2.2. Construction Phase

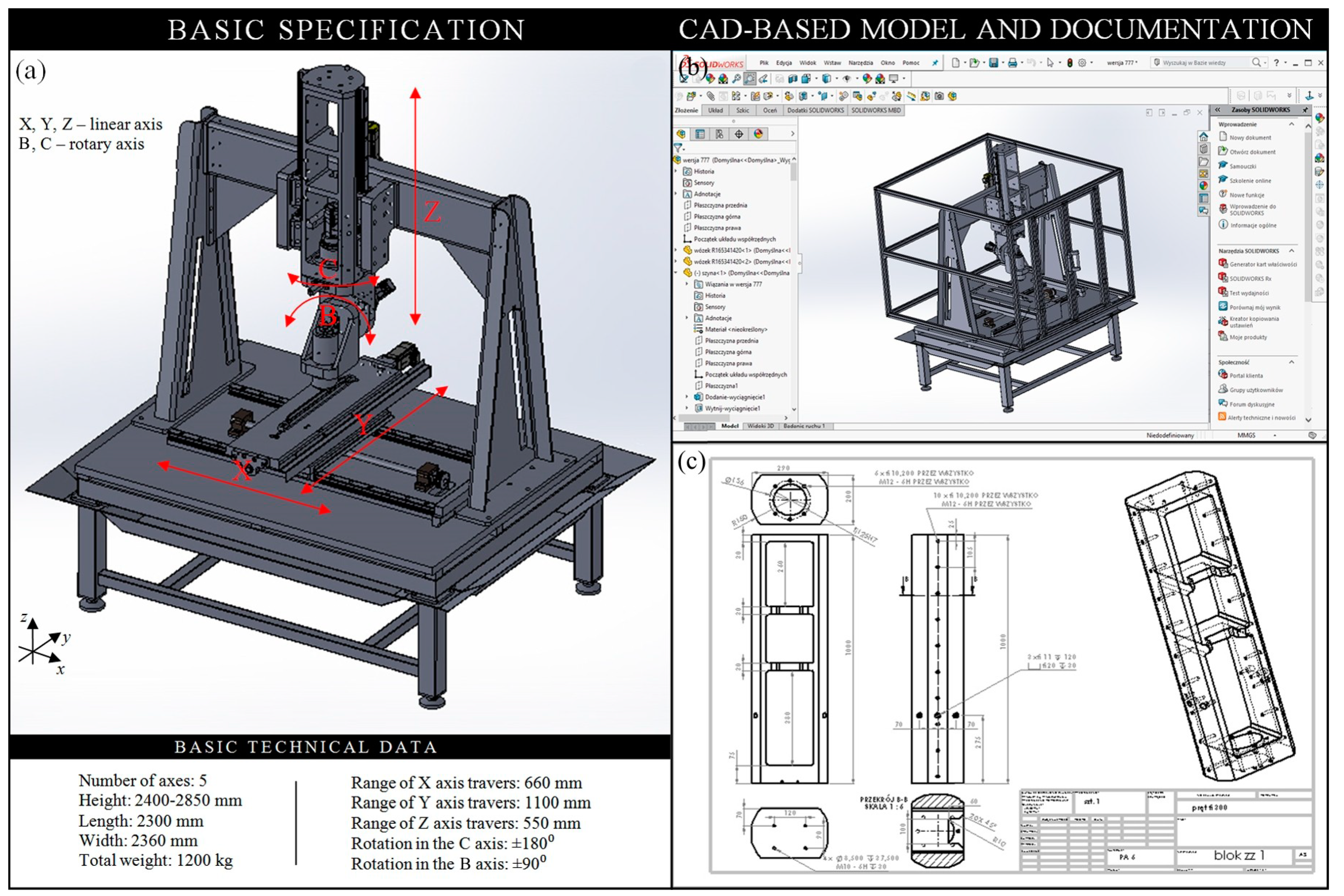

The main element of the 5-axis CNC grinding machine was a high-stiffness lower body, constituting the basis for the whole technological machine. It was made of cold-bent hard-walled profiles in a truss shape with dimensions 120 × 120 × 6 mm which, after the welding process, was subjected to a stress annealed treatment. The bottom part of the lower body was equipped with adjustable supports, enabling the proper leveling of the technological machine. In addition, the body was equipped with a drip tray for efficient collection and discharge of the coolant fed in the grinding process. An intermediate element between the frame and the further parts of the technological machine was an aluminum plate, attached to the bottom part of the frame and constituting the assembly base for subsequent components/units of the machine. The lower body had a structure consisting of two side bars and one upper bar twisted together into one compact whole in the form of a gate, for ensuring high-stiffness during operation. Such a construction, forming the upper body, was an extremely important element of the 5-axis CNC grinding machine, necessary for the correct vertical operation of the Z linear axis and the accompanying B and C rotary axes, respectively. The upper body was produced of high-quality sheet metal with thickness

t = 12 mm, shaped in the bending process to obtain a sufficiently high-stiffness and to provide adequate parameters of vibration damping and high thermal resistance. All elements, after the welding process, were annealed in order to eliminate internal stresses, and then machining of the base elements was performed. Additionally, in order to ensure proper work safety, a protective cage made of aluminum profiles and plates made of transparent polycarbonate (PC) with a thickness

t = 15 mm was used. In the front part, it was equipped with a servicing door. An axonometric view of the three-dimensional (3D) model of the lower and upper body and detailed views of its construction are presented in

Figure 2.

An extremely important role in the described 5-axis CNC grinding machine was played by the vertical auxiliary body of the Z linear axis (travel in the range 0–550 mm). This body created an integral part, together with the remaining bodies of the B and C rotary axes (rotations in the range ±90° and ±180°, respectively). The linear guides were attached to the body, together with the runner blocks. One of the two rotary axes of the technological machine was the C axis. The auxiliary body of the C rotary axis was attached to the auxiliary body of the Z linear axis, forming an integral whole with it. Properly designed reinforcing ribs ensure high structural stiffness. The body of the C axis was the geometric basis for the B axis, which was the second rotary axis of the 5-axis CNC grinding machine, to which the grinding spindle was directly attached. The body of the B rotary axis created a kinetic pair, together with the body of the Z linear axis and the body of the C rotary axis. All the auxiliary bodies were made of high-grade aluminum to obtain the smallest possible mass and adequate high-stiffness. Axonometric views of the 3D models and construction details of the auxiliary body of the Z linear axis, as well as bodies of the C and B rotary axes, are presented in

Figure 3.

In the auxiliary body of the B rotary axis, a main drive was installed. In this case, grinding electrospindle type PTShPp-30-36Km120 (FŁT Kraśnik SA, Kraśnik, Poland) was used. When selecting it, the correct speed of the machining being carried out and its control range, as well as process accuracy, were taken into account. In the electrospindle, an asynchronous motor enabling to obtain a range of rotational speeds ns = 3000–30,000 min−1, at a power P = 2.7–3.2 kW and electric voltage U = 153–183 V, was used. Due to the high inrush electric current I = 14 A, for the proper functioning of the electrospindle, a dedicated frequency converter (inverter) providing power Pmin = 7.5 kW was equipped. The exchange of machining tools (various types of small-sized grinding wheels made of CBN abrasive grains) in the electrospindle takes place manually.

The important element of the main drive, necessary to ensure unchangeable operating para- meters and relatively long service life time, was the system for producing and supplying lubrication to the electrospindle bearings in the form of an air–oil aerosol. The UDL-5 EP system (FŁT Kraśnik SA, Kraśnik, Poland) with a low oil level sensor and a pressure transmitter was used, due to its compatibility with the selected electrospindle type. The system was characterized by the following work parameters: Input pressure pin = 0.3–0.7 MPa, output pressure pout = 0.04–0.10 MPa, the range of drops adjustment 20–100 drops/min, the spray tank capacity Q = 500 cm3, and mass m = 3 kg. The cooling agent recommended by the manufacturer was an air–oil aerosol based on Hydrol® L-HL hydraulic oil (PKN Orlen SA, Poland), given in the amount ~20 drops/min, in pressure range p = 0.10–0.12 MPa, and in range of rotational speeds ns = 3500–50,000 min−1. An additional component of the main drive was also the electrospindle cooling system type EP-18-150K (Euro Products, Poznań, Poland), in which the Ergolid® EKO (Boryszew SA, Sochaczew, Poland), a non-freezing fluid, was used. The system provided the efficiency of grinding fluid flow rate QGF = 24 L/min.

In the 5-axis CNC grinding machine, the linear-guide connectors on the three main linear axes X, Y, and Z was used. In accordance with the current trends in the construction of CNC machines, the describing technological machine was equipped with ready-made commercial rolling elements. For all axes, the SNS-type ball rails (size 45 mm, accuracy H) and FNS-type standard flanges runner blocks (size 45 mm, accuracy C1) (Bosh Rexroth AG, Schweinfurt, Germany) were used. These elements guaranteed the expected high positioning accuracy with high linear speed. For the drive of linear guide systems, the appropriate SEM-E-S-type screw–nut pair (Bosh Rexroth AG, Schweinfurt, Germany) was used. The whole was powered by BSM63N-275 AC servo motors (Baldor, ABB group, Zurich, Switzerland), in an intermediate configuration for each axis, respectively. The AC servo motor (TC = 1.47 Nm, I = 1.97 A, ns = 10,000 min−1, m = 2.3 kg) was equipped with a precise positioning system containing an encoder that provided the possibility of feedback, which also allowed to treat it as a measurement-control system.

Important elements of the 5-axis CNC grinding machine construction were also two C and B rotary axes, which ensured precise positioning and, thus, repeatability of results—which is a key issue of obtaining the given machining parameters. For their proper functioning, which is understood as a precise rotation, the bearing blocks embedded in specially designed bushes, which in turn were embedded in the auxiliary bodies of the C and B rotary axes, were responsible. Conical bearings with the appropriate voltage value were used here, which ensured the correct realization of this function. Requirements regarding the accuracy and precision of motion executive elements forced the use of precise reinforced output bearing for the rotary axes drive. For several years, manufacturers have been using them successfully for tilting–turning tables of CNC machines, resulting in highly backlash-free kinematic systems. As in the case of ball rails and flanges runner blocks, also in this case, ready-made commercial components were used. CPU-25A (TA = 108 Nm, TM = 284 Nm, TN = 67 Nm, TR = 157 Nm, nin(max) = 5600 min−1, nav(max) = 3500 min−1) reinforced output bearing (Harmonic Drive AG, Limburg an der Lahn, Germany).

The control and monitoring systems in the 5-axis CNC grinding machine were included elements indirectly involved in controlling the technological machine (control program) and directly controlling the electrical systems (servo amplifiers, frequency converters, contactors, etc.) and measuring elements (encoders in servo motors, limit switches in individual linear and rotary axes, etc.). Because the assumptions took into account the conducting of the machining process in an automated and repeatable manner, it was necessary to use the appropriate software to control the machining parameters (feed, direction, rotational speed, automatic positioning). A control program in the form of G-codes was introduced into the technological machine through the advanced Mach3 ver. R3.043.022 software (Newfangled Solutions LLC, Livermore Falls, ME, USA). The software allowed for control of movement of the X, Y, Z, C, and B axes, operation of the electrospindle, operation of the cooling system of the machining zone and processing parameters. Elements of industrial automation necessary to control the operation of the technological machine were mostly placed in the main control cabinet, including servo amplifiers compatible with servo motors (Baldor, ABB Group), frequency converter (inverter), control card that provides communication between the Mach3 software and the servo amplifiers of individual axes, Windows workstation, and other electrical elements, e.g., contactors, relays, overload protections, and electrical-signal cables.

The machine was also equipped with cooling–lubricating systems supporting the grinding process based on the minimum quantity lubrication (MQL) and cold air gun (CAG) methods. Both systems used nozzle MQL for supplying oil mist by compressed air and nozzle CAG for supplying low-temperature compressed air, which were specially designed to ensure that, in addition to the cooling and lubricating function of the machining zone, they also provided effective fluid cleaning and dirt separation. Details of above-mentioned systems are presented in

Figure 4a,b.

A properly designed and made fixing grip plays a key role in the regeneration of industrial cutting blades. In this case, repeatability of the process, precision of the workpiece placement, proper stiffness in the whole process, and proper access of the grinding wheel to the workpiece were very important. The grip was based to the technological machine table by clamping jaws, while the workpiece was clamped by means of several clamping screws located on the side of the grip. General and detailed views of the fixing grip are presented in

Figure 4c,d, whereas a general view of a complete technological machine and its key systems and elements is presented in

Figure 5.

2.3. Testing Phase

After successfully finishing the construction phase, the authors went on to the phase, related to testing the constructed 5-axis CNC grinding machine. The tests included:

Checking the correctness of the assembly and making modifications to the configuration of the main and auxiliary bodies, hydraulic and pneumatic systems, manipulation systems X, Y, and Z linear axes, as well as the C and B rotary axes, control systems with the software, systems for the feeding of cooling and lubricating fluid to the grinding zone and fixing grip for the workpiece.

Development of a suitable program to carry out machining tasks intended for the process of precision grinding of cutting edges of industrial cutting blades, as well as conducting preliminary precision grinding for determining the correctness of parameter selection during this process.

A set of seven planar cutting tools, used in the ST600VU automatic skinning machine (STEEN F.P.M. International, Kalmthout, Belgium) that works in a technological line for skinning flat fishes (Baltic species of flounder,

Platichthys flesus trachurus, and plaice,

Platessa platessa baltica, obtained from Danish fisheries), was chosen for the regeneration process. The general view of one of the industrial cutting blades prepared in the machining process is presented in

Figure 6, whereas the characteristics of all blades are given in

Table 1. Additionally, in

Table 2 and

Table 3, chemical composition and selected properties of X39CR13 high carbon martensitic stainless steel (material from which the described blades were made) is given.

Before abrasive processing started, all of the low-stiffness planar industrial cutting blades (Kuno Wasser GmbH, Solingen, Germany for Steen F.P.M. International, Kalmthout, Belgium) were properly prepared (degreased and cleaned with compressed air). The precision grinding process was carried out for the following conditions given in

Table 4.

After the end of the abrasive processing, all industrial cutting blades were subjected to high-accuracy 3D optical measurements in order to assess the influence of the preset machining parameters of the expected cutting edge surface texture. In the measurements, a multisensory optical profilometer Talysurf CLI 2000 (Taylor-Hobson Ltd., Leicester, Great Britain) equipped with LK-031 optical displacement sensor (

λ = 670 nm,

P = 0.95 mW,

ds ~ 30 mm,

r = 1 µm) and LK-2001 controller (Keyence Corp., Osaka, Japan) was used. Detailed characteristics of this instrument were presented in the work [

26], whereas its view during measurements is shown in

Figure 7.

The measurements methodology included 1.50 × 1.50 mm measurements of the topographies of the selected surface fragment of each of the industrial cutting blade for conditions given in

Table 5. After the measurement, the saved *.SUR file with measurement data was opened in specialized TalyMap Silver ver. 4.1.2 (Digital Surf, Besançon, France) software. Before starting the proper analyses, the measurement data were leveled and (if necessary) non-measured points were filled out. A proper analysis was carried out on the basis of a surface map in indexed colors (where the height of the surface elements was encoded with the color), and topography of measured surface and calculated values of selected parameters from the amplitude, spatial, and hybrid groups is given in

Table 6. Additionally, from 1.50 × 1.50 mm surface topography, a fragment, which presented area of cutting blade, was extracted. In this way, a 0.90 × 1.25 mm surface topography was obtained. After filtering out waviness, for such surface topography, the software calculated selected parameters.

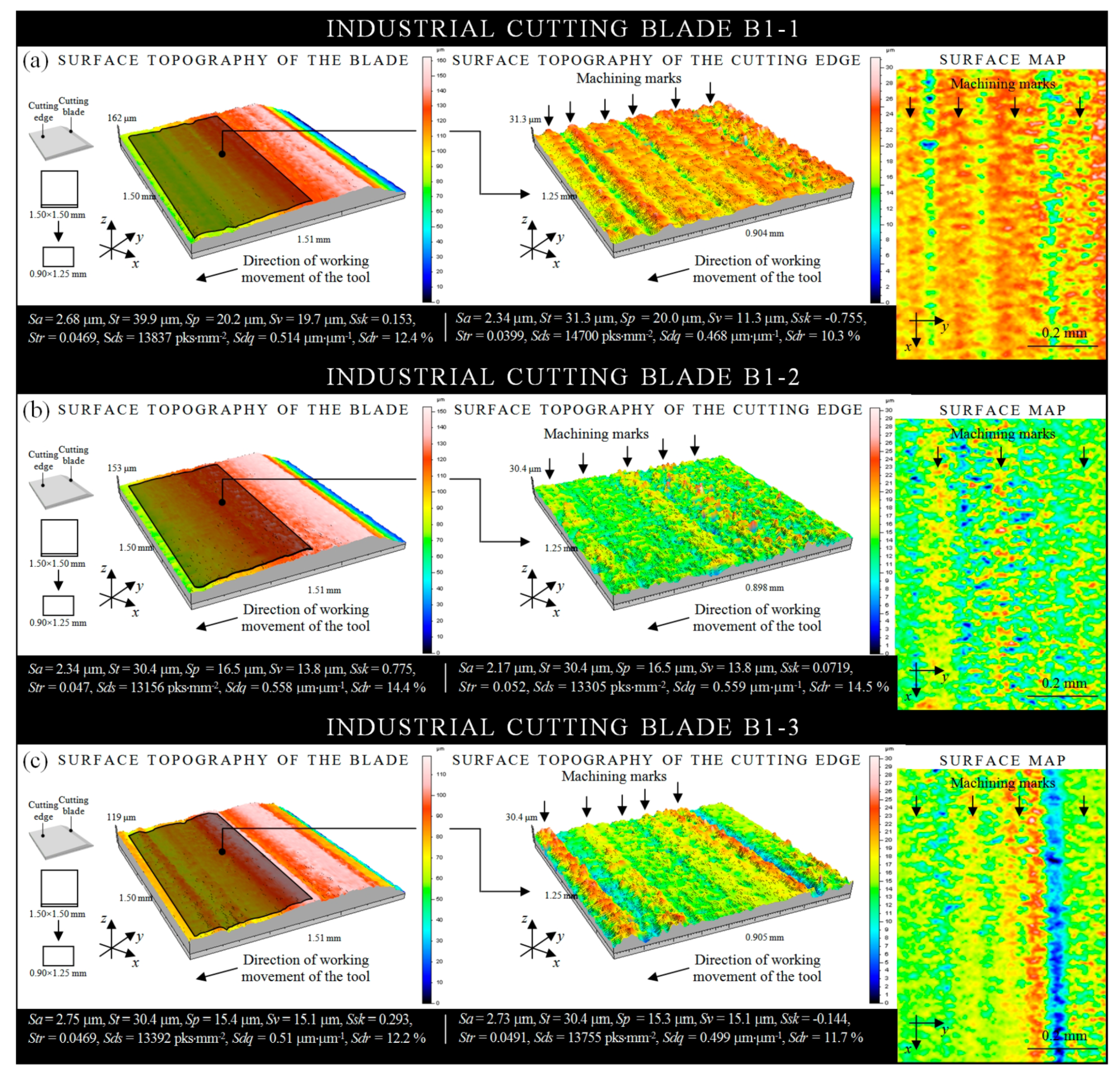

The collection of results of the measurements obtained by the use of multisensory optical profilometer Taylor-Hobson Talysurf CLI 2000 for a surfaces of three low-stiffness planar industrial cutting blades regenerated by the peripheral grinding process (

vw = 300–400 mm/min,

ns = 38,000 min

−1) realized in a 5-axis CNC grinding machine is presented in

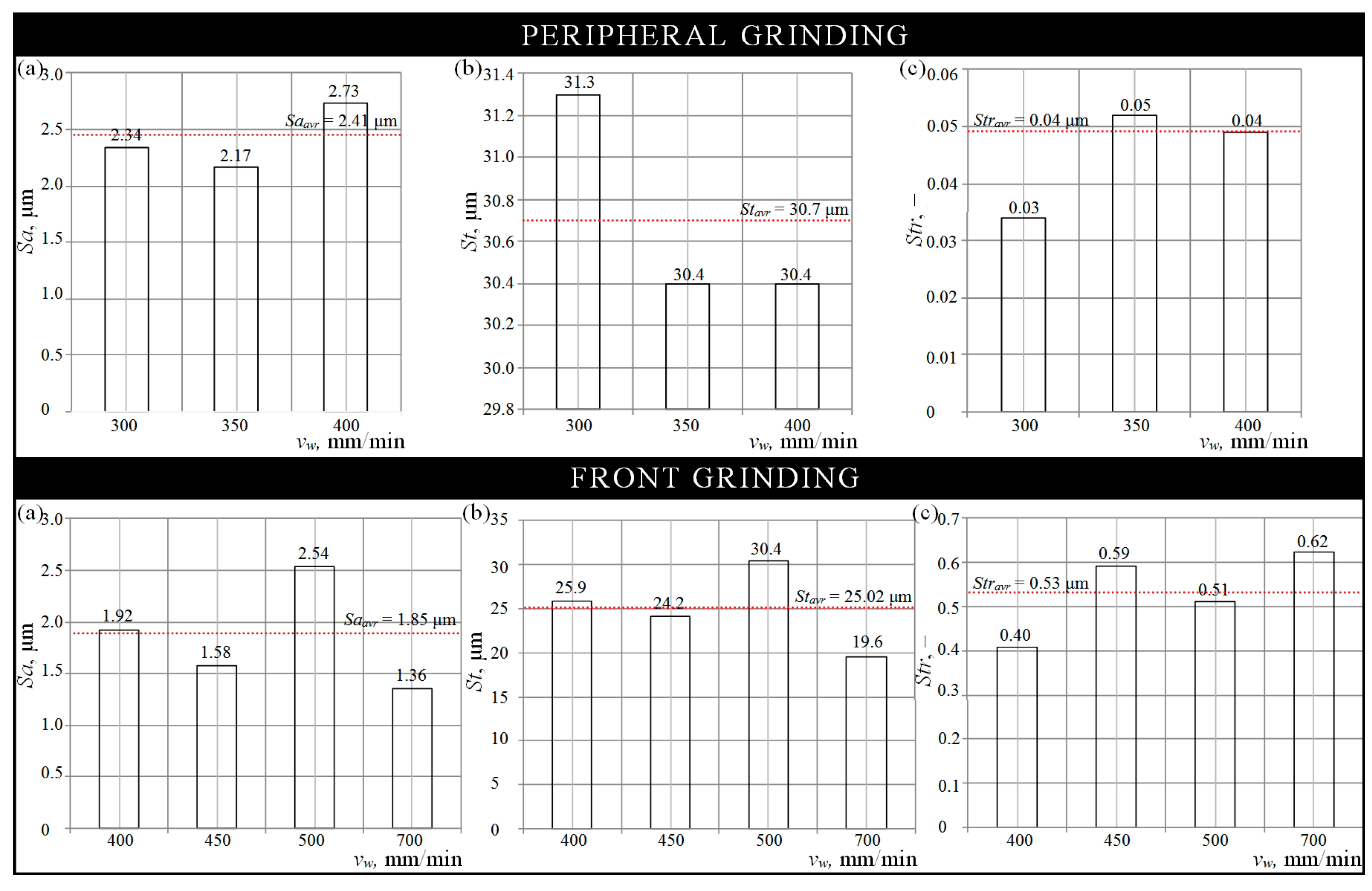

Figure 8. The analysis of the above results allows to state that for all regenerated surfaces of cutting edges, one can observe clear machining marks characteristic of the grinding process. Marks, perpendicular to the working movement direction of the cutting edges, were shaped more or less regularly with similar spacing. Their height (given by

St amplitude parameter) was in a level ~15–16 μm (samples B1-1 and B1-3—

Figure 8a,c, respectively) and ~5–6 μm (sample B1-2—

Figure 8b). A comparison of the results of the analyses, presented in graphical form with the values of surface texture parameters, is listed in

Figure 10a–c (top). It can be noticed that for the cutting edge of sample B1-2, the lowest values were obtained (

Sa = 2.17 μm,

St = 30.4 μm, and

Str = 0.03 μm). The

Sds spatial parameter was also characterized by lower values, whereas for two hybrid parameters (

Sdr and

Sdq), higher values were obtained. The sign of the

Ssk amplitude parameter indicated the predominance of peaks comprising the surface. In regard to the above, the sample B1-2 can be considered as regenerated in the most appropriate way from those presented in

Figure 8. Nevertheless, the geometry of the surface has not been fully reproduced correctly, which forced to change the kinematics of the grinding process. Subsequent tests were carried out using front grinding.

The other collection of results of the measurements obtained by the use of multisensory optical profilometer Taylor-Hobson Talysurf CLI 2000 for a surfaces of four low-stiffness planar industrial cutting blades regenerated by the front grinding process (

vw = 400–700 mm/min,

ns = 38,000 min

−1) realized on a 5-axis CNC grinding machine is presented in

Figure 9.

The analysis of the above results allows to state that for all regenerated surfaces of the cutting edges, one can observe only machining mark residues. All surfaces were relatively smoother than those obtained in the peripheral grinding process. Their height (given by

St amplitude parameter) was in a level ~10 μm (machining mark residues) and ~5 μm (smooth area) in relation to samples B1-4, B1-5, and B1-6 (

Figure 9a–c, respectively), as well as in a level ~5–6 μm (machining mark residues) and ~3–4 μm (smooth area) in relation to sample B1-7 (

Figure 9d). A comparison of the results of the analyses, presented in graphical form with the values of surface texture parameters, is listed in

Figure 10a–c (bottom). It can be noticed that for the cutting edge of sample B1-7, the lowest values were obtained (

Sa = 1.26 μm,

St = 19.6 μm, and

Str = 0.622 μm). The values of the two essential

Sa and

St amplitude parameters, in this case, were lower by 62.68% and 64.48%, respectively, to values obtained for the cutting edge surface of the most effectively regenerated sample B1-2. The

Sds spatial parameter was characterized by higher values, whereas for the two hybrid parameters (

Sdr and

Sdq), lower values were obtained. As with the sample B1-2, the sign of the

Ssk amplitude parameter for sample B1-7 indicated the predominance of peaks comprising the surface. For all the surfaces of the samples presented in

Figure 9, the best geometrically-shaped was found to be sample B1-7. It was characterized by a relatively flat surface with low values of the heights of surface irregularities without visible machining marks. In this case, a combination of high workpiece peripheral speed and abrasive tool rotational speed allowed for a satisfactory effect and relatively correct restoration of the surface geometry. Two kinematic variations of the grinding process tested confirmed that front grinding is much more beneficial than peripheral. This type of grinding will be used in subsequent, much more intensive testing that will help to optimize the process parameters and improve, to a greater extent, the geometry of regenerated cutting edge surfaces of industrial cutting blades.