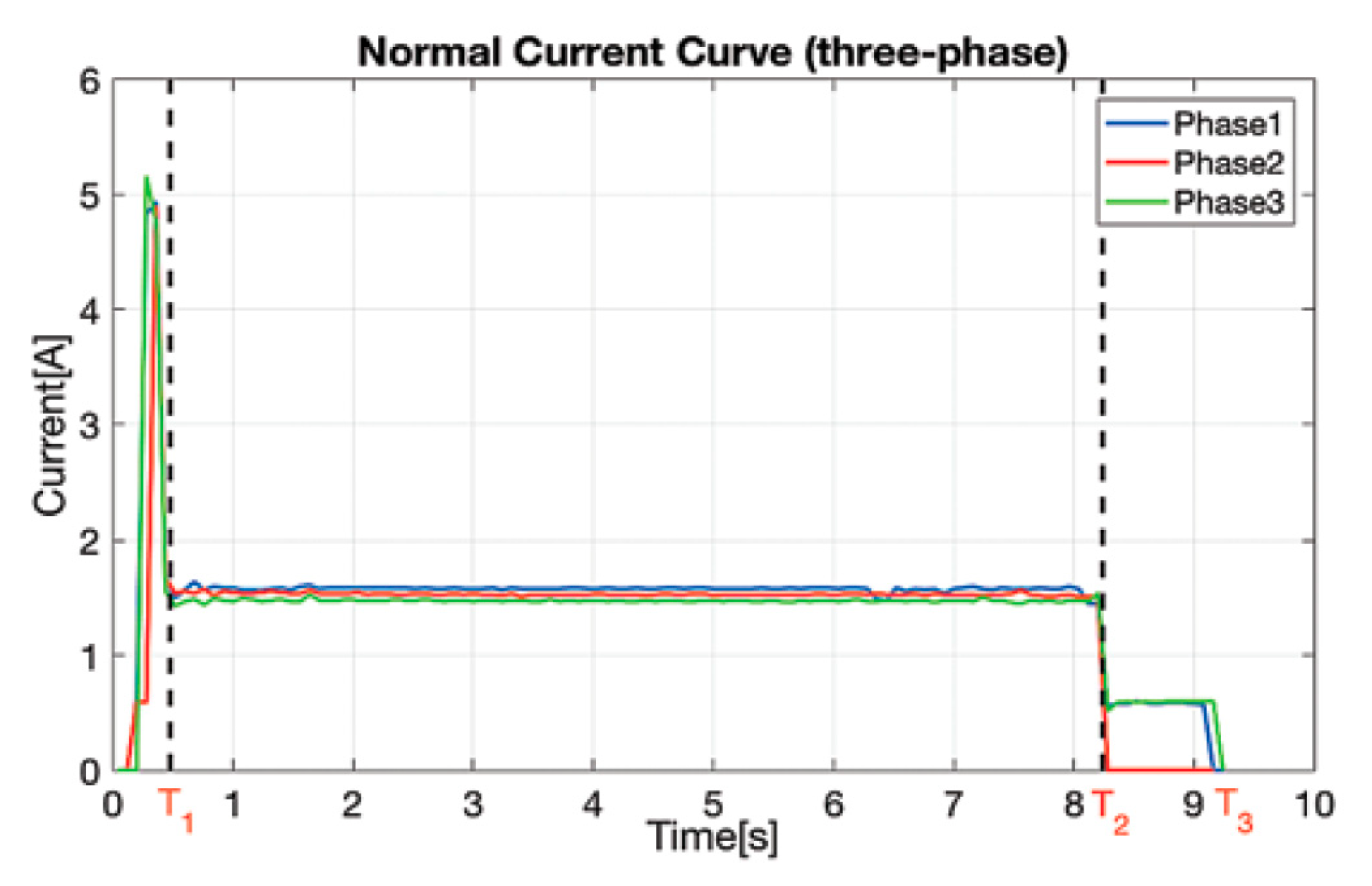

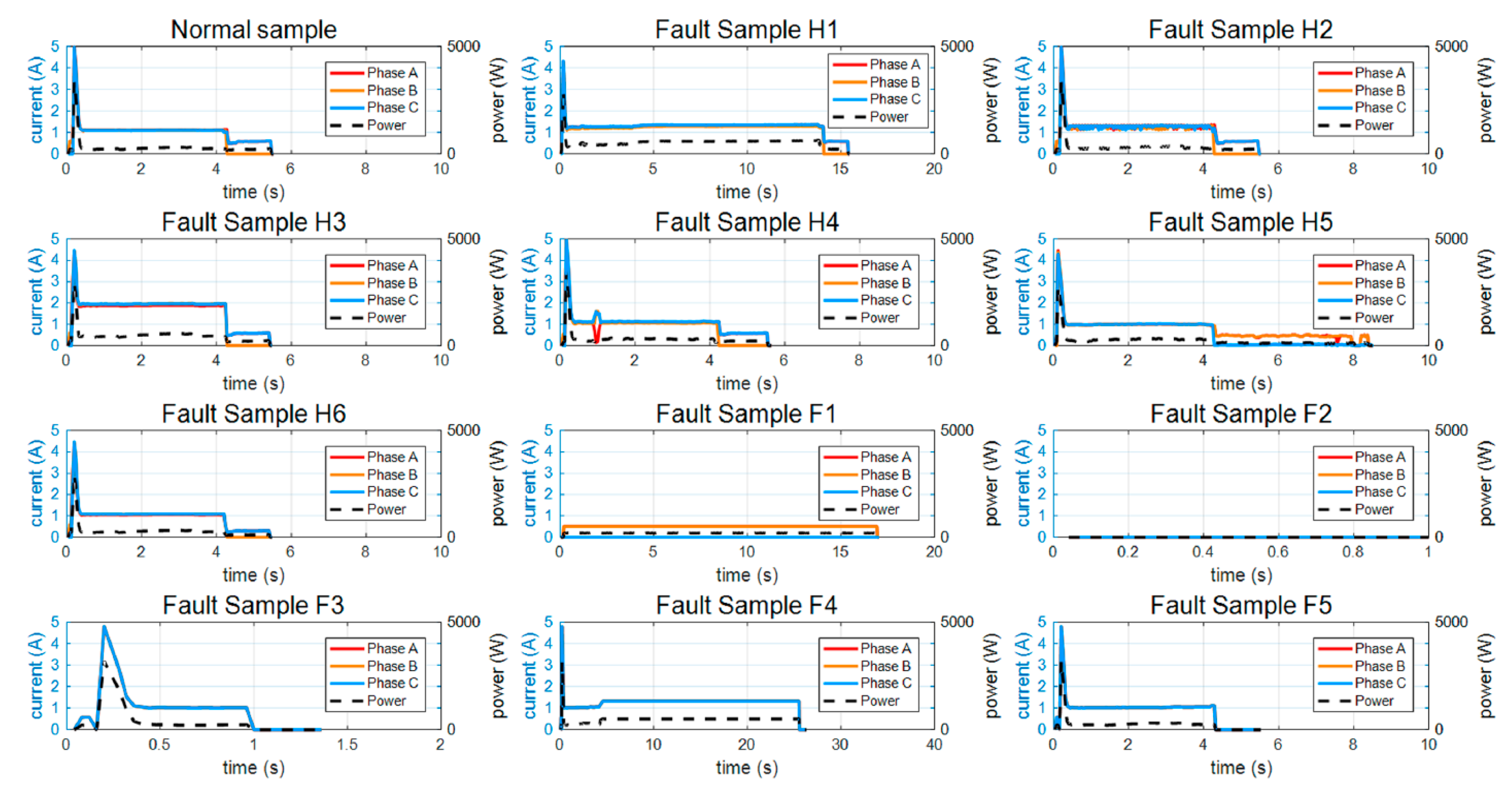

3.2.2. FDD Methods

- Phase 1 (start stage, T1): time span, maximum value, mean current value, median current value.

- Phase 2 (action stage, T2): time span, maximum current value, minimum current value, mean, median, standard deviation, peak factor, fluctuation factor.

- Phase 3 (slow release stage, T3): time span, max current value, minimum current value, mean, median, standard deviation, peak factor, fluctuation factor.

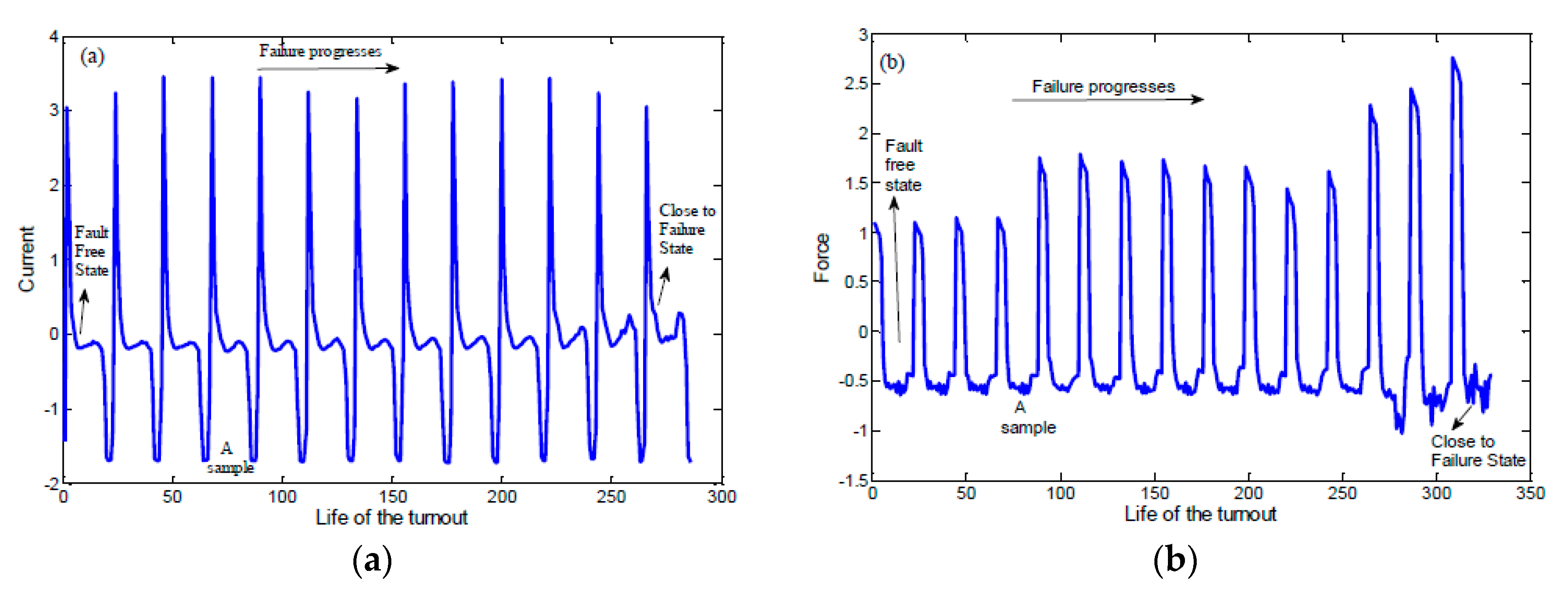

3.2.3. FP Methods

4. Summary and Concluding Remarks

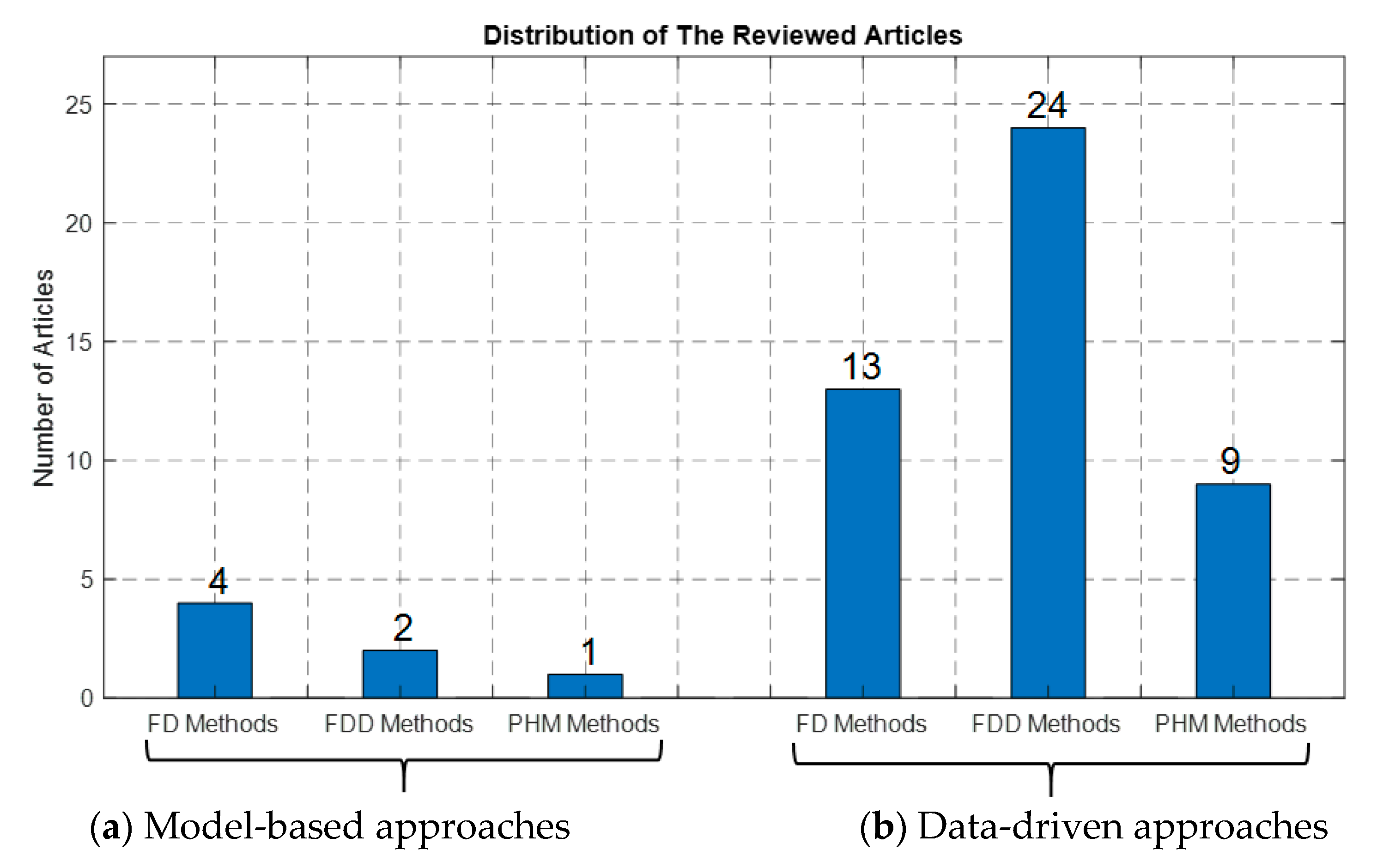

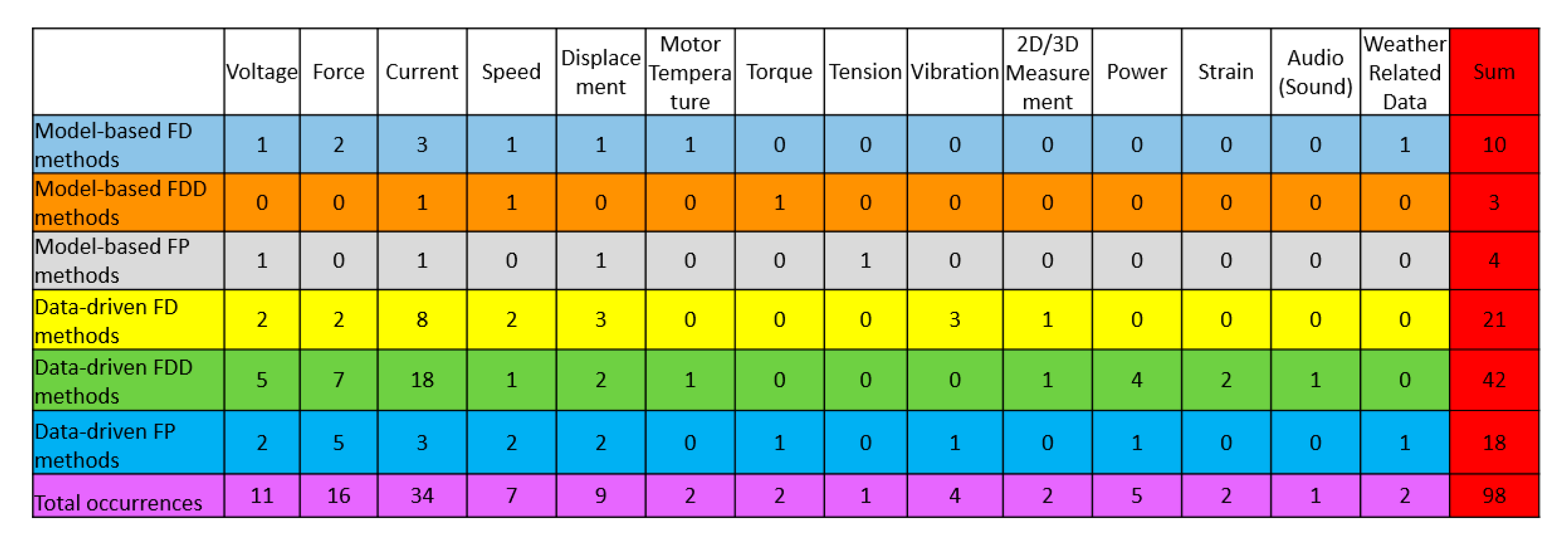

- Only six papers, as shown in Figure 18, were found that applied a model-based FDD method for railway S&C CMS, and only one paper dealt with FP using a model-based method. In addition, only a few possible fault scenarios of the S&C system were considered and tested for model-based FDD methods, mainly focusing on slide chair-related faults (i.e., dry, contaminated, excessive friction or resistance) and switch-related faults (such as stuck, bad contact with the base plate, idle, resistance, hard to release, cannot lock, or misalignments). For the PHM application in S&C systems, only a contaminated slide chair fault scenario was studied when applying a model-based method. Considering the large number of published papers and the amount of research work done in modeling a whole railway S&C system or only part (subsystem) of it, the authors anticipated finding several if not dozens of papers applying a model-based FDD method to different railway S&C systems. However, only a few papers (seven in total) were found. This is due to the several difficulties that researchers can face when trying to apply a model-based FDD method for railway S&C CMS:

- -

- the complexity of S&C systems that comes from their ramified structures makes finding an accurate enough reference model challenging.

- -

- the amount of potential failure modes and their predictability.

- -

- the different drawbacks of model-based techniques such as the fact that the accuracy of the reference model developed directly affects performance of the fault detection, diagnosis, and/or prognosis process; and that the construction of high-fidelity mathematical models from physical principles of such a complex system (i.e., railway S&C system) can become very complicated, time-consuming, and even sometimes unfeasible.

- -

- development of the model requires much prior knowledge (e.g., physical, mechanical, or electrical laws) about the real system.

- It is well known in the CMS field that if researchers can construct an accurate enough reference model, using a model-based FDD method for fault detection, diagnosis, and/or prognosis is the best choice. Thus, building and merging dynamic models of a railway S&C system as a whole or for each of its subsystems could enhance the performance of model-based FDD methods for S&C systems. However, because of the complexity of the S&C system as a whole and the diversity of its components as well as its failures, it is recommended that researchers consider incorporating those dynamic models for each of its subsystems, one by one at first, and then integrating them into a more complete model if possible. In addition, there are many model-based techniques that researchers have not used for railway S&C CMSs, and which are well known to be good solutions, such as parameter estimation methods (e.g., least square and its variants), state estimation methods (e.g., observer-based algorithms), and parity space methods (e.g., state space-based or input–output-based techniques. The benefit of considering hybrid techniques to better detect, diagnose, and/or prognose railway S&C system health conditions should not be forgotten.

- In contrast to the lack of model-based FDD methods applied for railway S&C systems, a dozen research papers were found and reviewed in this paper that applied a data-driven FDD method for railway S&C systems because they are known to be more practical since there is no need to build a reference model (i.e., less prior knowledge is required). But they do need a large amount of (historical) data, basically from the output signal(s) to extract different features (indices, criteria), for synthesizing the information available from the raw data to better represent railway S&C system health conditions.

- There are a huge number of features and data-driven FDD approaches, as reviewed by Hamadache et al. [84], that researchers are encouraged to consider and investigate to extend the fault detection, diagnosis, and/or prognosis field with application to different railway S&C systems. These are not only limited to some of the data-driven FDD methods reviewed previously (in Table 2) such as the SVM algorithm and its variants, the PCA method, the WT technique and its variants, the SOM algorithm, and the DTW method. In particular, researchers could incorporate contemporary techniques—i.e., shallow learning-based PHM (SL-based PHM) and deep learning-based PHM (DL-based PHM) techniques—especially nowadays in the age of the Internet of Things (IoT) and big data [84].

- Although several fault scenarios have been considered when applying either a model-based FDD technique or a data-driven approach, almost all are related to wear-induced faults (i.e., slide chair-related faults and/or switch-related faults). However, other possible faults (as shown in Figure 9) could be also taken into consideration, especially the electrical fault modes.

- The authors’ analysis shows that there is a clear tendency toward applying specific signals (i.e., voltage, force, current, speed, and displacement) for FD, FDD, and FP of railway S&C system health conditions, with current signal most used for FD and FDD and force signal for FP. Analyzing these signals does indeed give good results; however, there is also an opportunity for researchers to adopt other signals such as the vibration signals that are sensitive to several faults, especially those related to any mechanical or structural deterioration of the system.

- It is worth mentioning that it is beneficial if researchers also take into account the proposal and/or design of a complete new whole or part S&C model such as the REPOINT light track switch developed by Loughborough University, UK [132]. Innovative rail track switching technology has been developed and implemented on a test track, aiming to improve reliability and safety, reduce maintenance costs, and possibly reduce train delays in around 90% of point failures (2010–2013).

Author Contributions

Funding

Conflicts of Interest

References

- Apking, A. 2018 Worldwide Market for Railway Industries Study: Market Volumes for OEM Business and After-Sales Service as well as Prospects for Market Developments of Infrastructure and Rolling Stock; SCI Verkehr GmbH: Köln, Germany, 2018; p. 7. [Google Scholar]

- Gendrot, C.; Wattignies, L.; Fletcher, S. Railway Technical Strategy Europe; International Union of Railways (UIC) Communication Department-ETF: Paris, France, 2019; p. 5. [Google Scholar]

- Rail Market, SCI Verkehr GmbH. Available online: https://www.railjournal.com/in_depth/sci-study-forecasts-upturn-in-global-rail-market (accessed on 12 April 2019).

- Asada, T. Novel Condition Monitoring Techniques Applied to Improve the Dependability of Railway Point Machines. Ph.D. Thesis, University of Birmingham, Birmingham, UK, May 2013. [Google Scholar]

- CAPACITY4RAIL. D13.1–Operational Failure Modes of Switches and Crossings, SCP3-GA-2013-605650; FP7 Project, Capacity for Rail (C4R); European Commision: Brussels, Belgium, 2015. [Google Scholar]

- Rail Accident Investigation Branch. Rail Accident Report: Derailment at Grayrigg, 23 February 2007: Rail Accident Investigation Branch, Report No: 20/2008; Department for Transport: Derby, UK, 2009.

- Cornish, A.; Smith, R.A.; Dear, J. Monitoring of strain of in-service railway switch rails through field experimentation. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2016, 230, 1429–1439. [Google Scholar] [CrossRef]

- Vitásek, S.; Měšťanová, D. Life cycle cost of a railroad switch. Procedia Eng. 2017, 196, 646–652. [Google Scholar] [CrossRef]

- Zwanenburg, W. Modelling Degradation Processes of Switches & Crossings for Maintenance & Renewal Planning on the Swiss Railway Network. Ph.D. Thesis, École Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, March 2009. [Google Scholar]

- Kassa, E.; Gebretsadik, D. Analysis of failures within railway switches and crossings using failure modes and effects analysis methodology. In Proceedings of the Third International Conference on Railway Technology: Research, Development and Maintenance, Cagliari, Sardinia, Italy, 5–8 April 2016. [Google Scholar]

- Fuqing, Y. Failure Diagnostics Using Support Vector Machine. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, December 2011. [Google Scholar]

- Cheng, Y.; Zhao, H. Fault detection and diagnosis for railway switching points using fuzzy neural network. In Proceedings of the 10th Conference on Industrial Electronics and Applications (ICIEA), Auckland, New Zealand, 15–17 June 2015; pp. 860–865. [Google Scholar]

- Silmon, J.A.; Roberts, C. Improving railway switch system reliability with innovative condition monitoring algorithms. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2010, 224, 293–302. [Google Scholar] [CrossRef]

- Cornish, A.T. Life-Time Monitoring of In Service Switches and Crossings Through Field Experimentation. Ph.D. Thesis, Imperial College London, London, UK, May 2014. [Google Scholar]

- Asada, T.; Roberts, C. Improving the dependability of DC point machines with a novel condition monitoring system. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2013, 227, 322–332. [Google Scholar] [CrossRef]

- Márquez, F.P.G.; Roberts, C.; Tobias, A.M. Railway point mechanisms: Condition monitoring and fault detection. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2010, 224, 35–44. [Google Scholar] [CrossRef]

- McHutchon, M.A.; Staszewski, W.J.; Schmid, F. Signal processing for remote condition monitoring of railway points. Strain 2005, 41, 71–85. [Google Scholar] [CrossRef]

- Shih, J.Y.; Hemida, H.; Stewart, E.; Roberts, C. Understanding the impact of train run-throughs on railway switches using finite element analysis. Proc. IMechE Part F J. Rail Rapid Transit 2019, 233, 359–369. [Google Scholar] [CrossRef]

- Cope, D.L. British Railway Track: Volume 1, Switches and Crossings; Permanent Way Institution: Warley, Brentwood, UK, 2009. [Google Scholar]

- Wright, N.; Bemment, S.; Ward, C.; Dixon, R. A model of a REPOINT track switch for control. In Proceedings of the 2014 UKACC International Conference on Control, CONTROL, Loughborough, UK, 9–11 July 2014; pp. 549–554. [Google Scholar]

- Bemment, S.; Dixon, R.; Goodall, R.; Brown, S. Redundantly engineered track switching for enhanced railway nodal capacity. IFAC Proc. Vol. 2013, 46, 25–30. [Google Scholar] [CrossRef]

- IRSE. Minor Railways Section Guideline on Mechanically Operated Points. Technical Report. Available online: http://www.irse.org/minorrailways/publicdocuments/PA01-Mechanically Operated Points v2.pdf (accessed on 21 August 2019).

- Márquez, F.P.G.; Schmid, F.; Collado, J.C. A reliability centered approach to remote condition monitoring: A railway points case study. Reliab. Eng. Syst. Safe. 2003, 80, 33–40. [Google Scholar]

- Márquez, F.P.G.; Schmid, F.; Collado, J.C. Wear assessment employing remote condition monitoring: A case study. Wear 2003, 255, 1209–1220. [Google Scholar] [CrossRef]

- Chen, J.; Roberts, C. Effective condition monitoring of line side assets. In Proceedings of the 2006 IET International Conference on Railway Condition Monitoring, Birmingham, UK, 29–30 November 2006; pp. 78–83. [Google Scholar]

- Zattoni, E. Detection of incipient failures by using an H2-norm criterion: Application to railway switching points. Control Eng. Prac. 2006, 14, 885–895. [Google Scholar] [CrossRef]

- Márquez, F.P.G.; Schmid, F. A digital filter-based approach to the remote condition monitoring of railway turnouts. Reliab. Eng. Syst. Saf. 2007, 92, 830–840. [Google Scholar] [CrossRef]

- Zhou, F.; Archer, N.; Bowles, J.; Duta, M.; Henry, M.; Tombs, M.; Zamora, M.; Baker, S.; Burton, C. Remote condition monitoring and validation of railway points. Comput. Control Eng. J. 2002, 13, 221–230. [Google Scholar] [CrossRef]

- Pabst, M. Remote monitoring of points based on effective power dissipation. In Proceedings of the IEE Seminar on Condition Monitoring for Rail Transport Systems (Ref. No. 1998/501), London, UK, 10 November 1998. [Google Scholar]

- Ovali, O. Comparison of Constructional Aspects of Different Railway Point Machines. Ph.D. Thesis, Middle East Technical University, Ankara, Turkey, January 2019. [Google Scholar]

- Igarashi, Y.; Siomi, S. Development of monitoring system for electric switch machine. Q. Rep. RTRI 2006, 47, 78–82. [Google Scholar] [CrossRef][Green Version]

- Asada, T.; Roberts, C.; Koseki, T. An algorithm for improved performance of railway condition monitoring equipment: Alternating-current point machine case study. Transport. Res. C Emerg. Technol. 2013, 30, 81–92. [Google Scholar] [CrossRef]

- Siemens AG. Switchguard Surelock Points Drive System [Brochure]. Available online: https://www.mobility.siemens.com/mobility/global/SiteCollectionDocuments/en/rail-solutions/rail-automation/signaling-components/switchguard-surelock-en.pdf (accessed on 19 August 2019).

- IAD Rail Systems. High Performance Switch System, Powered by the High Performance Switch Actuator and the ‘Powerlink’ Backdrive; IAD Rail Systems, Claverham Ltd.: Bristol, UK, 2001. [Google Scholar]

- Sarmiento-Carnevali, M.L.; Harrison, T.J.; Dutta, S.; Ward, C.P.; Dixon, R. On the development of a full-scale REPOINT Light track switch. In Proceedings of the 8th International Conference on Railway Engineering (ICRE 2018), London, UK, 16–17 May 2018. [Google Scholar]

- Kaijuka, P.L.; Dixon, R.; Ward, C.P.; Dutta, S.; Bemment, S. Model-based controller design for a lift-and-drop railway track switch actuator. IEEE/ASME Trans. Mechatron. 2019. [Google Scholar] [CrossRef]

- Thales Transportation Systems GmbH. Point Machine L710H [Brochure]. Available online: https://myproducts-thales.com/brochures-documents/812-leaflet-point-machine-l710h/file (accessed on 20 August 2019).

- Bemment, S.D. Improving the Performance of Railway Track-Switching Through the Introduction of Fault Tolerance. Ph.D. Thesis, Loughborough University, Loughborough, UK, July 2018. [Google Scholar]

- Voestalpine Signaling Zeltweg GmbH. Switching Systems Standard AH950 [Brochure]. Available online: https://www.voestalpine.com/signaling/static/sites/signaling/.downloads/produkte/ah950-weichenantrieb/voestalpine_signaling_ah950_pointmachine_switchmachine.pdf (accessed on 20 August 2019).

- Dutta, S.; Harrison, T.J.; Sarmiento-Carnevali, M.L.; Ward, C.P.; Dixon, R. Modelling and controller design for self-adjusting railway track switch system. In Proceedings of the 7th Transport Research Arena (TRA), Vienna, Ausatria, 16–19 April 2018. [Google Scholar]

- Bemment, S.D.; Dixon, R.; Goodall, R. An evaluation of redundancy concepts for fault tolerant railway track switching. IFAC Proc. Vol. 2012, 8, 763–769. [Google Scholar] [CrossRef]

- Shih, J.Y.; Hemida, H.; Stewart, E.; Roberts, C.; Dixon, R.; Ward, C.P. A conceptual design for a new railway switch and crossing system. In Proceedings of the Fourth International Conference on Railway Technology: Research, Development and Maintenance, Barcelona, Spain, 3–7 September 2018. [Google Scholar]

- Oyebande, B.O.; Renfrew, A.C. Condition monitoring of railway electric point machines. IEE Proc. Elec. Power Appl. 2002, 149, 465–473. [Google Scholar] [CrossRef]

- Zhou, F.B.; Duta, M.D.; Henry, M.P.; Baker, S.; Burton, C. Remote condition monitoring for railway point machine. In Proceedings of the ASME/IEEE Joint Railroad Conference, Washington, DC, USA, 23–25 April 2002; pp. 103–108. [Google Scholar]

- Zhou, F.; Duta, M.; Henry, M.; Baker, S.; Burton, C. Condition monitoring and validation of railway point machines. In Proceedings of the ASME/IEEE Joint Railroad Conference, Washington, DC, USA, 19 April 2001; pp. 6/1–6/7. [Google Scholar]

- Institution of Railway Signal Engineers. On Mechanically Operated Points, Minor Railways Section Guideline PA01 Issue 2.0, Mechanically Operated Points Periodic Review; IRSE: London, UK, 2013. [Google Scholar]

- Rusu, M.F. Automation of Railway Switch and Crossing Inspection. Ph.D. Thesis, University of Birmingham, Birmingham, UK, December 2015. [Google Scholar]

- Rail Safety and Standards Board. Formal Inquiry: Derailment of Train 1T60, 1245 hrs Kings Cross to Kings Lynn at Potters Bar on 10 May 2002, Appendix; RSSB: London, UK, 2005; pp. 1–164. [Google Scholar]

- Baysari, M.T.; McIntosh, A.S.; Wilson, J.R. Understanding the human factors contribution to railway accidents and incidents in Australia. Accid. Anal. Prev. 2008, 40, 1750–1757. [Google Scholar] [CrossRef]

- Minde, S.I.; Jorg, L. Switch Rolling System BWG-S—Voestalpine BWG GmbH. Available online: https://www.voestalpine.com/bwg/en/products/Switch-Rolling-System-BWG-S/ (accessed on 19 August 2019).

- Bemment, S.D.; Goodall, R.M.; Dixon, R.; Ward, C.P. Improving the reliability and availability of railway track switching by analysing historical failure data and introducing functionally redundant subsystems. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2018, 232, 1407–1424. [Google Scholar] [CrossRef]

- Zwanenburg, W.J. The Swiss experience on the wear of railway switches & crossings. In Proceedings of the 7th Swiss Transport Research Conference, Monte Verità/Ascona, Switzerland, 12–14 September 2007. [Google Scholar]

- Rail Accident Investigation Branch. Rail Accident Report; RAIB: Derby, UK, 2008.

- Kande, M.; Isaksson, A.J.; Thottappillil, R.; Taylor, N. Rotating electrical machine condition monitoring automation—A review. Machines 2017, 5, 24. [Google Scholar] [CrossRef]

- Hamadache, M.; Lee, D.; Veluvolu, K.C. Rotor speed-based bearing fault diagnosis (RSB-BFD) under variable speed and constant load. IEEE Trans. Ind. Electro. 2015, 62, 6486–6495. [Google Scholar] [CrossRef]

- Isermann, R. Fault-Diagnosis Systems; Springer: Berlin, Germany, 2006; p. 20. [Google Scholar]

- Venkatasubramanian, V. A review of process fault detection and diagnosis Part I: Quantitative model-based methods. Comput. Chem. Eng. 2003, 27, 293–311. [Google Scholar] [CrossRef]

- Venkatasubramanian, V. A review of process fault detection and diagnosis Part II: Qualitative models and search strategies. Comput. Chem. Eng. 2003, 27, 313–326. [Google Scholar] [CrossRef]

- Venkatasubramanian, V. A review of process fault detection and diagnosis Part III: Process history based methods. Comput. Chem. Eng. 2003, 27, 327–346. [Google Scholar] [CrossRef]

- Kassa, E.; Nielsen, J.C.O. Dynamic interaction between train and railway turnout: Full-scale field test and validation of simulation models. Veh. Syst. Dyn. 2008, 46, 521–534. [Google Scholar] [CrossRef]

- Lagos, R.F.; Alonso, A.; Vinolas, J.; Pérez, X. Rail vehicle passing through a turnout: Analysis of different turnout designs and wheel profiles. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2012, 226, 587–602. [Google Scholar] [CrossRef]

- Guo, S.L.; Sun, D.Y.; Zhang, F.C.; Feng, X.Y.; Qian, L.H. Damage of a Hadfield steel crossing due to wheel rolling impact passages. Wear 2013, 305, 267–273. [Google Scholar] [CrossRef]

- Pålsson, B.A. Optimisation of Railway Switches and Crossings. Ph.D. Thesis, Chalmers University of Technology, Göteborg, Sweden, February 2014. [Google Scholar]

- Dos Santos, G.F.M.; Barbosa, R.S. Modeling of a railway vehicle travelling through a turnout. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2016, 230, 1397–1404. [Google Scholar] [CrossRef]

- Wiedorn, J.; Daves, W.; Ossberger, U.; Ossberger, H.; Pletz, M. Simplified explicit finite element model for the impact of a wheel on a crossing: Validation and parameter study. Tribol. Int. 2017, 111, 254–264. [Google Scholar] [CrossRef]

- Wiedorn, J.; Daves, W.; Ossberger, U.; Ossberger, H.; Pletz, M. Finite element model for predicting the initiation of subsurface damage in railway crossings: A parametric study. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2018, 233, 614–628. [Google Scholar] [CrossRef]

- Wiedorn, J.; Daves, W.; Ossberger, U.; Ossberger, H.; Pletz, M. Numerical assessment of materials used in railway crossings by predicting damage initiation: Validation and application. Wear 2018, 414–415, 136–150. [Google Scholar] [CrossRef]

- Sun, Y.Q.; Colea, C.; Boyd, P. A numerical method using VAMPIRE modelling for prediction of turnout curve wheel–rail wear. Wear 2011, 271, 482–491. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, F.; Qian, L. Numerical simulation of stress and deformation in a railway crossing. Eng. Fail. Anal. 2011, 18, 2296–2304. [Google Scholar] [CrossRef]

- Johansson, A.; Pålsson, B.; Ekh, M.; Nielsen, J.C.O.; Ander, M.K.A.; Brouzoulis, J.; Kassa, E. Simulation of wheel–rail contact and damage in switches & crossings. Wear 2011, 271, 472–481. [Google Scholar]

- Xin, L.; Markine, V.L.; Shevtsov, I.Y. Numerical analysis of rolling contact fatigue crack initiation and fatigue life prediction of the railway crossing. In Proceedings of the 10th International Conference on Contact Mechanics CM2015, Colorado Springs, CO, USA, 30 August–3 September 2015. [Google Scholar]

- Nielsen, J.C.O.; Pålsson, B.A.; Torstensson, P.T. Switch panel design based on simulation of accumulated rail damage in a railway turnout. Wear 2016, 366–367, 241–248. [Google Scholar] [CrossRef]

- Kolitsch, S.; Gänsera, H.; Pippan, R. Damage tolerance concepts for railway switch components. Struct. Integ. Procedia 2017, 4, 95–105. [Google Scholar] [CrossRef]

- Márquez, F.P.G.; Tercero, D.J.P.; Schmid, F. Unobserved component models applied to the assessment of wear in railway points: A case study. Eur. J. Oper. Res. 2007, 176, 1703–1712. [Google Scholar] [CrossRef]

- Wang, G.; Xu, T.; Tang, T.; Yuan, T.; Wang, H. A Bayesian network model for prediction of weather-related failures in railway turnout systems. Expert Syst. Appl. 2017, 69, 247–256. [Google Scholar] [CrossRef]

- Hamadache, M.; Dutta, S.; Ambur, R.; Olaby, O.; Stewart, E.; Dixon, R. Residual-based fault detection method: Application to railway switch & crossing (S&C) system. In Proceedings of the 19th International Conference on Control, Automation and Systems (ICCAS 2019), ICC Jeju, Jeju, Korea, 15–18 October 2019. in press. [Google Scholar]

- Liu, X. High speed switch switching equipment problems and their solutions. Pop. Sci. Technol. 2006, 2, 126–127. [Google Scholar]

- Feng, L. Analysis of speed-up switch faults through current curve on microcomputer monitoring system. Railw. Signal. Commun. Eng. 2011, 1, 73–75. [Google Scholar]

- Xue, F. Find hidden trouble of high speed switch and diagnose the faults using the microcomputer monitoring. Shanghai Railw. Sci. Technol. 2011, 4, 48–49. [Google Scholar]

- Shi, Z.; Liu, Z.; Lee, J. An auto-associative residual based approach for railway point system fault detection and diagnosis. Measurement 2018, 119, 246–258. [Google Scholar] [CrossRef]

- Hines, J.W.; Seibert, R.; Usynin, A. Technical Review of On-Line Monitoring Techniques for Performance Assessment; United States Nuclear Regulatory Commission: Rockville, MD, USA, 2016; Volume 2. [Google Scholar]

- Güçlü, A.; Yılboga, H.; Eker, O.F.; Camci, F.; Jennions, I. Prognostics with autoregressive moving average for railway turnouts. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, Portland, OR, USA, 10–16 October 2010. [Google Scholar]

- Sobhani-Tehrani, E.; Khorasani, K. Fault Diagnosis of Nonlinear Systems Using a Hybrid Approach, Lecture Notes in Control and Information Sciences; Springer: New York, NY, USA, 2009; p. 39. [Google Scholar]

- Hamadache, M.; Jung, J.H.; Park, J.; Youn, B.D. A comprehensive review of artificial intelligence-based approaches for rolling element bearing PHM: Shallow & deep learning. JMST Adv. 2019, 1, 125–151. [Google Scholar] [CrossRef]

- Hamadache, M.; Lee, D.; Mucchi, E.; Dalpiaz, G. Vibration-based bearing fault detection and diagnosis via image recognition technique under constant and variable speed conditions. Appl. Sci. 2018, 8, 1392. [Google Scholar] [CrossRef]

- Adachi, H.; Kikuchi, M.; Watanabe, Y. Electric switch machine failure detection using data-mining technique. Q. Rep. RTRI 2006, 47, 182–186. [Google Scholar] [CrossRef][Green Version]

- Márquez, F.P.G.; Pedregal, D.J. Applied RCM2 algorithms based on statistical methods. Int. J. Autom. Comput. 2007, 4, 109–116. [Google Scholar] [CrossRef]

- Zoll, A.; Luke, D. Diagnosis and State Monitoring of Junctions, Crossings, Cross Roads or Rail Joints by Means of a Rail Vehicle. US Patent N. US 7,539,596 B2, 4 March 2010. [Google Scholar]

- Atamuradov, V.; Camci, F.; Baskan, S.; Sevkli, M. Failure diagnostics for railway point machines using expert systems. In Proceedings of the 2009 IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Cargese, France, 31 August–3 September 2009. [Google Scholar]

- Eker, O.F.; Camci, F.; Kumar, U. Failure diagnostics on railway turnout systems using support vector machines. In Proceedings of the 1st International Workshop and Congress on eMaintenance, Luleå, Sweden, 22–24 June 2010; pp. 22–24. [Google Scholar]

- Kaewunruen, S. Monitoring structural deterioration of railway turnout systems via dynamic wheel/rail interaction. Case Stud. Nondestr. Test. Eval. 2014, 1, 19–24. [Google Scholar] [CrossRef]

- Wei, Z.; Núñez, A.; Li, Z.; Dollevoet, R. Evaluating degradation at railway crossings using axle box acceleration measurements. Sensors 2017, 17, 2236. [Google Scholar] [CrossRef]

- Márquez, G.F.P.; Pedregal, D.J.; Roberts, C. Time series methods applied to failure prediction and detection. Reliab. Eng. Syst. Safe. 2010, 95, 698–703. [Google Scholar]

- Ardakani, H.D.; Lucas, C.; Siegel, D.; Chang, S.; Dersin, P.; Bonnet, B.; Lee, J. PHM for railway system—A case study on the health assessment of the point machines. In Proceedings of the 2012 IEEE Conference on Prognostics and Health Management, Detroit, MI, USA, 8–10 June 2012. [Google Scholar]

- Bolbolamiri, N.; Sanai, M.S.; Mirabadi, A. Time-domain stator current condition monitoring: Analyzing point failures detection by Kolmogorov-Smirnov (K-S) test. WASET Int. J. Elec. Comp. Eng. 2012, 6, 587–592. [Google Scholar]

- Vileiniskis, M.; Remenyte-Prescott, R.; Rama, D. A fault detection method for railway point systems. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2016, 230, 852–865. [Google Scholar] [CrossRef]

- Alessi, A.; Piero La-Cascia, P.; Lamoureux, B.; Pugnaloni, M.; Dersin, P. Health assessment of railway turnouts: A case study. In Proceedings of the Third European Conference of the Prognostics and Health Management Society, Bilbao, Spain, 5–8 July 2016. [Google Scholar]

- Wright, N.P.; Gan, R.; McVae, C. Software and machine learning tools for monitoring railway track switch performance. In Proceedings of the 7th IET Conference on Railway Condition Monitoring 2016 (RCM 2016), Birmingham, UK, 27–28 September 2016. [Google Scholar]

- Bryan, K.J.; Solomon, M.; Jensen, E.; Coley, C.; Rajan, K.; Tian, C.; Mijatovic, N.; Kiss, J.M.; Lamoureux, B.; Dersin, P.; et al. Classification of rail switch data using machine learning techniques. In Proceedings of the 2018 Joint Rail Conference, Pittsburgh, PA, USA, 18–20 April 2018. [Google Scholar]

- Güçlü, A.; Yilboga, H.; Eker, O.F.; Camci, F. Classification of uncertain data streams using modified k-nearest neighbor method: A case study on railway turnouts. In Proceedings of the International Symposium on Innovations in Intelligent SysTems and Applications, Kayseri, Turkey, 21–24 June 2010. [Google Scholar]

- Asada, T.; Roberts, C. Development of an effective condition monitoring system for AC point machines. In Proceedings of the 5th IET Conference on Railway CM and Non-Destructive Testing (RCM 2011), Derby, UK, 29–30 November 2011. [Google Scholar]

- Márquez, F.P.G.; Muñoz, J.M.C. A pattern recognition and data analysis method for maintenance management. Int. J. Syst. Sci. 2012, 43, 1014–1028. [Google Scholar] [CrossRef]

- Böhm, T. Accuracy improvement of condition diagnosis of railway switches via external data integration. In Proceedings of the 6th European Workshop on Structural Health Monitoring, German Aerospace Center, Institute of Transportation Systems, Braunschweig, Germany, 3–6 July 2012. [Google Scholar]

- Eker, O.F.; Camci, F.; Kumar, U. SVM based diagnostics on railway turnouts. Int. J. Perform. Eng. 2012, 8, 289–298. [Google Scholar]

- Mo, X.; Fang, Y.; Yang, Y. Method on the fault detection and diagnosis for the railway turnout based on the current curve of switch machine. Appl. Mech. Mater. 2013, 427–429, 1022–1027. [Google Scholar] [CrossRef]

- Zhang, K.; Du, K.; Ju, Y. Algorithm of railway turnout fault detection based on PNN neural network. In Proceedings of the Seventh International Symposium on Computational Intelligence and Design, Hangzhou, China, 14–15 December 2014; pp. 545–547. [Google Scholar] [CrossRef]

- Zhang, K. The railway turnout fault diagnosis algorithm based on BP neural network. In Proceedings of the 2014 IEEE International Conference on Control Science and Systems Engineering, Yantai, China, 29–30 December 2014; pp. 135–138. [Google Scholar] [CrossRef]

- Jin, W.; Shi, Z.; Siegel, D.; Dersin, P.; Douziech, C.; Pugnaloni, M.; Cascia, P.L.; Lee, J. Development and evaluation of health monitoring techniques for railway point machines. In Proceedings of the 2015 IEEE Conference on Prognostics and Health Management (PHM), Austin, TX, USA, 22–25 June 2015. [Google Scholar] [CrossRef]

- Lee, J.; Choi, H.; Park, D.; Chung, Y.; Kim, H.; Yoon, S. Fault detection and diagnosis of railway point machines by sound analysis. Sensors 2016, 16, 549. [Google Scholar] [CrossRef]

- Zhou, F.; Xia, L.; Dong, W.; Sun, X.; Yan, X.; Zhao, Q. Fault diagnosis of high-speed railway turnout based on support vector machine. In Proceedings of the 2016 IEEE International Conference on Industrial Technology (ICIT), Taipei, Taiwan, 14–17 March 2016; pp. 1539–1544. [Google Scholar] [CrossRef]

- Kim, H.; Sa, J.; Chung, Y.; Park, D.; Yoon, S. Fault diagnosis of railway point machines using dynamic time warping. Electron. Lett. 2016, 52, 818–819. [Google Scholar] [CrossRef]

- Kollment, W.; O’Leary, P.; Harker, M.; Oßberger, U.; Eck, S. Towards condition monitoring of railway points: Instrumentation, measurement and signal processing. In Proceedings of the IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Taipei, Taiwan, 20–23 May 2016; pp. 612–617. [Google Scholar] [CrossRef]

- Oßberger, U.; Kollment, W.; Eck, S. Insights towards condition monitoring of fixed railway crossings. Procedia Struct. Integ. 2017, 4, 106–114. [Google Scholar] [CrossRef]

- Huang, S.; Zhang, F.; Yu, R.; Chen, W.; Hu, F.; Dong, D. Turnout fault diagnosis through dynamic time warping and signal normalization. J. Adv. Transport. 2017, 2017, 3192967. [Google Scholar] [CrossRef]

- Ou, D.; Tang, M.; Xue, R.; Yao, H. Hybrid fault diagnosis of railway switches based on the segmentation of monitoring curves. Ekspl. Niezawodn. Maint. Reliab. 2018, 20, 514–522. [Google Scholar] [CrossRef]

- Huang, S.; Yang, X.; Wang, L.; Chen, W.; Zhang, F.; Dong, D. Two-stage turnout fault diagnosis based on similarity function and fuzzy c-means. Adv. Mech. Eng. 2018, 10, 1–12. [Google Scholar] [CrossRef]

- Ou, D.; Xue, R.; Cui, K. A data-driven fault diagnosis method for railway turnouts. Transport. Res. Rec. 2019, 2673, 448–457. [Google Scholar] [CrossRef]

- Hamadache, M.; Lee, D. Principal component analysis based signal-to-noise ratio improvement for inchoate faulty signals: Application to ball bearing fault detection. Int. J. Control Autom. Syst. 2017, 15, 506–517. [Google Scholar] [CrossRef]

- Hamadache, M.; Lee, D. Improving signal-to-noise ratio (SNR) for inchoate fault detection based on principal component analysis (PCA). In Proceedings of the 14th International Conference on Control, Automation and Systems (ICCAS 2014), KINTEX, Seoul, South Korea, 22–25 October 2014; pp. 561–566. [Google Scholar]

- Matei, I.; Kleer, J.D.; Feldman, A.; Zhenirovskyy, M.; Rai, R. Classification based diagnosis: Integrating partial knowledge of the physical system. In Proceedings of the Annual Conference of the PHM Society 2019, Scottsdale, AZ, USA, 21–26 September 2019. [Google Scholar]

- Yilboga, H.; Eker, Ö.F.; Güçlü, A.; Camci, F. Failure prediction on railway turnouts using time delay neural networks. In Proceedings of the 2010 IEEE International Conference on Computational Intelligence for Measurement Systems and Applications, Taranto, Italy, 28 October 2010. [Google Scholar] [CrossRef]

- Eker, O.F.; Camci, F.; Güçlü, A.; Yilboga, H.; Sevkli, M.; Baskan, S. A simple state-based prognostic model for railway turnout systems. IEEE Trans. Ind. Electron. 2011, 58, 1718–1726. [Google Scholar] [CrossRef]

- Maulik, U.; Bandyopadhyay, S. Performance evaluation of some clustering algorithms and validity indices. IEEE Trans. Pattern Anal. Mach. Intell. 2002, 24, 1650–1654. [Google Scholar] [CrossRef]

- Eker, O.F.; Camcia, F. State-based prognostics with state duration information. Qual. Reliab. Eng. Int. 2013, 29, 465–476. [Google Scholar] [CrossRef]

- Letot, C.; Dersin, P.; Pugnaloni, M.; Dehombreux, P.; Fleurquin, G.; Douziech, C.; La-Cascia, P. A data driven degradation-based model for the maintenance of turnouts: A case study. IFAC PapersOnLine 2015, 48, 958–963. [Google Scholar] [CrossRef]

- Marugán, A.P.; Márquez, F.P.G. A novel approach to diagnostic and prognostic evaluations applied to railways: A real case study. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2016, 230, 1440–1456. [Google Scholar] [CrossRef]

- Camci, F.; Eker, O.F.; Baskan, S.; Konur, S. Comparison of sensors and methodologies for effective prognostics on railway turnout systems. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2016, 230, 24–42. [Google Scholar] [CrossRef]

- Böhm, T. Remaining useful life prediction for railway switch engines using classification techniques. Int. J. Progn. Health Manag. 2017, 8, 1–15. [Google Scholar]

- Márquez, F.P.G.; Pliego, A.; Lorente, J.; Trapero, J. A new ranking approach for decision making in maintenance management. Lect. Notes Electr. Eng. 2014, 241, 27–38. [Google Scholar]

- Atamuradov, V.; Medjaher, K.; Camci, F.; Dersin, P.; Zerhouni, N. Degradation-level assessment and online prognostics for sliding chair failure on point machines. IFAC PapersOnLine 2018, 51, 208–213. [Google Scholar] [CrossRef]

- Sysyn, M.; Nabochenko, O.; Kovalchuk, V.; Gruen, D.; Pentsak, A. Improvement of inspection system for common crossings by track side monitoring and prognostics. Struct. Monit. Maint. 2019, 6, 219–235. [Google Scholar]

- REPOINT: Innovative Rail Track Switching Technology with the Potential to Improve Reliability and Safety, Reduce Maintenance Costs, and Boost Capacity on Rail Networks. Available online: https://www.lboro.ac.uk/enterprise/repoint/ (accessed on 29 May 2019).

| Actuation Mechanism | Actuation Type | Reference |

|---|---|---|

| Mechanical | Manual | [22] |

| Electromechanical | HW | [23,24] |

| P80 | [25,26] | |

| Style 63 | [27,28] | |

| S700K | [29,30] | |

| NTS-type | [31,32] | |

| SURELOCK | [33] | |

| High-performance switch system (HPSS) | [34] | |

| REPOINT | [20,35,36] | |

| Hydraulic/electrohydraulic | L700H, L710H | [37] |

| Clamplock | [19,38] | |

| AH90 | [39] |

| Approach | Application | Method(s) Used | Signals (Sensors) Acquired | Faults Type(s) Considered |

|---|---|---|---|---|

| Model-based approaches | FD methods [10,74,75,76] | KF combined with FIS algorithm and ML approach [74]; Bayesian network model [75]; Monte Carlo simulation [75]; accumulative residual based method [76]. | Voltage [74,76]; force [74,76]; current [10,74,76]; weather-related data (e.g., date, min and max temperature, wind speed) [75]; motor temperature [75]; speed [76]; linear position of the switch rails [76]. | Slide chair-related faults (i.e., dry, contaminated, excessive friction or resistance) [74,75,76]; switch-related faults (i.e., stuck, bad contact with the base plate, idle, resistance, hard to release, cannot lock, misalignments) [75]. |

| FDD methods [12,80] | Fuzzy neural network algorithm [12]; AAR technique (i.e., AAMSET approach) [80]. | Current [12]; speed [80]; torque [80]. | Slide chair-related faults (i.e., dry, contaminated, excessive friction or resistance) [12,80]; switch-related faults (i.e., stuck, bad contact with the base plate, idle, resistance, hard to release, cannot lock, misalignments) [12,80]. | |

| FP methods [82] | ARMA model [82]. | Voltage; force; current; tension; distance between the stock rail and switch rail; linear position of the switch rails [82]. | Slide chair-related faults (only contaminated slide chair fault) [82]. | |

| Data-driven approaches | FD methods [86,87,88,89,90,91,92,93,94,95,96,97,98,99] | SVM with Gaussian kernel [90]; OCSVM [96]; SOM technique [97]; PCA [94]; data-mining techniques [86]; harmonic regression and VARMA [93]; K-S test [95]; DTW [89]; GNB [98]; LSTM and DWST [99]. | Voltage [86,96]; force [87,90]; current [86,90,92,93,95,96,98]; speed [88,90]; vibration [88,94,97]; linear position of the switch rails [90]; maneuver information [96]; GPS [97]; 3D measurements [97], pressure [98]. | Slide chair-related faults [87,93,95]; wear in junction, crossing [88,97]; drive rod out of adjustment [89,90]; obstacles (hard or soft) [93,96]; structural deterioration [94]; crushed cables [95]; switch-related faults [86,91,92,96]; switch hard to release [98]; sensor fault [98]. |

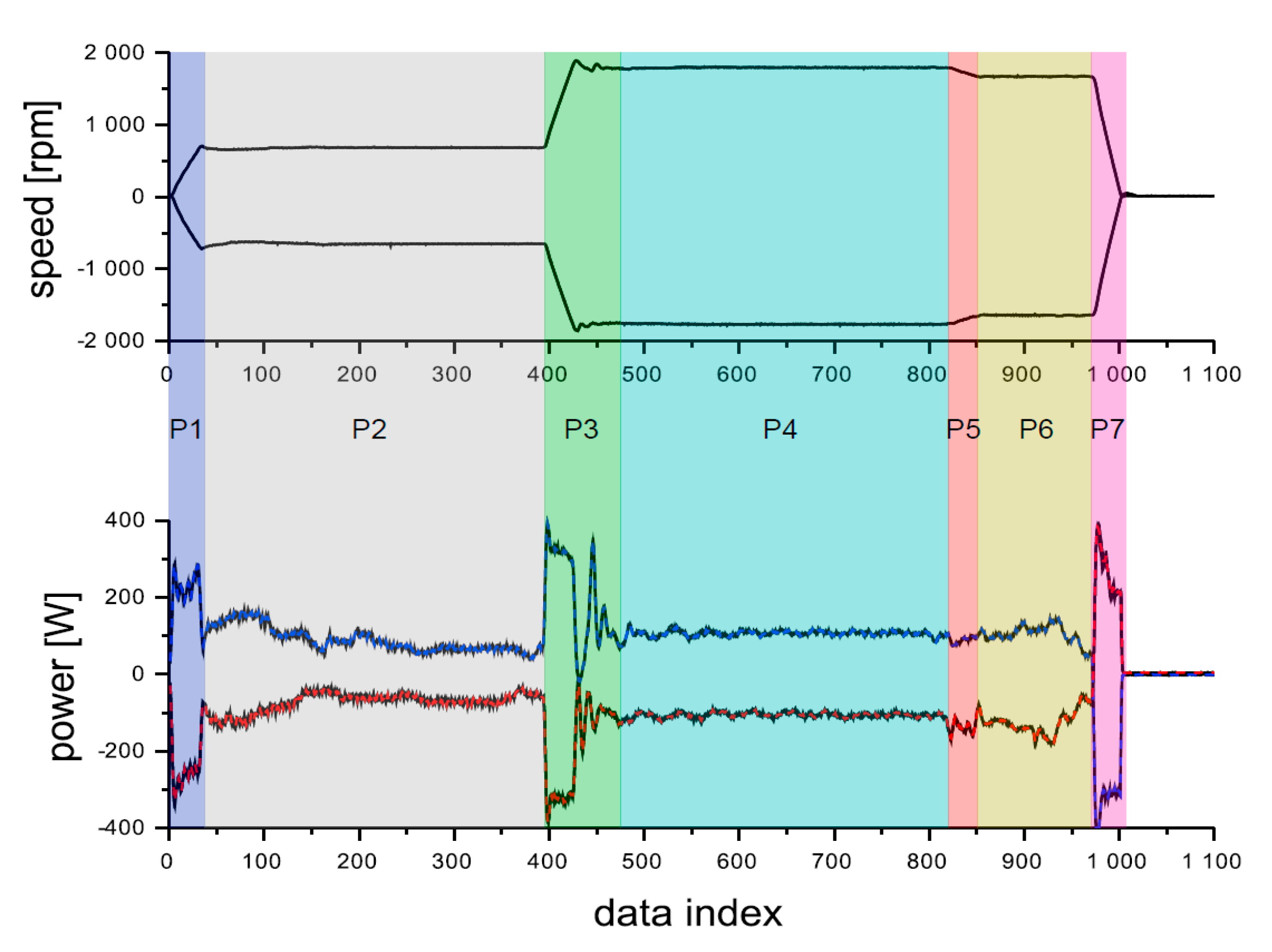

| FDD methods [11,13,15,28,34,100,101,102,103,104,105,106,107,108,109,110,111,112,113,114,115,116,117,120] | PCA [102,117]; SVM [11,104,105,110]; SVM combined with other algorithms (e.g., PCA, envelope, etc.) [15,101,117]; wavelet transform (WT) and its variants (e.g., CWT and discrete WT (DWT)) [15,101]; DTW [111,112,114,115]; SOM [108]; backpropagation (BP) neural network (NN) [107]; probabilistic NN (PNN) [106]; 3D reconstruction [113]; k-nearest neighbor method [100]; fuzzy c-mean [116]; qualitative trend analysis (QTA) [13]; ANN [103]; BLT and NN [120]. | Voltage [15,100,101,104,108]; force [13,15,34,100,101,102,120]; current [13,15,28,100,101,102,103,105,106,107,108,110,111,114,115,116,117]; power [11,34,117,120]; strain signal [110,113]; switch displacement [13]; linear position of the switch rails [104]; motor temperature [108]; audio signal (sound sensor) [117]; 2D measurements [113]; speed [120]. | Wear in crossing [113]; switch-related faults [105,106,107,110,111,112,114,117]; slide chair-related faults [109,117]; startup circuit disconnection (bad contact) [106,107,114,115,117]; actuator is not flexible [114,115]; abnormal fluctuations [115]; electric relay switch failure [115]; mechanical jam fault [117]; abnormal impedance [117]; lack of motor lubrication [11]; overdriven and underdriven [13,15,34,101]; drive rod out of adjustment [104]; motor deblocking [107]; obstacles (hard or soft) [108,120]; left and right misaligned adjuster bolts [120]; missing bearings [120]. | |

| FP methods [121,122,124,125,126,127,128,130,131] | ANN and TDNN algorithms [121]; SSBP method [122]; SBPD technique [124]; mean active power index and Monte Carlo simulation [125]; fault tree analysis (i.e., BDD approach) [126]; ANN and SVM [128]; k-mean clustering and double exponential function [130]; MODWPT, SE, and Lasso [131]. | Voltage [122,127]; force [121,122,124,127,130]; current [121,122,127]; linear position of the switch rails [122,127]; distance between the stock rail and switch rail [122,127]; speed [125,127]; torque [125]; power [128]; weather-related data (e.g., temperature and humidity) [128], vibration [131]. | Electromechanical S&C failure degradation [121,122,124,125,127,130]; electromechanical S&C failure degradation focusing on dry slide chair failure mode [122,124,127,130]; M63 point machine failure degradation [126]; S700K electromechanical engine failures [128]. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hamadache, M.; Dutta, S.; Olaby, O.; Ambur, R.; Stewart, E.; Dixon, R. On the Fault Detection and Diagnosis of Railway Switch and Crossing Systems: An Overview. Appl. Sci. 2019, 9, 5129. https://doi.org/10.3390/app9235129

Hamadache M, Dutta S, Olaby O, Ambur R, Stewart E, Dixon R. On the Fault Detection and Diagnosis of Railway Switch and Crossing Systems: An Overview. Applied Sciences. 2019; 9(23):5129. https://doi.org/10.3390/app9235129

Chicago/Turabian StyleHamadache, Moussa, Saikat Dutta, Osama Olaby, Ramakrishnan Ambur, Edward Stewart, and Roger Dixon. 2019. "On the Fault Detection and Diagnosis of Railway Switch and Crossing Systems: An Overview" Applied Sciences 9, no. 23: 5129. https://doi.org/10.3390/app9235129

APA StyleHamadache, M., Dutta, S., Olaby, O., Ambur, R., Stewart, E., & Dixon, R. (2019). On the Fault Detection and Diagnosis of Railway Switch and Crossing Systems: An Overview. Applied Sciences, 9(23), 5129. https://doi.org/10.3390/app9235129