1. Introduction

The solid rotor induction motors (SRIM) is applied in many fields due to its simple structure, high reliability, and good starting performance [

1]. Toroidal winding structures, such as high-frequency inductors, transformers, and electric machines, are used in various applications because of their short end winding, low maintenance cost, and flexible speed regulation [

2,

3,

4]. Applying toroidal winding to SRIM, results in a solid rotor induction motor with toroidal winding (TWSRIM) that combines the advantages of a solid rotor and toroidal winding can be obtained [

5]. The equivalent circuit model is an important way to achieve motor design and performance analysis [

6]. In order to quickly and intuitively analyze the performance of TWSRIM, it is crucial to establish an equivalent circuit model.

composite SRIM consists of steel and copper layers. The common equivalent magnetic circuit method has difficulty analyzing the electromagnetic field and calculating the equivalent circuit parameters. Therefore, finite element methods (FEMs) are generally used to analyze composite SRIM [

7,

8,

9]. However, FEMs require a large amount of calculation time. To address this disadvantage, Reference [

10] proposed a multilayer theory to analyze a smooth solid rotor induction motor. Reference [

11] provided a novel multi-slice and multi-layer method for a novel dual stator solid rotor axial flux induction motor. Reference [

12] developed a semi-analytical 3D model based on Fourier analysis; this model can calculate the fringe field in a 3D slotted structure. Moreover, several complex propagation constants have been proposed to calculate composite rotor parameters [

13,

14].

Toroidal windings are widely used in various types of motors [

15,

16,

17,

18,

19]. Reference [

15] conducted a dynamic analysis of a toroidal winding switched reluctance motor (TSRM). Reference [

16] proposed a new type of TSRM with a single, continuous, multi-wire winding and compared its performance with that of a conventional switched reluctance motor. Reference [

17] developed a novel self-bearing motors based on a toroidally-wound brushless DC motor. To improve machine torque density and efficiency substantially. Reference [

18] presented a novel toroidally wound permanent magnet machine. Meanwhile, a complex study of the performance of an outer rotor induction motor with multipole stator winding was performed in [

19].

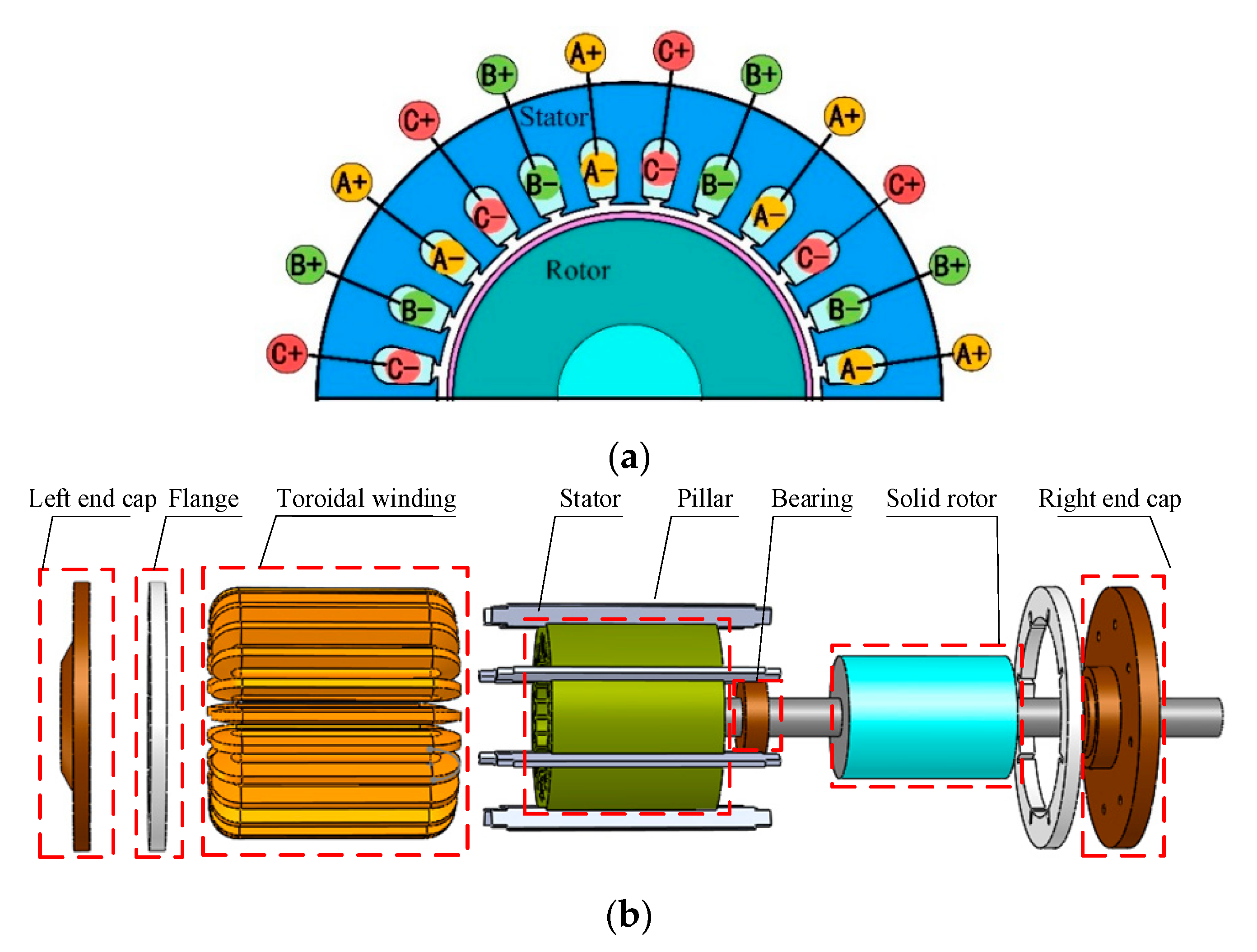

In this paper, a novel solid rotor induction motor with toroidal winding (N-TWSRIM) is proposed. For the N-TWSRIM, composite multilayer theory is used to calculate the motor parameters.

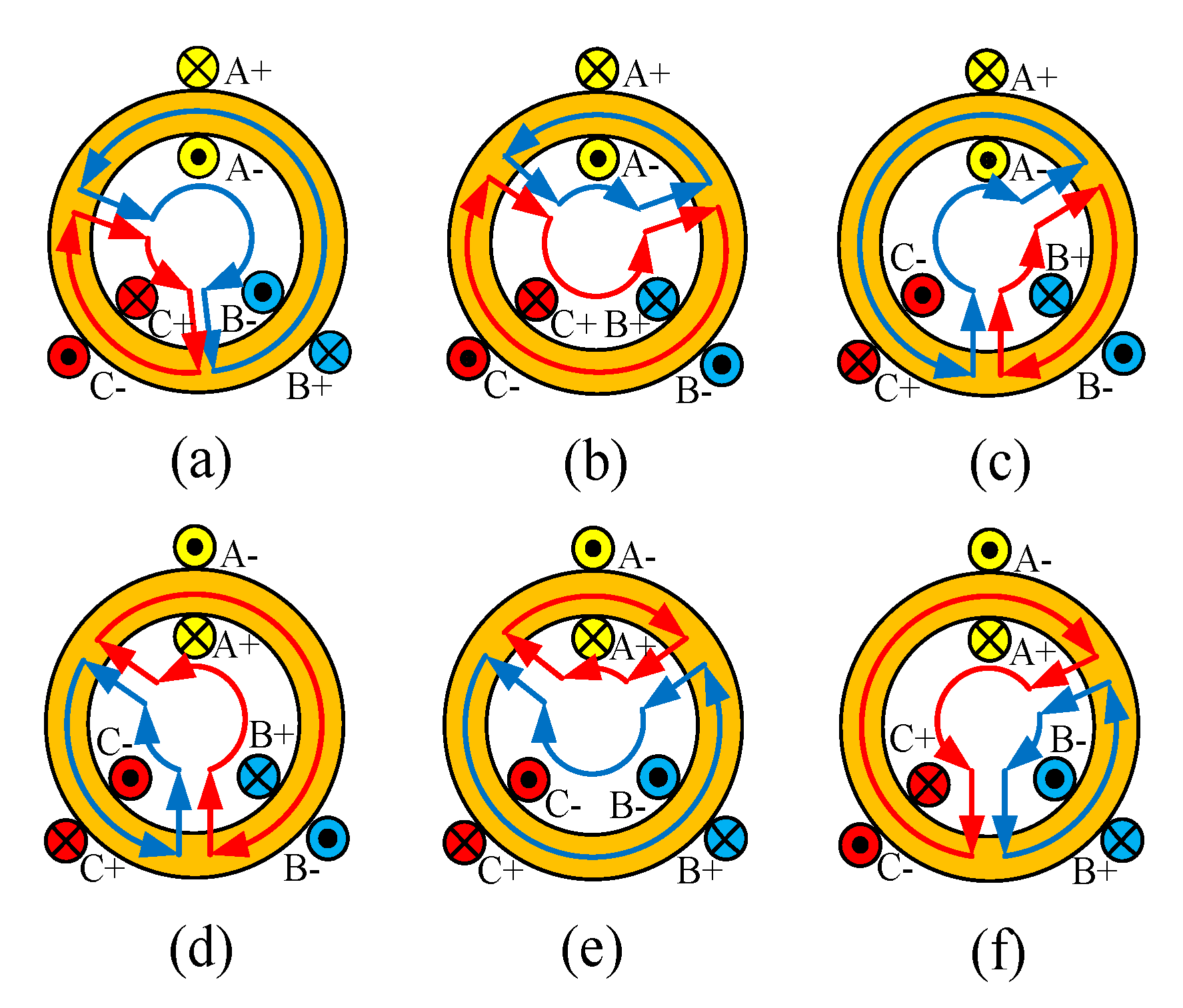

Section 2 presents the motor structure, main structure parameters and operating principle of N-TWSRIM.

Section 3 introduces the established ECM, and the parameters are calculated with composite multilayer theory.

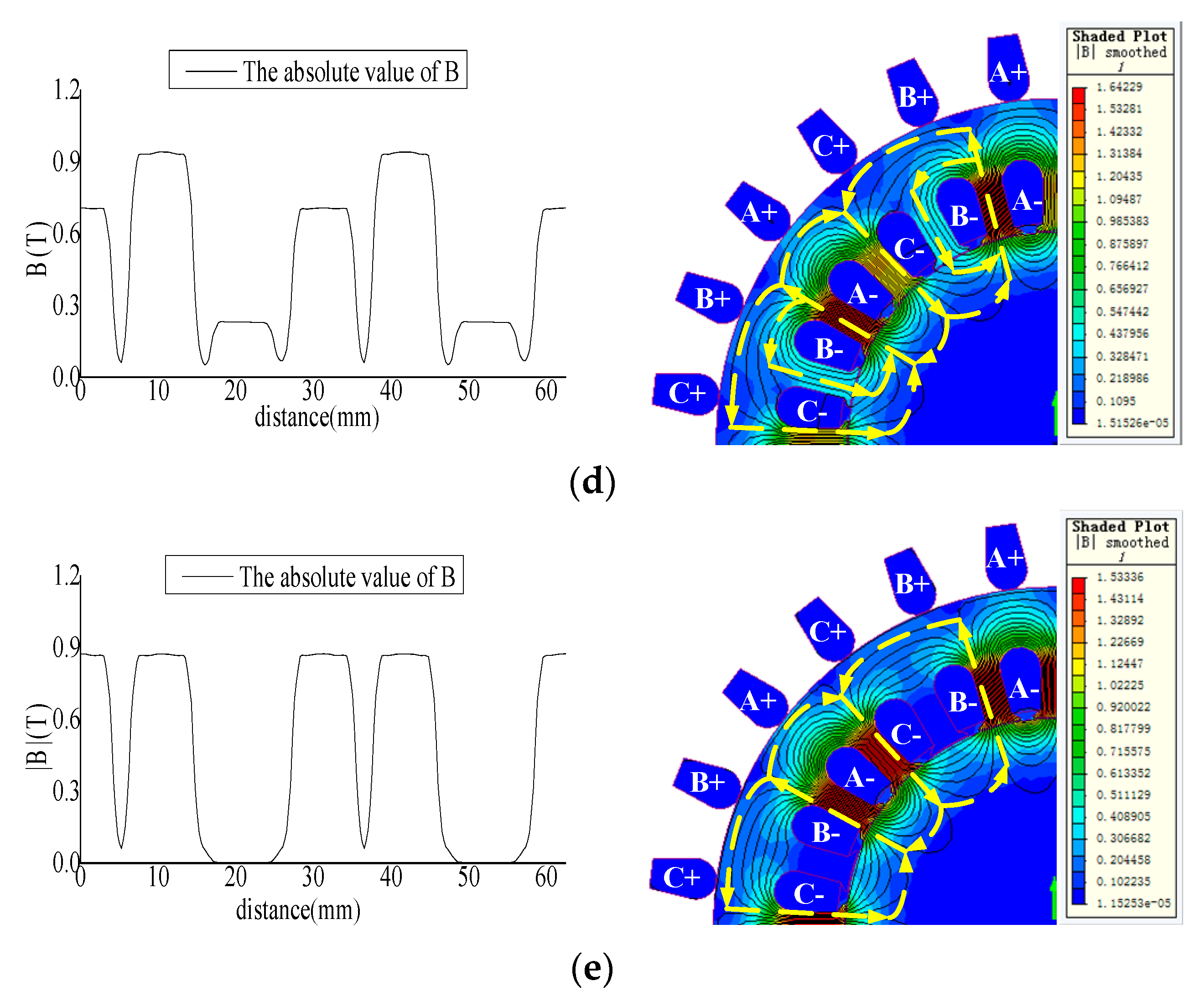

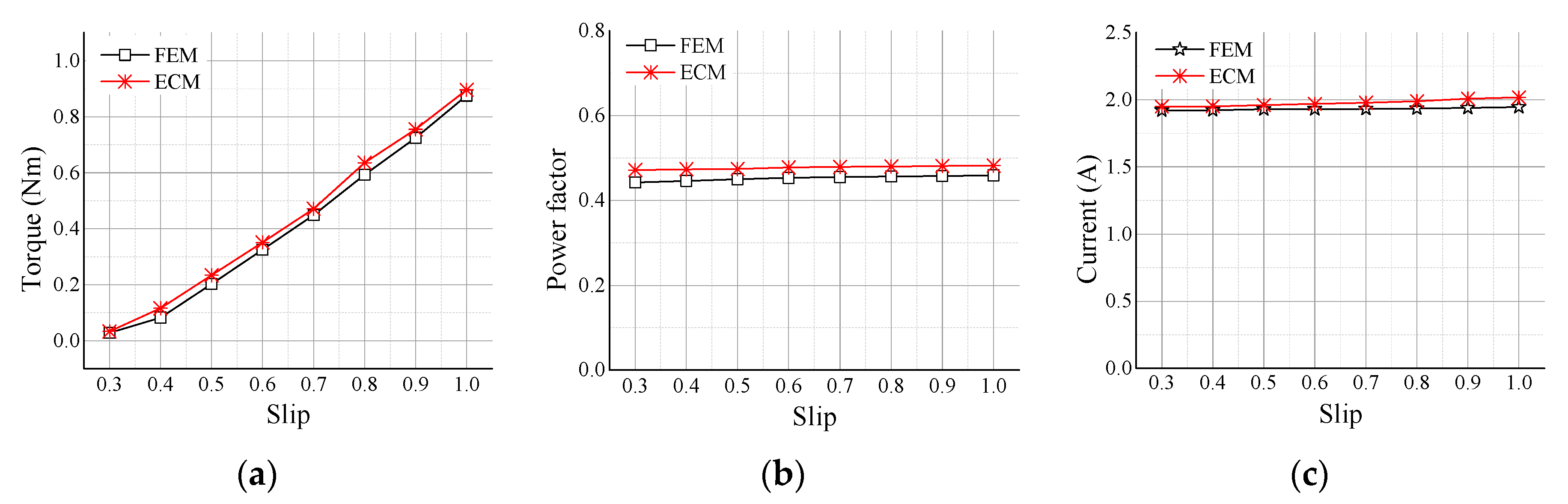

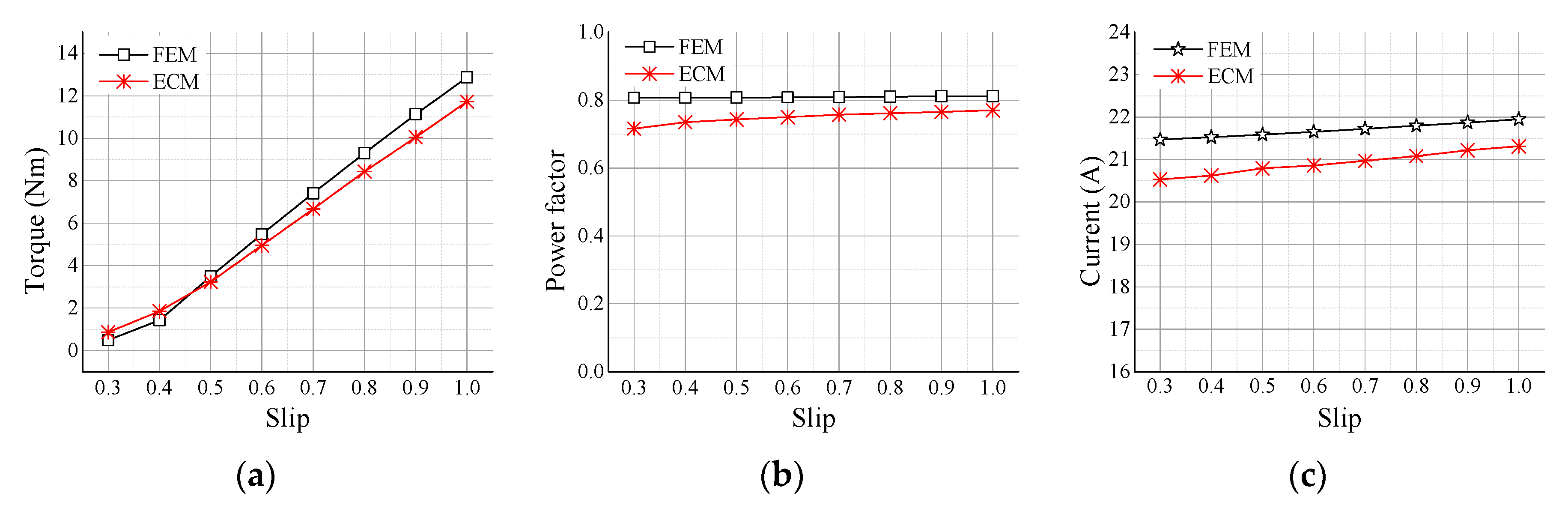

Section 4 presents the analysis results for different copper layer thicknesses. Such results are compared with those of FEM.

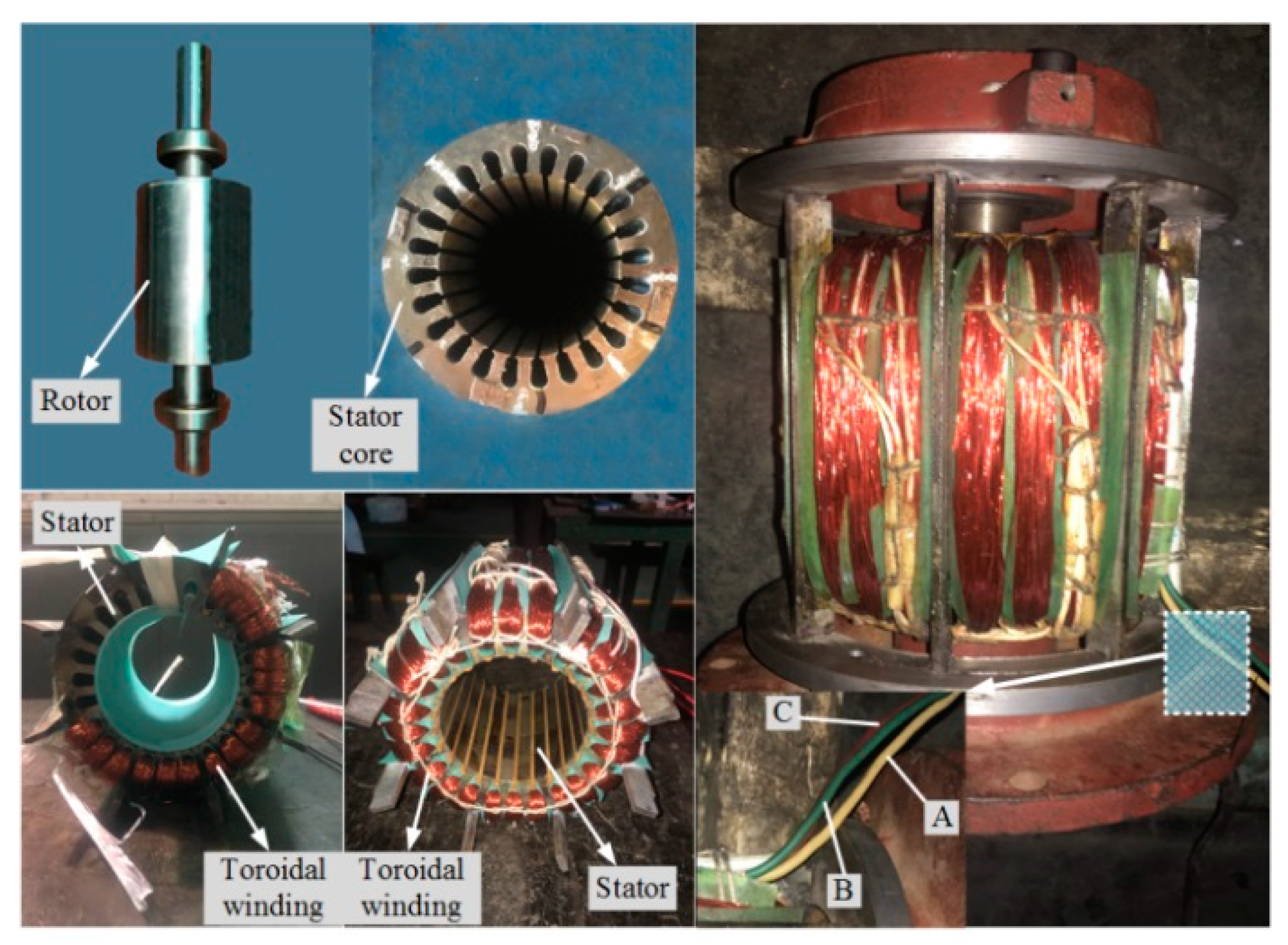

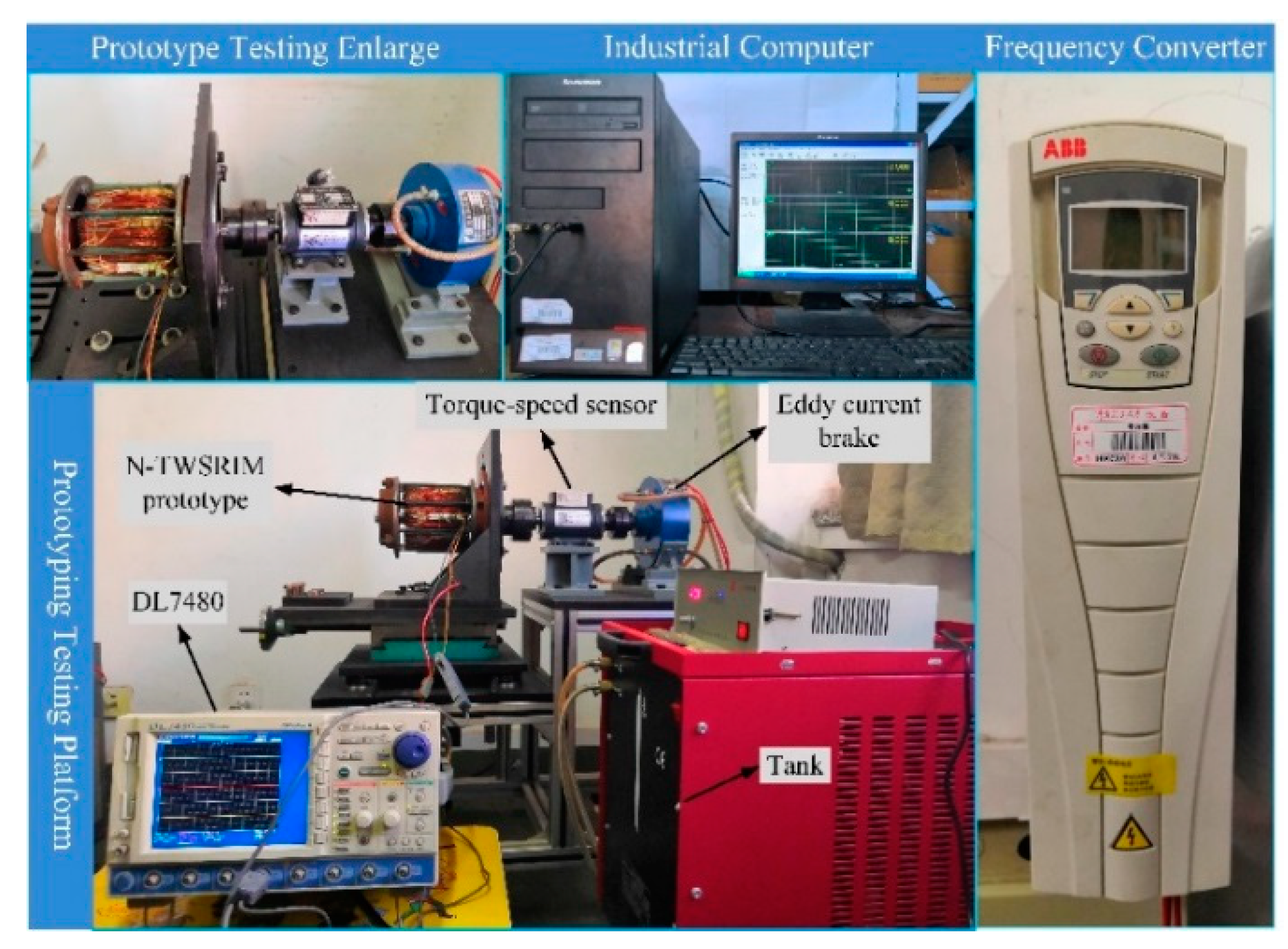

Section 5 shows the manufacturing and testing of a simple prototype. The correctness of ECM, FEM, and the operating principle are also verified.

Section 6 provides the conclusions.

3. Equivalent Circuit Model of the N-TWSRIM

The equivalent circuit is the main method used to study the electromagnetic theory, working characteristics, and parameter design of SRIM. The impedance of the equivalent circuit parameters of SRIM is critical to the design calculations for the motor, whose ECM is shown in

Figure 5. The equivalent circuit can be used to represent the voltage, current, and energy conversion relationship between the stator and the rotor.

In this model, is the input phase voltage, is the stator current, is the stator winding resistance, is the stator reactance, E is the electromotive force, is the excitation reactance, is the rotor current, is the equivalent resistance of the copper layer, is the equivalent resistance of the steel layer, is the equivalent reactance of the copper layer, is the equivalent reactance of the copper layer, is the rotor equivalent resistance, and is the rotor equivalent reactance.

In order to analyze the complex eddy current field distribution in a solid rotor and calculate the rotor equivalent impedance, the following basic assumptions are used:

1. The Carter coefficient is used to consider the stator core slotting effect.

2. The motor is deployed in the circumferential direction and the stator and rotor extend infinitely along the axial direction.

3. The harmonic components in the field are not considered and the displacement current is ignored.

4. The stator winding current is equivalent to the current sheet at the interface of the air gap and stator. The current layer is infinitely long along the circumference but the current layer thickness is ignored.

5. The end effect is expressed as end effect coefficient .

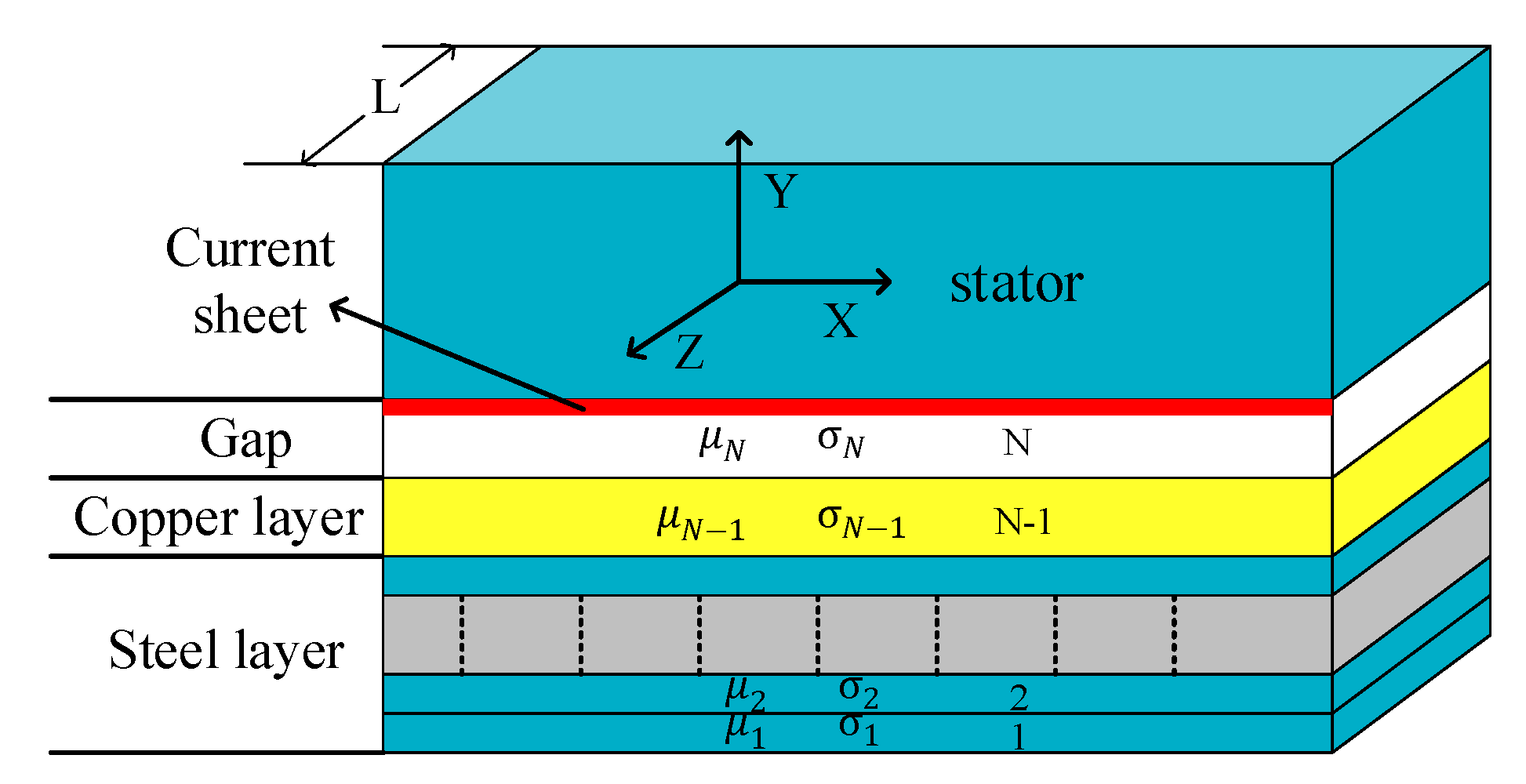

On the basis of the traditional multilayer model [

20],

Figure 6 shows the composite multilayer model of the N-TWSRIM, in which the rotor is divided into

layered regions. The

layers represent the steel layer, the s

layer represents the air gap, and the

layer represents the copper layer. In general, the more the number of layers is divided, the higher the corresponding calculation accuracy.

is the conductivity of each layer and

is the permeability of the

layer. X is the circumferential direction, Y is the radial direction, and Z is the axial direction.

The stator winding current is equivalent to the current sheet at the interface of the stator and air gap, as shown in

Figure 6. The internal surface current

of the stator is represented by Equation (1).

where

is the magnitude of the stator interface current density,

,

is the pole pitch, and

is the angular frequency.

can be expressed as

where

is the stator phase number,

is the number of effective conductors in series per phase,

is the current of the stator phase, and

is the diameter of the stator inner.

According to this assumption, the electromagnetic field relationship can be expressed as

where

is the magnetic density,

is the magnetic field intensity, and

,

,

represent the unit vectors in the X, Y, and Z directions, respectively.

According to Maxwell’s equations, the equations in the layer can be expressed as shown in Equations (4) and (5).

The equation can be expressed as shown in Equation (6).

By solving Equation (6), Equation (7) becomes available.

where

.

Equation (8) gives the boundary conditions for each layer and Equation (9) gives the transfer matrix for the electromagnetic field.

where

is the junction of the

layer and

layer,

is the

layer thickness,

is the tangential magnetic field intensity of the

layer, and

is the radial magnetic flux density of the

layer.

where

.

The overall boundary conditions are given as

The difference between composite multilayer theory and traditional multilayer theory is the difference in the calculation method of the N − 1 layer (copper layer), in which composite multilayer theory uses the propagation constant to calculate the copper layer parameters.

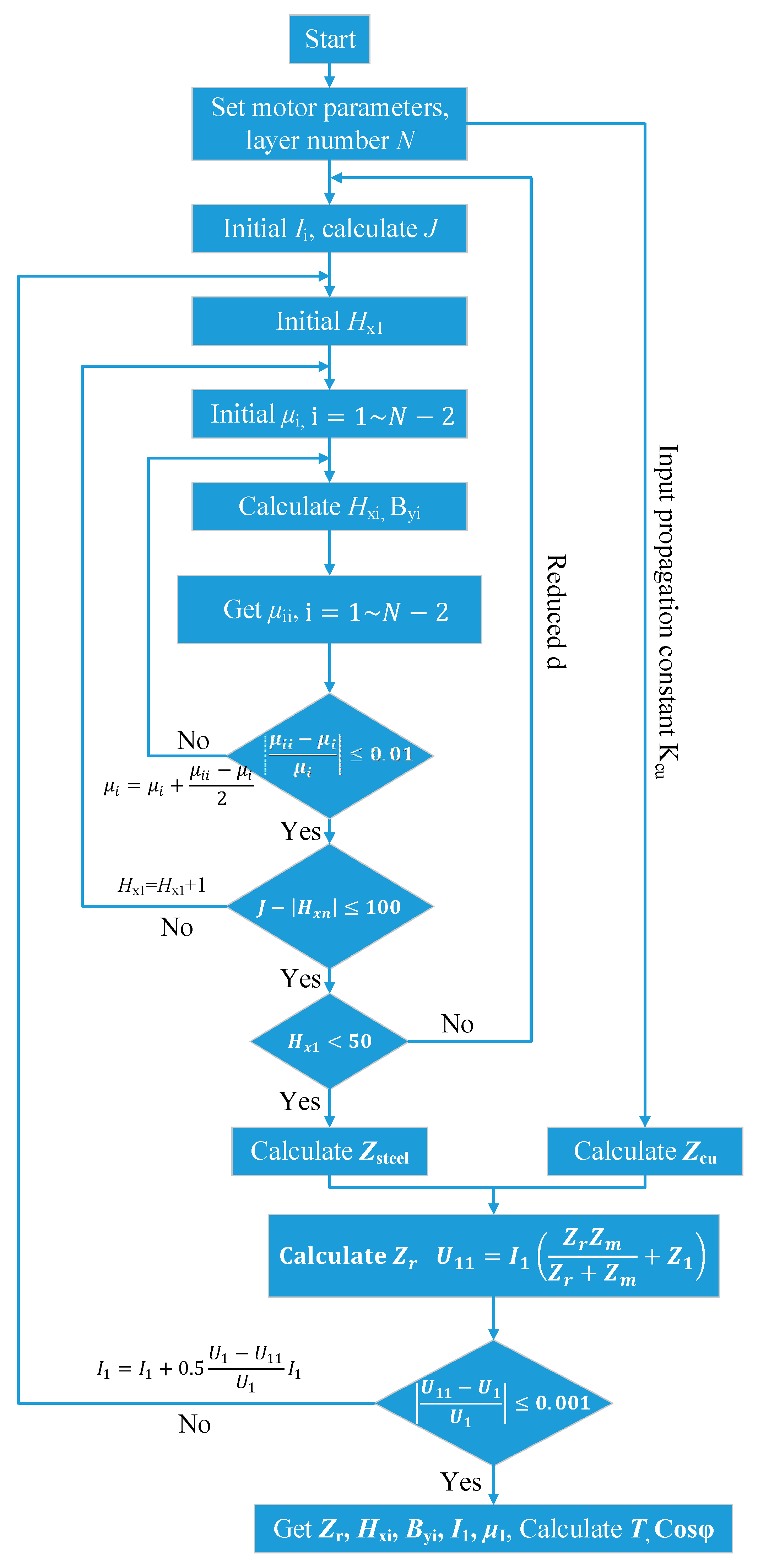

Figure 7 shows a block diagram of the calculation process for the N-TWSRIM multilayer composite model. The explanation of the relevant steps is as follows.

- (1)

N is an arbitrary value of the number of layers, and, generally speaking, the larger is, the thinner each layer is and the more accurate the results are, but the greater the calculation time is.

- (2)

Set the stator current and values based on actual motor parameters.

- (3)

The magnetic field components

and

are calculated by the transfer matrix (7) and boundary condition (8). Thus, the resultant

is derived. To consider the nonlinearity of the rotor, the

curve is represented [

21].

For the N-TWSRIM rotor steel . By applying into Equation (11), the new permeability is obtained.

- (4)

According to the transfer matrix, magnetic field intensity is calculated. A loop ensures that .

- (5)

When the cycle meets the conditions, the steel layer impedance

can be obtained according to Equation (12).

where

is the diameter of the rotor,

is the wave impedance,

, and

is the slip.

is the tangential magnetic field intensity of the

layer and

is the radial magnetic flux density of the

layer.

- (6)

When the traditional multilayer theory is used to calculate the copper layer parameters, the iteration speed is slow. So, to calculate the equivalent circuit parameters of the copper layer, the propagation constant

is used [

11], as shown in Equations (14)–(16).

where

is the copper layer thickness,

is the copper layer angular frequency,

, and

is the conductivity of copper.

- (7)

The rotor impedance is calculated by Equation (17).

- (8)

We can calculate the stator voltage by the rotor impedance. When the accuracy of and is not satisfied, the loop continues. When the accuracy is satisfied, the values of are given.

The rotor equivalent parameters of the solid rotor motor of the toroidal winding are calculated in cases where the stator winding phase voltage is 220 V and the voltage frequency is 50 Hz. The results are shown in

Table 3. Hence, the output torque, stator current, and power factor of the N-TWSRIM can be computed accordingly.