1. Introduction

The maintenance and periodic replacement of railway wheelsets represents a significant cost faced by train operating companies. Railway vehicle wheels wear away relatively slowly and could be expected to last for many years (sometimes more than 20 years) based only on wear considerations. However, they are also subject to tread damage caused by wheel slide events, rolling contact fatigue, flange wear, and tread roll over. These events are more likely in the case of poorly maintained railways, where debris is accumulated on highly eroded tracks. Wheels, therefore, require regular re-profiling by machining on a wheel lathe. Massive maintenance service on a wheelset is done one or two times in its entire service life. The reprofiling of the worn wheels and the machining of the brake-disc are the usual main corrective actions.

This reprofiling operation is carried out by reducing the diameter of the wheel in accordance with local standards [

1,

2]. For train operating companies, an optimum strategy for wheel maintenance and lathe operation is required to achieve two main goals: maintaining wheels within operational safety and efficiency limits, and minimizing the costs. Thus, performing the repair operation as fast as possible while retaining the tolerances of the wheel profile is essential. The problem arises when trying to reshape severely damaged freight train wheelsets, where the high deterioration of the tread profile requires a high depth of cut turning operation. This fact, linked to the usual forged steel material of the wheel and its hardened outer layer, makes machining of the parts very demanding. For this reason, chatter vibrations that compromise wheel surface finish and machine-tool life expectancy and reliability may arise during turning. It is usual to reprofile a freight wheelset in several cutting passes instead of one to avoid chattering, leading to a significant loss of productivity.

The first step in designing a smart system for chatter suppression is the automatic identification of chatter vibrations. Most of the available in-process methods for chatter identification rely on extracting certain features from the acoustic or vibration signals and comparing them against some predefined chatter benchmarks. They can be broadly divided into two groups: categorization of feature matrix extraction (signal spectrum and decompositions) and classifiers (supervised and non-supervised) [

3,

4]. In the first group, different methods have been proposed based on analysis of the signal spectrum [

5], and decomposition of the signal based on wavelet packet transform [

6] or empirical mode decomposition [

7]. The general detection of chatter vibrations is a complex problem, and alternative types of classifier have been applied, including the hidden Markov model [

8] and neural network classification [

9].

Chatter vibrations in turning operations have been extensively studied, and many solutions to overcome the problem have been presented [

10]. It is well known that the stability lobe diagram can be used to optimize the cutting capacity by selecting the correct process parameters [

11,

12,

13,

14]. The selection of an adequate tool–tool holder geometry based on stability diagrams can also increase the cutting capacity [

15,

16]; however, this solution is rarely applicable to structural chattering cases in turning. The process damping effect raises the effective damping by increasing the friction between tool and workpiece [

17], and can be applied to stabilize the cutting [

18]. The increase of stiffness of the vibrating structure could also be a feasible way to avoid chatter, especially if there is a dominant mode, although massive structural changes are sometimes required to achieve a substantial effect [

10,

19]. Passive and active damping solutions, on the other hand, can be used to add damping to the critical mode/s by means of external subassembly devices, leading to a higher stability limit [

20,

21,

22,

23,

24]. Finally, continous spindle speed variation (CSSV) techniques increase stability by disrupting the regenerative effect [

25,

26,

27,

28].

By applying the previous structured engineering thinking and techniques to the industrial use of AI or machine learning, a transformation from collected raw data to enriched information or smart data [

29] will be generated. The smart data are responsible for detecting relevant signals and patterns through intelligent digital signal-processing algorithms. Smart data makes sense out of big data, providing actionable information and improving decision making.

The present work addressed the implementation of a hybrid edge–cloud smart system in a portal lathe for optimal wheelset reprofiling. The edge computing expert system consisted of a chatter detection and suppression tool, which generated and evaluated the smart data. The process was continuously monitored through embedded sensors which decided when chatter was occurring and, depending on the severity, applied different chatter suppression strategies. Additionally, a cloud computing system obtained the fingerprint of wheel profile machining.

Finally, the correct behavior of the system was experimentally validated through industrial real wheel reprofiling tests where the vibration of the process was removed through the smart system and the turning process was optimally performed. Moreover, the data provided from the system were collected, creating a fingerprint for each machining operation in the cloud. The data were remotely accessed and analyzed allowing a forensic examination.

2. Description and Diagnosis: Engineering Knowledge for Smart Data Collection

The productivity of the machine in the case of freight train wheel reprofiling is limited by the presence of strong marks in the surface of the reshaped wheels and the premature breakage of mechanical elements due to the presence of strong vibrations. Proper diagnosis of the origin of the problem by domain experts is fundamental for successful design of the system. In this case, several cutting and impact tests were performed to identify the problem and select the proper sensors, broadbands, and admissible vibration limits. These tests were the key to defining the hardware of the smart system and the different vibration levels that were used to classify the status of the cutting process.

2.1. Portal Lathe Machine

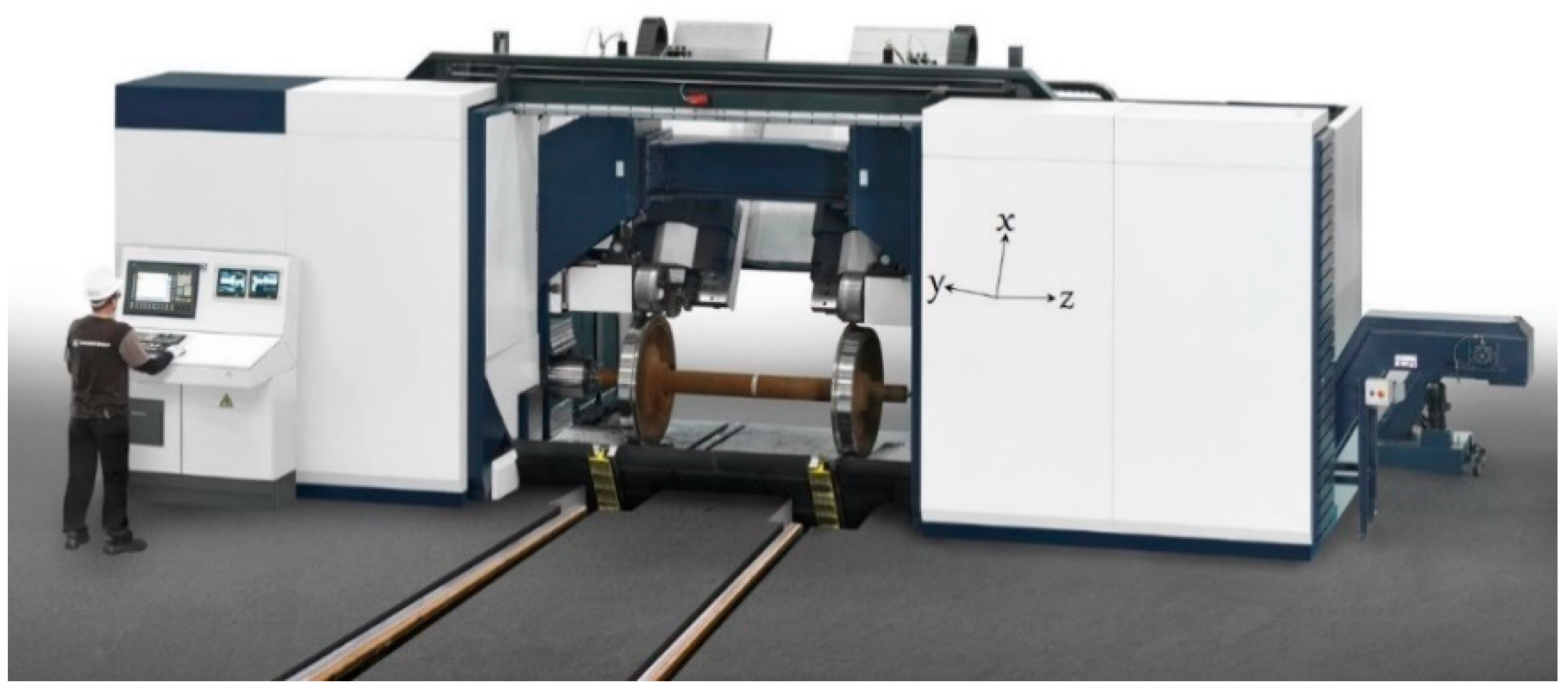

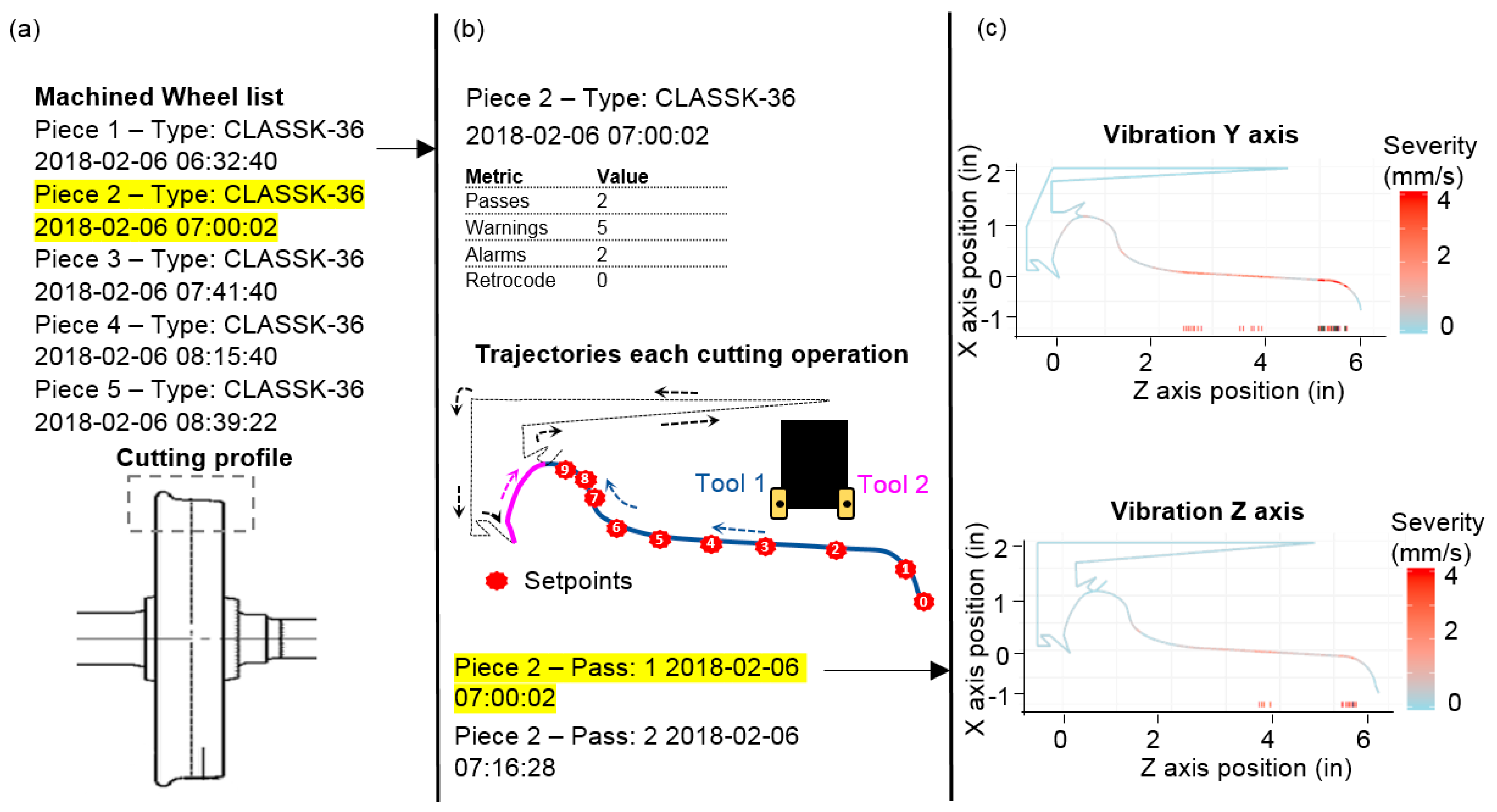

This work was carried out in a portal lathe, which is a machine specifically conceived for wheelset machining (see

Figure 1). The machine has a machining unit composed of two pairs of crossed carriages (X, radial and Z, axial), one for each wheel, as well as a measuring unit to determine the amount corrective depth of cut required.

The wheelset rotation is driven by electric motors, which in turn drive rollers attached at the end of the shaft. These rollers are hydraulically preloaded against the wheel, thus rotating the wheelset by friction.

2.2. Cutting Tests

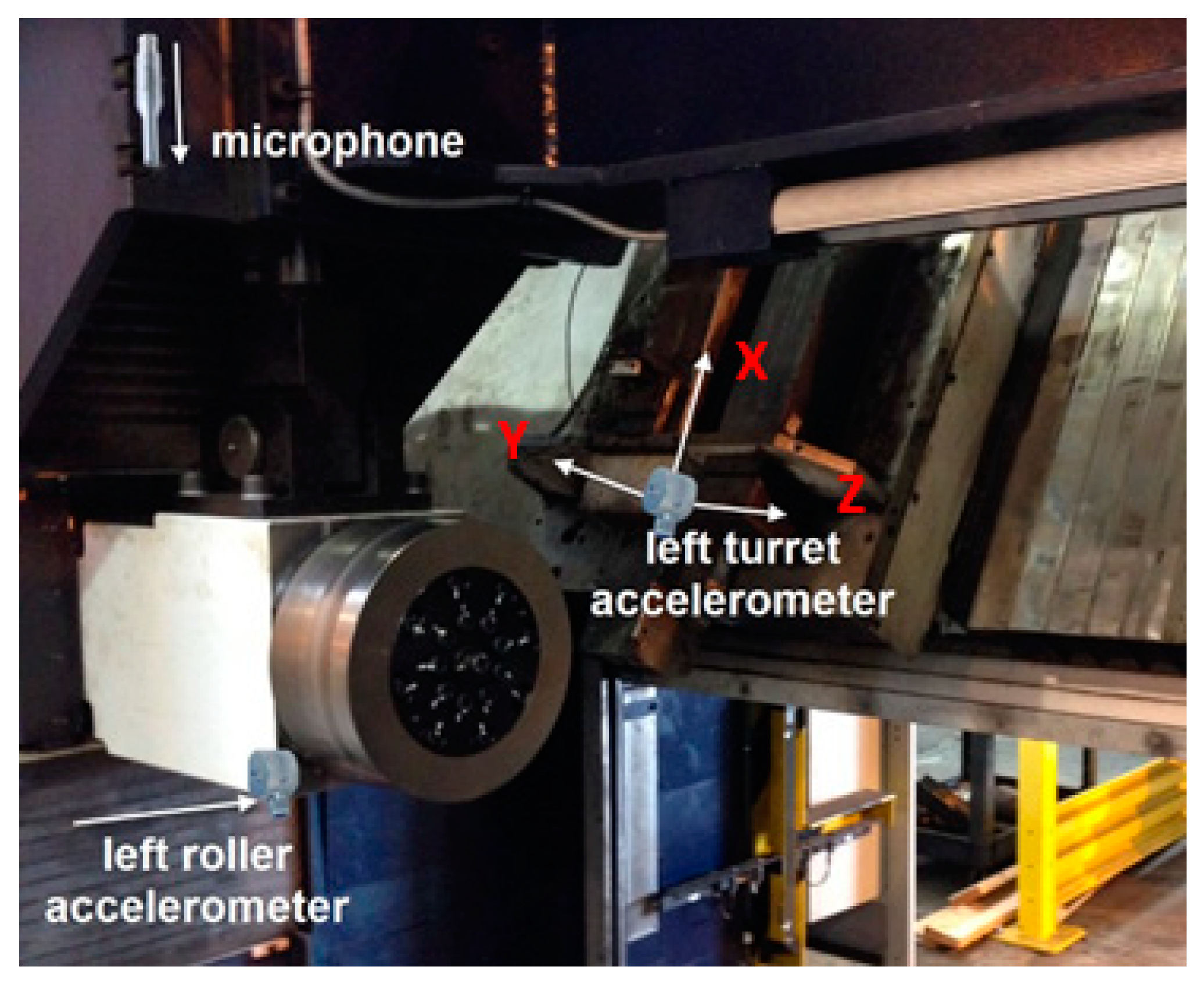

Cutting tests in different diameter wheelsets (33″, 36″, and 38″) were performed while varying the depth of cut until the stability limit was found. The material was a standard wheelset steel approved by the Association of American Railroads (AAR). A temporary set up of the sensors based on external shielded cables permitted a fast change of the position, being the type of sensor used suitable for an industrial environment. Finally, vibrations were successfully recorded by means of a triaxial piezoelectric accelerometer (IMI 604B31) placed in the left turret and a uniaxial (IMI 627A01) accelerometer in the left upper roller (see

Figure 2). Sound pressure was also measured with a microphone (MG MK250). All the signals were processed in a vibration analyzer.

In these tests, the presence of the self-excited vibrations popularly known as chatter was detected and related to the marks in the wheel surface. A summary of the tests is shown below in

Table 1. The green ticks stand for the stable tests, whereas the red crosses represent the unstable ones (chatter tests). Four different wheelsets were studied. The depth of cut (mm in radius) was increased until the stability limit was reached at different cutting speeds.

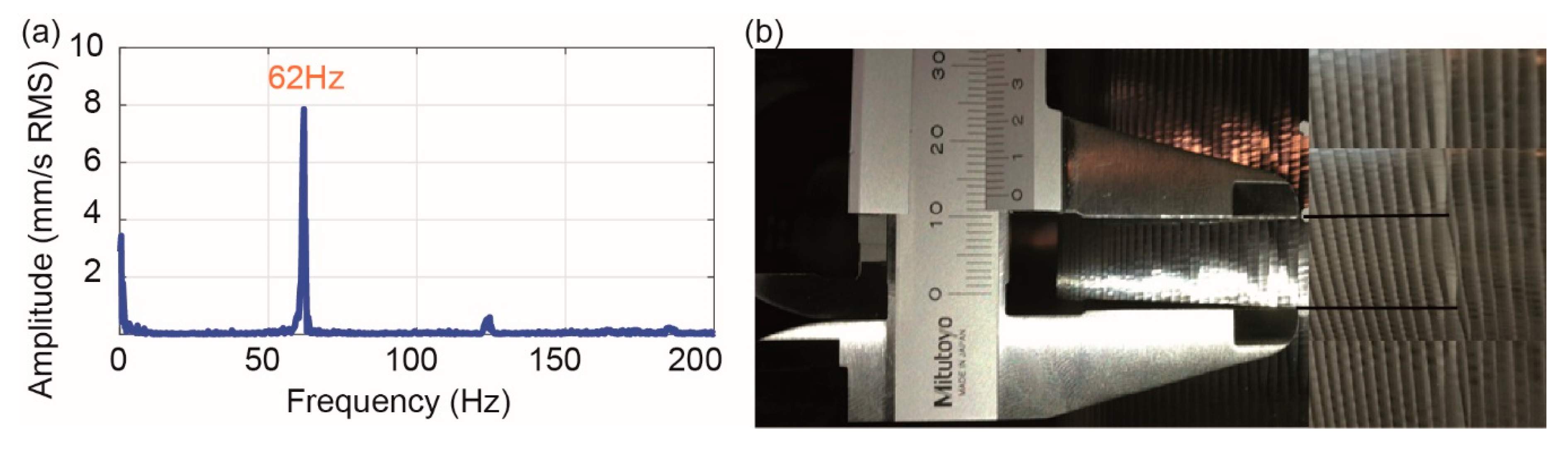

The recorded chatter cases featured a high vibration amplitude (see

Figure 3a), which turned out to be very harmful for the machine and the machined wheelset, resulting in scrapped parts due to severe surface marks (see

Figure 3b). Vibration amplitudes up to 16 mm/s rms in the left turret and up to 40 mm/s rms in the upper roller were measured. The chatter frequency lay between 60–62 Hz at every unstable test. Both accelerometers showed similar vibration patterns and were more robust at detecting chatter than the microphone. Therefore, only one accelerometer, the left turret triaxial accelerometer, was selected to be included in the smart system. Additionally, based on the vibration levels of the left turret accelerometer, different machining stability conditions were defined in this phase.

The measured distance between chatter marks in the wheel was around 13 mm, which in a 900 mm diameter wheel and at a rotating speed of 18 rpm approximately matched the measured chatter frequency (62 Hz).

The lobe number

k or the number of waves per revolution was calculated through Equation (1):

where:

fc: chatter frequency (Hz),

Z: number of inserts,

N: spindle speed (rpm).

Therefore, the part was marked with around 207 marks in the peripheral surface of the machined train wheel, with an approximate distance of 13 mm.

2.3. Frequency Response Functions

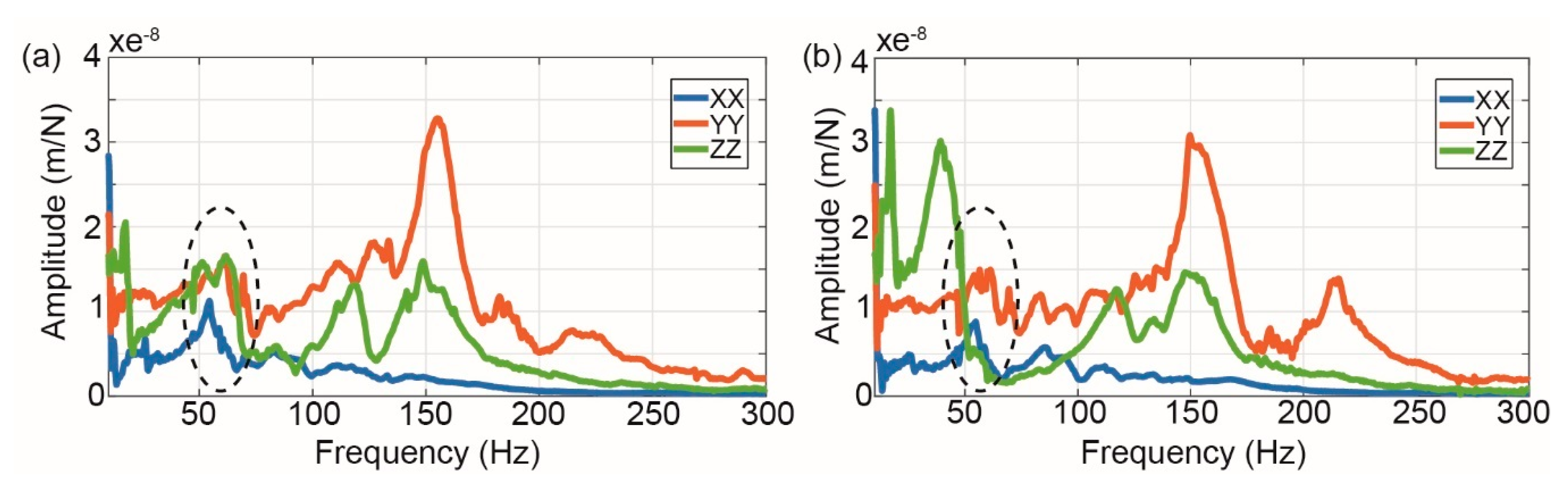

The frequency response functions (FRF) of the machine were obtained by means of impact tests. The objective was to identify the vibration modes responsible for the chatter vibrations during machining. The FRFs shown in

Figure 4 were obtained by shaking the structure in both turrets close to the tip (see

Figure 2) using an impact hammer (PCB086D20/C41) and measuring the response at the same point using a high sensitivity triaxial accelerometer (PCB356A17). The averaged FRFs were obtained by repeating the process four times in the machining position with the wheelset clamped.

The dynamic properties of the main modes are summarized in

Table 2:

Considering the high vibration amplitude at around 60 Hz that was recorded during the chatter tests, the mode at 55 Hz in X direction was determined to be causing the instability. The presence of this mode at 55 Hz definitely confirmed the presence of chatter. Although the dynamic stiffness (94–117 N/μm) and the damping value (5.8%) of this mode were high, the demanding operation over a heavily worn out wheel jeopardized the cutting stability. In addition, the high damping of the critical mode at 55 Hz ruled out the inclusion of the active damping technique in the chatter suppression smart system [

10,

23,

24].

Three important conclusions were obtained from the tests carried out in

Section 2 to inform the design of a hybrid edge–cloud-based smart system for train wheel repair. First, the cutting tests and the FRF measurement showed that regenerative chatter related to a structural mode around 55 Hz was the responsible for the marks that are endangering the productivity of the portal lathe. Therefore, the smart system focused on the detection, control, and suppression of chatter. Secondly, the industrial accelerometer located close to the tool tip in the left turret was selected as the main sensor to determine the status of the process, and the critical vibration levels in this position for the sensors were defined. Finally, the self-excited mode had considerable damping and the ratio between the chatter frequency and the cutting frequency

k was very high (

k > 200). These two characteristics were considered to select the most proper techniques to suppress chatter.

3. Smart Chatter Suppression in Wheel Reprofiling

3.1. Selection of the Adaptative Chatter Suppression Techniques for the Smart System

In

Section 1, several chatter suppression techniques were mentioned. However, not all solutions are applicable in every scenario. Munoa et al. [

10] studied the different chatter suppression techniques and discussed the most suitable application for each chatter problem. The number of waves per revolution or lobe order (

k) was defined as one of the key factors in selecting the optimal solution. In the present case of structural vibrations arising in wheel reprofiling turning operations, the ratio between the chatter frequency and the cutting frequency

k was very high (

k > 200), due to the low rotating frequency of the machined wheel. This located the process in the A zone of the stability diagram (

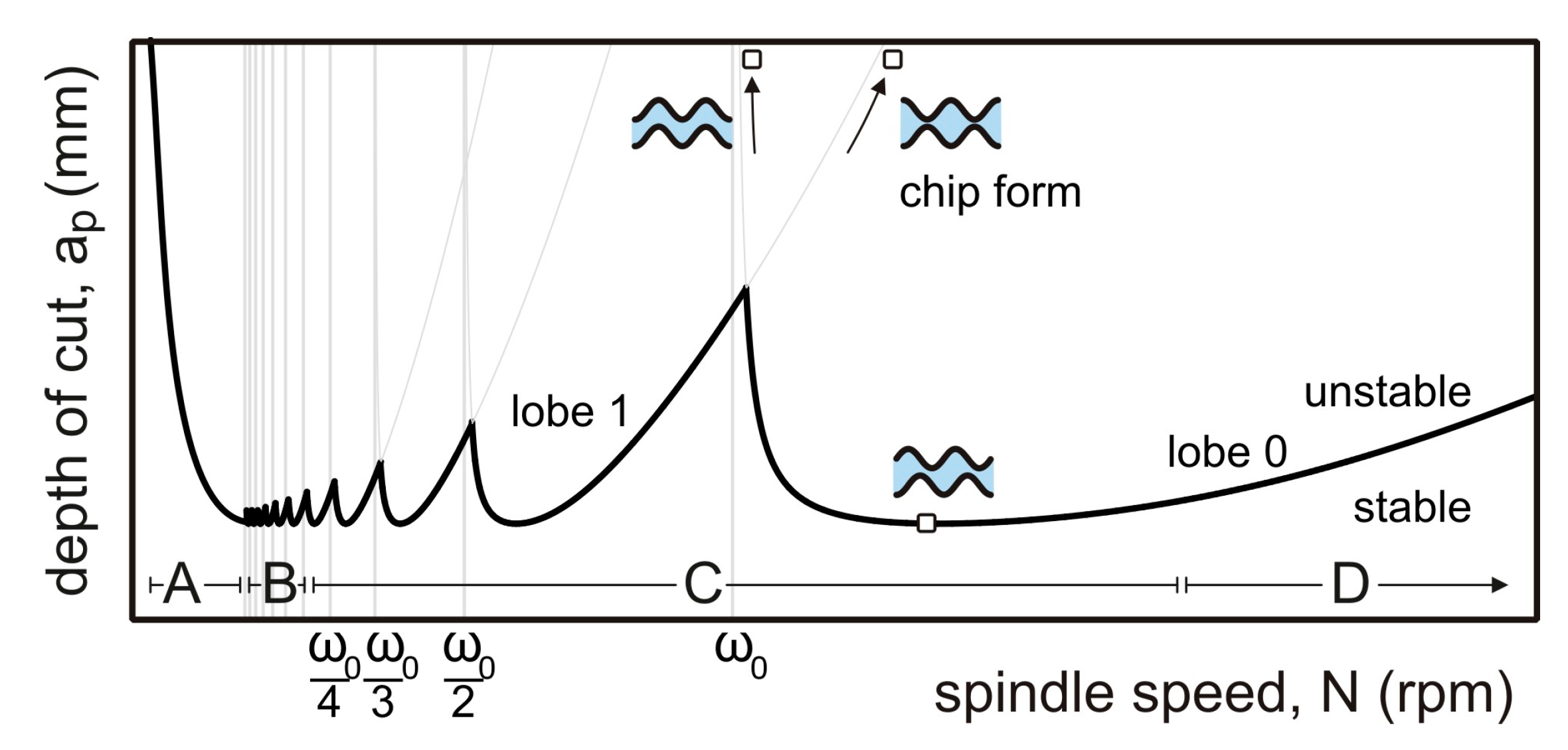

Figure 5), or the so-called process damping zone [

10].

In this zone, according to the domain experts [

10], two techniques are especially effective, the above-mentioned process damping maximization, and CSSV [

10]. Although active damping could be also a suitable solution for chatter removal in this zone, the high damping of the critical mode at 55 Hz discouraged its use for the chatter suppression smart system [

10,

23,

24].

3.2. Process Damping Maximization

For the case described in

Figure 3,

k = 207. This implies that the working conditions were in Zone A, or the process damping zone in the stability lobe diagram (

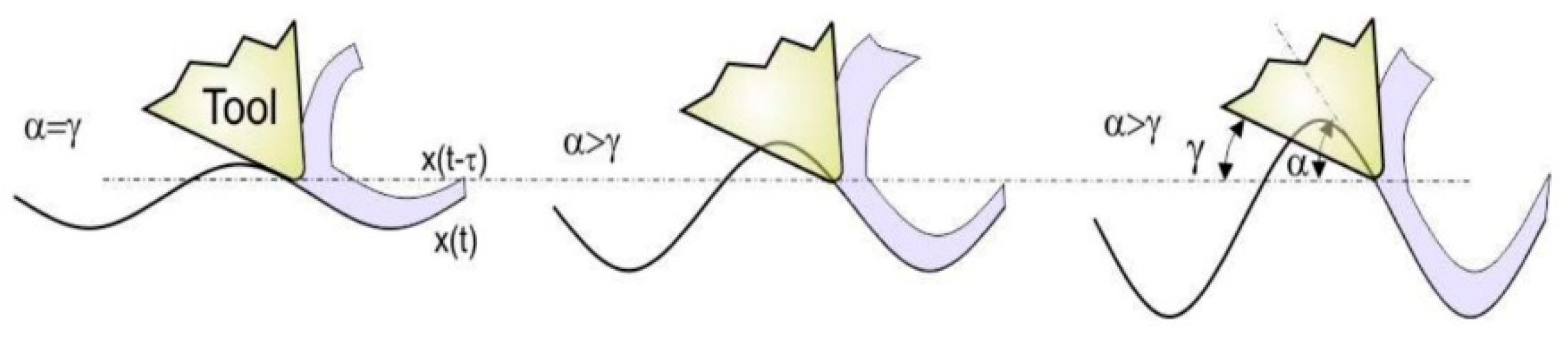

Figure 5). The effectiveness of process damping grows as the ratio between the tooth passing frequency and the chatter frequency decreases, therefore, the lower the spindle speed is set, the higher the stability boundary is. The physical effect for this stability increase is the rubbing phenomenon between the flank face and the wavy surface (see

Figure 6).

In order to take advantage of the process damping effect, two practical alternatives are feasible. On one hand, the spindle speed can be reduced to increase the number of vibration waves per revolution, and thus increase process damping. However, the application of this technique can reduce productivity and can be limited by machinability constraints. On the other hand, worn tools can be used to avoid chatter, as the process damping increases with flank wear. However, worn tools increase the static cutting loads, and excessive wear may lead to tool breakage and poor surface finish. Special edge geometries can be also used to avoid sharp edges and reproduce the performance of a worn tool. Several authors [

18,

30] have studied the effect of cutting edge geometry on process damping.

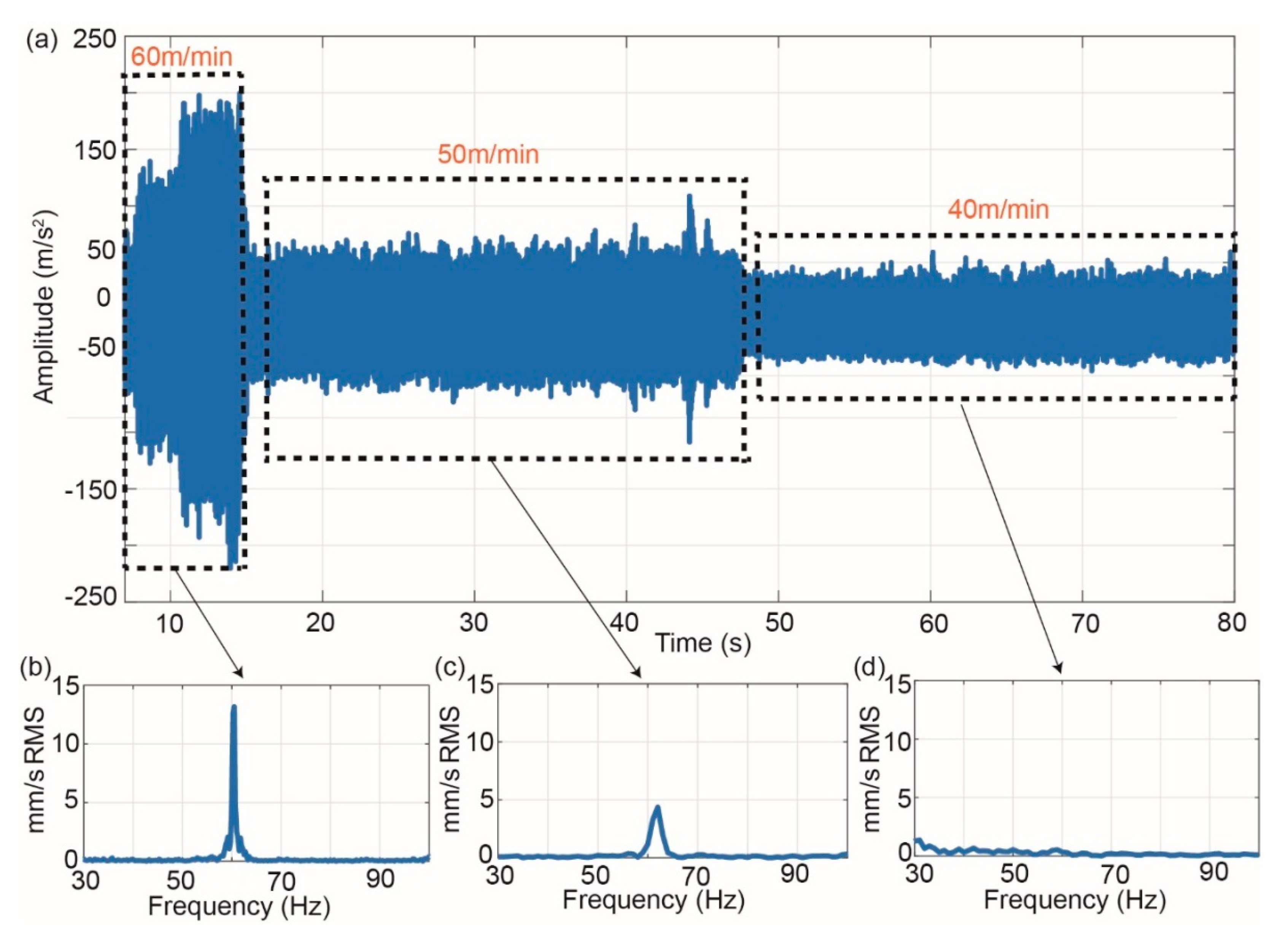

Process damping was proven to be a valid solution for chatter avoidance in the studied portal lathe case. The applied solution consisted of reducing the cutting speed and thus the revolutions per minute of the wheelset.

Figure 7 shows how reducing the cutting speed from 60 m/min to 40 m/min made the chatter vibration disappear, leading to a stable cutting condition.

This technique was effective and easy to implement, but it reduced the productivity as the spindle speed was also decreased. Feed per tooth could be increased at the same time to preserve productivity, but there was a risk of side effects such as early tool wear or breakage.

3.3. Continuous Spindle Speed Variation (CSSV)

Some authors [

25,

26,

27,

28,

31] have proposed the distortion of the regenerative effect by CSSV around a nominal speed. CSSV creates a time dependency in the delay that can improve stability. The effectiveness of this technique has been demonstrated in several studies in the literature [

32,

33,

34].

This technique is based on the introduction of a perturbation in the spindle speed command. There are different methods for varying the spindle speed, including sinusoidal [

35,

36,

37,

38], triangular [

39], rectangular [

31], random [

40], or continuous linear perturbation [

41]. The sinusoidal signal has emerged as the most efficient technique compared to random, rectangular, or triangular shapes. Therefore, the sinusoidal spindle speed variation (SSSV) was selected. This consisted of a simple harmonic variation applied on the spindle speed around the nominal speed value.

When the machining process takes place at low spindle speeds (A & B zones in

Figure 5), small variations in the spindle speed bring about relatively large variations in the delay between successive waves. Therefore, low spindle speed amplitude variations can increase the stability in these zones without any relevant side effects. In these areas, the application of CSSV supposes a small increase in the surface roughness and does not jeopardize the life of the main drive if the correct variation is applied [

42]. Out of these zones, CSSV is not effective because the variation requirements are not physically reachable [

10]. The selection of the amplitude and frequency for sinusoidal CSSV is already an open issue. Al Regib et al. [

37] proposed simple formulae to define the parameters of the variation. These formulae are only approximate and do not consider the effect of process damping, which was dominant in the present case. Nevertheless, some facts related to CSSV are well-known, such as the fact that the variation of the amplitude has a bigger effect than the frequency variation [

36,

43].

The portal lathe chattering problem in this work was placed in Zone A, which made the application of CSSV appropriate. In the case, the amplitude and frequency were selected experimentally, introducing the minimum possible variation in terms of amplitude and frequency. A soft variation based on a frequency of 0.5 Hz and an amplitude variation of 5% of the original speed were enough to stabilize all the cutting tests shown in

Table 1.

Figure 8 shows the variation of the vibration spectra in a cutting test of 15 mm depth of cut, 60 m/min cutting speed, and 1.3 mm/rev feed rate with and without CSSV.

It can be concluded that CSSV technique for chatter suppression worked effectively in the present case study and, in addition, it did not alter productivity. However, sinusoidal variation of the rotating speed may lead to slipping between the wheels and the rollers due to the continuous acceleration/deceleration. On the other hand, the application of CSSV in stable conditions can reduce tool life [

44], but its application in unstable condition drastically increases the tool life [

45]. Therefore, this solution should be considered as a secondary option to be used only when the presence of chatter is confirmed.

4. Industrial Internet of Things (IIoT) Platform for Hybrid Edge and Cloud Computing

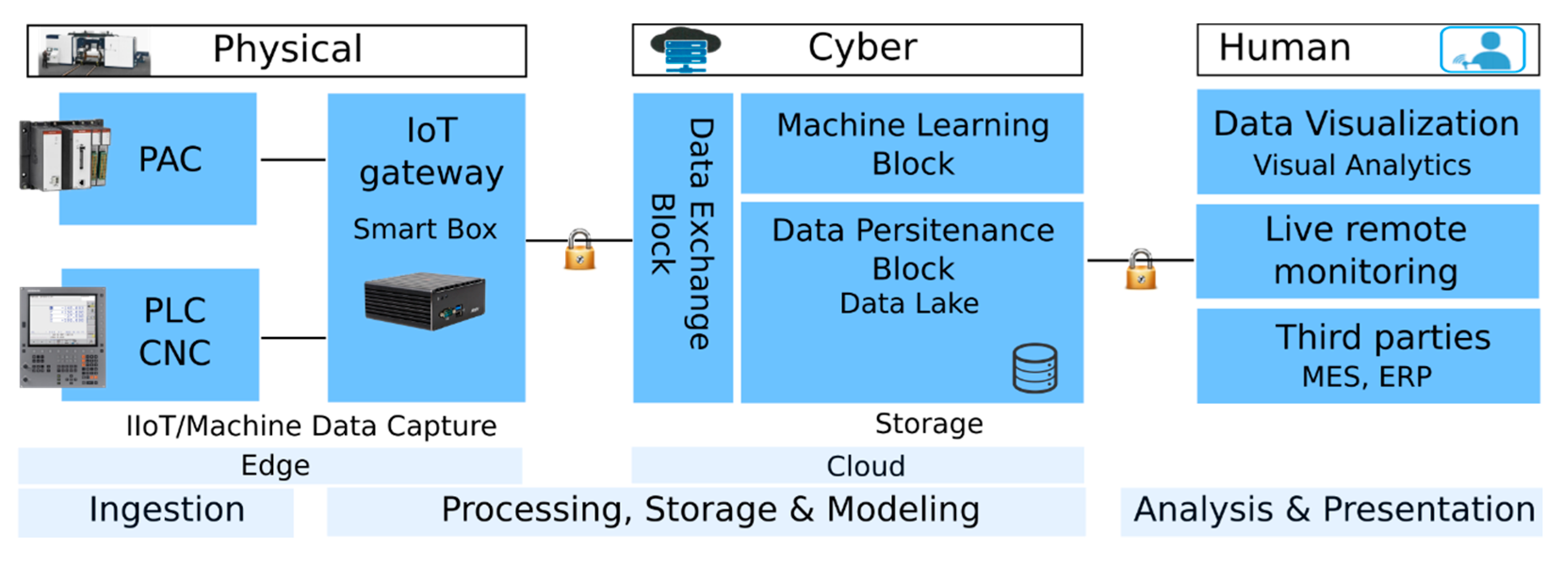

An Industrial Internet of Things (IIoT) platform (see

Figure 9) is a form of middleware that sits between the layers of Internet of Things (IoT) devices (hardware, sensors) and IoT gateways (and thus, data) on the one hand, and applications (software) on the other hand. The reality of IIoT platforms is complex because applications and solutions come with different architectures, ways of connecting and managing devices, possibilities for managing and analyzing data, capabilities to build applications, and options to leverage IIoT in a meaningful way for any given use of IIoT in any given context.

An IIoT platform needs hardware, such as sensors or devices (the “physical” part). These sensors and devices collect data from the machine/components, machining process, and performed actions. Three requirements can be established for the design of an IIoT platform:

An IIoT platform needs connectivity. The hardware needs a way to transmit all the collected data to the cloud, or needs a way to receive commands from the cloud. There is usually an intermediate step between hardware and the connection to the cloud, such as an IIoT gateway.

An IIoT platform needs software (the “cyber” part). This software is hosted in the cloud and is responsible for storing and analyzing the vast amount of data collected from the sensors, and for making decisions based on learned patterns due to the high computing power of the cloud. Nevertheless, the analysis, processing, and transmission of some types of data can be critical in contexts where fast actions need analytics and intelligence at the so-called edge (where the devices/assets and IIoT gateways are). This is what edge computing and fog computing are partially about and where edge platforms come into play.

Finally, a complete IIoT platform needs a user interface. To make all this useful, there must be a way for users to interact with the IIoT platform (for instance, a web-based app with dashboards for visual data analytics or live remote data monitoring).

4.1. The Edge

At the edge, the data come in from the physical world via sensors, and actions are taken to change physical state via various forms of output and actuators. The data processing, analysis, and evaluation are performed at the edge. The communications have real-time and deterministic behavior, while the quantity of the analyzed data is reduced.

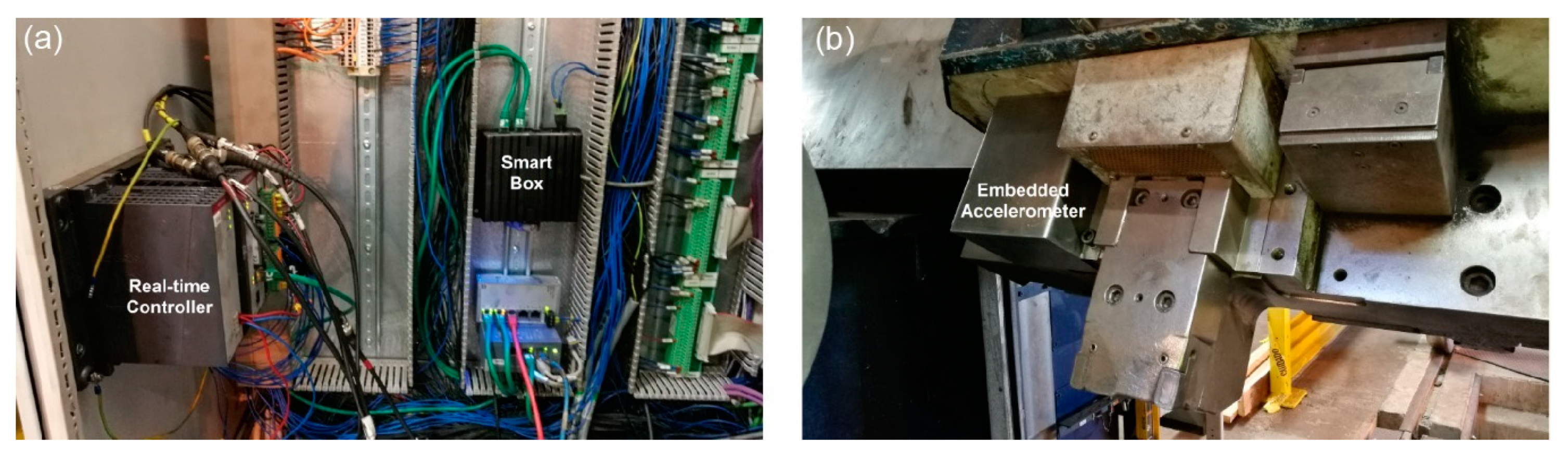

A triaxial accelerometer was embedded in the machine close to the cutting point and its signal was sent to a real-time controller located in the electrical cabinet of the machine. An expert algorithm which ran in this real-time programmable automation controller (PAC) processed this signal and when the machining becomes unstable, it commanded an action from the computer numerical control (CNC) to solve the vibration problem. This controller was surveyed by a higher-level cloud-based monitoring system, which was used as a follow-up and analytics tool. This surveillance was done through an IoT monitoring hub or gateway which gathered the data from the controller, managed them, and uploaded them onto the cloud. The physical platform used is shown in

Figure 10.

4.2. The Cloud

The cloud is a huge, interconnected network of powerful servers that performs services for business. The Savvy Data Systems cloud, used in this system, can be divided in three major parts: communication to the cloud, cloud processing, storage and modeling, and cloud data analysis and presentation.

Communications: The cloud provider, Savvy Data Systems, uses transport layer security (TLS) to offer secure data transmission to the cloud. TLS is a widely adopted security protocol designed to facilitate privacy and data security for communication over the Internet. A primary use of TLS is encrypting the communication between web applications and servers, such as web browsers loading a website.

Cloud processing, storage and modeling: There are three main parts. The first one, named the data exchange block, allows connectivity to the smart box, the IoT hub, through optimal security actions. Companies gain secure and real-time access to new data and lightweight, instant interactions with other blocks; the second block is formed by the data persistence block that deals with persisting (storing and retrieving) data from a data lake. The machine CNC data (power consumption, depth of cut, feed rates, spindle speeds, program name, alarms…) and PAC data (vibration data) are stored in an unstructured way in the Savvy Data Systems data lake. Finally, the machine learning (ML) block is a managed service that allows developers and data scientists to create superior models of machine learning and take them to production. The Cloud ML Engine offers preparation and prediction services that can be used together or separately. In the proposed use, the gathered data from the CNC and the PAC for the many train wheels machined were aggregated using the Cloud ML Engine, which helped to find weak points during the machining operation for different workpiece references.

Cloud data analysis and presentation: The data visualization block is responsible for the graphical display of the acquired information (historical data) for two purposes: sense-making (also called data analysis) and communication. The data can be effectively visualized following design principles that are derived from an understanding of human perception. In the train wheel repair manufacturing process, machining data fingerprint visualization was proposed (see

Figure 11). The unstructured data of the cloud were transformed for human understanding, mixing process data, manufacturing orders, and quality results. On the other hand, the live remote monitoring block was used for the visualization of machine operation data in the moment. Live machine data could be visualized remotely in real-time. Finally, interoperability with third party software, manufacturing execution system (MES) and enterprise resource planning (ERP), was also possible using the full-rest API. Interoperability with human devices is also possible; the cloud could send an e-mail in case of failure or damage detection during the machining operation.

5. Hybrid Edge–Cloud-Based Smart System for Chatter Detection and Suppression

The complete solution required processing algorithms on both edge and cloud. Therefore, a hybrid edge and cloud platform was required to develop the smart system for chatter detection and suppression.

Considering the tests carried out in

Section 3, process damping and CSSV techniques were determined to be, in principle, the most appropriate techniques to remove chatter vibrations, since the ratio of the chatter frequency and the tooth passing frequency lay in Zone A (

Figure 5;

k = 207 for the portal lathe case) of the stability diagram, which is called the process damping zone [

10,

18]. Both techniques were tested for the selected case to verify their effectiveness and learn about the vibration signature of the cutting process. The hybrid edge–cloud-based smart system for chatter detection and suppression was based on the computation of signals obtained by the accelerometers for chatter detection, and the smart combination of the aforementioned two techniques to suppress it.

5.1. Edge-Computing-Based Smart System for Chatter Detection and Suppression

The applied expert algorithm first processes the time domain signal captured by the accelerometer and converts it to the frequency domain through a fast Fourier transform (FFT). A frequency domain integration is then performed based on the acceleration spectrum, and a vibration severity is calculated. The severity calculation is a simple quadratic sum of the calculated vibration velocity values over the selected range, in accordance with the ISO-10816 standard [

46], as in Equation (2):

It was determined from the experimental testing carried out in

Section 2 that if the cutting process was stable, the severity in this range would lie below 0.5 mm/s rms. When light chatter appeared, this value rapidly rose over 1 mm/s rms, up to around 2.4 mm/s rms. Strong chatter cases clearly exceeded 4 mm/s rms. With this experimental learning in mind, the implemented algorithm is roughly described in

Table 3.

Depending on the severity value detected, different actions were taken. First, a decrease in cutting speed was programmed, which was observed to be the most effective solution. If the severity value did not go below 4 mm/s rms, CSSV was added to the cutting speed decrease. In case that both solutions applied simultaneously were not capable of reducing the vibration values after 10 s, the system prompted an alarm and moved the tool out of the workpiece to a safety position, preserving the machine mechanics and avoiding having to scrap a wheelset. The system then proposed to finish the cutting operation by doing an additional roughing pass at half the original depth of cut.

If the chatter is suppressed, various resetting points were programmed all over the wheel profile, in order not to carry out the machining entirely either at low spindle speed or with SSV active, since this could have side effects in terms of productivity decrease or early tool wear. Based on the experience obtained in the cutting tests carried out in

Section 2, the process was divided in 10 zones connected by 9 resetting points (see

Figure 11).

5.2. Cloud Computing for Machining Fingerprint Analytics

The cutting conditions for each workpiece were recorded. The recorded data consisted of the instantaneous position, feed rate, and power consumption for each axis, the rotational speed and power consumption of the spindle head, and the vibration severity values in X, Y, and Z directions. Thus, each workpiece had its own fingerprint, which was stored in the data persistence block in the cloud. Traceability of the cutting process was therefore made possible thanks to the cloud’s massive storage capacity.

Using the data visualization block, the user was able to access the desired workpiece, for instance. Piece2-Type Class-36 2018-02-06 07:00:02 (see

Figure 11). It was then possible to check the number of cutting passes required for machining the wheel profile and to observe relevant data such as required machining time, number of alarms, and vibration severity. If one of the cutting passes was selected, then all the recorded data were shown, including a vibration map indicating the maximum vibration levels on the wheel profile, a power consumption map showing the load required at each position for the axes and the spindle head, and finally a feed rate map showing the different speeds during the trajectory of the tool (see

Figure 11). Machine analytics was used to describe the chatter problem, crossing the data coming from the accelerometers with the cutting position obtained from the machine sensors. Only descriptive analytics were used in this study.

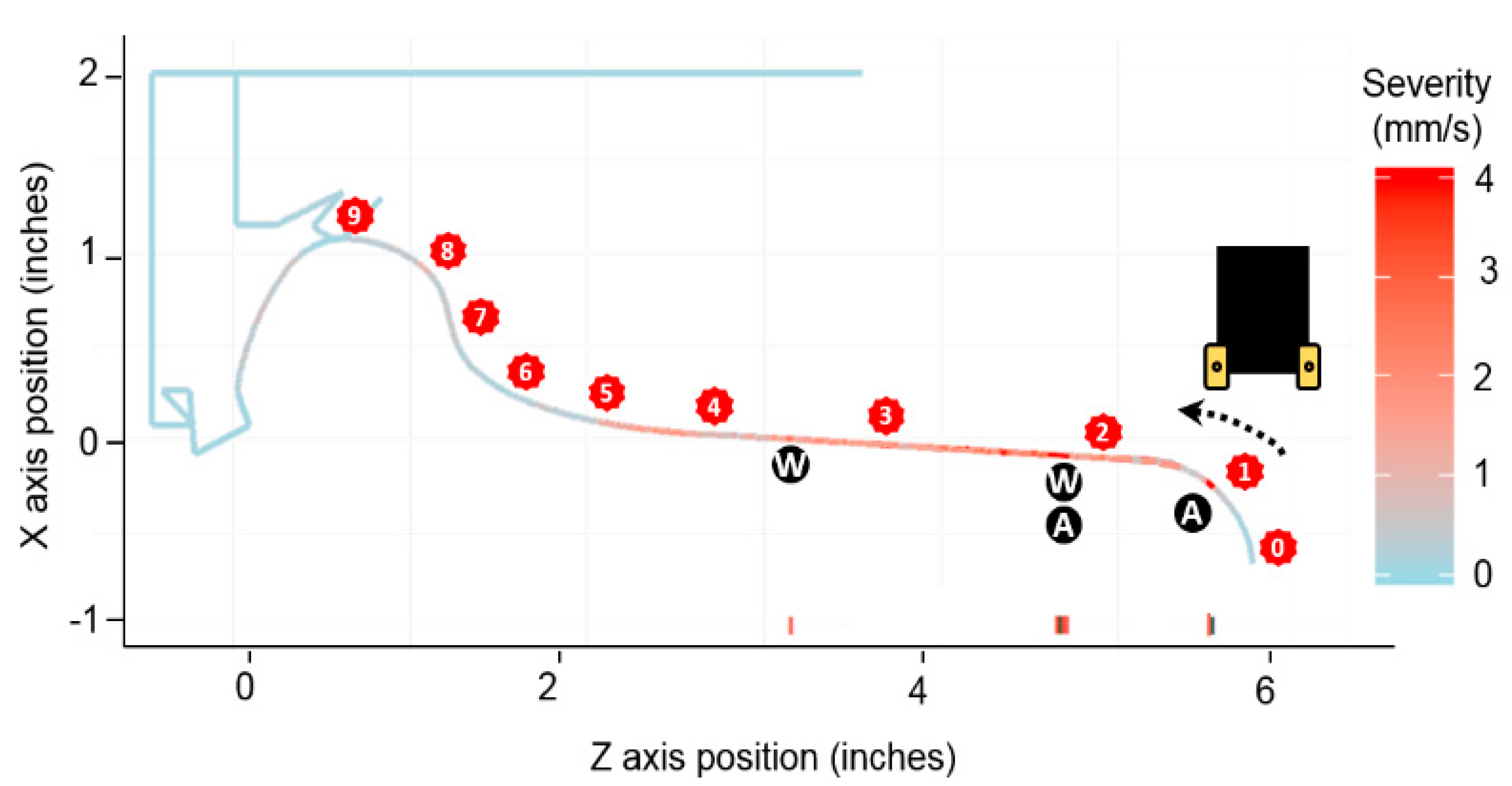

It is important to remember that this process is a maintenance operation where the part is not homogenous, and the depth of cut and hardness of the surface can vary considerably. The aggregation of the same type of workpiece fingerprints can highlight hidden insights that would be very difficult to detect any other way. For instance,

Figure 12 shows the probability of a certain machining position having a vibration higher than the alarm level when the smart system is working. The ratio between the number of occurrences (cases where the heuristically extracted vibration limit was exceeded) and the total number of possible cases (the total number of machined wheels) was analyzed for each position and reference.

It was noticed that the points with the highest probability of having the maximum vibration level were always the same (

Figure 12). Two points concentrated the risk of having high vibration from the same references and were not close to reset points.

The trajectory of the first insert crossed the wheel in the negative Z direction and found the first critical zone between reset point 1 and 2 in the initial radius. The wheel withstood a plastic deformation during its operative life, and a considerable difference in terms of depth of cut between the central part and this radius were found. Therefore, the depth of cut was bigger during the reshaping process and the risk of chatter increased.

The second critical point was located before the fourth reset point. In this area, the depth of cut did not have any important increase, but the material was hardened due to the deformation created during operation. The deformation process of the wheel profile was comparable with a rolling process in the positive Z direction [

47].

Once a great number of fingerprints had been recorded, the smart system had a machine learning block prepared to house any machine learning technique. The idea was to use a machine learning technique that will enable the automatic customization of section length and reset point locations for each railway wheel reference. Therefore, the actual cutting-test-based section and reset point definition will be optimized using machine learning techniques and deployed in the Cloud ML engine. This way, the CSSV and the reduction of spindle speed will be managed automatically for each train wheel reference.

6. Experimental Validation

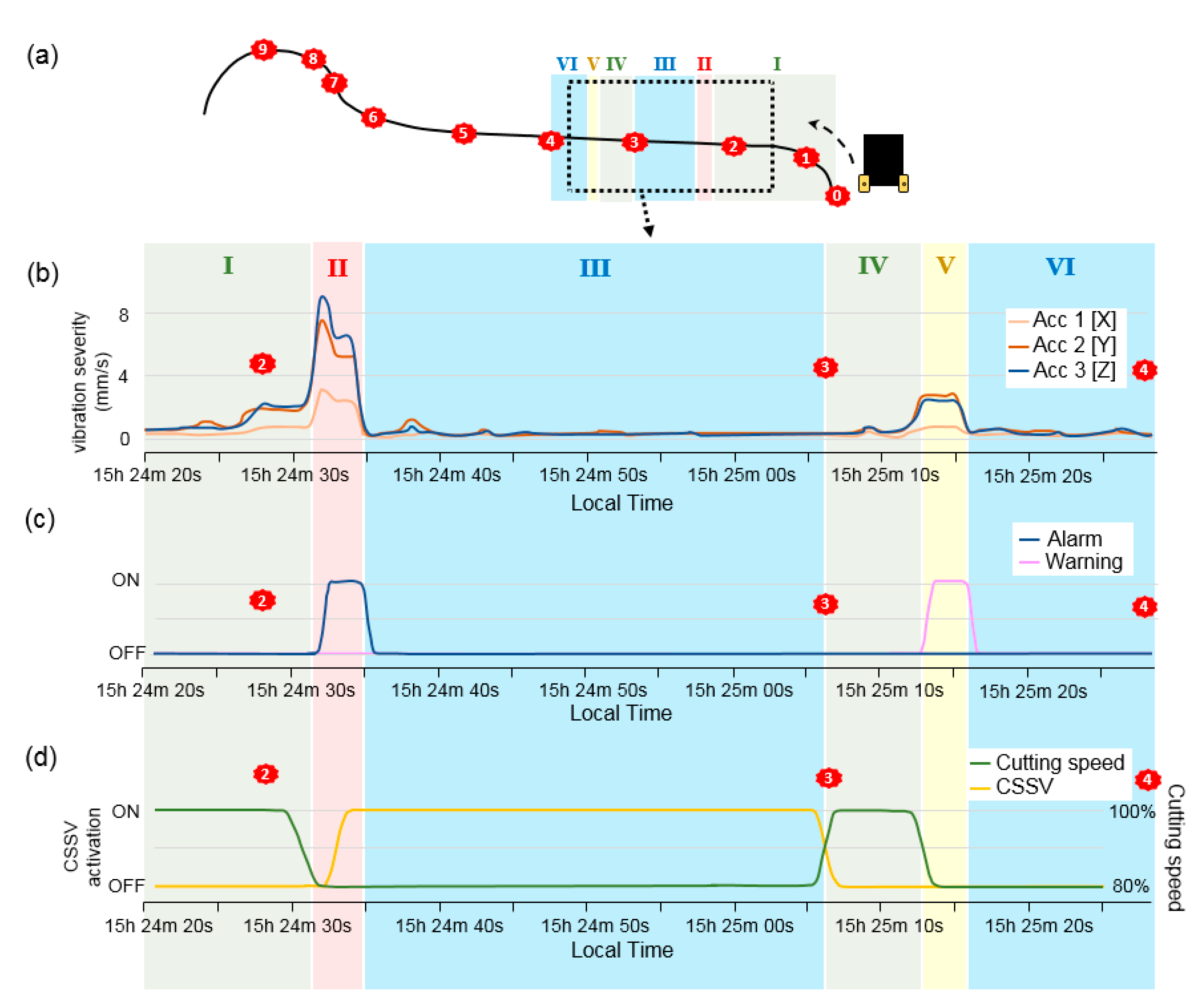

After the full integration of the chatter detection and suppression system, it was tested under normal production conditions. The process was performed using Kennametal KRR658675 SP97CV rectangular inserts with TiAlN coating and 3/16 inch corner radius. A theoretical depth of cut of 15 mm, a feed per revolution of 1.2 mm/rev, and a cutting speed of 50 m/min were used in the validation tests (

Figure 13 and

Figure 14).

The cloud-based monitoring system was used to analyze the cutting process and valuable information was obtained, such as the graph shown in

Figure 13, where the wheel profile was drawn from the tool trajectory. The severity values recorded at each instant were overlapped on this graph, thus obtaining a graphic representation of the location of the main critical machining areas.

As highlighted in

Figure 12, the critical zones were concentrated in the segment between the first and the fourth reset points. In the beginning of the initial radius, chatter grew until the alarm level was reached. The spindle speed was reduced and CSSV was activated, stabilizing the process. The vibration gradually increased below the warning level until the second reset point.

Table 4 shows in detail the performance of the chatter detection and suppression system in a chronological sequence, starting before the second reset point and continuing the fourth reset point. All data were gathered and analyzed using the cloud-based monitoring system.

At the beginning, the machining was stable (I) and the situation was maintained over the second reset point. At a certain point, a high vibration amplitude was measured (II). The smart system prompted a warning first and subsequently an alarm. Therefore, the real-time controller sent the command to the CNC to apply the spindle speed reduction and CSSV. The cutting became stable again (III) with the help of the chatter suppression techniques. After a while, the third resetting point was reached (IV) and cutting conditions returned to the original values. Machining remained stable until light chatter started (V) and a warning was displayed. In this case, only the spindle speed reduction technique was applied, and the cutting became stable again (VI).

Figure 14 shows the actuation of the smart system in a graphical way.

7. Conclusions

A hybrid edge–cloud-based smart system for chatter detection and suppression in a specific operation of freight train wheelset reprofiling was developed. The system relies on an embedded accelerometer to detect chatter and uses a smart algorithm to select the most appropriate action in accordance with the measured signal. Thus, the process stability is assured. The data recorded by the sensor as well as the actions taken for every wheelset can be surveyed using the cloud-based monitoring system, which is connected to the machine PLC and to the process controller. This provides very useful information for follow-up and the traceability of the production system.

The system was validated using a portal lathe in an industrial environment. The results were very satisfactory, achieving a proper automatic machining performance optimization.

The developed system is an ad hoc utility for a specific industrial problem which has been previously characterized. The future challenge is to extend its application to different machining processes in which the actuation criteria can be determined automatically by the smart system itself, based on a thorough historical data analysis of the gathered information from previous events in a machine learning approach.