1. Introduction

In seasonal frozen–soil regions, the freeze-thaw cycle (FTC) is an important factor affecting soil’s physical and mechanical properties [

1]. As the temperature decreases, water in soil turns into ice, volume expansion increases pores, and the freezing process leads to aggregate separation and the breaking of soil particles. Changes in soil structure during the freezing process do not completely recover as the temperatures rises [

2]. Under the effect of repeated FTCs, the soil structure is repeatedly adjusted, so its physical and mechanical properties are changed, such as porosity [

3,

4], severity [

5], hydrologic properties [

6], permeability [

7,

8], and strength and deformation [

9]. Thus, soil mechanical properties are key considerations in construction projects in cold areas.

Because soil- structure changes caused by FTCs have a significant influence on soil properties, there are many previous studies on shear-strength changes of soils after FTCs [

5,

9,

10,

11]. In one, the expansive soil remained stable after the first cycle, but soil volume increased, and c and φ decreased as the number of FTCs increased [

5]. In another, the elastic modulus, failure strength, and c and φ of silt sand varied with the increase of FTCs [

9]. One study showed that the shear strength of saline-soil samples decreased with the increase of S, and long-term FTC could break down soil particles and change soil structure [

10]. After seven cycles, the volume of Qinghai-Tibet clay increased, c decreased, and φ was minorly affected by the FTC [

11].

Therefore, it is imperative to study soil strength and deformation after FTC. The stress-strain relationship is a comprehensive reflection of soil deformation and strength characteristics. To master the working state of soil in engineering structures, it is necessary to select the appropriate material constitutive model for analysis according to the actual situation [

12]. The Duncan-Chang constitutive model has clear concepts and is easy to understand [

13,

14], so it is widely used in hydraulic and geotechnical engineering because it can better reflect the nonlinear behavior of soil [

15,

16,

17].

In view of geotechnical engineering problems in western Jilin, this paper took Nong’an saline soil as the research object and analyzed the FTC effect on the soil’s strength and deformation. Undergoing 0, 1, 5, 10, 30, 60, and 120 FTCs, remolded samples with salt contents (S) of 0%, 0.5%, 1%, 2%, and 3% were tested with an unconsolidated-undrained triaxial test. The stress-strain relationship and sheer strength of the saline soil affected by FTCs was analyzed. Considering FTC influence, the Duncan-Chang constitutive model was established to simulate the deformation and failure process of remolded saline soil. Empirical formulas of the model parameters were obtained by regression analysis that could provide reference for relevant geotechnical engineering design.

3. Experiment Results and Analysis

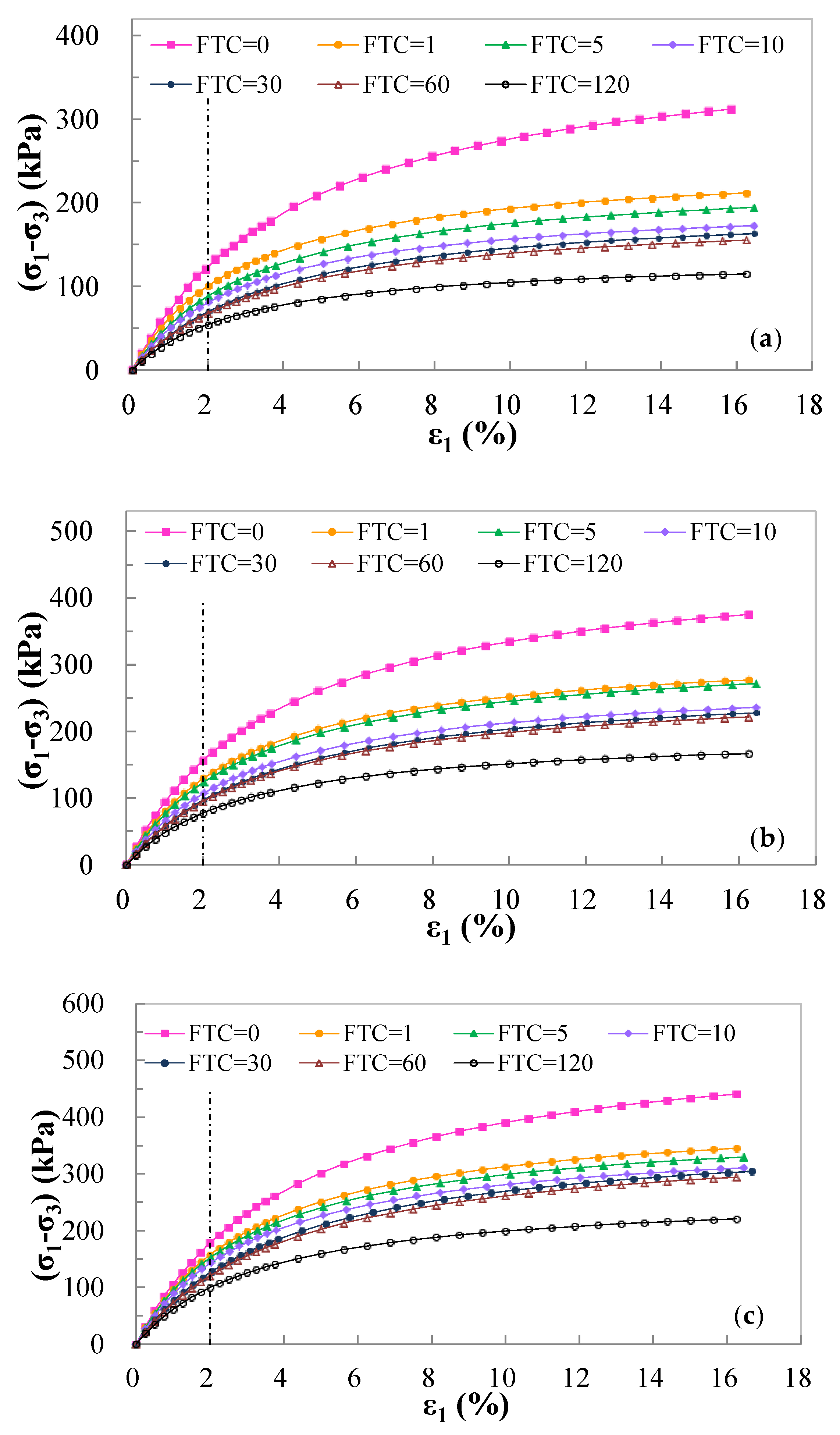

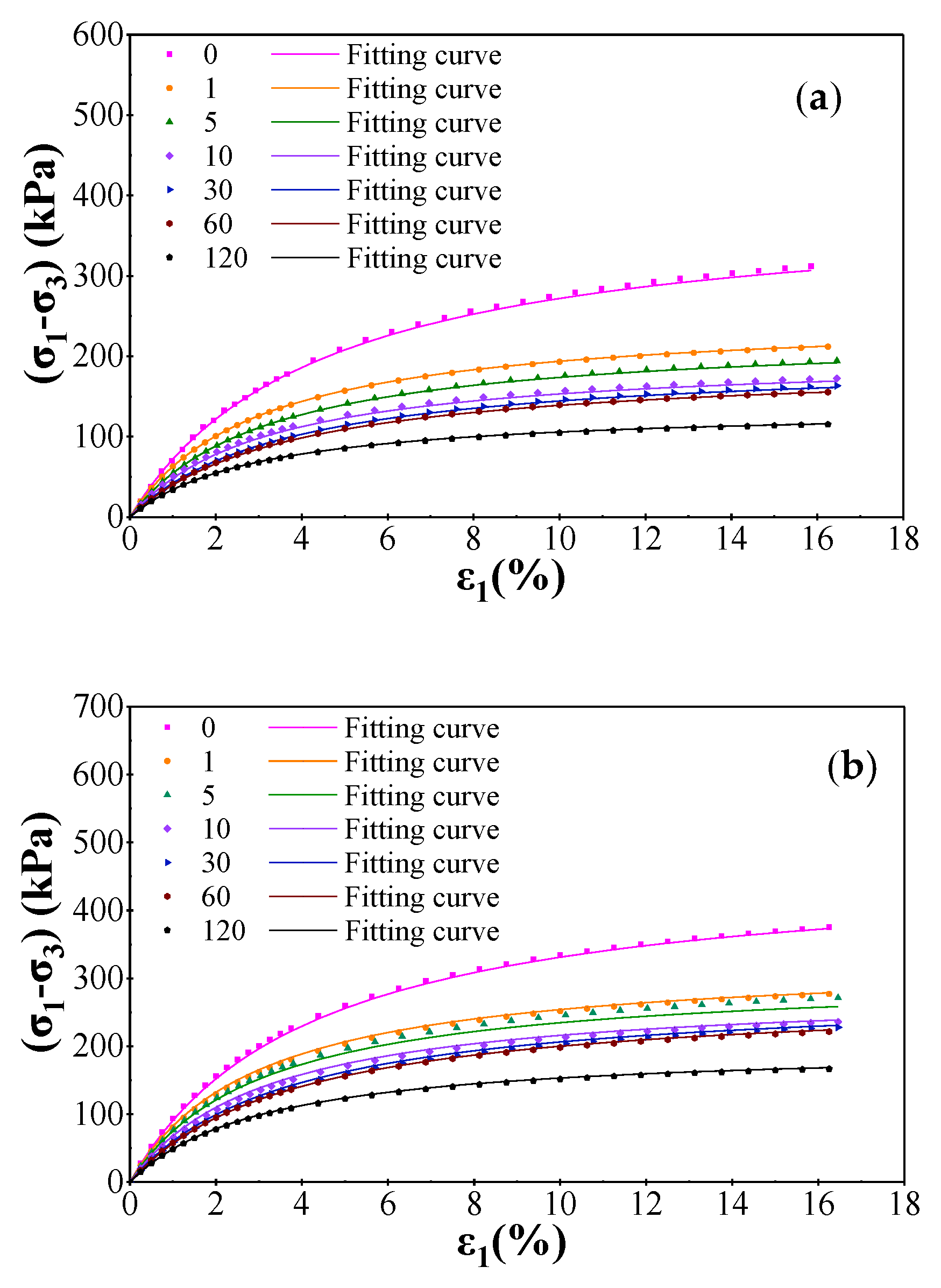

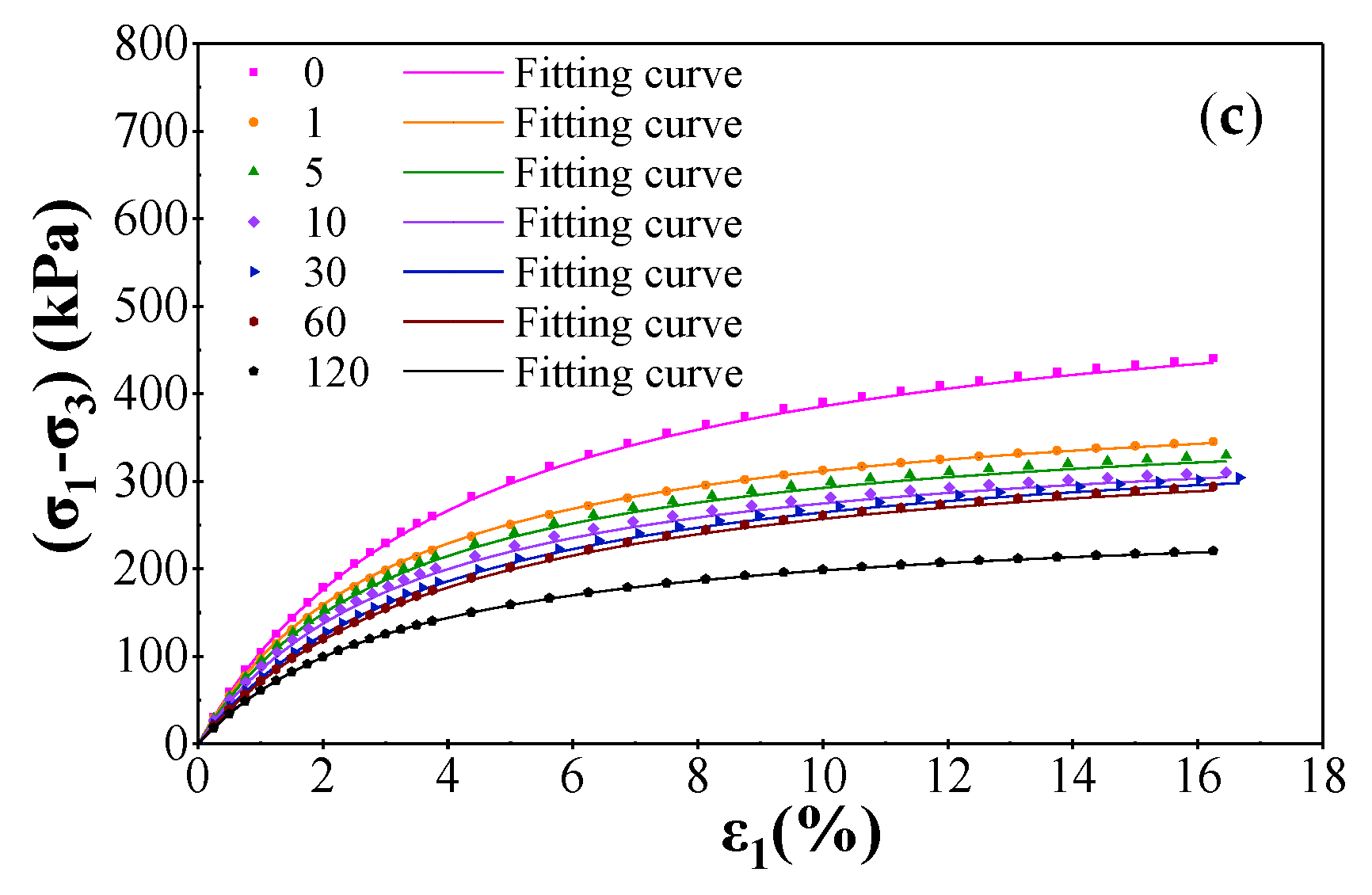

The relational curves between principal-stress deviation (σ

1 − σ

3) and axial strain ε

1 of samples with 0.5% salt content are shown in

Figure 1. Because the laws of stress-strain curve affected by FTCs were similar under different S, the stress-strain curve with 0.5% salt content is illustrated here.

As shown in

Figure 1, the principal stress deviation (σ

1 − σ

3) had nonlinear growth with the increase of axial strain ε

1. When σ

3 was the same, the (σ

1 − σ

3) -ε

1 curve-variation tendency of the samples with different FTC was similar. All (σ

1 − σ

3) -ε

1 curves were of the strain-hardening type, and the shape of curves was hyperbolic. The stress-strain curve could be divided into three stages: the quasi-elastic stage, the elastic-plastic deformation stage, and the stable stage.

In the repeated process of freezing and thawing, salt expansion, pore water migration, particle breaking and rearranging, and fracture development, gradually changed the force between soil particles, affecting the macromechanical behavior of saline soil [

2,

28,

29]. The initial yield point of the samples decreased with more FTCs (

Figure 1). The samples that underwent more FTCs were easier to damage, and their strength was lower.

For strain-hardening soil, there is no peak on the stress-strain curves, so principal-stress deviation when the strain value is 15% is usually defined as the shear strength of Nong’an saline soil. It was recorded as (σ

1 − σ

3)

f and called failure principal-stress difference, which is summarized in

Table 2. (σ

1 − σ

3)

f of soil varied with FTC change, as shown in

Figure 2. The following exponential function was used for curve fitting:

where

x is the FTC number that the samples underwent, and A

1, B

1, C

1, and D

1 are the fitting parameters. Fitting results are shown in

Figure 2, and parameter values are shown in

Table 3.

The (σ

1 − σ

3)

f of the samples with different S decreased rapidly within 10 cycles, especially about 31.22%–36.42% after the first cycle. At this stage, the structure of Nong’an saline soil was damaged. Then, it slowly declined between 10 and 60 cycles, and it declined faster after samples underwent 120 cycles (24.85%–57.13%). During the first freezing, water in the soil became ice and the volume expanded, which made small particles agglomerate and the aggregates separated from each other. Moreover, pore volume in the soil increased. When the ice melted, aggregate changes and the pore volume in the soil could not recover completely during the thawing process. After the first cycle, the structure of Nong’an saline soil was seriously damaged and its strength decreased rapidly. After 5 and 10 cycles, the micro and small pores in the soil gradually became medium and large pores, large particles or aggregates were separated, and small particles were reunited; finally, the soil entered into a new dynamic and stable equilibrium state [

10,

30]. Therefore, the decreasing rate of (σ

1 − σ

3)

f was obviously reduced when samples underwent 30 and 60 cycles. However, as the number of FTCs increased, pores in the soil gradually spread into cracks, so soil strength had an accelerated decline after 120 cycles.

The exponential function can reflect the relationship between (σ1 − σ3)f and FTC. Correlation coefficient R2 was above 0.93, so this function is suitable to explain the relationship between (σ1 − σ3)f and FTC.

(σ

1 − σ

3)

f increased with confining pressure, which indicated that the latter could inhibit pore-volume changes caused by axial pressure. So, confining pressure can slightly enhance the strength of the samples and have a certain inhibitory effect on deformation and failure [

11,

31].

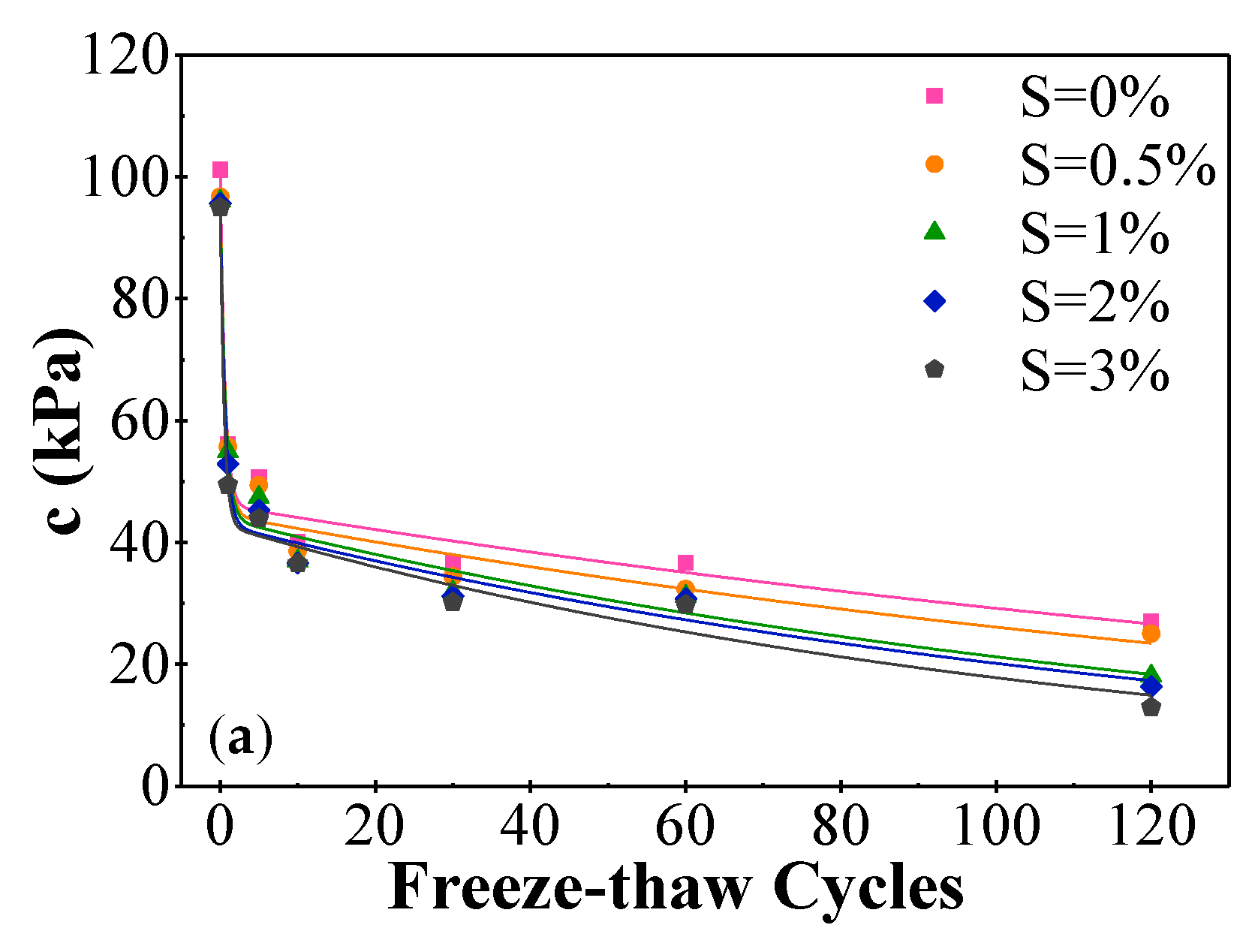

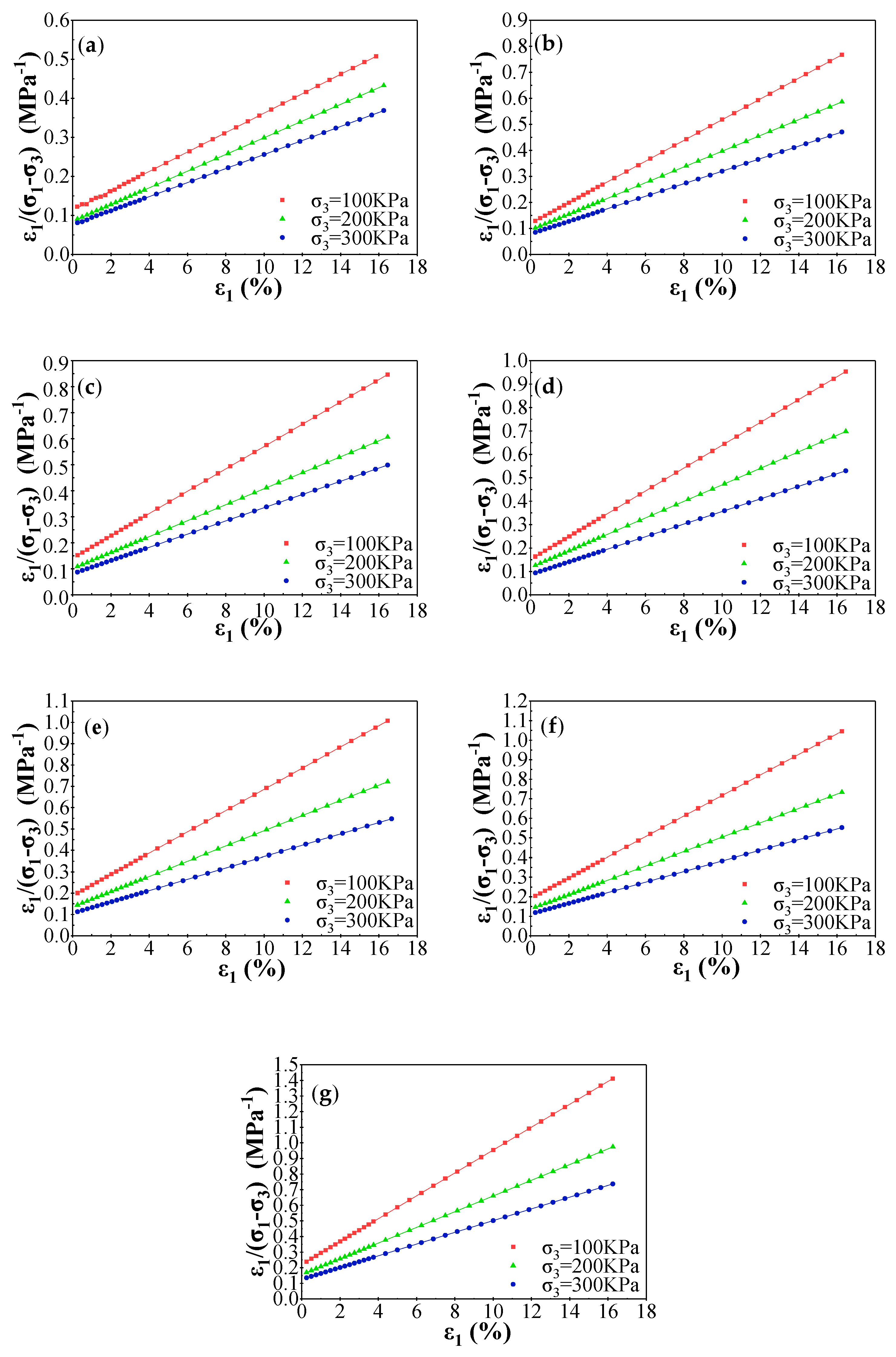

c and the φ are two important indices for evaluating soil’s shear strength that are mainly affected by particle-size composition, arrangement, and cementation [

32,

33,

34]. Recurrent FTC and changes in S change these factors, thus affecting soil c and φ. According to the experiment data, c and φ of the sample could be obtained, as shown in

Table 4. As shown in

Figure 3, c and φ were related to FTCs. The exponential function (Equation (1)) could explain the relationship between c and FTC, while the Fourier function could explain the relationship between φ and FTC. The two functions’ parameters are shown in

Table 5.

The Fourier function is as follows:

where

x is the number of FTCs the samples underwent, and A

2, B

2, C

2, and D

2 are the fitting parameters.

According to

Figure 3, the exponential function can reflect well the variation regulation of c with FTC. The overall trend of c decreased with FTC number, and c decreased considerably when FTCs varied from 0 to 10, especially when samples underwent the first cycles. After that, decline was slow and c was basically stable at around 30 kPa between 10 and 60 cycles; φ increased when below 30 cycles, and then decreased rapidly after 60 cycles. The Fourier function reflects the law of φ with FTC very well.

4. Determination of Duncan-Chang Model Parameters

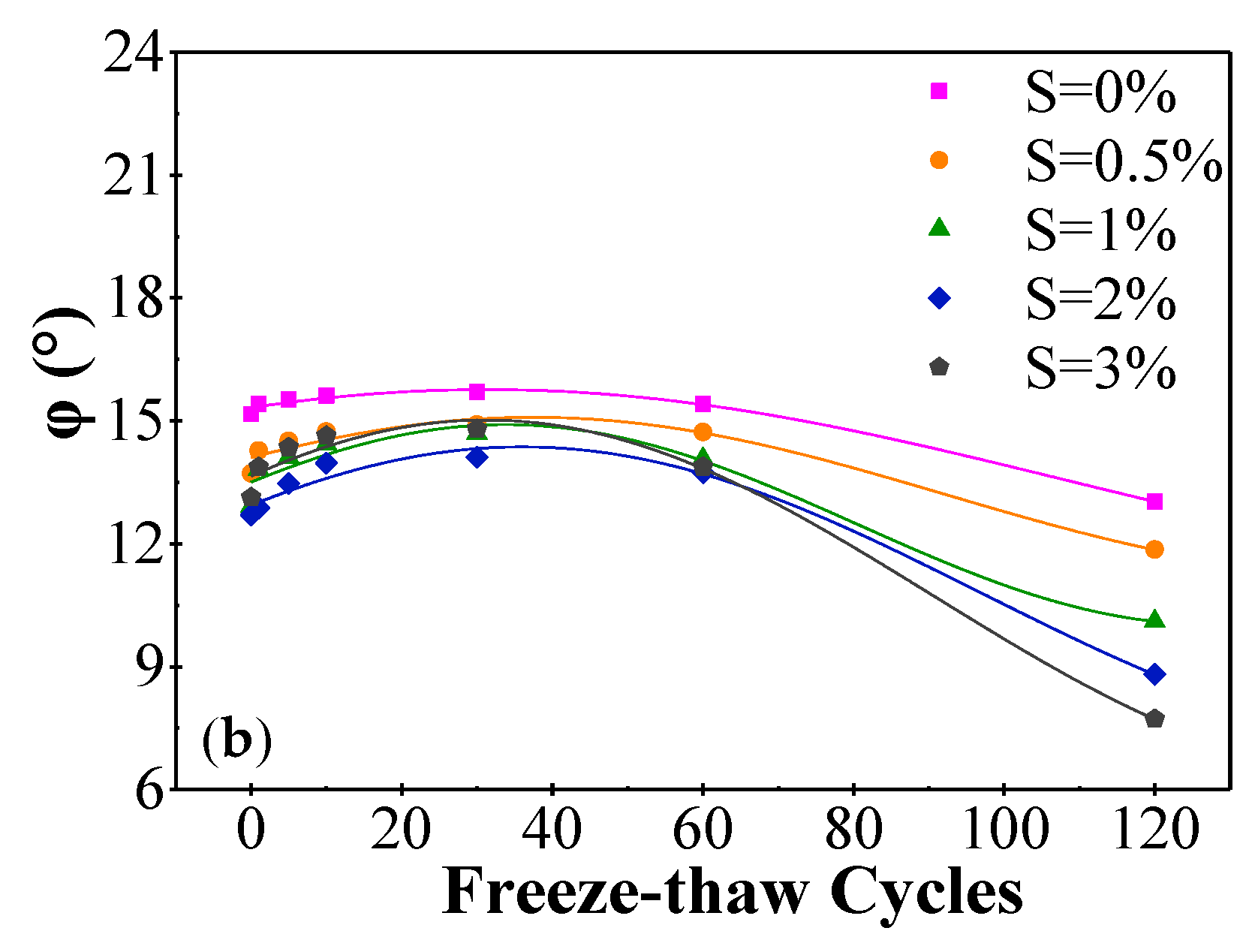

As shown in

Figure 1, relational curves between principal-stress deviation (σ

1 − σ

3) and axial strain ε

1 of samples are hyperbolic. Therefore, the Duncan-Chang model was suitably applied to analyze the relationship between sample stress and strain [

13]. The relationship between model parameters and FTC is discussed below.

Kondner et al. (1963) [

13] analyzed the stress-strain curve of soil morphology on the basis of a large number of triaxial shear-test data, and suggested that the hyperbolic function was suitable for simulating the stress-strain relationship of soils:

where a and b are parameters that could be determined by conventional triaxial shear test.

Since

dσ

2 =

dσ

3 = 0 in the triaxial test, tangent elastic modulus E

t could be obtained by taking the derivative of Equation (3) and eliminating axial strain ε

1:

where E

i is the initial elastic modulus, and (σ

1 − σ

3)

ult is the ultimate principal-stress deviation.

Ultimate principal-stress deviation is difficult to be directly obtained through the test, but failure principal-stress difference is easy to determine. Therefore, in order to obtain the ultimate principal-stress deviation, the failure ratio was defined as follows:

According to Mohr-Coulomb strength theory:

We transformed the coordinate system of Equation (3) to get the following equation:

According to Equation (7), triaxial test data are transformed into another coordinate, and curves of ε

1/(σ

1 − σ

3) and ε

1 were drawn in

Figure 4. It can be seen from

Figure 4 that there was a first-order linear correlation between stress and strain in the ε

1/(σ

1 − σ

3) − ε

1 coordinate. The stress-strain curve of the sample conformed to the hyperbolic function. The y-intercept of the fitting line was parameter a, and the slope was parameter b, as shown in

Table 6. The reciprocal of parameters a and b are E

i and (σ

1 − σ

3)

ult, respectively.

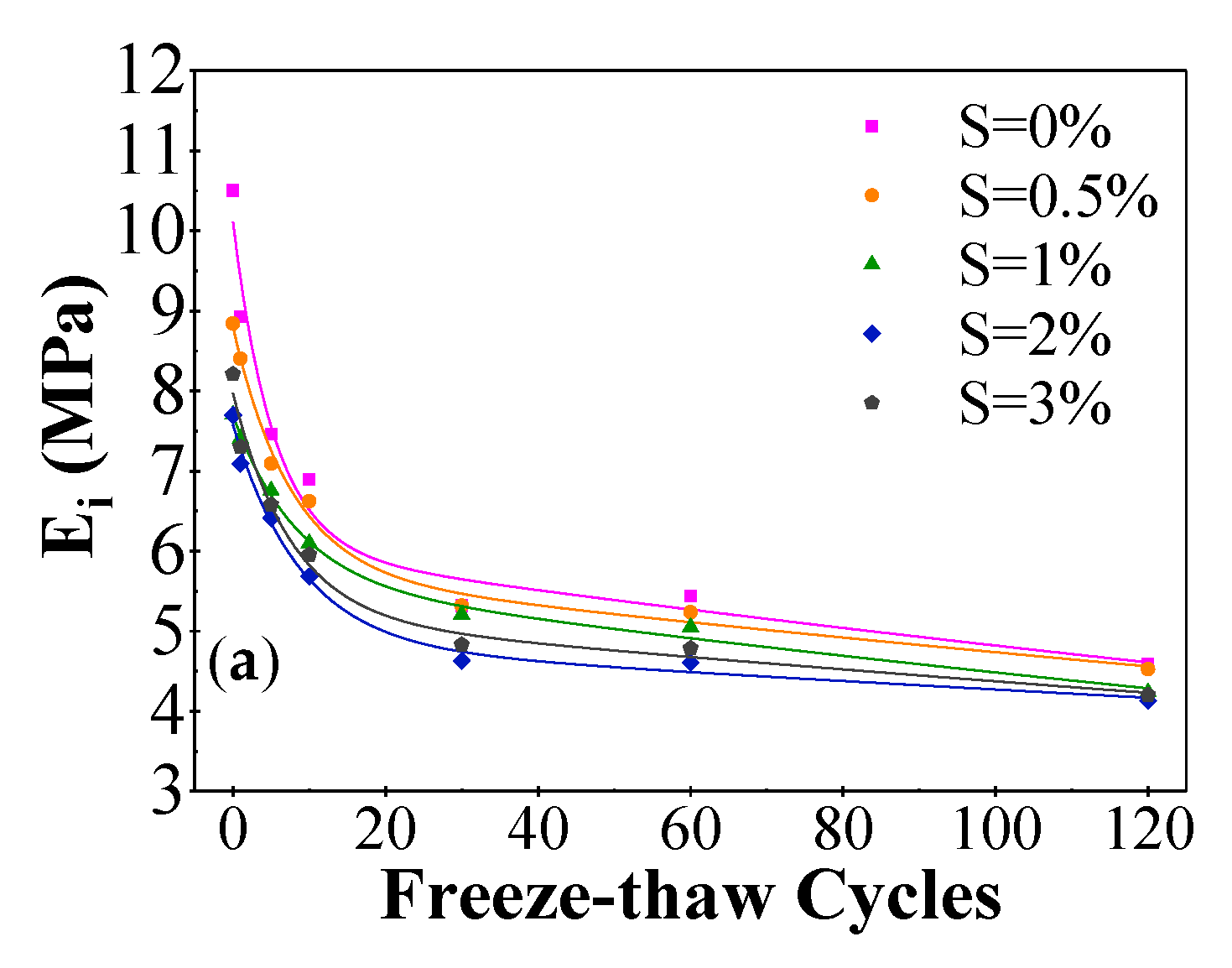

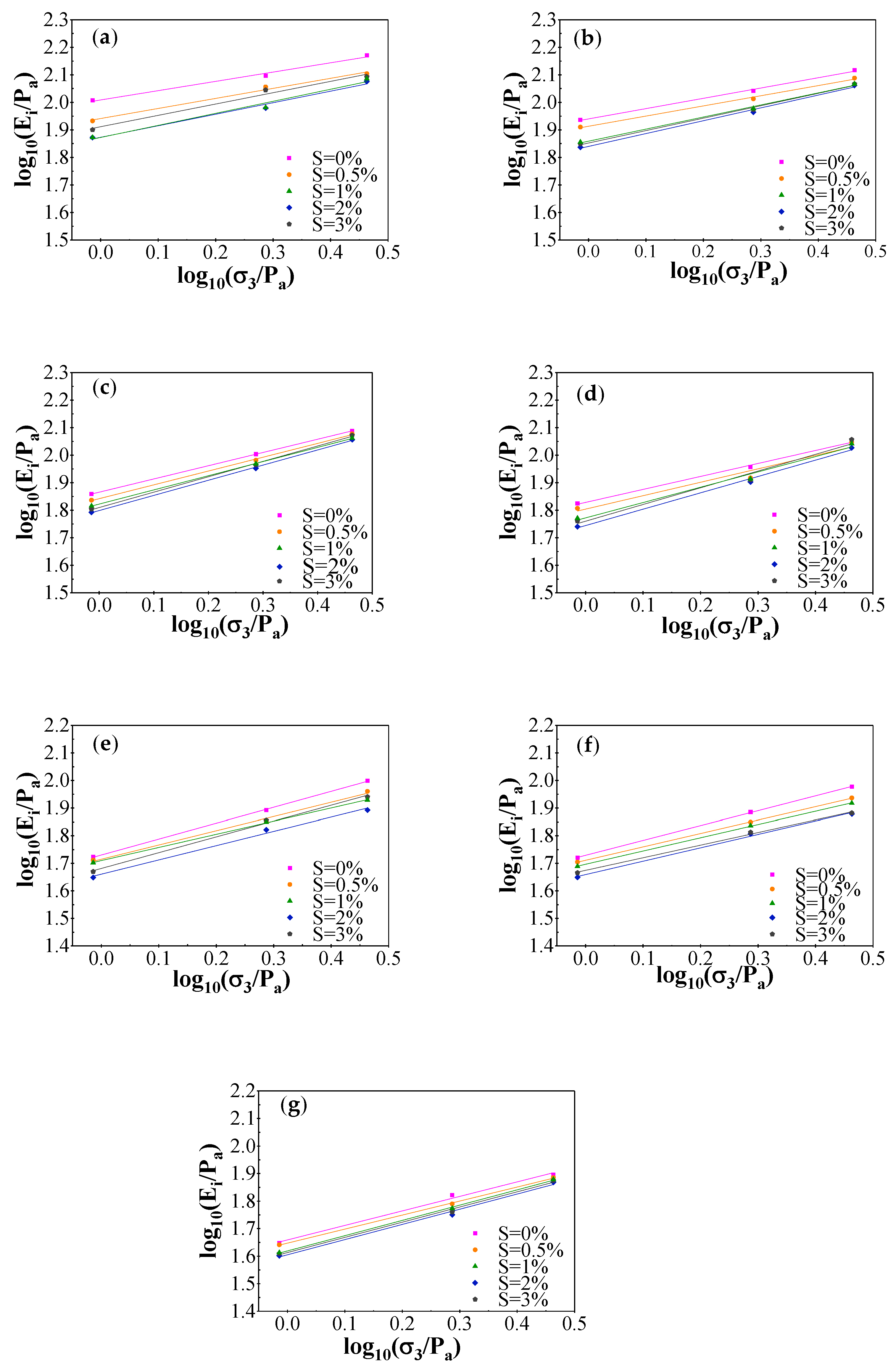

In

Figure 5, under different confining pressures, the variation tendencies of initial tangent modulus E

i and FTC were similar, decreasing rapidly below 30 cycles, and then decreasing slowly after 30 cycles. The regression relation of E

i to FTC could be fitted by the exponential function, and fitting parameters are shown in

Table 7.

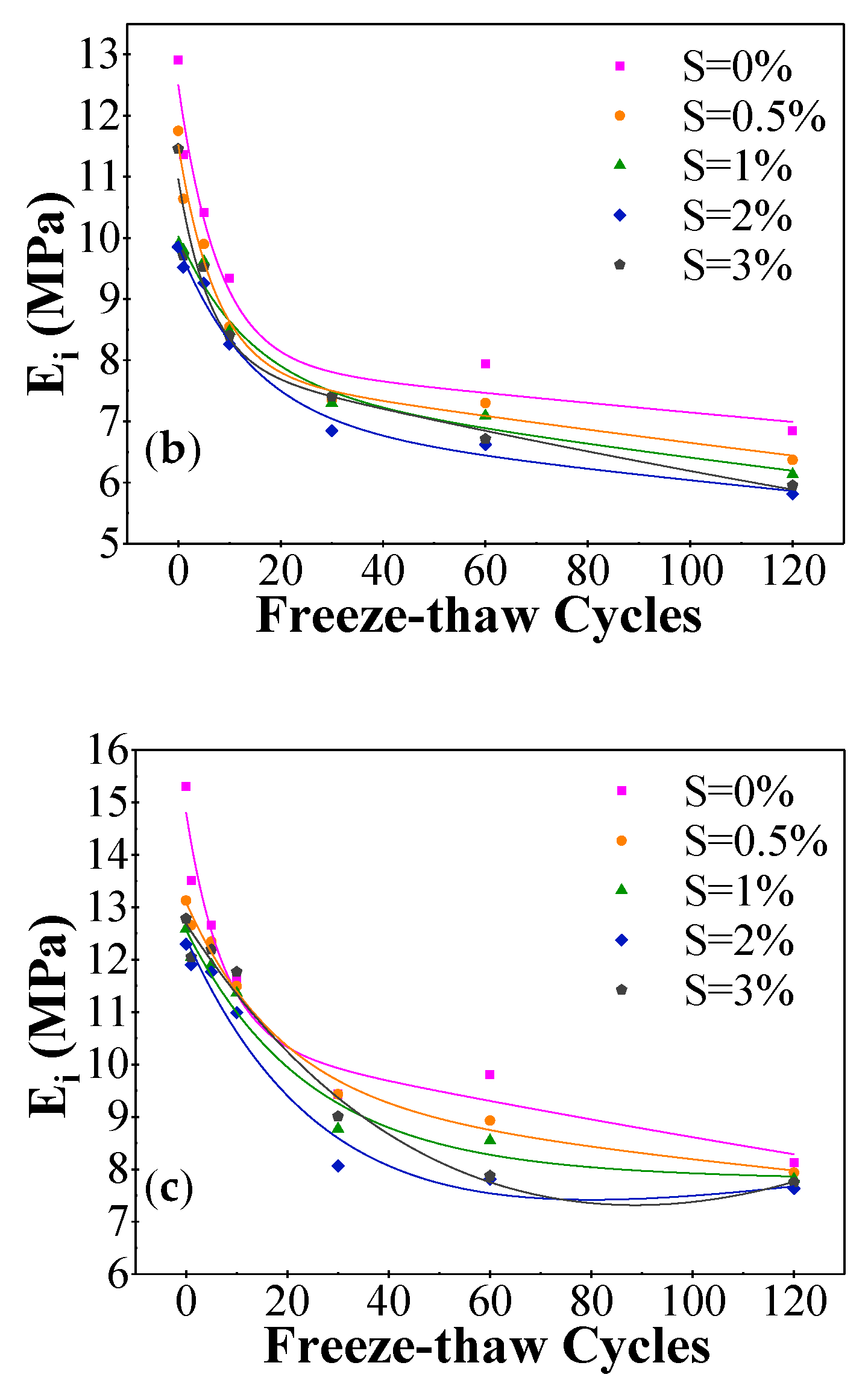

The failure principal-stress deviator (σ

1 − σ

3)

f and limiting principal-stress deviator (σ

1 − σ

3)

ult were determined. According to Equation (5), fracture ratio R

f could be obtained. As shown in

Figure 6, R

f increased after the first cycle, and then decreased between five and 60 cycles. After 120 cycles, R

f obviously increased. The following rational function was used for curve fitting:

where

x is the FTC number that the samples underwent, and A

3, B

3, C

3, D

3, and E

3 are fitting parameters. The fitting result is shown in

Figure 6, and parameter values are shown in

Table 8.

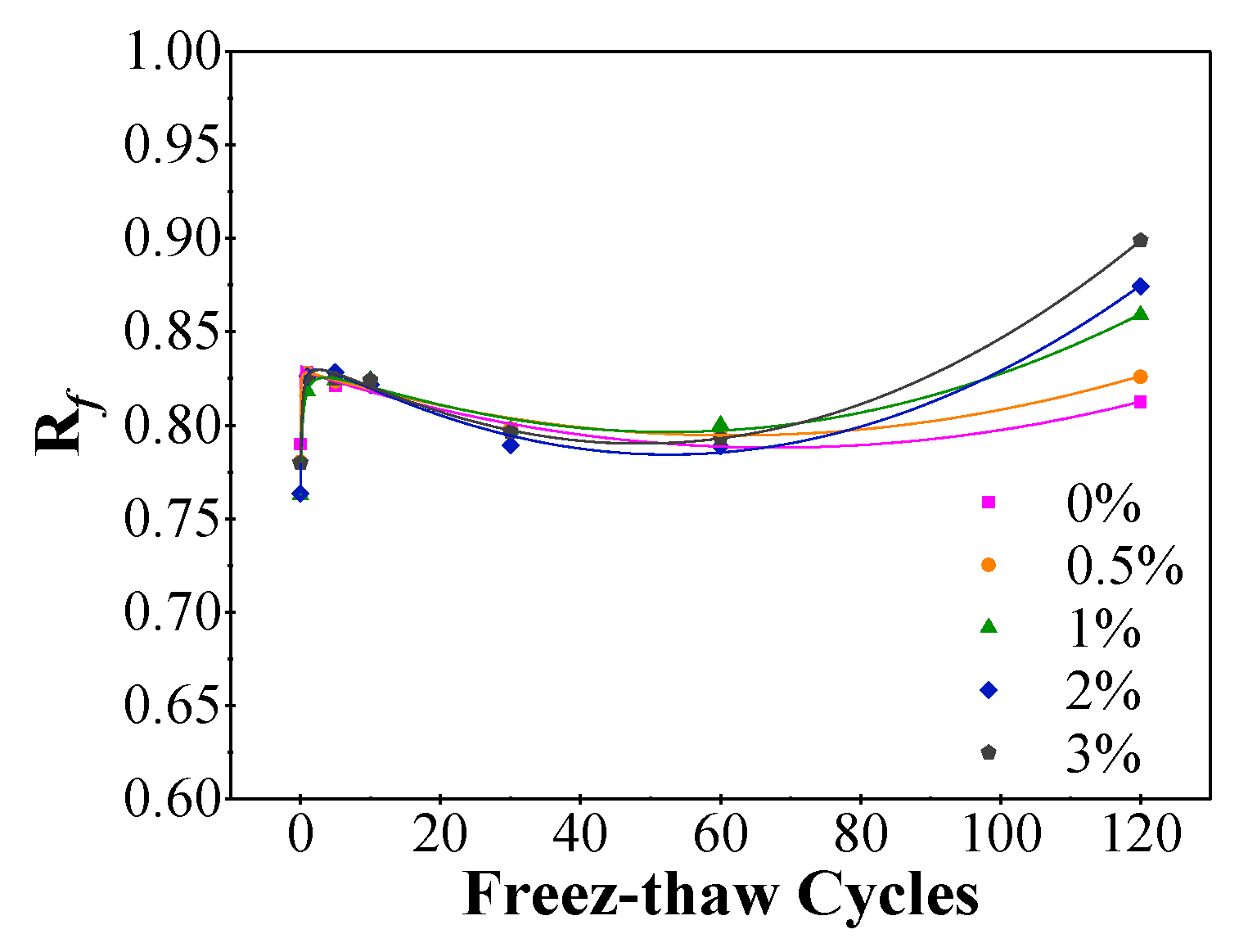

According to Janbu’s suggestion, initial tangent modulus E

i is related to σ

3, and its empirical relationship is as follows:

where K and N are material constant and P

a = 101.4 kPa is the standard atmospheric pressure.

We drew the diagram of log

10(σ

3/P

a) and log

10 (E

i/P

a), as shown in

Figure 7. According to the relationship between log

10(σ

3/P

a) and log

10(E

i/P

a), the y-intercept and slope of the fitting line were log

10(K) and N, respectively, so material constants K and N were obtained, as shown in

Table 9.

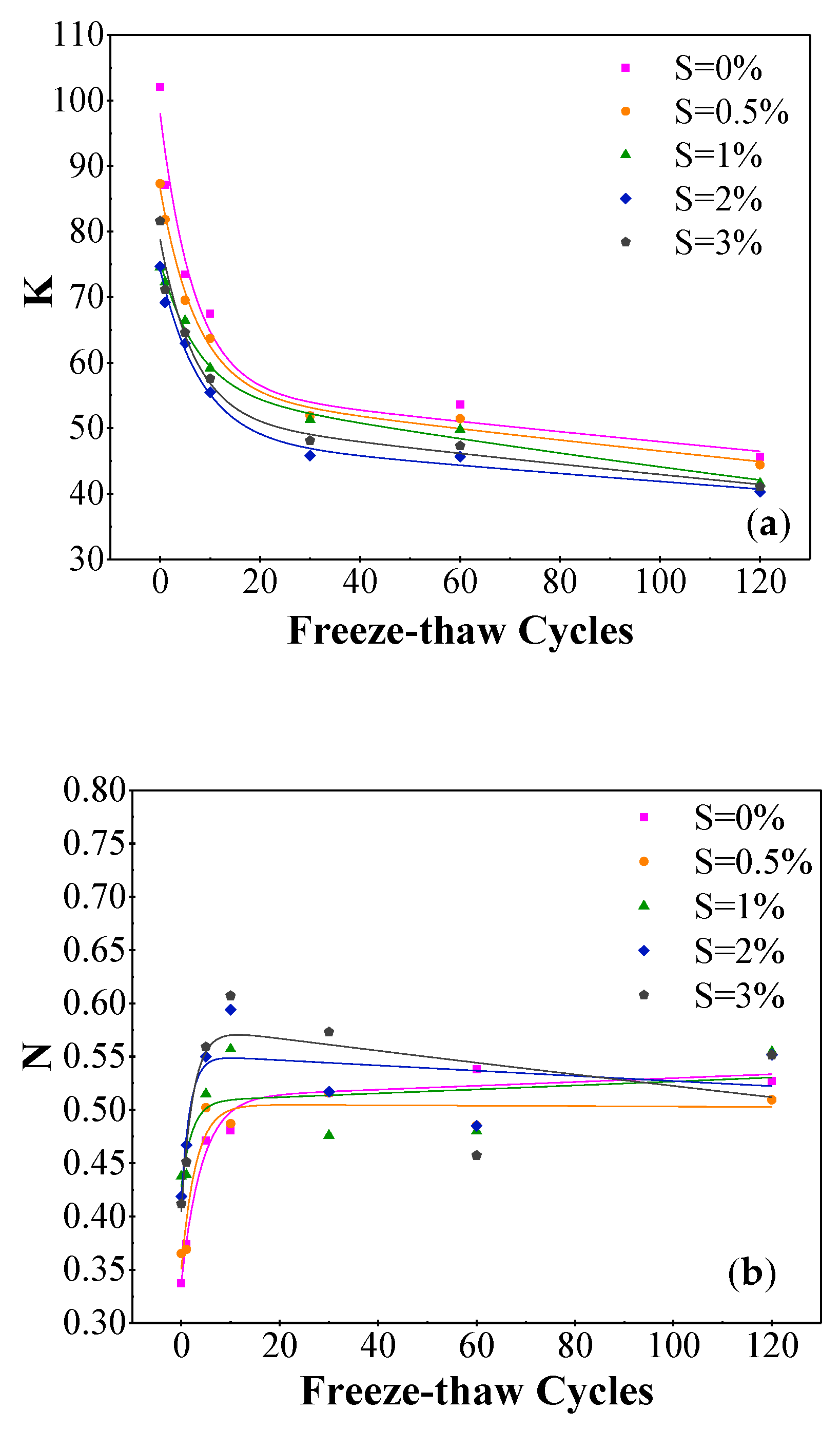

With the increase of FTC, the change rule of material constant K rapidly decreased below 30 cycles, and then slowly decreased after 60 cycles. The regulation of N increased below 10 cycles, and then decreased between 10 and 60 cycles; it then increased after 120 cycles. The regression relation of K-FTC and N-FTC could be fitted by the exponential function; parameters of this function are shown in

Table 10. And the fitting result is shown in

Figure 8.

Stress level S

L is defined as the ratio of actual principal-stress difference (σ

1 − σ

3) to failure principal-stress difference (σ

1 − σ

3)

f:

By substituting Equations (5), (6), (9) and (10) into Equation (4), we can get the following formula:

In conclusion, the experience formula of the five material constants contained in the tangent deformation modulus of the Duncan-Chang model were established, so the variation regular of the tangent deformation modulus with the FTC could be determined by unconsolidated undrained tests.

In the triaxial unconsolidated, undrained shear tests, no volumetric strain occurred in the samples. So, material constants G, F, and D that calculate tangential Poisson’s ratio in the E-μmodel (initial tangent modulus - tangent Poisson’s ratio model) could not be obtained, nor could the K

b and m of the E-B model (initial tangent modulus -bulk modulus model) be obtained. According to the generalized Hooke’s law, the value of μ

t was 0.5 when the sample strain was 0. In order to ensure the stability of numerical calculation, Poisson’s ratio is usually 0.49 [

35].

6. Conclusions

In this paper, Nong’an saline soil from Western Jilin was taken as the research object. Through unconsolidated, undrained triaxial shear tests, the relationship between the mechanical properties of Nong’an saline soil and freeze-thaw cycles was studied, and a modified Duncan-Zhang constitutive model was established.

The stress-strain curves of the remolded saline soil were strain-hardening. There was linear elastic deformation in the initial loading stage, and it entered into the elastic-plastic deformation stage when strain reached 2%. With the increase of FTCs, (σ1 − σ3)f and c both decreased, rapidly decreasing after the first cycle and becoming stable between 30 and 60 cycles. φ increased at first, and then decreased. Using the exponential function could explain the relationship of (σ1 − σ3)f and c to FTC, and φ to FTC could be fitted by the Fourier function. Fitting results showed that the two functions reflected their variation rule well.

On the basis of Duncan-Chang model theory and regression analysis of the experimental data, a modified Duncan-Chang model was established for Nong’an saline soil, and the relationships of parameters Ei, K, N, and Rf to FTCs were analyzed. The analysis results indicated that Ei and K decreased rapidly at first and then became stable. Rf and N increased at first and then decreased. After 120 cycles, Rf and N all obviously increased. The relationships of Ei, K, and N to FTC could be explained by the exponential function, and the relationship of Rf to FTC could be explained by the rational function.

The rationality of the model was verified by comparing the simulation and experiment curves. It was found that, in the low-strain elastic-deformation stage, the model simulation results were consistent with the experiment results. When the strain was higher than 4%, there was little difference between simulated and experimental curves. Therefore, the Duncan-Chang model could well reflect the stress-strain relationship of the remolded Nong’an saline soil as a whole.