Seismic Damage Analysis of Box Metro Tunnels Accounting for Aspect Ratio and Shear Failure

Abstract

:1. Introduction

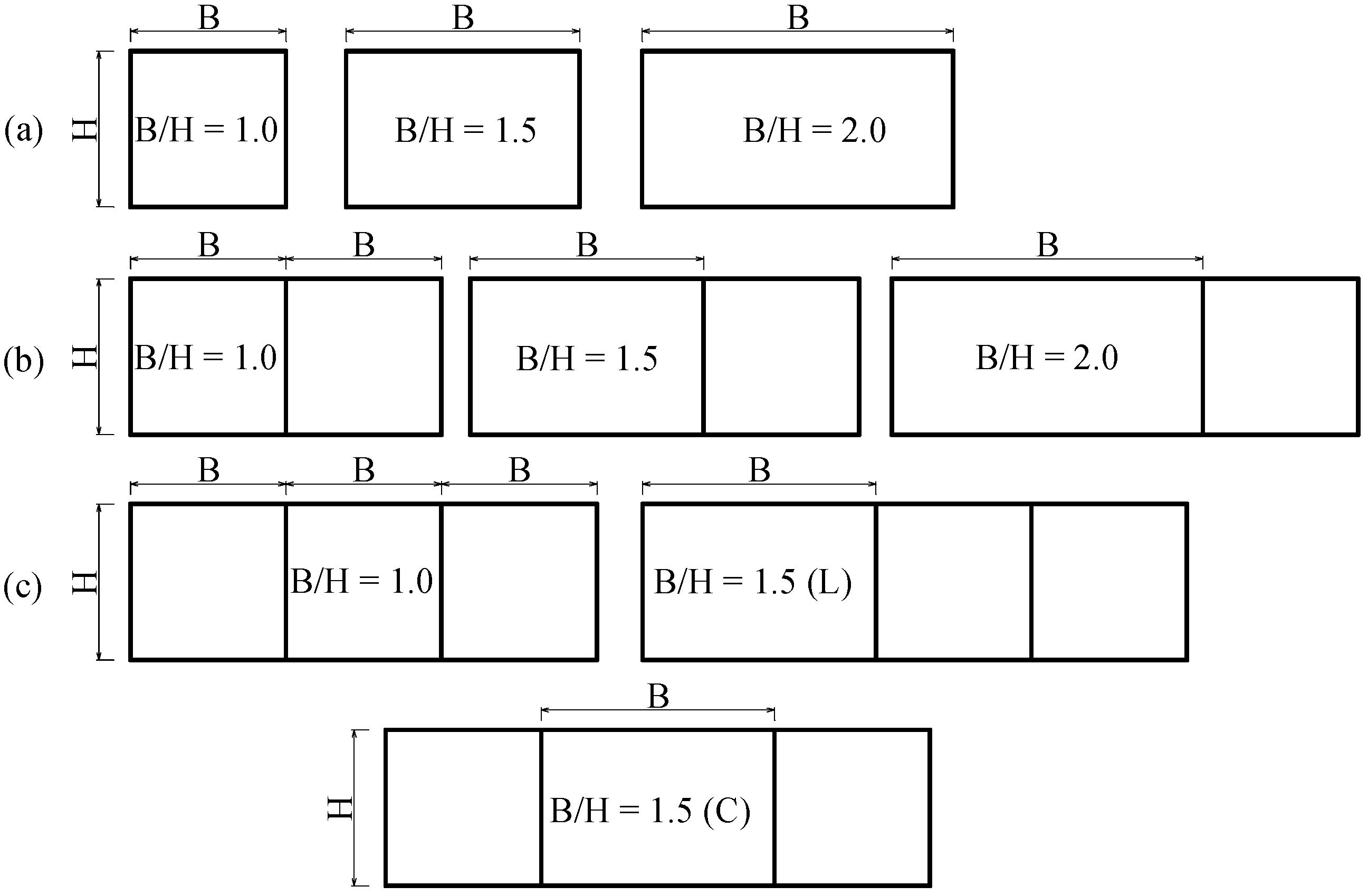

2. Description of Tunnels and Site Conditions

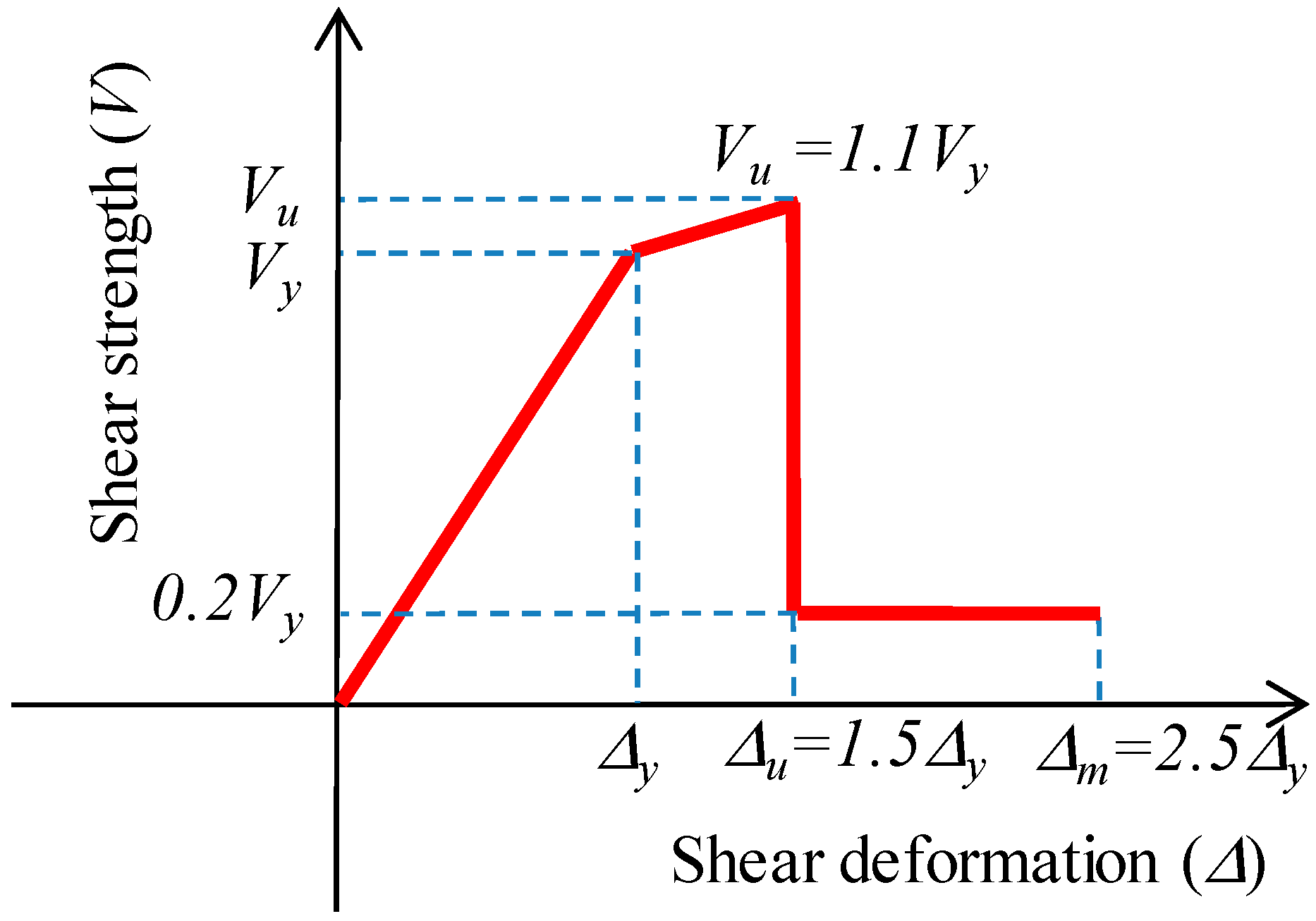

3. Numerical Modeling

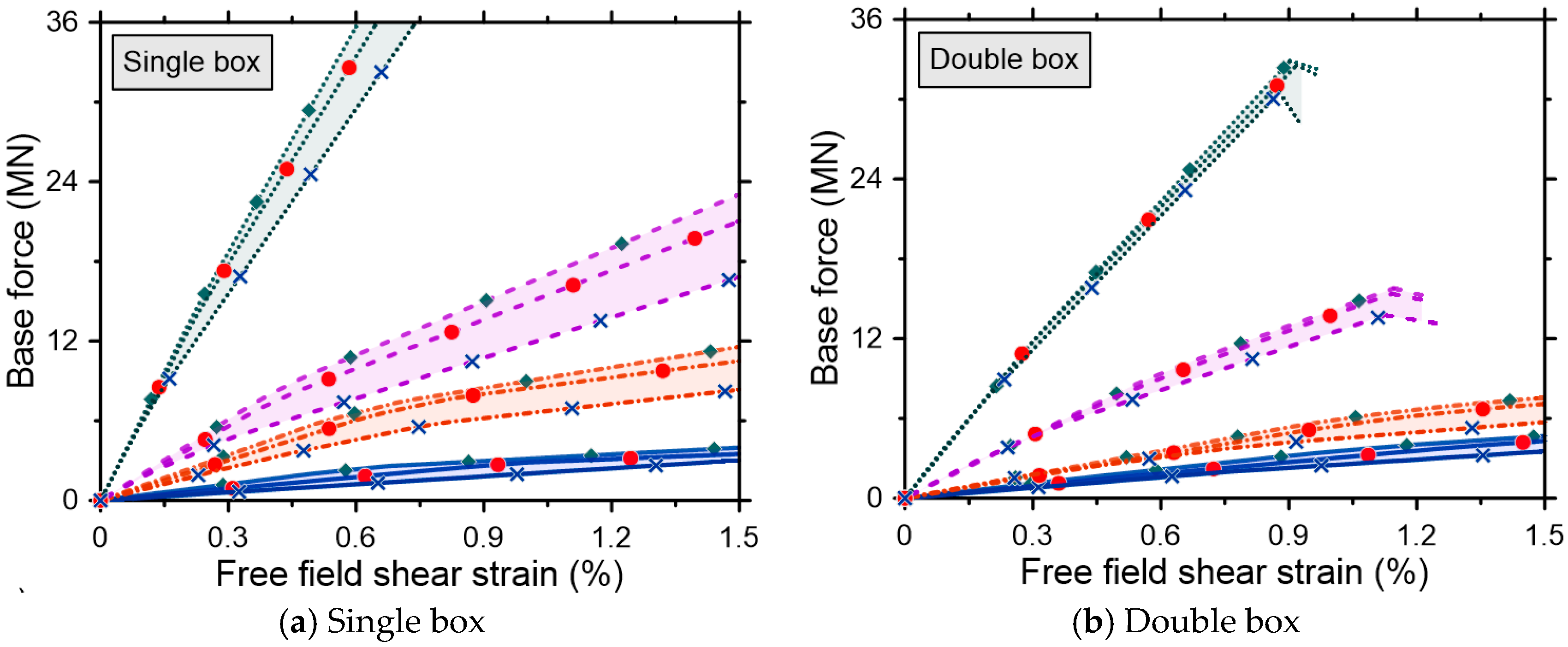

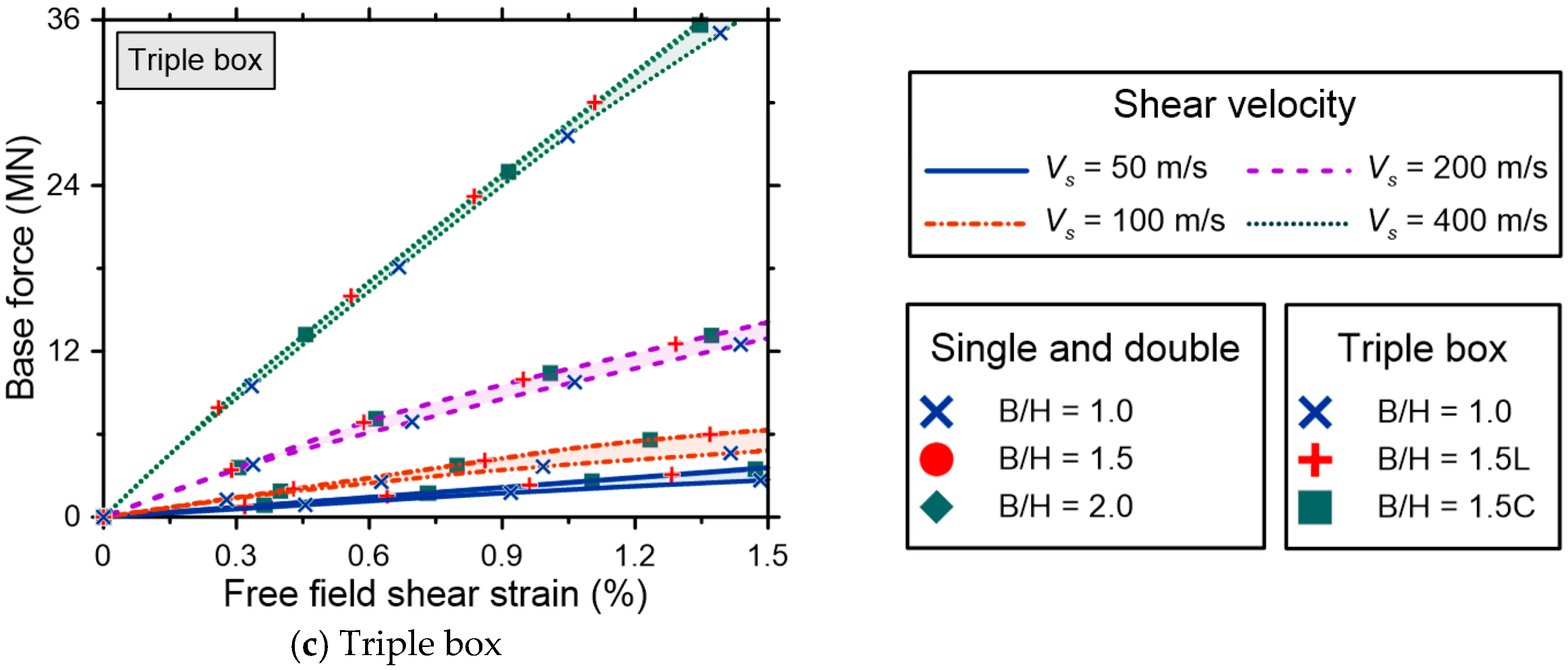

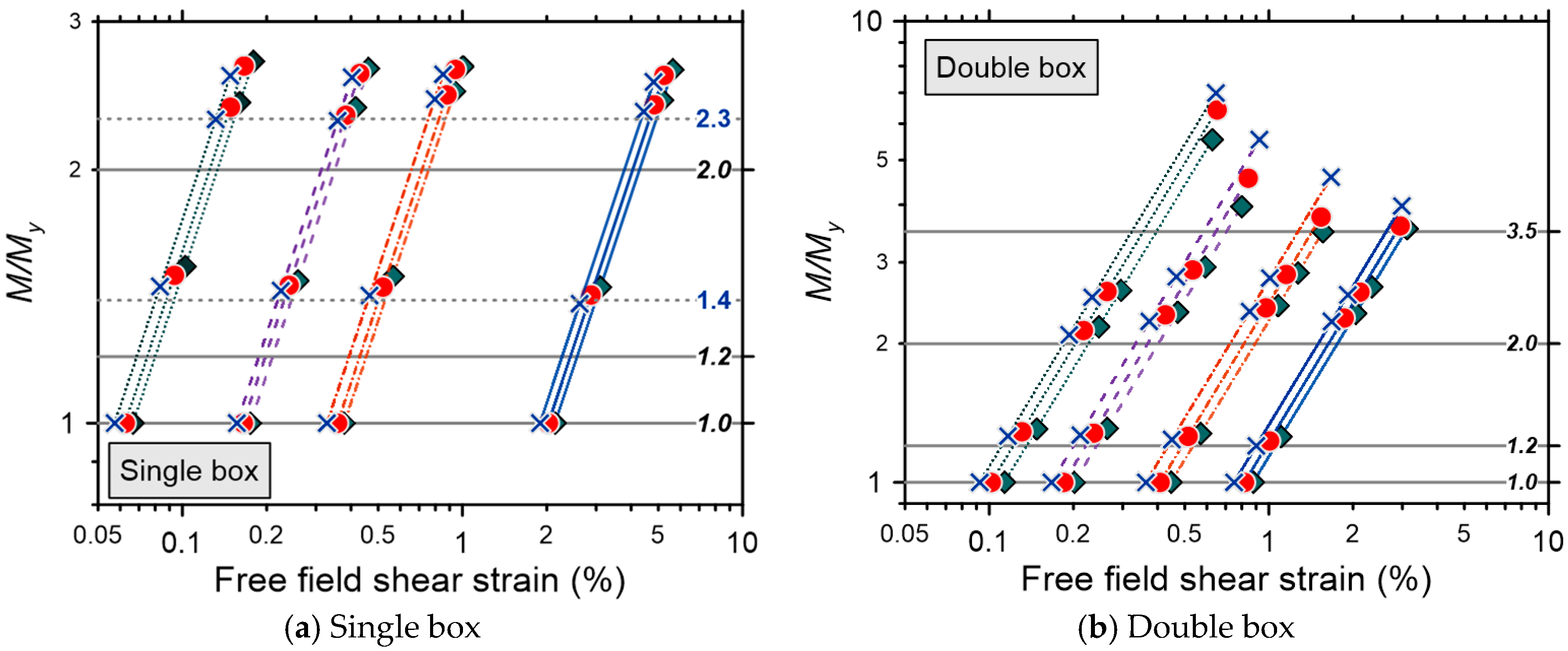

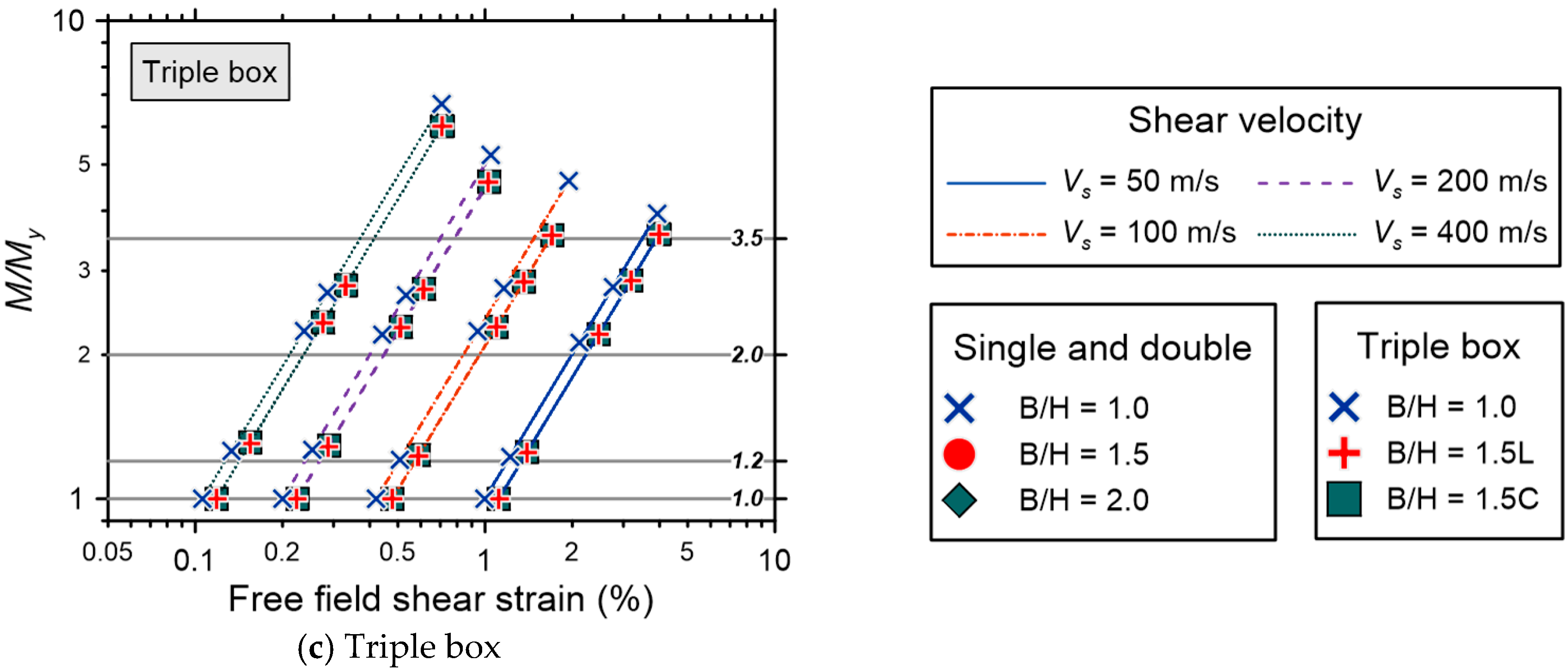

4. Results and Discussion

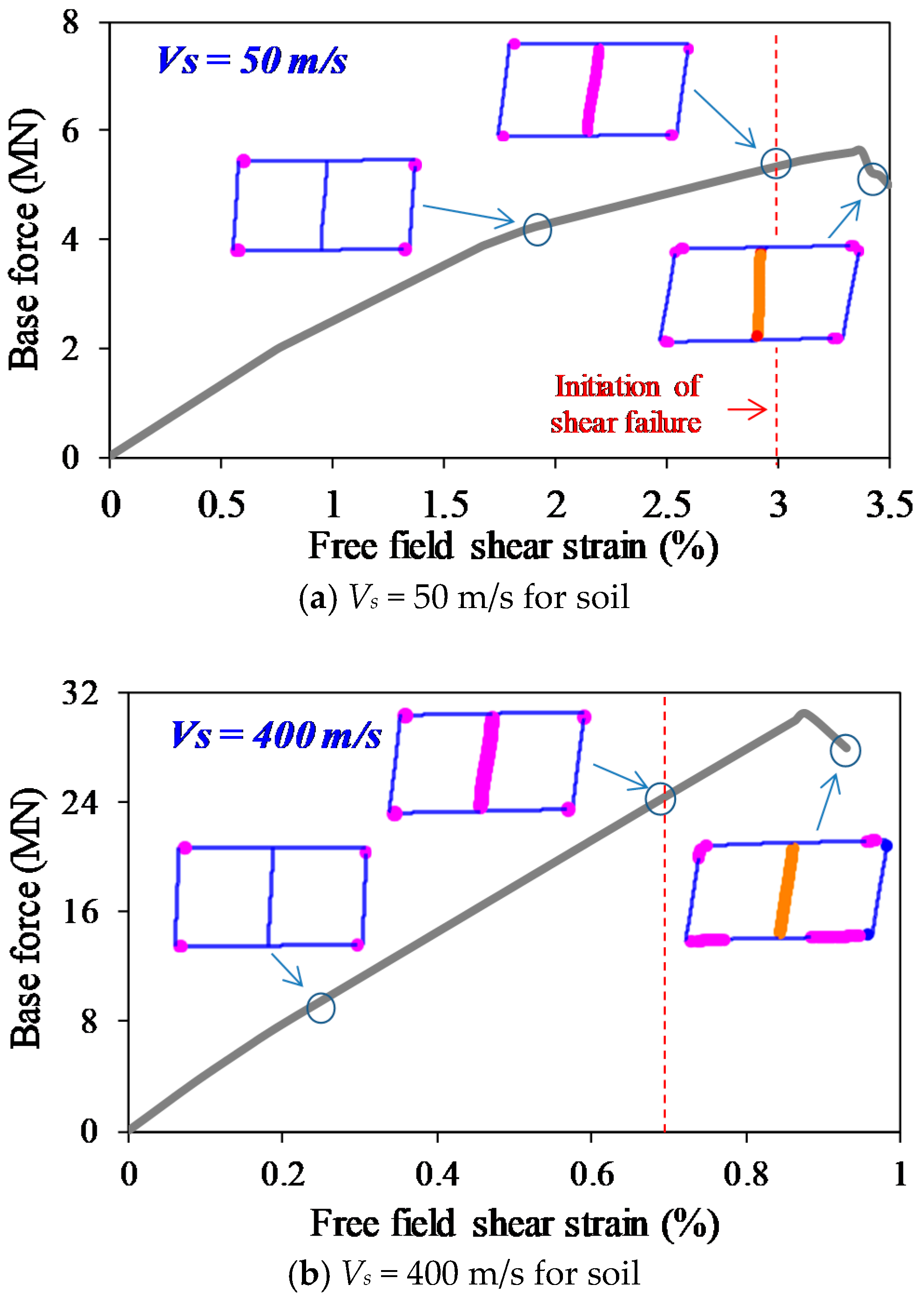

4.1. Failure Mechanism of Tunnels with B/H = 1.0

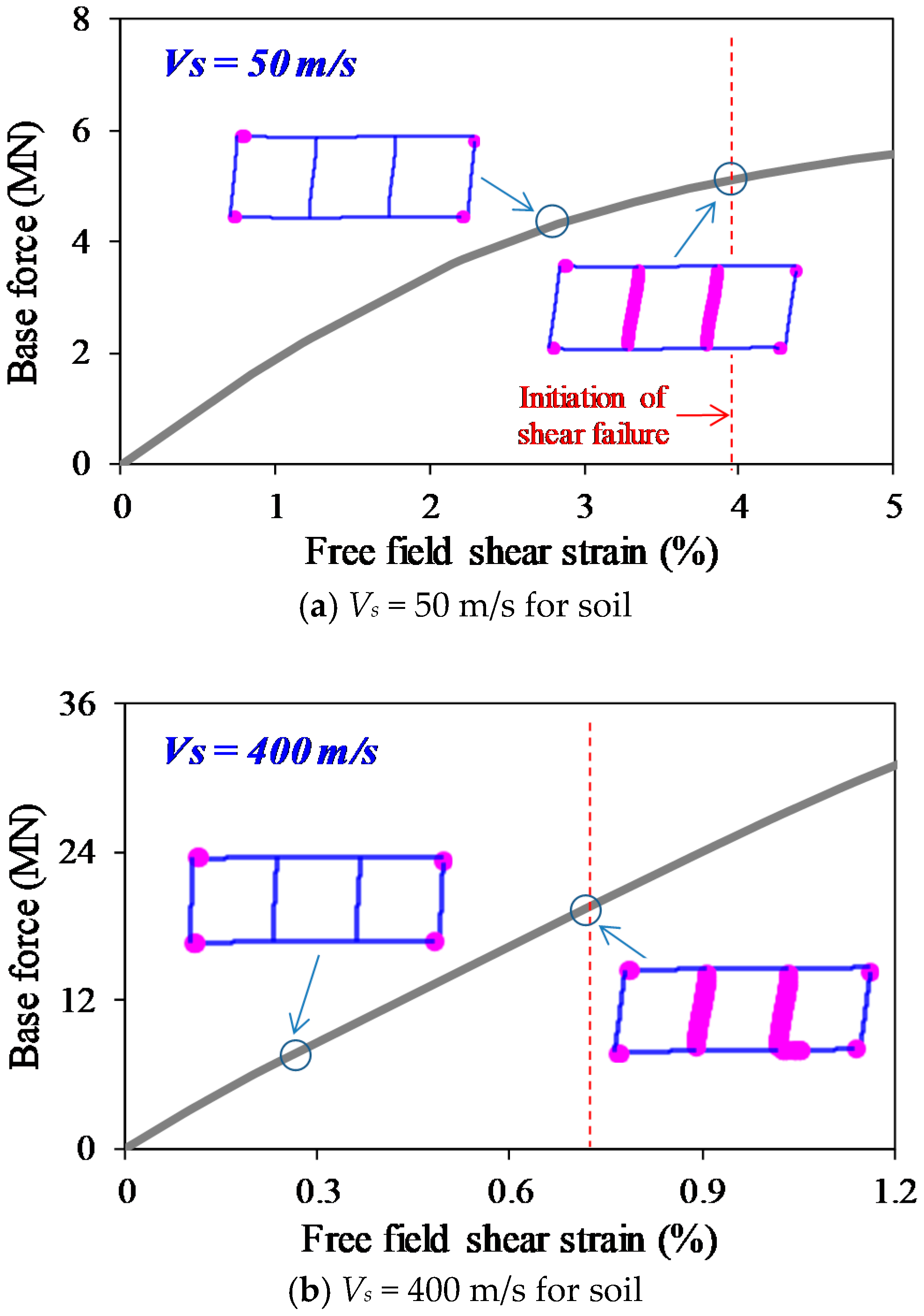

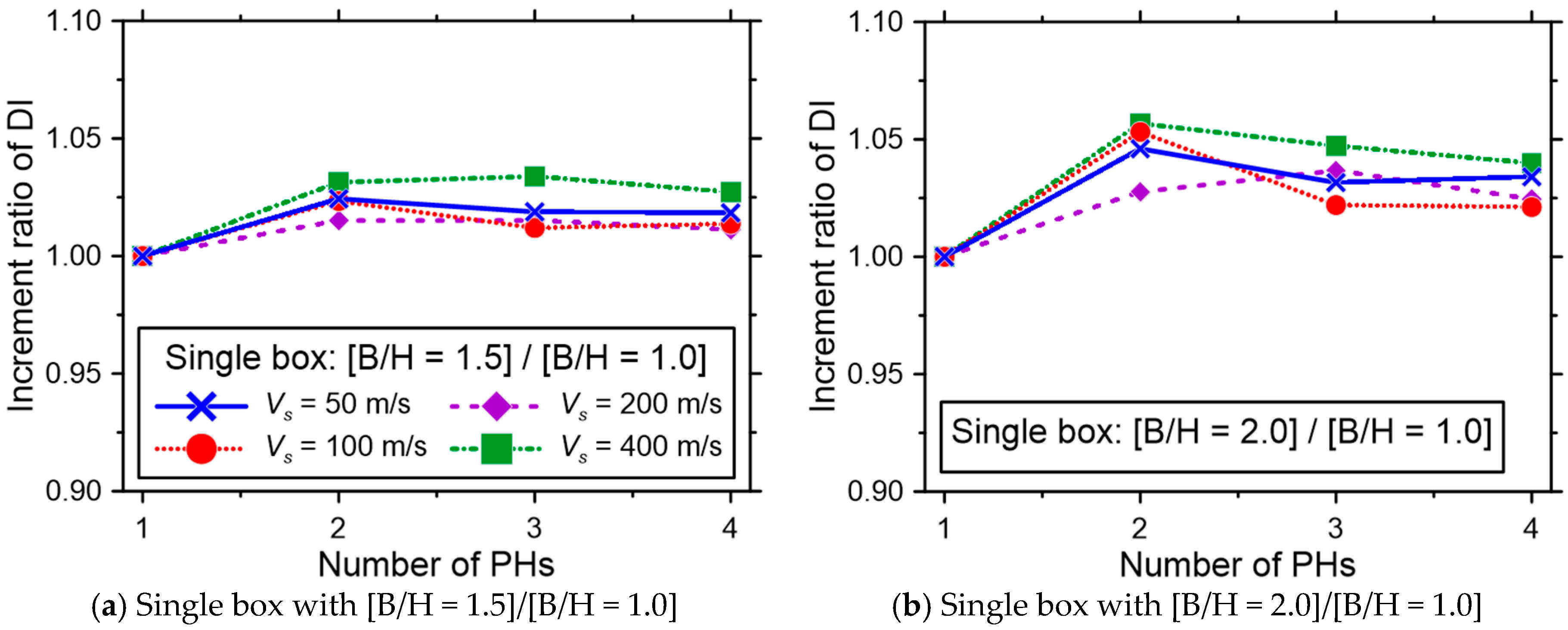

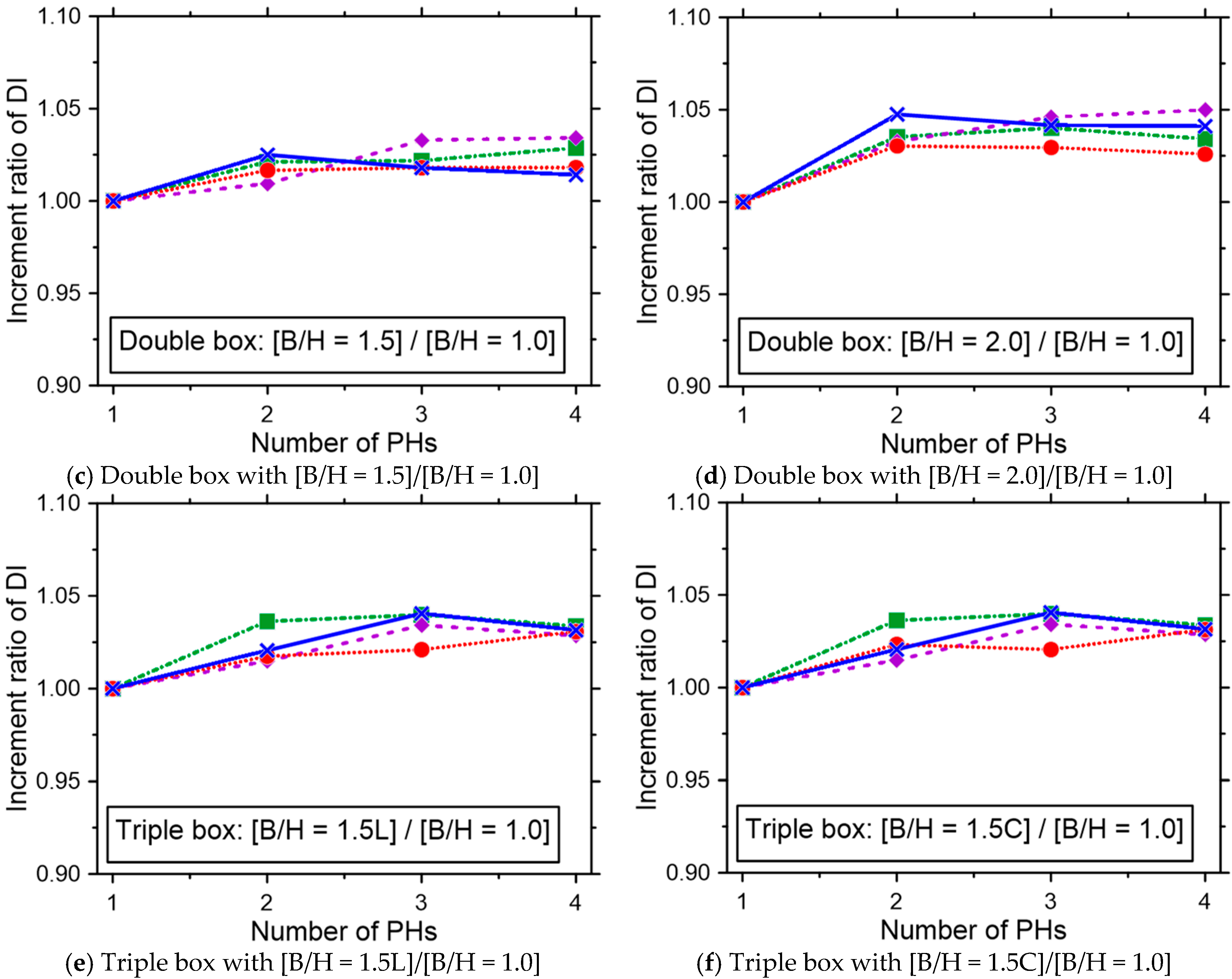

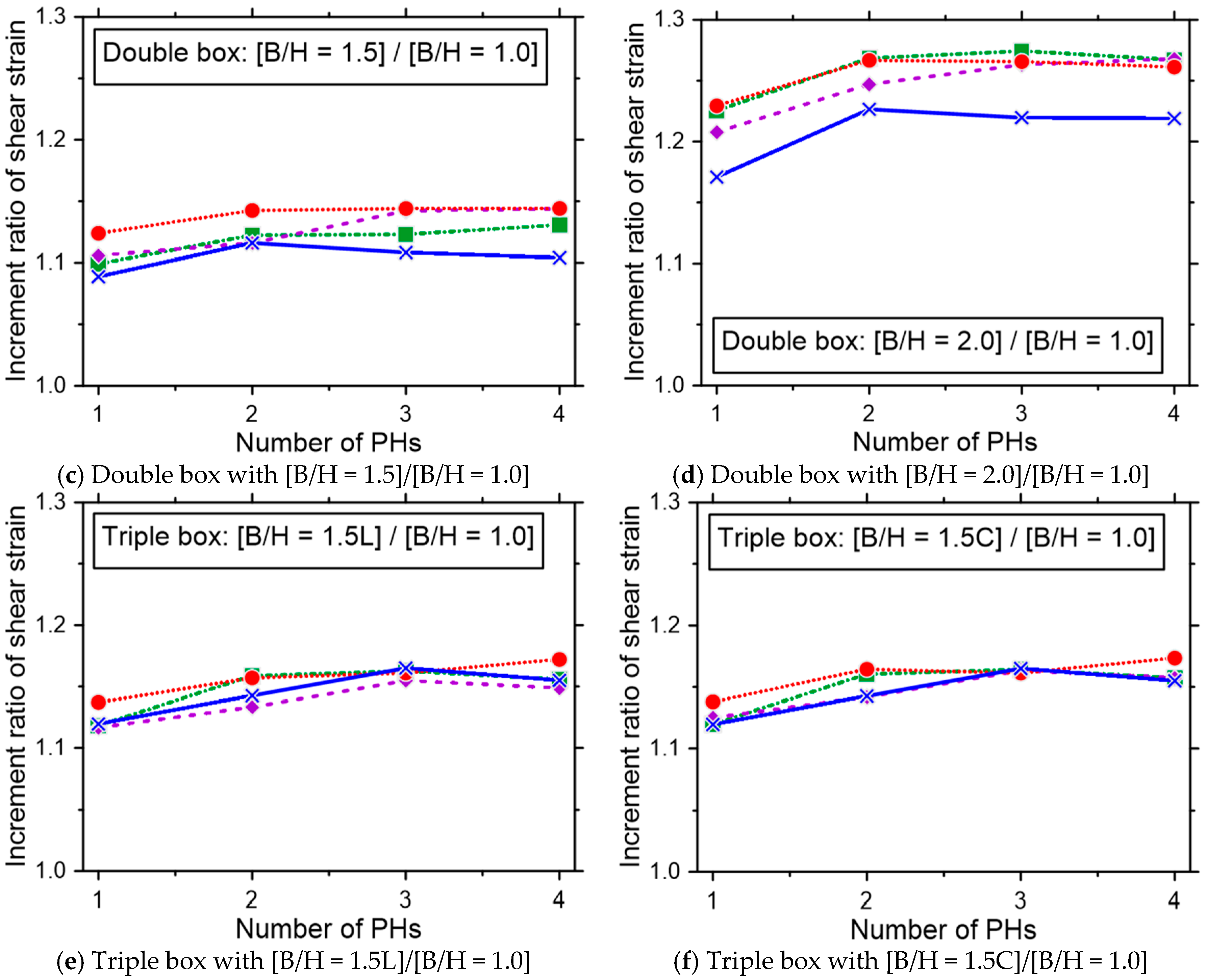

4.2. Effect of B/H on Damage of Box Tunnels

4.3. Updated Damage States and DIs of Box Tunnels

5. Conclusions

- A collapse damage state was not observed for the single box tunnels even after plastic hinges formed at all corners, primarily due to the support from the surrounding soil medium. The shear plastic hinge did not form in the single tunnel.

- For double and triple tunnels, the shear plastic hinges formed at the interior columns after flexure plastic hinges developed at all outer frame corners. The shear failure at the interior column may lead to a brittle structural collapse for multi-box tunnels. This failure should be avoided in design practices.

- The aspect ratio did not significantly influence the damage index (DI) of the single box tunnels. For double and triple tunnels, DIs at which the inner column failed was dependent on the aspect ratio. The shear strains corresponding to the damage states were more sensitive to the aspect ratio compared with DI.

- Damage states of box tunnels and corresponding DIs were updated from the study of Lee et al. [21]. DIs range from 1.0 to 2.3 for three damage states of single box tunnels, which were minor, moderate, and extensive states. The collapse damage state was newly proposed and the corresponding DI was presented for double and triple box tunnels. DIs ranged from 1.0 to 3.5.

Author Contributions

Funding

Conflicts of Interest

References

- Hashash, Y.M.; Hook, J.J.; Schmidt, B.; John, I.; Yao, C. Seismic design and analysis of underground structures. Tunn. Undergr. Space Tech. 2001, 16, 247–293. [Google Scholar] [CrossRef]

- Roy, N.; Sarkar, R. A Review of Seismic Damage of Mountain Tunnels and Probable Failure Mechanisms. Geotech. Geol. Eng. 2017, 35, 1–28. [Google Scholar] [CrossRef]

- Dowding, C.H.; Rozan, A. Damage to rock tunnels from earthquake shaking. J. Soil Mech. Found. Div. 1978, 104, 175–191. [Google Scholar]

- Owen, G.N.; Scholl, R.E. Earthquake Engineering of Large Underground Structures; The Division, National Technical Information Service: Alexandria, VA, USA, 1981. [Google Scholar]

- Sharma, S.; Judd, W.R. Underground opening damage from earthquakes. Eng. Geol. 1991, 30, 263–276. [Google Scholar] [CrossRef]

- Wang, J. The distribution of earthquake damage to underground facilities during the 1976 Tang-Shan earthquake. Earthq. Spectra 1985, 1, 741–757. [Google Scholar]

- Wang, Z.; Zhang, Z. Seismic damage classification and risk assessment of mountain tunnels with a validation for the 2008 Wenchuan earthquake. Soil Dyn. Earthq. Eng. 2013, 45, 45–55. [Google Scholar] [CrossRef]

- Nakamura, S.; Yoshida, N.; Iwatate, T. Damage to Daikai subway station during the 1995 Hyogoken-Nambu earthquake and its investigation. Jpn. Soc. Civ. Eng. Comm. Earthq. Eng. 1996, 287–295. [Google Scholar]

- Shen, Y.; Gao, B.; Yang, X.; Tao, S. Seismic damage mechanism and dynamic deformation characteristic analysis of mountain tunnel after Wenchuan earthquake. Eng. Geol. 2014, 180, 85–98. [Google Scholar] [CrossRef]

- Wang, W.; Wang, T.; Su, J.; Lin, C.; Seng, C.; Huang, T. Assessment of damage in mountain tunnels due to the Taiwan Chi-Chi Earthquake. Tunn. Undergr. Space Tech. 2001, 16, 133–150. [Google Scholar] [CrossRef]

- Yu, H.; Chen, J.; Bobet, A.; Yuan, Y. Damage observation and assessment of the Longxi tunnel during the Wenchuan earthquake. Tunn. Undergr. Space Tech. 2016, 54, 102–116. [Google Scholar] [CrossRef]

- Zou, Y.; Liu, H.; Jing, L.; Cui, J. A pseudo-static method for seismic responses of underground frame structures subjected to increasing excitations. Tunn. Undergr. Space Tech. 2017, 65, 106–120. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, W.; Li, Y.; Yuan, Y. Shaking table test of a multi-story subway station under pulse-like ground motions. Soil Dyn. Earthq. Eng. 2016, 82, 111–122. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, W.; Zhang, W.; Lou, M. Effects of Axial Compression Ratio of Central Columns on Seismic Performance of a Multi-Story Underground Structure. Int. J. Comput. Methods 2016, 13, 1641014. [Google Scholar] [CrossRef]

- Li, W.; Chen, Q. Seismic performance and failure mechanism of a subway station based on nonlinear finite element analysis. KSCE J. Civ. Eng. 2018, 22, 765–776. [Google Scholar] [CrossRef]

- Ma, C.; Lu, D.-C.; Du, X.-L.; Qi, C.-Z.; Zhang, X.-Y. Structural components functionalities and failure mechanism of rectangular underground structures during earthquakes. Soil Dyn. Earthq. Eng. 2019, 119, 265–280. [Google Scholar] [CrossRef]

- Lu, C.C.; Hwang, J.H. Nonlinear collapse simulation of Daikai Subway in the 1995 Kobe earthquake: Necessity of dynamic analysis for a shallow tunnel. Tunn. Undergr. Space Tech. 2019, 87, 78–90. [Google Scholar] [CrossRef]

- Sayed, M.A.; Kwon, O.S.; Park, D.; Van Nguyen, Q. Multi-platform soil-structure interaction simulation of Daikai subway tunnel during the 1995 Kobe earthquake. Soil Dyn. Earthq. Eng. 2019, 125, 105643. [Google Scholar] [CrossRef]

- Liu, J.; Liu, X. Pushover analysis of Daikai subway station during the Osaka-Kobe earthquake in 1995. In Proceedings of the 14th World Conference on Earthquake Engineering, Beijing, China, 12–17 October 2008; pp. 12–17. [Google Scholar]

- Liu, T.; Chen, Z.; Yuan, Y.; Shao, X. Fragility analysis of a subway station structure by incremental dynamic analysis. Adv. Struct. Eng. 2017, 20, 111–1124. [Google Scholar] [CrossRef]

- Lee, T.H.; Park, D.; Nguyen, D.D.; Park, J.S. Damage analysis of cut-and-cover tunnel structures under seismic loading. Bull. Earthq. Eng. 2016, 14, 413–431. [Google Scholar] [CrossRef]

- Hashash, Y.; Karina, K.; Koutsoftas, D.; O’Riordan, N. Seismic design considerations for underground box structures. In Proceedings of the Earth Retention Conference, Bellevue, WA, USA, 1–4 August 2010; pp. 620–637. [Google Scholar]

- Argyroudis, S.; Pitilakis, K. Seismic fragility curves of shallow tunnels in alluvial deposits. Soil Dyn. Earthq. Eng. 2012, 35, 1–12. [Google Scholar] [CrossRef]

- Debiasi, E.; Gajo, A.; Zonta, D. On the seismic response of shallow-buried rectangular structures. Tunn. Undergr. Space Tech. 2013, 38, 99–113. [Google Scholar] [CrossRef]

- Park, D.; Sagong, M.; Kwak, D.Y.; Jeong, C.G. Simulation of tunnel response under spatially varying ground motion. Soil Dyn. Earthq. Eng. 2009, 29, 1417–1424. [Google Scholar] [CrossRef]

- Wang, J.N. Seismic Design of Tunnels: A Simple State-of-the-Art Design Approach; Parsons Brinckerhoff: New York, NY, USA, 1993. [Google Scholar]

- Wood, J.H. Earthquake Design Procedures for Rectangular Underground Structures; Earthquake Commission Research Foundation: Wellington, New Zealand, 2004. [Google Scholar]

- Yoo, J.K.; Park, J.S.; Park, D.; Lee, S.W. Seismic response of circular tunnels in jointed rock. KSCE J. Civ. Eng. 2018, 22, 1121–1129. [Google Scholar] [CrossRef]

- Tsinidis, G.; Rovithis, E.; Pitilakis, K.; Chazelas, J.L. Seismic response of box-type tunnels in soft soil: Experimental and numerical investigation. Tunn. Undergr. Space Tech. 2016, 59, 199–214. [Google Scholar] [CrossRef]

- Katona, M.G. Seismic design and analysis of buried culverts and structures. J. Pipeline Syst. Eng. Pract. 2010, 1, 111–119. [Google Scholar] [CrossRef]

- Liu, R.; Shi, H. An improved pseudo-static method for seismic resistant design of underground structures. Earthq. Eng. Eng. Vib. 2006, 5, 189–193. [Google Scholar] [CrossRef]

- Lu, C.C.; Hwang, J.H. Implementation of the modified cross-section racking deformation method using explicit FDM program: A critical assessment. Tunn. Undergr. Space Tech. 2017, 68, 58–73. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, X.; Zhang, J.; Meng, F. Three-dimensional limit analysis of seismic stability of tunnel faces with quasi-static method. Geomech. Eng. 2017, 13, 301–318. [Google Scholar]

- Do, N.A.; Dias, D.; Oreste, P.; Djeran-Maigre, I. 2D numerical investigations of twin tunnel interaction. Geomech. Eng. 2014, 6, 263–275. [Google Scholar] [CrossRef]

- Nguyen, D.D.; Park, D.; Shamsher, S.; Nguyen, V.Q.; Lee, T.H. Seismic vulnerability assessment of rectangular cut-and-cover subway tunnels. Tunn. Undergr. Space Tech. 2019, 86, 247–261. [Google Scholar] [CrossRef]

- Xu, Z.; Du, X.; Xu, C.; Jiang, J.; Han, R. Simplified equivalent static methods for seismic analysis of shallow buried rectangular underground structures. Soil Dyn. Earthq. Eng. 2019, 121, 1–11. [Google Scholar] [CrossRef]

- Huh, J.; Tran, Q.H.; Haldar, A.; Park, I.; Ahn, J.H. Seismic Vulnerability Assessment of a Shallow Two-Story Underground RC Box Structure. Appl. Sci. 2017, 7, 735. [Google Scholar] [CrossRef]

- CSI SAP2000 Software, ver15; Computer and Structures Inc.: Berkeley, CA, USA, 2011.

- ACI-318. Building Code Requirements for Structural Concrete and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2008.

- FEMA-356. Prestandard and Commentary for the Seismic Rehabilitation of Buildings; Federal Emergency Management Agency: Washington, DC, USA, 2000.

- Park, R.; Paulay, T. Reinforced Concrete Structures; John Wiley & Sons: Hoboken, NJ, USA, 1975. [Google Scholar]

- MLTM. Earthquake Resistance Design Regulations for Subway Structures; Ministry of Land, Transport and Maritime Affairs of Korea: Sejong, Korea, 2009.

- Anderson, D.G. Seismic Analysis and Design of Retaining Walls, Buried Structures, Slopes, and Embankments; 0309117658; Transportation Research Board: Washington, DC, USA, 2008. [Google Scholar]

- Penzien, J. Seismically induced racking of tunnel linings. Earthq. Eng. Struct. Dyn. 2000, 29, 683–691. [Google Scholar] [CrossRef]

- An, X.; Maekawa, K. Failure analysis of underground RC frame subjected to seismic actions. J. Mater. Conc. Struct. Pav. JSCE 1997, 36, 251–267. [Google Scholar]

- Moehle, J.; Elwood, K.; Sezen, H. Gravity load collapse of building frames during earthquakes. ACI Spec. Pub. 2001, 197, 215–238. [Google Scholar]

- Yoshimura, M.; Takaine, Y.; Nakamura, T. Axial collapse of reinforced concrete columns. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004; pp. 1–6. [Google Scholar]

- Yoshida, N.; Nakamura, S. Damage to Daikai Subway Station. During The 1995 Hyogoken-Nunbu Earthquake and Its Investigation. In Proceedings of the 11th World Conference on Earthquake Engineering, Acapulco, Mexico, 23–28 June 1996; pp. 287–295. [Google Scholar]

- Husain, M.; Tsopelas, P. Measures of structural redundancy in reinforced concrete buildings. I: Redundancy indices. J. Struct. Eng. 2004, 130, 1651–1658. [Google Scholar] [CrossRef]

| Tunnel Type | Damage State | Number of Plastic Hinges (NPH) | DI of Lee et al. [21] | Updated DI |

|---|---|---|---|---|

| Single box | None | 0 | DI < 1.0 | DI < 1.0 |

| Minor | 1 ≤ NPH < 2 | 1.0 ≤ DI < 1.2 | 1.0 ≤ DI < 1.4 | |

| Moderate | 2 ≤ NPH < 3 | 1.2 ≤ DI < 2.0 | 1.4 ≤ DI < 2.3 | |

| Extensive | 3 ≤ NPH | 2.0 ≤ DI | 2.3 ≤ DI | |

| Double box Triple box | None | 0 | DI < 1.0 | DI < 1.0 |

| Minor | 1 ≤ NPH < 2 | 1.0 ≤ DI < 1.2 | 1.0 ≤ DI < 1.2 | |

| Moderate | 2 ≤ NPH < 3 | 1.2 ≤ DI < 2.0 | 1.2 ≤ DI < 2.0 | |

| Extensive | 3 ≤ NPH < 5 | 2.0 ≤ DI | 2.0 ≤ DI < 3.5 | |

| Collapse | 5 ≤ NPH | N.A. | 3.5 ≤ DI |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, D.-D.; Lee, T.-H.; Nguyen, V.-Q.; Park, D. Seismic Damage Analysis of Box Metro Tunnels Accounting for Aspect Ratio and Shear Failure. Appl. Sci. 2019, 9, 3207. https://doi.org/10.3390/app9163207

Nguyen D-D, Lee T-H, Nguyen V-Q, Park D. Seismic Damage Analysis of Box Metro Tunnels Accounting for Aspect Ratio and Shear Failure. Applied Sciences. 2019; 9(16):3207. https://doi.org/10.3390/app9163207

Chicago/Turabian StyleNguyen, Duy-Duan, Tae-Hyung Lee, Van-Quang Nguyen, and Duhee Park. 2019. "Seismic Damage Analysis of Box Metro Tunnels Accounting for Aspect Ratio and Shear Failure" Applied Sciences 9, no. 16: 3207. https://doi.org/10.3390/app9163207

APA StyleNguyen, D.-D., Lee, T.-H., Nguyen, V.-Q., & Park, D. (2019). Seismic Damage Analysis of Box Metro Tunnels Accounting for Aspect Ratio and Shear Failure. Applied Sciences, 9(16), 3207. https://doi.org/10.3390/app9163207