Effect of Disintegration Times of the Homogeneity of Soil prior to Treatment

Abstract

1. Introduction

2. Materials and Methodology

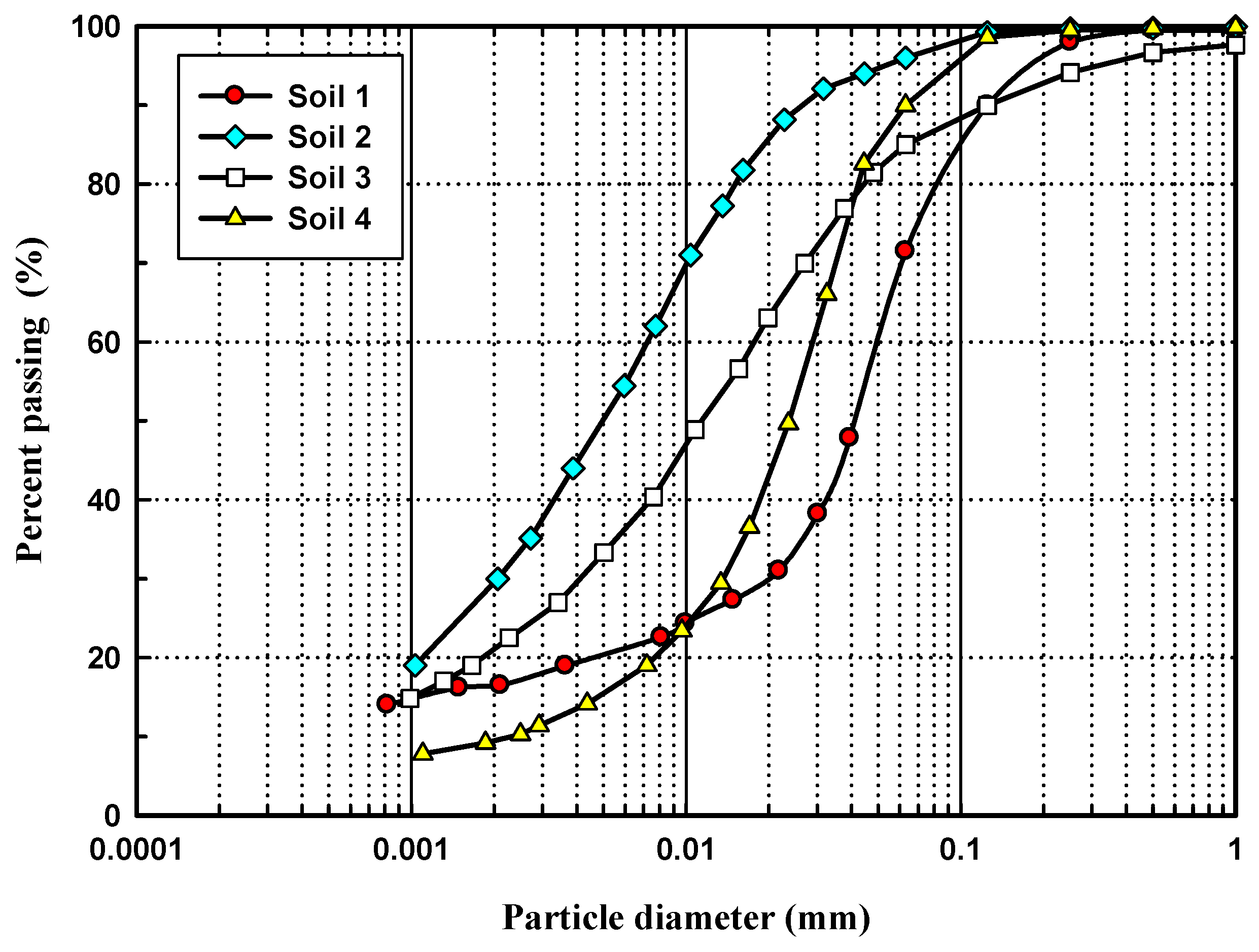

2.1. Materials

2.2. Testing Program

3. Results

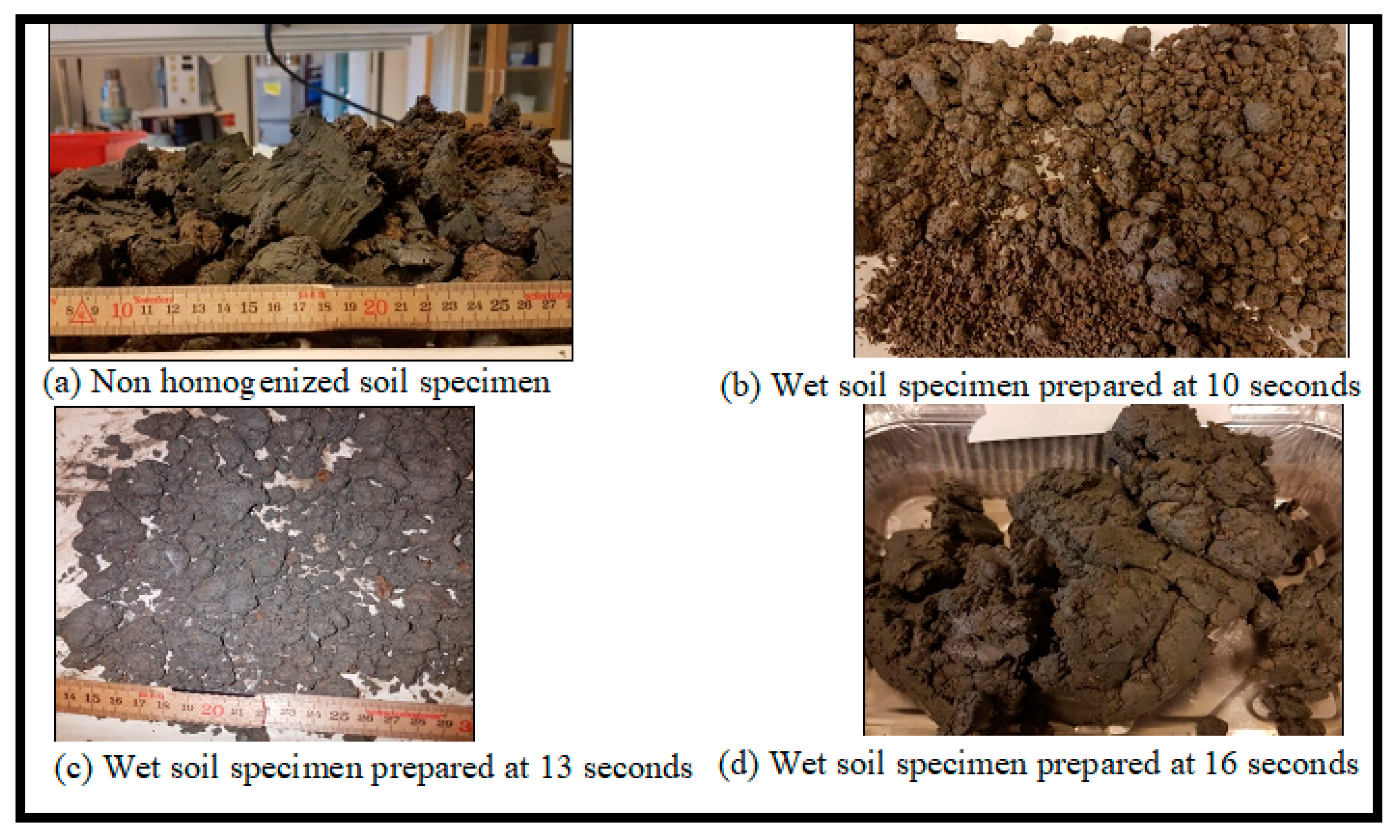

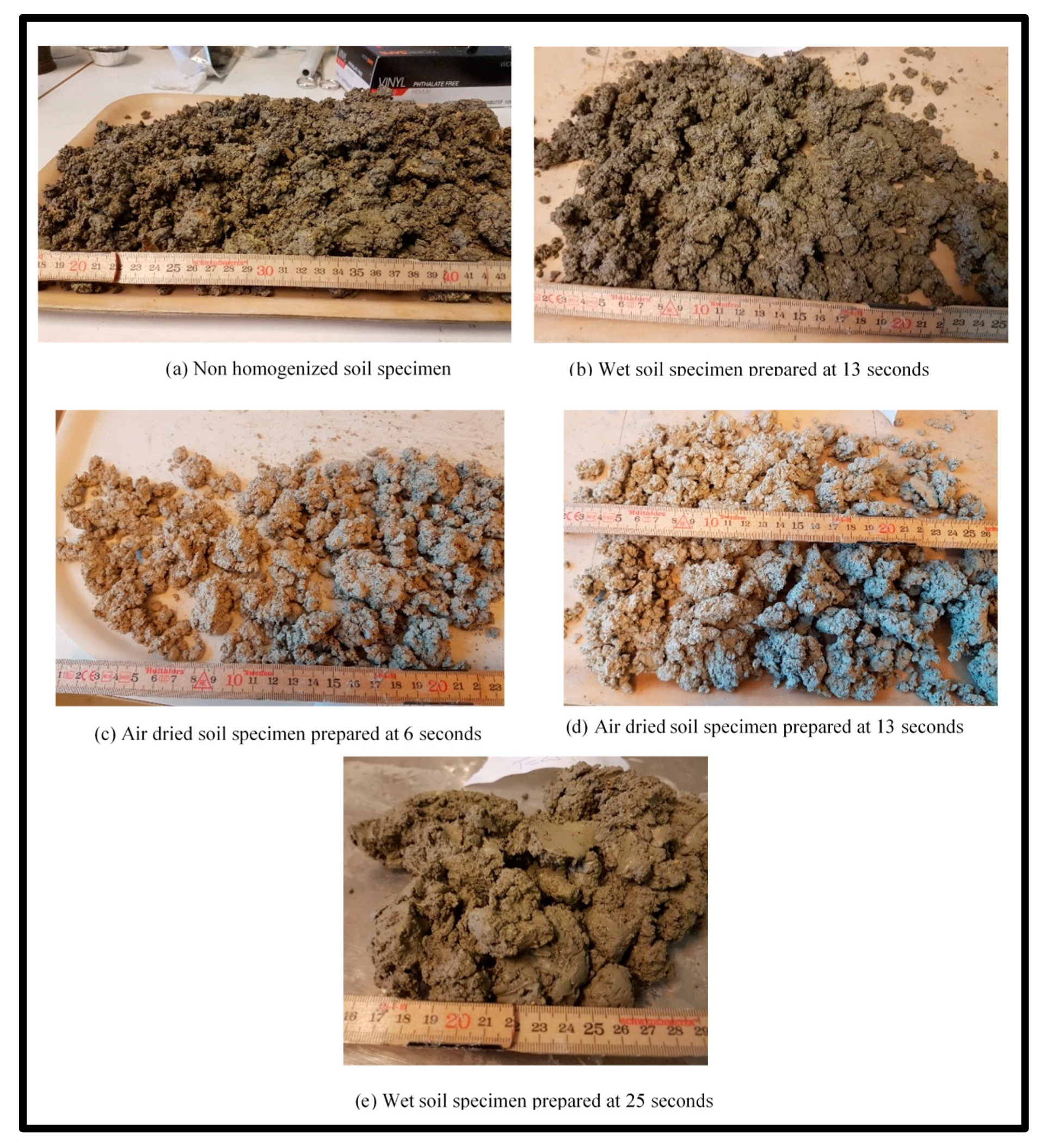

3.1. Visual Evaluation

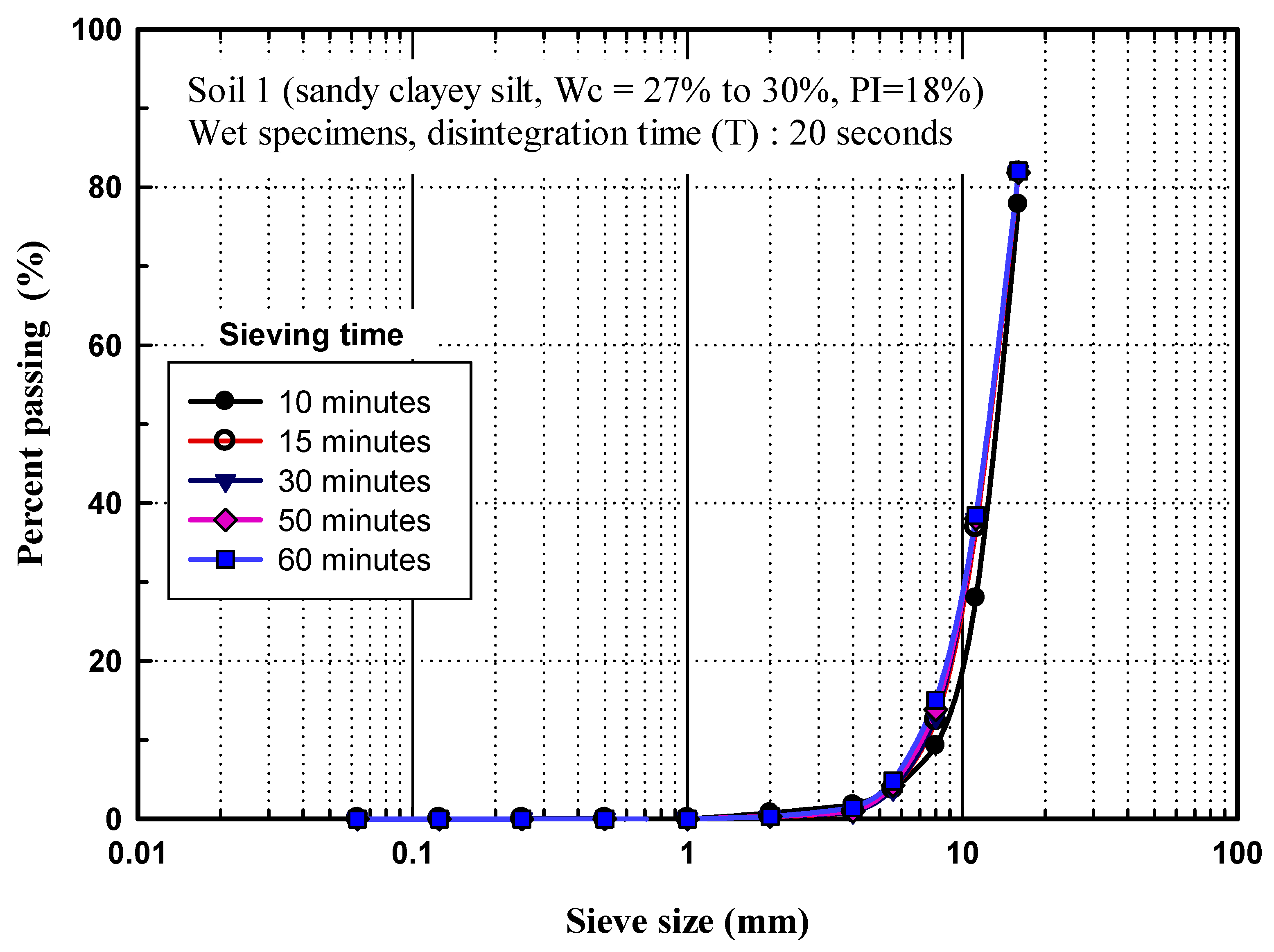

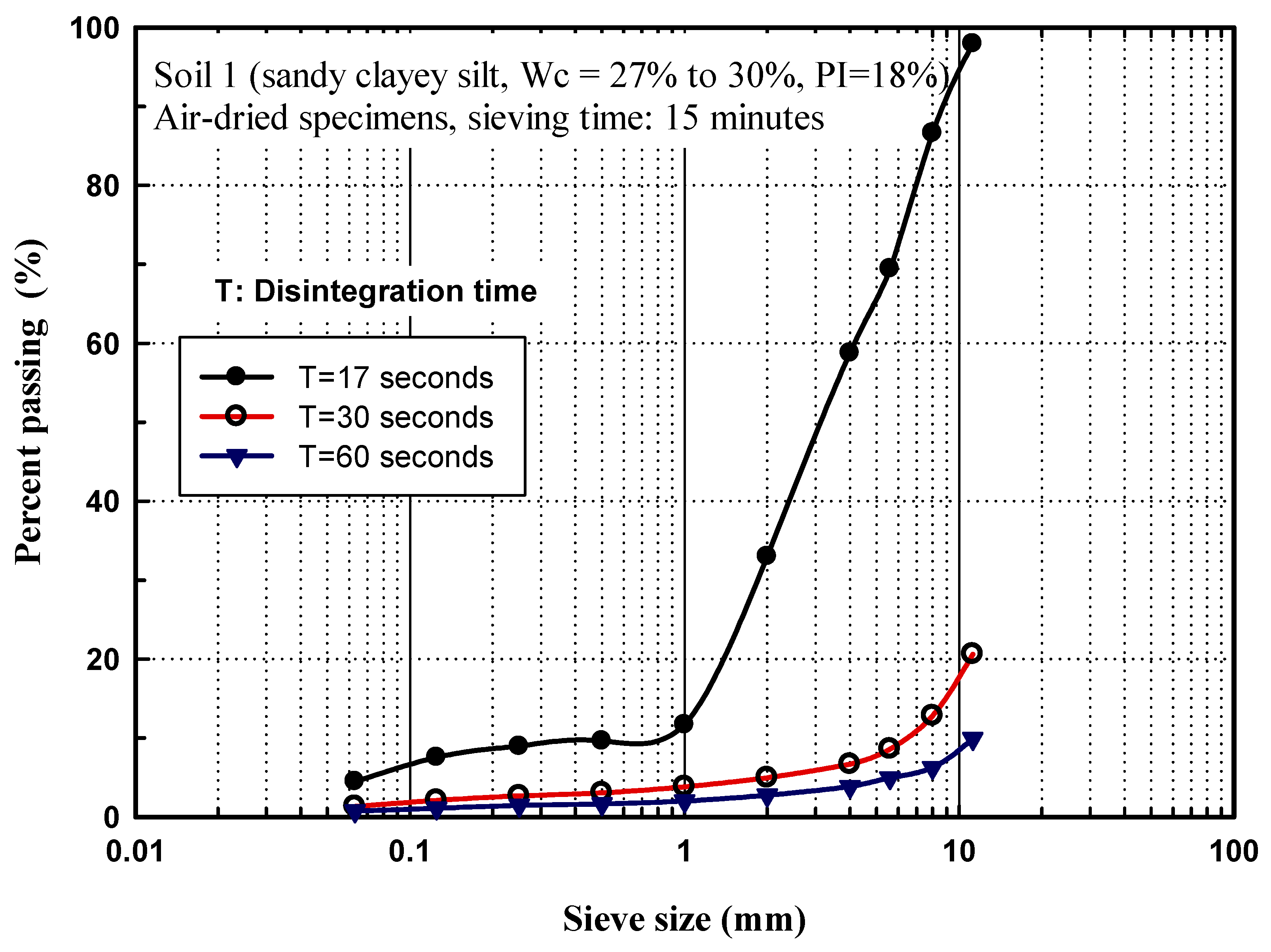

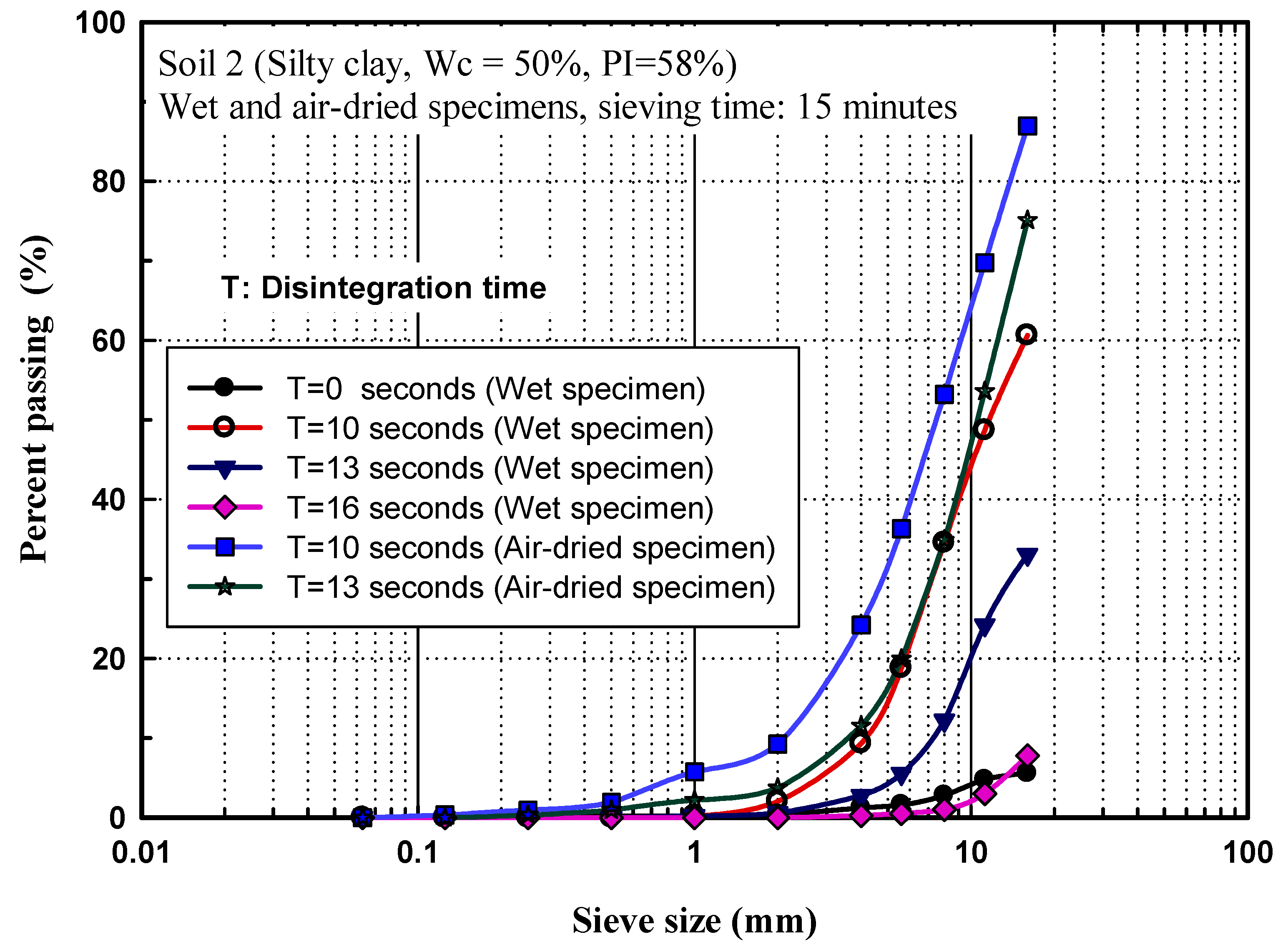

3.2. Dry Sieve Tests

3.2.1. Sieving Time

3.2.2. Proper (Ideal) Disintegration Time

4. Discussion

- Mechanical interlocking: this mainly occurs if the material’s particles are long and thin in shape, leading to large masses becoming completely interlocked.

- Surface attraction: force between soil particles can increase the substantial bonds between particles. This effect is more pronounced in very fine particles (with less than 10-micrometre diameter) due to a high ratio of specific surface to unit volume.

- Plastic welding: this occurs due to the development of very high pressures on an extremely small surface area between irregular particles.

- Electrostatic attraction: the movement of the particles is caused by the electrostatic forces between particles

- Effect of moisture: Moisture has the effect of raising the surface tension effects by collecting near points of contact between particles. It may also dissolve small sections of the particles and act as a bonding agent on subsequent evaporation.

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Kitazume, M. Influence of specimen preparation on unconfined compressive strength of cement-stabilized Kaolin clay. In Proceedings of the International Symposium on Recent Research, Advances & Execution Aspects of Ground Improvement Works, Brussels, Belgium, 13 May–1 June 2012; Volume 2, pp. 385–393. [Google Scholar]

- European Committee for Standardization. Execution of Special Geotechnical Works—Deep Mixing; EN 14679; English Version; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- EuroSoilStab. Development of Design and Construction Methods to Stabilize Soft Organic Soils: Design Guide for Soft Soil Stabilization; CT97-0351; Industrial and Materials Technologies Programme (Rite-EuRam III); European Commission: Bryssel, Belgium, 2002. [Google Scholar]

- Carlsten, P.; Ekström, J.E. Lime and Lime Cement Columns. Guide for Project Planning, Construction and Inspection; Report 4:95E; Swedish Geotechnical Society: Linköping, Sweden, 1997; p. 111. [Google Scholar]

- Åhnberg, H.; Holm, G. Influence of laboratory procedures on properties of stabilized soil specimens. In Proceedings of the International Symposium on Deep Mixing & Admixture Stabilization, Okinawa, Japan, 19–21 May 2009; pp. 1–6. [Google Scholar]

- Bitir, A.C.; Musat, V.; Larsso, S. Laboratory methods used to assess the mechanical properties of soft soils improved by deep mixing. Bull. Inst. Politeh. Sect. Constr. Arhit. 2015, 61, 165. [Google Scholar]

- Japanese Geotechnical Society (JGS 0821-00 2000). Practice for making and curing stabilized soil specimens without compaction, Report 13. In Proceedings of the International Conference on Deep Mixing, Best Practice and Recent Advances, Stockholm, Sweden, 23–25 May 2005; Volume 2, pp. 816–835. [Google Scholar]

- Kitazume, M.; Terashi, M. The Deep Mixing Method; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Bhadriraju, V.; Puppala, A.J.; Madhyannapu, R.S.; Williammee, R. Laboratory procedure to obtain well-mixed soil binder samples of medium stiff to stiff expansive clayey soil for deep soil mixing simulation. Geotech. Test. J. 2007, 31, 225–238. [Google Scholar] [CrossRef]

- Bruce ME, C.; Berg, R.R.; Collin, J.G.; Filz, G.M.; Terashi, M.; Yang, D.S. Deep Mixing for Embankment and Foundation Support; Publication No. FHWA-HRT-13-046; Federal Highway Administration Design Manual; Federal Highway Administration: Washington, DC, USA, 2013.

- Kitazume, M.; Grisolia, M.; Leder, E.; Marzano, I.P.; Correia, A.A.S.; Oliveira PJ, V.; Åhnberg, H.; Andersson, M. Applicability of molding procedures in laboratory mix tests for quality control and assurance of the deep mixing method. Soils Found. 2015, 55, 761–777. [Google Scholar] [CrossRef]

- Grisolia, M.; Leder, E.; Marzano, I.P. Standardization of the molding procedures for stabilized soil specimens as used for QC/QA in deep mixing application. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, 2013, 2–6 September; pp. 2481–2484.

- Marzano, I.P.; Leder, E.; Grisolia, M.; Danisi, C. Laboratory study on the molding techniques for QC/QA process of a Deep Mixing work. In Proceedings of the 3rd International Conference on New Developments in Soil Mechanics and Geotechnical Engineering, Near East University, Nicosia, North Cyprus, 28–30 June 2012; ISBN 975-8359-28-2. [Google Scholar]

- Grisolia, M.; Kitazume, M.; Leder, E.; Marzano, I.P.; Morikawa, Y. Laboratory study on the applicability of molding procedures for the preparation of cement stabilized specimens. In Proceedings of the IS-GI Brussels 2012, Brussels, Belgium, 30 May–1 June 2012. [Google Scholar]

- Correia, A.; Venda Oliveir, P.; Lemos, L. Prediction of the unconfined compressive strength in soft soil chemically stabilized. In Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris, France, 2–6 September 2013; pp. 2457–2460. [Google Scholar]

- Åhnberg, H.; Andersson, G. SGI Laboratory Tests—Influence of Molding Technique. International Collaborative Study on Deep Mixing Method; Task Report, SGI14187/14598; Swedish Geotechnical Society: Linköping, Sweden, 2011; 11p. [Google Scholar]

- Jacobson, J.R.; Filz, G.M.; Mitchell, J.K. Factors Affecting Strength Gain in Lime-Cement Columns and Development of a Laboratory Testing Procedure; Final Report; Virginia Transportation Research Council: Charlottesville, VA, USA, 2003. [Google Scholar]

- Janz, M.; Johansson, S.E. The Function of Different Binding Agents in Deep Stabilization; Report 9; Swedish Deep Stabilization Research Centre: Linköping, Sweden, 2002; pp. 1–47. [Google Scholar]

- Edstam, T. Laboratorieinblandning för Stabilisering av lera- Referensmetod; Arbetsrapport 16; Swedish Deep Stabilization Research Centre: Linköping, Sweden, 2000. (In Swedish) [Google Scholar]

- ASTM International. Standard Practice for Laboratory Preparation of Soil-Lime Mixtures Mechanical Mixer; ASTM D3551; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Methods for Unconfined Compressive Strength of Compacted Soil-Lime Mixtures; ASTM D 5102; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- ASTM International. ASTM Standards on Soil Stabilization with Admixtures, 2nd ed.; ASTM International: Philadelphia, PA, USA, 1992. [Google Scholar]

- European Committee for Standardization. Earthworks—Part 4: Soil Treatment with Lime and/or Hydraulic Binders; EN 16907-4; European Committee for Standardization: Brussels, Belgium, 2018. [Google Scholar]

- Central Laboratory Ponts Et Chaussees (LCPC). Soil Treatment with Limé and/or Hydraulic Binders. In Application to the Construction of Fills and Capping Layers; Technical Guide; LCPC: Paris, France, 2004. [Google Scholar]

- Association Française de Normalisation. Unbound and Hydraulically Bound Mixtures-Part 53: Method for the Manufacture of Test Specimens of Hydraulically Bound Mixtures Using Axial Compression; NF EN 13286-53; Association Française de Normalisation (AFNOR): Brussels, Belgium, 2005. [Google Scholar]

- British Standard. Stabilized Materials for Civil Engineering Purposes; BS 1924–1:1990: Part 1 and 2; British Standard Institution: London, UK, 1990. [Google Scholar]

- Huang, P.; Patel, M.; Santagata, M.C.; Bobet, A. Classification of Organic Soils; Publication FHWA/IN/JTRP-2008/02; Joint Transportation Research Program, Indiana Department of Transportation and Purdue University; Purdue University: West Lafayette, IN, USA, 2009. [Google Scholar] [CrossRef]

- Karlsson, R.; Hansbo, S. Soil Classification and Identification; Swedish Council for Building and Research: Stockholm, Sweden, 1981; Part 2. [Google Scholar]

- Swedish Standard. Geotechnical Tests—Cone Liquid Limit; Swedish Standard SS 027120; Swedish Standards Commission: Stockholm, Sweden, 1990. (In Swedish) [Google Scholar]

- Swedish Standard. Geotechnical Tests—Plastic Limit; Swedish Standard SS 027121; Swedish Standards Commission: Stockholm, Sweden, 1990. (In Swedish) [Google Scholar]

- Swedish Standard. Geotechnical Tests—Organic Content-Ignition Loss Method; Swedish Standard SS 027105; Swedish Standards Commission: Stockholm, Sweden, 1990. (In Swedish) [Google Scholar]

- Swedish Standard. Geotechnical Tests—Particle Size Distribution-Sedimentation; Swedish Standard SS 027124; Swedish Standards Commission: Stockholm, Sweden, 1990. (In Swedish) [Google Scholar]

- Swedish Standard. Geotechnical Tests—Particle Size Distribution-Sieving; Swedish Standard SS 027123; Swedish Standards Commission: Stockholm, Sweden, 1990. (In Swedish) [Google Scholar]

- Larsson, S. Mixing Processes for Ground Improvement by Deep Mixing; Report 12; Swedish Deep Stabilisation Research Centre: Linköping, Sweden, 2000. [Google Scholar]

- Coulson, J.M.; Richardson, J.F.; Peacock, D.G. Chemical Engineering, 2nd ed.; Pergamon Press: Oxford, UK, 1979; Volume 3. [Google Scholar]

- Ferraro, A.; Farina, I.; Race, M.; Colangelo, F.; Cioffi, R.; Fabbricino, M. Pre-treatments of MSWI fly-ashes: A comprehensive review to determine optimal conditions for their reuse and/or environmentally sustainable disposal. Rev. Environ. Sci. Bio/Technol. 2019, 1–19. [Google Scholar] [CrossRef]

| Preparation Standards and Reference | Natural Soil Homogenization Method | Mixer Type |

|---|---|---|

| Tokyo Institute of Technology, Japan [11] | Soil is homogenized by mixing with its initial water content. | Domestic dough mixer with a 5000 to 30,000 cm3 mixing bowl |

| Sapienza University of Rome, Italy [12,13,14] | The soil is homogenized by remixing alone. Water is added at this stage to adjust the soil water content. | Hobart mixer |

| University of Coimbra, Portugal [15] | The soil is homogenized by re-mixing with a mixing speed of 136 rpm. To readjust the soil water content, water is added to the soil as a slurry of water and binder mixture. | Hobart mixer (model N50) |

| Swedish Geotechnical Society (SGS) [4,16] | The soil is first homogenized thoroughly by mixing the soil alone. | Dough mixer or kitchen mixer with sufficient capacity and rpm |

| Japanese Geotechnical Society (JGS) [7,8] | The soil is homogenized by stirred it using a mixer. The soil water content is adjusted by adding water. | Domestic dough mixer with a 5000 to 30,000 cm3 mixing bowl |

| [3] | The soil is mixed until becoming visually homogenous. | Dough mixer or kitchen mixer with sufficient capacity and rpm |

| [17] | Mixing the conglomerate of soil thoroughly for three to four minutes. | Kitchen Aid® dough mixer with dough hook. Outer spindle rotating at 155 rpm and inner spindle at 68 rpm. |

| [18,19] | Homogenizing the soil by mixing it alone for two to six minutes. It normally takes place the day before the stabilizer is added. | Kitchen mixer or concrete mixer |

| ASTM [20,21,22] | Soil is air-dried for 24 hours and mixed with dry binder for one minute or until the mixture homogenized visually. | Mechanical mixer, capable of producing uniform and homogeneous mixtures |

| Federal Highway Administration [10] | Mixing the soil for approximately three minutes at the lowest setting of the mixer (approximate rotation of the mixing tool of 100 to 175 cycles/min). Water is added to adjust the soil water content. | Kitchen mixer with sufficient capacity |

| European standard [23] | The soil in the field corrected to the particle size distribution before adding the binder by blending the soil alone to break up large blocks or boulders. | Dough mixer or kitchen mixer with sufficient capacity and rpm |

| French standard [24,25] | The sample is disintegrated or homogenized for several minutes. | Mixer with enough capacity |

| British standard [26] | Mixing the untreated soil alone either by mechanical mixer or by hand. | Kitchen mixer with sufficient capacity |

| Parameters | Soil 1 | Soil 2 | Soil 3 | Soil 4 |

|---|---|---|---|---|

| Soil location | Gothenburg | Sunderbyn, Luleå | Umeå | |

| Soil conditions | Aerobic | Anaerobic (N) | Aerobic | Anaerobic |

| Depth, m | 1–2 | 1.8–2 | 0.3–0.4 | 2.7–4 |

| Particle-size distribution (%) **** | ||||

| Fine sand (%) (1–0.63 mm) | 29 | 4 | 15 | 10 |

| Silt (%) (0.063–0.002 mm) | 55 | 67 | 64 | 80 |

| Clay (%) (<0.002 mm) | 16 | 29 | 21 | 10 |

| Consistency limits (%) | ||||

| Liquid limit (%) * | 37 | 95 | 48 | 45 |

| Plasticity limit (%) ** | 20 | 37 | 32 | 35 |

| Plasticity index (%) | 18 | 58 | 16 | 10 |

| Natural water content (%) | 27–30 | 50 | 43–45 | 40–50 |

| Particle density | 2.69 | 2.69 | 2.67 | 2.71 |

| Loss of ignition % *** | 4.1 | 7 | 4.8 | 2.8 |

| Bulk density (g/cm3) | 1.51 | 1.73 | 1.76 | |

| pH | 5 | 7 | 4.6 | 6.4 |

| Soil Classification | Sandy clayey silt | Silty clay | Silty clay | Silt |

| Medium plasticity | Very high plasticity | Medium plasticity | Low–medium plasticity | |

| Soil | Soil 1 | Soil 2 | Soil 3 | Soil 4 |

|---|---|---|---|---|

| Soil location | Gothenburg | Sunderbyn, Luleå | Umeå | |

| Soil conditions | Aerobic | Anaerobic (N) | Aerobic | Anaerobic |

| Silicon oxide (SiO2) % | 65.7 | 54.7 | 54.1 | 63.3 |

| Aluminum oxide (Al2O3) % | 12.3 | 12.8 | 11.3 | 10.8 |

| Calcium oxide (CaO) % | 2.4 | 2.11 | 1.88 | 1.9 |

| Iron oxide (Fe2O3) | 3.42 | 4.33 | 4.93 | 3.7 |

| Potassium oxide (K2O) % | 2.84 | 2.77 | 2.67 | 2.29 |

| Magnesium oxide (MgO) % | 1.31 | 2.25 | 1.4 | 1.29 |

| MnO % | 0.15 | 0.217 | 0.0482 | 0.0644 |

| Sodium oxide (Na2O) % | 0.55 | 2.56 | 2.68 | 2.47 |

| P2O5 % | 0.15 | 0.182 | 0.16 | 0.176 |

| TiO2 % | 0.55 | 0.677 | 0.615 | 0.603 |

| Sulfate content, mg/kg TS | 24800 | 3400 | 2800 | |

| Soil Types | Water Content % | Specimen Type | Disintegration Time (T) (Second) | Number of Samples | Sieving Time (Minutes) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Soil 1 (Silty clay, PI = 18%) | 27–30 | Wet | 0 | 10 | 16 | 30 | 45 | 60 | 75 | 90 | 120 | 15 | 10 | 15 | 30 | 50 | 60 |

| Air dry | 17 | 30 | 60 | 4 | |||||||||||||

| Soil 2 (Silty clay, PI = 58%) | 50 | Wet | 0 | 10 | 13 | 16 | 8 | ||||||||||

| Air dry | 10 | 13 | |||||||||||||||

| Soil 3 (Silty clay, PI = 16%) | 47 | Wet | 0 | 6 | 12 | 22 | 8 | ||||||||||

| Air dry | 6 | 13 | 4 | ||||||||||||||

| Soil 4 (Silt, PI = 11%) | 40–50 | Wet | 0 | 7 | 15 | 30 | 10 | ||||||||||

| Air dry | 15 | 30 | 4 | ||||||||||||||

| Soil Types | Plasticity Index, PI% | Water Content % | Proper Disintegration Time (T), (Seconds) | D50, mm | |

|---|---|---|---|---|---|

| Between | Not Exceed | ||||

| Soil 1 (sandy clayey silt) | 18 | 27–30 | 10–20 | 30 | 4–5 |

| Soil 2 (silty clay) | 58 | 50 | 10–13 | 16 | 10.5 |

| Soil 3 (silty clay) | 16 | 47 | 6–13 | 25 | 10–11 |

| Soil 4 (silt) | 11 | 40 | 15–20 | 30 | 6.5 |

| 50 | 7 | 17 | 10.5 | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Jabban, W.; Laue, J.; Knutsson, S.; Al-Ansari, N. Effect of Disintegration Times of the Homogeneity of Soil prior to Treatment. Appl. Sci. 2019, 9, 4791. https://doi.org/10.3390/app9224791

Al-Jabban W, Laue J, Knutsson S, Al-Ansari N. Effect of Disintegration Times of the Homogeneity of Soil prior to Treatment. Applied Sciences. 2019; 9(22):4791. https://doi.org/10.3390/app9224791

Chicago/Turabian StyleAl-Jabban, Wathiq, Jan Laue, Sven Knutsson, and Nadhir Al-Ansari. 2019. "Effect of Disintegration Times of the Homogeneity of Soil prior to Treatment" Applied Sciences 9, no. 22: 4791. https://doi.org/10.3390/app9224791

APA StyleAl-Jabban, W., Laue, J., Knutsson, S., & Al-Ansari, N. (2019). Effect of Disintegration Times of the Homogeneity of Soil prior to Treatment. Applied Sciences, 9(22), 4791. https://doi.org/10.3390/app9224791