Comparison of Spray Deposition, Control Efficacy on Wheat Aphids and Working Efficiency in the Wheat Field of the Unmanned Aerial Vehicle with Boom Sprayer and Two Conventional Knapsack Sprayers

Abstract

1. Introduction

2. Materials and Methods

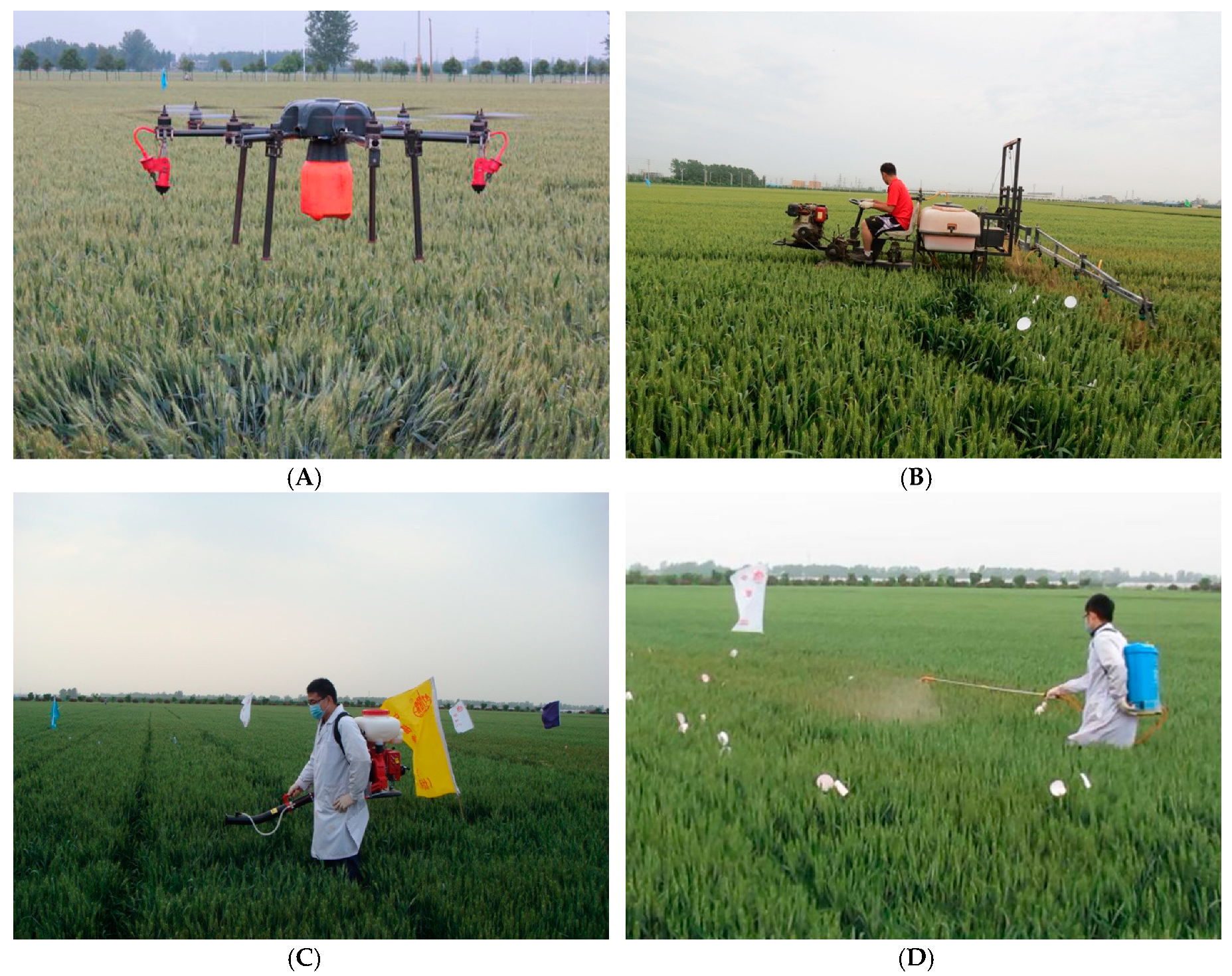

2.1. Spray Equipment

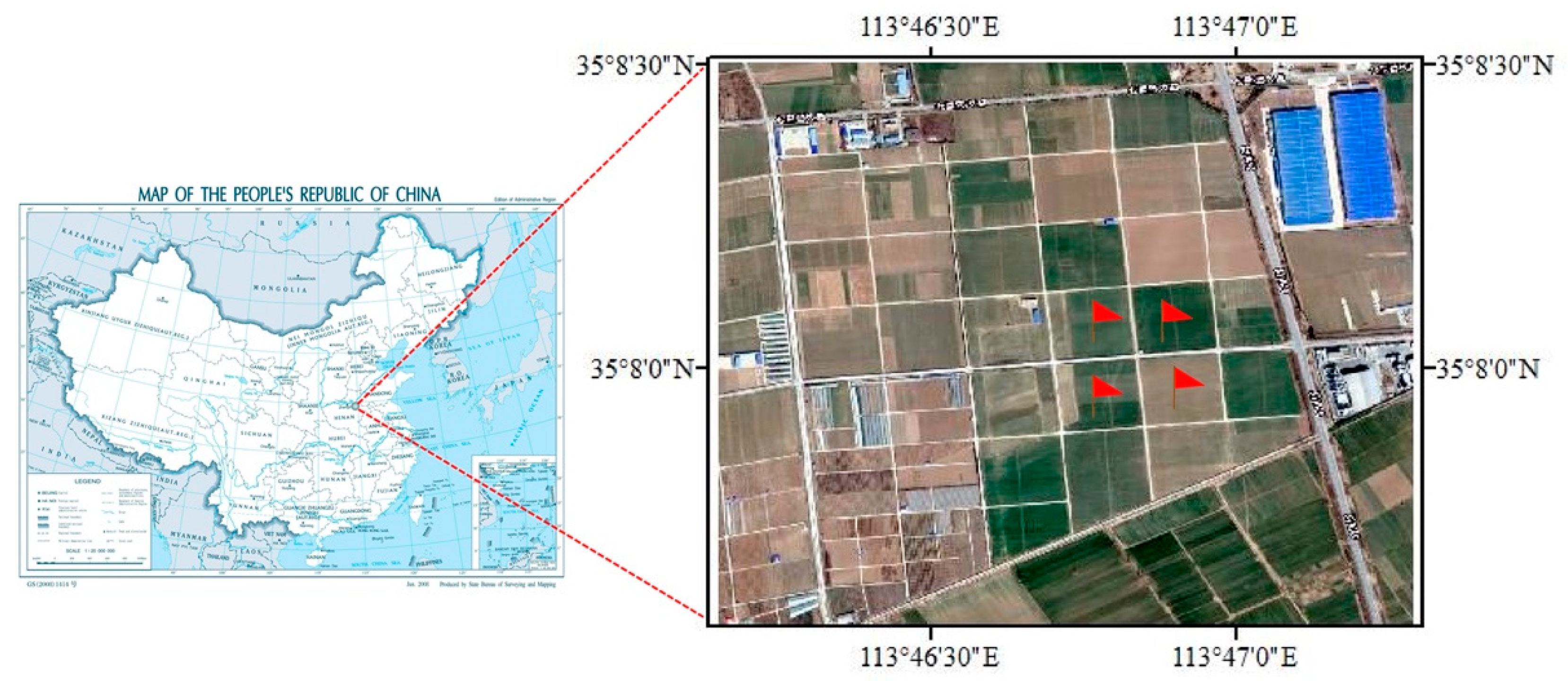

2.2. Experiment Design

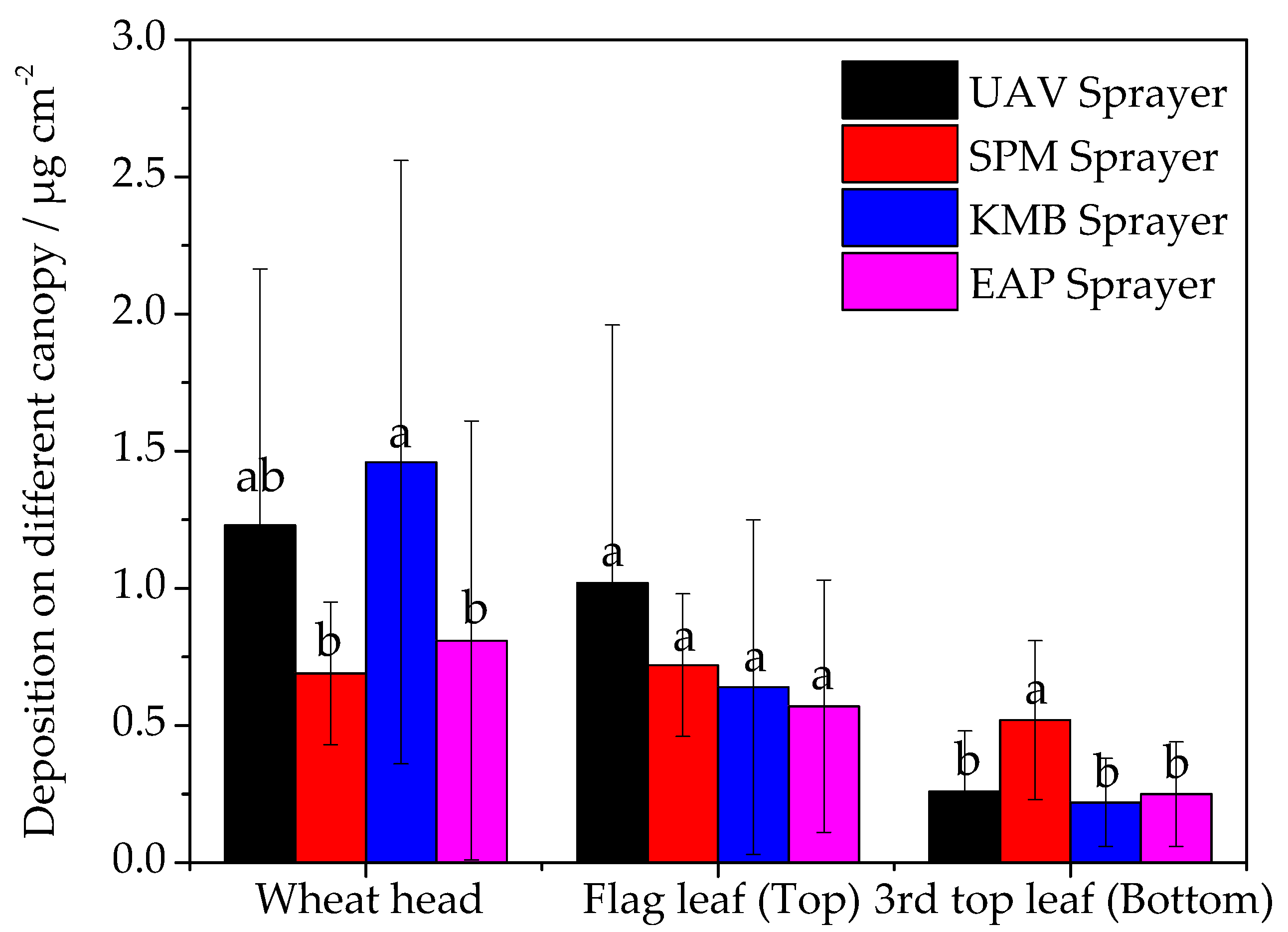

2.2.1. Field Plots

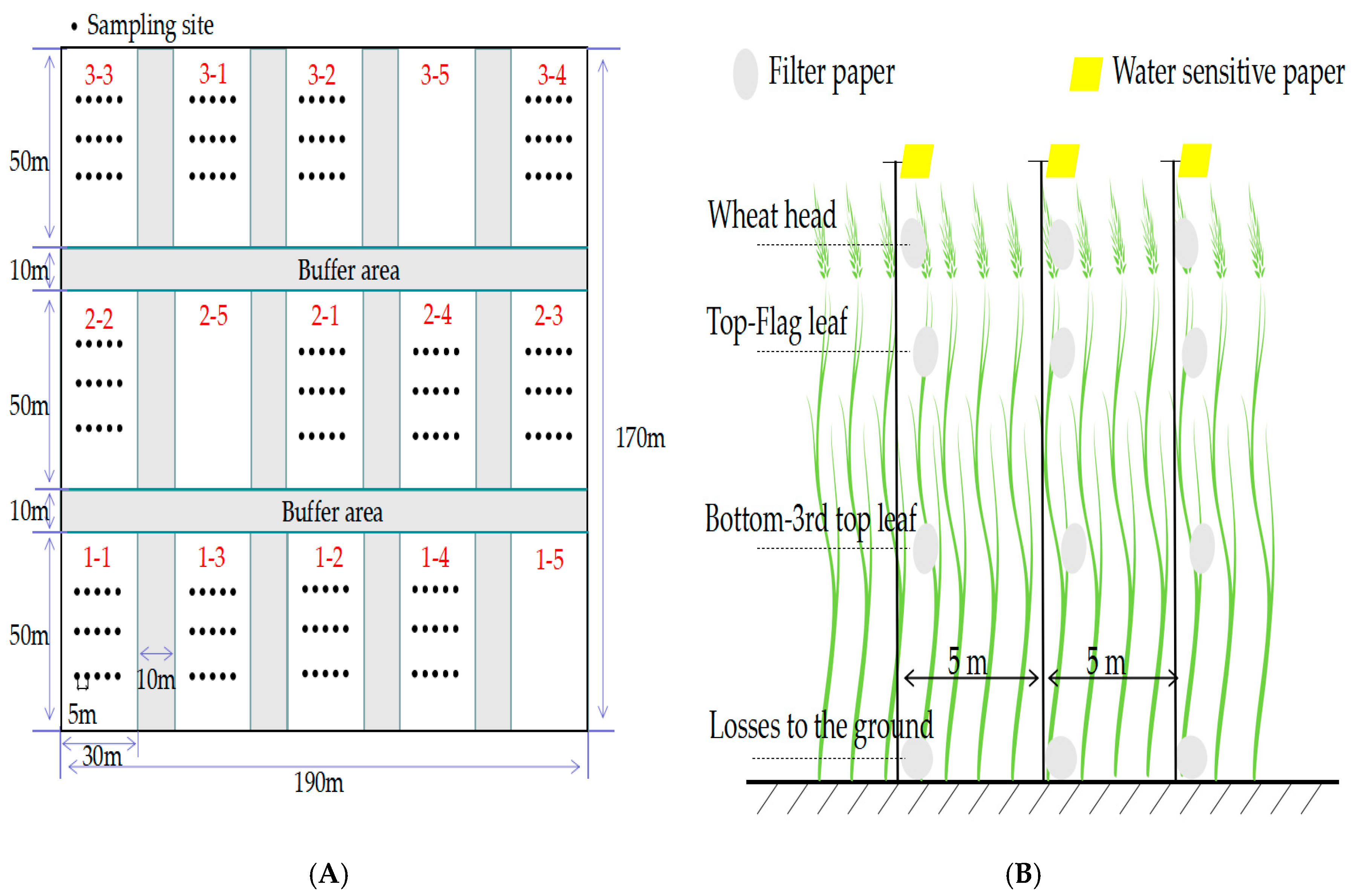

2.2.2. Spray-Deposition Measurements

2.2.3. Investigation of Control Efficacy

2.2.4. Working Efficiency Test

2.2.5. Statistical Analysis

3. Results and Discussion

3.1. Spray Deposition

3.1.1. Total Deposition on the Crops and Losses to the Ground

3.1.2. The Uniformity of the Deposition

3.1.3. Droplets Penetrability

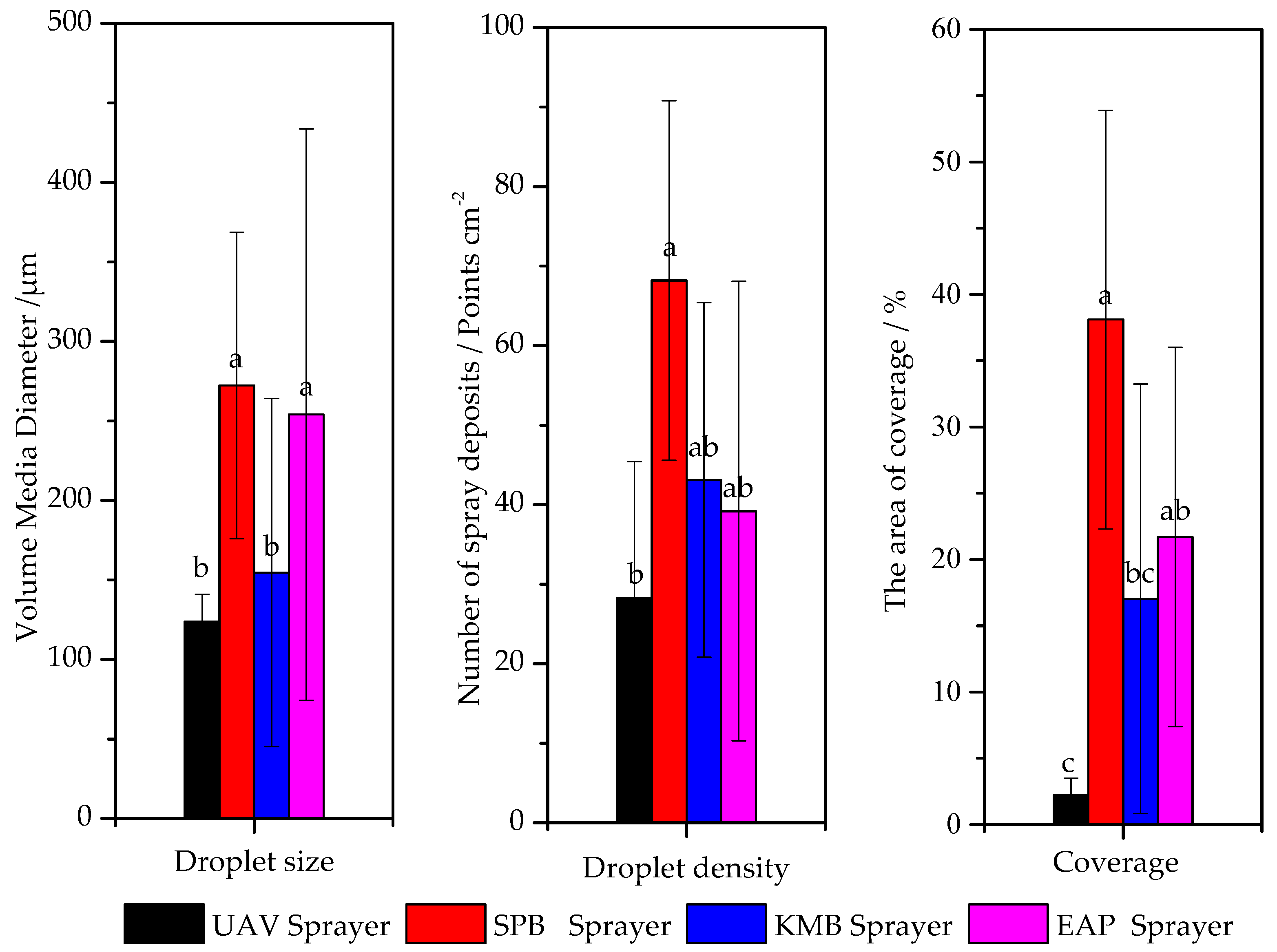

3.1.4. Characterization of Deposition

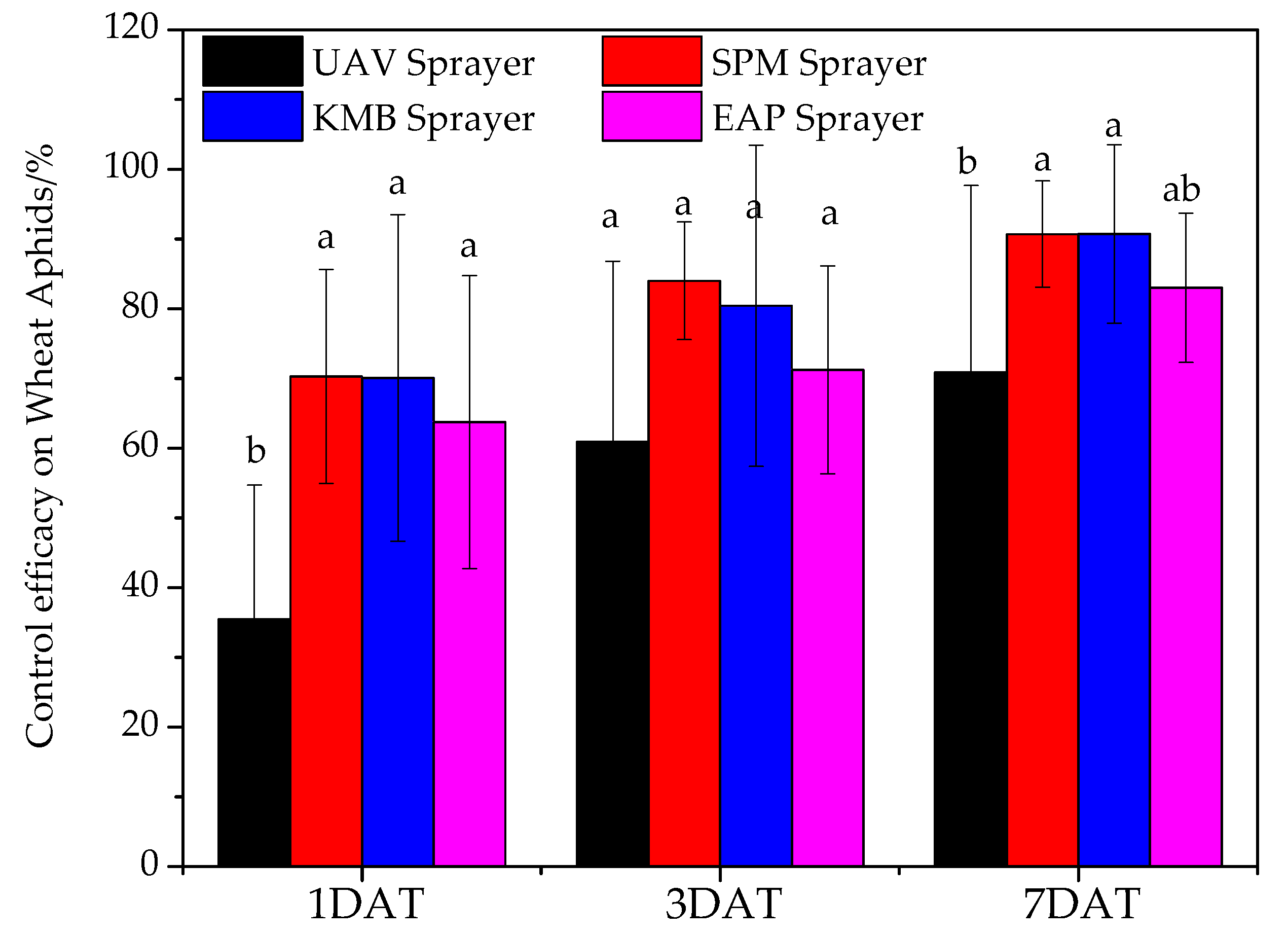

3.2. Control of Wheat Aphids

3.3. Working Efficiency

4. Conclusions

- 1)

- The total deposition of the UAV sprayer was not significantly different from the other three sprayers, but the losses to the ground were the lowest.

- 2)

- The UAV sprayer had a poor deposition uniformity (CV = 87.2%) and droplets penetrability (0.26 μg/cm2 on the third top leaf), which need to further improve in the future. By comparison, the SPB sprayer has the best deposition uniformity (CV = 32.1%) and droplets penetrability (0.52 μg/cm2 on the third top leaf).

- 3)

- The area of coverage, number of spray deposits and droplet size varied with spray volume and the nozzle type of the different sprayers. Compared with other sprayers, the deposition characterizations of the UAV sprayer were a lower area of coverage (2.2%), a lfewer spray deposits (28.2 points/cm2), finer droplet size (VMD = 124.0 μm), higher concentration and lower spray volume.

- 4)

- Although the spray deposition characterizations of the UAV sprayer were different from the three other sprayers, the control efficacy of applying 70% Imidacloprid·Regent WDG on wheat aphids was comparable with other sprayers. The control efficacy of UAV sprayer on Day 7 after the application was 70.9%.

- 5)

- The working efficiency of the UAV sprayer was 4.11 ha/h, which was 1.7, 2.6, and 20.0 times those of SPB, KMB and EAP sprayer, respectively. This is the greatest advantage of the UAV sprayer.

Author Contributions

Funding

Conflicts of Interest

References

- Yang, S.; Yang, X.; Mo, J. The application of unmanned aircraft systems to plant protection in China. Precis. Agric. 2018, 19, 278–292. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, W.; Jing, R.; Wheeler, K.; Smith, G.A.; Stallones, L.; Xiang, H. Work-related pesticide poisoning among farmers in two villages of Southern China: A cross-sectional survey. BMC Public Health 2011, 11, 429. [Google Scholar] [CrossRef] [PubMed]

- Cao, L.; Cao, C.; Wang, Y.; Li, X.; Zhou, Z.; Li, F.; Yan, X.; Huang, Q. Visual determination of potential dermal and inhalation exposure using allura red as an environmentally friendly pesticide surrogate. ACS Sustain. Chem. Eng. 2017, 5, 3882–3889. [Google Scholar] [CrossRef]

- Ghugare, B.D.; Adhaoo, S.H.; Gite, L.P.; Pandya, A.C.; Patel, S.L. Ergonomics evaluation of a lever-operated knapsack sprayer. Appl. Ergon. 1991, 22, 241–250. [Google Scholar] [CrossRef]

- Sánchez-Hermosilla, J.; Rincón, V.J.; Páez, F.; Fernández, M. Comparative spray deposits by manually pulled trolley sprayer and a spray gun in greenhouse tomato crops. Crop Prot. 2012, 31, 119–124. [Google Scholar] [CrossRef]

- Xiongkui, H.; Bonds, J.; Herbst, A.; Langenakens, J. Recent development of unmanned aerial vehicle for plant protection in East Asia. Int. J. Agric. Biol. Eng. 2017, 10, 18–30. [Google Scholar] [CrossRef]

- Qin, W.C.; Qiu, B.J.; Xue, X.Y.; Chen, C.; Xu, Z.F.; Zhou, Q.Q. Droplet deposition and control effect of insecticides sprayed with an unmanned aerial vehicle against plant hoppers. Crop Prot. 2016, 85, 79–88. [Google Scholar] [CrossRef]

- Xue, X.; Lan, Y.; Sun, Z.; Chang, C.; Hoffmann, W.C. Develop an unmanned aerial vehicle based automatic aerial spraying system. Comput. Electron. Agric. 2016, 128, 58–66. [Google Scholar] [CrossRef]

- Wang, S.; Song, J.; He, X.; Song, L.; Wang, X.; Wang, C.; Wang, Z.; Ling, Y. Performances evaluation of four typical unmanned aerial vehicles used for pesticide application in China. Int. J. Agric. Biol. Eng. 2017, 10, 22–31. [Google Scholar] [CrossRef]

- Zhang, P.; Deng, L.; Lyu, Q.; He, S.; Yi, S.; Liu, Y.; Yu, Y.; Pan, H. Effects of citrus tree-shape and spraying height of small unmanned aerial vehicle on droplet distribution. Int. J. Agric. Biol. Eng. 2016, 9, 45–52. [Google Scholar] [CrossRef]

- Giles, D.; Billing, R. Deployment and performance of an unmanned aerial vehicle for spraying of specialty crops. In Proceedings of the International Conference of Agricultural Engineering, Zurich, Switzerland, 6–10 July 2014. [Google Scholar]

- Law, S.E. Embedded-electrode electrostatic-induction spray-charging nozzle: Theoretical and engineering design. Trans. ASAE 1978, 21, 1096–1104. [Google Scholar] [CrossRef]

- Zhang, C.; Kovacs, J.M. The application of small unmanned aerial systems for precision agriculture: A review. Precis. Agric. 2012, 13, 693–712. [Google Scholar] [CrossRef]

- Huang, Y.; Hoffmann, W.C.; Lan, Y.; Wu, W.; Fritz, B.K. Development of a spray system for an unmanned aerial vehicle platform. Appl. Eng. Agric. 2009, 25, 803–809. [Google Scholar] [CrossRef]

- Fritz, B. Meteorological effects on deposition and drift of aerially applied sprays. Trans. ASAE 2006, 49, 1295–1301. [Google Scholar] [CrossRef]

- Bird, S.L.; Perry, S.G.; Ray, S.L.; Teske, M.E. Evaluation of the AgDISP aerial spray algorithms in the AgDRIFT model. Environ. Toxicol. Chem. 2002, 21, 672–681. [Google Scholar] [CrossRef]

- Wang, X.; He, X.; Wang, C.; Wang, Z.; Li, L.; Wang, S.; Jane, B.; Andreas, H.; Wang, Z. Spray drift characteristics of fuel powered single-rotor UAV for plant protection. Trans. ASAE 2017, 33, 117–123, (In Chinese with English abstract). [Google Scholar] [CrossRef]

- Chen, S.; Lan, Y.; Li, J.; Zhou, Z.; Liu, A.; Mao, Y. Effect of wind field below unmanned helicopter on droplet deposition distribution of aerial spraying. Int. J. Agric. Biol. Eng. 2017, 10, 67–77. [Google Scholar] [CrossRef]

- Xue, X.; Tu, K.; Qin, W.; Lan, Y.; Zhang, H. Drift and deposition of ultra-low altitude and low volume application in paddy field. Int. J. Agric. Biol. Eng. 2014, 7, 23–28. [Google Scholar] [CrossRef]

- Zhao, H.; Xie, C.; Liu, F.; He, X.; Zhang, J.; Song, J. Effects of sprayers and nozzles on spray drift and terminal residues of imidacloprid on wheat. Crop Prot. 2014, 60, 78–82. [Google Scholar] [CrossRef]

- Wolters, A.; Linnemann, V.; Zande, J.C.v.d.; Vereecken, H. Field experiment on spray drift: Deposition and airborne drift during application to a winter wheat crop. Sci. Total Environ. 2008, 405, 269–277. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Z.; Yuan, H.; Lou, S.; Ji, M.; Yu, J.; Song, X. The research of water soluble dyes of Allura Red and Ponceau-G as tracers for determing pesticide spray distribution. Agrochemicals 2007, 46, 323–325, (In Chinese with English abstract). [Google Scholar] [CrossRef]

- Zhu, H.; Salyani, M.; Fox, R.D. A portable scanning system for evaluation of spray deposit distribution. Comput. Electron. Agric. 2011, 76, 38–43. [Google Scholar] [CrossRef]

- Ebert, T.A.; Taylor, R.A.J.; Downer, R.A.; Hall, F.R. Deposit structure and efficacy of pesticide application. 2: Trichoplusia ni control on cabbage with fipronil. Pestic. Sci. 1999, 55, 793–798. [Google Scholar] [CrossRef]

- Rincón, V.J.; Sánchez-Hermosilla, J.; Páez, F.; Pérez-Alonso, J.; Callejón, Á.J. Assessment of the influence of working pressure and application rate on pesticide spray application with a hand-held spray gun on greenhouse pepper crops. Crop Prot. 2017, 96, 7–13. [Google Scholar] [CrossRef]

- Sánchez-Hermosilla, J.; Rincón, V.J.; Páez, F.; Agüera, F.; Carvajal, F. Field evaluation of a self-propelled sprayer and effects of the application rate on spray deposition and losses to the ground in greenhouse tomato crops. Pest Manag. Sci. 2011, 67, 942–947. [Google Scholar] [CrossRef] [PubMed]

- Agricultural and Forestry Machinery–Inspection of Sprayers in Use–Part 2: Horizontal Boom Sprayers; ISO/TC 23/SC 6. ISO 16122-2:2015; International Organization for Standardization (ISO): Geneva, Switzerland, 2015.

- Yang, D.B.; Zhang, L.N.; Yan, X.J.; Wang, Z.Y.; Yuan, H.Z. Effects of droplet distribution on insecticide toxicity to asian corn borers (Ostrinia furnaealis) and spiders (Xysticus ephippiatus). J. Integr. Agric. 2014, 13, 124–133. [Google Scholar] [CrossRef]

- Bae, Y.; Koo, Y.M. Flight attitudes and spray patterns of a roll-balanced agricultural unmanned helicopter. Appl. Eng. Agric. 2013, 29, 675–682. [Google Scholar] [CrossRef]

- Hislop, E.C.; Western, N.M.; Butler, R. Experimental air-assisted spraying of a maturing cereal crop under controlled conditions. Crop Prot. 1995, 14, 19–26. [Google Scholar] [CrossRef]

- Zhu, H.; Dorner, J.W.; Rowland, D.L.; Derksen, R.C.; Ozkan, H.E. Spray penetration into peanut canopies with hydraulic nozzle tips. Biosyst. Eng. 2004, 87, 275–283. [Google Scholar] [CrossRef]

- Ferguson, J.C.; Chechetto, R.G.; Hewitt, A.J.; Chauhan, B.S.; Adkins, S.W.; Kruger, G.R.; O’Donnell, C.C. Assessing the deposition and canopy penetration of nozzles with different spray qualities in an oat (Avena sativa L.) canopy. Crop Prot. 2016, 81, 14–19. [Google Scholar] [CrossRef]

- Craig, I.P.; Hewitt, A.; Terry, H. Rotary atomiser design requirements for optimum pesticide application efficiency. Crop Prot. 2014, 66, 34–39. [Google Scholar] [CrossRef]

- Xu, L.; Zhu, H.; Ozkan, H.E.; Bagley, W.E.; Krause, C.R. Droplet evaporation and spread on waxy and hairy leaves associated with type and concentration of adjuvants. Pest Manag. Sci. 2011, 67, 842–851. [Google Scholar] [CrossRef] [PubMed]

- Van Zyl, S.A.; Brink, J.-C.; Calitz, F.J.; Fourie, P.H. Effects of adjuvants on deposition efficiency of fenhexamid sprays applied to Chardonnay grapevine foliage. Crop Prot. 2010, 29, 843–852. [Google Scholar] [CrossRef]

- Latheef, M.A.; Carlton, J.B.; Kirk, I.W.; Hoffmann, W.C. Aerial electrostatic-charged sprays for deposition and efficacy against sweet potato whitefly (Bemisia tabaci) on cotton. Pest Manag. Sci. 2009, 65, 744–752. [Google Scholar] [CrossRef] [PubMed]

- Yanliang, Z.; Qi, L.; Wei, Z. Design and test of a six-rotor unmanned aerial vehicle (UAV) electrostatic spraying system for crop protection. Int. J. Agric. Biol. Eng. 2017, 10, 68–76. [Google Scholar] [CrossRef]

- Ebert, T.A.; Taylor, R.A.J.; Downer, R.A.; Hall, F.R. Deposit structure and efficacy of pesticide application. 1: Interactions between deposit size, toxicant concentration and deposit number. Pestic. Sci. 1999, 55, 783–792. [Google Scholar] [CrossRef]

- Maczuga, S.A.; Mierzejewski, K.J. Droplet size and density effects of bacillus thuringiensis kurstaki on gypsy moth (Lepidoptera: Lymantriidae) Larvae. J. Econ. Entomol. 1995, 88, 1376–1379. [Google Scholar] [CrossRef]

- Washington, J.R. Relationship between the spray droplet density of two protectant fungicides and the germination of mycosphaerella fijiensis ascospores on banana leaf surfaces. Pest Manag. Sci. 1997, 50, 233–239. [Google Scholar] [CrossRef]

- Lan, Y.; Chen, S.; Fritz, B.K. Current status and future trends of precision agricultural aviation technologies. Int. J. Agric. Biol. Eng. 2017, 10, 1–17. [Google Scholar] [CrossRef]

| Spray Equipment | Total Deposition | Losses to the Ground | Recovery Rate | ||

|---|---|---|---|---|---|

| Avg. (μg/Plant) | CV (%) | Avg. (μg/cm2) | CV (%) | Avg. (%) | |

| UAV sprayer | 76.8 a | 87.2 | 0.13 b | 78.2 | 70.0 a |

| SPB sprayer | 68.7 a | 32.1 | 0.39 a | 39.0 | 62.7 a |

| EAP Sprayer | 84.8 a | 84.4 | 0.14 b | 118.2 | 77.3 a |

| KMB Sprayer | 61.9 a | 81.2 | 0.50 a | 97.1 | 56.5 a |

| Sprayer | Tank Capacity (L) | Spray Area (Means ± Standard Error, ha) | Spray Time (Means ± Standard Error, h) | Working Efficiency (ha/h) |

|---|---|---|---|---|

| UAV sprayer | 5 | 0.39 ± 0.04 | 0.095 ± 0.01 | 4.11 |

| SPB sprayer | 280 | 0.93 ± 0.06 | 0.39 ± 0.03 | 2.38 |

| KMB Sprayer | 18 | 0.22 ± 0.02 | 0.14 ± 0.01 | 1.57 |

| EAP Sprayer | 16 | 0.039 ± 0.004 | 0.19 ± 0.01 | 0.21 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Lan, Y.; Yuan, H.; Qi, H.; Chen, P.; Ouyang, F.; Han, Y. Comparison of Spray Deposition, Control Efficacy on Wheat Aphids and Working Efficiency in the Wheat Field of the Unmanned Aerial Vehicle with Boom Sprayer and Two Conventional Knapsack Sprayers. Appl. Sci. 2019, 9, 218. https://doi.org/10.3390/app9020218

Wang G, Lan Y, Yuan H, Qi H, Chen P, Ouyang F, Han Y. Comparison of Spray Deposition, Control Efficacy on Wheat Aphids and Working Efficiency in the Wheat Field of the Unmanned Aerial Vehicle with Boom Sprayer and Two Conventional Knapsack Sprayers. Applied Sciences. 2019; 9(2):218. https://doi.org/10.3390/app9020218

Chicago/Turabian StyleWang, Guobin, Yubin Lan, Huizhu Yuan, Haixia Qi, Pengchao Chen, Fan Ouyang, and Yuxing Han. 2019. "Comparison of Spray Deposition, Control Efficacy on Wheat Aphids and Working Efficiency in the Wheat Field of the Unmanned Aerial Vehicle with Boom Sprayer and Two Conventional Knapsack Sprayers" Applied Sciences 9, no. 2: 218. https://doi.org/10.3390/app9020218

APA StyleWang, G., Lan, Y., Yuan, H., Qi, H., Chen, P., Ouyang, F., & Han, Y. (2019). Comparison of Spray Deposition, Control Efficacy on Wheat Aphids and Working Efficiency in the Wheat Field of the Unmanned Aerial Vehicle with Boom Sprayer and Two Conventional Knapsack Sprayers. Applied Sciences, 9(2), 218. https://doi.org/10.3390/app9020218