Isothermal Drying Process and its Effect on Compressive Strength of Concrete in Multiscale

Abstract

:1. Introduction

2. Materials and Methods

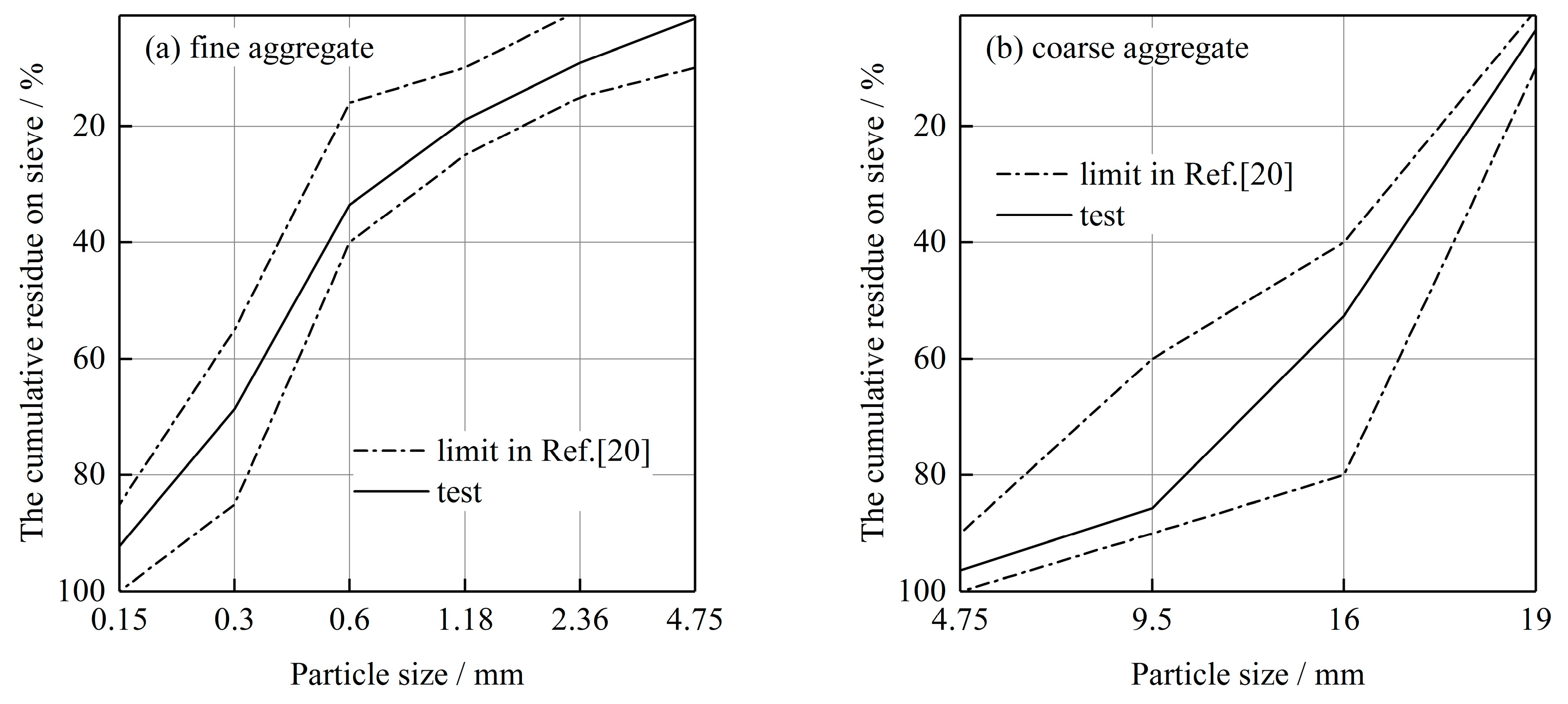

2.1. Materials and Sample Preparation

2.2. Test Procedures

2.2.1. Isothermal Drying Process

2.2.2. Deformation in drying process

2.2.3. Compression test

2.3. Microstructural Analyzing Techniques

3. Results

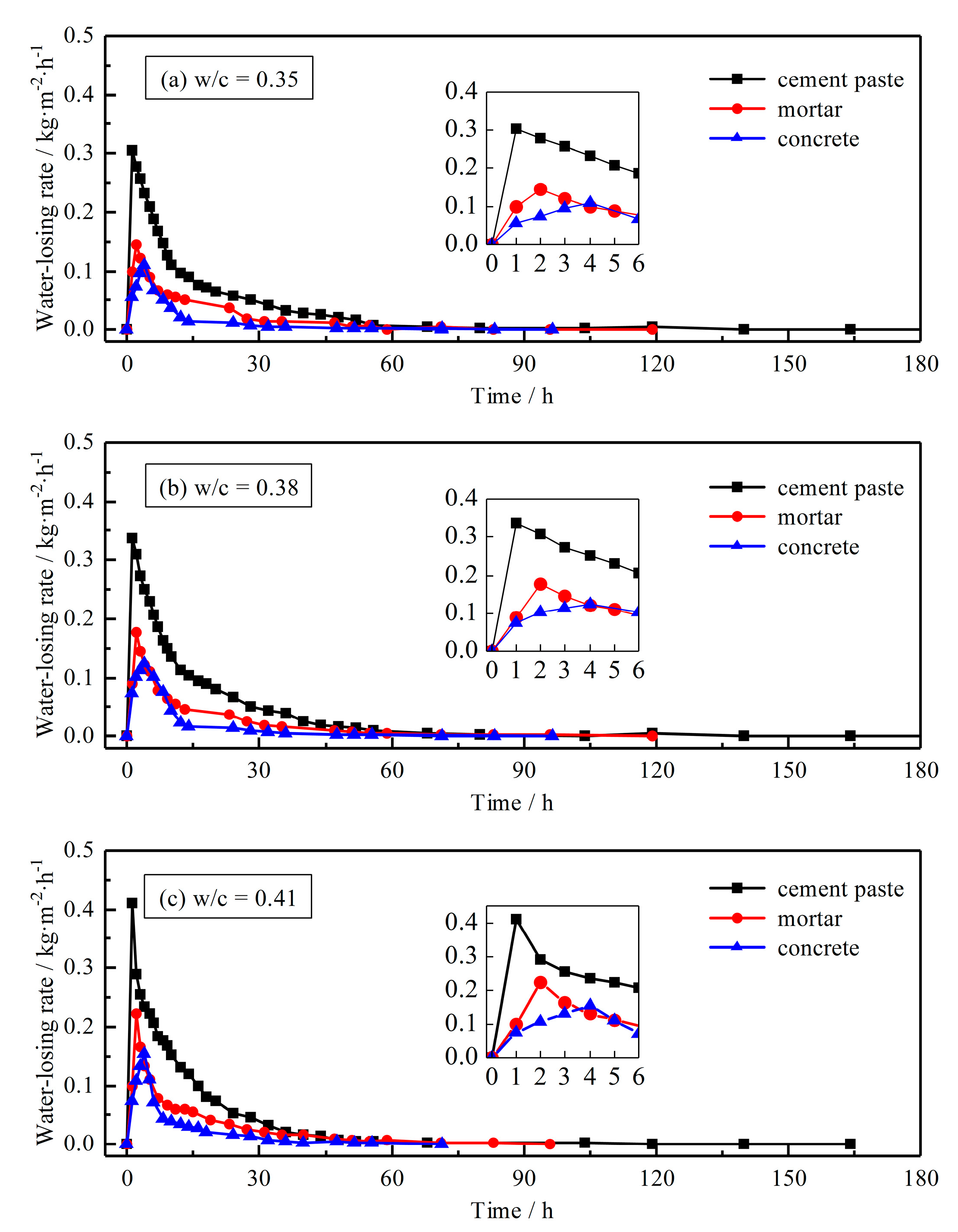

3.1. Isothermal Drying Process

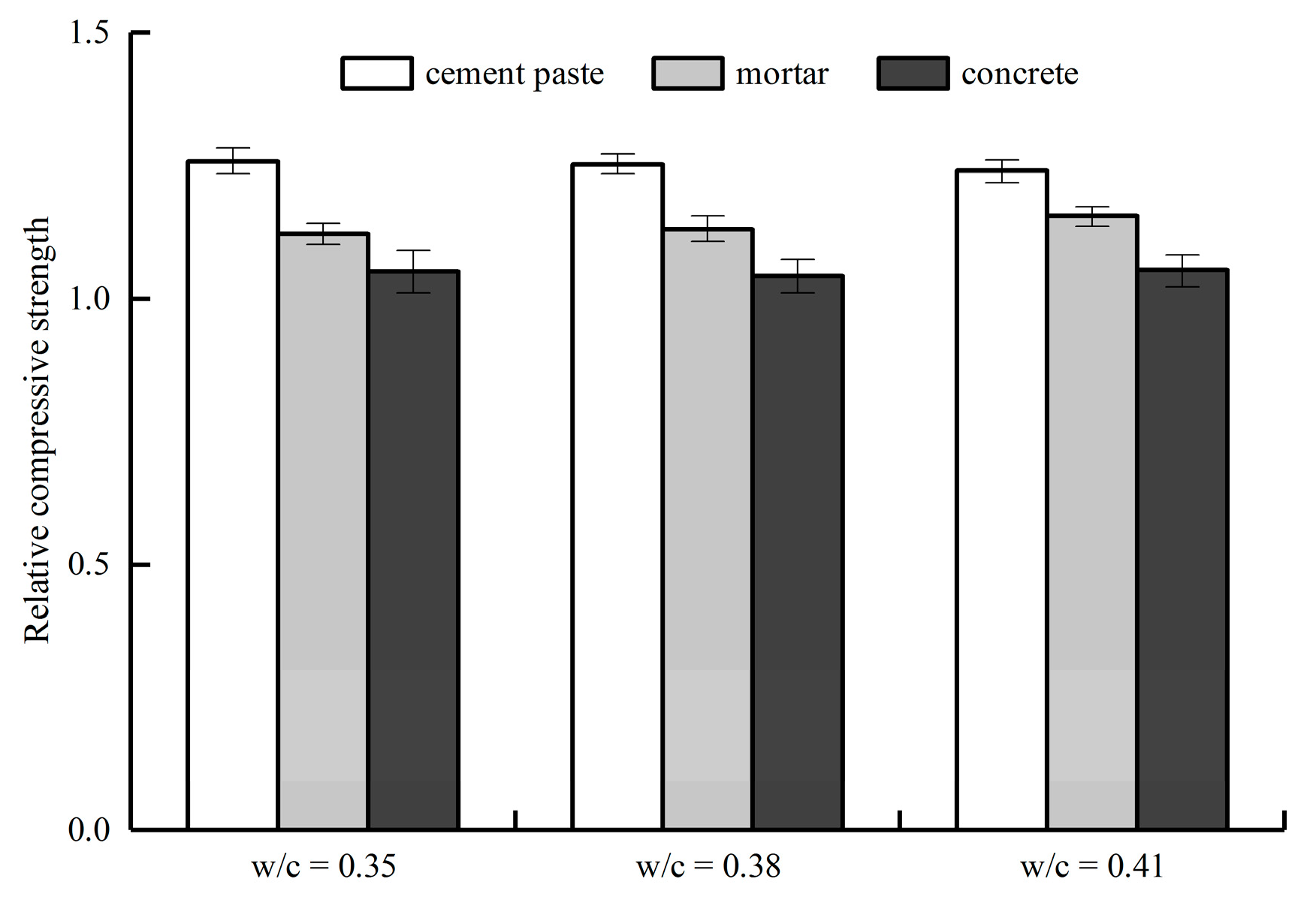

3.2. Compression Test

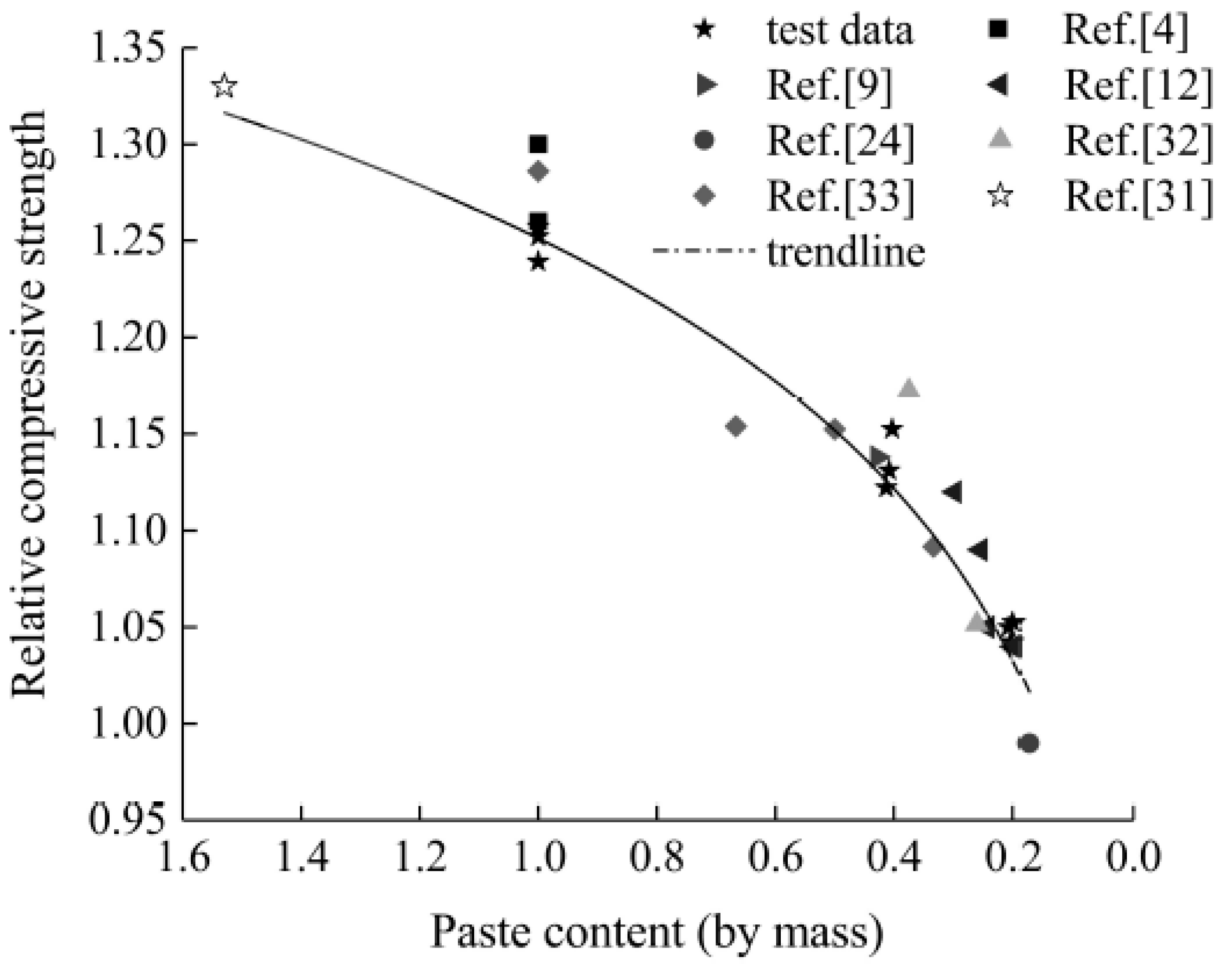

3.2.1. Compression Strength

3.2.2. Failure Mode

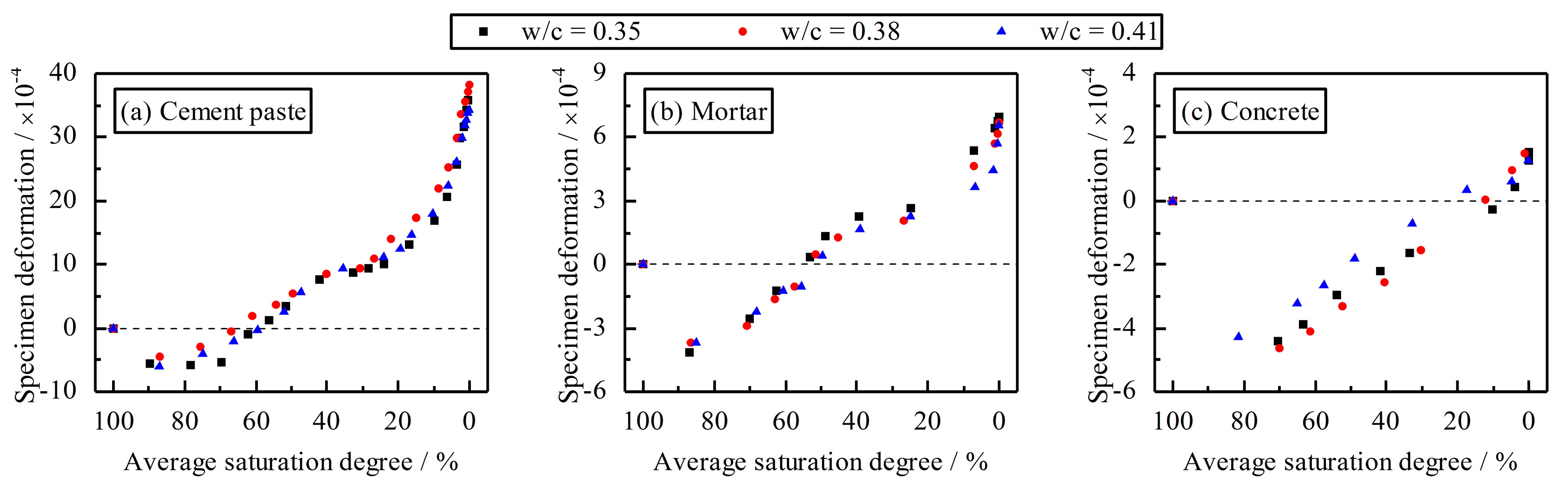

3.3. Drying Deformation

3.4. Microstructure Analysis

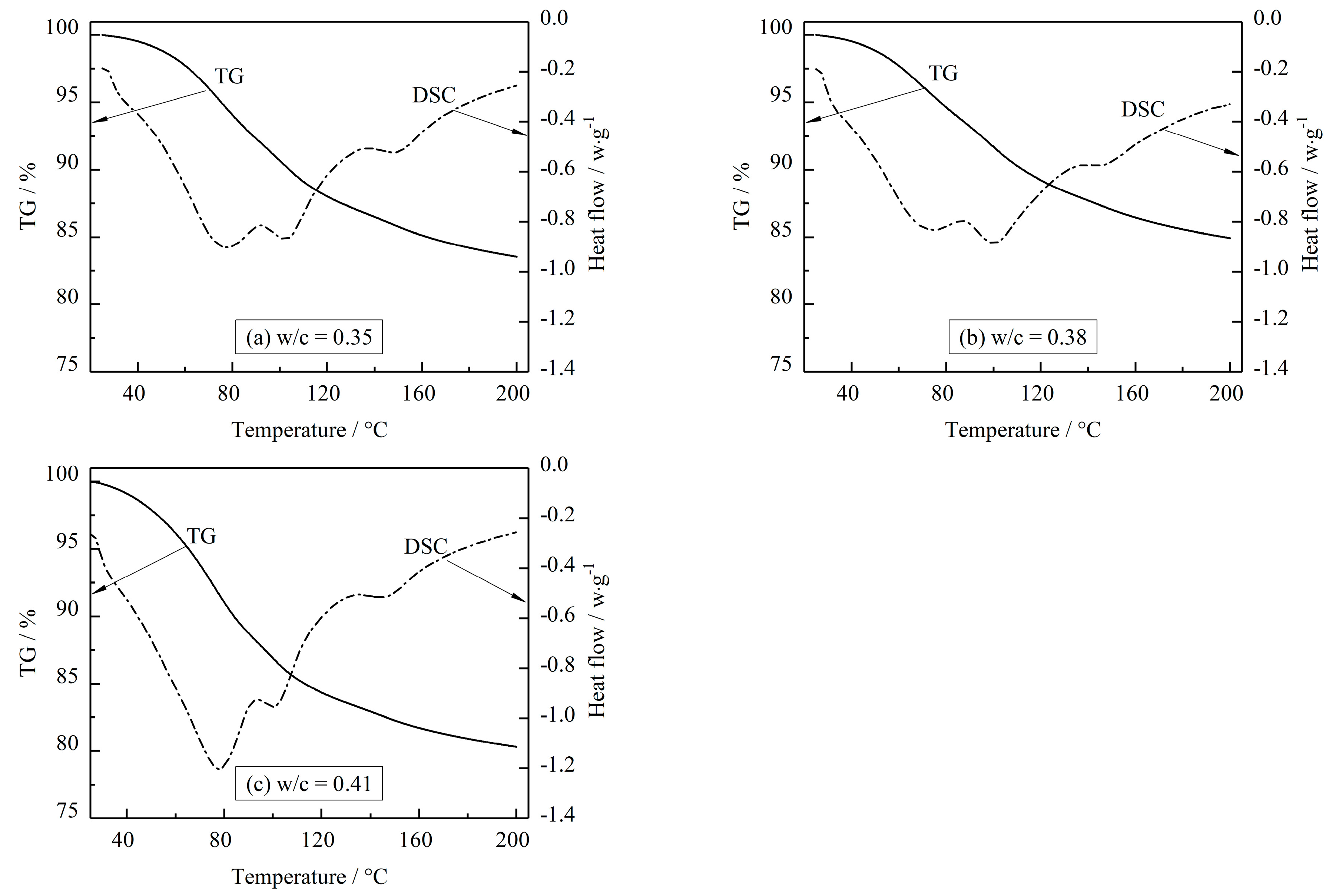

3.4.1. TGA/DSC Analysis

3.4.2. MIP Results Analysis

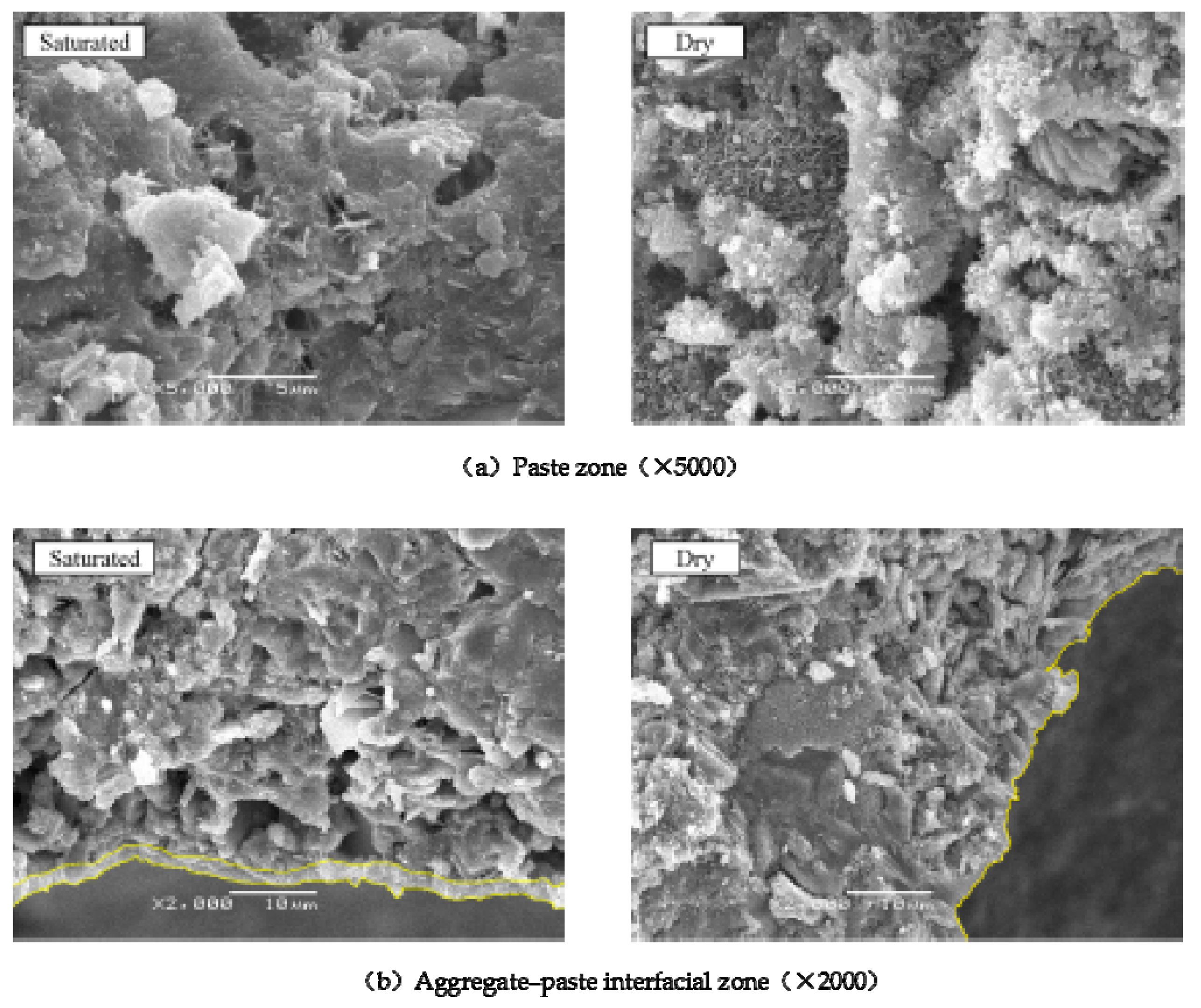

3.4.3. SEM Analysis

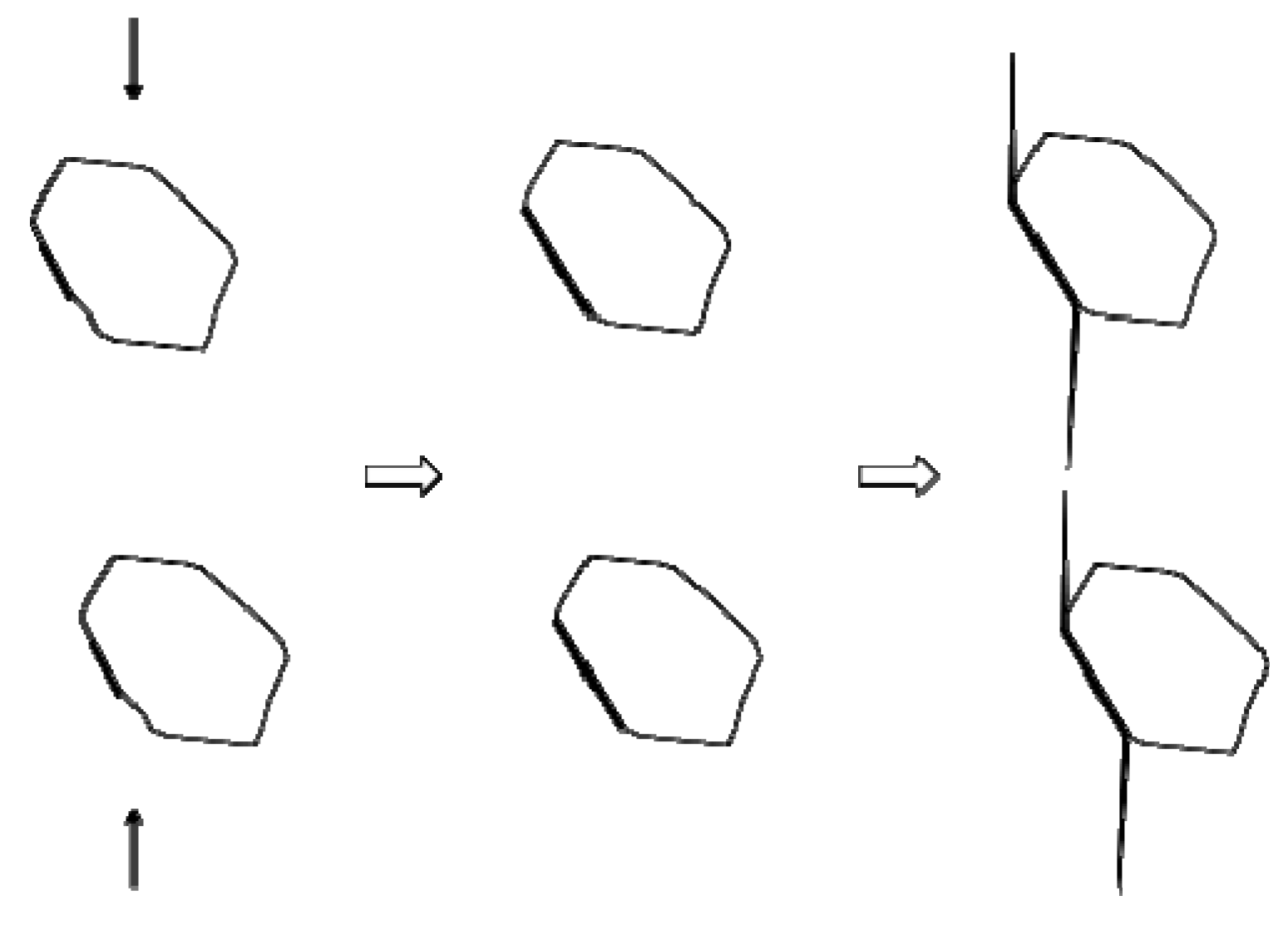

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References and Note

- Bartlett, F.M.; Macgregor, J.G. Effect of moisture condition on concrete core strengths. ACI Mater. J. 1994, 91, 227–236. [Google Scholar]

- Glucklich, J.; Korin, U. Effect of Moisture Content on Strength and Strain Energy Release Rate of Cement Mortar. J. Am. Ceram. Soc. 1975, 58, 517–521. [Google Scholar] [CrossRef]

- Wu, Z.; Wong, H.S.; Buenfeld, N.R. Transport properties of concrete after drying-wetting regimes to elucidate the effects of moisture content, hysteresis and microcracking. Cem. Concr. Res. 2017, 98, 136–154. [Google Scholar] [CrossRef]

- Ross, C.A.; Jerome, D.M.; Tedesco, J.W. Moisture and strain rate effects on concrete strength. ACI Mater. J. 1996, 93, 293–300. [Google Scholar]

- Wittmann, F.H. Interaction of hardened cement paste and water. J. Am. Ceram. Soc. 2010, 56, 409–415. [Google Scholar] [CrossRef]

- Bažant, Z.P. Constitutive equation for concrete creep and shrinkage based on thermodynamics of multiphase systems. Matériaux Constr. 1970, 3, 3–36. [Google Scholar] [CrossRef]

- Liu, B.D.; Lv, W.J.; Li, L.; Li, P.F. Effect of moisture content on static compressive elasticity modulus of concrete. Constr. Build. Mater. 2014, 69, 133–142. [Google Scholar] [CrossRef]

- Korpa, A.; Trettin, R. The influence of different drying methods on cement paste microstructures as reflected by gas adsorption: Comparison between freeze-drying (F-drying), D-drying, P-drying and oven-drying methods. Cem. Concr. Res. 2006, 36, 634–649. [Google Scholar] [CrossRef]

- Zhou, J.K.; Chen, X.D.; Wu, L.Q.; Kan, X.W. Influence of free water content on the compressive mechanical behavior of cement mortar under high strain rate. Sadhana 2011, 36, 357–369. [Google Scholar] [CrossRef]

- Wang, H.L.; Li, Q.B. Experiments of the compressive properties of dry and saturated concrete under different loading rates. J. Hydraul. Eng. 2007, 26, 84–89. [Google Scholar]

- Pihlajavaara, S.E. On the Main Features and Methods of Investigation of Drying and Related Phenomena in Concrete; State Institute for Technical Research: Helsinki, Finland, 1965. [Google Scholar]

- Han, J.S.; Li, Z.L.; Liu, H.J.; Zhang, G.H.; Tan, C.; Han, J.J. Study on the process of isothermal continuous dry and its effect on the strength of concrete of different strength grades. Constr. Build. Mater. 2018, 187, 14–24. [Google Scholar] [CrossRef]

- Kanna, V.; Olson, R.A.; Jennings, H.M. Effect of shrinkage and moisture content on the physical characteristics of blended cement mortars. Cem. Concr. Res. 1998, 28, 1467–1477. [Google Scholar] [CrossRef]

- Skoczylasa, F.; Burlionb, N.; Yurtdas, I. About drying effects and poro-mechanical behaviour of mortars. Cem. Concr. Compos. 2007, 29, 383–390. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P. Concrete: Structure, Properties and Materials; Prentice-Hall, Inc.: Englewood Cliffs, NJ, USA, 2006. [Google Scholar]

- Wittmann, F.H. Surface tension, shrinkage and strength of hardened cement paste. Matériaux Constr. 1968, 1, 547–552. [Google Scholar] [CrossRef]

- Maruyama, I.; Sasano, H.; Nishioka, Y.; Igarashi, G. Strength and Young’s modulus change in concrete due to long-term drying and heating up to 90 C. Cem. Concr. Res. 2014, 66, 48–63. [Google Scholar] [CrossRef]

- Maruyama, I.; Nishioka, Y.; Igarashi, G. Microstructural and bulk property changes in hardened cement paste during the first drying process. Cem. Concr. Res. 2014, 58, 20–34. [Google Scholar] [CrossRef]

- The National standards of the People’s Republic of China. Test Code for Hydraulic Concrete SL 352-2006.

- Taylor, H.F.W. Cement Chemistry, 2nd ed.; Thomas Telford Publishing: London, UK, 1997. [Google Scholar]

- Hansen, T.C. Physical structure of hardened cement paste. A classical approach. Mater. Struct. 1986, 19, 423–436. [Google Scholar] [CrossRef]

- Chen, D.Y.; Li, M.; Zhu, X.F. TG-DSC method applied to drying characteristics and heat requirement of cotton stalk during drying. Heat Mass Transf. 2012, 48, 2087–2094. [Google Scholar] [CrossRef]

- Bazant, Z.P.; Najjar, L.J. Drying of concrete as a nonlinear diffusion problem. Cem. Concr. Res. 1971, 1, 461–473. [Google Scholar] [CrossRef]

- Carlson, R.W. Drying shrinkage of large concrete members. ACI J. 1937, 33, 327–336. [Google Scholar]

- Zhang, G.H.; Li, Z.L.; Zhang, L.F.; Shang, Y.J.; Wang, H. Experimental research on drying control condition with minimal effect on concrete strength. Constr. Build. Mater. 2016, 135, 194–202. [Google Scholar] [CrossRef]

- Jennings, H.M. Refinements to colloid model of C-S-H in cement: CM-II. Cem. Concr. Res. 2008, 38, 275–289. [Google Scholar] [CrossRef]

- Wang, J.; Lacarrièren, L.; Sellierm, A. Multicomponent modelling of cement paste dehydration under different heating rates. Mater. Struct. 2019, 52, 136–145. [Google Scholar] [CrossRef]

- Okpala, D.C. Pore structure of hardened cement paste and mortar. Int. J. Cem. Compos. Lightweight Concr. 1989, 11, 245–254. [Google Scholar] [CrossRef]

- Stepkowska, E.T.; Blanes, J.M.; Franco, F.; Real, C.; Pérez-RodríGuez, J.L. Phase transformation on heating of an aged cement paste. Thermochim. Acta 2004, 420, 79–87. [Google Scholar] [CrossRef]

- Zhang, Q.; Ye, G.; Koenders, E. Investigation of the structure of heated Portland cement paste by using various techniques. Constr. Build. Mater. 2013, 38, 1040–1050. [Google Scholar] [CrossRef]

- Hou, D.S.; Ma, H.Y.; Zhu, Y.; Li, Z.J. Calcium silicate hydrate from dry to saturated state—Structure dynamics and mechanical properties. Acta Mater. 2014, 67, 81–94. [Google Scholar] [CrossRef]

- Wang, H.L.; Jin, W.; Li, Q. Saturation effect on dynamic tensile and compressive strength of concrete. Adv. Struct. Eng. 2009, 12, 279–286. [Google Scholar] [CrossRef]

- Li, Q.H.; Yao, Y.; Sun, B.; Li, Z.J. Mechanism of effect of elevated temperature on compressive strength of cement mortar. J. Build. Mater. 2008, 11, 699–703. (In Chinese) [Google Scholar]

| Density/kg·m−3 | Initial Setting Time/min | Final Setting Time/min | Soundness | Compressive Strength at 28 Days/MPa |

|---|---|---|---|---|

| 3150 | 90 | 320 | qualified | 37.3 |

| Fineness Modulus | Dense Packing Density/kg·m−3 | Apparent Density/kg·m−3 | Clay Content/% |

|---|---|---|---|

| 2.54 | 1764 | 2560 | 0.7 |

| Particle Size/cm | Bulk Density/kg·m−3 | Apparent Density/kg·m−3 | Clay Content/% |

|---|---|---|---|

| 5–20 | 1638 | 2680 | 0.5% |

| Material | Water/Cement Ratio | Cement/kg | Water/kg | Fine Aggregate/kg | Coarse Aggregate/kg |

|---|---|---|---|---|---|

| cement paste | 0.35 | 1498 | 524 | - | - |

| 0.38 | 1434 | 545 | - | - | |

| 0.41 | 1375 | 564 | - | - | |

| mortar | 0.35 | 690 | 242 | 1381 | - |

| 0.38 | 676 | 257 | 1352 | - | |

| 0.41 | 663 | 272 | 1326 | - | |

| concrete | 0.35 | 368 | 129 | 735 | 1252 |

| 0.38 | 364 | 138 | 727 | 1239 | |

| 0.41 | 360 | 148 | 720 | 1225 |

| Water/Cement Ratio | Material | Mass Fraction of Paste/% | Time Required to Completely Dry State/h | Water Loss (by Mass)/% | Maximum Water-Losing Rate/(kg·m−2·h−1) |

|---|---|---|---|---|---|

| 0.35 | cement paste | 1.0 | 180 | 16.832 | 0.304 |

| mortar | 0.403 | 120 | 6.817 | 0.144 | |

| concrete | 0.200 | 80 | 2.950 | 0.111 | |

| 0.38 | cement paste | 1.0 | 172 | 18.268 | 0.338 |

| mortar | 0.408 | 104 | 7.289 | 0.178 | |

| concrete | 0.203 | 72 | 3.135 | 0.111 | |

| 0.41 | cement paste | 1.0 | 164 | 19.483 | 0.411 |

| mortar | 0.413 | 96 | 7.978 | 0.222 | |

| concrete | 0.207 | 68 | 4.204 | 0.154 |

| Material | State | Porosity/% | Average Pore Diameter/nm | |||

|---|---|---|---|---|---|---|

| <100 nm | 100~1000 nm | >1000 nm | Total Porosity | |||

| Cement paste | Saturated | 11.98 | 0.51 | 0.48 | 12.97 | 10.9 |

| Dry | 18.70 | 0.45 | 0.89 | 20.04. | 18.8 | |

| Mortar | Saturated | 4.33 | 2.60 | 3.00 | 9.93 | 17.7 |

| Dry | 3.29 | 7.64 | 2.85 | 13.78 | 110 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, X.; Li, Z.; Tong, T.; Li, B.; Liu, H. Isothermal Drying Process and its Effect on Compressive Strength of Concrete in Multiscale. Appl. Sci. 2019, 9, 4015. https://doi.org/10.3390/app9194015

Du X, Li Z, Tong T, Li B, Liu H. Isothermal Drying Process and its Effect on Compressive Strength of Concrete in Multiscale. Applied Sciences. 2019; 9(19):4015. https://doi.org/10.3390/app9194015

Chicago/Turabian StyleDu, Xiangqin, Zongli Li, Taotao Tong, Bo Li, and Hengjie Liu. 2019. "Isothermal Drying Process and its Effect on Compressive Strength of Concrete in Multiscale" Applied Sciences 9, no. 19: 4015. https://doi.org/10.3390/app9194015

APA StyleDu, X., Li, Z., Tong, T., Li, B., & Liu, H. (2019). Isothermal Drying Process and its Effect on Compressive Strength of Concrete in Multiscale. Applied Sciences, 9(19), 4015. https://doi.org/10.3390/app9194015