Influence of Commercial Biochar Fillers on Brittleness/Ductility of Epoxy Resin Composites

Abstract

Highlights

- Ultrasonication based procedure was developed to easily disperse biochar into epoxy matrix;

- Using wheat straw derived biochar as a filler, the Young’s modulus doubles that of neat epoxy resin;

- Using a Miscanthus derived biochar, an increment of 40% of the maximum elongation value is obtained;

- A relationship between biochar and composites brittleness/ductility is found and an interpretative model was proposed.

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results

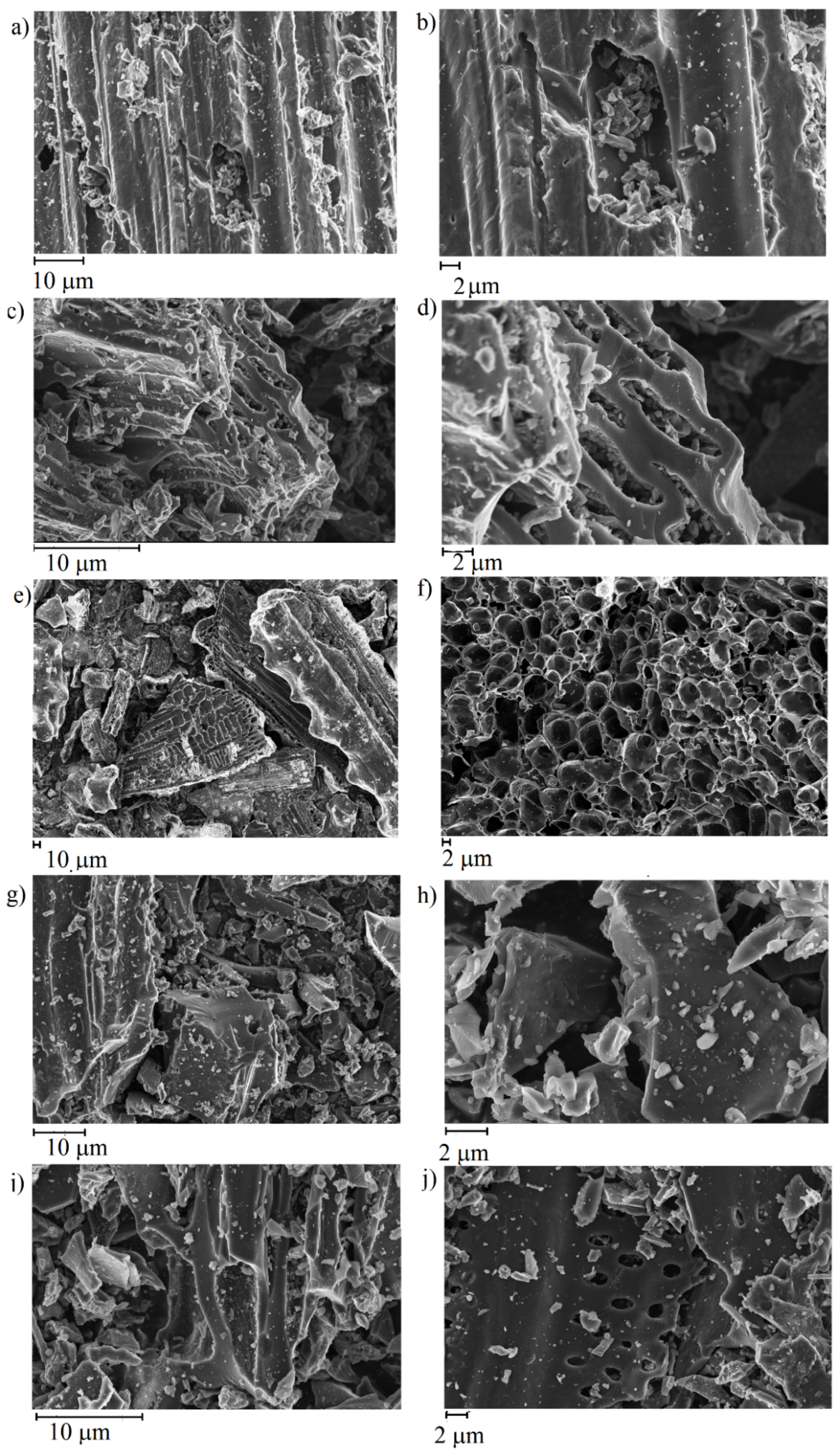

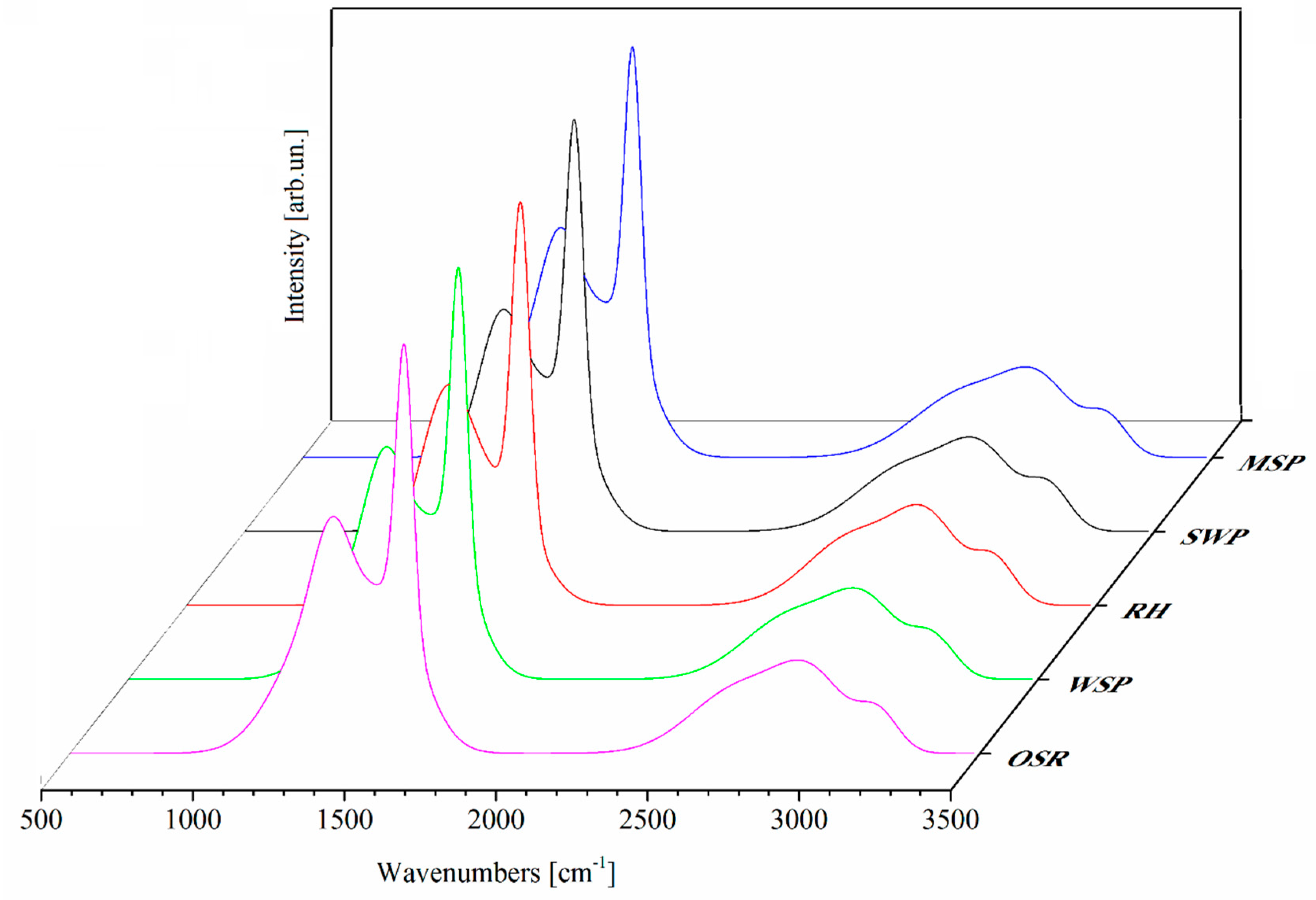

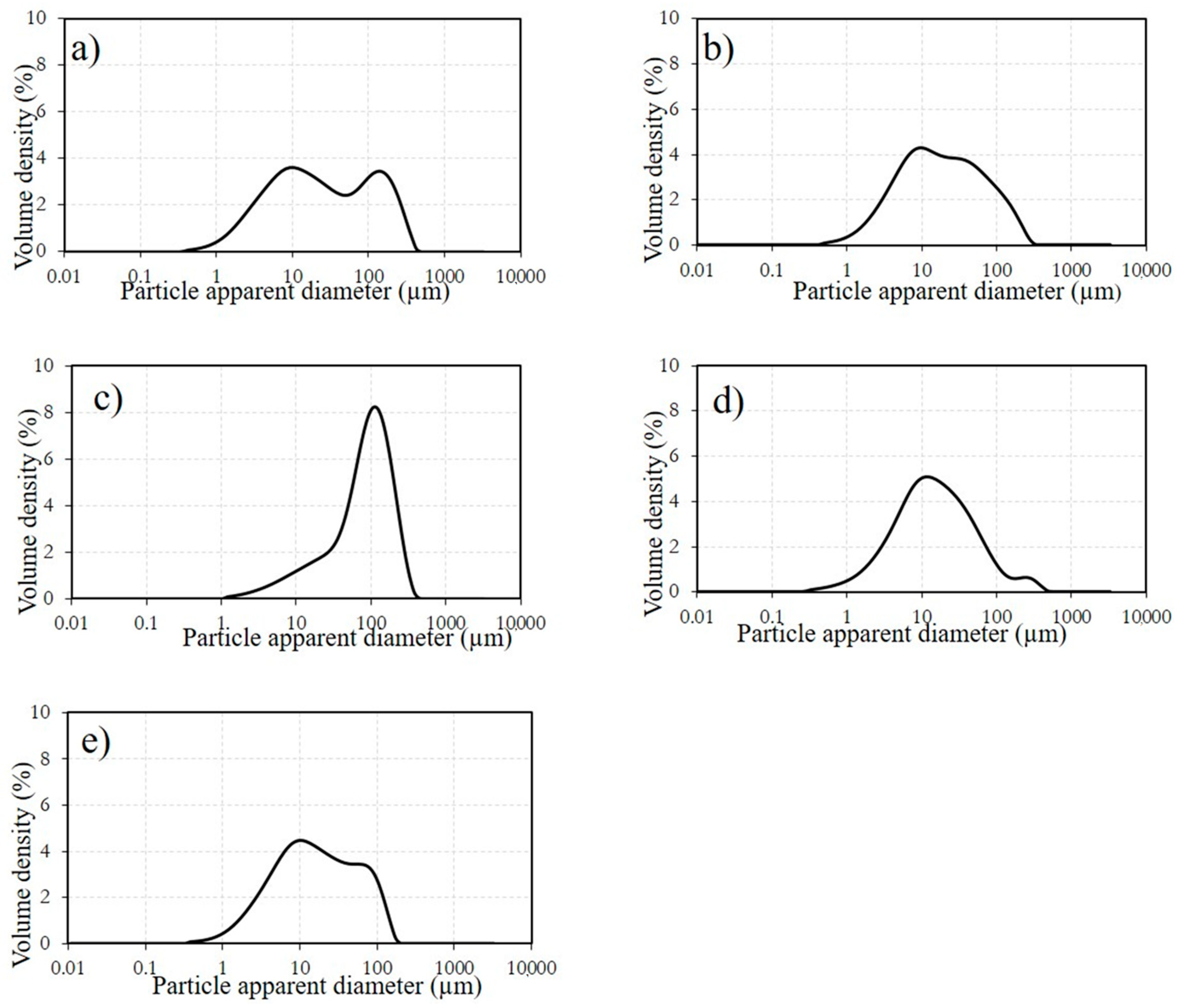

3.1. Biochars Characterization

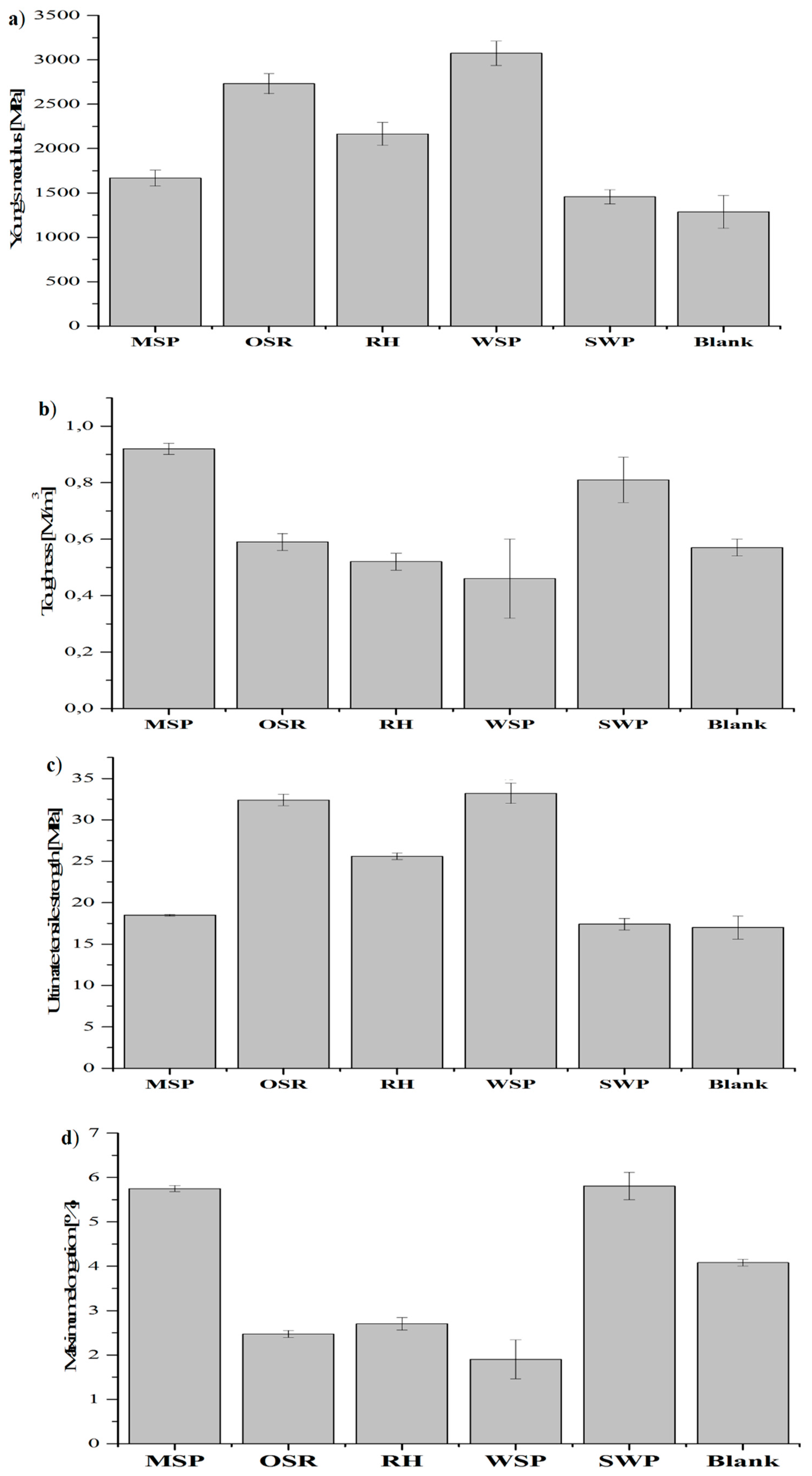

3.2. Mechanical Properties of the Biochar-Based Composites

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Jin, F.L.; Li, X.; Park, S.J. Synthesis and application of epoxy resins: A review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Friedrich, K.; Almajid, A.A. Manufacturing aspects of advanced polymer composites for automotive applications. Appl. Compos. Mater. 2013, 20, 107–128. [Google Scholar] [CrossRef]

- Chatterjee, B.; Bhowmik, S. Evolution of Material Selection in Commercial Aviation Industry—A Review. In Sustainable Engineering Products and Manufacturing Technologies; Elsevier BV: Amsterdam, The Netherlands, 2019; pp. 199–219. [Google Scholar]

- Allaoui, A. Mechanical and electrical properties of a MWNT/epoxy composite. Compos. Sci. Technol. 2002, 62, 1993–1998. [Google Scholar] [CrossRef]

- Naebe, M.; Wang, J.; Amini, A.; Khayyam, H.; Hameed, N.; Li, L.H.; Chen, Y.; Fox, B. Mechanical Property and Structure of Covalent Functionalised Graphene/Epoxy Nanocomposites. Sci. Rep. 2014, 4, 4375. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.S.; Youn, J.R. Influence of dispersion states of carbon nanotubes on physical properties of epoxy nanocomposites. Carbon 2005, 43, 1378–1385. [Google Scholar] [CrossRef]

- Lahelin, M.; Annala, M.; Nykänen, A.; Ruokolainen, J.; Seppälä, J. In situ polymerized nanocomposites: Polystyrene/CNT and Poly (methyl methacrylate)/CNT composites. Compos. Sci. Technol. 2011, 71, 900–907. [Google Scholar] [CrossRef]

- Downie, A.; Crosky, A.; Munroe, P. Physical Properties of Biochar. In Biochar for Environmental Management: Science and Technology; Earthscan Publications Ltd.: London, UK, 2009; pp. 13–32. [Google Scholar]

- Khan, A.; Savi, P.; Quaranta, S.; Rovere, M.; Giorcelli, M.; Tagliaferro, A.; Rosso, C.; Jia, C.Q. Low-Cost Carbon Fillers to Improve Mechanical Properties and Conductivity of Epoxy Composites. Polymers 2017, 9, 642. [Google Scholar] [CrossRef]

- Khan, A.; Jagdale, P.; Rovere, M.; Nogués, M.; Rosso, C.; Tagliaferro, A. Carbon from waste source: An eco-friendly way for strengthening polymer composites. Compos. Part B Eng. 2018, 132, 87–96. [Google Scholar] [CrossRef]

- Giorcelli, M.; Khan, A.; Pugno, N.M.; Rosso, C.; Tagliaferro, A. Biochar as a cheap and environmental friendly filler able to improve polymer mechanical properties. Biomass Bioenergy 2019, 120, 219–223. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. Structure–mechanics property relationship of waste derived biochars. Sci. Total. Environ. 2015, 538, 611–620. [Google Scholar] [CrossRef]

- Das, O.; Sarmah, A.K.; Bhattacharyya, D. A sustainable and resilient approach through biochar addition in wood polymer composites. Sci. Total Environ. 2015, 512, 326–336. [Google Scholar] [CrossRef] [PubMed]

- Mašek, O.; Buss, W.; Roy-Poirier, A.; Lowe, W.; Peters, C.; Brownsort, P.; Mignard, D.; Pritchard, C.; Sohi, S. Consistency of biochar properties over time and production scales: A characterisation of standard materials. J. Anal. Appl. Pyrolysis 2018, 132, 200–210. [Google Scholar] [CrossRef]

- UK Biochar Research Centre-Reducing and Removing CO2 while Improving Soils: a Significant and Sustainable Response to Climate Change. Available online: https://www.biochar.ac.uk/standard_materials.php (accessed on 29 July 2019).

- Hara, O. Curing Agents for Epoxy Resin; Three Bond Co., LTD.: Tokyo, Japan, 1990; Volume 32, pp. 1–10. [Google Scholar]

- Jiang, L.; Gao, L.; Sun, J. Production of aqueous colloidal dispersions of carbon nanotubes. J. Colloid Interface Sci. 2003, 260, 89–94. [Google Scholar] [CrossRef]

- Ramasubramaniam, R.; Chen, J.; Liu, H. Homogeneous carbon nanotube/polymer composites for electrical applications. Appl. Phys. Lett. 2003, 83, 2928–2930. [Google Scholar] [CrossRef]

- Rae, J.; AshokKumar, M.; Eulaerts, O.; Von Sonntag, C.; Reisse, J.; Grieser, F. Estimation of ultrasound induced cavitation bubble temperatures in aqueous solutions. Ultrason. Sonochem. 2005, 12, 325–329. [Google Scholar] [CrossRef] [PubMed]

- Grønli, M.G.; Melaaen, M.C. Mathematical Model for Wood PyrolysisComparison of Experimental Measurements with Model Predictions. Energy Fuels 2000, 14, 791–800. [Google Scholar] [CrossRef]

- Masulili, A.; Utomo, W.H.; Ms, S. Rice Husk Biochar for Rice Based Cropping System in Acid Soil 1. The Characteristics of Rice Husk Biochar and Its Influence on the Properties of Acid Sulfate Soils and Rice Growth in West Kalimantan, Indonesia. J. Agric. Sci. 2010, 2, 39. [Google Scholar] [CrossRef]

- Orlovius, K. Fertilizing for High Yield and Quality Oilseed Rape. IPI Bull. 2003, 16, 125. [Google Scholar]

- Baltrėnas, P.; Baltrėnaitė, E.; Spudulis, E. Biochar from Pine and Birch Morphology and Pore Structure Change by Treatment in Biofilter. Water Air Soil Pollut. 2015, 226, 69. [Google Scholar] [CrossRef]

- Plötze, M.; Niemz, P. Porosity and pore size distribution of different wood types as determined by mercury intrusion porosimetry. Eur. J. Wood Wood Prod. 2011, 69, 649–657. [Google Scholar] [CrossRef]

- Chia, C.H.; Gong, B.; Joseph, S.D.; Marjo, C.E.; Munroe, P.; Rich, A.M. Imaging of mineral-enriched biochar by FTIR, Raman and SEM–EDX. Vib. Spectrosc. 2012, 62, 248–257. [Google Scholar] [CrossRef]

- Feifel, S.C.; Lisdat, F. Silica nanoparticles for the layer-by-layer assembly of fully electro-active cytochrome c multilayers. J. Nanobiotechnol. 2011, 9, 59. [Google Scholar] [CrossRef] [PubMed]

- Prakongkep, N.; Gilkes, R.J.; Wiriyakitnateekul, W.; Duangchan, A.; Darunsontaya, T. The effects of pyrolysis conditions on the chemical and physical properties of rice husk biochar. Int. J. Mater. Sci. 2013, 3, 97–103. [Google Scholar]

- Guo, J.; Chen, B. Insights on the Molecular Mechanism for the Recalcitrance of Biochars: Interactive Effects of Carbon and Silicon Components. Environ. Sci. Technol. 2014, 48, 9103–9112. [Google Scholar] [CrossRef] [PubMed]

- Liou, T.H.; Yang, C.C. Synthesis and surface characteristics of nanosilica produced from alkali-extracted rice husk ash. Mater. Sci. Eng. B 2011, 176, 521–529. [Google Scholar] [CrossRef]

- James, J.; Rao, M. Silica from rice husk through thermal decomposition. Thermochim. Acta 1986, 97, 329–336. [Google Scholar] [CrossRef]

- Merlen, A.; Buijnsters, J.G.; Pardanaud, C. A Guide to and Review of the Use of Multiwavelength Raman Spectroscopy for Characterizing Defective Aromatic Carbon Solids: From Graphene to Amorphous Carbons. Coatings 2017, 7, 153. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095–14107. [Google Scholar] [CrossRef]

- Weber, K.; Quicker, P. Properties of biochar. Fuel 2018, 217, 240–261. [Google Scholar] [CrossRef]

- Allaoui, A. How carbon nanotubes affect the cure kinetics and glass transition temperature of their epoxy composites?—A review. Express Polym. Lett. 2009, 3, 588–594. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.; Kohlhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-based composite materials. Nature 2006, 442, 282. [Google Scholar] [CrossRef] [PubMed]

- Ramanathan, T.; Abdala, A.A.; Stankovich, S.; Dikin, D.A.; Herrera-Alonso, M.; Piner, R.D.; Adamson, D.H.; Schniepp, H.C.; Chen, X.; Ruoff, R.S.; et al. Functionalized graphene sheets for polymer nanocomposites. Nat. Nanotechnol. 2008, 3, 327–331. [Google Scholar] [CrossRef] [PubMed]

| Feedstock | ID | Heating Rate (°C/min) | Residence Time (min) | Biochar Yield (wt.%) | |

|---|---|---|---|---|---|

| Kiln Residence Time | HTT Residence Time | ||||

| Miscanthus straw | MSP | 65 | 12 | 4 | 22.8 |

| Wheat straw | WSP | 80 | 15 | 5 | 24.1 |

| Rice husk | RH | 98 | 15 | 8 | 37.2 |

| Mixed softwoods | SWP | 78 | 12 | 4 | 21.8 |

| Oil seed rape | OSR | 78 | 12 | 5 | 28.9 |

| Proximate Analysis (wt.%) | Ultimate Analysis (%) | Specific Surface Area (m2/g) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| ID | Moisture | Ash | VOCs | Fixed Carbon a | C | H | N | Ob | |

| MSP | 1.83 | 12.15 | 11.62 | 74.40 | 75.41 | 2.42 | 0.78 | 9.24 | 33.6 |

| WSP | 1.68 | 10.55 | 21.25 | 66.52 | 68.26 | 2.10 | 1.39 | 6.92 | 26.4 |

| RH | 1.54 | 47.93 | 7.48 | 43.05 | 48.49 | 1.24 | 1.04 | 2.47 | 20.1 |

| SWP | 1.52 | 1.25 | 14.20 | 83.03 | 85.53 | 2.77 | 0.10 | 10.36 | 26.4 |

| OSR | 2.61 | 19.50 | 16.38 | 61.51 | 68.85 | 1.82 | 1.59 | 8.91 | 7.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartoli, M.; Giorcelli, M.; Rosso, C.; Rovere, M.; Jagdale, P.; Tagliaferro, A. Influence of Commercial Biochar Fillers on Brittleness/Ductility of Epoxy Resin Composites. Appl. Sci. 2019, 9, 3109. https://doi.org/10.3390/app9153109

Bartoli M, Giorcelli M, Rosso C, Rovere M, Jagdale P, Tagliaferro A. Influence of Commercial Biochar Fillers on Brittleness/Ductility of Epoxy Resin Composites. Applied Sciences. 2019; 9(15):3109. https://doi.org/10.3390/app9153109

Chicago/Turabian StyleBartoli, Mattia, Mauro Giorcelli, Carlo Rosso, Massimo Rovere, Pravin Jagdale, and Alberto Tagliaferro. 2019. "Influence of Commercial Biochar Fillers on Brittleness/Ductility of Epoxy Resin Composites" Applied Sciences 9, no. 15: 3109. https://doi.org/10.3390/app9153109

APA StyleBartoli, M., Giorcelli, M., Rosso, C., Rovere, M., Jagdale, P., & Tagliaferro, A. (2019). Influence of Commercial Biochar Fillers on Brittleness/Ductility of Epoxy Resin Composites. Applied Sciences, 9(15), 3109. https://doi.org/10.3390/app9153109