A Study of the Dynamic Response of Carbon Fiber Reinforced Epoxy (CFRE) Prepregs for Musical Instrument Manufacturing

Abstract

1. Introduction

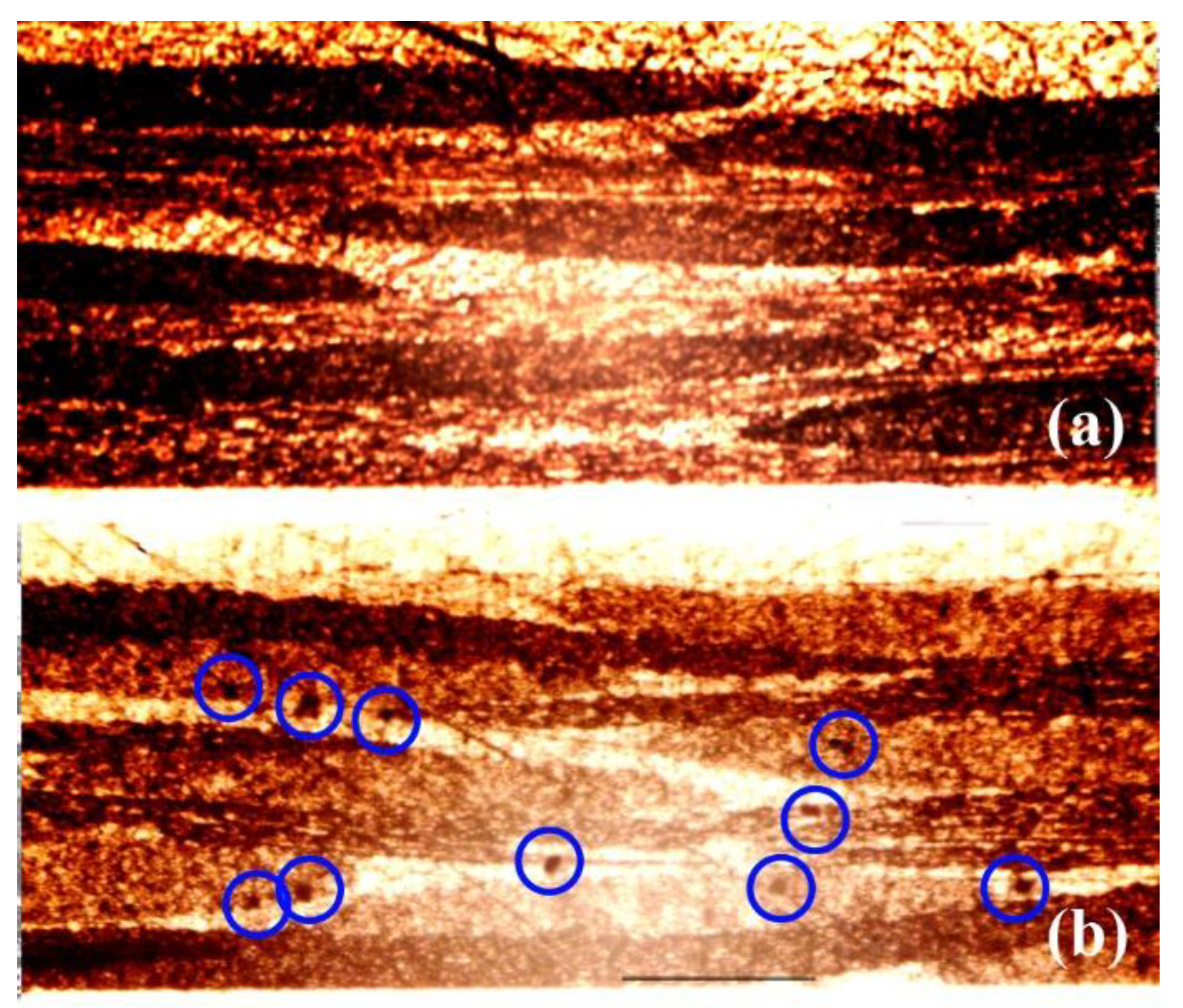

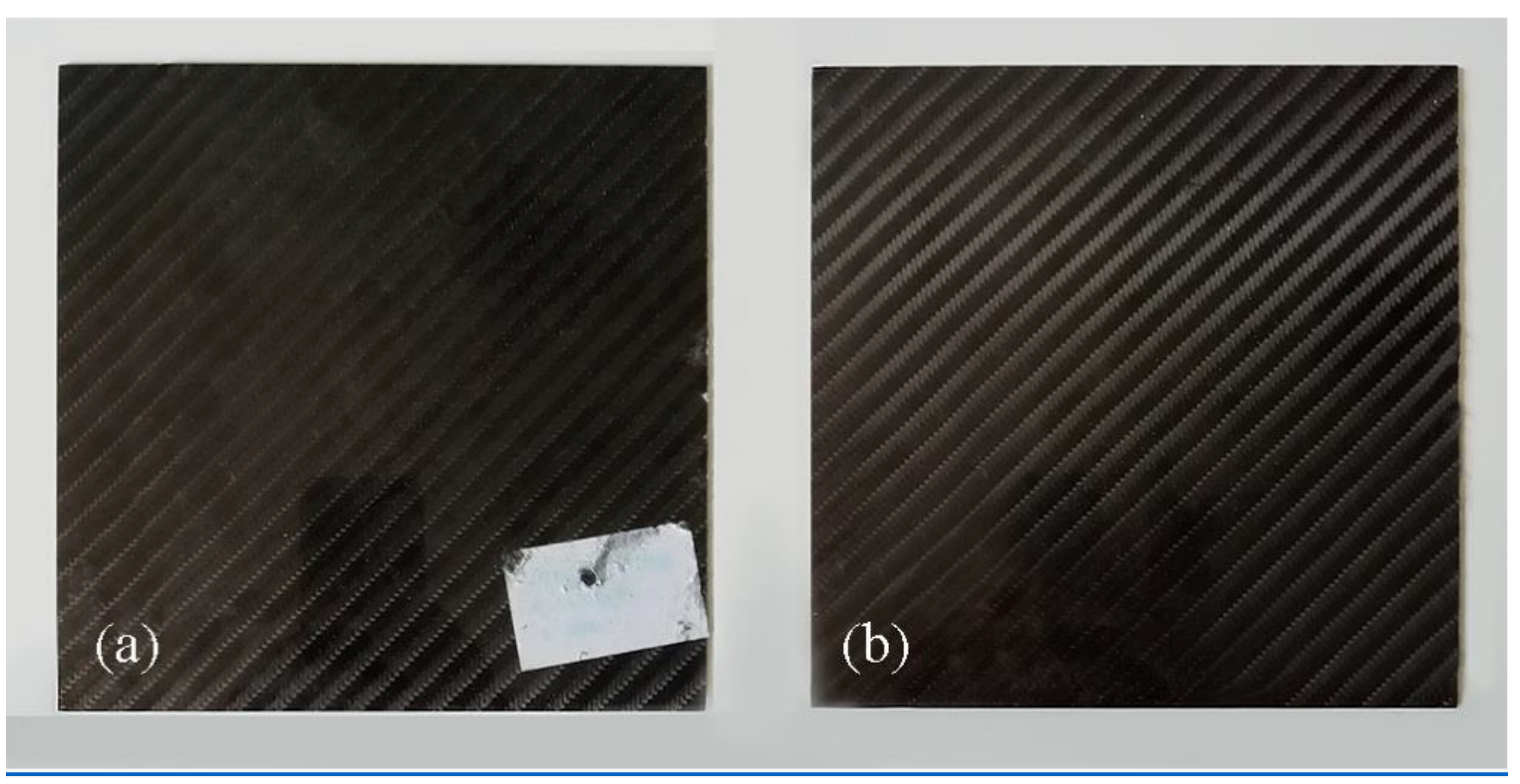

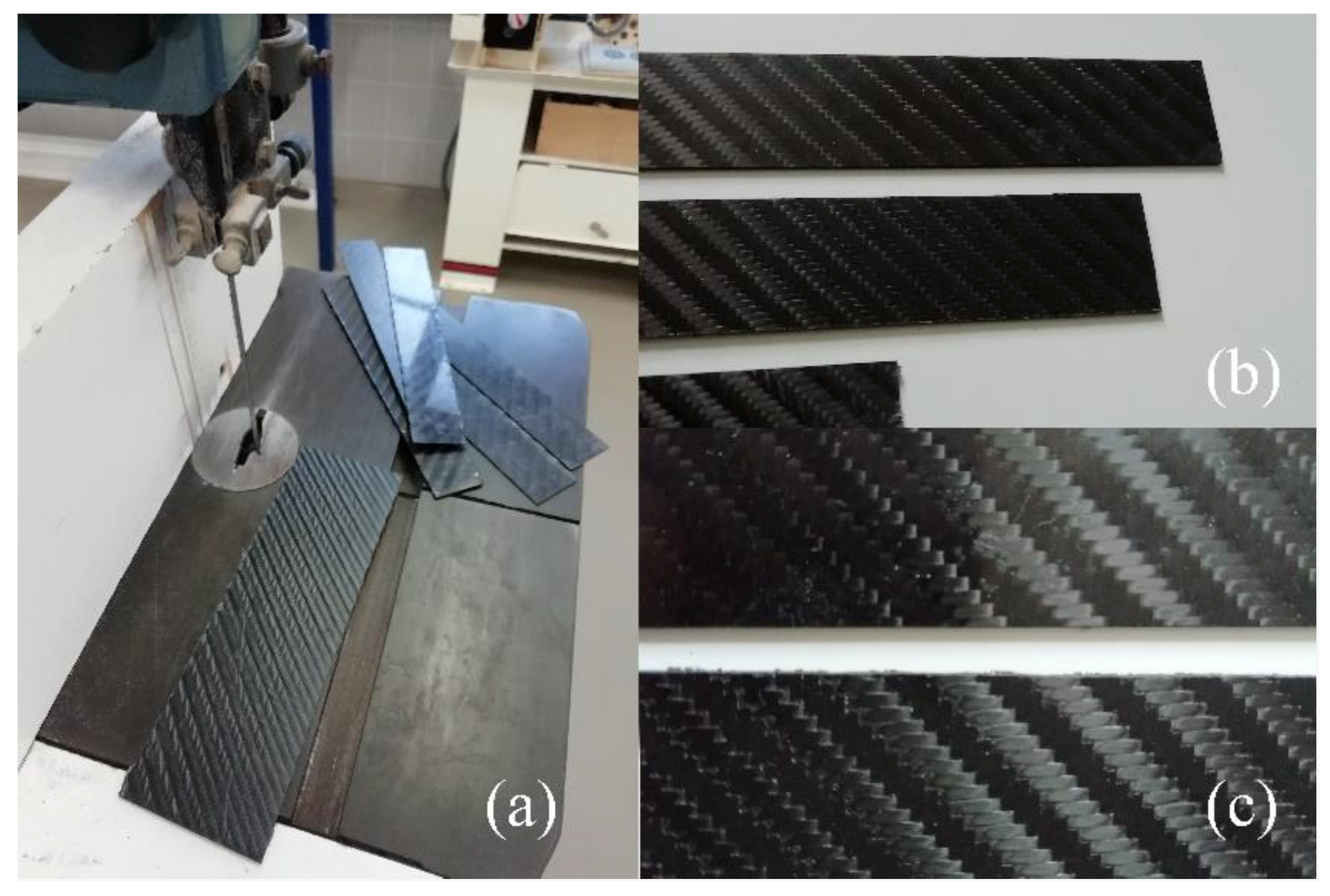

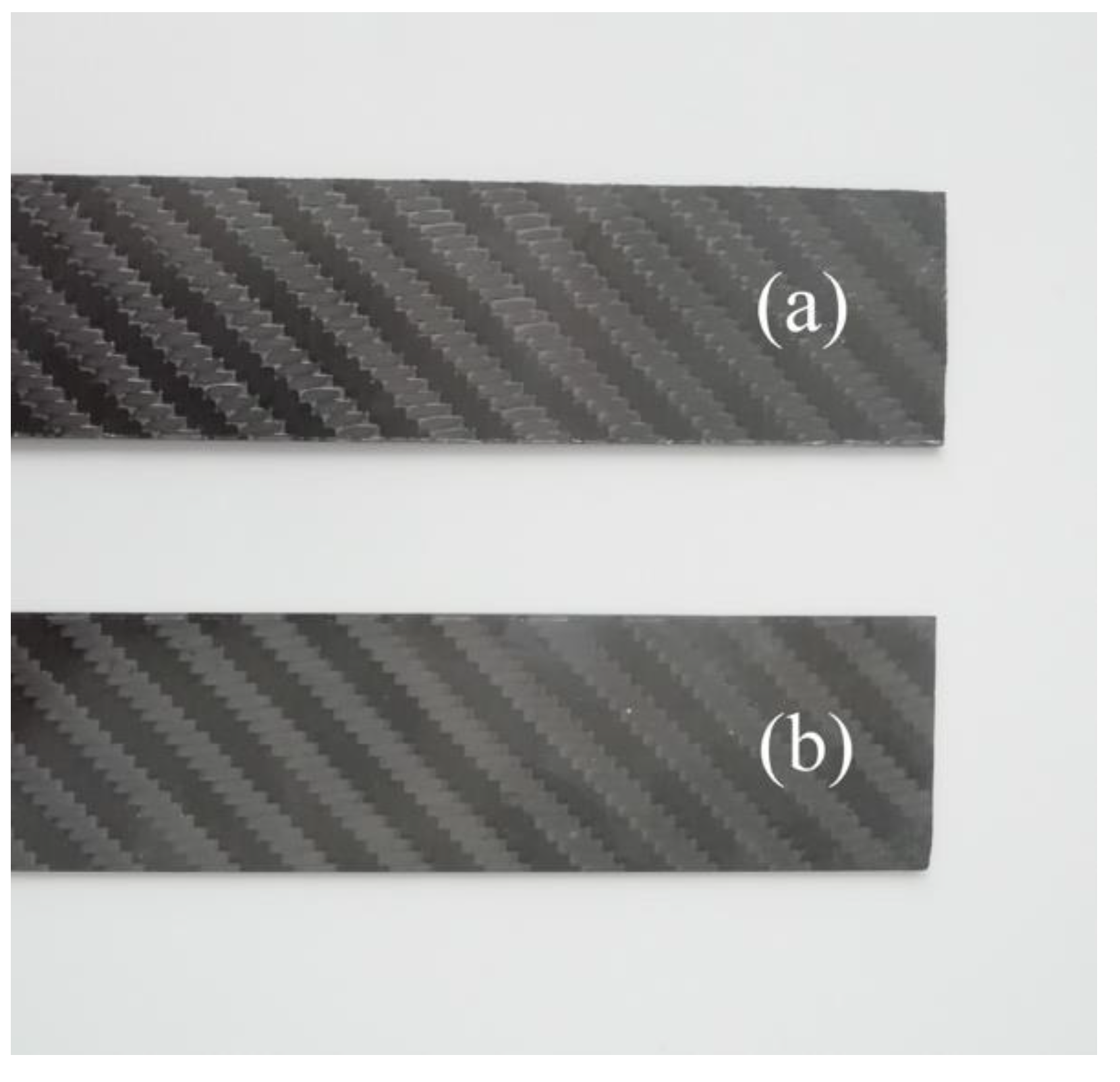

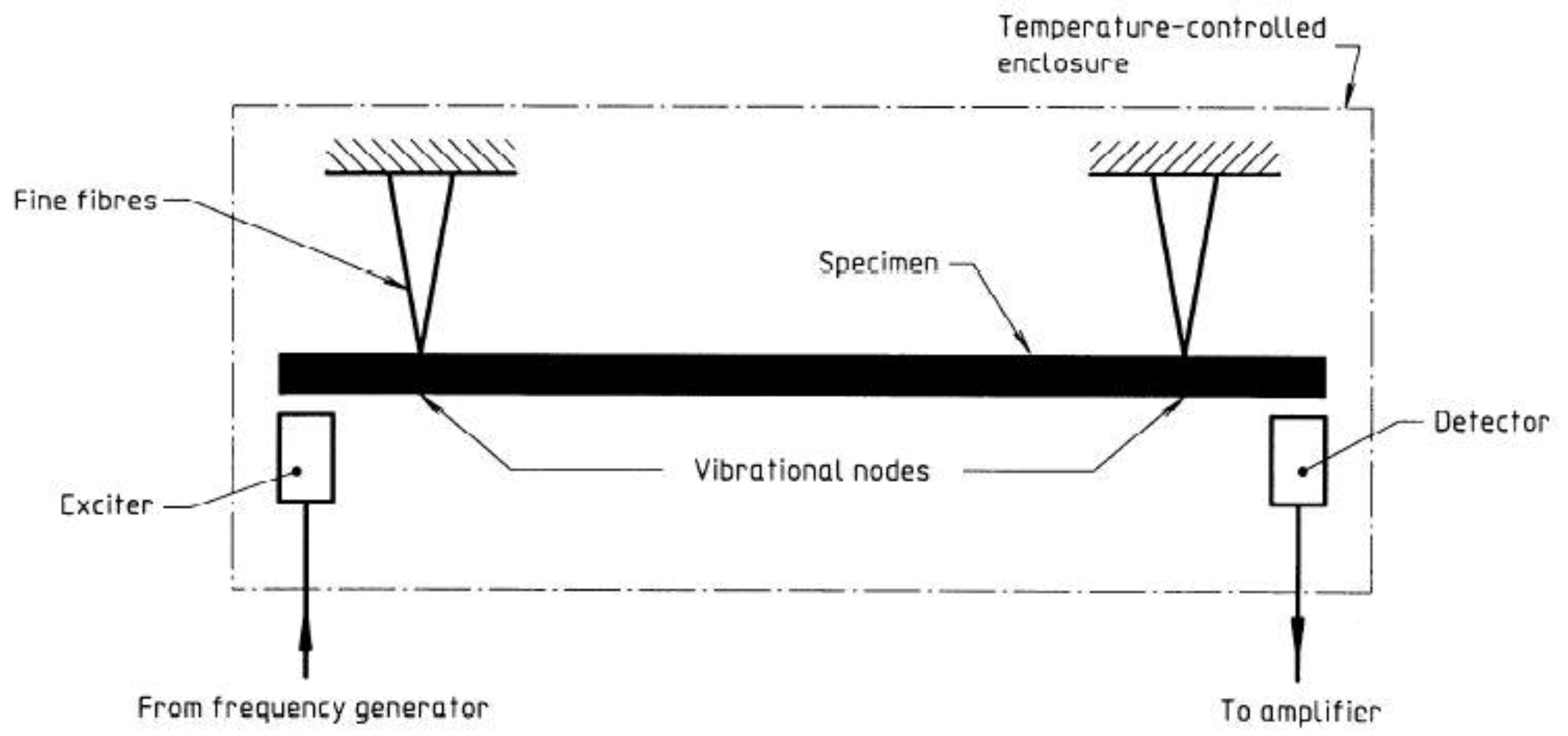

2. Materials and Methods

3. Results and Discussion

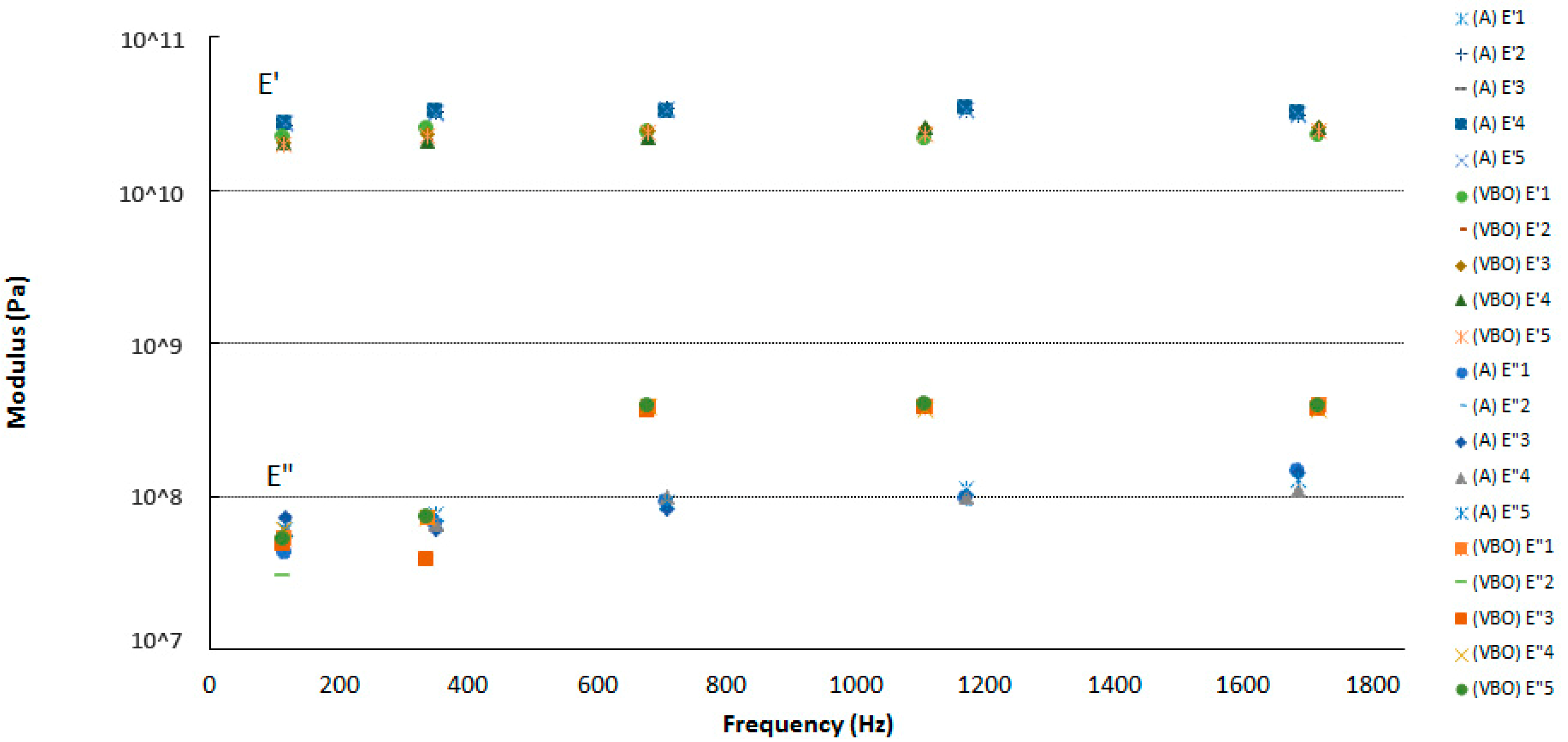

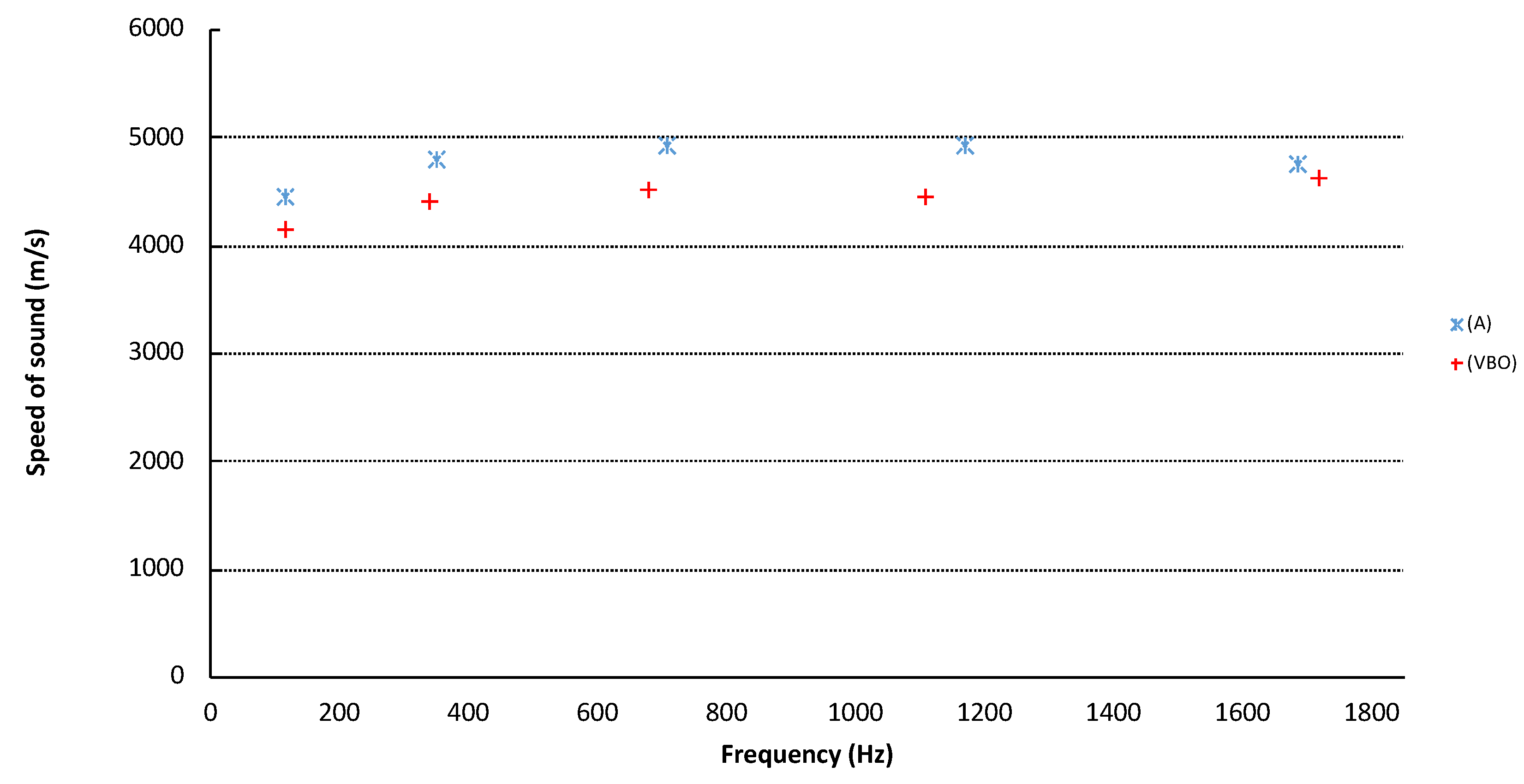

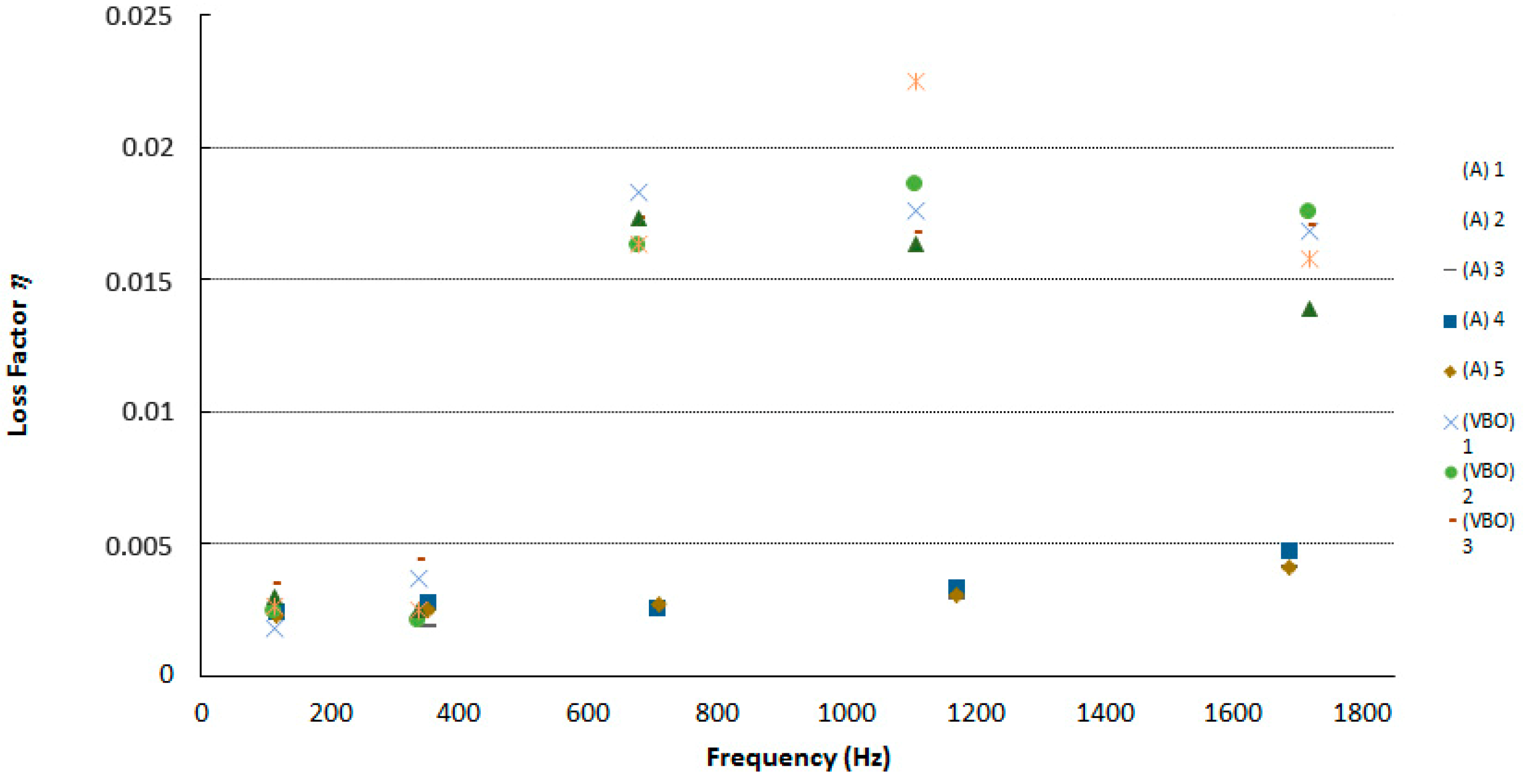

3.1. Dynamic Characterization

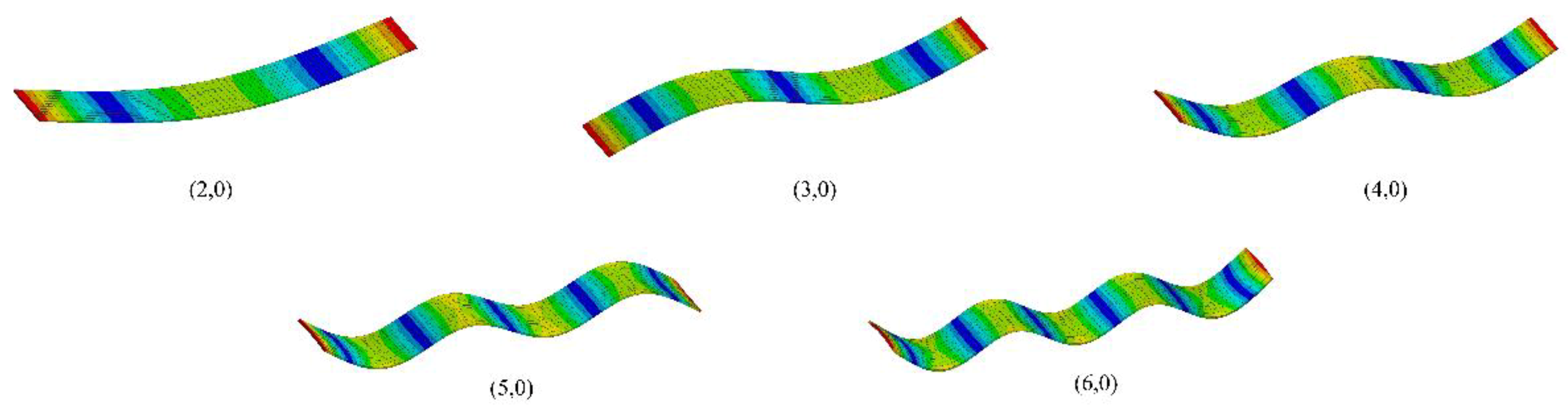

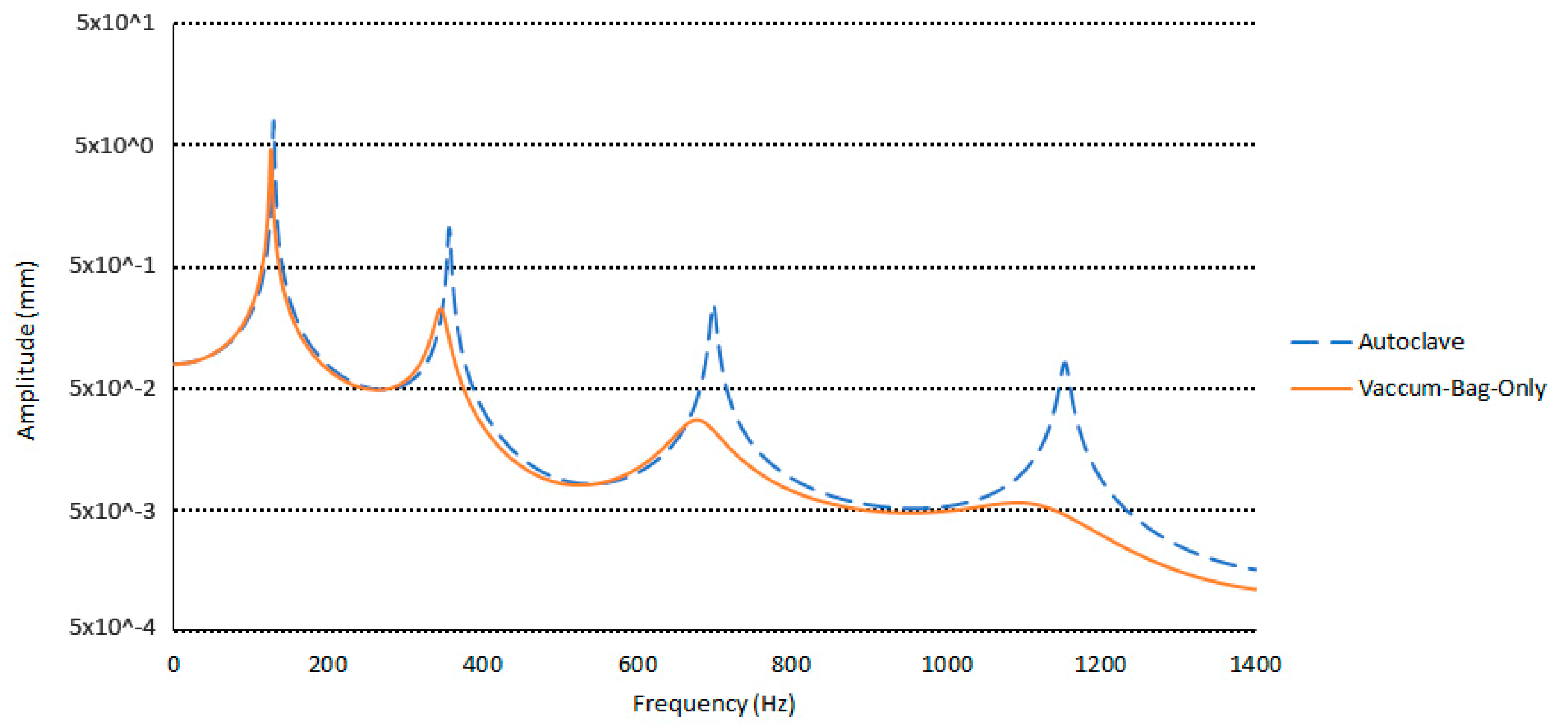

3.2. Effects on The Vibrational Behavior.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lee, H.G.; Lee, J. Damping mechanism model for fatigue testing of a full-scale composite wind turbine blade, Part 2: Application of fairing. Compos. Struct. 2018, 202, 1121–1125. [Google Scholar] [CrossRef]

- Lee, H.G.; Lee, J. Damping mechanism model for fatigue testing of a full-scale composite wind turbine blade, Part 1: Modeling. Compos. Struct. 2018, 202, 1216–1228. [Google Scholar] [CrossRef]

- Henning, F.; Kärger, L.; Dörr, D.; Schirmaier, F.J.; Seuffert, J.; Bernath, A. Fast processing and continuous simulation of automotive structural composite components. Compos. Sci. Technol. 2019, 171, 261–279. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, H.; Zhai, J.; Chen, H.; Zhu, Q.; Han, Q. Vibration reduction of the blisk by damping hard coating and its intentional mistuning design. Aerosp. Sci. Technol. 2019, 84, 1049–1058. [Google Scholar] [CrossRef]

- Tekin, E.; Kapan, Ö. Composite Manufacturing Data Management in Aerospace Industry. Procedia CIRP 2016, 41, 1039–1042. [Google Scholar] [CrossRef]

- Sumi, T.; Ono, T. Classical guitar top board design by finite element method modal analysis based on acoustic measurements of guitars of different quality. Acoust. Sci. Technol. 2008, 29, 381–383. [Google Scholar] [CrossRef]

- Torres, J.A.; Boullosa, R.R. Influence of the bridge on the vibrations of the top plate of a classical guitar. Appl. Acoust. 2009, 70, 1371–1377. [Google Scholar] [CrossRef]

- Bilbao, S.; Torin, A.; Chatziioannou, V. Numerical modeling of collisions in musical instruments. Acta Acust. United Acust. 2015, 101, 155–173. [Google Scholar] [CrossRef]

- Caldersmith, G. Designing a guitar family. Appl. Acoust. 1995, 46, 3–17. [Google Scholar] [CrossRef]

- Elejabarrieta, M.J.; Santamaría, C.; Ezcurra, A. Air cavity modes in the resonance box of the guitar: The effect of the sound hole. J. Sound Vib. 2002, 252, 584–590. [Google Scholar] [CrossRef]

- Ono, T.; Isomura, D. Acoustic characteristics of carbon fiber-reinforced synthetic wood for musical instrument soundboards. Acoust. Sci. Technol. 2004, 25, 475–477. [Google Scholar] [CrossRef][Green Version]

- Torres, J.A.; Torres-Torres, D. Cambios en la propagación de ondas en una tapa de guitarra debidos al abanico y el puente. Rev. Int. Métodos Numér. Cálc. Diseño Ing. 2015, 31, 228–234. [Google Scholar] [CrossRef]

- Nishimura, K.; Nishimura, K. A study on timbre and sound quality of an electric guitar by selection of material around pickup. In Proceedings of the ICSV 23rd International Congress on Sound and Vibration: From Ancient to Modern Acoustics, Athens, Greece, 10–14 July 2016. [Google Scholar]

- Paté, A.; Le Carrou, J.L.; Fabre, B. Modal parameter variability in industrial electric guitar making: Manufacturing process, wood variability, and lutherie decisions. Appl. Acoust. 2015, 96, 118–131. [Google Scholar] [CrossRef]

- Knott, G.A.; Shin, Y.S.; Chargin, M. A modal analysis of the violin. Finite Elem. Anal. Des. 1989, 5, 269–279. [Google Scholar] [CrossRef]

- Yu, Y.; Jang, I.G.; Kim, I.K.; Kwak, B.M. Nodal line optimization and its application to violin top plate design. J. Sound Vib. 2010, 329, 4785–4796. [Google Scholar] [CrossRef]

- Inácio, O.; Antunes, J.; Wright, M.C.M.M. Computational modelling of string–body interaction for the violin family and simulation of wolf notes. J. Sound Vib. 2008, 310, 260–286. [Google Scholar] [CrossRef]

- Corradi, R.; Liberatore, A.; Miccoli, S. Experimental modal analysis and finite element modelling of a contemporary violin. In Proceedings of the ICSV 23rd International Congress on Sound and Vibration: From Ancient to Modern Acoustics, Athens, Greece, 10–14 July 2016. [Google Scholar]

- Bissinger, G. Modal analysis of a violin octet. J. Acoust. Soc. Am. 2003, 113, 2105–2113. [Google Scholar] [CrossRef]

- Berthaut, J.; Ichchou, M.N.; Jézéquel, L. Piano soundboard: Structural behavior, numerical and experimental study in the modal range. Appl. Acoust. 2003, 64, 1113–1136. [Google Scholar] [CrossRef]

- Boutillon, X.; Ege, K. Vibroacoustics of the piano soundboard: Reduced models, mobility synthesis, and acoustical radiation regime. J. Sound Vib. 2013, 332, 4261–4279. [Google Scholar] [CrossRef][Green Version]

- Ege, K.; Boutillon, X.; Rébillat, M. Vibroacoustics of the piano soundboard: (Non)linearity and modal properties in the low- and mid-frequency ranges. J. Sound Vib. 2013, 332, 1288–1305. [Google Scholar] [CrossRef]

- Ibáñez, M.; Sánchez, F. Material characterization and vibro-acoustic analysis of a Preinpregnated Carbon Fiber reinforced epoxy Drum Shell. In Proceedings of the 20th International Conference on Composite Materials, Copenhagen, Denmark, 19–24 July 2015. [Google Scholar]

- Ibañez, M.; Muñoz, E.; Domenech, L.; Cortés, E.; Sánchez, F.; García, J.A. On the influence of mechanical and processing characterization on the vibro-acoustic response of lcm and preimpregnated composite laminates. In Proceedings of the 13th International Conference on Flow Processes in Composite Materials, Kioto, Japan, 6–9 July 2016. [Google Scholar]

- Sathej, G.; Adhikari, R. The eigenspectra of Indian musical drums. J. Acoust. Soc. Am. 2009, 125, 831–838. [Google Scholar] [CrossRef] [PubMed]

- Luis and Clark Carbon Fiber Instruments. Available online: https://luisandclark.com (accessed on 12 October 2019).

- Rasch Drums. Available online: www.raschdrums.com (accessed on 10 October 2019).

- Boganyi Piano. Available online: http://www.boganyi-piano.com (accessed on 12 October 2019).

- Klos Carbon Fiber Guitars. Available online: https://klosguitars.com (accessed on 12 October 2019).

- Nilsson, A.; Liu, B. Vibro-Acoustics; Springer: Berlin/Heidelberg, Germany, 2012; Volume 1, ISBN 9783662478066. [Google Scholar]

- Chaigne, A.; Campbell, M. Acoustics of Musical Instruments; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 9781493936779. [Google Scholar]

- Fletcher, N.H.; Rossing, T.D. The Physics of Musical Instruments; Springer: New York, NY, USA, 1998. [Google Scholar]

- Wu, Z.H.; Li, J.H. Carbon fiber material in musical instrument making. Mater. Des. 2016, 89, 660–664. [Google Scholar] [CrossRef]

- Ono, T.; Takahashi, I.; Takasu, Y.; Miura, Y.; Watanabe, U. Acoustic characteristics of wadaiko (traditional Japanese drum) with wood plastic shell. Acoust. Sci. Technol. 2009, 30, 410–416. [Google Scholar] [CrossRef]

- Phillips, S.; Lessard, L. Application of natural fiber composites to musical instrument top plates. J. Compos. Mater. 2012, 46, 145–154. [Google Scholar] [CrossRef]

- Koruk, H.; Genc, G. Investigation of the acoustic properties of bio luffa fiber and composite materials. Mater. Lett. 2015, 157, 166–168. [Google Scholar] [CrossRef]

- Holzweissig, F.; Leissa, A.W. Vibration of Plates. (Nasa Sp-160). VII + 353 S. m. Fig. Washington 1969. Office of Technology Utilization National Aeronautics and Space Administration. Preis brosch. $ 3.50. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/zamm.19710510331 (accessed on 1 September 2019).

- Leissa, A.W. Vibration of shells. J. Chem. Inf. Model. 1973, 288, 1689–1699. [Google Scholar] [CrossRef]

- Jones, R.M. Mechanics of Composite Materials; Taylor & Francis: Philadelphia, PA, USA, 1999. [Google Scholar]

- Ibáñez, M.; Gimenez, A.; Sanchez, F. Material Characterization and Vibro-Acoustic Analysis of a Preimpregnated Carbon Fiber Drum Shell. In Proceedings of the 20th International Conference on Composite Materials, Copenhagen, Denmark, 19–24 July 2015. [Google Scholar]

- Centea, T.; Grunenfelder, L.K.; Nutt, S.R. A review of out-of-autoclave prepregs—Material properties, process phenomena, and manufacturing considerations. Compos. Part. A Appl. Sci. Manuf. 2015, 70, 132–154. [Google Scholar] [CrossRef]

- Levy, A.; Kratz, J.; Hubert, P. Air evacuation during vacuum bag only prepreg processing of honeycomb sandwich structures: In-plane air extraction prior to cure. Compos. Part. A Appl. Sci. Manuf. 2015, 68, 365–376. [Google Scholar] [CrossRef]

- Kourkoutsaki, T.; Comas-Cardona, S.; Binetruy, C.; Upadhyay, R.K.; Hinterhoelzl, R. The impact of air evacuation on the impregnation time of Out-of-Autoclave prepregs. Compos. Part. A Appl. Sci. Manuf. 2015, 79, 30–42. [Google Scholar] [CrossRef]

- Hamill, L.; Centea, T.; Nutt, S. Surface porosity during vacuum bag-only prepreg processing: Causes and mitigation strategies. Compos. Part. A Appl. Sci. Manuf. 2015, 75, 1–10. [Google Scholar] [CrossRef]

- Saenz-Castillo, D.; Martín, M.I.; Calvo, S.; Rodriguez-Lence, F.; Güemes, A. Effect of processing parameters and void content on mechanical properties and NDI of thermoplastic composites. Compos. Part. A Appl. Sci. Manuf. 2019, 121, 308–320. [Google Scholar] [CrossRef]

- Tai, J.-H.; Kaw, A. Transverse shear modulus of unidirectional composites with voids estimated by the multiple-cells model. Compos. Part. A Appl. Sci. Manuf. 2018, 105, 310–320. [Google Scholar] [CrossRef]

- Turteltaub, S.; de Jong, G. Multiscale modeling of the effect of sub-ply voids on the failure of composite materials. Int. J. Solids Struct. 2019, 165, 63–74. [Google Scholar] [CrossRef]

- Grunenfelder, L.K.; Nutt, S.R. Void formation in composite prepregs—Effect of dissolved moisture. Compos. Sci. Technol. 2010, 70, 2304–2309. [Google Scholar] [CrossRef]

- Zheng, C.; Liang, S. Preparation and damping properties of medium-temperature co-cured phenolic resin matrix composite structures. Compos. Struct. 2019, 217, 122–129. [Google Scholar] [CrossRef]

- Zhang, H.; Ding, X.; Li, H.; Xiong, M. Multi-scale structural topology optimization of free-layer damping structures with damping composite materials. Compos. Struct. 2019, 212, 609–624. [Google Scholar] [CrossRef]

- ISO 6721-3 Plastics-Determination of Dynamic Mechanical Properties—Flexural Vibration—Resonance Curve Method. Available online: https://www.iso.org/standard/13169.html (accessed on 1 September 2019).

- Graesser, E.J.; Wong, C.R. ASTM Special Technical Publication; ASTM: West Conshohocken, PA, USA, 1992; pp. 316–343. [Google Scholar]

| Young Modulus (GPa) | Poisson Ratio | Shear Modulus (GPa) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Density (kg/m3) | x | y | z | Xy | yz | xz | xy | yz | xz |

| 1420 | 35.9 | 35.9 | 6.9 | 0.04 | 0.34 | 0.34 | 11.5 | 2.7 | 2.7 |

| Mode | c (m/s) | |||||||

|---|---|---|---|---|---|---|---|---|

| 1.39 × 103 | 2.0 | 1.17 × 102 | 2.73 × 1010 | 6.12 × 107 | 2.24 × 10−3 | 2.24 × 10−3 | 7.05 × 10−3 | 4.44 × 103 |

| 3.0 | 3.52 × 102 | 3.19 × 1010 | 7.85 × 107 | 2.46 × 10−3 | 2.46 × 10−3 | 7.74 × 10−3 | 4.80 × 103 | |

| 4.0 | 7.09 × 102 | 3.37 × 1010 | 9.18 × 107 | 2.73 × 10−3 | 2.73 × 10−3 | 8.57 × 10−3 | 4.93 × 103 | |

| 5.0 | 1.17 × 103 | 3.36 × 1010 | 1.02 × 108 | 3.04 × 10−3 | 3.04 × 10−3 | 9.55 × 10−3 | 4.92 × 103 | |

| 6.0 | 1.69 × 102 | 3.12 × 1010 | 1.28 × 108 | 4.10 × 10−3 | 4.10 × 10−3 | 1.29 × 10−2 | 4.74 × 103 |

| Mode | c (m/s) | |||||||

|---|---|---|---|---|---|---|---|---|

| 1.16 × 103 | 2.0 | 1.15 × 102 | 2.00 × 1010 | 5.18 × 107 | 2.59 × 10−3 | 2.59 × 10−3 | 8.14 × 10−3 | 4.15 × 103 |

| 3.0 | 3.38 × 102 | 2.25 × 1010 | 5.60 × 107 | 2.49 × 10−3 | 2.49 × 10−3 | 7.81 × 10−3 | 4.40 × 103 | |

| 4.0 | 6.78 × 102 | 2.37 × 1010 | 3.86 × 108 | 1.63 × 10−2 | 1.63 × 10−2 | 5.12 × 10−2 | 4.51 × 103 | |

| 5.0 | 1.11 × 103 | 2.31 × 1010 | 3.93 × 108 | 6.60 × 10−2 | 6.59 × 10−2 | 2.07 × 10−1 | 4.46 × 103 | |

| 6.0 | 1716.18 | 2.48 × 1010 | 3.91 × 108 | 1.58 × 10−2 | 1.58 × 10−2 | 4.95 × 10−2 | 4.62 × 103 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibáñez-Arnal, M.; Doménech-Ballester, L.; Sánchez-López, F. A Study of the Dynamic Response of Carbon Fiber Reinforced Epoxy (CFRE) Prepregs for Musical Instrument Manufacturing. Appl. Sci. 2019, 9, 4615. https://doi.org/10.3390/app9214615

Ibáñez-Arnal M, Doménech-Ballester L, Sánchez-López F. A Study of the Dynamic Response of Carbon Fiber Reinforced Epoxy (CFRE) Prepregs for Musical Instrument Manufacturing. Applied Sciences. 2019; 9(21):4615. https://doi.org/10.3390/app9214615

Chicago/Turabian StyleIbáñez-Arnal, Manuel, Luis Doménech-Ballester, and Fernando Sánchez-López. 2019. "A Study of the Dynamic Response of Carbon Fiber Reinforced Epoxy (CFRE) Prepregs for Musical Instrument Manufacturing" Applied Sciences 9, no. 21: 4615. https://doi.org/10.3390/app9214615

APA StyleIbáñez-Arnal, M., Doménech-Ballester, L., & Sánchez-López, F. (2019). A Study of the Dynamic Response of Carbon Fiber Reinforced Epoxy (CFRE) Prepregs for Musical Instrument Manufacturing. Applied Sciences, 9(21), 4615. https://doi.org/10.3390/app9214615