Reducing Critical Hindrances to Building Information Modeling Implementation: The Case of the Singapore Construction Industry

Abstract

1. Introduction

2. Literature Review

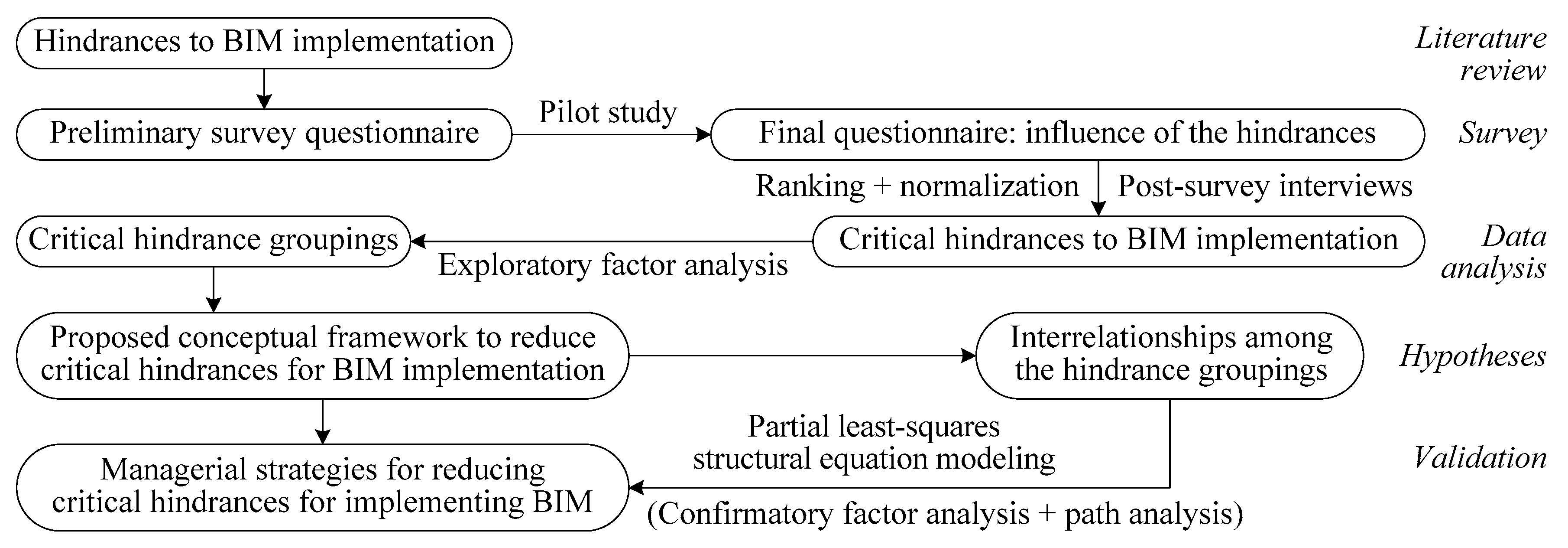

3. Method and Data Presentation

4. Results and Discussion

4.1. Ranking of Hindrances to BIM Implementation

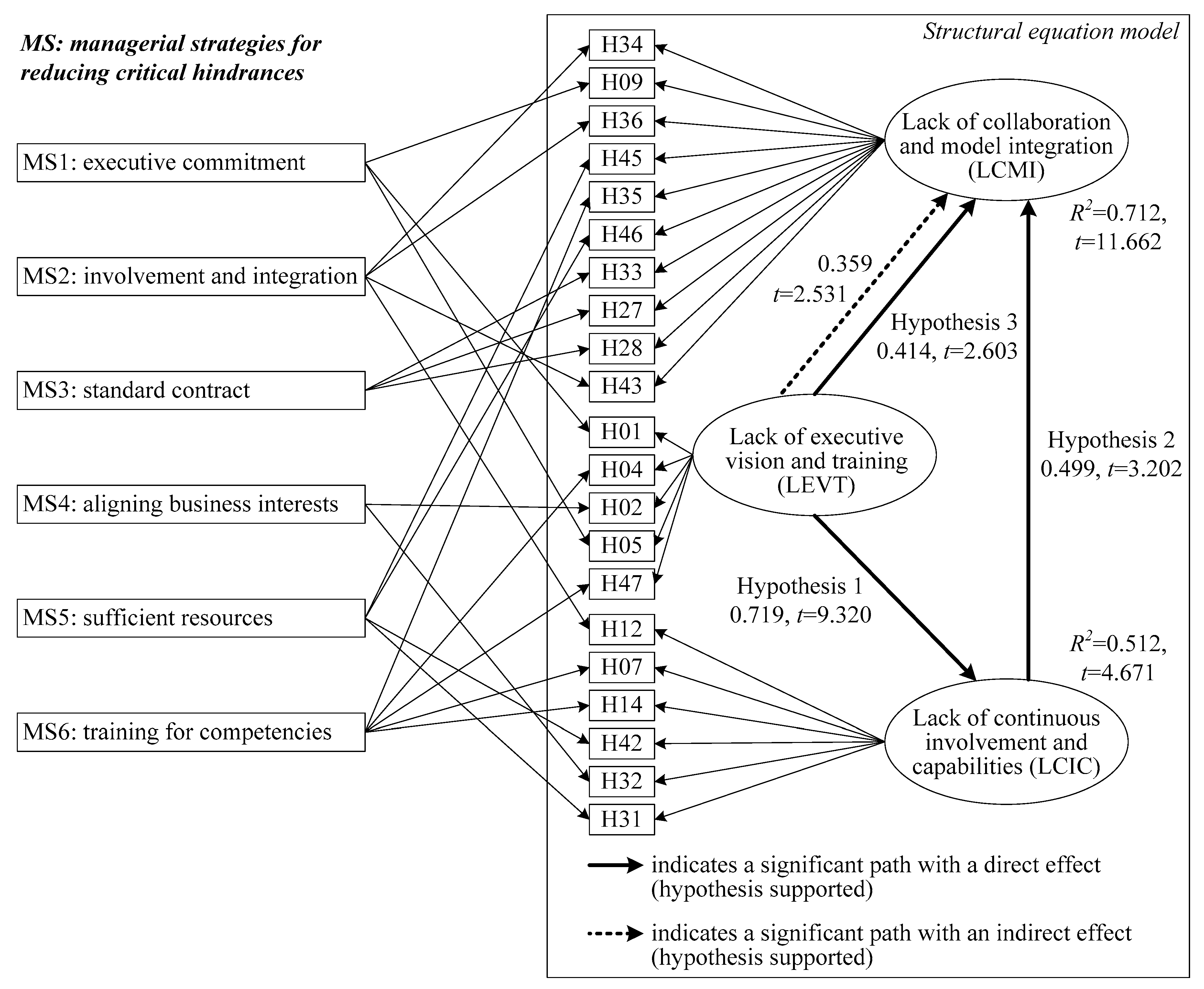

4.2. Underlying Hindrance Groupings

4.2.1. Lack of Collaboration and Model Integration

4.2.2. Lack of Continuous Involvement and Capabilities

4.2.3. Lack of Executive Vision and Training

4.3. Conceptual Framework and Validation

4.3.1. Hypothesis 1

4.3.2. Hypothesis 2

4.3.3. Hypothesis 3

4.4. Managerial Strategies

5. Conclusions and Recommendations

Author Contributions

Funding

Conflicts of Interest

References

- Miettinen, R.; Paavola, S. Beyond the BIM utopia: Approaches to the development and implementation of building information modelling. Autom. Constr. 2014, 43, 84–91. [Google Scholar] [CrossRef]

- Cha, H.S.; Lee, D.G. A case study of time/cost analysis for aged-housing renovation using a pre-made BIM database structure. KSCE J. Civ. Eng. 2015, 19, 841–852. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, N.; Wu, J. Combining BIM and Ontology to facilitate intelligent green building evaluation. J. Comput. Civ. Eng. 2018, 32, 04018039. [Google Scholar] [CrossRef]

- Jiang, S.; Wu, Z.; Zhang, B.; Cha, H.S. Combined MvdXML and Semantic technologies for green construction code checking. Appl. Sci. 2019, 9, 1463. [Google Scholar] [CrossRef]

- Ding, Z.; Liu, S.; Liao, L.; Zhang, L. A digital construction framework integrating building information modeling and reverse engineering technologies for renovation projects. Autom. Constr. 2019, 102, 45–58. [Google Scholar] [CrossRef]

- Chelson, D.E. The Effects of Building Information Modeling on Construction Site Productivity. Ph.D. Thesis, University of Maryland, College Park, MD, USA, 2010. [Google Scholar]

- Khosrowshahi, F.; Arayici, Y. Roadmap for implementation of BIM in the UK construction industry. Eng. Constr. Archit. Manag. 2012, 19, 610–635. [Google Scholar] [CrossRef]

- Forsythe, P.; Sankaran, S.; Biesenthal, C. How far can BIM reduce information asymmetry in the Australian construction context? Proj. Manag. J. 2015, 46, 75–87. [Google Scholar] [CrossRef]

- Juan, Y.K.; Lai, W.Y.; Shih, S.G. Building information modeling acceptance and readiness assessment in Taiwanese architectural firms. J. Civ. Eng. Manag. 2017, 23, 356–367. [Google Scholar] [CrossRef]

- Cheng, J.C.; Lu, Q. A review of the efforts and roles of the public sector for BIM adoption worldwide. J. Inf. Technol. Constr. 2015, 20, 442–478. [Google Scholar]

- BCA. Reaching New Milestones with Design for Manufacturing and Assembly; Build Smart, Building and Construction Authority: Singapore, 2016.

- Lam, S.W. The Singapore BIM Roadmap. In Proceedings of the Government BIM Symposium 2014, Singapore, 13 October 2014; Available online: http://bimsg.org/wp-content/uploads/2014/10/BIM-SYMPOSIUM_MR-LAM-SIEW-WAH_Oct-13-v6.pdf (accessed on 15 June 2019).

- Fischer, M.; Reed, D.; Khanzode, A.; Ashcraft, H. A Simple Framework for Integrated Project Delivery. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014; pp. 1319–1330. [Google Scholar]

- Liao, L.; Teo, E.A.L. Managing critical drivers for building information modelling implementation in the Singapore construction industry: An organizational change perspective. Int. J. Constr. Manag. 2019, 19, 240–256. [Google Scholar] [CrossRef]

- ESC. Report of the Economic Strategies Committee; Economic Strategies Committee: Singapore, 2010.

- AIA and AIACC. Integrated Project Delivery: A Guide; American Institute of Architects: Sacramento, CA, USA, 2007. [Google Scholar]

- AIA and AIACC. Experiences in Collaboration: On the Path to IPD; American Institute of Architects: Sacramento, CA, USA, 2009. [Google Scholar]

- Aranda-Mena, G.; Crawford, J.; Chevez, A.; Froese, T. Building information modelling demystified: Does it make business sense to adopt BIM? Int. J. Manag. Proj. Bus. 2009, 2, 419–434. [Google Scholar] [CrossRef]

- Arayici, Y.; Coates, P.; Koskela, L.; Kagioglou, M.; Usher, C.; O’Reilly, K. BIM adoption and implementation for architectural practices. Struct. Surv. 2011, 29, 7–25. [Google Scholar] [CrossRef]

- Autodesk. Improving Building Industry Results Through Integrated Project Delivery and Building Information Modeling; Autodesk Inc.: San Rafael, CA, USA, 2008. [Google Scholar]

- Autodesk. A Framework for Implementing a BIM Business Transformation; Autodesk Inc.: San Rafael, CA, USA, 2012. [Google Scholar]

- Azhar, N.; Kang, Y.; Ahmad, I.U. Factors influencing integrated project delivery in publicly owned construction projects: An information modelling perspective. Procedia Eng. 2014, 77, 213–221. [Google Scholar] [CrossRef]

- Bernstein, P.G.; Pittman, J.H. Barriers to the Adoption of Building Information Modelling in the Building Industry; Autodesk, Inc.: San Rafael, CA, USA, 2004. [Google Scholar]

- Bernstein, H.M.; Jones, S.A.; Russo, M.A. The Business Value of BIM in North America: Multi-Year Trend Analysis and User Rating (2007–2012); McGraw-Hill Construction: Bedford, MA, USA, 2012. [Google Scholar]

- Blismas, N.; Wakefield, R. Drivers, constraints and the future of offsite manufacture in Australia. Constr. Innov. 2009, 9, 72–83. [Google Scholar] [CrossRef]

- Eastman, C.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Fischer, M. Reshaping the life cycle process with virtual design and construction methods. In Virtual Futures for Design, Construction and Procurement; Brandon, P., Kocatürk, T., Eds.; Blackwell Publishing Ltd.: Malden, MA, USA, 2008; pp. 104–112. [Google Scholar]

- Fox, S.; Hietanen, J. Interorganizational use of building information models: Potential for automational, informational and transformational effects. Constr. Manag. Econ. 2007, 25, 289–296. [Google Scholar] [CrossRef]

- Gao, J.; Fischer, M. Case Studies on the Implementation and Impacts of Virtual Design and Construction (VDC) in Finland; Center for Integrated Facility Engineering, Stanford University: Stanford, CA, USA, 2006. [Google Scholar]

- Gibb, A.; Isack, F. Re-engineering through pre-assembly: Client expectations and drivers. Build. Res. Inf. 2003, 31, 146–160. [Google Scholar] [CrossRef]

- Kent, D.C.; Becerik-Gerber, B. Understanding construction industry experience and attitudes toward integrated project delivery. J. Constr. Eng. Manag. 2010, 136, 815–825. [Google Scholar] [CrossRef]

- Kiani, I.; Sadeghifam, A.N.; Ghomi, S.K.; Marsono, A.K.B. Barriers to implementation of building information modeling in scheduling and planning phase in Iran. Aust. J. Basic Appl. Sci. 2015, 9, 91–97. [Google Scholar]

- Kunz, J.; Fischer, M. Virtual Design and Construction: Themes, Case Studies and Implementation Suggestions; Center for Integrated Facility Engineering, Stanford University: Stanford, CA, USA, 2012. [Google Scholar]

- McFarlane, A.; Stehle, J. DfMA: Engineering the Future. In Proceedings of the Council on Tall Buildings and Urban Habitat (CTBUH) 2014 Shanghai Conference, Shanghai, China, 16 September 2014; pp. 508–516. [Google Scholar]

- Ross, K.; Cartwright, P.; Novakovic, O. A Guide to Modern Methods of Construction; IHS BRE Press: Bucks, UK, 2006. [Google Scholar]

- Sattineni, A.; Mead, K. Coordination Guidelines for Virtual Design and Construction. In Proceedings of the 30th International Association for Automation and Robotics in Construction, Montreal, QC, Canada, 11–15 August 2013; pp. 1491–1499. [Google Scholar]

- Zahrizan, Z.; Ali, N.M.; Haron, A.T.; Marshall-Ponting, A.; Hamid, Z.A. Exploring the adoption of Building Information Modelling (BIM) in the Malaysian construction industry: A qualitative approach. Int. J. Res. Eng. Technol. 2013, 2, 384–395. [Google Scholar]

- Oo, T.Z. Critical Success Factors for Application of BIM for Singapore Architectural Firms. Master’s Thesis, Heriot-Watt University, Edinburgh, UK, 2014. [Google Scholar]

- Teo, E.A.L.; Chan, S.L.; Tan, P.H. Empirical investigation into factors affecting exporting construction services in SMEs in Singapore. J. Constr. Eng. Manag. 2007, 133, 582–591. [Google Scholar] [CrossRef]

- Hwang, B.G.; Zhu, L.; Tan, J.S.H. Identifying critical success factors for green business parks: Case study of Singapore. J. Manag. Eng. 2017, 33, 04017023. [Google Scholar] [CrossRef]

- Miller, G.A. The magical number seven, plus or minus two: Some limits on our capacity for processing information. Psychol. Rev. 1956, 63, 81–97. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Hwang, B.G.; Low, S.P.; Wu, P. Reducing hindrances to enterprise risk management implementation in construction firms. J. Constr. Eng. Manag. 2014, 141, 04014083. [Google Scholar] [CrossRef]

- Zhao, X.; Hwang, B.G.; Low, S.P. Enterprise risk management in international construction firms: Drivers and hindrances. Eng. Constr. Archit. Manag. 2015, 22, 347–366. [Google Scholar] [CrossRef]

- Liao, L.; Teo, E.A.L. Critical success factors for enhancing the building information modelling implementation in building projects in Singapore. J. Civ. Eng. Manag. 2017, 23, 1029–1044. [Google Scholar] [CrossRef]

- Liao, L.; Teo, E.A.L. Organizational change perspective on people management in BIM implementation in building projects. J. Manag. Eng. 2018, 34, 04018008. [Google Scholar] [CrossRef]

- Wilkins, J.R. Construction workers’ perceptions of health and safety training programmes. Constr. Manag. Econ. 2011, 29, 1017–1026. [Google Scholar] [CrossRef]

- Nunnally, J.C. Psychometric Theory, 2nd ed.; McGraw-Hill: New York, NY, USA, 1978. [Google Scholar]

- Magal, S.R.; Carr, H.H.; Watson, H.J. Critical success factors for information center managers. MIS Q. 1988, 12, 413–425. [Google Scholar] [CrossRef][Green Version]

- Shen, Q.; Liu, G. Critical success factors for value management studies in construction. J. Constr. Eng. Manag. 2003, 129, 485–491. [Google Scholar] [CrossRef]

- Nitithamyong, P.; Skibniewski, M.J. Key success/failure factors and their impacts on system performance of web-based project management systems in construction. J. Inf. Technol. Constr. 2007, 12, 39–59. [Google Scholar]

- Xu, Y.; Yeung, J.F.Y.; Chan, A.P.C.; Chan, D.W.M.; Wang, S.Q.; Ke, Y. Developing a risk assessment model for PPP projects in China—A fuzzy synthetic evaluation approach. Autom. Constr. 2010, 19, 929–943. [Google Scholar] [CrossRef]

- Won, J.; Lee, G.; Dossick, C.; Messner, J. Where to focus for successful adoption of building information modeling within organization. J. Constr. Eng. Manag. 2013, 139, 04013014. [Google Scholar] [CrossRef]

- El Asmar, M.; Hanna, A.S.; Loh, W.Y. Quantifying performance for the integrated project delivery system as compared to established delivery systems. J. Constr. Eng. Manag. 2013, 139, 04013012. [Google Scholar] [CrossRef]

- Peterson, R.A. A meta-analysis of variance accounted for and factor loadings in exploratory factor analysis. Mark. Lett. 2000, 11, 261–275. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 7th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2009. [Google Scholar]

- NIBS. United States National Building Information Modeling Standard Version 1—Part 1: Overview, Principles, and Methodologies; National Institute of Building Sciences: Washington, DC, USA, 2007. [Google Scholar]

- Anumba, C.; Dubler, C.; Goodman, S.; Kasprzak, C.; Kreider, R.; Messner, J.; Saluja, C.; Zikic, N. BIM Project Execution Planning Guide—Version 2.0; Computer Integrated Construction Research Program, Pennsylvania State University: University Park, PA, USA, 2010. [Google Scholar]

- Lim, B.T.H.; Ling, F.Y.Y.; Ibbs, C.W.; Raphael, B.; Ofori, G. Mathematical models for predicting organizational flexibility of construction firms in Singapore. J. Constr. Eng. Manag. 2012, 138, 361–375. [Google Scholar] [CrossRef]

- Reinartz, W.; Haenlein, M.; Henseler, J. An empirical comparison of the efficacy of covariance-based and variance-based SEM. Int. J. Res. Mark. 2009, 26, 332–344. [Google Scholar] [CrossRef]

- Fornell, C.; Bookstein, F.L. Two structural equation models: LISREL and PLS applied to consumer exit-voice theory. J. Mark. Res. 1982, 19, 440–452. [Google Scholar] [CrossRef]

- Hair, J.F.; Sarstedt, M.; Pieper, T.M.; Ringle, C.M. The use of partial least squares structural equation modeling in strategic management research: A review of past practices and recommendations for future applications. Long Range Plan. 2012, 45, 320–340. [Google Scholar] [CrossRef]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. PLS-SEM: Indeed a silver bullet. J. Mark. Theory Pract. 2011, 19, 139–151. [Google Scholar] [CrossRef]

- Doloi, H. Rationalizing the implementation of web-based project management systems in construction projects using PLS-SEM. J. Constr. Eng. Manag. 2014, 140, 04014026. [Google Scholar] [CrossRef]

- Le, Y.; Shan, M.; Chan, A.P.C.; Hu, Y. Investigating the causal relationships between causes of and vulnerabilities to corruption in the Chinese public construction sector. J. Constr. Eng. Manag. 2014, 140, 05014007. [Google Scholar] [CrossRef]

- Davison, A.C.; Hinkley, D.V. Bootstrap Methods and Their Application; Cambridge University Press: New York, NY, USA, 1997. [Google Scholar]

- Tabachnick, B.G.; Fidell, L.S. Using Multivariate Statistics, 5th ed.; Pearson/Allyn & Bacon: Boston, MA, USA, 2007. [Google Scholar]

- Fornell, C.; Larcker, D.F. Evaluating structural equation models with unobservable variables and measurement error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Barclay, D.W.; Higgins, C.A.; Thompson, R. The partial least squares approach to causal modeling: Personal computer adoption and use as illustration. Technol. Stud. 1995, 2, 285–309. [Google Scholar]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A new criterion for assessing discriminant validity in variance-based structural equation modelling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef]

- Low, S.P. Managing total service quality: A systemic view. Manag. Serv. Qual. 1998, 8, 34–45. [Google Scholar]

- Rezgui, Y.; Beach, T.; Rana, O. A governance approach for BIM management across lifecycle and supply chains using mixed-modes of information delivery. J. Civ. Eng. Manag. 2013, 19, 239–258. [Google Scholar] [CrossRef]

- Ma, Z.; Ma, J. Formulating the application functional requirements of a BIM-based collaboration platform to support IPD projects. KSCE J. Civ. Eng. 2017, 21, 2011–2026. [Google Scholar] [CrossRef]

- Wickersham, J. Legal and Business Implications of Building Information Modeling (BIM) and Integrated Project Delivery (IPD), BIM-IPD Legal and Business Issues; Rocket Press Publishing: Lafayette, LA, USA, 2009. [Google Scholar]

- Teo, A.L.; Heng, P.S.N. Deployment Framework to Promote the Adoption of Automated Quantities Taking-Off System. In Proceedings of the CRIOCM2007 International Research Symposium on Advancement of Construction Management and Real Estate, Sydney, Australia, 8–13 August 2007; Zou, P.X.W., Newton, S., Wang, J., Eds.; Chinese Research Institute of Construction Management: Hong Kong, China, 2007. [Google Scholar]

- Smith, P. BIM implementation—Global strategies. Procedia Eng. 2014, 85, 482–492. [Google Scholar] [CrossRef]

- McAuley, B.; Hore, A.; West, R. BICP Global BIM Study–Lessons for Ireland’s BIM Programme; Dublin Institute of Technology: Dublin, Ireland, 2017. [Google Scholar]

| Code | Hindrances to BIM Implementation | References | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | ||

| H01 | Executives failing to recognize the value of BIM-based processes and needing training | √ | √ | √ | √ | √ | √ | ||||||||||||||||||||

| H02 | Concerns over or uninterested in sharing liabilities and financial rewards | √ | √ | √ | √ | √ | √ | ||||||||||||||||||||

| H03 | Construction lawyers and insurers lacking understanding of roles/responsibilities in new process | √ | √ | √ | |||||||||||||||||||||||

| H04 | Lack of skilled employees and need for training them on BIM and off-site manufacture (OSM) | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||

| H05 | Industry’s conservativeness, fear of the unknown, and resistance to change comfortable routines | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||||

| H06 | Employees still being reluctant to use new technology after being pushed to training programs | √ | √ | √ | |||||||||||||||||||||||

| H07 | Entrenchment in two-dimensional (2D) drafting and unfamiliarity to use BIM | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||||

| H08 | Financial benefits cannot outweigh implementation and maintenance costs | √ | √ | √ | √ | √ | |||||||||||||||||||||

| H09 | Lack of sufficient evidence to warrant BIM use | √ | √ | √ | √ | √ | |||||||||||||||||||||

| H10 | Liability of BIM such as the liability for common data for subcontractors | √ | √ | √ | |||||||||||||||||||||||

| H11 | Resistance to changes in corporate culture and structure | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||||||

| H12 | Need for all key stakeholders to be on board to exchange information | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||||||

| H13 | Lack of trust/transparency/communication/partnership and collaboration skills | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||||

| H14 | BIM operators lacking field knowledge | √ | √ | √ | |||||||||||||||||||||||

| H15 | Field staff dislike BIM coordination meetings looking at a screen | √ | |||||||||||||||||||||||||

| H16 | Lack of consultants’ feedbacks on subcontractors’ model coordination | √ | |||||||||||||||||||||||||

| H17 | Few benefits from BIM go to designers while most to contractors and owners | √ | |||||||||||||||||||||||||

| H18 | Lack of legal support from authorities | √ | √ | √ | √ | ||||||||||||||||||||||

| H19 | Lack of owner request or initiative to adopt BIM | √ | √ | √ | √ | ||||||||||||||||||||||

| H20 | Decision-making depending on relationships between project stakeholders | √ | √ | ||||||||||||||||||||||||

| H21 | Owners set minimal risk and minimum first cost as crucial selection criteria | √ | √ | ||||||||||||||||||||||||

| H22 | Poor knowledge of using OSM and assessing its benefits | √ | |||||||||||||||||||||||||

| H23 | Requiring higher onsite skills to deal with low tolerance OSM interfaces | √ | |||||||||||||||||||||||||

| H24 | OSM relies on suppliers to train contractors to install correctly | √ | |||||||||||||||||||||||||

| H25 | Owners’ desire for particular structures or finishes when considering OSM | √ | |||||||||||||||||||||||||

| H26 | Market protection from traditional suppliers/manufacturers and limited OSM expertise | √ | |||||||||||||||||||||||||

| H27 | Contractual relationships among stakeholders and need for new frameworks | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | ||||||||||||||

| H28 | Traditional contracts protect individualism rather than best-for-project thinking | √ | √ | √ | |||||||||||||||||||||||

| H29 | Lack of effective data interoperability between project stakeholders | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||

| H30 | Owners cannot receive low-price bids if requiring three-dimensional models | √ | |||||||||||||||||||||||||

| H31 | Firms’ unwillingness to invest in training due to initial cost and productivity loss | √ | √ | √ | √ | ||||||||||||||||||||||

| H32 | Assignment of responsibility/risk to constant updating for broadly accessible BIM information | √ | √ | ||||||||||||||||||||||||

| H33 | Lack of standard contracts to deal with responsibility/risk assignment and BIM ownership | √ | √ | √ | √ | √ | |||||||||||||||||||||

| H34 | BIM model issues (such as ownership and management) | √ | √ | √ | √ | ||||||||||||||||||||||

| H35 | Poor understanding of OSM process and its associated costs | √ | |||||||||||||||||||||||||

| H36 | OSM requires design to be fixed early using BIM | √ | √ | ||||||||||||||||||||||||

| H37 | Seeing design fees of OSM as more expensive than traditional process | √ | |||||||||||||||||||||||||

| H38 | Difficulty in logistics and stock management of OSM | √ | √ | ||||||||||||||||||||||||

| H39 | Unclear legislations and qualifications for precasters and inadequate codes for OSM varieties | √ | |||||||||||||||||||||||||

| H40 | Interpretations resulted from unclear contract documents | √ | |||||||||||||||||||||||||

| H41 | Using monetary incentive for team collaboration results in blaming rather than resolving issues | √ | |||||||||||||||||||||||||

| H42 | Costly investment in BIM hardware and software solutions | √ | √ | √ | √ | √ | √ | √ | √ | √ | |||||||||||||||||

| H43 | Interoperability issues such as software selection and insufficient standards | √ | √ | √ | √ | √ | |||||||||||||||||||||

| H44 | Need for increasingly specialized software for specialized functions | √ | √ | √ | √ | ||||||||||||||||||||||

| H45 | Difficulty in multi-discipline and construction-level integration | √ | √ | ||||||||||||||||||||||||

| H46 | Technical needs for multiuser model access in multi-discipline integration | √ | √ | √ | |||||||||||||||||||||||

| H47 | Firms cannot make most use of Industrial Foundation Classes (IFC) and use proprietary formats | √ | √ | √ | |||||||||||||||||||||||

| Characteristics | Categorization | N | % | Characteristics | Categorization | N | % |

|---|---|---|---|---|---|---|---|

| Respondents | Organizations | ||||||

| Discipline | Government agent | 2 | 2.3 | Main business | Architectural firm | 18 | 20.7 |

| Developer | 5 | 5.7 | Structural engineering firm | 6 | 6.9 | ||

| Architect | 21 | 24.1 | MEP engineering firm | 13 | 14.9 | ||

| Structural designer | 9 | 10.3 | General construction firm | 30 | 34.5 | ||

| MEP designer | 9 | 10.3 | Trade construction firm | 3 | 3.4 | ||

| General contractor | 28 | 32.2 | Facility management firm | 3 | 3.4 | ||

| Subcontractor | 6 | 6.9 | Others | 14 | 16.1 | ||

| Supplier/Manufacturer | 2 | 2.3 | |||||

| Facility manager | 5 | 5.7 | |||||

| Work experience | 5–10 years | 39 | 44.8 | Years of BIM implementation | 0 | 9 | 10.3 |

| 11–15 years | 10 | 11.5 | 1–3 | 41 | 47.1 | ||

| 16–20 years | 8 | 9.2 | 4–5 | 22 | 25.3 | ||

| 21–25 years | 9 | 10.3 | 6–10 | 13 | 14.9 | ||

| >25 years | 21 | 24.1 | >10 | 2 | 2.3 | ||

| Code | Mean | Rank | Normalization * | Code | Mean | Rank | Normalization * | Code | Mean | Rank | Normalization * |

|---|---|---|---|---|---|---|---|---|---|---|---|

| H01 | 3.644 | 8 | 0.782 | H17 | 3.161 | 46 | 0.018 | H33 | 3.540 | 13 | 0.618 |

| H02 | 3.494 | 20 | 0.545 | H18 | 3.184 | 45 | 0.055 | H34 | 3.529 | 14 | 0.600 |

| H03 | 3.241 | 41 | 0.145 | H19 | 3.414 | 26 | 0.418 | H35 | 3.506 | 19 | 0.564 |

| H04 | 3.690 | 3 | 0.855 | H20 | 3.264 | 40 | 0.182 | H36 | 3.494 | 20 | 0.545 |

| H05 | 3.678 | 5 | 0.836 | H21 | 3.345 | 34 | 0.309 | H37 | 3.448 | 22 | 0.473 |

| H06 | 3.414 | 26 | 0.418 | H22 | 3.333 | 35 | 0.291 | H38 | 3.402 | 30 | 0.400 |

| H07 | 3.690 | 3 | 0.855 | H23 | 3.402 | 30 | 0.400 | H39 | 3.241 | 41 | 0.145 |

| H08 | 3.368 | 33 | 0.345 | H24 | 3.241 | 41 | 0.145 | H40 | 3.391 | 32 | 0.382 |

| H09 | 3.529 | 14 | 0.600 | H25 | 3.149 | 47 | 0.000 | H41 | 3.218 | 44 | 0.109 |

| H10 | 3.310 | 37 | 0.255 | H26 | 3.414 | 26 | 0.418 | H42 | 3.667 | 6 | 0.818 |

| H11 | 3.414 | 26 | 0.418 | H27 | 3.713 | 2 | 0.891 | H43 | 3.517 | 17 | 0.582 |

| H12 | 3.782 | 1 | 1.000 | H28 | 3.655 | 7 | 0.800 | H44 | 3.425 | 23 | 0.436 |

| H13 | 3.310 | 37 | 0.255 | H29 | 3.425 | 23 | 0.436 | H45 | 3.529 | 14 | 0.600 |

| H14 | 3.621 | 10 | 0.745 | H30 | 3.299 | 39 | 0.236 | H46 | 3.644 | 8 | 0.782 |

| H15 | 3.425 | 23 | 0.436 | H31 | 3.621 | 10 | 0.745 | H47 | 3.563 | 12 | 0.655 |

| H16 | 3.322 | 36 | 0.273 | H32 | 3.517 | 17 | 0.582 | – | – | – | – |

| Code | Hindrances to BIM Implementation | Communality | Hindrance Grouping | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| Grouping 1: Lack of Collaboration and Model Integration (LCMI) | |||||

| H34 | BIM model issues (such as ownership and management) | 0.757 | 0.948 | — | — |

| H09 | Lack of sufficient evidence to warrant BIM use | 0.515 | 0.707 | — | — |

| H36 | OSM requires design to be fixed early using BIM | 0.701 | 0.707 | — | — |

| H45 | Difficulty in multi-discipline and construction-level integration | 0.512 | 0.657 | — | — |

| H35 | Poor understanding of OSM process and its associated costs | 0.712 | 0.646 | — | — |

| H46 | Technical needs for multiuser model access in multi-discipline integration | 0.587 | 0.545 | — | — |

| H33 | Lack of standard contracts to deal with responsibility/risk assignment and BIM ownership | 0.727 | 0.524 | — | — |

| H27 | Contractual relationships among stakeholders and need for new frameworks | 0.649 | 0.516 | — | — |

| H28 | Traditional contracts protect individualism rather than best-for-project thinking | 0.574 | 0.463 | — | — |

| H43 | Interoperability issues such as software selection and insufficient standards | 0.594 | 0.431 | — | — |

| Grouping 2: Lack of Continuous Involvement and Capabilities (LCIC) | |||||

| H12 | Need for all key stakeholders to be on board to exchange information | 0.673 | — | 0.780 | — |

| H07 | Entrenchment in 2D drafting and unfamiliarity to use BIM | 0.712 | — | 0.760 | — |

| H14 | BIM operators lacking field knowledge | 0.676 | — | 0.739 | — |

| H42 | Costly investment in BIM hardware and software solutions | 0.630 | — | 0.652 | — |

| H32 | Assignment of responsibility/risk to constant updating for broadly accessible BIM information | 0.568 | — | 0.600 | — |

| H31 | Firms’ unwillingness to invest in training due to initial cost and productivity loss | 0.555 | — | 0.557 | — |

| Groping 3: Lack of Executive Vision and Training (LEVT) | |||||

| H01 | Executives failing to recognize the value of BIM-based processes and needing training | 0.758 | — | — | 0.814 |

| H04 | Lack of skilled employees and need for training them on BIM and OSM | 0.725 | — | — | 0.770 |

| H02 | Concerns over or uninterested in sharing liabilities and financial rewards | 0.537 | — | — | 0.654 |

| H05 | Industry’s conservativeness, fear of the unknown, and resistance to change comfortable routines | 0.699 | — | — | 0.620 |

| H47 | Firms cannot make most use of IFC and use proprietary formats | 0.596 | — | — | 0.554 |

| Eigenvalue | 11.142 | 1.256 | 1.057 | ||

| Variance (%) | 53.059 | 5.979 | 5.033 | ||

| CPV (%) | 53.059 | 59.038 | 64.070 | ||

| Grouping | Hindrance Code | Factor Loading | p-Value | AVE | Cronbach’s Alpha | CR |

|---|---|---|---|---|---|---|

| LCMI | H34 | 0.813 | 0.000 * | 0.618 | 0.931 | 0.942 |

| H09 | 0.680 | 0.000 * | ||||

| H36 | 0.848 | 0.000 * | ||||

| H45 | 0.706 | 0.000 * | ||||

| H35 | 0.849 | 0.000 * | ||||

| H46 | 0.766 | 0.000 * | ||||

| H33 | 0.850 | 0.000 * | ||||

| H27 | 0.798 | 0.000 * | ||||

| H28 | 0.770 | 0.000 * | ||||

| H43 | 0.762 | 0.000 * | ||||

| LCIC | H12 | 0.798 | 0.000 * | 0.622 | 0.878 | 0.908 |

| H07 | 0.825 | 0.000 * | ||||

| H14 | 0.833 | 0.000 * | ||||

| H42 | 0.803 | 0.000 * | ||||

| H32 | 0.711 | 0.000 * | ||||

| H31 | 0.757 | 0.000 * | ||||

| LEVT | H01 | 0.866 | 0.000 * | 0.624 | 0.848 | 0.892 |

| H04 | 0.847 | 0.000 * | ||||

| H02 | 0.756 | 0.000 * | ||||

| H05 | 0.732 | 0.000 * | ||||

| H47 | 0.739 | 0.000 * |

| HTMT | Original Sample | Sample Mean | t-Value | p-Value |

|---|---|---|---|---|

| LEVT→LCIC | 0.829 | 0.831 | 9.797 | 0.000 |

| LCIC→LCMI | 0.879 | 0.880 | 10.937 | 0.000 |

| LEVT→LCMI | 0.866 | 0.866 | 19.653 | 0.000 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, L.; Teo, E.A.L.; Chang, R. Reducing Critical Hindrances to Building Information Modeling Implementation: The Case of the Singapore Construction Industry. Appl. Sci. 2019, 9, 3833. https://doi.org/10.3390/app9183833

Liao L, Teo EAL, Chang R. Reducing Critical Hindrances to Building Information Modeling Implementation: The Case of the Singapore Construction Industry. Applied Sciences. 2019; 9(18):3833. https://doi.org/10.3390/app9183833

Chicago/Turabian StyleLiao, Longhui, Evelyn Ai Lin Teo, and Ruidong Chang. 2019. "Reducing Critical Hindrances to Building Information Modeling Implementation: The Case of the Singapore Construction Industry" Applied Sciences 9, no. 18: 3833. https://doi.org/10.3390/app9183833

APA StyleLiao, L., Teo, E. A. L., & Chang, R. (2019). Reducing Critical Hindrances to Building Information Modeling Implementation: The Case of the Singapore Construction Industry. Applied Sciences, 9(18), 3833. https://doi.org/10.3390/app9183833