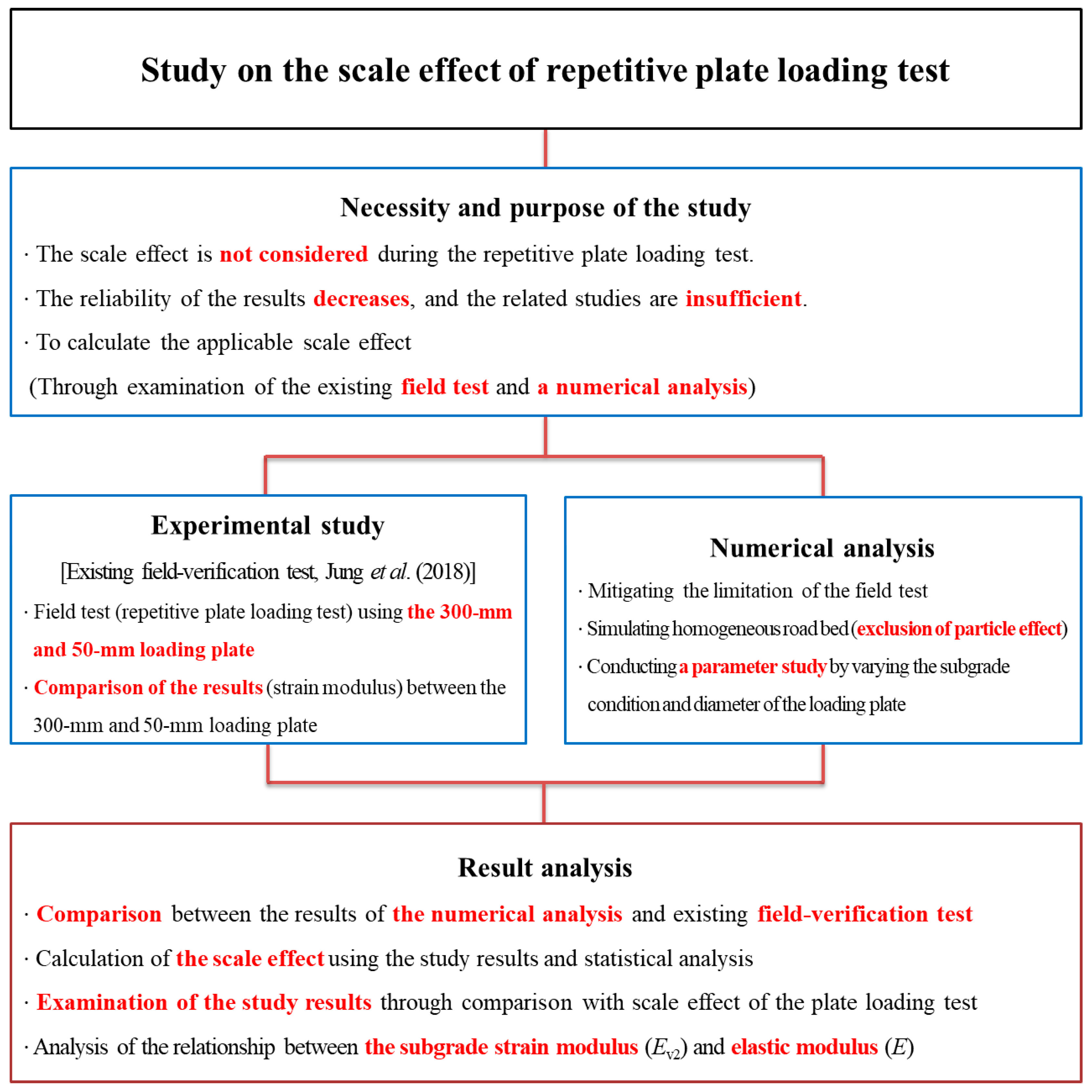

4.1. Comparison with the Results of the Existing Field-Verification Test

In a previous study mentioned earlier, Jung et al. [

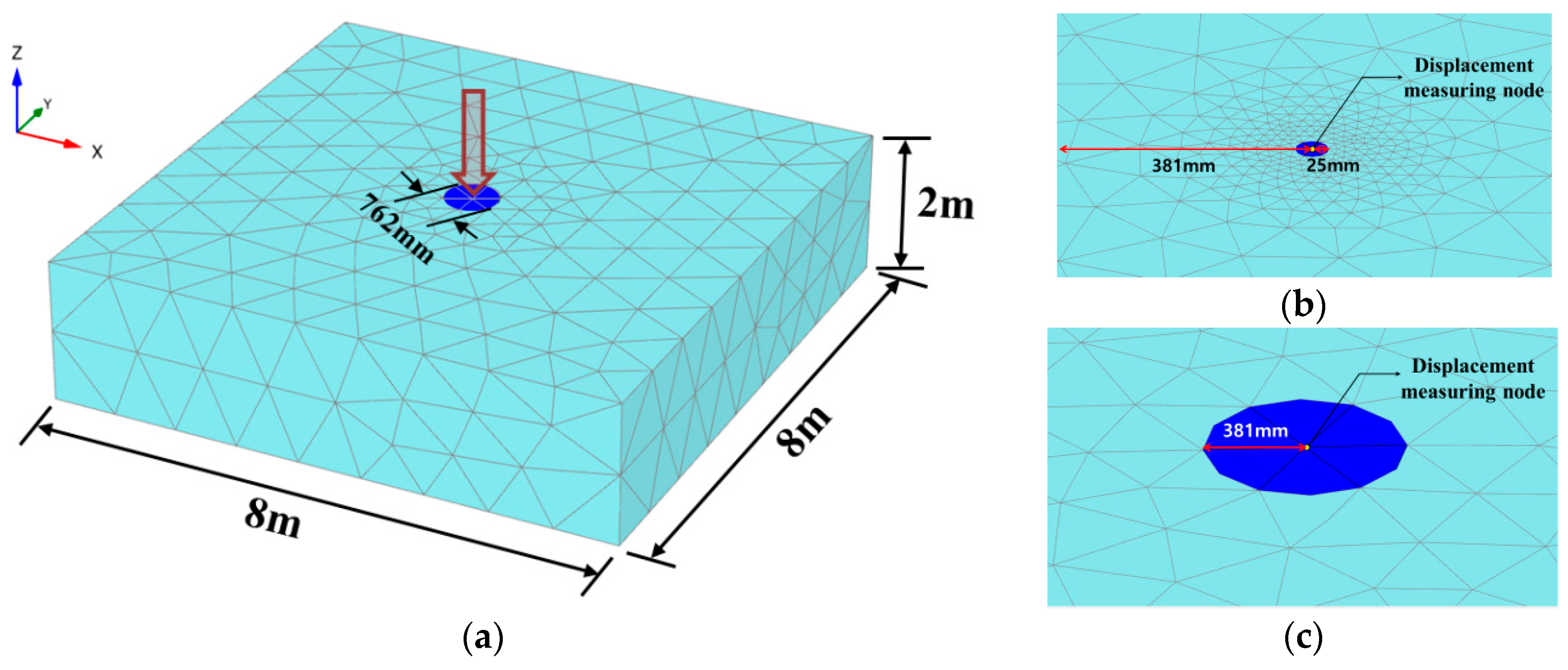

6] conducted a field test to verify the small loading plate with of 50 mm in diameter and compared the results with those of the 300-mm loading plate. In this section, the repetitive plate-loading tests of the 50-mm and 300-mm loading plates were numerically analyzed by modeling the embankment roadbed where the existing field test was conducted. The results were compared with those of the existing field-verification test. Areas with various strain moduli were simulated similar to those in the field-verification test by varying the value of the elastic modulus among the input properties. All conditions except for the size of the loading plate were the same.

Table 3 and

Table 4 list the results of the field test and numerical analysis, respectively. The primary strain modulus (

Ev1), secondary strain modulus (

Ev2), and ratio of the secondary to the primary strain moduli (

Ev2/Ev1) were summarized. In particular, the difference in E

v2 applied as the subgrade strain modulus is shown as graphs in

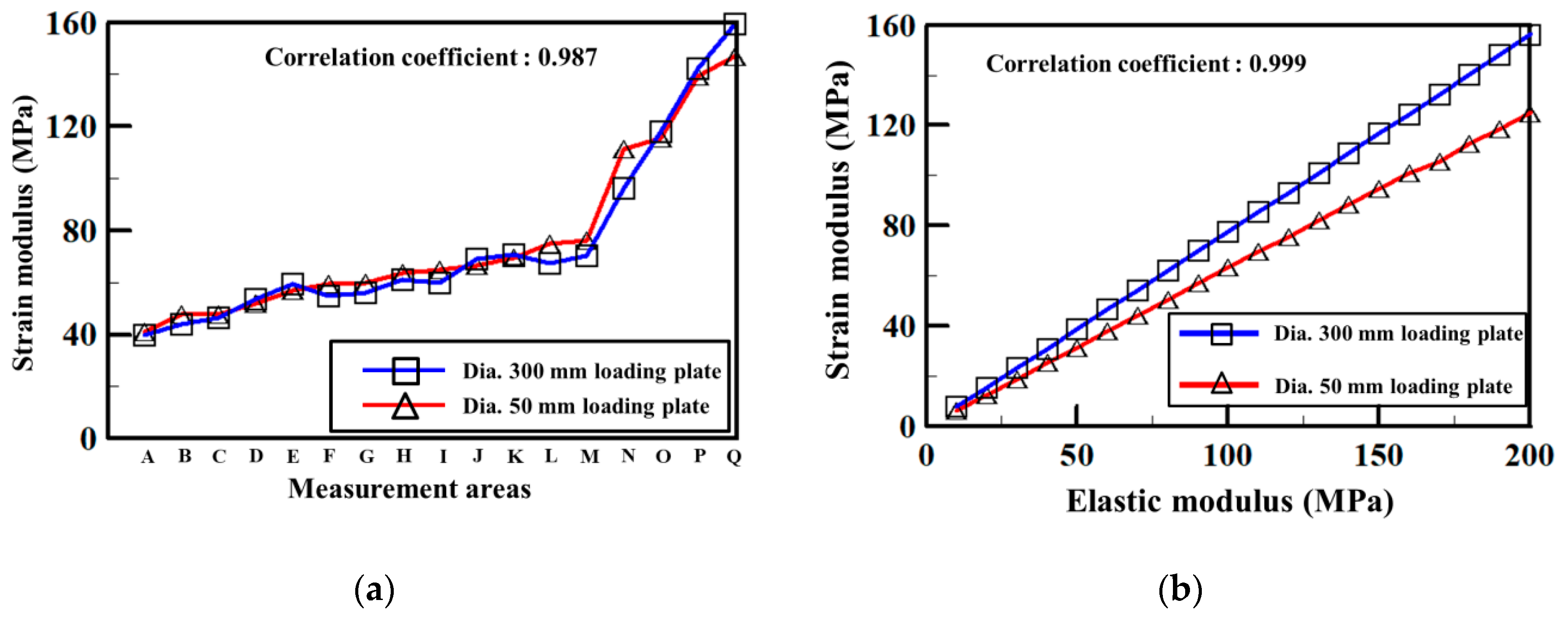

Figure 3, and the correlation between the two results was analyzed.

When the degree of compaction was lower, the roadbed exhibited a large plastic strain at the initial load and gradually exhibited an elastic behavior at repetitive loads. In other words, Ev1 is a strain modulus expressing the initial settlement, and Ev2 is a strain modulus expressing the subsequent elastic settlement. Accordingly, Ev1 is more affected by the degree of compaction. In South Korea, among the measurements of a repetitive plate-loading test, Ev2 is conventionally used as the strain modulus to manage the quality of the roadbed, whereas Ev1 is not adopted for roadbed management. However, the ratio between Ev2 and Ev1 (Ev2/Ev1) is used to manage the degree of compaction of the roadbed. Accordingly, Ev2 is the strain modulus of the roadbed, and Ev2/Ev1 indicates the compaction degree of the roadbed.

In the field test, the difference in the measurements between Ev1 and Ev2 was irregular both for the 50 mm and 300 mm loading plates. The results of either loading plate did not show a tendency to be smaller or larger. In every area, both the 50 mm and 300 mm loading plates exhibited a variety of distribution in the values of Ev2/Ev1, and the difference between Ev1 and Ev2 was also irregular. On the other hand, in the numerical analysis, the results of the 50 mm loading plate were smaller than those of the 300 mm loading plate, and the deviation was not large for both Ev1 and Ev2. The value of Ev2/Ev1 was also 2.0 for both the loading plates in every range, and the difference between Ev2 and Ev1 tended to be constant.

As for the result of the field test, Jung et al. (2018) found that the 50-mm loading plate was more affected by solid materials with large particle sizes, which are often included in rough embankment roadbeds, than the 300-mm loading plate, and thus, the strain modulus was excessively measured. As the elasto-plastic model used in this numerical analysis assumed homogeneous areas and excluded the effect of roadbed materials with large particle sizes, the strain modulus for the 50 mm loading plate was not excessively measured and the values of Ev2/Ev1 were constant. Consequently, the numerical analysis could improve the limitations of the field test, and the sole effect of the loading plates could be identified.

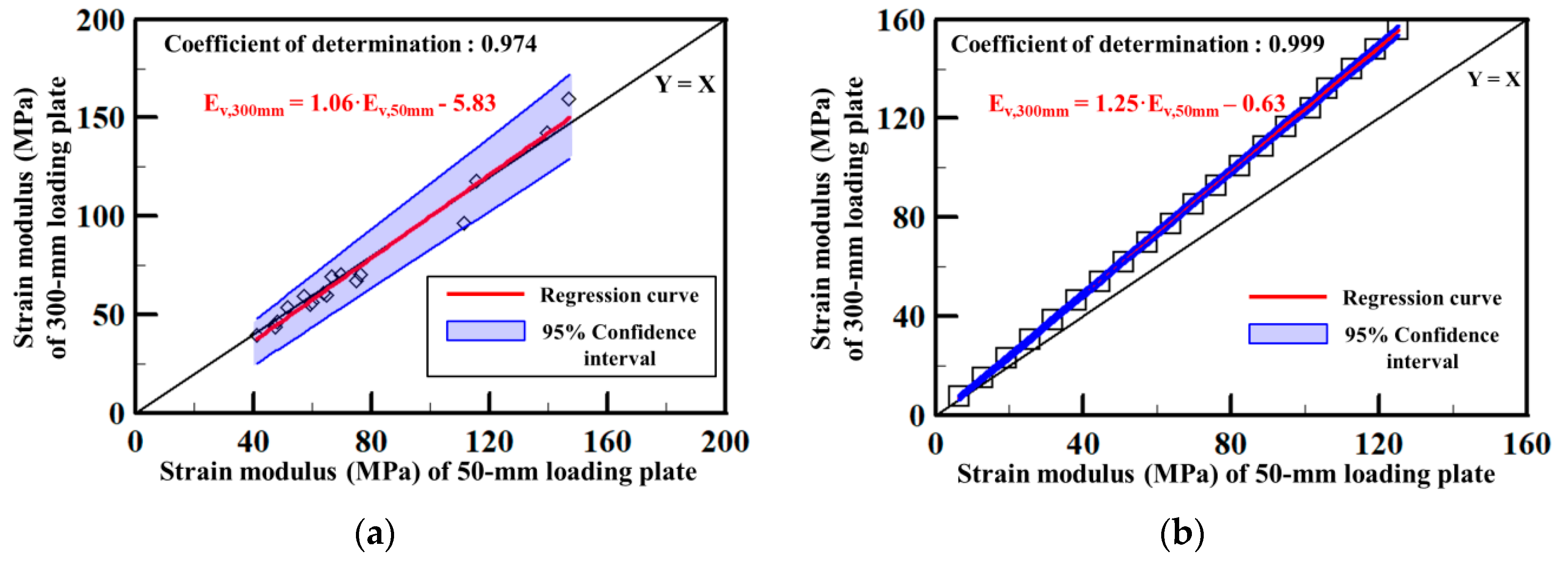

Figure 4 shows the linear regression analysis of the field test and numerical analysis results of the 50-mm and 300-mm loading plates. Equation (5) represents the regression equation of the field test, and Equation (6) represents the regression equation of the numerical analysis results derived from the analysis. The coefficient of determination of the field-test regression equation was 0.974, and the standard error was approximately 3.7. The average difference from the actual data was approximately 5.5%. For the regression equation of the numerical analysis results, the coefficient of determination was 0.999, and the standard error was approximately 0.7. The average difference from the actual data was approximately 1.8%. Therefore, the reliability of the regression equation was higher than that of the field test. These results indicated that the regression equation derived from the numerical analysis results could estimate the results of the 300-mm loading plate with a higher reliability than those measured using the 50-mm loading plate.

where

Ev2,300mm is the strain modulus measured using the 300-mm loading plate, and

Ev2,50mm is that measured using the 50-mm loading plate.

4.2. Loading-Plate Scale Effect of the Repetitive Plate-Loading Test under Field-Test Roadbed Condition

Because the subgrade reaction modulus of the plate-loading test is the solution to the boundary-value problem in which the loading plate contacts the subgrade, the original properties of the subgrade were approached, and the modulus decreased when the size of the loading plate increased. Therefore, the subgrade reaction modulus was used considering the effect of the loading plate size, as expressed in Equation (3). Because the repetitive plate-loading test is also the solution of the boundary-value problem in the same manner, the scale effect must be considered and corrected when the original properties of the subgrade were approached when the loading-plate size increased. The calculated value of the strain modulus also varied depending on the loading-plate size in the same subgrade.

Under the condition of the field-test embankment roadbed, we confirmed that the results of the 50-mm loading plate were approximately 19% lower than those of the 300-mm loading plate. Therefore, further research was conducted using 150-mm, 400-mm, 600-mm, and 762-mm loading plates under the same subgrade condition, and the results were compared with those of the 762-mm loading plate, which had the largest diameter among the employed loading plates, as listed in

Table 5. The analysis results showed that the calculated strain-modulus value decreased as the loading-plate diameter decreased under the same subgrade condition. The ratios of the result of the 762-mm loading plate to each of the loading plates were 1.44, 1.22, 1.17, 1.09, and 1.08 for the 50-mm, 150-mm, 300-mm, 400-mm, and 600-mm loading plates, respectively. The deviation was close to zero under all subgrade conditions with different elastic moduli.

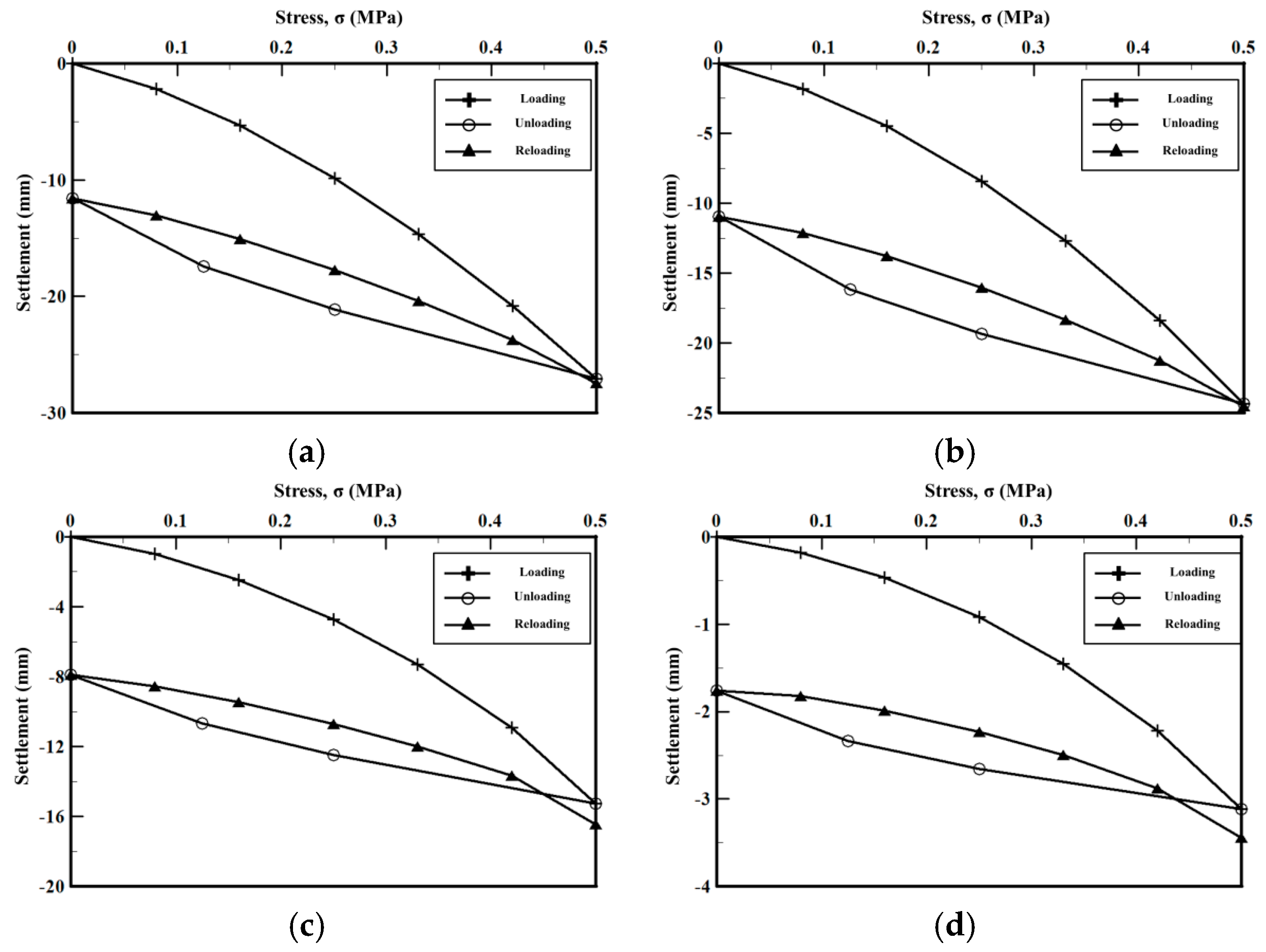

Figure 5 shows the stress–settlement curves of the 762-mm, 600-mm, 300-mm, and 50-mm loading plates in the subgrade with an elastic modulus of 20 MPa.

Figure 5 shows that the nonlinearity of the stress–settlement curve increased as the loading-plate diameter decreased. In other words, nonlinear behavior was observed as the loading-plate size decreased in the subgrade area with the same elastic behavior. Because the strain-modulus estimation equation of the repetitive plate-loading test is a theoretical equation derived based on the elastic theory, the error increased as the nonlinear behavior increased, which was determined to cause the decrease in the calculated strain-modulus value as the loading-plate size decreased. Apparently, therefore, the scale effect must be considered, as expressed in Equation (7), when a loading plate with a diameter of 762 mm or less is used.

4.3. Loading-Plate Scale Effect of the Repetitive Plate-Loading Test under Subgrade Condition

In a previous study mentioned earlier, Chung and Kim [

10] suggested that the scale effect applied to the plate-loading test be differently applied depending on the subgrade condition. In other words, the scale effect of the repetitive plate-loading test expressed by Equation (7) represents the value under the field-test subgrade condition, and it can be changed if the subgrade condition changes. Thus, in this section, the subgrade was classified into four types by referring to the embankment roadbeds classified in the Road Design Manual [

16], and numerical analysis was conducted under each subgrade condition using the loading-plate diameters applied earlier. In the same manner, areas with various strain moduli were simulated by varying the value of the elastic modulus among the input properties. As a result, the scale effect of the loading plate varied depending on the subgrade condition. Therefore, the scale effect apparently must be considered for strain-modulus measurement results of a loading plate that is smaller than 762 mm according to the subgrade condition of the repetitive plate-loading test, as listed in

Table 6.

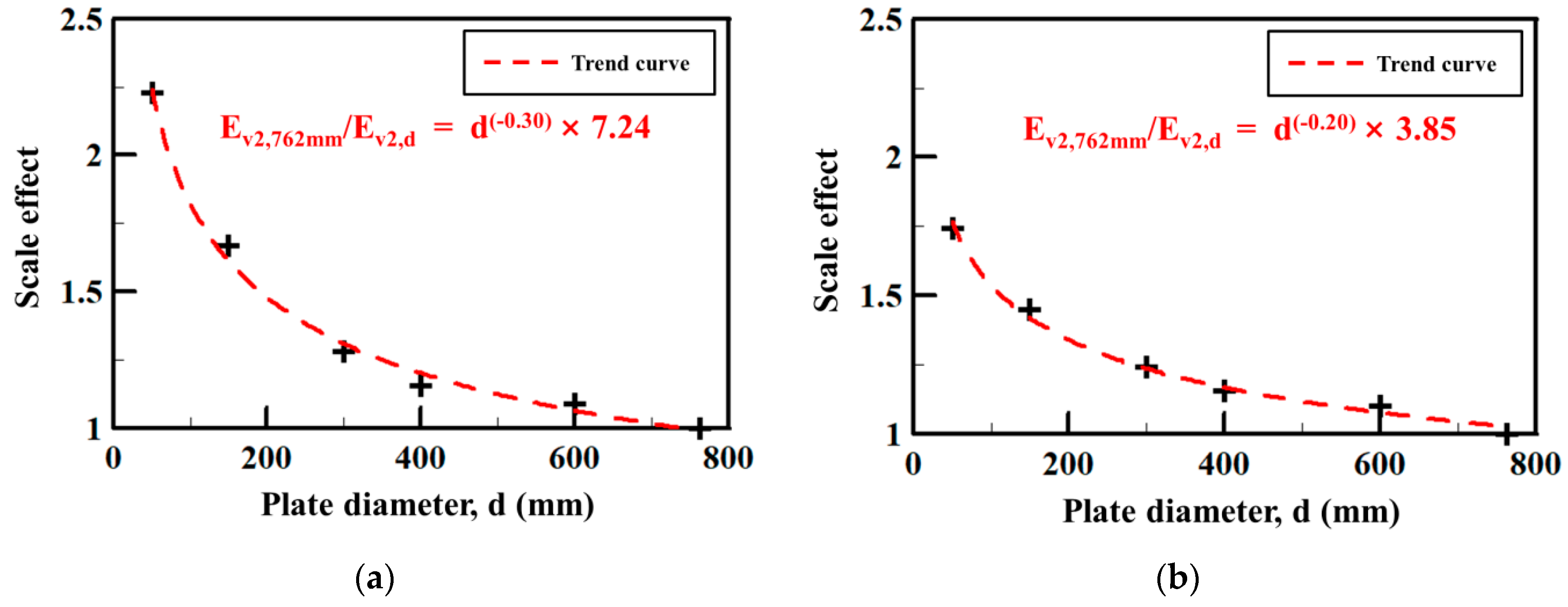

Figure 6 shows the trend curves of the scale-effect results of the six loading plate diameters used in this study, and the trend equations (Equations (8)–(11)) were derived from the curves. These results can be used to roughly estimate the scale effect to be considered when a loading plate with a diameter that is not considered in this study is used.

where

Ev2,d is the secondary strain modulus when the loading plate diameter is d.

4.4. Examination through Comparison with the Scale Effect of the Existing Plate-Loading Test

For the examination and reliability verification of the scale-effect results of the repetitive plate-loading test obtained through the numerical analysis in this study, the results were compared with the scale-effect results of the existing plate-loading test.

Thus, the scale effect of the repetitive plate-loading test proposed in this study was converted into a form similar to Equation (3), which was the scale effect of the plate-loading test as expressed by Equations (12) and (13). In Equation (12),

Ek is the ratio of the amount of stress change to that of the settlement change and had a form similar to the subgrade reaction modulus of the plate-loading test, i.e., k. Therefore, if the two moduli are assumed to be the same, an equation on the scale effect of the repetitive plate-loading test is derived with the same form as Equation (3), as expressed in Equation (13). Here, B, which is the diameter of the foundation in the plate-loading test, was changed to the reference loading plate. Thus, in this study, the 762-mm loading plate selected as the reference loading plate was applied.

where B is the diameter of the reference loading plate (mm), B

o is the diameter of the used loading plate (mm),

Ek is the ratio of the amount of stress change to that of the settlement change at points with 30% and 70% of the maximum stress (△σ/△s), N is the scale-effect calculation factor of the plate-loading test, a is the scale-effect calculation factor of the repetitive plate-loading test (

n + 1), and

k is the subgrade reaction modulus of the plate-loading test (σ/s).

To determine the scale-effect calculation factor of the repetitive plate-loading test, i.e., a, the loading-plate diameter, which is the x axis shown in

Figure 6, was normalized to the diameter of the reference loading plate (762 mm), as shown in

Figure 7. Regression equations were derived through regression analysis, and the value of the x-intercept was close to one under all subgrade conditions. Therefore, when this value was ignored, the scale-effect calculation factor of the strain modulus, namely, a, was found to be 0.3 for the gravel and fine gravel, 0.2 for sand, 0.12 for sandy soil, and 0.11 for cohesive soil.

Table 7 summarizes these results and the results obtained by replacing the scale-effect calculation factor of the existing plate-loading test, i.e.,

n, with a.

The list in

Table 7 indicates that the scale-effect calculation factor of the plate-loading test was approximately 0.5, on average, for the subgrade condition of sand and zero for cohesive soil, and a median value appeared to have been used in Korean Standard Assocation [

11]. On the other hand, the scale-effect calculation factor of the repetitive plate-loading test obtained through the numerical analysis in this study was approximately 0.25, on average, for the subgrade condition of sand and approximately 0.1 for cohesive soil, which were somewhat different from those of the plate-loading test. However, the tendency that the scale-effect calculation factor of sand was higher than that of cohesive soil was the same.

The difference in the scale-effect calculation factor between the two tests can be attributed to various causes. First, it could be caused by the assumed or changed conditions in the course of derived Equation (13). The factors were the slope of the stress and amount of settlement under a single loading in the plate-loading test and the slope under the repetitive loading in the repetitive plate-loading test, which may have also caused the difference. Moreover, the results were from the laboratory test and numerical analysis, respectively, and the subgrade condition was not identical despite the condition of the same sand or cohesive soil. The difference appeared to have been caused by these, and further studies by laboratory tests are required for more accurate comparison and analysis.

4.5. Analysis of the Relationship between the Subgrade Strain Modulus (Ev2) of the Repetitive Plate-Loading Test and Elastic Modulus (E)

As aforementioned, the subgrade strain modulus of the repetitive plate-loading test is currently used in the field as a quality-control method. However, it represents the solution of the boundary-value problem, and its value varies depending on the condition. Therefore, it cannot be considered as a property of the subgrade material and is different from the elastic modulus, which is a property of the subgrade. Choi et al. [

2] proposed a method of estimating the elastic modulus using the subgrade reaction and strain moduli and indirectly estimated the relationship between the strain and elastic moduli using the relationship between the subgrade reaction and strain moduli. In the field or roadbed cases designed for laboratory tests, assessing an accurate elastic modulus of the corresponding subgrade is difficult. On the other hand, in the numerical analysis, the elastic modulus of the subgrade clearly exists as an input property. Therefore, directly analyzing the relationship between the strain modulus, measured from the repetitive plate-loading test simulated through the numerical analysis, and the elastic modulus is possible in the same subgrade.

This section presents the comparison of the strain modulus results of the repetitive plate-loading test simulated using numerical analysis with the elastic modulus of the corresponding subgrade according to the subgrade conditions classified in this study. The results are shown in

Figure 8. The red solid lines represent the elastic modulus, and the results of the strain modulus according to the loading-plate size are displayed. As shown in

Figure 8, the 50-mm loading plate with the smallest diameter exhibited the largest difference in the elastic modulus, and the difference gradually decreased as the loading-plate diameter increased. This phenomenon was also explained by the increase in the nonlinear behavior due to the decrease in the loading-plate size, and we confirmed that the strain modulus was generally assessed to be somewhat smaller than the elastic modulus.

The strain and elastic moduli were compared using the 762-mm loading plate, which was the reference loading plate, and the summary of the results is listed in

Table 8. The standard deviation of the ratio of the elastic modulus to the strain modulus was zero in most of the subgrade conditions, and the elastic modulus of the subgrade appeared to be estimated from the result of the strain modulus. We found that the strain modulus was higher than the elastic modulus in the sandy and cohesive soil. Apparently, this was because the estimation equation of the strain modulus was calculated as an approximate value by the regression equation of the repetitive loading curve, and errors occurred in the process. In other words, the ratio of the elastic modulus to the strain modulus was determined to be 1:1 for the sandy and cohesive soil, which was the same as the relationship between the strain and elastic moduli proposed by Choi et al. [

2]. By summarizing these results,

Table 9 lists the relationship between the strain modulus of the repetitive plate-loading test and the elastic modulus according to the subgrade condition. From these results, we expect that the elastic modulus of the corresponding subgrade can be assessed using the repetitive plate-loading test.