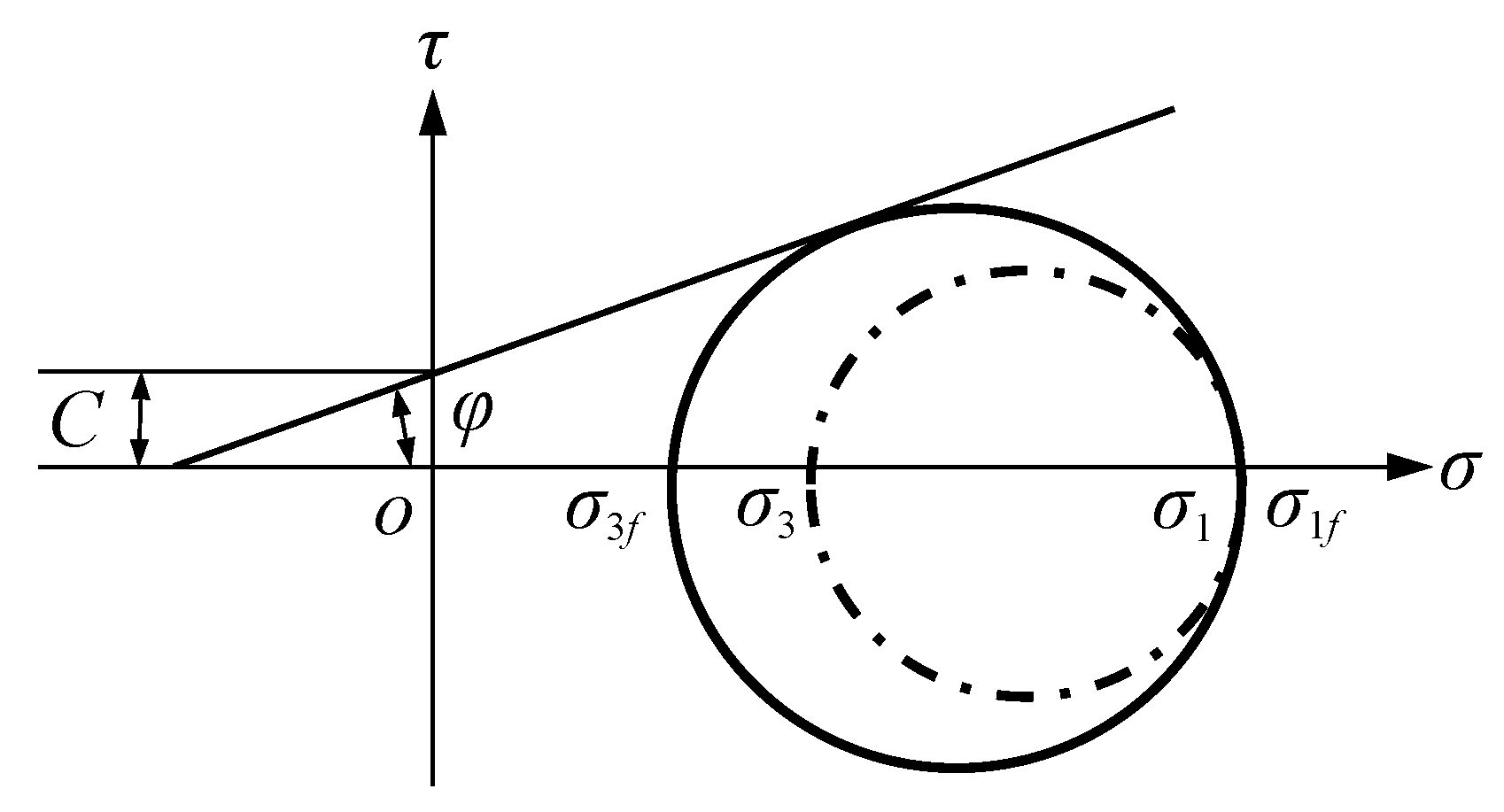

Figure 1.

Strength envelope of asphalt concrete triaxial test.

Figure 1.

Strength envelope of asphalt concrete triaxial test.

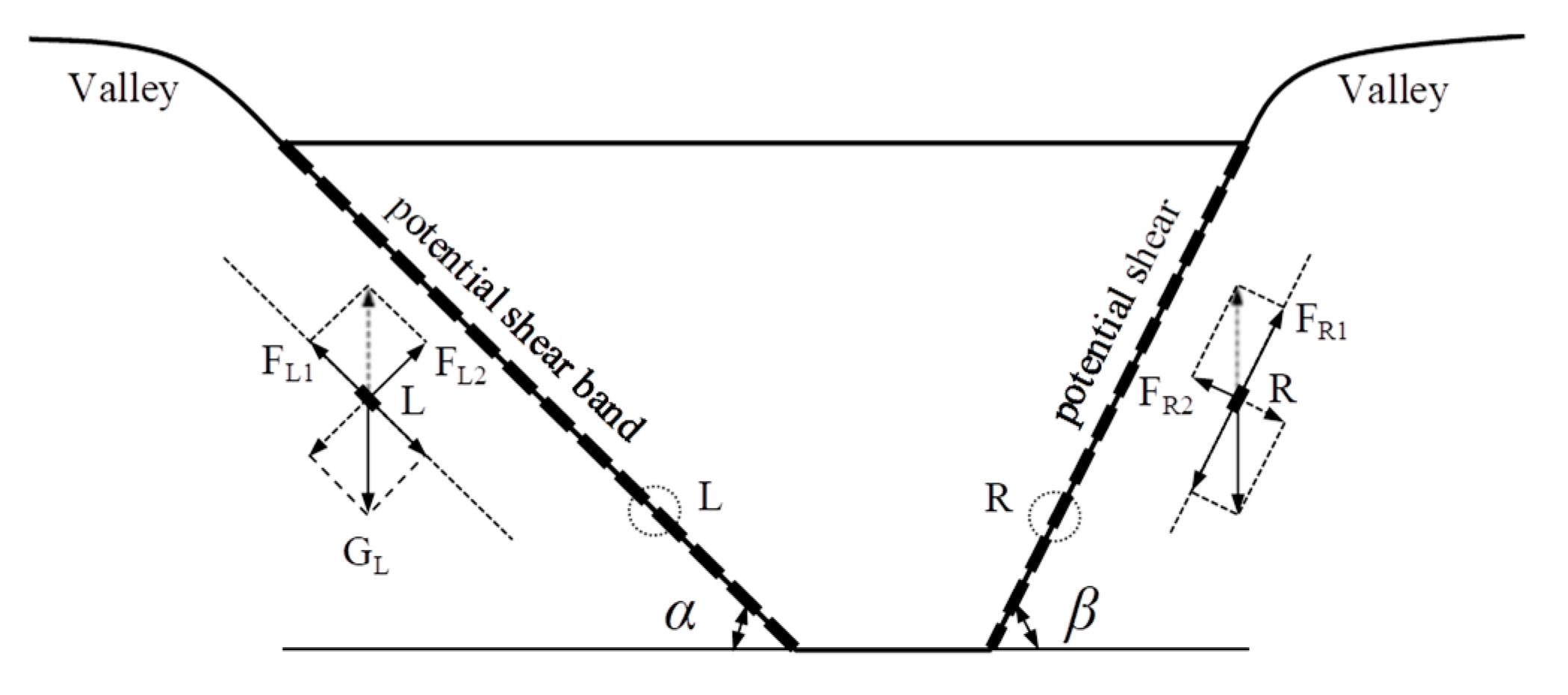

Figure 2.

Mechanical diagram of asphalt concrete core in potential shear band.

Figure 2.

Mechanical diagram of asphalt concrete core in potential shear band.

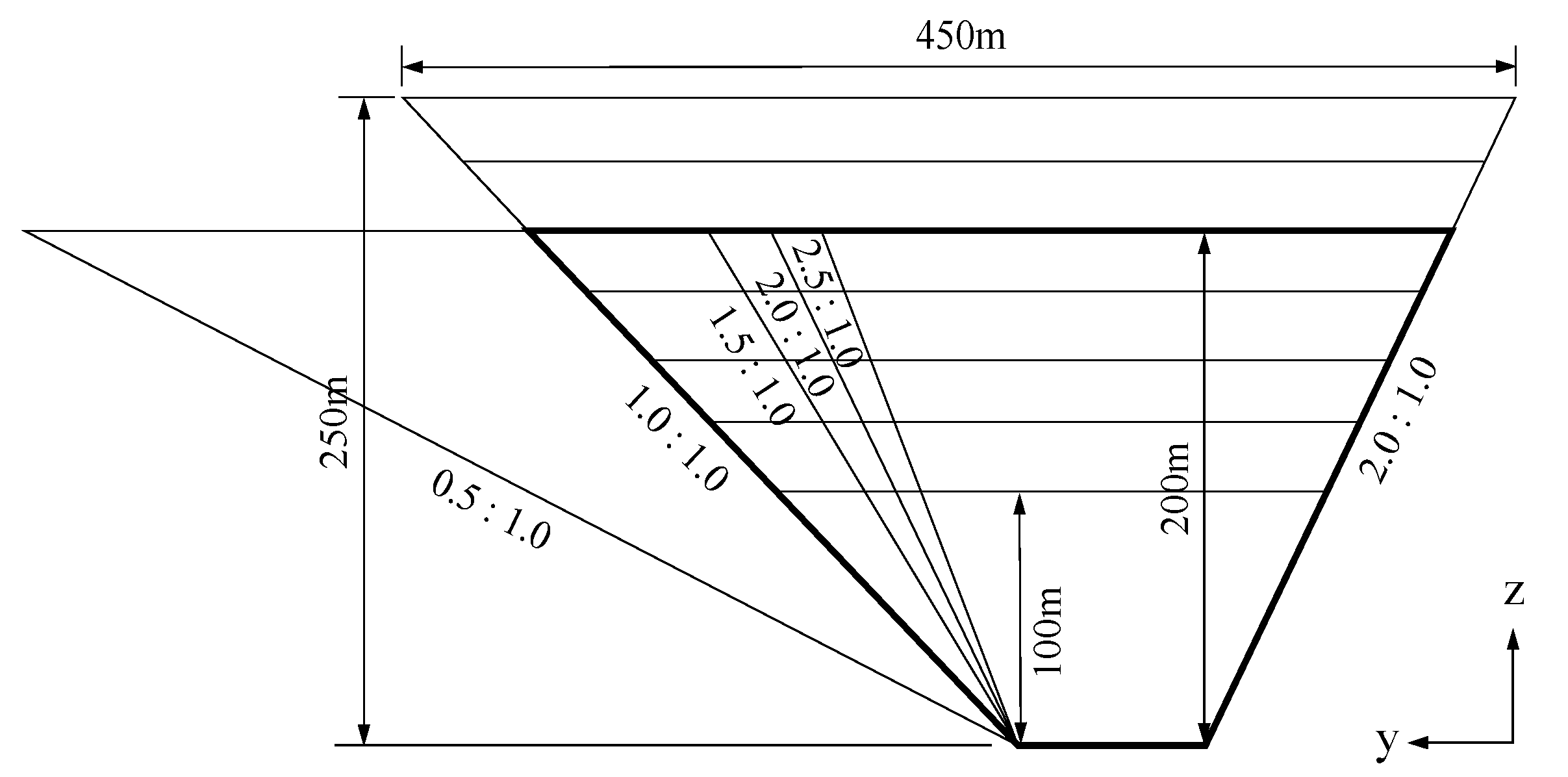

Figure 3.

Diagram of calculation schemes.

Figure 3.

Diagram of calculation schemes.

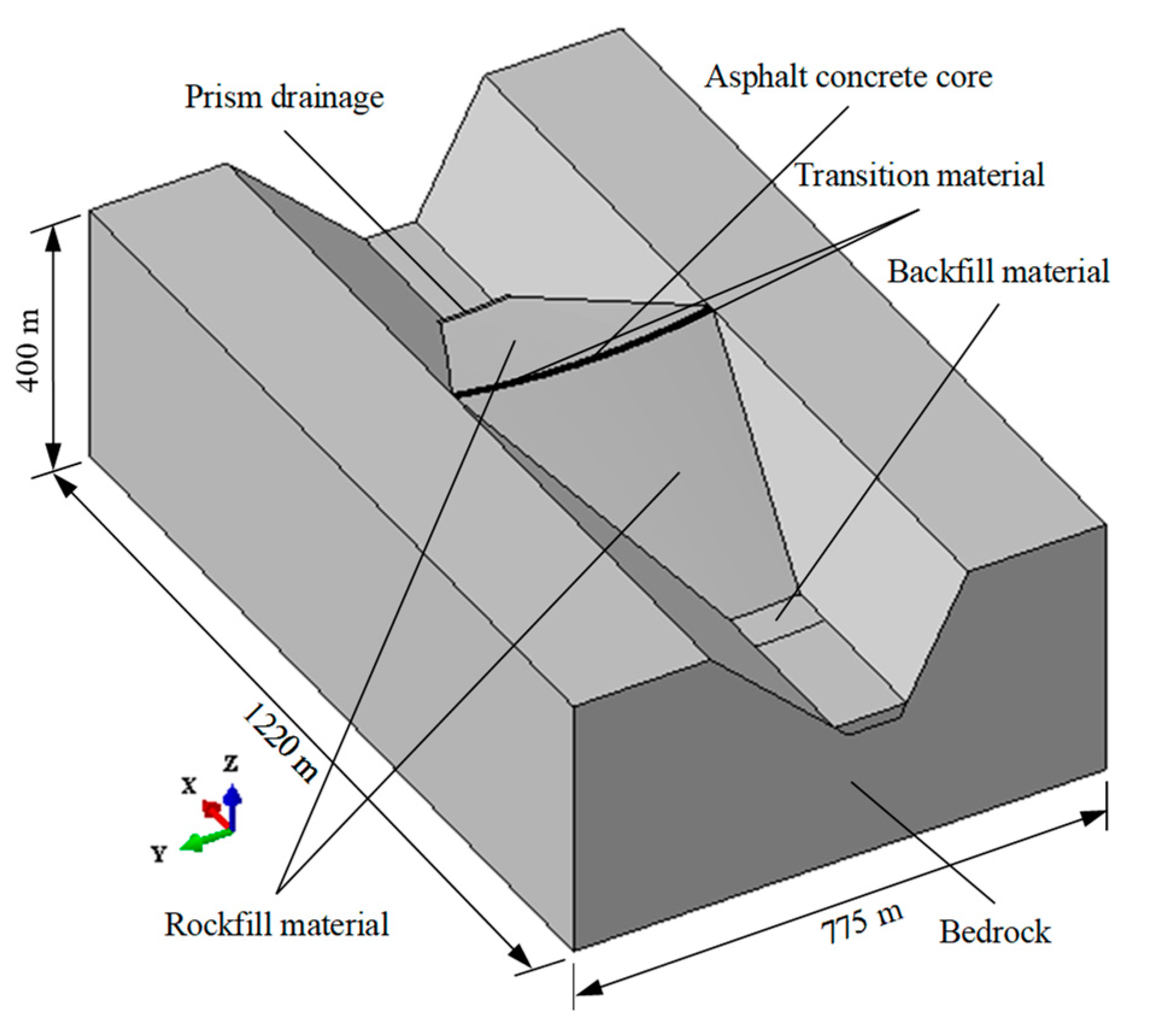

Figure 4.

Material regions of finite element method (FEM) standard model for asphalt concrete core rockfill dams (ACCRDs).

Figure 4.

Material regions of finite element method (FEM) standard model for asphalt concrete core rockfill dams (ACCRDs).

Figure 5.

Meshes of FEM standard model for ACCRDs.

Figure 5.

Meshes of FEM standard model for ACCRDs.

Figure 6.

Settlement contour of ACC (h =200 m).

Figure 6.

Settlement contour of ACC (h =200 m).

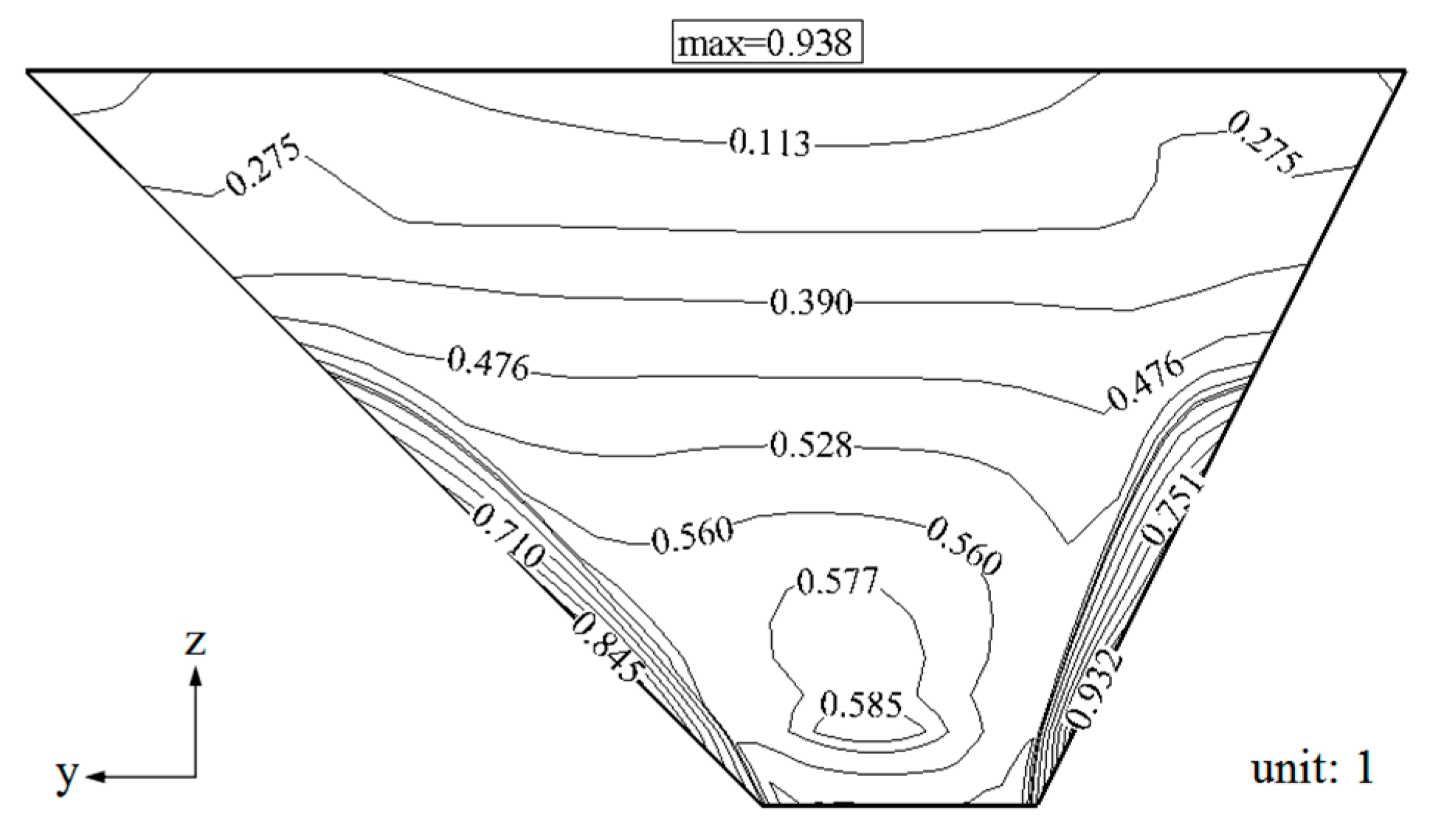

Figure 7.

Stress level contours of ACC (h =200 m).

Figure 7.

Stress level contours of ACC (h =200 m).

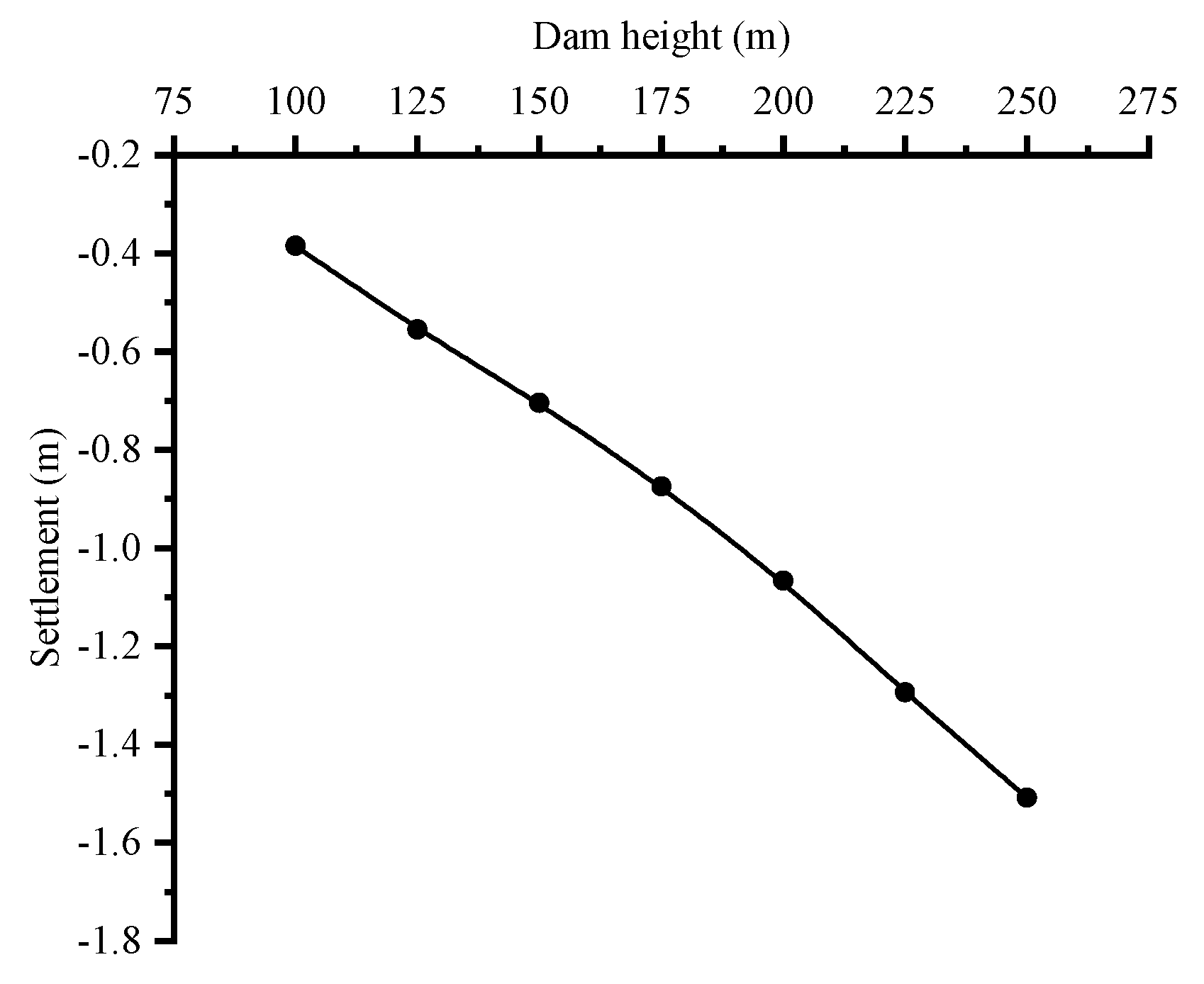

Figure 8.

Relationship between settlement maximum of ACC and dam height.

Figure 8.

Relationship between settlement maximum of ACC and dam height.

Figure 9.

Relationship between stress level maximum of ACC and dam height.

Figure 9.

Relationship between stress level maximum of ACC and dam height.

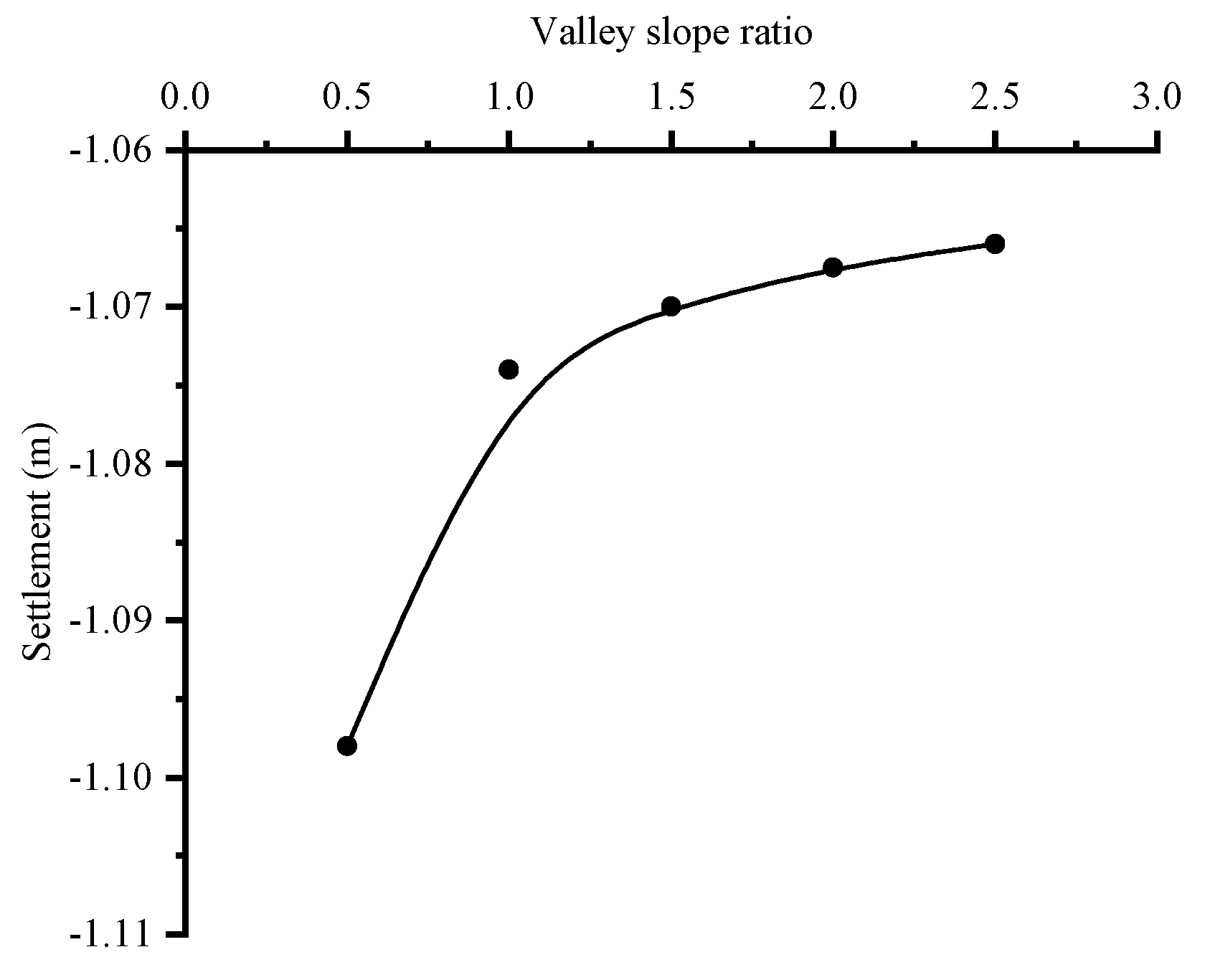

Figure 10.

Relationship between settlement maximum of ACC and valley slope ratio.

Figure 10.

Relationship between settlement maximum of ACC and valley slope ratio.

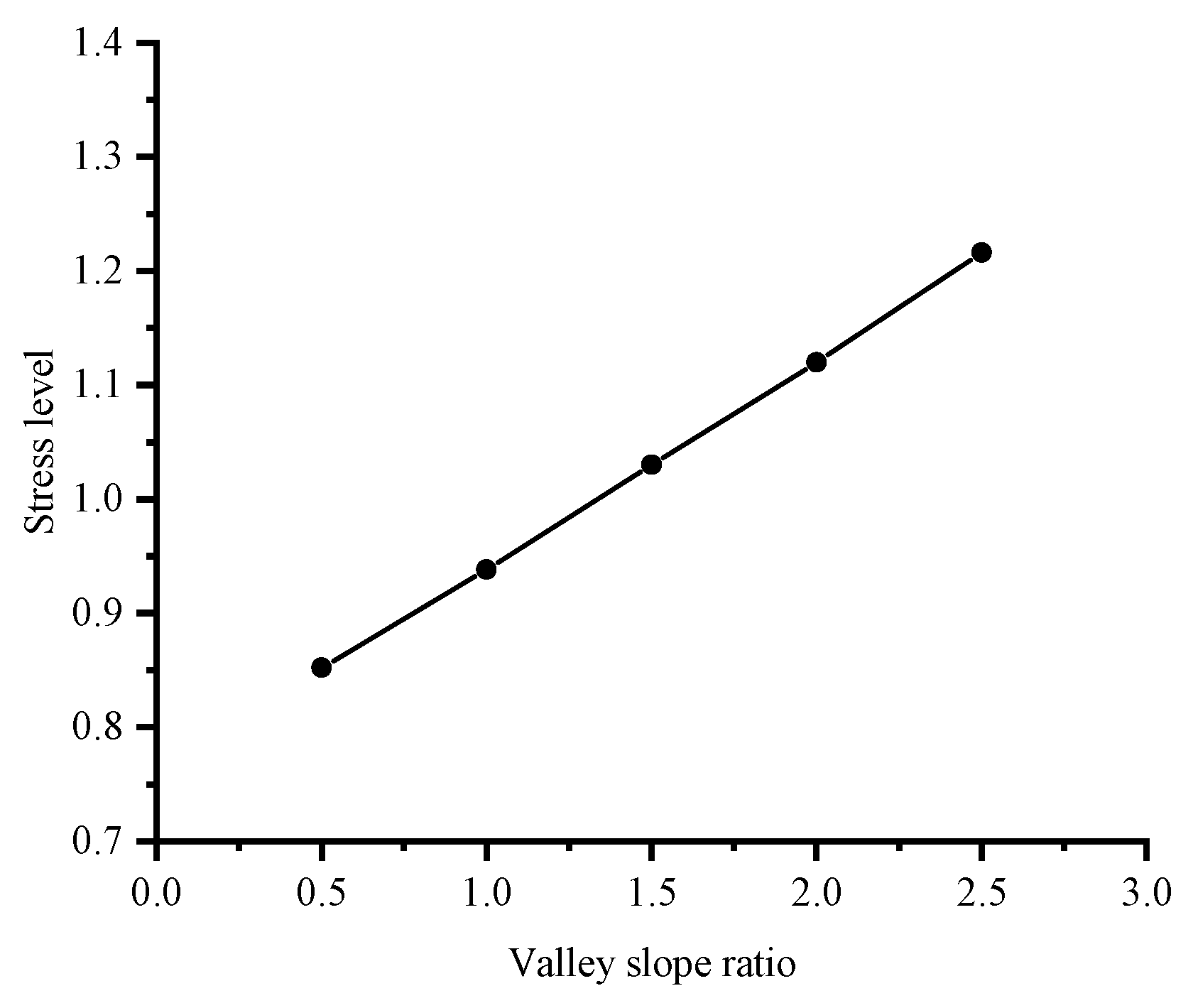

Figure 11.

Relationship between stress level maximum of ACC and valley slope ratio.

Figure 11.

Relationship between stress level maximum of ACC and valley slope ratio.

Figure 12.

Relationship between failure ratio of ACC that meets YSFCS and dam height.

Figure 12.

Relationship between failure ratio of ACC that meets YSFCS and dam height.

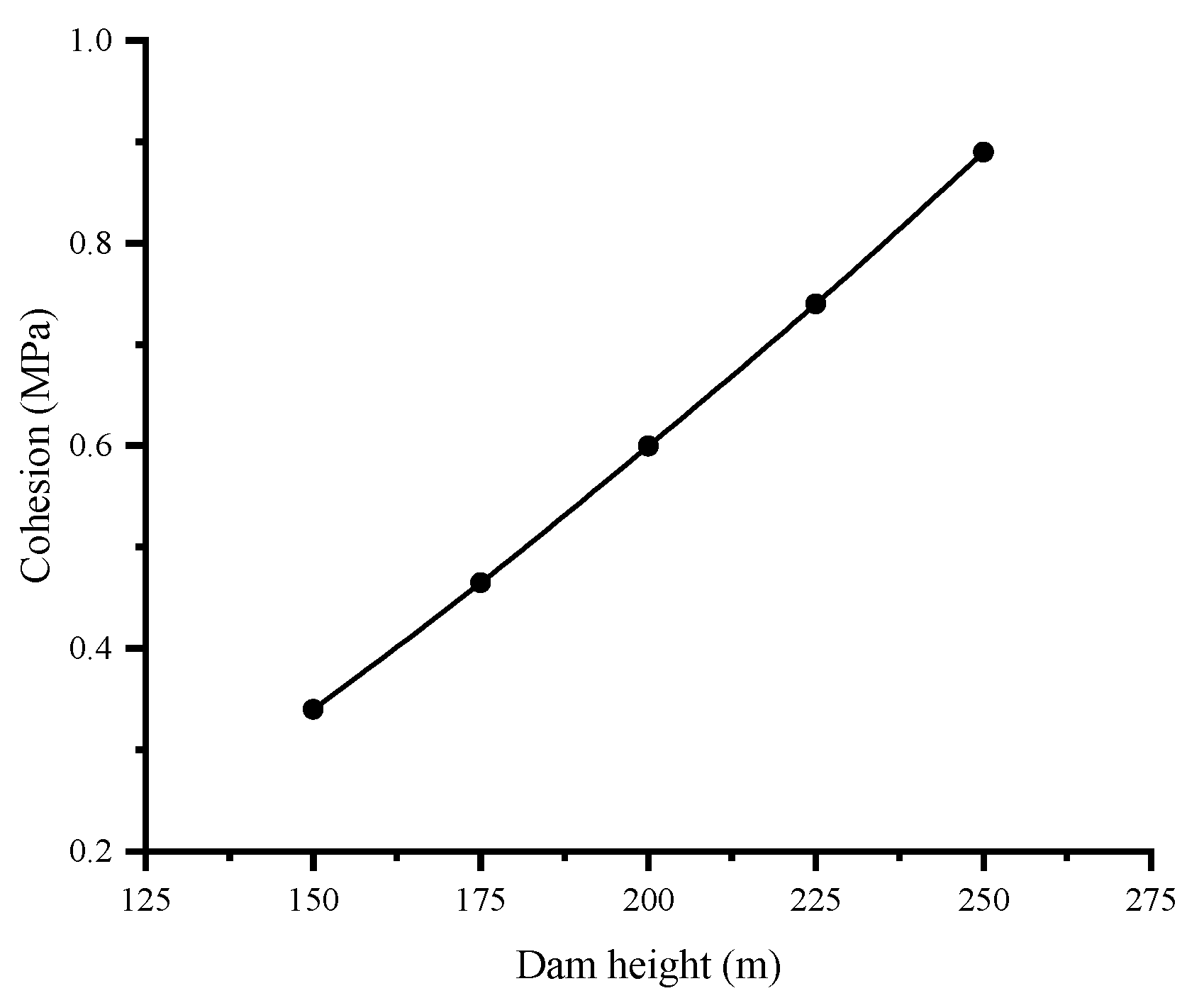

Figure 13.

Relationship between cohesion of ACC that meets YSFCS and dam height.

Figure 13.

Relationship between cohesion of ACC that meets YSFCS and dam height.

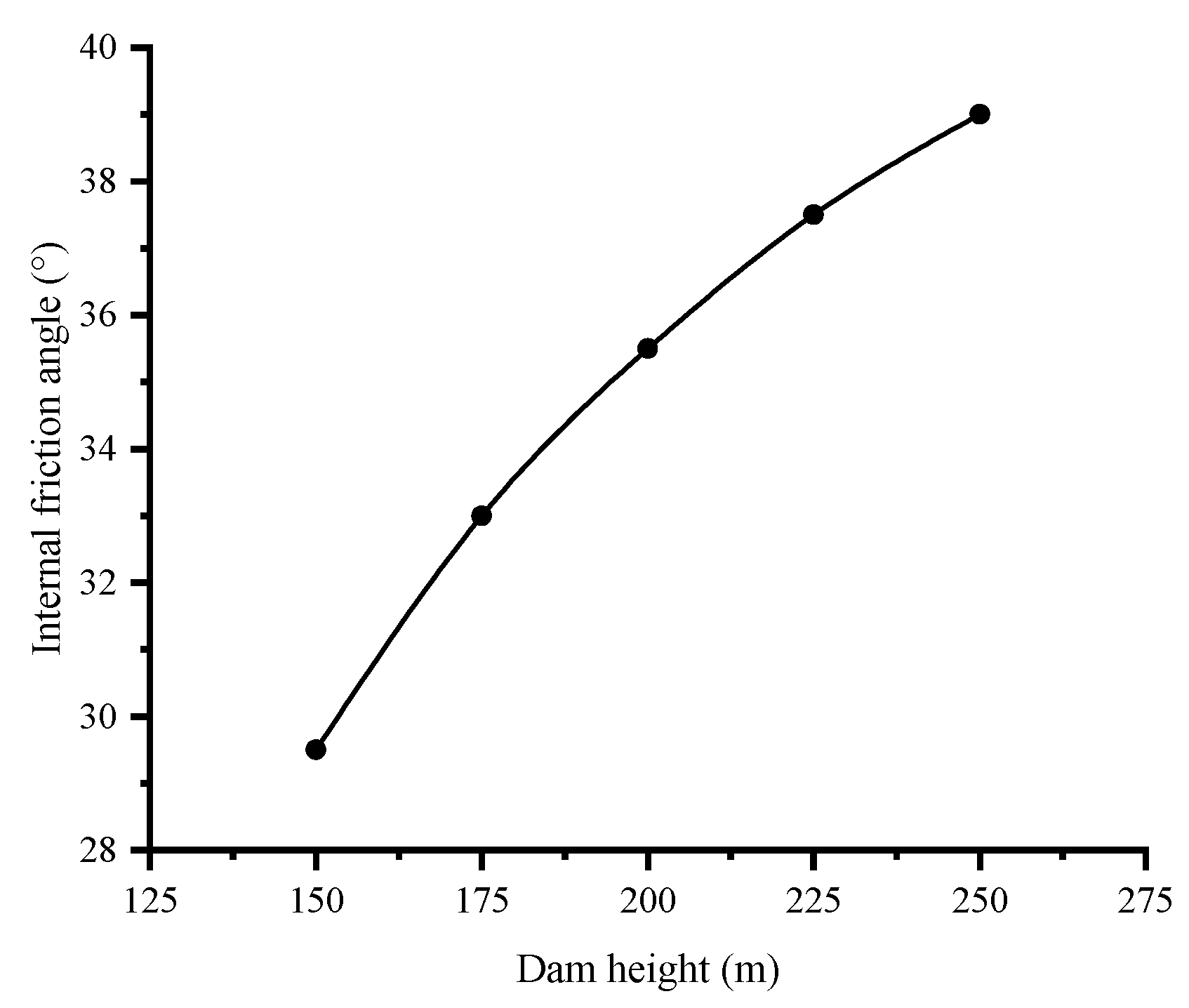

Figure 14.

Relationship between internal friction angle of ACC that meets YSFCS and dam height.

Figure 14.

Relationship between internal friction angle of ACC that meets YSFCS and dam height.

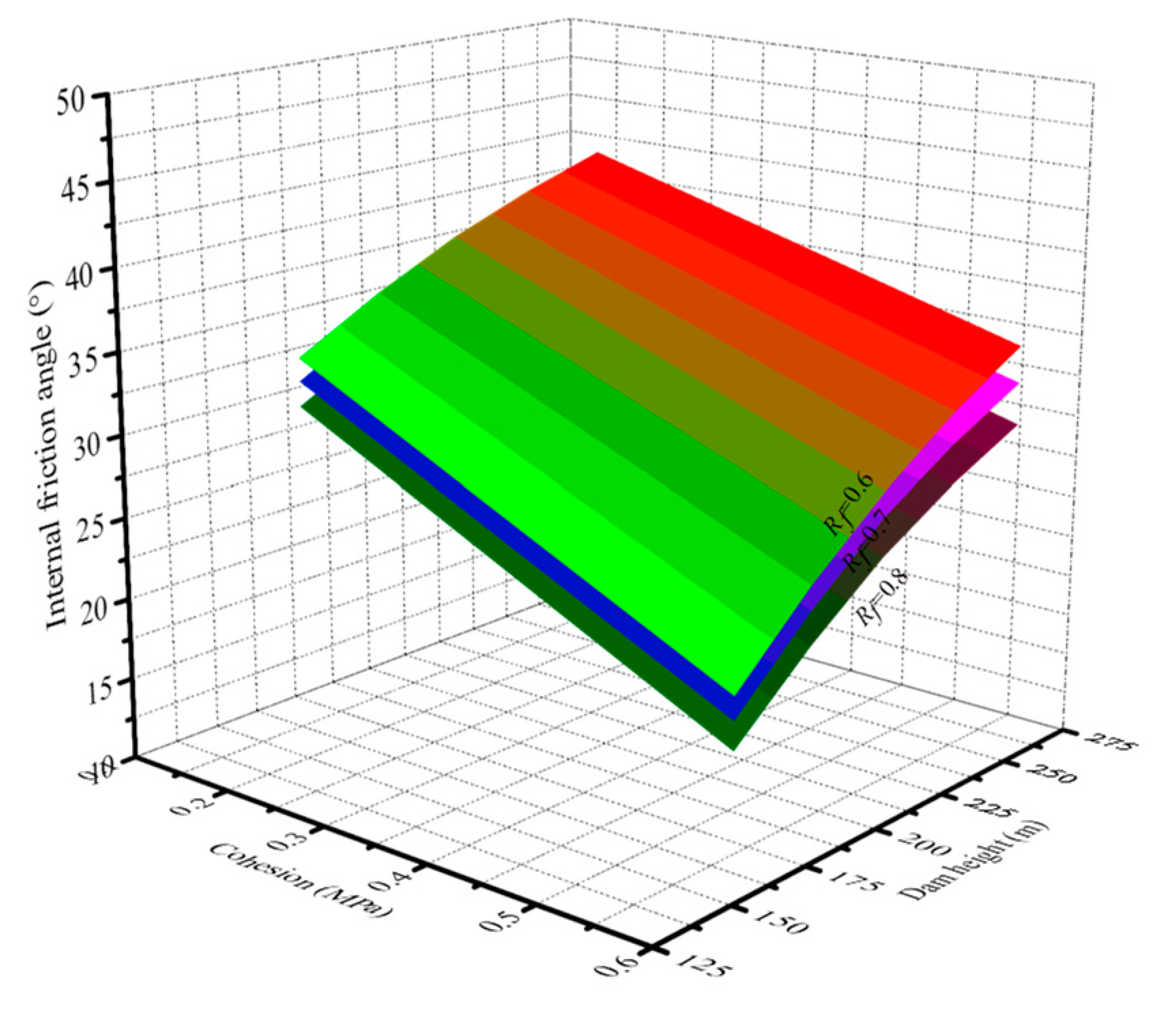

Figure 15.

Reasonable value ranges for the failure ratio, cohesion, and internal friction angle of ACC that comprehensively meet YSFCS under different dam heights.

Figure 15.

Reasonable value ranges for the failure ratio, cohesion, and internal friction angle of ACC that comprehensively meet YSFCS under different dam heights.

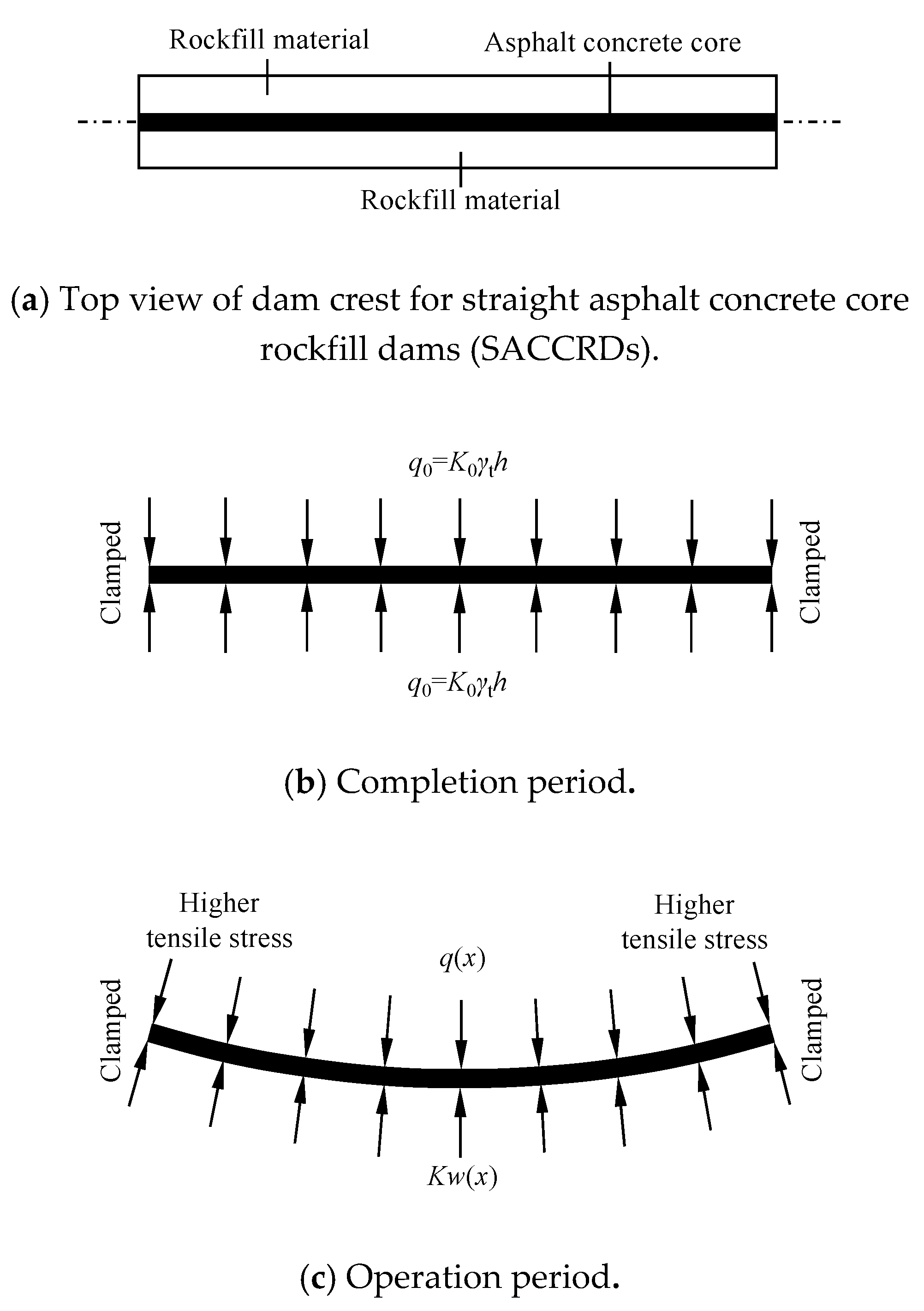

Figure 16.

Mechanical diagram of SACC (completion period and operation period).

Figure 16.

Mechanical diagram of SACC (completion period and operation period).

Figure 17.

Mechanical diagram of curved asphalt concrete core (CACC) (completion period and operation period).

Figure 17.

Mechanical diagram of curved asphalt concrete core (CACC) (completion period and operation period).

Figure 18.

Flexural deformation contours of SACC (h = 200 m).

Figure 18.

Flexural deformation contours of SACC (h = 200 m).

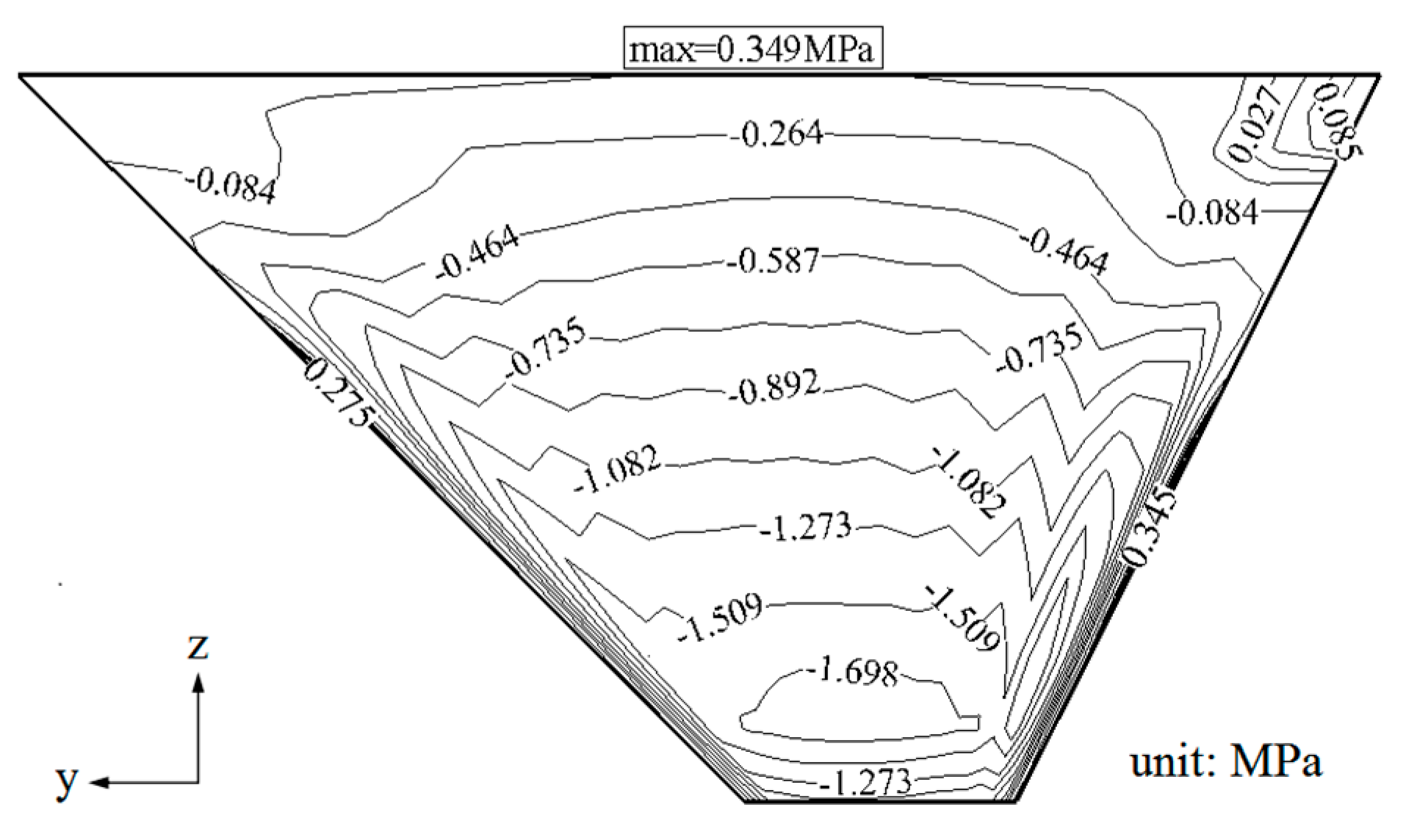

Figure 19.

Major principal stress contours of SACC (h = 200 m).

Figure 19.

Major principal stress contours of SACC (h = 200 m).

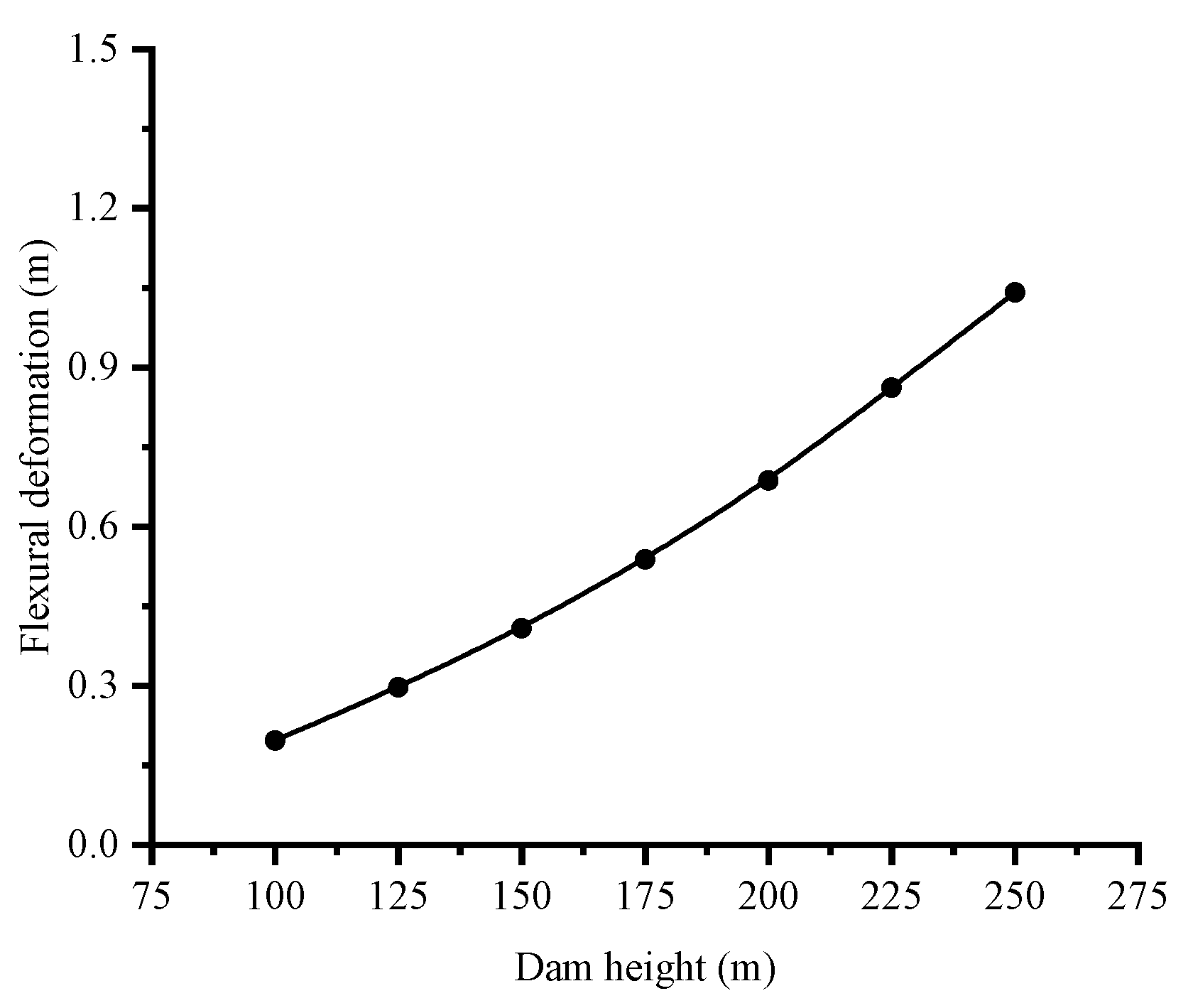

Figure 20.

Relationship between flexural deformation maximum of SACC and dam height.

Figure 20.

Relationship between flexural deformation maximum of SACC and dam height.

Figure 21.

Relationship between tensile stress maximum of SACC and dam height.

Figure 21.

Relationship between tensile stress maximum of SACC and dam height.

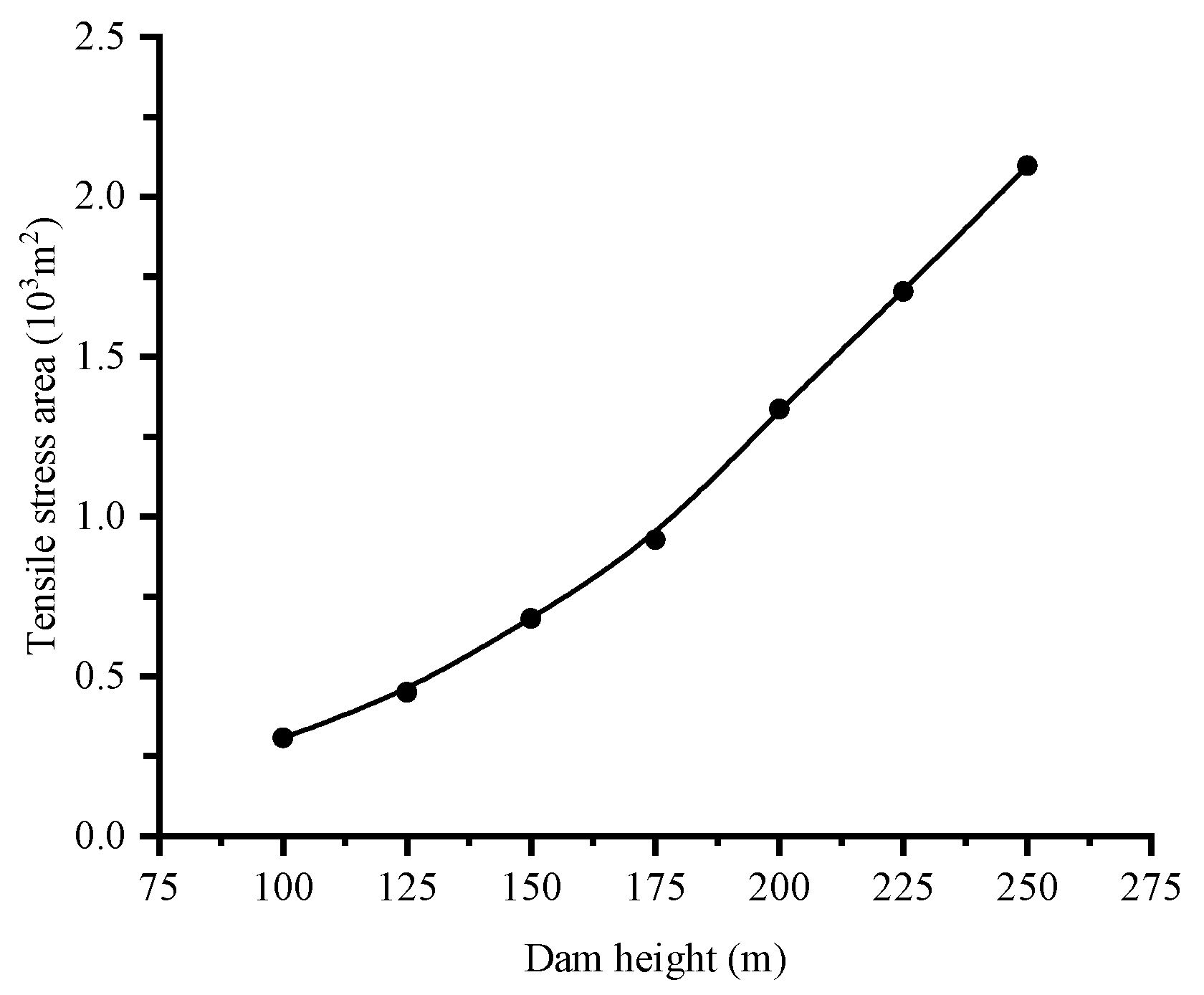

Figure 22.

Relationship between tensile stress area maximum of SACC and dam height.

Figure 22.

Relationship between tensile stress area maximum of SACC and dam height.

Figure 23.

Relationship between flexural deformation maximum of SACC and valley slope ratio.

Figure 23.

Relationship between flexural deformation maximum of SACC and valley slope ratio.

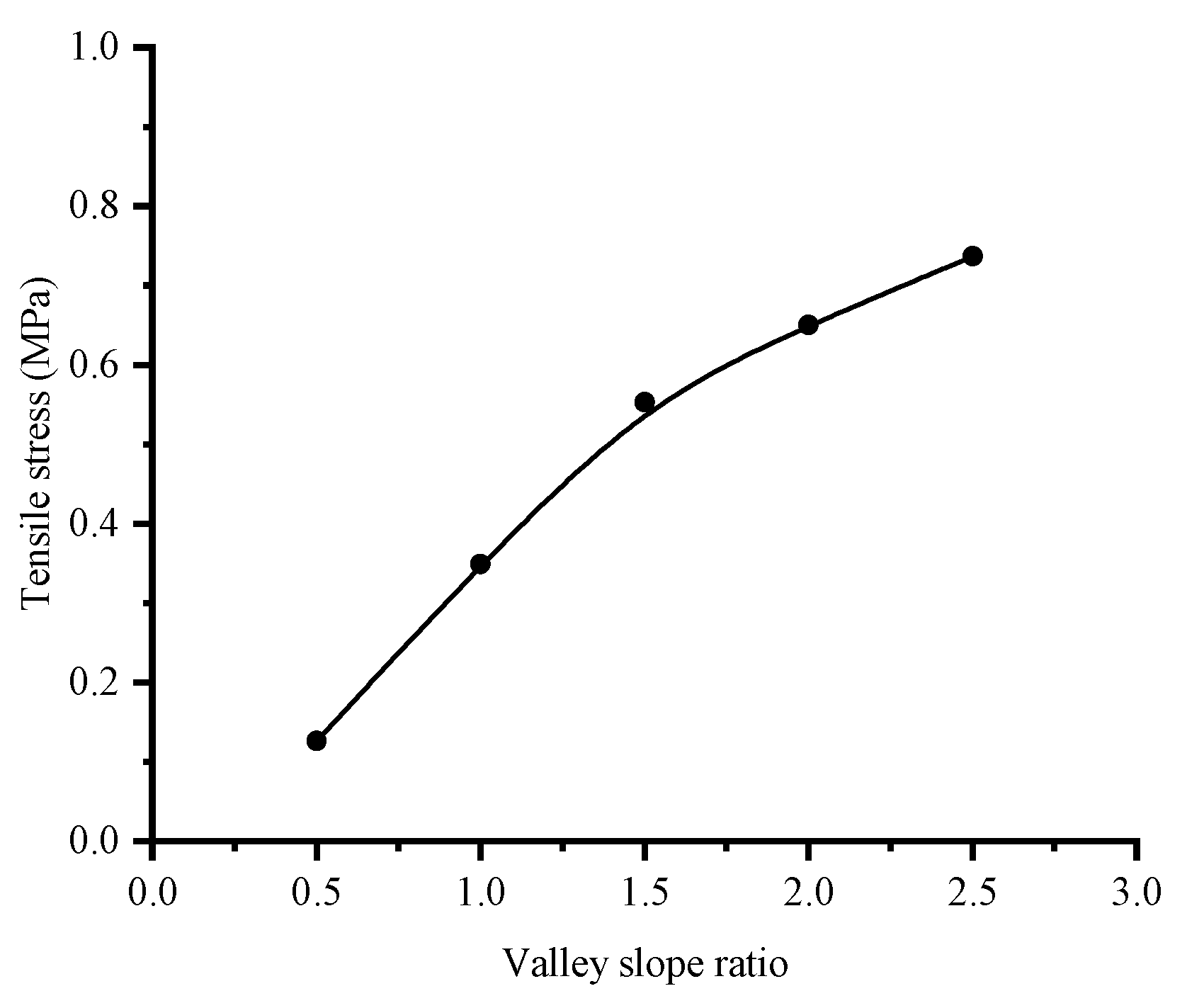

Figure 24.

Relationship between tensile stress maximum of SACC and valley slope ratio.

Figure 24.

Relationship between tensile stress maximum of SACC and valley slope ratio.

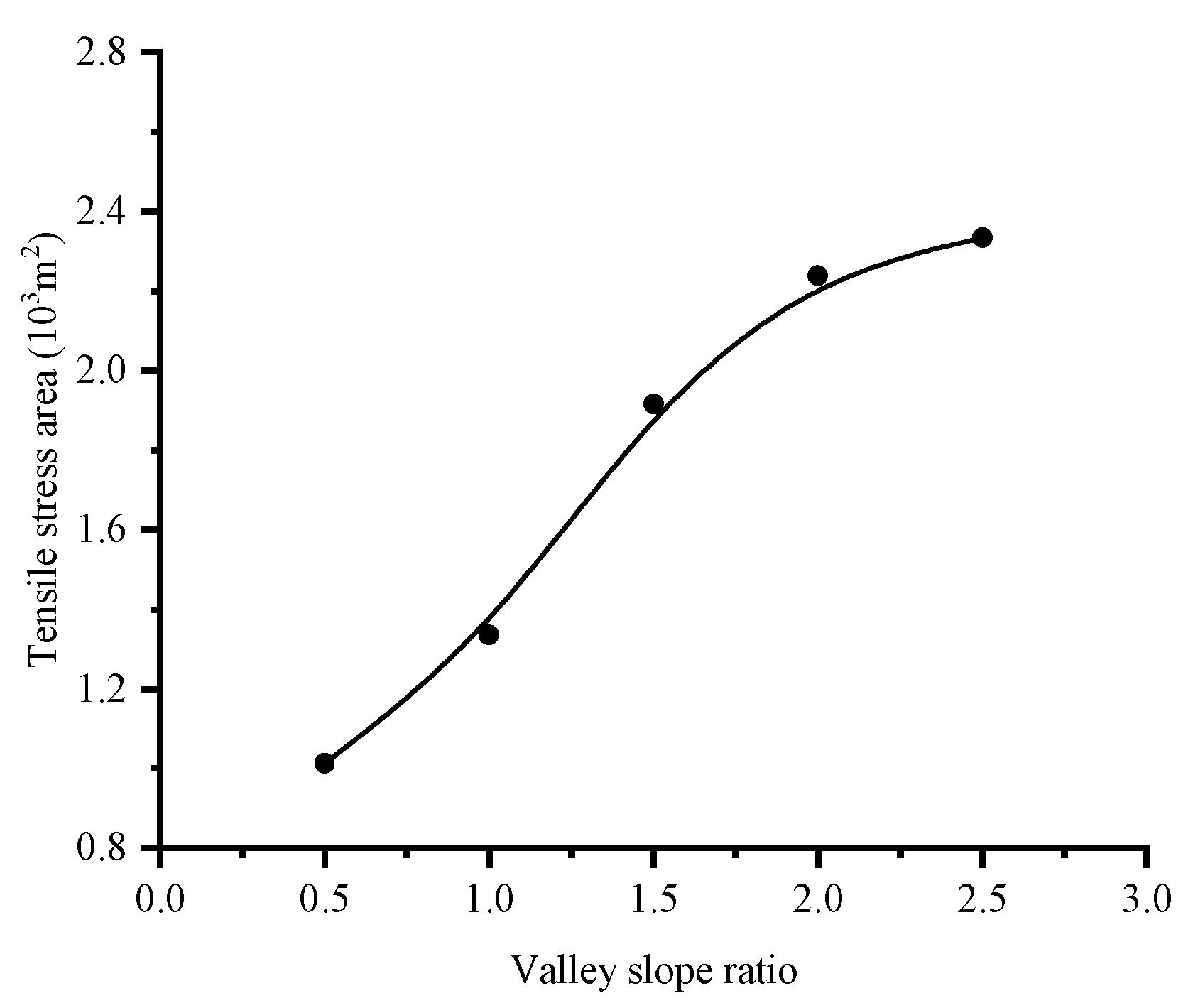

Figure 25.

Relationship between tensile stress area maximum of SACC and valley slope ratio.

Figure 25.

Relationship between tensile stress area maximum of SACC and valley slope ratio.

Figure 26.

Material regions of FEM standard model for CACCRDs.

Figure 26.

Material regions of FEM standard model for CACCRDs.

Figure 27.

Meshes of FEM standard model for CACCRDs.

Figure 27.

Meshes of FEM standard model for CACCRDs.

Figure 28.

Flexural deformation contours of CACC (k = 0.85 × 10−3).

Figure 28.

Flexural deformation contours of CACC (k = 0.85 × 10−3).

Figure 29.

Major principal stress contours of CACC (k = 0.85 × 10−3).

Figure 29.

Major principal stress contours of CACC (k = 0.85 × 10−3).

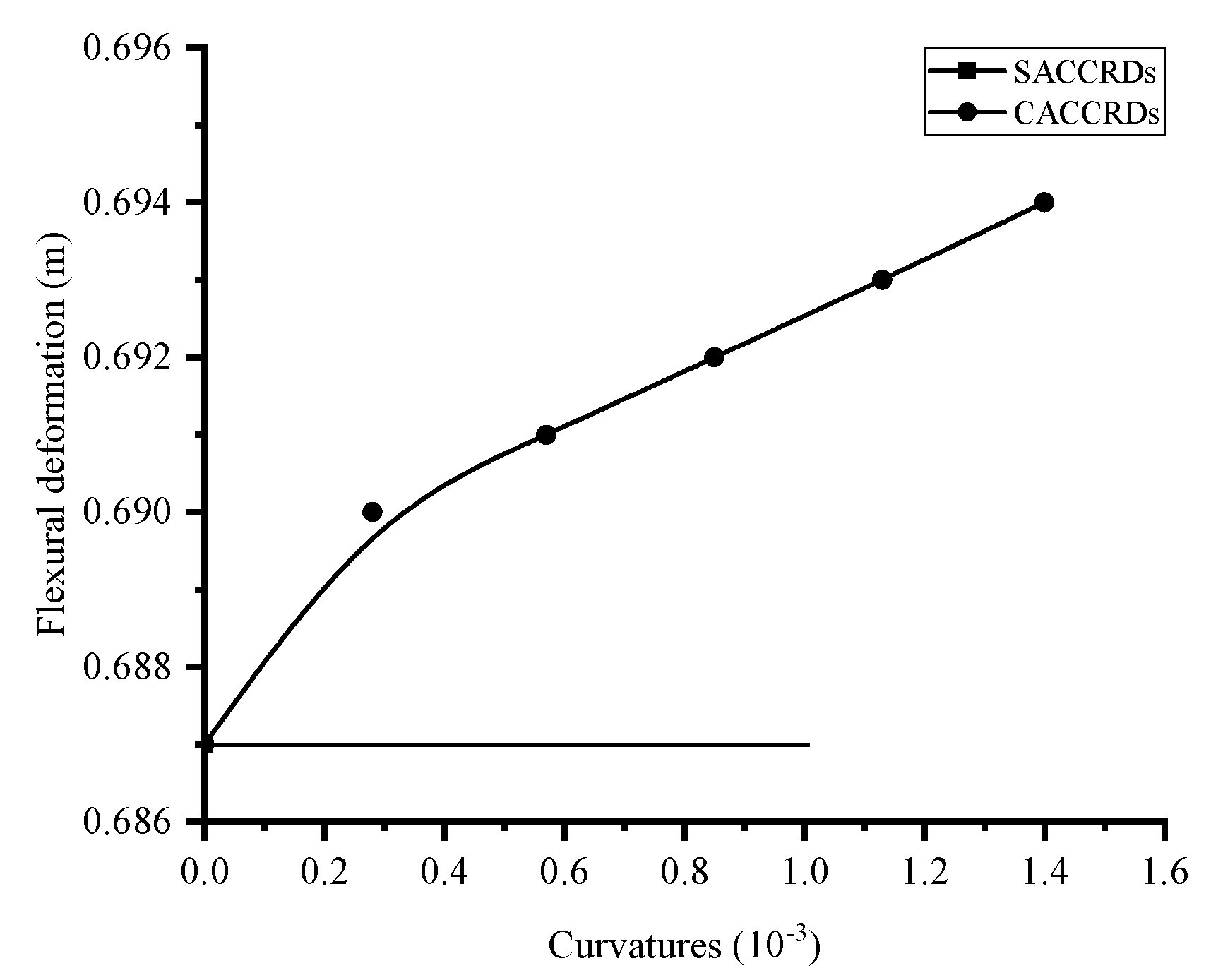

Figure 30.

Relationship between flexural deformation maximum of CACC and curvature of CACC.

Figure 30.

Relationship between flexural deformation maximum of CACC and curvature of CACC.

Figure 31.

Relationship between tensile stress maximum of CACC and curvature of CACC.

Figure 31.

Relationship between tensile stress maximum of CACC and curvature of CACC.

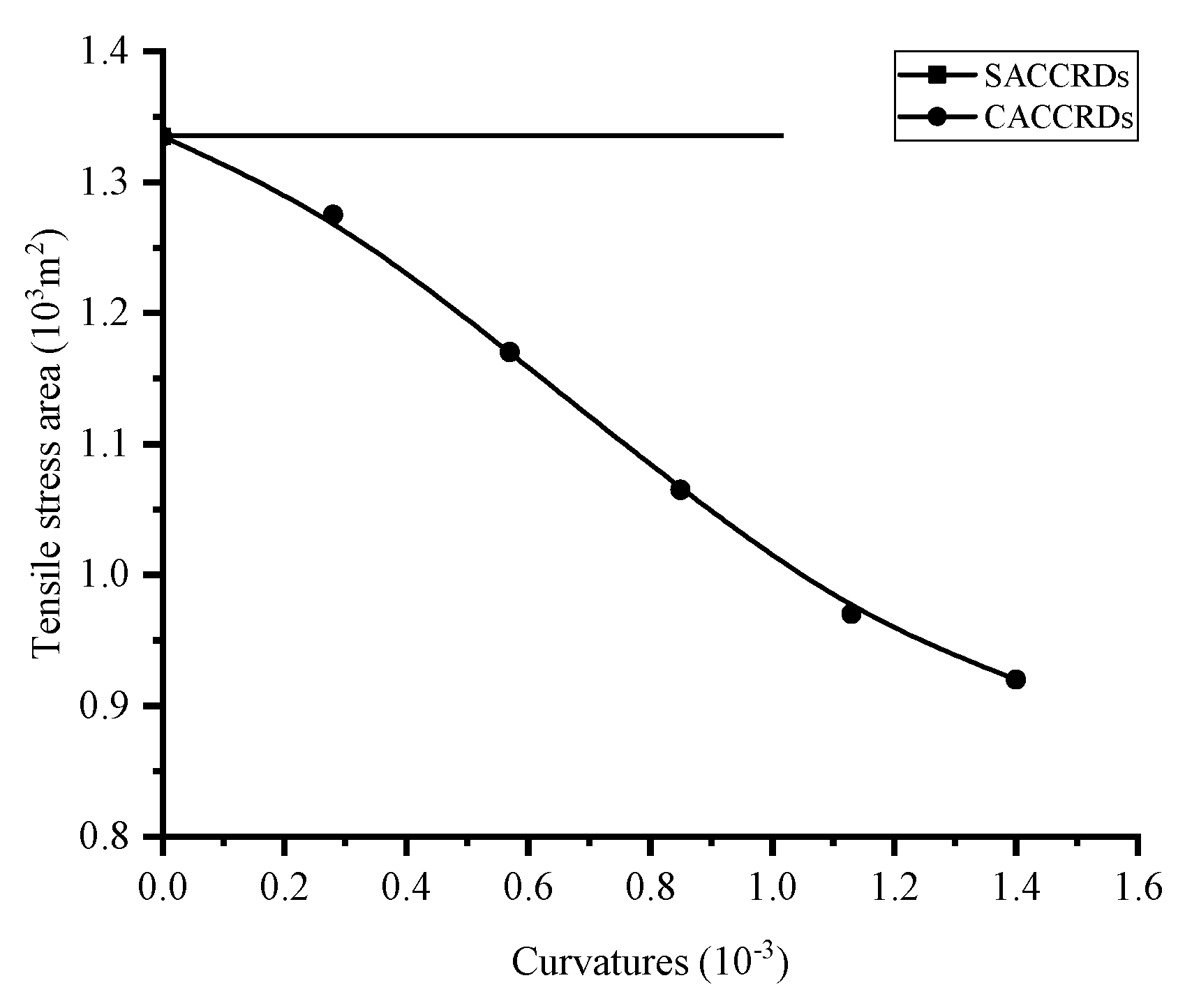

Figure 32.

Relationship between tensile stress area maximum of CACC and curvature of CACC.

Figure 32.

Relationship between tensile stress area maximum of CACC and curvature of CACC.

Table 1.

Characteristic parameters of dam materials (E-B model).

Table 1.

Characteristic parameters of dam materials (E-B model).

Parameters

Materials | K | n | Rf | C/kPa | φ/° | △φ/° | Kb | m | Kur | ρ(g/cm3) |

|---|

| Rockfill material | 1100 | 0.4 | 0.75 | 75 | 50 | 8 | 550 | 0.25 | 2100 | 2.15 |

| Transition material | 1200 | 0.45 | 0.8 | 20 | 44.5 | 7 | 700 | 0.375 | 2400 | 2.35 |

| Asphalt concrete core | 450 | 0.5 | 0.7 | 300 | 28 | 5.5 | 1200 | 0.4 | 1550 | 2.45 |

| Prism drainage | 1000 | 0.375 | 0.65 | 15 | 52 | 10 | 525 | 0.35 | 2000 | 2.3 |

| Backfill material | 850 | 0.35 | 0.6 | 45 | 47.5 | 8.5 | 475 | 0.3 | 1700 | 2.1 |

| Bedrock | Ρ = 2.75 g/cm3; E = 12.5 GPa; μ = 0.2 |

Table 2.

Settlement, stress level, and shear safety factor of ACC with different dam heights.

Table 2.

Settlement, stress level, and shear safety factor of ACC with different dam heights.

| Dam Height (m) | 100 | 125 | 150 | 175 | 200 | 225 | 250 |

|---|

| Settlement (m) | −0.385 | −0.555 | −0.704 | −0.875 | −1.067 | −1.294 | −1.508 |

| Stress level | 0.558 | 0.684 | 0.807 | 0.884 | 0.948 | 0.996 | 1.036 |

| Shear safety factor | 1.79 | 1.46 | 1.24 | 1.13 | 1.05 | 1.01 | 0.97 |

Table 3.

Settlement, stress level, and shear safety factor of ACC with different valley slope ratios.

Table 3.

Settlement, stress level, and shear safety factor of ACC with different valley slope ratios.

| Valley Slope Ratio | 0.5:1.0 | 1.0:1.0 | 1.5:1.0 | 2.0:1.0 | 2.5:1.0 |

|---|

| Settlement (m) | −1.098 | −1.074 | −1.070 | −1.067 | −1.066 |

| Stress level | 0.852 | 0.938 | 1.030 | 1.120 | 1.216 |

| Shear safety factor | 1.17 | 1.07 | 0.97 | 0.89 | 0.82 |

Table 4.

Failure ratio, cohesion, and internal friction angle minimums of ACC that independently meet YSFCS with different dam heights.

Table 4.

Failure ratio, cohesion, and internal friction angle minimums of ACC that independently meet YSFCS with different dam heights.

| Dam Height (m) | 150 | 175 | 200 | 225 | 250 |

|---|

| Failure ratio | 0.75 | 0.95 | 1.08 | 1.15 | 1.20 |

| Cohesion (MPa) | 0.34 | 0.47 | 0.60 | 0.74 | 0.89 |

| Internal friction angle (°) | 29.5 | 33.0 | 35.5 | 37.5 | 39.0 |

Table 5.

Failure ratio, cohesion, and internal friction angle minimums of ACC that comprehensively meet YSFCS with different dam heights.

Table 5.

Failure ratio, cohesion, and internal friction angle minimums of ACC that comprehensively meet YSFCS with different dam heights.

Strength Parameters

Dan Height (m) | Failure Ratio Rf = 0.6, 0.7, 0.8 |

|---|

| Cohesion (MPa) | Internal Friction Angle (°) |

|---|

| 150 | 0.2 | 34.7, 33.3, 31.8 |

| 0.3 | 31.5, 30.1, 28.5 |

| 0.4 | 28.3, 26.9, 25.3 |

| 0.5 | 25.1, 23.7, 22.1 |

| 0.6 | 21.9, 20.5, 18.8 |

| 175 | 0.2 | 37.4, 36.1, 34.5 |

| 0.3 | 34.6, 33.3, 31.6 |

| 0.4 | 31.9, 30.5, 28.7 |

| 0.5 | 29.1, 27.7, 25.7 |

| 0.6 | 26.3, 24.9, 22.8 |

| 200 | 0.2 | 39.7, 38.2, 36.5 |

| 0.3 | 37.3, 35.8, 33.9 |

| 0.4 | 34.9, 33.4, 31.4 |

| 0.5 | 32.4, 30.9, 28.8 |

| 0.6 | 31.2, 28.5, 26.2 |

| 225 | 0.2 | 41.5, 39.7, 38.0 |

| 0.3 | 39.4, 37.5, 35.7 |

| 0.4 | 37.3, 35.4, 33.4 |

| 0.5 | 35.2, 33.3, 31.1 |

| 0.6 | 33.1, 31.2, 28.8 |

| 250 | 0.2 | 43.0, 40.8, 38.8 |

| 0.3 | 41.2, 38.9, 36.8 |

| 0.4 | 39.3, 37.1, 34.8 |

| 0.5 | 37.5, 35.3, 32.9 |

| 0.6 | 35.6, 33.4, 30.9 |

Table 6.

Stress levels and shear safety factors of ACC with different dam heights.

Table 6.

Stress levels and shear safety factors of ACC with different dam heights.

| Dam Height (m) | 150 | 175 | 200 | 225 | 250 |

|---|

| Failure ratio | 0.75 | 0.788 | 0.825 | 0.863 | 0.90 |

| Cohesion (MPa) | 0.30 | 0.345 | 0.39 | 0.435 | 0.48 |

| Internal friction angle (°) | 28.5 | 29.93 | 31.35 | 32.78 | 34.2 |

| Stress level | 0.77 | 0.77 | 0.75 | 0.74 | 0.72 |

| Shear safety factor | 1.30 | 1.30 | 1.33 | 1.35 | 1.39 |

Table 7.

Flexural deformation, tensile stress, tensile stress area, and tensile safety factor of SACC with different dam heights.

Table 7.

Flexural deformation, tensile stress, tensile stress area, and tensile safety factor of SACC with different dam heights.

| Dam Height (m) | 100 | 125 | 150 | 175 | 200 | 225 | 250 |

|---|

| Flexural deformation (m) | 0.197 | 0.297 | 0.408 | 0.538 | 0.687 | 0.862 | 1.042 |

| Tensile stress (MPa) | 0.078 | 0.138 | 0.232 | 0.298 | 0.349 | 0.445 | 0.522 |

| Tensile stress area (103 m2) | 0.307 | 0.450 | 0.681 | 0.927 | 1.335 | 1.704 | 2.097 |

| Tensile safety factor | 3.85 | 2.17 | 1.29 | 1.01 | 0.86 | 0.67 | 0.57 |

Table 8.

Flexural deformation, tensile stress, tensile stress area, and tensile safety factor of SACC with different valley slope ratios.

Table 8.

Flexural deformation, tensile stress, tensile stress area, and tensile safety factor of SACC with different valley slope ratios.

| Valley Slope Ratio | 0.5:1.0 | 1.0:1.0 | 1.5:1.0 | 2.0:1.0 | 2.5:1.0 |

|---|

| Flexural deformation (m) | 0.750 | 0.688 | 0.660 | 0.642 | 0.64 |

| Tensile stress (MPa) | 0.126 | 0.349 | 0.553 | 0.650 | 0.737 |

| Tensile stress area (103 m2) | 1.013 | 1.335 | 1.917 | 2.238 | 2.334 |

| Tensile safety factor | 2.38 | 0.86 | 0.542 | 0.46 | 0.41 |

Table 9.

Flexural deformation, tensile stress, tensile stress area, and tensile safety factor of CACC with different curvatures of CACC.

Table 9.

Flexural deformation, tensile stress, tensile stress area, and tensile safety factor of CACC with different curvatures of CACC.

| Curvature (10−3) | 0.00 | 0.28 | 0.57 | 0.85 | 1.13 | 1.40 |

|---|

| Flexural deformation (m) | 0.687 | 0.690 | 0.691 | 0.692 | 0.693 | 0.694 |

| Tensile stress (MPa) | 0.349 | 0.305 | 0.253 | 0.203 | 0.165 | 0.138 |

| Tensile stress area (103 m2) | 1.335 | 1.275 | 1.172 | 1.065 | 0.973 | 0.925 |

| Tensile safety factor | 0.86 | 0.98 | 1.19 | 1.48 | 1.82 | 2.17 |