1. Introduction

Fatigue cracks, which originate from a damaged precursor at an imperceptible level under repetitive loading, is one of the cardinal reasons for the failure of metallic structures. It is reported that up to 90% of the failures of in-service metallic structures are typically caused by fatigue cracks [

1], and the formation of an initial fatigue crack does not necessarily result in immediate failure for the real-world structure [

2]. Under cyclic loads, fatigue cracks at the scale of a few micrometers are then accumulated into microcracks by accumulation, which can deteriorate continuously and eventually amalgamate to form macrocracks [

3,

4]. Under repetitive loads, the macrocracks can be further propagated to a crucial level at an amazing rate without sufficient warning, causing detrimental effects on structural integrity and potentially resulting in catastrophic consequences [

5]. Therefore, the early perception of small-scale fatigue cracks has become a critical measure to ensure the durability, reliability, and integrity of engineering structures [

6,

7].

The majority of current guided wave-based non-destructive testing (NDT) and structural health monitoring (SHM) techniques [

3,

8,

9,

10,

11,

12,

13] have been proposed for monitoring crack propagation in different engineering structures, which exploit the variations from temporal features associated with baseline signals. More research studies of temporal signal features primarily focus on the magnitude-based and energy-based signals [

14,

15], wave reflections or transmissions [

16,

17], energy dissipation [

18], and mode conversions [

19]. Meanwhile, acoustic emission (AE) technology is widely used for continuously monitoring fatigue cracks, and AE-based fatigue crack evaluation techniques are exploited based on counting the number of signals allured by crack propagation [

20,

21]. The scattering and attenuation of ultrasonic guided waves caused by fatigue cracks are applied to quantify the cracks’ growth [

22,

23,

24]. Although most approaches of temporal features have the capacity to locate fatigue cracks, characterizing the orientation and size of fatigue cracks accurately still remains an extremely challenging task [

25], because small-scale fatigue cracks can lead to a feeble signal difference for the damage-scattered waves in the time domain. Therefore, signal features processing and analysis associated with the frequency domain are then extracted to characterize the fatigue crack propagation, because the signal features in the frequency domain are more stable, accurate, and recognizable than those of the temporal domain.

The ultrasonic guided waves methods based on damage indices (DIs) have become research hotspots in the field of damage detection over the years, which aim to highlight the variations of structural fatigue cracks. The accuracy and effectiveness of the techniques substantially rely on the means of the defined DI at each path [

25], thus, there is an increasing interest in introducing DI for guided wave-based SHM [

26]. Based on linear (time of flight (TOF) and energy) and nonlinear temporal features of guided waves, damage indices (DIs) are respectively constructed, which are used to locate fatigue damage near a rivet hole of an aluminum plate [

3,

9,

25]. Moreover, the synthetic DI methods are easily interpretable, which can intuitively reflect the overall health status in the inspected structure. A hybrid DI characterization scheme for ultrasonic guided waves is developed and experimentally validated in aluminum plate specimens, which can be used to evaluate the statistical distribution of fatigue cracks under uncertainties and update the prognosis results. However, according to the aforementioned literature survey, damage indices are used to locate cracks and identify the existence of multi-scale cracks in practice [

25]. The crack growth is a gradually patulous process, the ultrasonic guided waves DI approach has been rarely employed to characterize the crack propagation quantitatively. In addition, a hybrid DI scheme is proposed that is associated with various acoustic features, which can be used to indicate the fatigue crack propagation quantitatively by experimental validation. This is deemed as an improvement to characterize crack growth in current monitoring studies. Although it is a highly challenging assignment in perceiving small-scale fatigue cracks, it is also of vital importance for continuously monitoring the crack propagation [

10].

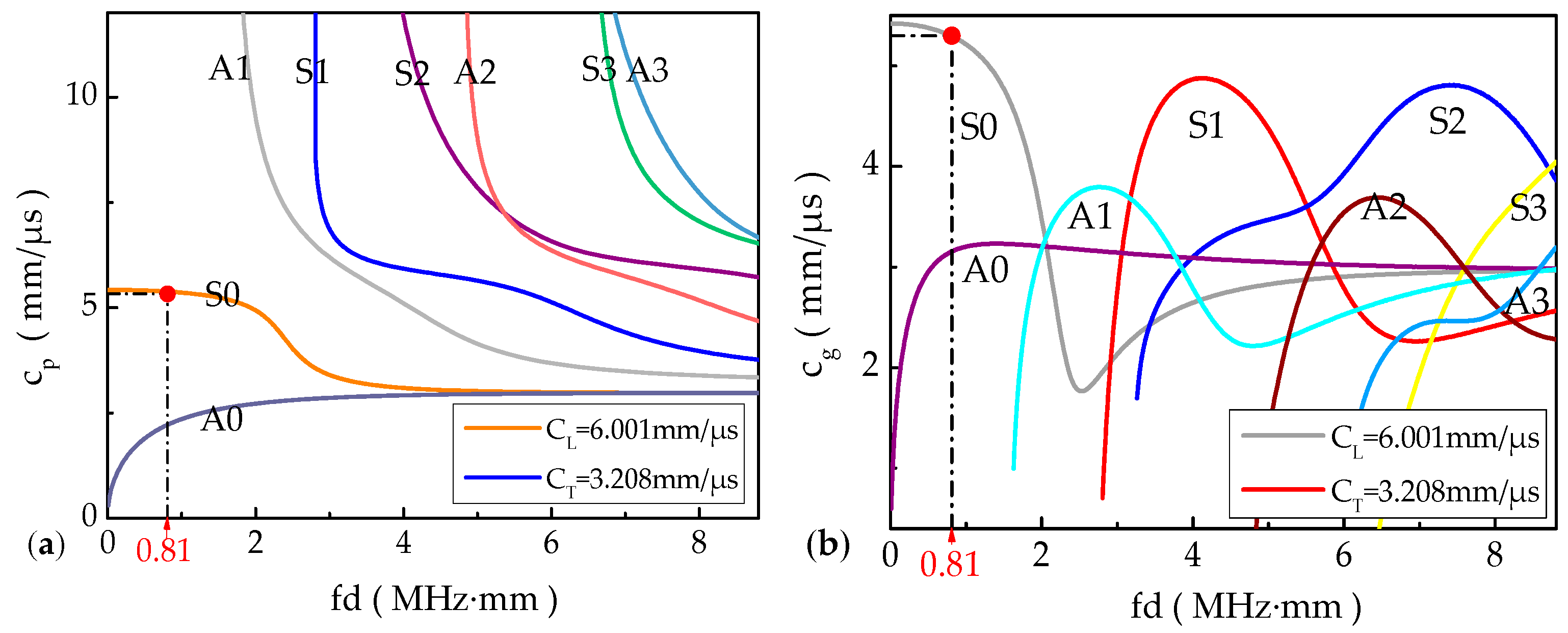

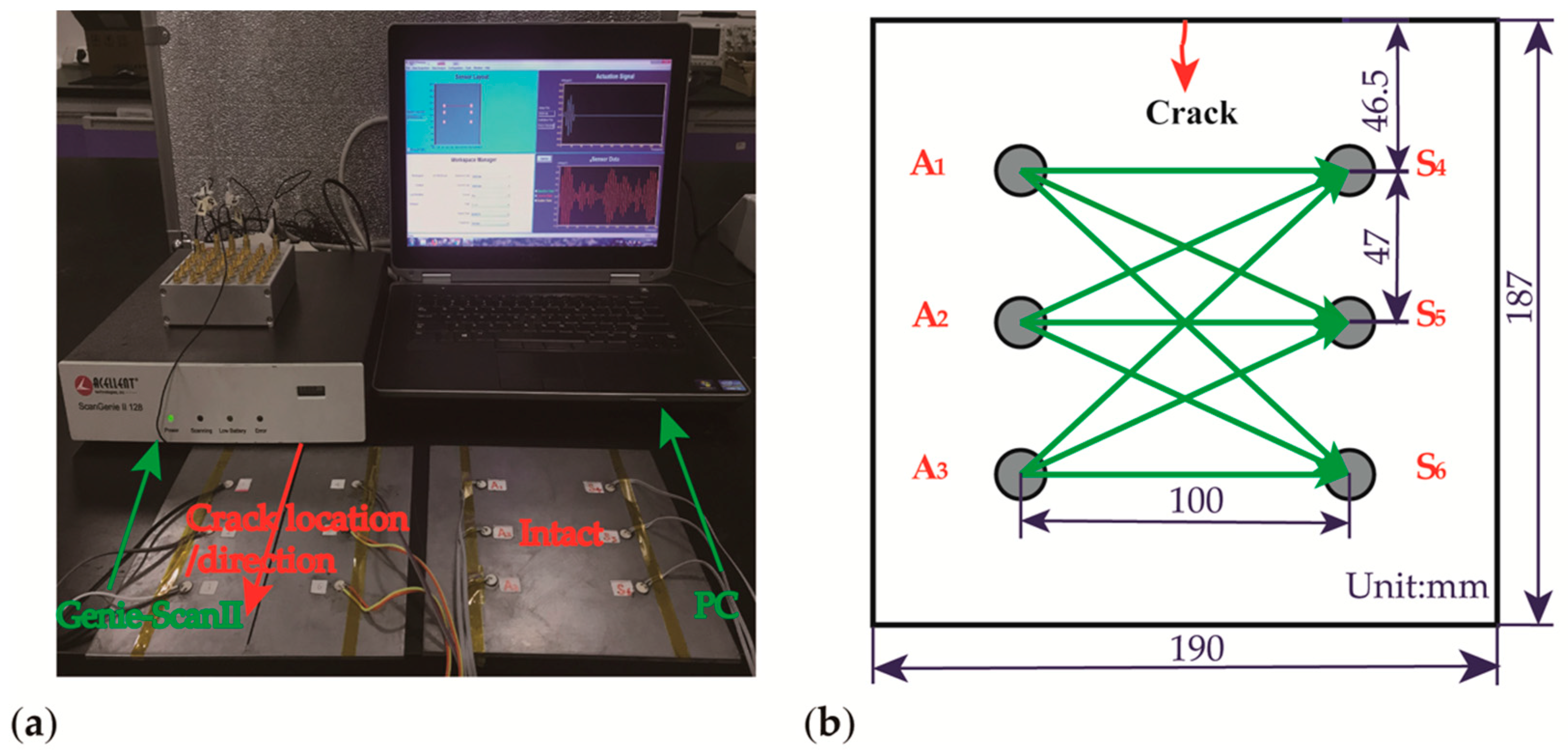

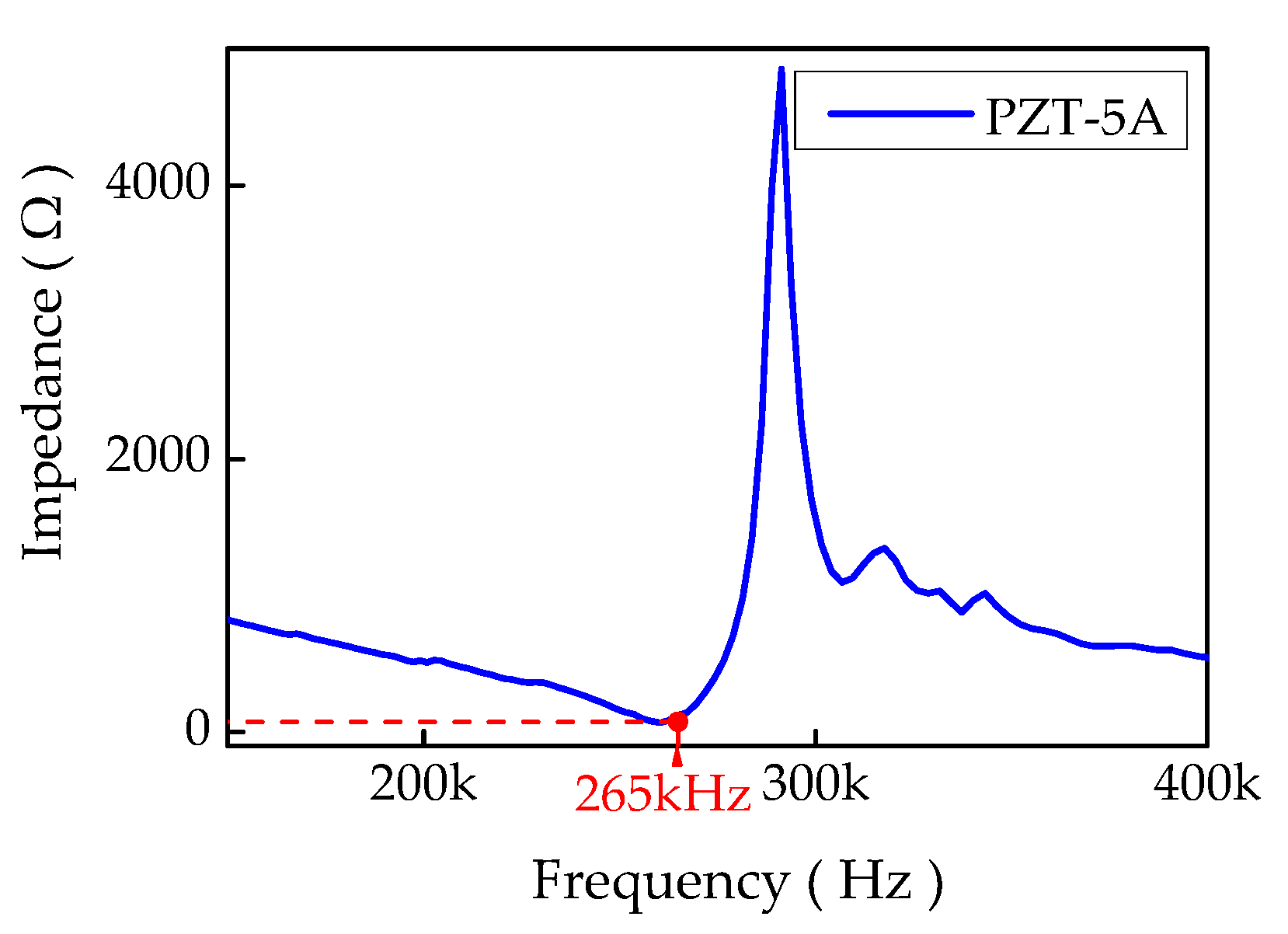

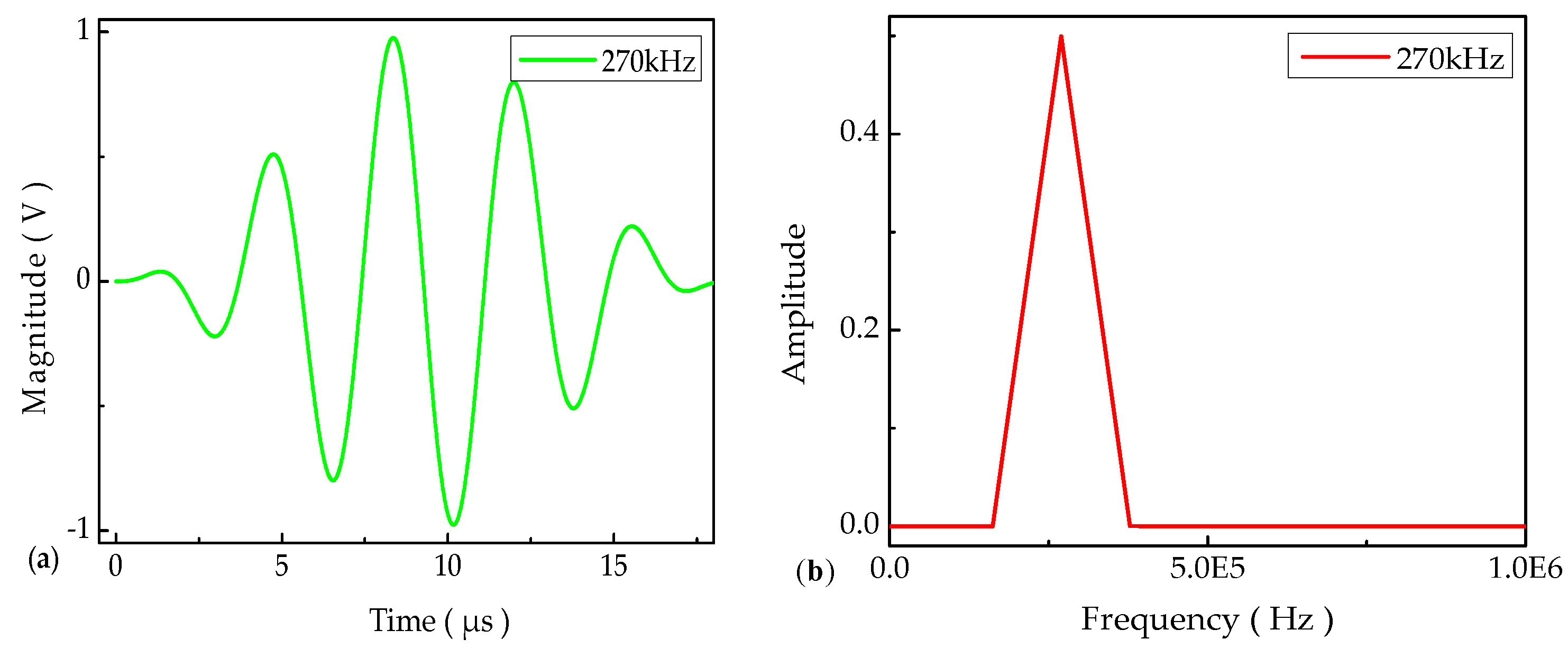

The objective of this paper is to propose a technique to monitor the fatigue crack propagation in an SMA490BW steel plate-like structure. Ultrasonic guided waves DIs calculated by various acoustic features are used to track the crack propagation. The features of crack characterization are firstly expressed by magnitude/amplitude-based and energy-based DIs extracted from time-frequency domain signals. Based on the DI weights of each actuator–sensor path, a hybrid fusion scheme is then proposed to fuse all the available DIs of each path. Subsequently, an experimental setup of an active sensor network with a sparse transducer configuration is used for actuating and sensing guided waves. Finally, the different synthetic fusion DI algorithms of the S0 guided waves mode are calculated to emphatically characterize the crack propagation and destruction level of an in-service metallic structure.

3. Fusion of DIs

Driven by the incentive to visualize the procedure of fatigue crack propagation, a damage index synthetic fusion algorithm of each actuator–sensor path is further developed in this study. Using a hybrid fusion method does not weaken the characterization of crack propagation, but it does intuitively and rapidly comprehend the overall health status within the inspection of the SMA490BW plate-like structure. The fatigue crack propagation can be described by the fitting correlation of hybrid fused DIs of various acoustic characteristics.

In terms of Equations (2)–(5), the extracted various signal features are used to establish different DIs. The corresponding magnitude/amplitude and energy DIs are calculated at each actuator–sensor path, which are applied to define the original DIs. The original DI has a prior perception for fatigue cracks on the current path. In practice, an original DI not only contains information associated with cracks, but also unwanted signal features such as ambient noise and measurement uncertainties, multiple guided waves modes conversion, and reflections from structural boundaries. These unwanted signal features possibly dilute crack-associated features and weaken the proportion from a single actuator–sensor path [

25]. Therefore, based on the DI weights of different paths, the signal representations of the fused DIs are embodied by Equations (6)–(9). The ultimate fitting result is a straight line, which can be used to indicate the fatigue crack propagation effectively.

To summarize the above, each actuator–sensor path (N in total) offers an original DI via a pitch–catch configuration. Then, a hybrid fusion scheme is proposed to coalesce all the available DIs of each path in the sensor network, as follows:

where

and

are the ultimate fusion DIs in the time domain, meanwhile,

and

are the synthetic DIs in the frequency domain. The k stands for the kth actuator–sensor path, while

refers to the weights of each path. The incentive to build such a hybrid fusion scheme is twofold:

(i) An arithmetic fusion equally takes into account prior perceptions from each actuator–sensor path and well decentralizes individual contributions. Although the arithmetic fusion fully encompasses previous perceptions from all paths, information including ambient noise and measurement uncertainties are also engaged, which might overstate the presence of fatigue cracks and lead to false alarms, and

(ii) The synthesized fusion DI method is obtained by implementing a probability weighting operation on the original DIs of each actuator–sensor path. A hybrid DI scheme is constructed to enhance the approach tolerance for environmental noise, measurement uncertainties, and erroneous perceptions from individual paths.

The hybrid fusion scheme can be used to represent the fatigue crack propagation quantitatively, which effectively strengthens the individual original DIs of crack-related information and enhances the availability, stability, and signal-to-noise ratio of the fitting signals.

5. Results and Discussions

The measured guided wave signals from the damaged specimen and baseline signals in intact specimen are used to construct magnitude/amplitude-based and energy-based DIs for quantitatively characterizing crack growth in an SMA490BW steel plate-like structure along with the actuator–sensor paths. In cases where a crack is exactly located near the path or the crack size is equivalent to the same order of magnitude of the detection wavelength, the representative acoustic features of the measured guided wave are changed significantly, which corresponds to the larger DI coefficient between two signals. In contrast, the signal deviation would be trivial if the crack is far away from the actuator–sensor path or the crack size is much smaller than the probing wavelength [

25]. In particular, the magnitude/amplitude-based and energy-based DIs have proven the susceptibility to signal magnitude/amplitude variation as well as signal energy transformation.

This section includes four parts: (1) data comparison of different sampling points, (2) magnitude-based and energy-based DIs in the time domain, (3) amplitude-based and energy-based DIs in the frequency domain, and (4) signal fusion for all the actuator–sensor paths.

5.1. Data Comparison of Different Sampling Points

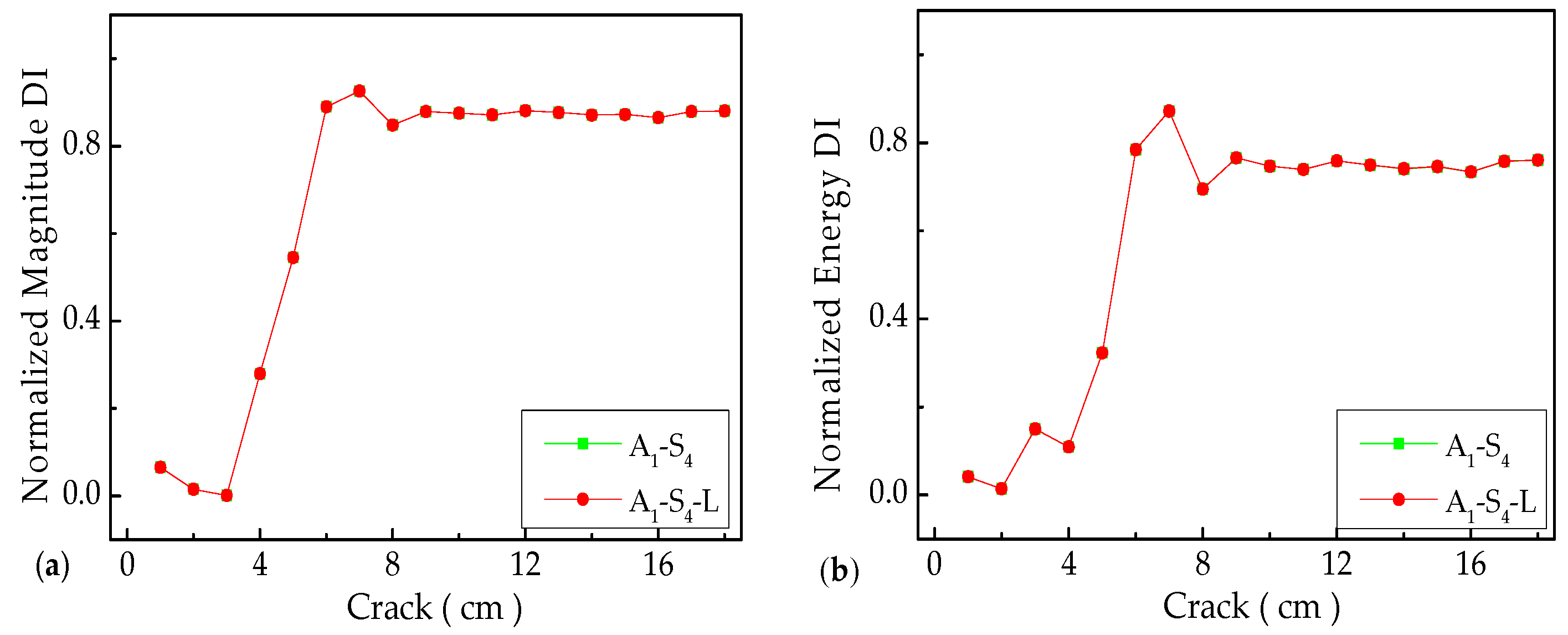

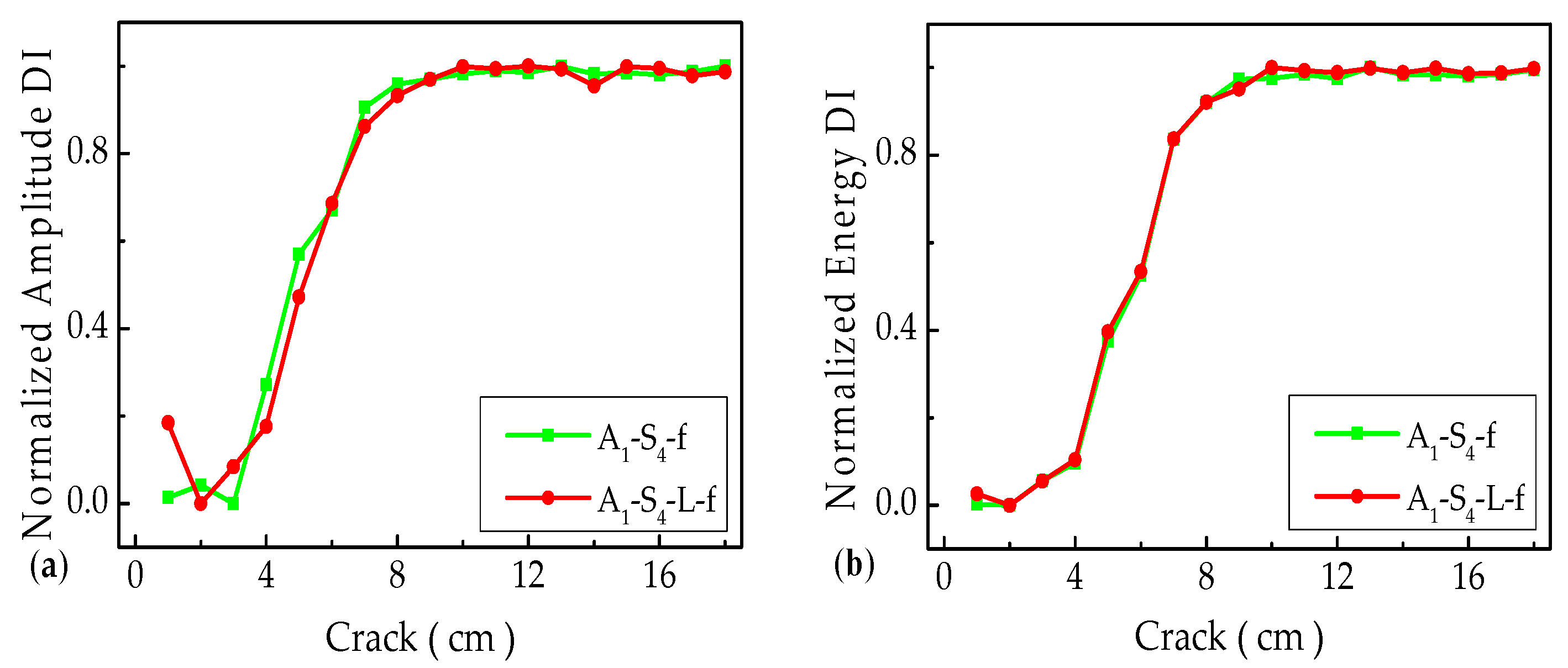

In general, it is well accepted that the more sampling points are acquired at an active sensor network, the better the signals are measured in an accurate, stable, and practicable manner. Different sampling points signals of S0 mode are extracted to calculate the magnitude/amplitude-based DIs and energy-based DIs in the time-frequency domain. We only select the representative path such as actuator–sensor path A

1–S

4, as shown in

Figure 5 and

Figure 6.

A

1-S

4 stands for the sampling points of the common length in the time domain, and A

1–S

4–L refers to the sampling points of the longer length from the time domain. A

1–S

4–f and A

1–S

4–L–f correspond to the common length and longer length in the frequency domain, respectively. In the time domain, the magnitude-based and energy-based DIs of two different types of sampling points are exactly identical, as shown in

Figure 5. Based on the amplitude-based DIs in the frequency domain, it is found that almost no fluctuations of DIs are observed for the reason that the measured signals are prone to be contaminated with lower noise and improved reliability in practice. Moreover, ultrasonic guided waves are highly dispersive and multimodal, which causes some difficulties in the process of signal feature extraction. Nevertheless, the overall distribution of magnitude/amplitude-based and energy-based DIs are well consistent. Considering that the differences between the magnitude/amplitude-based and energy-based DIs of different sampling points are very small, and they can be ignorable, to some extent. Therefore, the sampling points of the common length are selected to analyze and process the acquired signals in the following studies.

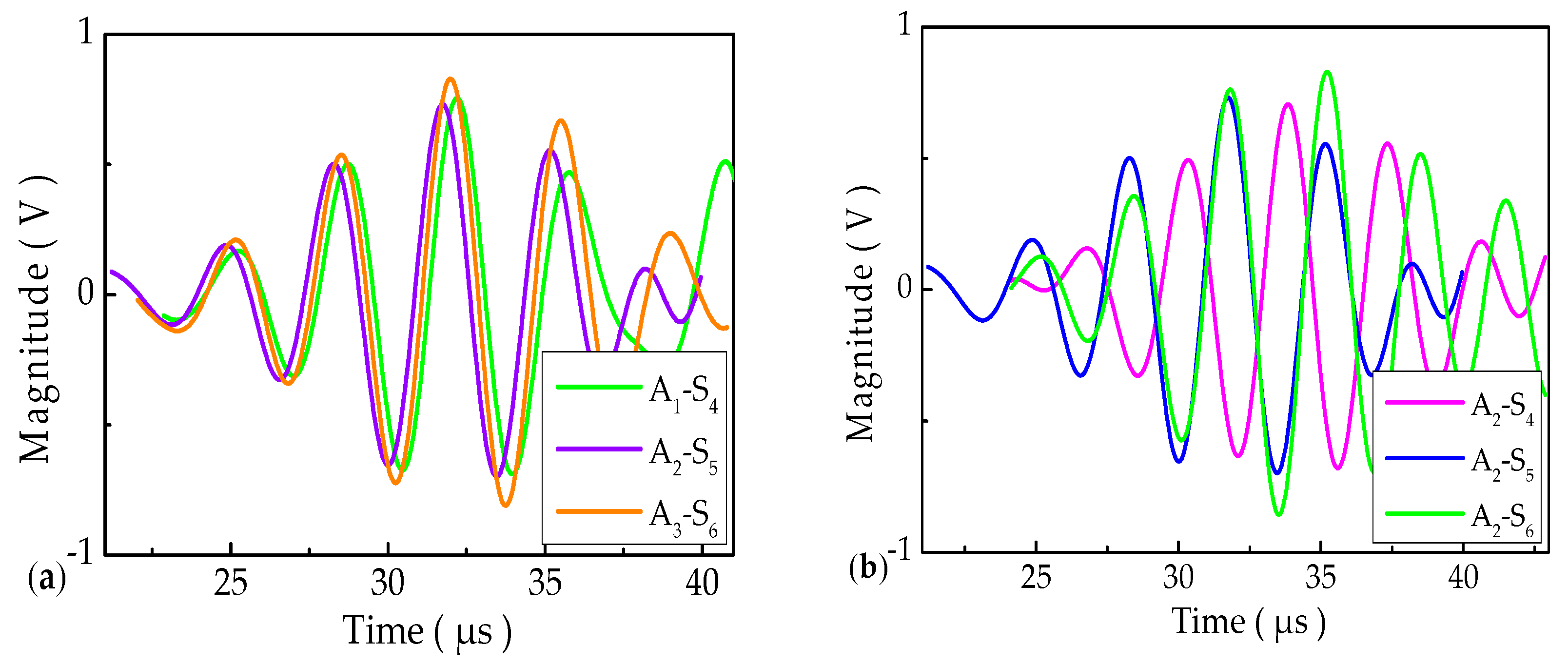

5.2. Magnitude-Based and Energy-Based DIs in Time Domain

The intensity of damage-reflected wave energy is taken as a sensitive indicator to determine the orientation of fatigue cracks, as correlated in which the strongest reflection is captured perpendicular to the direction of incidence. With the increase of the incidence angle of the guided waves, the intensity of the crack-reflected signal energy declines quickly. Based on this, the actuator–sensor paths are selected by extracting signal features associated with higher intensity energy [

30], the gained signals also have a higher signal-to-noise ratio. Therefore, the investigations successively select the actuator–sensor paths A

1−S

4, A

2−S

5, A

3−S

6, A

2−S

4, and A

2−S

6 as representative paths in the time-frequency domain, as displayed in

Figure 7,

Figure 8,

Figure 9 and

Figure 10. On this condition, the different paths A

1–S

4, A

2−S

5, and A

3−S

6 are perpendicular to the crack orientation with a fixed crack length of 1.0 cm. Similarly, A

2−S

4, A

2−S

5, and A

2−S

6 are selected as the comparison paths of A

1−S

4, A

2−S

5, and A

3−S

6, the magnitude variations of the extracted S0 mode in the time domain are presented in

Figure 7.

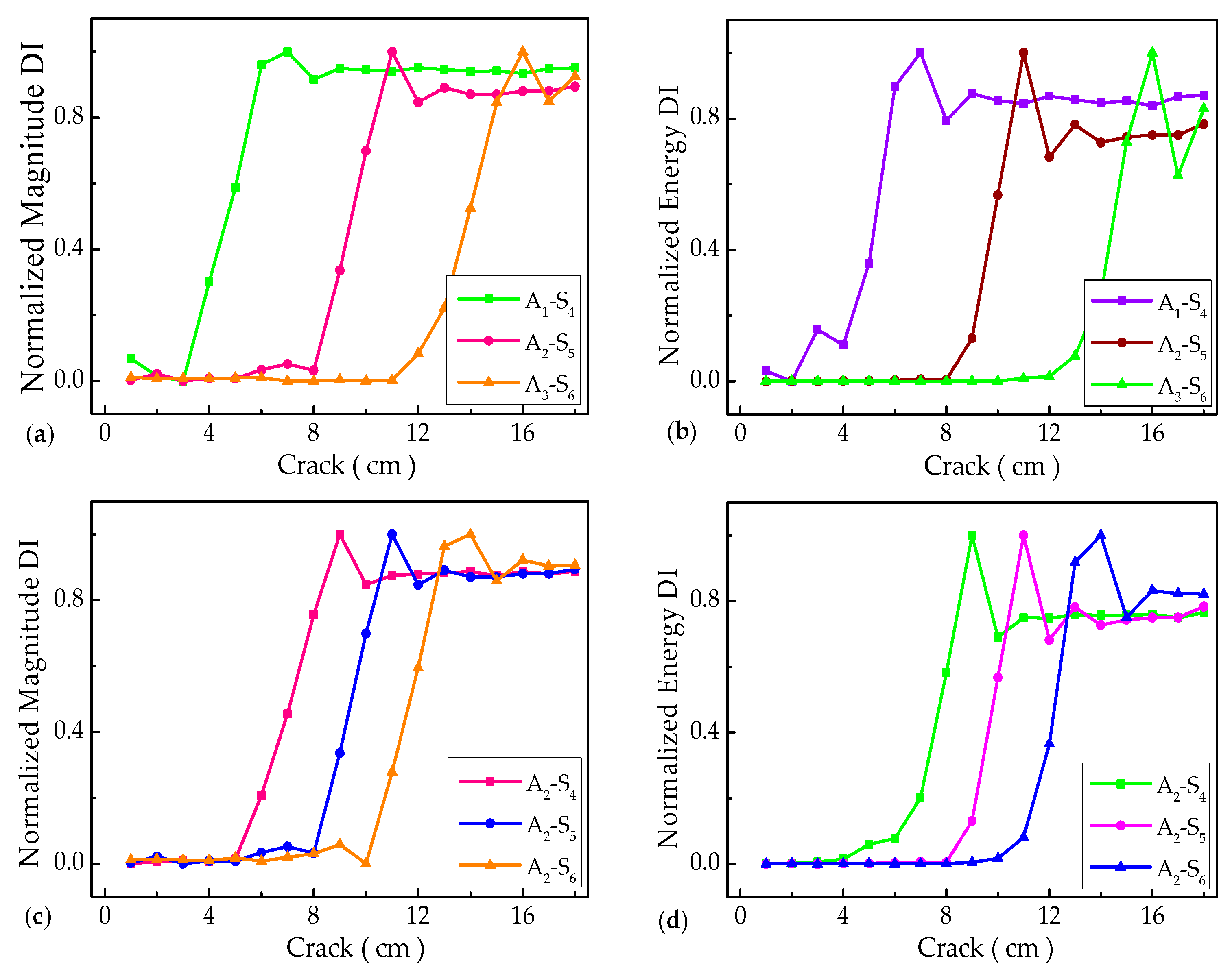

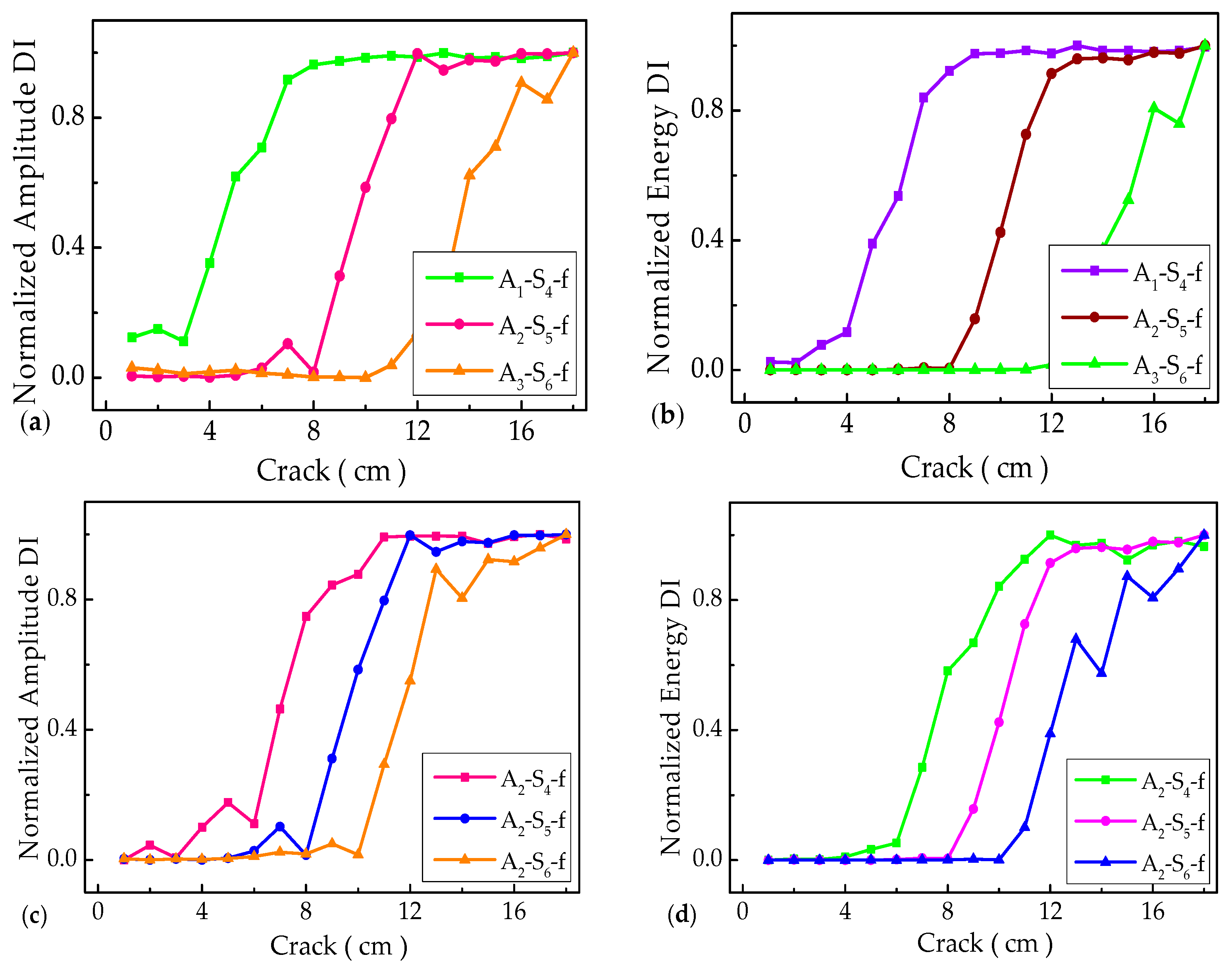

The normalized magnitude-based and energy-based DIs in the time domain are calculated by Equations (2) and (4). As shown in

Figure 8, in cases where the crack of the A

1−S

4 actuator–sensor path propagates from 0.0 cm to 3.0 cm, the A

2−S

5 actuator–sensor path propagates from 0.0 cm to 8.0 cm, or the A

3−S

6 actuator–sensor path propagates from 0.0 cm to 12.0 cm, there are no obvious variations in the DIs with some negligible fluctuations. The detection features of magnitude-based and energy-based DIs are substantially restricted to evaluate the fatigue crack, in case that the crack size is comparable with the probing wavelength. It is also found that the temporal features of guided waves are fairly limited to characterize the fatigue crack growth near the actuator–sensor paths with high sensitivity. When the progressive crack is large enough or near the actuator–sensor paths, with an increase of the fatigue crack, the remarkable DIs can be obtained. On the contrary, when the extended fatigue crack locates far from the actuator–sensor paths, it shows that the DIs are less sensitive to characterizing the crack variations without significant changes.

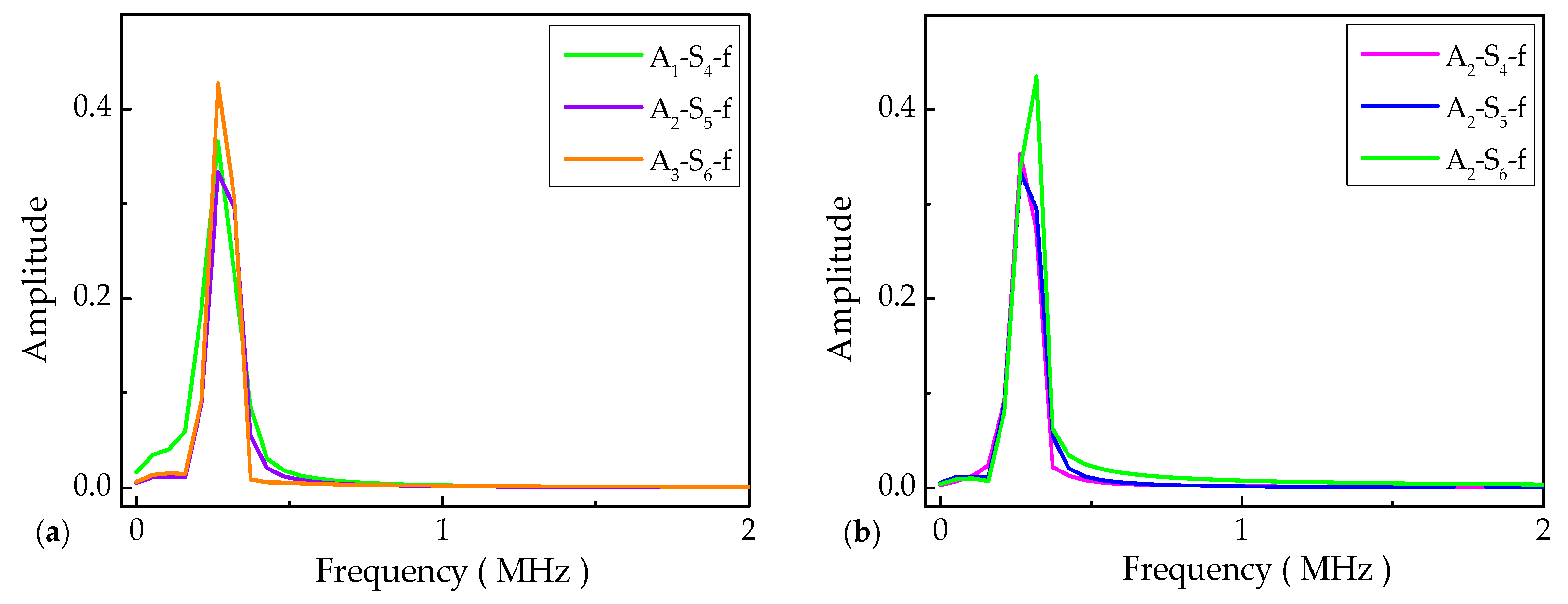

5.3. Amplitude-Based and Energy-Based DIs in Frequency Domain

The normalized magnitude-based and energy-based DIs in the time domain can provide convenient conditions for crack propagation quantification, but their effectiveness in depicting crack size and damage level are still controversial. This is because small-scale cracks can cause a feeble variety for the crack-scattered wave in the time domain, that is, the magnitude of fatigue crack is often altered at an imperceptible level within the temporal information. Therefore, the signal features associated with the frequency domain are extracted to improve the sensitivity and stability of amplitude-based and energy-based DIs, in accordance with a pitch–catch sensor network configuration [

25]. Fast Fourier transform (FFT) is used to process time-domain signals to obtain a frequency spectrum [

31], as shown in

Figure 9. Compared with the magnitude variations in the time domain from

Figure 7, the amplitude variations in the frequency domain are illustrated in a more obvious and reliable manner.

The signals shown in

Figure 8 are subsequently preformed with fast Fourier transform (FFT) to obtain the corresponding frequency spectrogram, as shown in

Figure 10. The overall trend of DIs obtained in the frequency domain is basically consistent with that of the time domain. However, when the crack of the A

1−S

4 actuator-sensor path spreads from 0.0 cm to 6.0 cm, the A

2−S

5 actuator–sensor path spreads from 0.0 cm to 11.0 cm, or the A

3−S

6 actuator–sensor path spreads from 0.0 cm to 15.0 cm, there are no outstanding peaks for the amplitude-based and energy-based DIs. It is clearly observed that the variations of DIs are gradually and steadily obverted to the stable stage. In addition, the variations of DIs can be regarded as insignificant in the stable stage, which are consistent with the observations in

Figure 8.

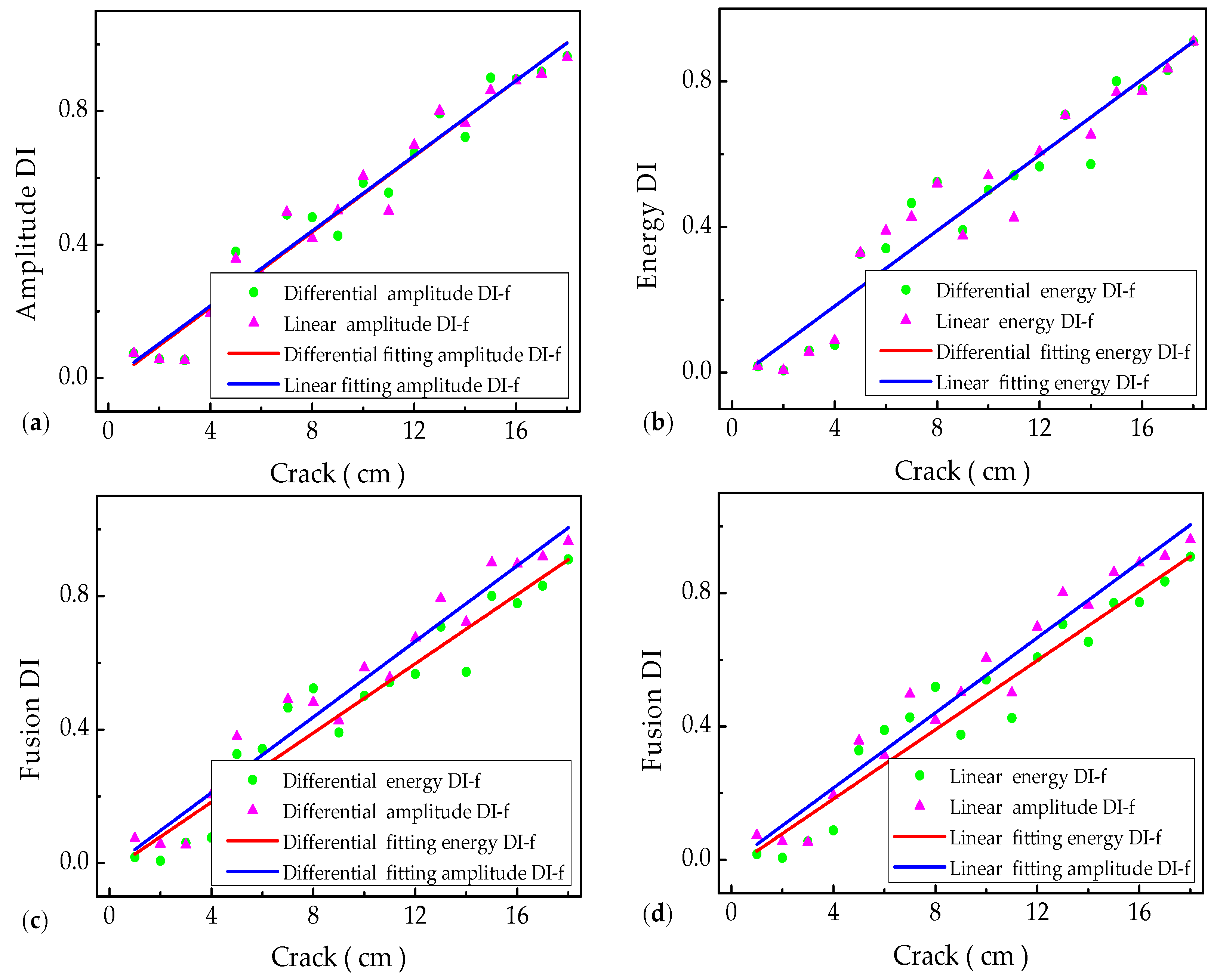

5.4. Signal Fusion for All Actuator–Sensor Paths

In order to strengthen the crack-interrelated features of the individual original DIs, the environmental noise and measurement uncertainties (unwanted information in individual original DIs) need to be lessened effectively, and the signal-to-noise ratio of the captured crack signal features need to be heightened as much as possible. According to the DI weights of each actuator–sensor path, the extracted original DIs are required to decentralize individual contributions equally and amalgamate all available signal features at each specific crack. A synthetic DI related with fatigue crack is proposed, which can be used to characterize the crack propagation at all paths. Based on the analysis in the time-frequency domain, the hybrid magnitude/amplitude-based DIs (defined by Equations (6) and (7)) and energy-based DIs (defined by Equations (8) and (9)) calculated by the fusion arithmetic are separately illustrated in

Figure 11 and

Figure 12.

Firstly, the linear fitting of DIs is conducted at different crack growth regions for each actuator–sensor path. Based on the DI weights of different paths, linear fusion DIs are extracted for all the actuator–sensor paths. The first-order differential is the difference between two consecutive neighbors in a discrete DI function. Differential fusion DIs are obtained by different weights of all the paths. Based on the analysis of linear fusion DIs and differential fusion DIs (including magnitude/amplitude-based and energy-based DIs),

Figure 11 severally displays the ultimate DIs in the time domain. Experimental results show that the propagation of the fatigue crack can be calibrated by the synthetic DIs quantitatively. It is found that the fitting differences between the linear magnitude and differential magnitude DIs are especially tiny, and the fitting straight lines are mostly coincident. Moreover, it can also be clearly observed that the stability of linear and differential magnitude fitting DIs is better than that of linear energy fitting and differential energy fitting DIs. Simultaneously, the results indicate that the stabilities of differential energy fitting DIs are the worst in the time domain. In other words, the fitting effectiveness from different fitting methods can be represented alternatively by the fitting correlation coefficients and mean squared error in

Table 3 and

Table 4.

Similarly, the fitting DIs from the frequency domain can characterize the propagation of crack accurately, as shown in

Figure 12. Obviously, it indicates that the overall fitting DIs in the frequency domain coincide with the fitting in the time domain. Whereas, it is corroborated that the stability and reliability of the fitting DIs in the frequency domain are better than those in the time domain. Simultaneously, it is particularly interesting that small differences between the experimental measurement DIs and the fitting DIs can be clearly identified in

Figure 12,

Table 3 and

Table 4.

It can be concluded that the synthetic fusion DIs of different acoustic features can be used to calibrate the propagation of fatigue crack quantitatively to a certain extent. However, considering the stability, reliability, and practicability of the signals, the linear and differential amplitude fusion schemes in the frequency domain are shown to have better promising alternatives for characterizing the crack propagation.

6. Conclusions

It is of great significance but also a highly challenging assignment to monitor small-scale fatigue crack continuously. In addition, it is of vital importance for calibrating the fatigue crack propagation quantitatively, synchronously. In this paper, the typical ultrasonic guided waves signal characteristics in the time-frequency domain are acquired from an SMA490BW steel plate associating with an active sensor network. The crack characterization approaches using various acoustic features (capitalizing on the magnitude/amplitude-based and energy-based DIs in the time-frequency domain) are established by constructing different DIs from the extracted S0 mode signals of ultrasonic guided waves, which are used for online monitoring of the fatigue crack propagation quantitatively. The results reveal that the magnitude/amplitude-based and energy-based DIs of individual actuator–sensor paths are substantially restricted to characterize the fatigue crack with a size on the same order of the magnitude of the central wavelength or indicate fatigue crack propagation near the paths with high sensitivity. Subsequently, according to the weights of individual paths, a synthetic fusion scheme is developed to fuse all available DIs for all paths. Using the linear fused DIs and differential fused DIs in the time-frequency domain, a synthetic fusion DI scheme of different acoustic features is proposed, which can indicate the propagation of fatigue crack accurately. It is also clear that the stability and reliability of the fused DIs calculated by the acoustic features in the frequency domain are better than those in the time domain. Ultimately, it is important to realize that the linear and differential amplitude fusion DIs of a bogie plate-like structure in the frequency domain are more promising to characterize the crack propagation quantitatively than other fused ones.