3.1. High Temperature Stability

The high temperature stability performance of asphalt mainly shows that it still has the ability to resist permanent deformation under the repeated shear at high temperatures, and the change of viscoelastic composition is relatively stable [

18,

19]. The following content will be analyzed from the complex modulus and damping factor of asphalt and their changing trends are displayed in

Figure 1 and

Table 4.

Figure 1a shows clearly that the complex moduli of AR and MAR were higher than those of AM with increasing temperature, and AM had the lowest complex modulus and both AR and MAR had a higher complex modulus with a similar declining trend. Because CR and MCR absorb most lightweight components, such as oil and resin, within asphalt during the rubber swelling process, the relative content of heavy components, like asphaltene, increases. In addition, due to organic functional groups of the silane coupling agent grafting on the rubber surface, MCR could absorb more oil and resin, which results in a higher complex modulus [

20]. Under these circumstances, since a stronger interface has been formed between MCR and asphalt, adhesion and bonding state are enhanced as a result of the chemical effects [

9] and asphalt still has a higher consistency and a better ability to resist deformation. Therefore, the ability of MAR to resist repeated shearing stress is enhanced by KH-550. However, the complex moduli of all samples decreased with increasing temperature, which means anti-shearing stress ability was gradually weakening.

Figure 1b shows the change in the phase angle of the asphalt sample with temperature. It is obvious that AM had the largest phase angle while MAR had the lowest phase angle. When the phase angle was converted to tan (

δ), this change in viscoelastic part within asphalt was more violent and moderate for AM and rubberized asphalt.

Figure 1c shows the damping factor changing trends of AM, AR, and MAR. The tan (

δ) of AM rapidly rose with increasing temperature and it reached near 60 at 80 °C. Because the non-Newtonian fluid characteristic of asphalt begins to appear with increasing temperature, at this point, the plasticity of asphalt increases and permanent deformation would occur [

21]. However, AR and MAR had a similar increasing trend of tan (

δ), and tan (

δ) was significantly lower than AM. This is because of the elastomer effect of rubber, which gives asphalt a better ability to recover from deformation and significantly reduces the tan (

δ) of asphalt. In addition, when the test temperature was higher than 70 °C, the tan (

δ) of MAR exhibited a downward trend and differences between AR and MAR increased. MCR was more stable and continuously swelled within asphalt and chemical bonds between MCR and asphalt were accrued through the polar groups of silane coupling agent, which means MCR acts as a better elastomer with a good compatibility with asphalt. As a result of the KH-550 modification, the increasing trend of asphalt plasticity was mitigated or stopped, which prevented permanent deformation and enhancing the mechanical behavior.

Rutting factor

G*/sin (

δ) reflects the ability of asphalt to resist the shearing deformation at high temperatures. American Strategic Highway Research Program (SHRP) points out that if this index of asphalt is lower than 1 kPa with increasing temperature, the test is finished and the specimen is failed [

22]. According to the results of DSR temperature scanning tests, the

G*/sin (

δ) of AM, AR, and MAR at 58 °C, 64 °C, 70 °C, and 76 °C were calculated and are presented in

Figure 2 and

Table 5.

It can be seen that

Figure 2 displays a similar decline trend of

G*/sin (

δ) for AM, AR, and MAR with increasing temperature, which presents a sensitivity of temperature. When the temperature had not yet reached 64 °C, the DSR tests of all AM samples had failed, while the

G*/sin (

δ) of AR and MAR samples were still 2.21 kPa and 2.99 kPa at a high temperature, respectively. In addition, the

G*/sin (

δ) of MAR samples were always higher than those of AR, which increased by 35.4% at 58 °C, 29.7% at 64 °C, 30.7% at 70 °C, and 35.3% at 76 °C. Because a more stable and stronger continuing integrity was formed between MCR and asphalt [

9], even if the test temperature rose, the ability of MAR to transmit force, redistribute internal stress, and resist shearing deformation was much better.

Through the above analysis of the DSR temperature scanning test, it can be determined that MCR helped to raise and reduce complex modulus S and damping factor tan (δ) of asphalt under high temperature conditions. The servicing performance under a high temperature environment was improved by a stronger interface adhesion state formed between MCR and asphalt through chemical reactions, which means the dynamic mechanical properties of rubberized asphalt are enhanced by KH-550.

3.2. Low Temperature Performance

The mechanical and deformation behavior of asphalt at low temperature is closely related to its composition. Without any modified materials, matrix asphalt often shows more deflection and brittleness, while rubber powder can greatly improve this situation [

23]. The BBR test results are shown in

Table 6.

According to

Table 6, the low temperature performance of AM was worse than that of rubberized asphalt. When the test temperature was −12 °C, the

S and

m-values of AM were 126.5 and 0.347, respectively. At this time, the

S of AR and MAR was 98.4 and 91.1, respectively, while the

m-value of AR was 18.7% higher than that of AM, and the

m-value of MAR was 30.8% and 10.2% higher than that of AM and AR, respectively. The above results indicate that rubber powder improved the low temperature performance of asphalt, produced less low temperature deflection deformation, and enhanced the abilities of stress transmission and internal stress dissipation of rubber asphalt, however, MCR had a better improvement effect. According to Chinese specifications,

S should not exceed 300 MPa and

m-value should not be less than 0.3. It can be seen from the table that when the temperature continued to drop to −24 °C, the low temperature performance of asphalt sample further declined, and the

S of AM sharply rose to 683.5, which is 123% higher than MAR. Although the

S of AR and MAR were both higher than 300 MPa, their low temperature performances were obviously better than that of AM. Meanwhile, the

m-value of AM was lower than 0.3, and its ability to dissipate internal stress was significantly reduced, while rubber asphalt was still higher than 0.3, and MCR gave asphalt a better stress and force transfer effect at a lower temperature.

The main reasons for this can be concluded as follows. Under the same load level, AM tends to transform the stress into larger bending deformation due to the insufficient level of stress dissipation, and its surface is prone to cracking and brittle fracture. The addition of rubber powder improves the mechanical and force transfer behavior of asphalt. Most of the load is absorbed by rubber powder, so its

S is smaller and

m-value is larger [

24]. At the same time and a lower temperature, due to the better combination of MCR and asphalt caused by chemical action, on the one hand, the movement of the asphalt molecular chain is relatively reduced, on the other hand, the friction between MCR and asphalt is enhanced, which builds a better dissipation of the internal stress state. Therefore, MAR has a better low temperature performance.

3.3. Specific Surface Area of Rubber Powder

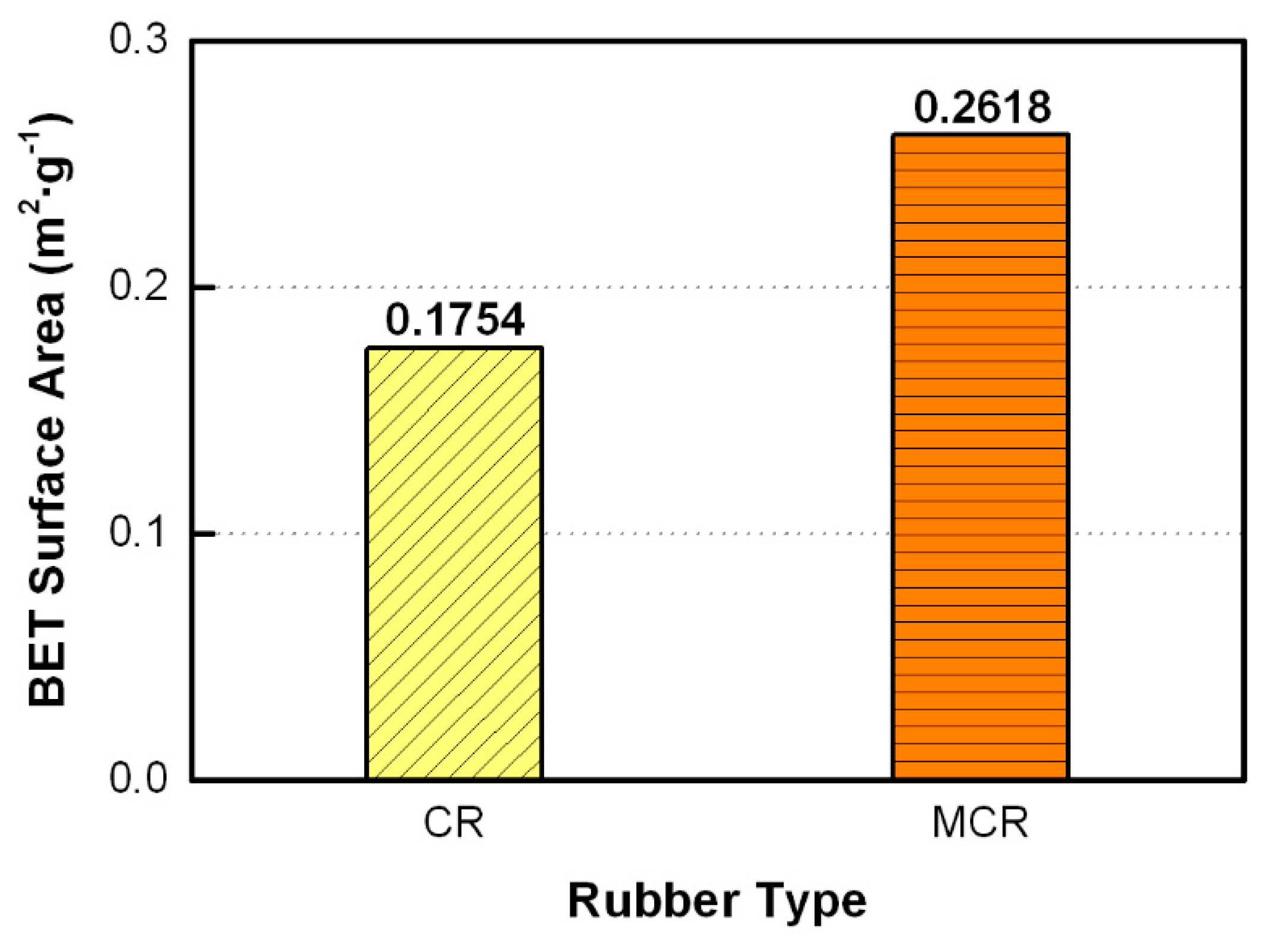

The combination of rubber powder and asphalt is mainly physical function. When silane coupling agent is introduced into the surface of rubber powder, the rubber powder is chemically combined with asphalt through the silane film attached to the surface of rubber powder. In order to further analyze the influence of silane coupling agent on the surface properties of rubber powder, and further explain the reasons of DSR and BBR test results, in this paper, the BET test of rubber powder was carried out to determine the effect of silane coupling agent on the specific surface area of rubber powder. The BET test results are shown in

Figure 3.

Figure 3 shows that the specific surface area of CR was 0.1754 m

2·g

−1 and that area of MCR rose to 0.2618 m

2·g

−1, which is 49.3% higher than CR after surface modification by silane coupling agent. Some studies have shown that the modification mechanism of silane coupling agent is to chemically attach a layer of silane film on the surface of modified material. The size, thickness, and shape of the silane film are different [

25]. It can be seen that the specific surface area of MCR increased significantly because of the successful grafting of silane coupling agent molecules on its surface, which would change the surface properties of some modified materials or “add” some required functions.

MCR, due to its larger specific surface area, firstly, absorbs more oil and resin within asphalt, which further raises the relative content of asphaltene and improves the ability to resist shearing stress; then, it facilitates the formation of stable chemical bonds between MCR and asphalt, which plays the role of elastomer to better improve mechanical properties at high temperatures; lastly, it still heightens frication action between MCR and asphalt, which helps to dissipate asphalt internal stress better.

MCR swells well and “suspends” within asphalt through chemical interactions, therefore, mechanical characteristics of MAR are further enhanced, which results in a better performance at high and low temperature environments.

3.4. Functional Group and Chemical Bond of Asphalt

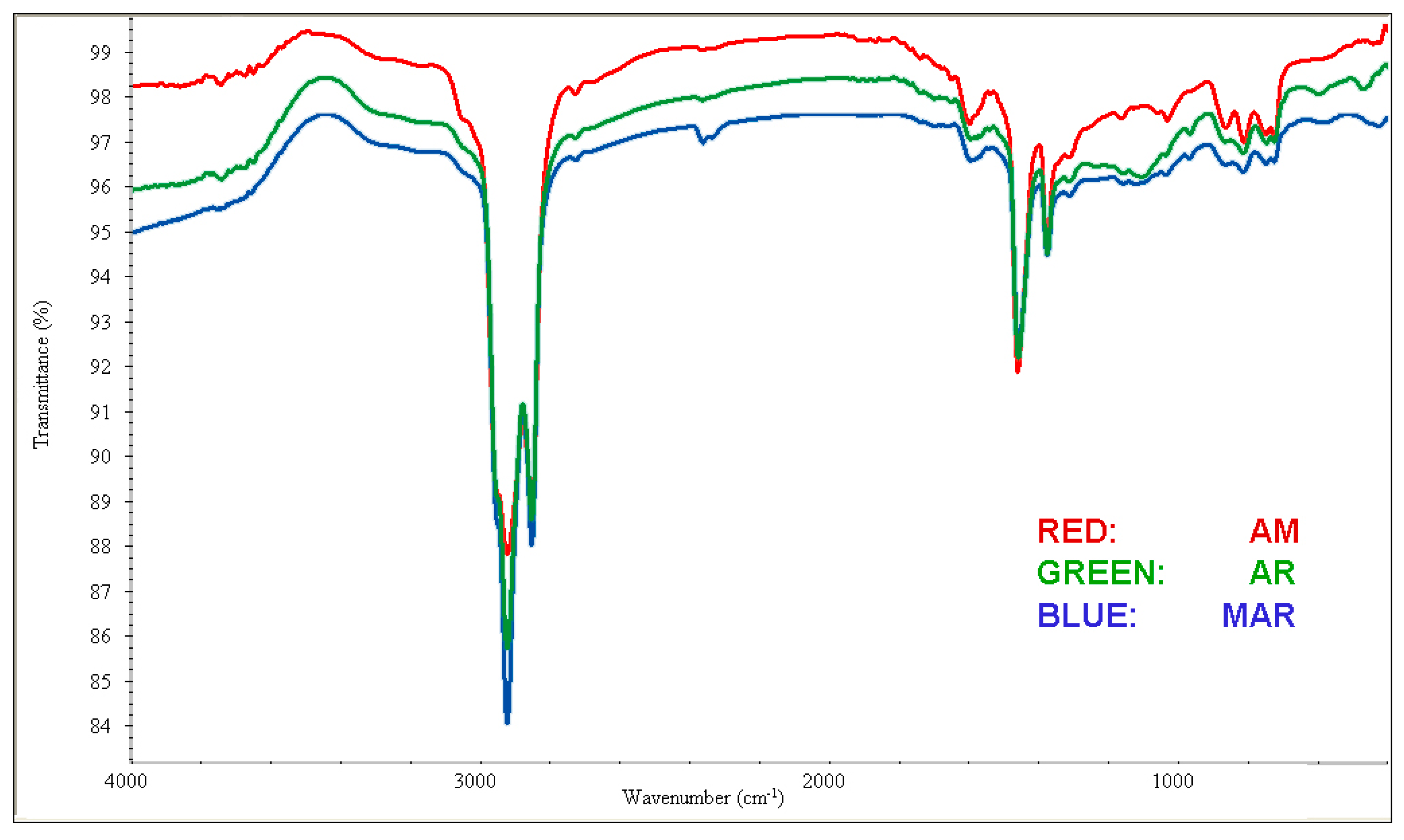

After understanding the influence of silane coupling agent on rubber powder, the mechanism of modified rubber powder on asphalt could be further analyzed. In this paper, the change in the functional group and chemical bond of asphalt caused by the silane coupling agent was revealed by the FTIR test, and the reason why the silane coupling agent enhances the rheological properties of asphalt at high and low temperatures was further explained. The FTIR test results are displayed in

Table 7 and

Figure 4.

It can be seen from

Figure 4 and

Table 7 that the silane coupling agent had little effect on the functional groups and chemical bonds of asphalt, but had a significant effect on the absorption of individual peaks. The absorption peaks of the C=C bond, methylene C–H, and some fingerprint area wavenumbers of AR and MAR were weakened, which indicates that the relative contents of oil and resin declined, while the relative content of heavy components like asphaltene rose. The formation of C≡C of MAR implies MCR strongly reacts with asphalt and produces new chemical bonds [

26]. In addition, because saturated C–H is already abundant in CR, these chemical bond absorption peaks of rubberized asphalt were higher than that of AM; on the other hand, MCR had an enhanced absorption peak of the saturated C–H within MAR. As a result of the addition of the CR and MCR, absorption peaks of these functional groups and chemical bonds of asphalt changed, but the changes of MAR were greater, which means that the chemical reaction between MCR and asphalt was stronger.