2.1. Overall Methodology

As long-term weather forecasts become increasingly uncertain, plans should be revised and extended continuously to stay reliable. Therefore, methods from the field of control theory, in particular, the Model Predictive Control (MPC) scheme, offer suitable tools to achieve this continuous adaptation. While other heuristic or metaheuristic optimization schemes can be found in the current literature on renewable energies (e.g. [

35]), only very few directly include feedback loops that are required to deal with uncertainty. The overall proposed methodology classifies as a predictive-reactive approach. For the reactive component, the methodology relies on a combination of a continuous rescheduling (MPC) with recourse actions. The continuous rescheduling is used to reduce the complexity of the overall problem to smaller prediction horizons. Semi-robust, predictive plans are calculated by estimating disturbances, i.e., dynamic operation times due to changing weather conditions to avoid a high number of recourse actions. In contrast to robust scheduling approaches, the proposed methodology does not assume the worst case but tries to make realistic assumptions based on provided weather forecasts.

Generally, MPC is used for the short-term control of continuous systems to cope with unanticipated or indescribable dynamics. Examples of such applications are robot motion control and collision avoidance [

36], production control [

34,

37], supplier management [

38], or energy and building management [

39]. Further information on examples, implementations, and MPC, in general, can be found, e.g., in [

40]. Nevertheless, the general scheme also applies to planning scenarios with longer time horizons.

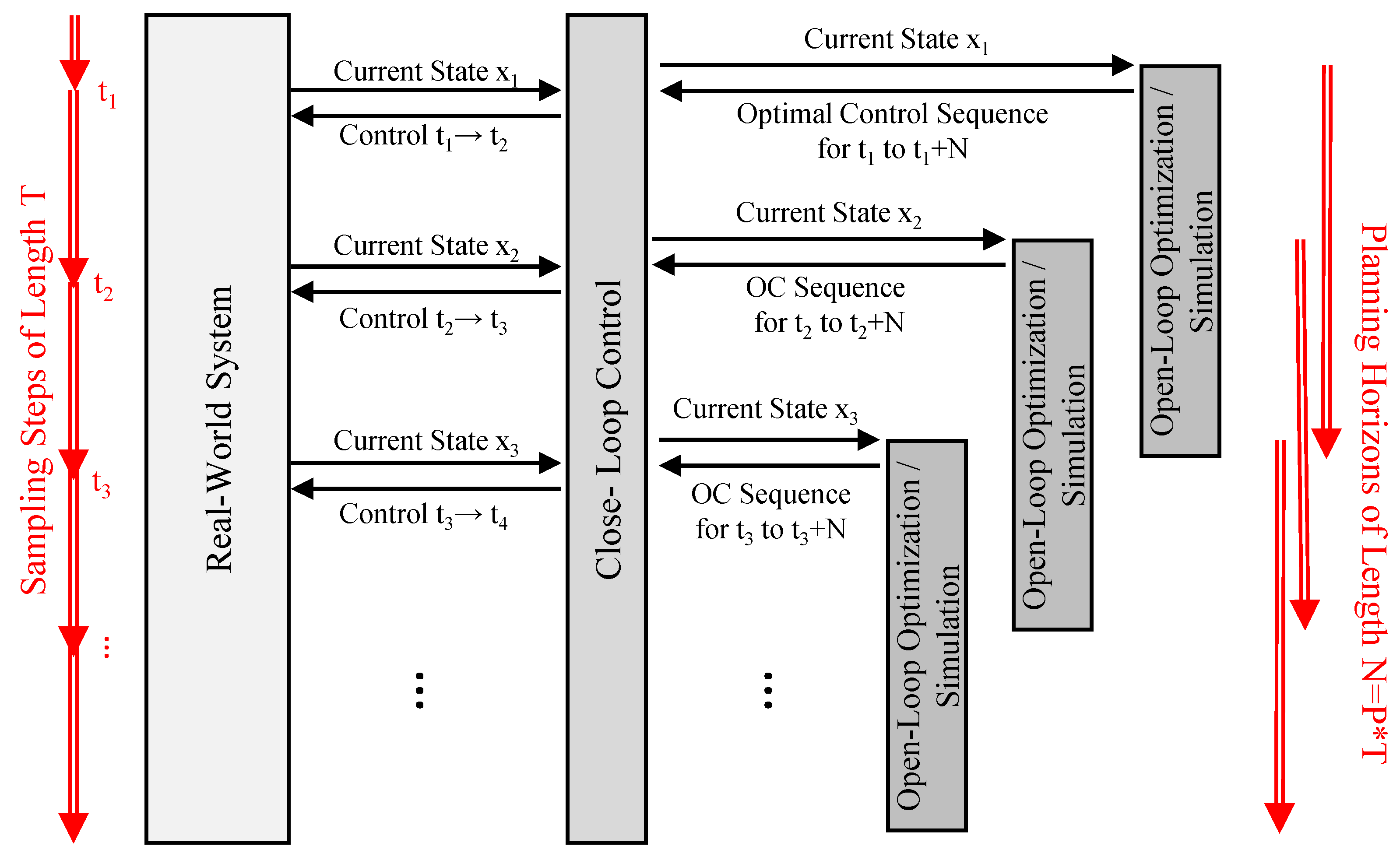

The MPC scheme applies a combination of two connected control loops, as depicted in

Figure 2. The closed loop tethers to the controlled, real-world system. At distinct sampling instance

, the closed loop measures the current state of the real-world system denoted as state

. These sampling instances are distributed according to the sampling step size

T. Afterward, the state gets forwarded to the open-loop optimization. This optimization uses so-called system models to estimate events and responses in the real-world system, and tries to obtain an optimal control sequence

for a simulated prediction horizon

with

P denoting the number of planning periods of length

T. The algorithm then passes this sequence back to the closed-loop control, which extracts the first control

for the current sampling instance

and applies it to the real-world system. As time progresses and reaches the next sampling instance

, the cycle starts over by measuring the current state of the system

and thus, by evaluating the effects of the provided control.

The MPC scheme provides a viable baseline for the implementation of a decision-support system. It thereby implements the monitoring policy by selecting suitable values for the sampling step size, whereas the state defines all values that must be measured and monitored. In terms of the scheduling of offshore operations, the decision-support system should monitor deviations from a given plan/schedule. As the open loop already provides an optimized plan, deviations can be recognized quickly. As an intervention policy, this approach devises new schedules as recourse action, reacting to deviations by incorporating them into a new plan.

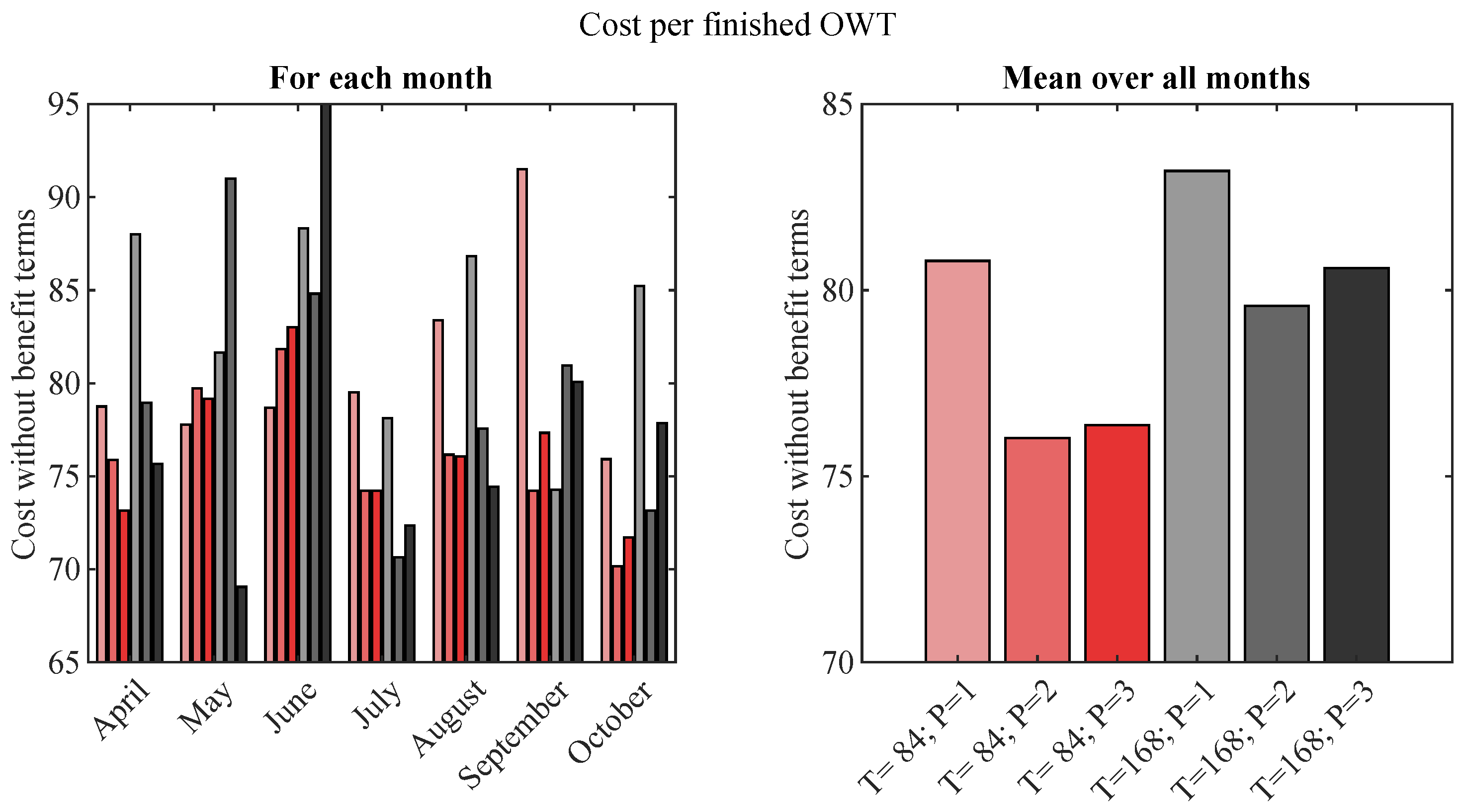

Where, for most common applications, the sampling step size

T is only a few seconds or less, the adaptation of the MPC to the scheduling of offshore operations allows for substantially longer horizons. For this article,

T is chosen as either 84 or 168 h, i.e., one week. The prediction horizon is generally varied between

h (one week) and

h (three weeks), as explained in more depth in

Section 2.3. Due to the long horizons, each control subsumes a set of operations to be conducted within the corresponding week, thus representing a plan. Therefore, the control for the next sampling step size is considered a short-term plan, while the open loop’s optimal control sequence can be considered a mid- to long-term plan depending on the choice of

P. As each plan consists of several operations, the realization of this plan is prone to failure. For the described scheduling problem, the primary source of dynamics stems from uncertainties in weather forecasts, and thus from uncertainties about the real duration of operations. In this context, a plan fails if an operation finishes too early or if it takes so long that follow-up operations cannot commence in time. Thus, plans may fail or finish before the next sampling instance. In the context of a decision-support system, it is a viable assumption that information on plan failures is available to the system. Moreover, as operations take a long time, it can be assumed that deviations from the plan can be anticipated early enough, to devise a new plan, i.e., to implement recourse actions. Therefore, the algorithm loosens the notion of sampling instances for this application. Instead of representing discrete time steps, a new sampling instance, and thus a new planning iteration, is initiated each time a plan finishes or fails. Nevertheless, every single plan aims to have a length equal to the sampling step size

T for the closed loop or the corresponding prediction horizon

N for the open loop.

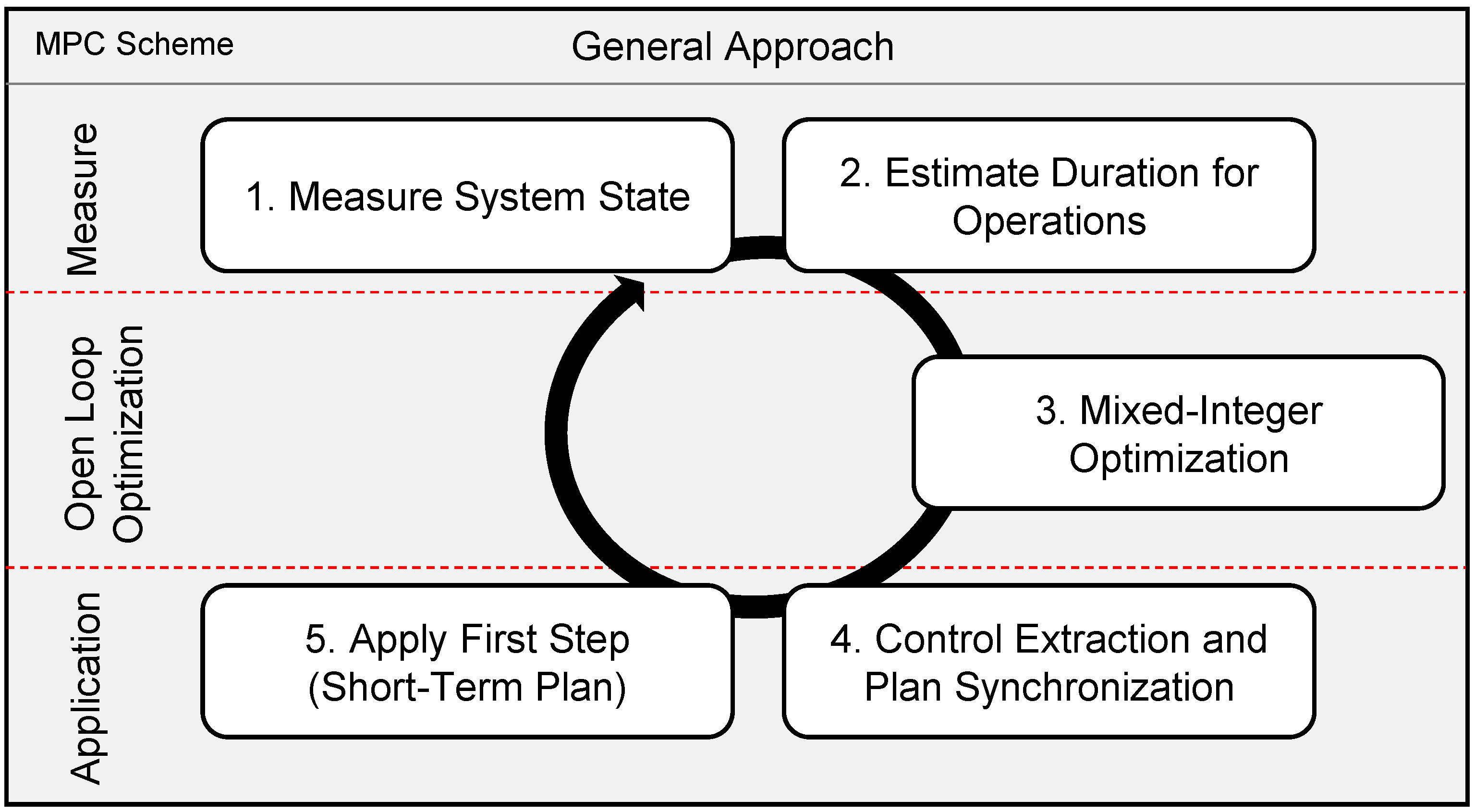

Following the MPC scheme, the proposed approach consists of five steps, which apply to each sampling instance, as depicted in

Figure 3. First, the current state of the real-world system is measured. This measurement includes updating the state of vessels, the number of built turbines, and weather forecasts. The second step estimates the duration of offshore operations for a prediction horizon

N. Using this information, the third step creates a plan using a Mixed-Integer Linear Program during the open-loop optimization and returns this plan to the closed loop. The closed loop extracts a short-term plan of length

T and calculates when the next sampling instance should occur if everything goes according to plan in step four. Finally, as the last step, the algorithm applies this plan to the real-world system.

For this article, we simulate the real-world system based on historical weather records. These records cover 50 years of hourly measurements of the wind speed and the wave height in Germany’s Northern Sea. As only measurements are available, the following evaluations simulate weather forecasts according to the stated accuracy given in

Section 1.1. Consequently, the following subsections also include descriptions of how these forecasts are simulated and how the state is updated based on a simulated real-world system. For a real-world application, these steps can be omitted or simplified.

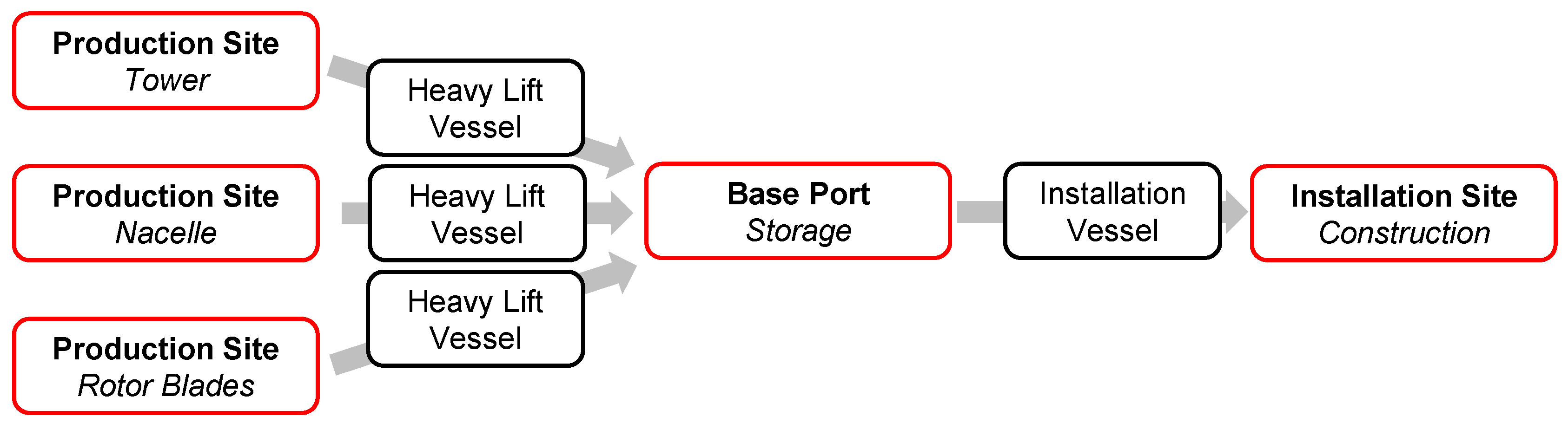

2.2. First Step: Representation of the State and Simulation of Weather Forecasts

The state comprises general information about the installation process and the current problem instance. The latter particularly subsumes information about the current date, the number, position, and loading state of vessels, the number of turbines to build, and the number of finished turbines. Additionally, the state contains general information, e.g., about costs or capacities required for the optimizer as given in

Table 2 and information on the duration and restrictions of the considered operations. As described in

Section 1.1, the installation of a wind turbine occurs sequentially from bottom to top. This sequentiality allows simplifying the planning problem by applying aggregate operations, effectively reducing the number of considered operations from 12 to 4. While the basic operations given in

Table 1 directly refer to tasks given in the process description, the aggregate operations, given in

Table 3, subsume sequences of basic operations. Therefore, the operation

Load OWT is comprised of the loading of one tower, one nacelle, three blades, and one hub. The operation

Install OWT subsumes the operations:

position at foundation,

jack-up,

install tower,

install nacelle, 3×

install blade,

install hub, and finally

jack-down.

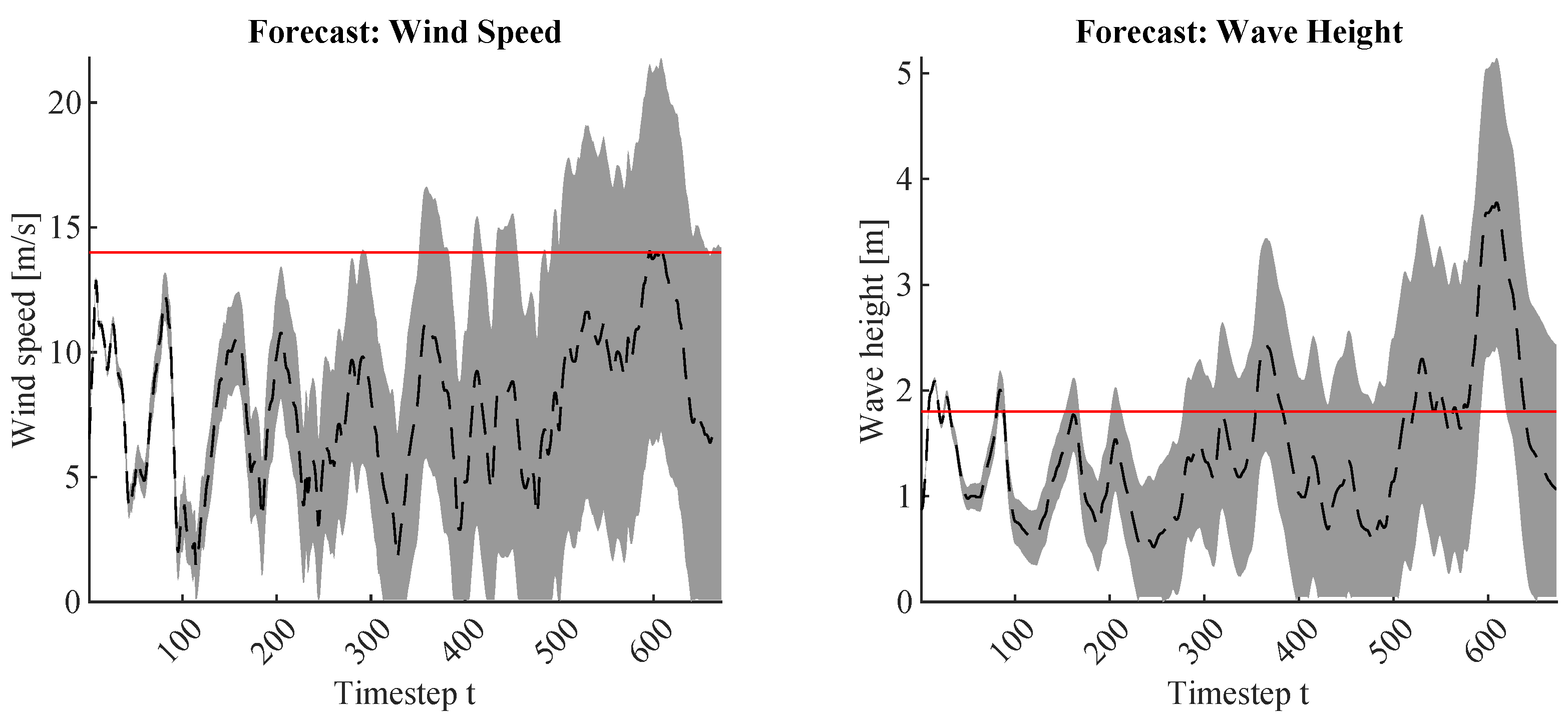

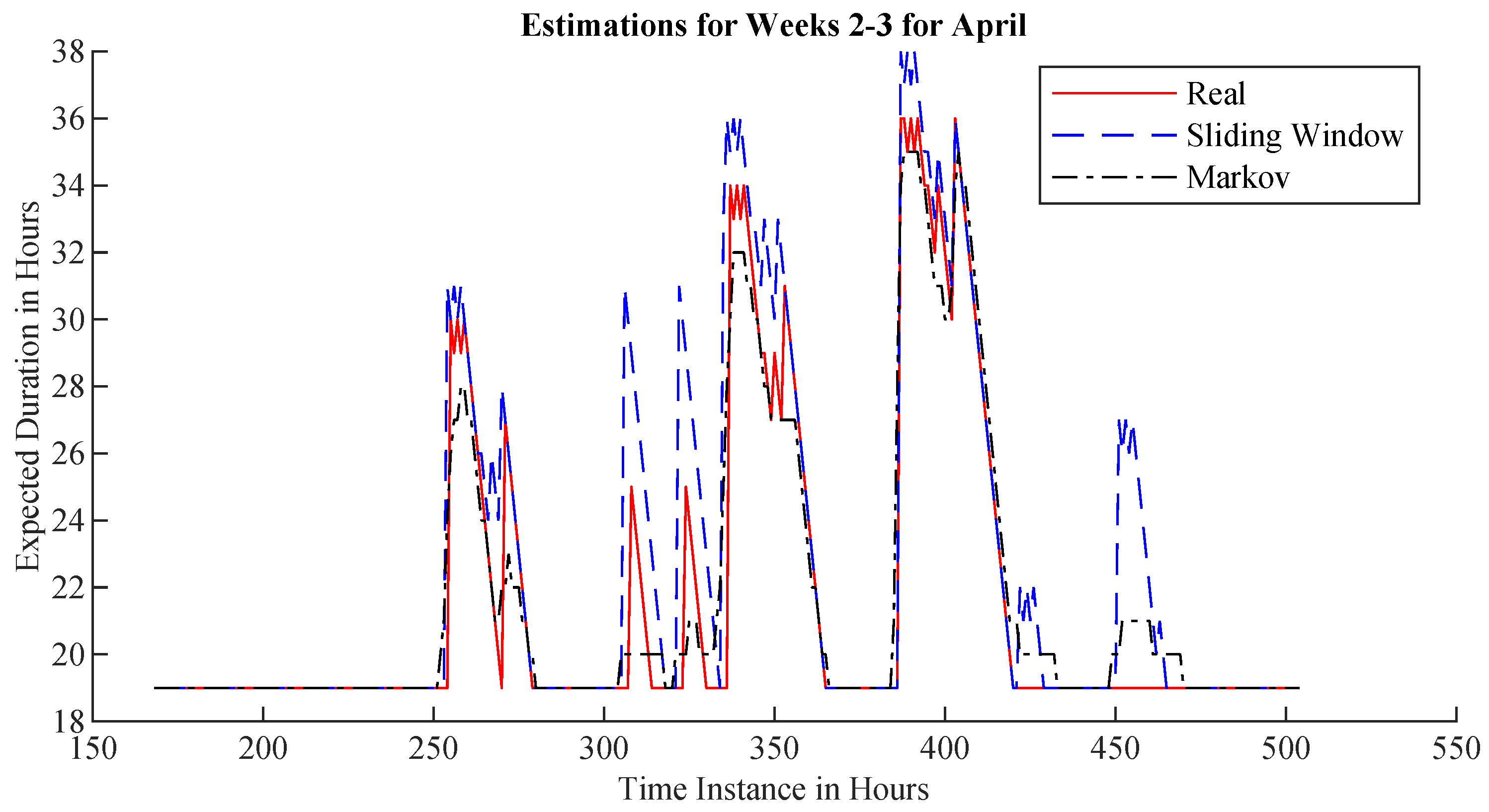

Finally, the state comprises the current weather forecast given as an interval of probable values for the wave height and wind speed for each hour within the prediction horizon

N. As for this article, no real-world forecasts are available, forecasts are simulated from historical weather records as proposed in [

9]. Compared to the original proposal, the forecast uncertainty has been adapted to provide more realistic assumptions. Therefore it is assumed that the uncertainty

starts at 0.0 for the current time instance, reaches 0.25 at 168 h into the future, and from there quickly increases to 0.65 at 336 h, 0.95 at 504 h, and from there increases even faster. The simulation first determines the average wind speed

and wave height

over the prediction horizon

N. Afterward, for each time instance, the simulation obtains the measured values

and

from the historical recordings. Finally, the simulation acquires the forecast interval by multiplying the average values with the uncertainty and then adding/subtracting this value from the measurement:

and

.

Figure 4 shows the measurements as a black, dotted line and the generated intervals as gray areas for each hour of a forecasting horizon of three weeks. Additionally, the figure denotes the limits for a jack-up operation as a red line. The figure shows that the intervals strictly conform to the measured values in the beginning but begin to broaden quite quickly. As a result, larger proportions of the forecast intervals exceed the limits. This increase effectively reduces the probability of meeting these limits further into the forecast.

2.4. Third Step: MILP Formulation for the Incremental Scheduling of Offshore Operations

After preprocessing the weather forecasts to obtain an estimation of the duration for each aggregate operation at each time instance, the open loop calculates a plan for the prediction horizon

N. As can be seen from the state of the art, several possible formulations and approaches exist for this task. Following the assumptions given in

Section 2.1, i.e., that plans cover about a week or even more and that deviations can be anticipated comparably early due to the long duration of operations, this article proposes to exploit these extended time frames and to strive for exact mathematical solutions. Consequently, this section proposes a Mixed-Integer Linear Program for the scheduling. As this article considers multiple vessels with equal capabilities, a Flexible JSSP formulation is selected. According to the classification in

Section 1.3, there exist three basic formulations: a precedence-based formulation, a sequence-based formulation, or a time-indexed formulation. Whereas time-indexed formulations are the slowest to compute, they provide several advantages over the other formulations for this application. On the one hand, it is possible to directly make use of varying processing times, i.e., to directly include the estimated duration for aggregate operations. For sequence-based formulations, this is hard to achieve due to their abstract representation of time. On the other hand, a time-indexed formulation can easily be parameterized to obtain plans for a predetermined time frame, i.e., the prediction horizon

N. This is very hard to formulate for precedence-based models. Such models index the scheduling problem over the number of operations, and thus, always must schedule all operations. For the proposed incremental approach, this will be impossible in most of the cases, as forecasts only remain reliable for comparably short forecast horizons. Therefore, the optimizer might not be able to schedule all operations within the prediction horizon, rendering the problem infeasible. For time-indexed models, the problem can be reformulated to instruct the optimizer to schedule as many operations as possible within the prediction horizon, favoring incremental approaches.

As stated before, the Mixed-Integer formulation used in this article is an extension to the one used in [

9]. This article extends the formulation to handle multiple installation vessels and by constraints, which limit the number of available loading bays in the base port. Moreover, it presents a modification to the overall formulation, which includes so-called penalty terms. These terms, e.g., provide benefits for finishing an operation early, to reduce the model’s symmetry, and to speed up the optimization.

Table 2 in

Section 1.6 provides an overview of the relevant model parameters and variables.

The model aims to minimize the cost function

J given in Equation (

1) under consideration of the constraints given in Equations (

2)–(

15). The MILP optimizes a plan for the prediction horizon

N determined by the sampling step size

T and the previously defined number of planning periods

P as

(c.f.

Section 2.1. Cost function

J sums the cost for vessels being offshore, fuel cost for traveling between the site and base port, and hourly costs for port operations. Therefore, it sums each occurrence of such an operation and, respectively, every hour a vessel is offshore and multiplies these sums with the associated costs (first line of Equation (

1)). It is advised to choose different costs for each vessel to reduce model symmetry. Even if the same vessels are applied, a small offset should be added to render some vessels slightly less favorable to the optimizer, e.g., by adding just 0.1 to the costs of vessel two, 0.2 to vessel three, and so forth. This offset guarantees that the plans are not interchangeable between vessels. Moreover, small offsets only have a marginal impact on the overall cost. Additionally, the cost function applies three different penalty terms (second line of Equation (

1)). The first term assigns a bonus

(negative cost) for each finished OWT. The other two terms assign an increasing bonus

the earlier an operation finishes during the prediction horizon. Therefore, the cost function first normalizes the finish time of an operation over

N to be between 0 and 1 and then inverts this value by subtracting one from it. Finally, this value is multiplied with

and added to the penalty term. For non-installation operations, this bonus is scaled down to prevent the optimizer from favoring shorter operations over longer ones, i.e., to prevent it from fully loading the vessel to get this bonus when it would be possible to finish installation tasks instead. These two penalty terms aim to reduce the symmetry of the model, as described later.

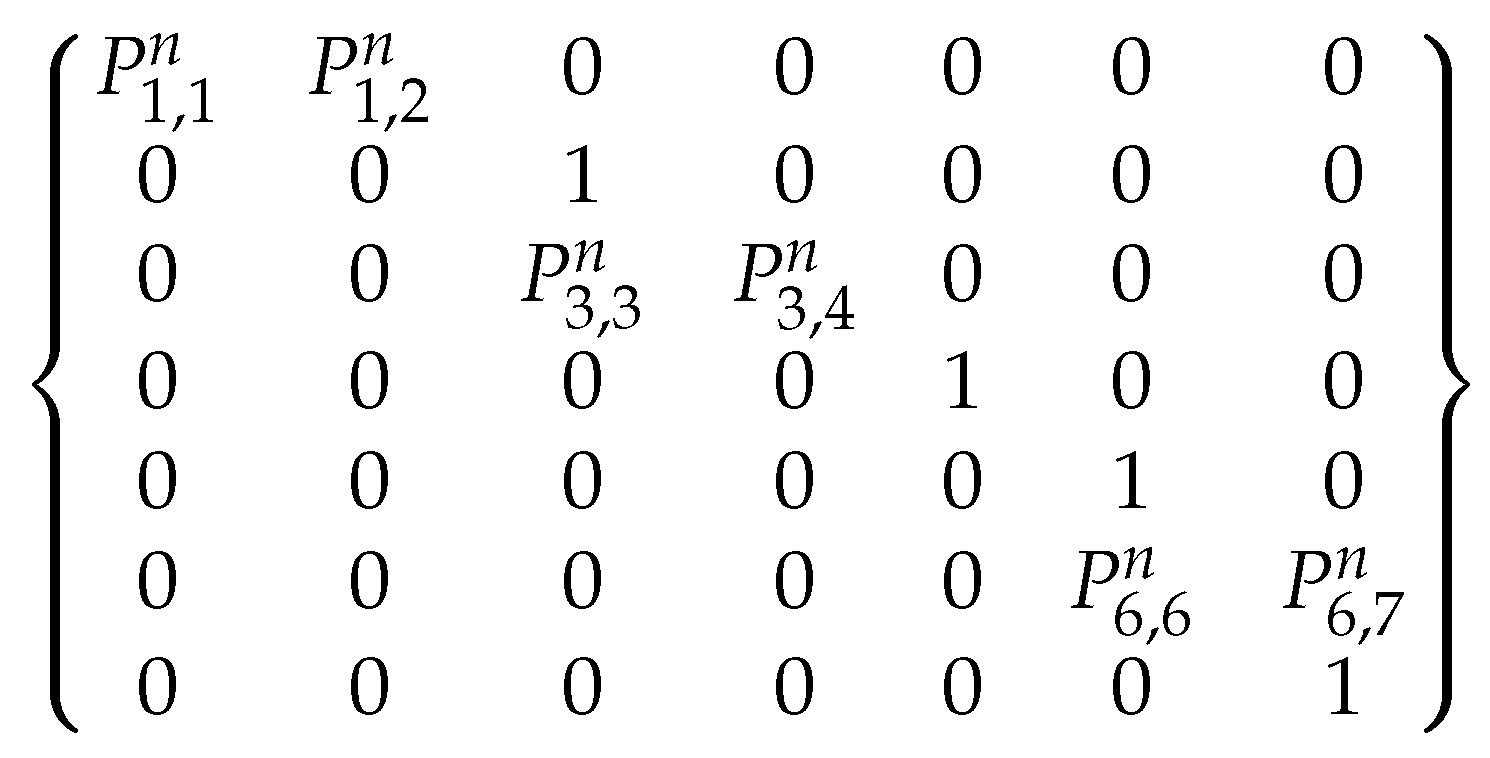

As the model uses an hourly, time-indexed formulation over several vessels, all decision and support variables have the dimensions of with V being the number of applied installation vessels and N representing the prediction horizon in hours. The extended model uses four binary decision variables , , , instead of only one in the original model. These denote if a specific vessel starts an aggregate operation of the given type (install OWT, load components, move to port, move to site) at a given time instance . Whereas these variables could be summarized as a single variable that is indexed over the operation, the model and the resulting code remain easier readable and maintainable by using distinct variables. Additionally, the model uses a total of six support variables, which directly depend on the four decision variables. These variables generally denote ongoing events. For example, if an installation is started, the MILP notes this as part of the decision variable . Additionally, it denotes the ongoing installation process using the dependent support variable . Moreover, this support variable records the duration of all ongoing operations, i.e., loading, movement and installation operations.

The variables

, and

record the position and amount of currently loaded components for each vessel at each time instance. Therefore, constraints (

2) and (

4) use a very similar formulation. For example, these constraints denote the capacity as equal to the last time step plus one for a started loading operation and minus one for a commenced installation operation. Additionally, they constrain the capacity by a specified maximum capacity

by constraint (

3). The location is formulated similarly but refers to movement operations instead. As both constraints rely on the previous time instance, the MILP contains additional constraints for the first time instance in a similar fashion. Instead of referring to the previous instance, these constraints use an initial value provided to the optimizer instead.

The support variables

, and

track if a specific vessel is generally busy and, additionally, if it is currently performing a loading operation at the base port. Constraints (

5)–(

9) record these durations. Constraints (

5)–(

8) thereby mark the corresponding entries in

for

to

for the corresponding vessel

v and the scheduled operation

o. This indicates that no other operation can be scheduled during this period (c.f. Constraint (

10)). As can be seen from this formulation, the constraints do not mark the time instance

k itself, as this is already marked in the corresponding decision variables. Consequently, these constraints also subtract one hour from the duration. In contrast,

denotes the full duration from

k to

.

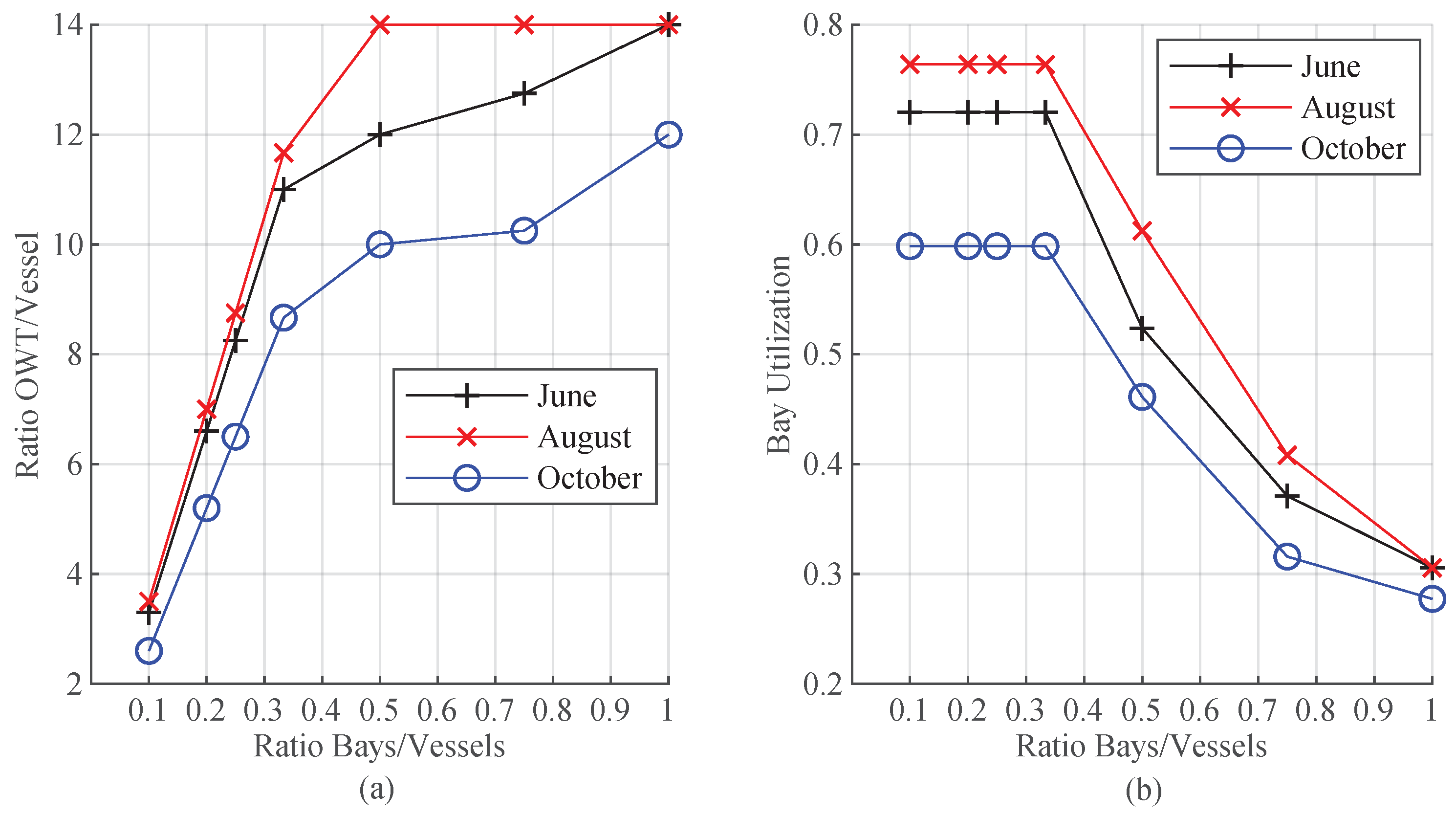

Constraint (

10) exploits this behavior and uses the resulting support variable

and the decision variables to ensure that each vessel is only involved in a single operation at a time.

Constraint (

11) limits the number of available loading bays to a specified value

. This constraint uses the parameter

, which denotes how many loading bays are in use by previous schedules at each time instance

k.

Constraint (

12) ensures that the optimizer only schedules installation activities if they can be finished within the prediction horizon

N. To record the duration, the model uses a provided matrix of expected durations

. This matrix denotes the duration of an operation

o if it is started at a time instance

k. Therefore, the index

o refers to the aggregate operations

install owt = 1,

move to port = 2,

move to site = 3 and

load components = 4. This matrix is calculated outside of the optimizer, as described before, in

Section 2.3.

The last two support variables reduce the symmetry of the formulation by recording the finishing time of operations. Symmetry occurs when two or more alternative solutions result in the same value for the cost function. For example, if an operation takes the same amount of time when it starts at hour 1 or hour 2, and this decision has no effect on the rest of the solution, a symmetrical situation occurs. By adding penalty terms to the cost function, it is possible to assign small benefits to operations that finish earlier in the process and, thus, to remove this symmetry. Therefore these variables record the expected finish times of installation operations

, and of all other operations

using constraints (

13) and (

14).

The final constraint (

15) is required to prevent the optimizer from scheduling vessels that are not currently available. As specified as part of the general methodology (

Section 2.1), the MPC-based algorithm applied an incremental planning and scheduling approach. If applying several vessels, the algorithm calculates a joint plan for all of them. Nevertheless, the vessels’ single sub-plans may end or fail at different times. For example, if the plan covers two vessels and one finishes at hour 90 while the other’s plan ends at hour 100, a new planning iteration will start at hour 90. As a result, the second vessel cannot be assigned for the first 10 h of the new planning iteration. Thus, the optimizer will not issue new operations to a vessel

v until the respective delay, provided as

, is reached. This ensures that the newly derived plan will not override unfinished, but already scheduled operations.