Modal Strain Energy-Based Structural Damage Detection Using Convolutional Neural Networks

Abstract

1. Introduction

2. Methods

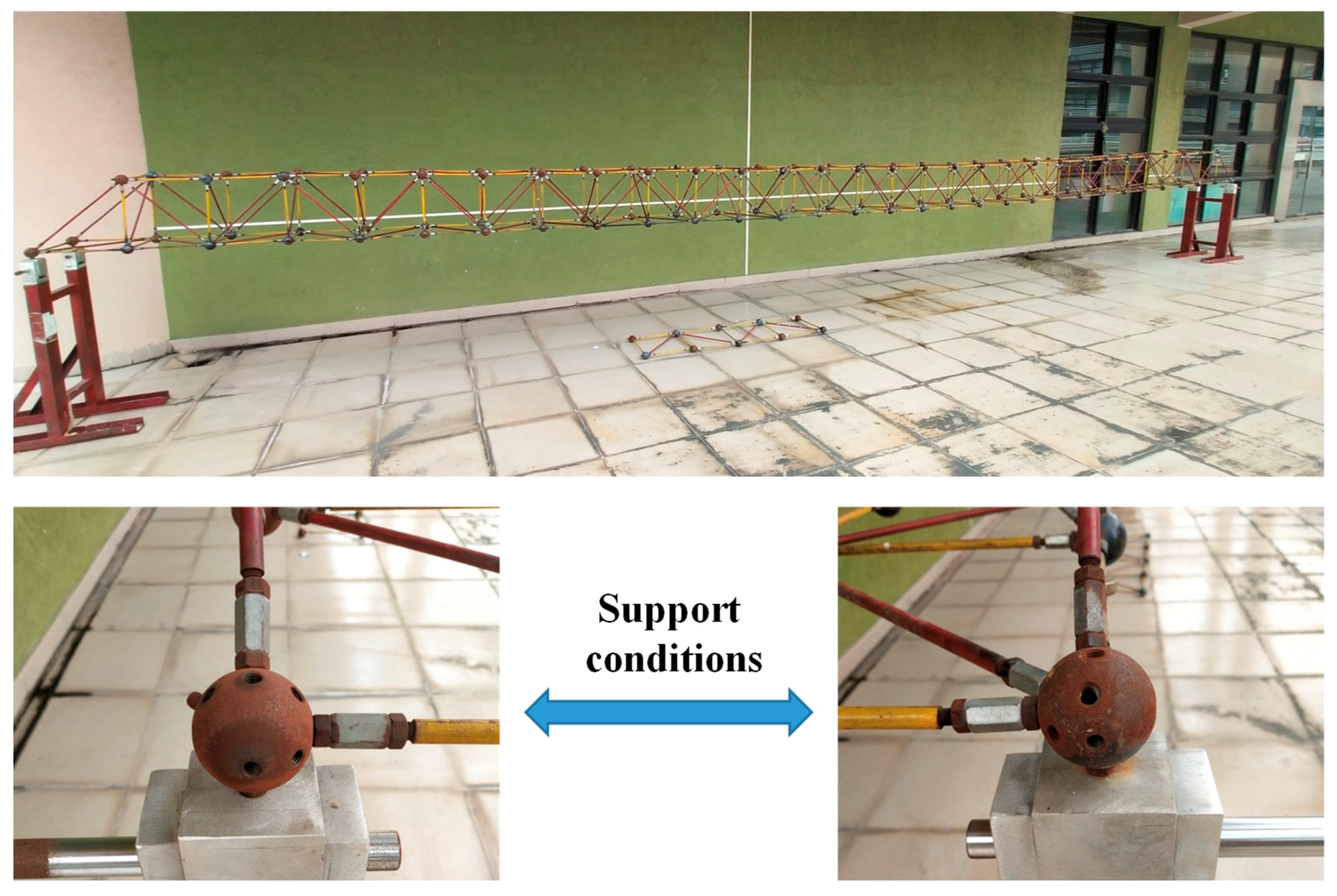

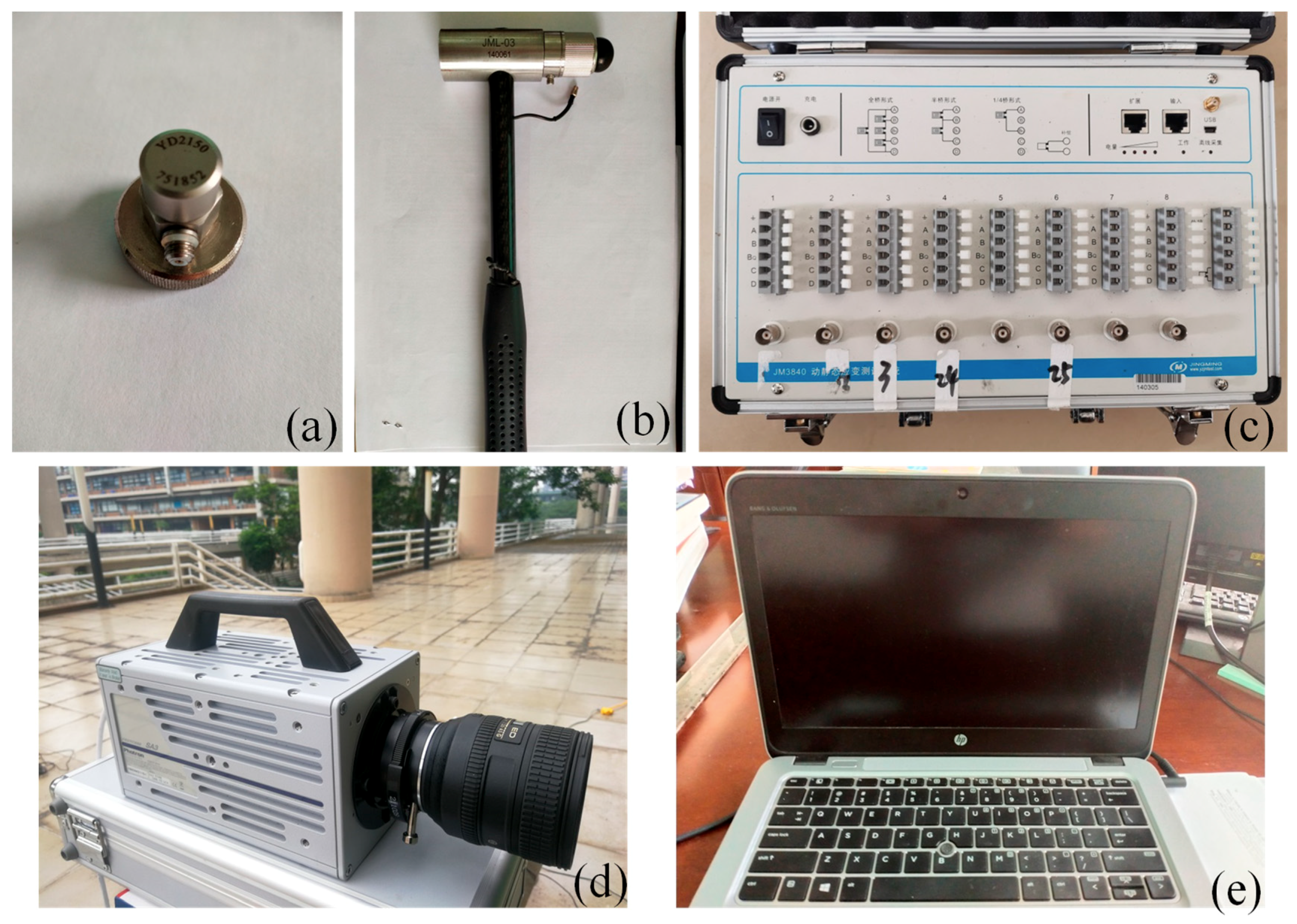

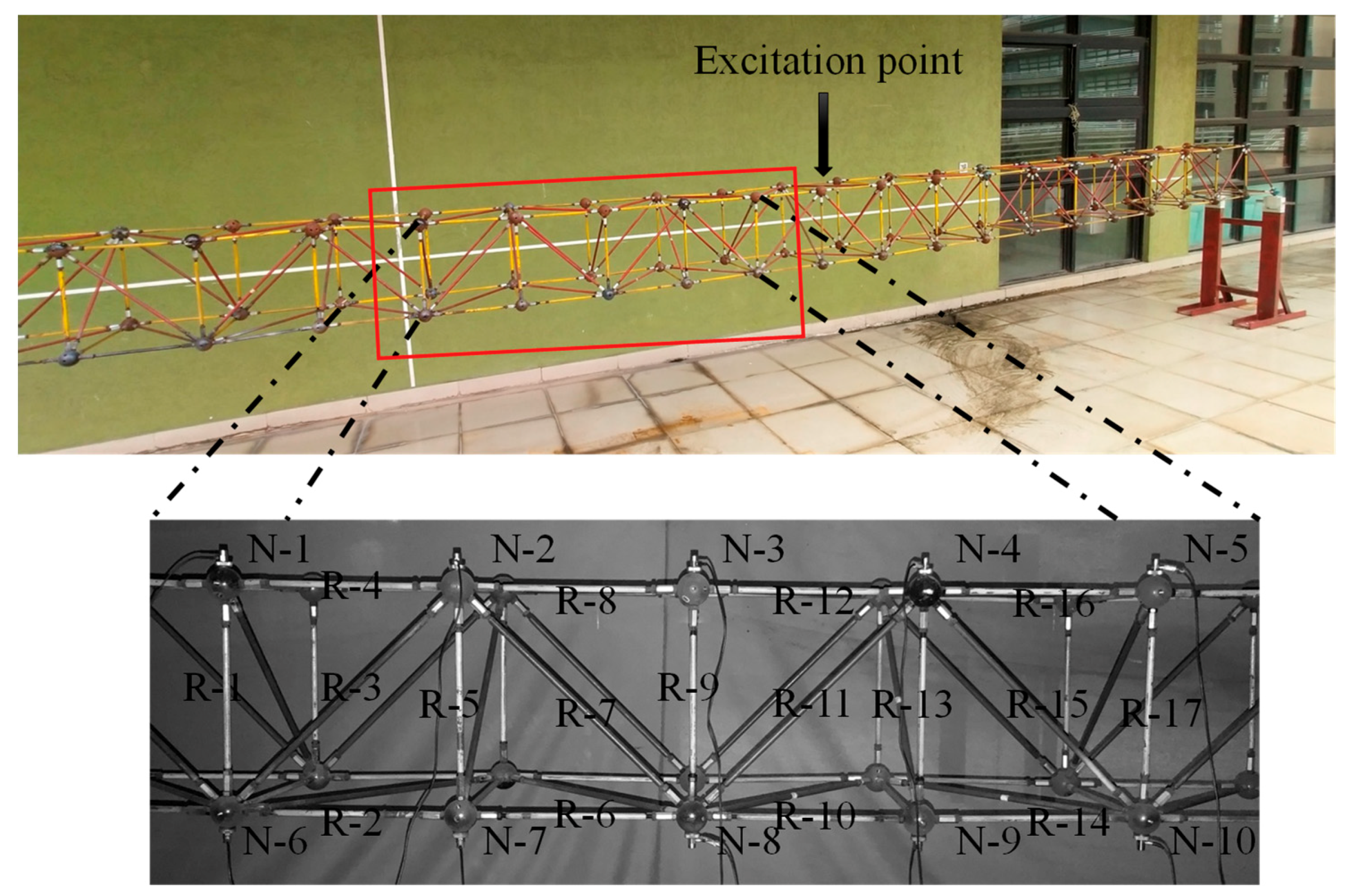

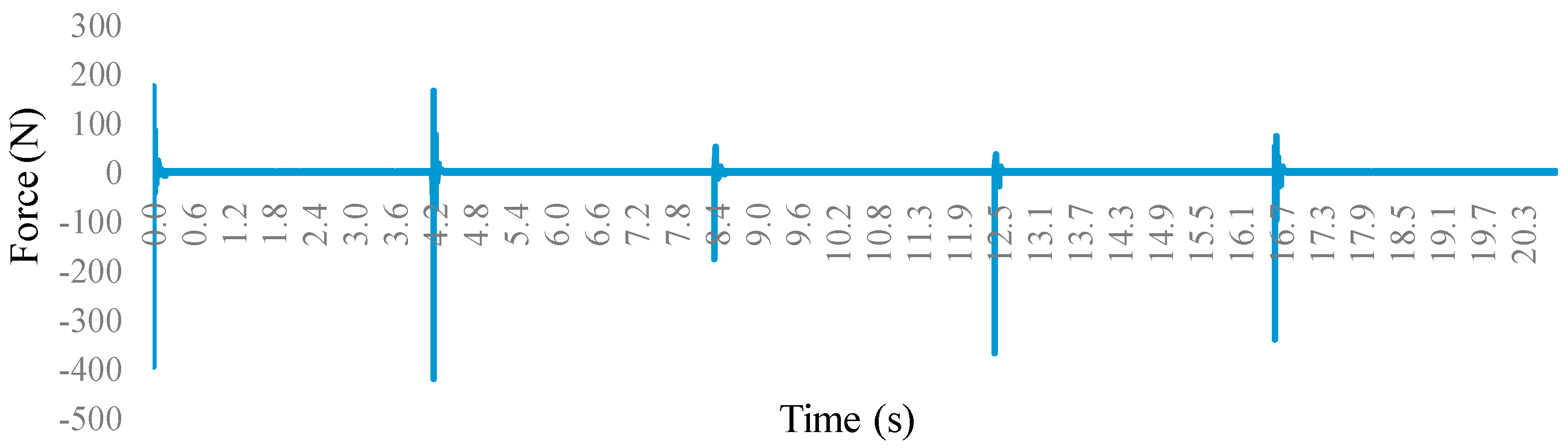

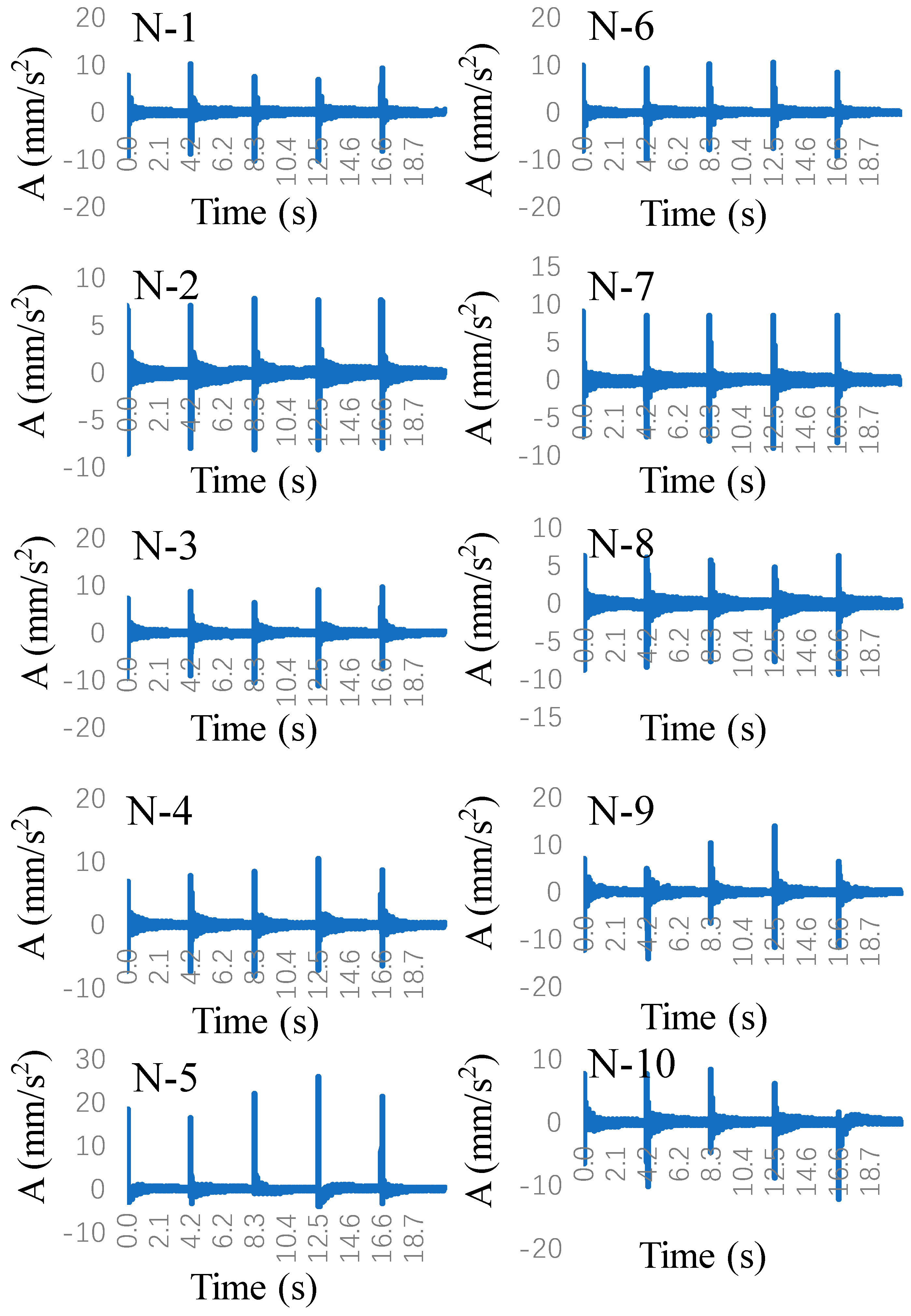

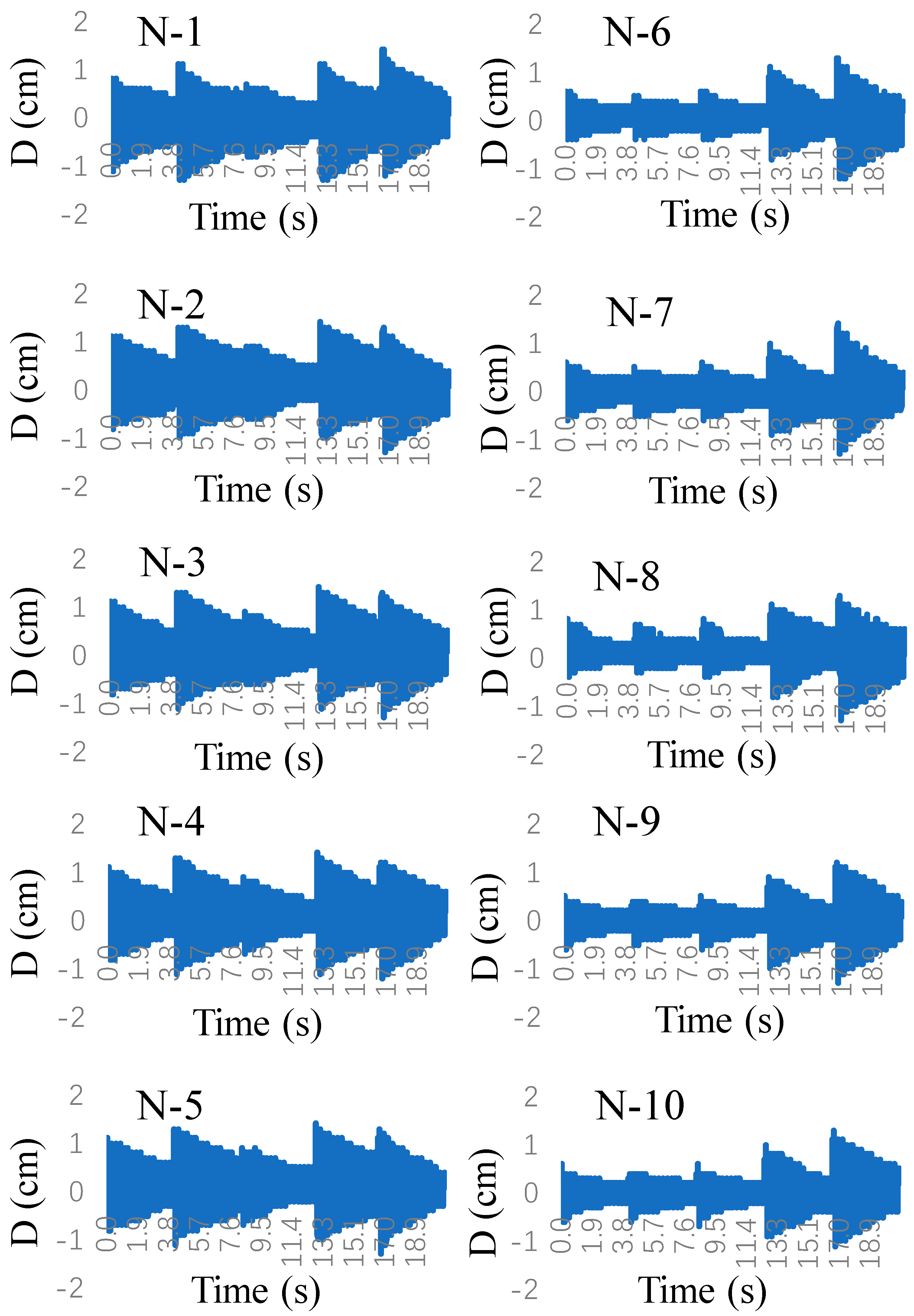

2.1. Vibration Experiment

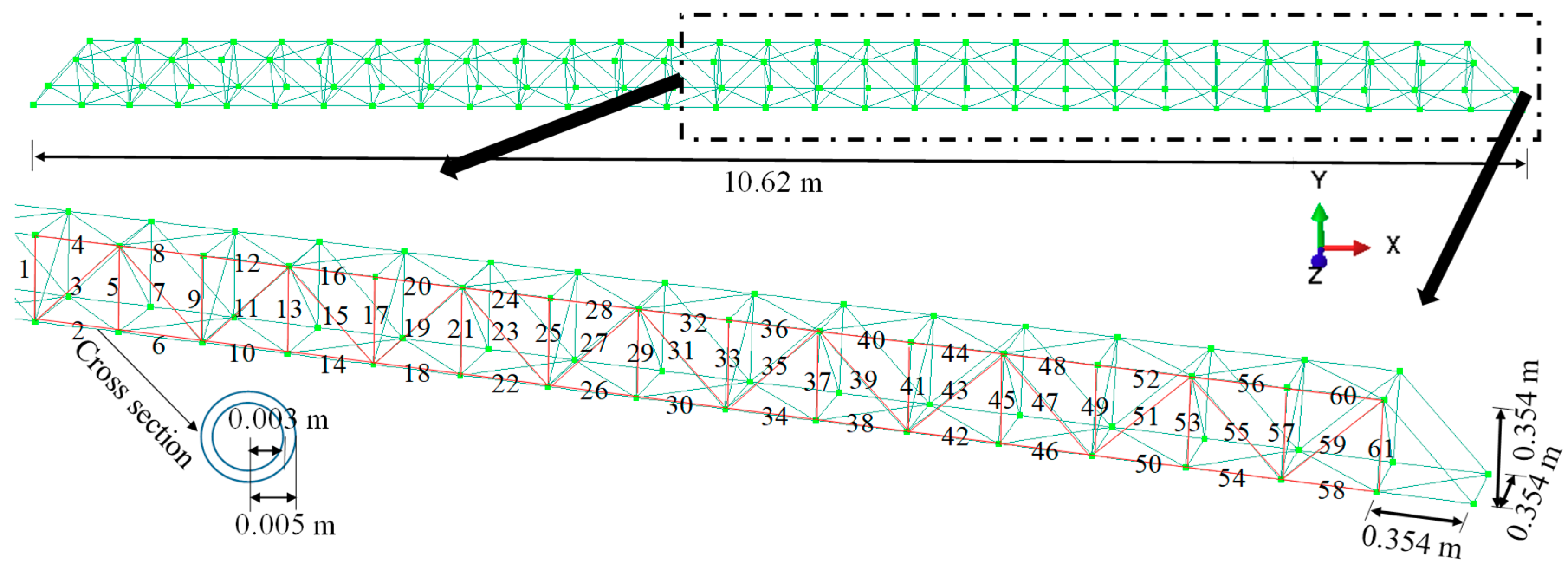

2.2. Numerical Simulation and CNN Samples

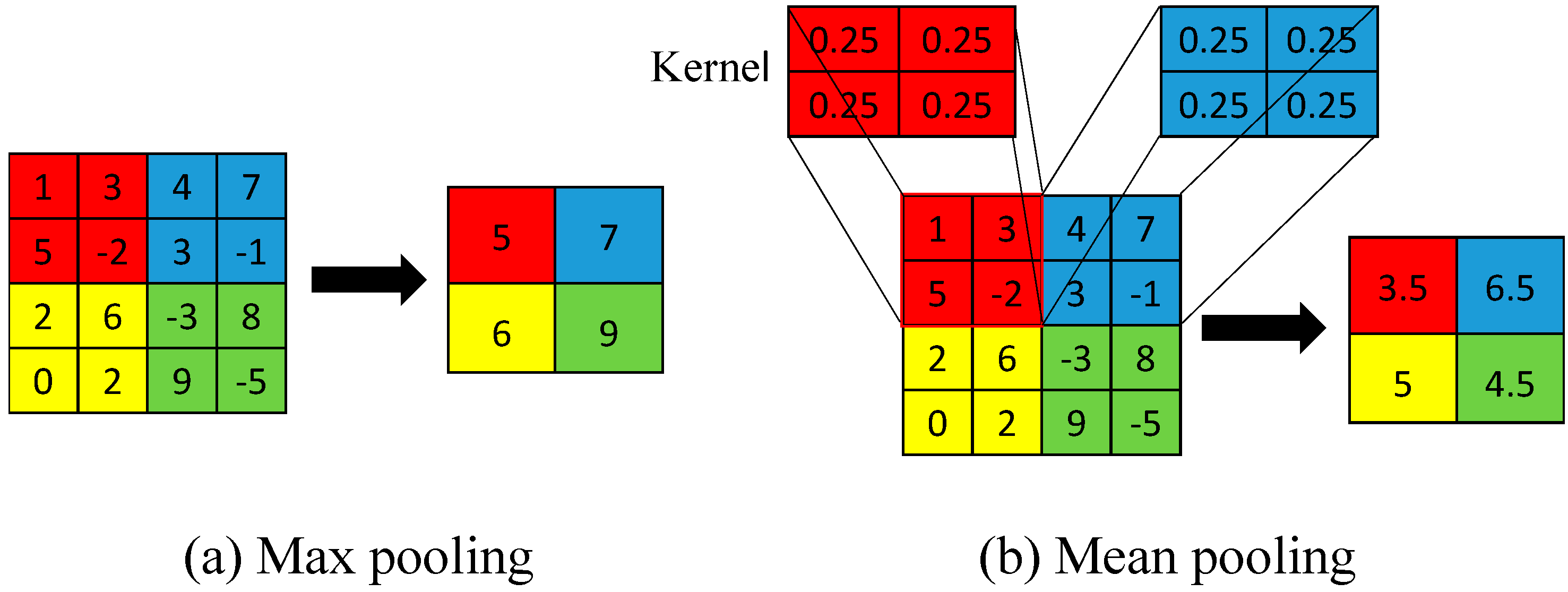

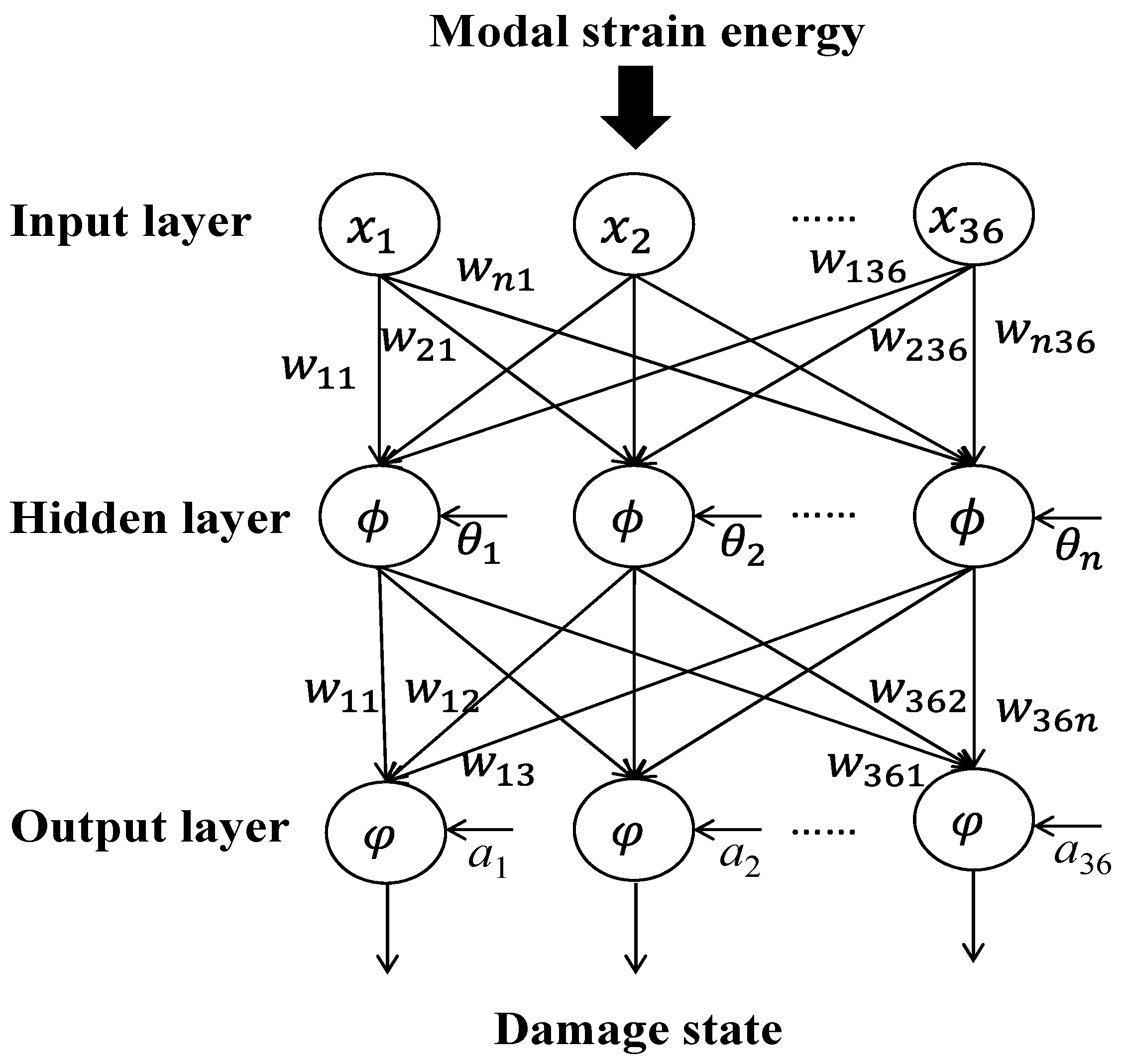

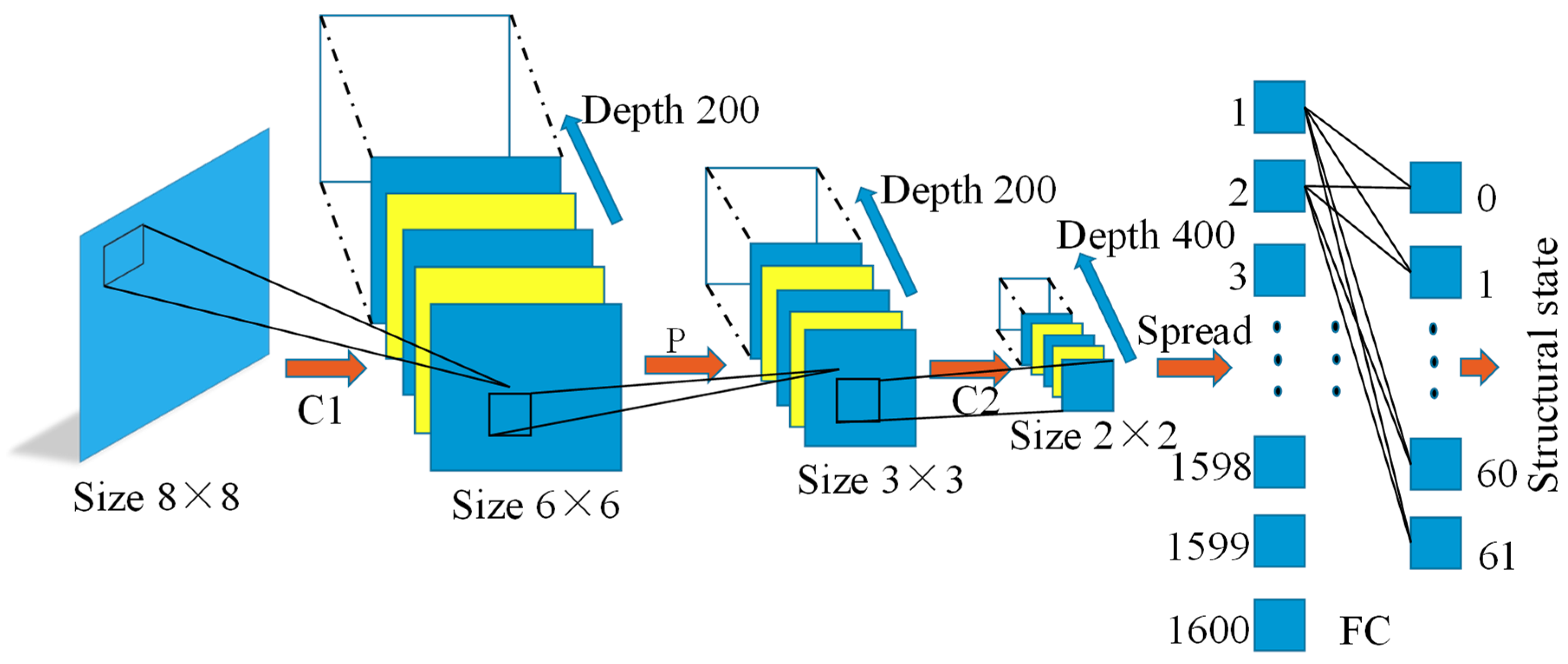

2.3. Convolutional Neural Network

2.4. Input and Output of CNN Samples

3. Results

3.1. Experimental Results

3.2. Structural Damage Detection

3.3. Damage Detection by BP Neural Network

4. Discussion and Conclusions

- As a classifier, the CNN can accurately detect structural damage.

- The CNN was more effective than the BP neural network in damage detection.

- The experimental verifications proved that the CNN can be trained by simulation data and applied to measured data.

- It was feasible to supplement the missing data of the experiment with the simulated data in the CNN input.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Appendix A

Appendix B

| Rod | State (2) | State (3) | State (4) |

|---|---|---|---|

| 1 | 0.183261 | 0.133159 | 0.750995 |

| 2 | 1 | 0.561122 | 1 |

| 3 | 0.122337 | 0.052117 | 0.232933 |

| 4 | 0.010588 | 0.068908 | 0.006570 |

| 5 | 0.011635 | 0.004779 | 0.026812 |

| 6 | 0.010611 | 0.082343 | 0.036997 |

| 7 | 0.004757 | 0.051624 | 0.012947 |

| 8 | 0.002340 | 0.051331 | 0.005684 |

| 9 | 0.008731 | 0.000386 | 0.004622 |

| 10 | 0.005128 | 0.073452 | 0.003947 |

| 11 | 0.007889 | 1 | 0.176934 |

| 12 | 0.012425 | 0.136464 | 0.003921 |

| 13 | 0.010072 | 0.093422 | 0.001367 |

| 14 | 0.006658 | 0.32554 | 0.009835 |

| 15 | 0.009221 | 0.054808 | 0.003069 |

| 16 | 0.011306 | 0.04327 | 0.00168 |

| 17 | 0.004889 | 0.008927 | 0.002931 |

| Rod | State (2) | State (3) | State (4) |

|---|---|---|---|

| 1 | 0.001567 | 0.102416 | 0.023301 |

| 2 | 1 | 0.057157 | 0.252800 |

| 3 | 0.862905 | 0.232290 | 0.070087 |

| 4 | 0.057893 | 0.225977 | 0.101593 |

| 5 | 0.070384 | 0.014668 | 1 |

| 6 | 0.579681 | 0.058479 | 0.017674 |

| 7 | 0.080107 | 0.034538 | 0.089115 |

| 8 | 0.434859 | 0.694200 | 0.005681 |

| 9 | 0.093982 | 0.343020 | 0.209198 |

| 10 | 0.120254 | 0.067707 | 0.001401 |

| 11 | 0.052387 | 1 | 0.632459 |

| 12 | 0.074442 | 0.108921 | 0.038028 |

| 13 | 0.120096 | 0.127849 | 0.100525 |

| 14 | 0.080986 | 0.089165 | 0.027459 |

| 15 | 0.081881 | 0.187616 | 0.015737 |

| 16 | 0.125719 | 0.454498 | 0.020225 |

| 17 | 0.136011 | 0.312810 | 0.011164 |

Appendix C

References

- Khatir, S.; Abdel Wahab, M. A computational approach for crack identification in plate structures using XFEM, XIGA, PSO and Jaya algorithm. Theor. Appl. Fract. Mech. 2019, 103, 102240. [Google Scholar] [CrossRef]

- Cha, Y.; Buyukozturk, O. Structural Damage Detection Using Modal Strain Energy and Hybrid Multiobjective Optimization. Comput. Aided Civ. Infrastruct. Eng. 2015, 30, 347–358. [Google Scholar] [CrossRef]

- Graybeal, B.A.; Phares, B.M.; Rolander, D.D.; Moore, M.; Washer, G. Visual Inspection of Highway Bridges. J. Nondestruct. Eval. 2002, 21, 67–83. [Google Scholar] [CrossRef]

- Hu, H.; Wu, C. Development of scanning damage index for the damage detection of plate structures using modal strain energy method. Mech. Syst. Signal Process. 2009, 23, 274–287. [Google Scholar] [CrossRef]

- Doebling, S.; Farrar, C.; Prime, M. A Summary Review of Vibration-Based Damage Identification Methods. Shock. Vib. Dig. 1998, 30, 91–105. [Google Scholar] [CrossRef]

- Khatir, S.; Tiachacht, S.; Le Thanh, C.; Khatir, T.; Capozucca, R.; Abdel Wahab, M. Damage Detection in Laminated Composite Plates Based on Local Frequency Change Ratio Indicator. In Proceedings of the 13th International Conference on Damage Assessment of Structures, Porto, Portugal, 9–10 July 2019; pp. 887–898. [Google Scholar]

- Cawley, P.; Adams, R.D. A Vibration Technique for Non-Destructive Testing of Fibre Composite Structures. J. Compos. Mater. 1979, 13, 161–175. [Google Scholar] [CrossRef]

- Cawley, P.; Adams, R.D. The location of defects in structures from measurements of natural frequencies. J. Strain Anal. Eng. Des. 1979, 14, 49–57. [Google Scholar] [CrossRef]

- Shen, M.H.H.; Grady, J.E. Free vibrations of delaminated beams. Aiaa J. 1992, 30, 1361–1370. [Google Scholar] [CrossRef]

- Pandey, A.K.; Biswas, M.; Samman, M.M. Damage detection from changes in curvature mode shapes. J. Sound Vib. 1991, 145, 321–332. [Google Scholar] [CrossRef]

- Zou, Y.; Tong, L.; Steven, G.P. Vibration-based model-dependent damage (delamination) identification and health monitoring for composite structures—A review. J. Sound Vib. 2017, 10, 165–193. [Google Scholar] [CrossRef]

- Shi, Z.Y.; Law, S.S.; Zhang, L.M. Structural damage localization from modal strain energy change. J. Eng. Mech. 2000, 218, 1216–1223. [Google Scholar] [CrossRef]

- Seyedpoor, S.M. A two stage method for structural damage detection using a modal strain energy based index and particle swarm optimization. Int. J. Non-Linear Mech. 2012, 47, 1–8. [Google Scholar] [CrossRef]

- Pal, J.; Banerjee, S. A combined modal strain energy and particle swarm optimization for health monitoring of structures. J. Civ. Struct. Health Monit. 2015, 5, 353–363. [Google Scholar] [CrossRef]

- Khatir, S.; Abdel Wahab, M.; Boutchicha, D.; Khatir, T. Structural health monitoring using modal strain energy damage indicator coupled with teaching-learning-based optimization algorithm and isogoemetric analysis. J. Sound Vib. 2019, 448, 230–246. [Google Scholar] [CrossRef]

- Kaveh, A.; Zolghadr, A. Cyclical Parthenogenesis Algorithm for guided modal strain energy based structural damage detection. Appl. Soft Comput. 2017, 57, 250–264. [Google Scholar] [CrossRef]

- Tran-Ngoc, H.; Khatir, S.; Roeck, G.D.; Bui-Tien, T.; Nguyen-Ngoc, L. Model Updating for Nam O Bridge Using Particle Swarm Optimization Algorithm and Genetic Algorithm. Sensors 2018, 18, 4131. [Google Scholar] [CrossRef] [PubMed]

- Guresen, E.; Kayakutlu, G. Definition of artificial neural networks with comparison to other networks. Procedia Comput. Sci. 2011, 3, 426–433. [Google Scholar] [CrossRef]

- Salehi, H.; Das, S.; Chakrabartty, S.; Biswas, S.; Burgueño, R. Structural damage identification using image-based pattern recognition on event-based binary data generated from self-powered sensor networks. Struct. Control Health Monit. 2018, 25, e2135. [Google Scholar] [CrossRef]

- Xu, H.; Humar, J.M. Damage Detection in a Girder Bridge by Artificial Neural Network Technique. Comput. Aided Civ. Infrastruct. Eng. 2010, 21, 450–464. [Google Scholar] [CrossRef]

- Yao, X. Evolutionary Artificial Neural Networks. Int. J. Neural Syst. 1993, 4, 203–222. [Google Scholar] [CrossRef]

- Yao, W.S. The Researching Overview of Evolutionary Neural Networks. Comput. Sci. 2004, 31, 125–129. [Google Scholar]

- Lin, Y.Z.; Nie, Z.H.; Ma, H.W. Structural Damage Detection with Automatic Feature extraction through Deep Learning. Comput. Aided Civ. Infrastruct. Eng. 2017, 32, 1–22. [Google Scholar] [CrossRef]

- Yuan, Z.W.; Zhang, J. Feature extraction and image retrieval based on AlexNet. In Proceedings of the Eighth International Conference on Digital Image Processing, Chengu, China, 29 August 2016. [Google Scholar]

- Krizhevsky, A.; Hinton, G. Learning multiple layers of features from tiny images. Tech. Rep. Univ. Tor. 2009, 1, 7. [Google Scholar]

- Lawrence, S.; Giles, C.L.; Tsoi, A.C.; Back, A.D. Face recognition: A convolutional neural-network approach. IEEE Trans. Neural Netw. 1997, 8, 98–113. [Google Scholar] [CrossRef] [PubMed]

- Tensmeyer, C.; Saunders, D.; Martinez, T. Convolutional Neural Networks for Font Classification. In Proceedings of the International Conference on Document Analysis and Recognition, Kyoto, Japan, 9–15 November 2017; pp. 985–990. [Google Scholar]

- Yao, D.; Zhu, W.; Chen, Y.; Zhang, L. Chinese license plate character recognition based on convolution neural network. In Proceedings of the Chinese Automation Congress, Jinan, China, 20–22 October 2017. [Google Scholar]

- Cha, Y.; Choi, W.; Büyüköztürk, O. Deep Learning-Based Crack Damage Detection Using Convolutional Neural Networks. Comput. Aided Civ. Infrastruct. Eng. 2017, 32, 361–378. [Google Scholar] [CrossRef]

- Li, R.; Yuan, Y.; Wei, Z.; Yuan, Y. Unified Vision-Based Methodology for Simultaneous Concrete Defect Detection and Geolocalization. Comput. Aided Civ. Infrastruct. Eng. 2018, 33, 527–544. [Google Scholar] [CrossRef]

- Zhang, Y.; Miyamori, Y.; Mikami, S.; Saito, T. Vibration-based structural state identification by a 1-dimensional convolutional neural network. Comput. Aided Civ. Infrastruct. Eng. 2019, 34, 1–18. [Google Scholar] [CrossRef]

- Tang, Z.; Chen, Z.; Bao, Y.; Li, H. Convolutional neural network-based data anomaly detection method using multiple information for structural health monitoring. Struct. Control Health Monit. 2019, 26, e2296. [Google Scholar] [CrossRef]

- Abdeljaber, O.; Avci, O.; Kiranyaz, M.S.; Boashash, B.; Sodano, H.; Inman, D.J. 1-D CNNs for structural damage detection: Verification on a structural health monitoring benchmark data. Neurocomputing 2018, 275, 1308–1317. [Google Scholar] [CrossRef]

- Abdeljaber, O.; Avci, O.; Kiranyaz, S.; Gabbouj, M.; Inman, D.J. Real-time vibration-based structural damage detection using one-dimensional convolutional neural networks. J. Sound Vib. 2017, 388, 154–170. [Google Scholar] [CrossRef]

- Kiranyaz, S.; Avci, O.; Abdeljaber, O.; Ince, T.; Gabbouj, M.; Inman, D.J. 1D Convolutional Neural Networks and Applications: A Survey. arXiv 2019, arXiv:1905.03554. [Google Scholar]

- Chu, T.C.; Ranson, W.F.; Sutton, M.A. Applications of digital-image-correlation techniques to experimental mechanics. Exp. Mech. 1985, 25, 232–244. [Google Scholar] [CrossRef]

- Pan, B.; Qian, K.; Xie, H.; Asundi, A. Two-dimensional digital image correlation for in-plane displacement and strain measurement: A review. Meas. Sci. Technol. 2009, 20, 152–154. [Google Scholar] [CrossRef]

- Bedon, C.; Dilena, M.; Morassi, A. Ambient vibration testing and structural identification of a cable-stayed bridge. Meccanica 2016, 51, 2777–2796. [Google Scholar] [CrossRef]

- Lee, J.J.; Lee, J.W.; Yi, J.H.; Yun, C.B.; Jung, H.Y. Neural networks-based damage detection for bridges considering errors in baseline finite element models. J. Sound Vib. 2005, 280, 555–578. [Google Scholar] [CrossRef]

- Bishop, C.M. Pattern Recognition and Machine Learning (Information Science and Statistics); Springer: New York, NY, USA, 2007. [Google Scholar]

- Guan, H.; Karbhari, V.M. Improved damage detection method based on Element Modal Strain Damage Index using sparse measurement. J. Sound Vib. 2008, 309, 465–494. [Google Scholar] [CrossRef]

- Scherer, D.; Müller, A.; Behnke, S. Evaluation of Pooling Operations in Convolutional Architectures for Object Recognition. In Proceedings of the International Conference on Artificial Neural Networks, Berlin, Germany, 17–19 September 2010. [Google Scholar]

- Geng, X.; Lu, S. Researchon FBG-Based CFRP Structural Damage Identification Using BP Neural Network. Photonic Sens. 2018, 8, 168–175. [Google Scholar] [CrossRef]

| Layer | Type | Kernel Num. | Kernel Size | Stride | Pad | Activation |

|---|---|---|---|---|---|---|

| 1 | Input | None | None | None | None | None |

| 2 | Convolution (C1) | 200 | 3 × 3 | [1,1] | 0 | Leaky ReLU |

| 3 | Max pooling (P) | None | 2 × 2 | [1,1] | 0 | None |

| 4 | Convolution (C2) | 400 | 2 × 2 | [1,1] | 0 | Leaky ReLU |

| 5 | FC | None | None | None | None | None |

| 6 | Softmax | None | None | None | None | None |

| 7 | Classification | None | None | None | None | None |

| Structure State | First-Order Natural Frequency (Hz) |

|---|---|

| state (1) | 3.906 |

| state (2) | 3.906 |

| state (3) | 3.906 |

| state (4) | 3.662 |

| Structure State | First-Order Natural Frequency (Hz) |

|---|---|

| State (1) | 3.906 |

| State (2) | 3.906 |

| State (3) | 3.906 |

| State (4) | 3.906 |

| Node | State (1) | State (2) | State (3) | State (4) | ||||

|---|---|---|---|---|---|---|---|---|

| Modal Shape | Rotation | Modal Shape | Rotation | Modal Shape | Rotation | Modal Shape | Rotation | |

| 1 | 0.645 | −0.0007 | 0.058 | 0.0060 | 0.655 | −0.0017 | 0.275 | 0.0066 |

| 2 | 0.641 | 0.0001 | 0.105 | −0.0002 | 0.627 | −0.0002 | 0.401 | −0.0009 |

| 3 | 0.624 | −0.0015 | 0.080 | −0.0018 | 0.625 | −0.0001 | 0.298 | −0.0022 |

| 4 | 0.551 | −0.0020 | 0.055 | −0.0010 | 0.606 | −0.0011 | 0.234 | −0.0005 |

| 5 | 0.535 | 0.0018 | 0.043 | −0.0003 | 0.537 | −0.0031 | 0.241 | 0.0007 |

| 6 | 0.615 | 0.0033 | 0.193 | −0.0039 | 0.599 | 0.0006 | 0.570 | −0.0035 |

| 7 | 0.665 | 0.0002 | 0.105 | −0.0011 | 0.651 | 0.0010 | 0.357 | −0.0006 |

| 8 | 0.646 | −0.0011 | 0.089 | −0.0001 | 0.649 | −0.0016 | 0.309 | −0.0007 |

| 9 | 0.606 | −0.0015 | 0.081 | −0.0003 | 0.524 | −0.0023 | 0.180 | −0.0009 |

| 10 | 0.558 | −0.0016 | 0.062 | −0.0007 | 0.544 | 0.0042 | 0.261 | 0.0020 |

| Node | State (1) | State (2) | State (3) | State (4) | ||||

|---|---|---|---|---|---|---|---|---|

| Modal Shape | Rotation | Modal Shape | Rotation | Modal Shape | Rotation | Modal Shape | Rotation | |

| 1 | 0.321 | 0.0021 | 0.044 | −0.0073 | 0.228 | 0.0020 | 0.264 | 0.0036 |

| 2 | 0.328 | 0.0003 | 0.037 | 0.0023 | 0.254 | 0.0005 | 0.291 | 0.0003 |

| 3 | 0.324 | −0.0017 | 0.048 | 0.0016 | 0.243 | −0.0017 | 0.279 | −0.0018 |

| 4 | 0.312 | −0.0019 | 0.046 | −0.0016 | 0.199 | −0.0020 | 0.250 | −0.0017 |

| 5 | 0.310 | 0.0018 | 0.044 | 0.0016 | 0.193 | 0.0021 | 0.245 | 0.0016 |

| 6 | 0.319 | 0.0065 | 0.039 | 0.0086 | 0.219 | 0.0055 | 0.241 | 0.0035 |

| 7 | 0.338 | 0.0007 | 0.045 | −0.0010 | 0.243 | −0.0006 | 0.259 | 0.0003 |

| 8 | 0.333 | −0.0019 | 0.041 | −0.0020 | 0.224 | −0.0019 | 0.251 | −0.0018 |

| 9 | 0.323 | −0.0013 | 0.040 | 0.0004 | 0.209 | −0.0008 | 0.231 | −0.0017 |

| 10 | 0.324 | 0.0021 | 0.041 | 0.0003 | 0.204 | −0.0012 | 0.228 | 0.0017 |

| Testing Data | Actual Location | Predicted Location | Probability |

|---|---|---|---|

| A-1 | 0 (Intact) | 0 (Intact) | 76.7% |

| A-2 | 2 | 2 | 63.8% |

| A-3 | 11 | 11 | 97.8% |

| H-1 | 0 (Intact) | 0 (Intact) | 99.6% |

| H-2 | 2 | 2 | 99.7% |

| H-3 | 11 | 11 | 86.9% |

| Testing Data | Actual Category | Predicted Category | Probability |

|---|---|---|---|

| A-M | 25 | 25 | 100% |

| H-M | 25 | 25 | 99.9% |

| Number of Hidden Layer Nodes | Actual Damage States | |||

|---|---|---|---|---|

| (1) | (2) | (3) | (4) | |

| 55 | 28 | 2 | 11 | 1 and 5 |

| 60 | 15 | 2 | 11 | 1 and 15 |

| 65 | 13 | 2 | 11 | 1 and 5 |

| 70 | 13 | 2 | 11 | 1 and 5 |

| Number of Hidden Layer Nodes | Actual Damage States | |||

|---|---|---|---|---|

| (1) | (2) | (3) | (4) | |

| 55 | 1 | 2 | 11 | 1 and 5 |

| 60 | 1 | 2 | 11 | 1 and 5 |

| 65 | 1 | 2 | 11 | 1 and 5 |

| 70 | 1 | 2 | 11 | 1 and 5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teng, S.; Chen, G.; Liu, G.; Lv, J.; Cui, F. Modal Strain Energy-Based Structural Damage Detection Using Convolutional Neural Networks. Appl. Sci. 2019, 9, 3376. https://doi.org/10.3390/app9163376

Teng S, Chen G, Liu G, Lv J, Cui F. Modal Strain Energy-Based Structural Damage Detection Using Convolutional Neural Networks. Applied Sciences. 2019; 9(16):3376. https://doi.org/10.3390/app9163376

Chicago/Turabian StyleTeng, Shuai, Gongfa Chen, Gen Liu, Jianbin Lv, and Fangsen Cui. 2019. "Modal Strain Energy-Based Structural Damage Detection Using Convolutional Neural Networks" Applied Sciences 9, no. 16: 3376. https://doi.org/10.3390/app9163376

APA StyleTeng, S., Chen, G., Liu, G., Lv, J., & Cui, F. (2019). Modal Strain Energy-Based Structural Damage Detection Using Convolutional Neural Networks. Applied Sciences, 9(16), 3376. https://doi.org/10.3390/app9163376