Operational Optimisation of a Non-Recuperative 1-kWe Organic Rankine Cycle Engine Prototype

Abstract

1. Introduction

2. Experimental Methods

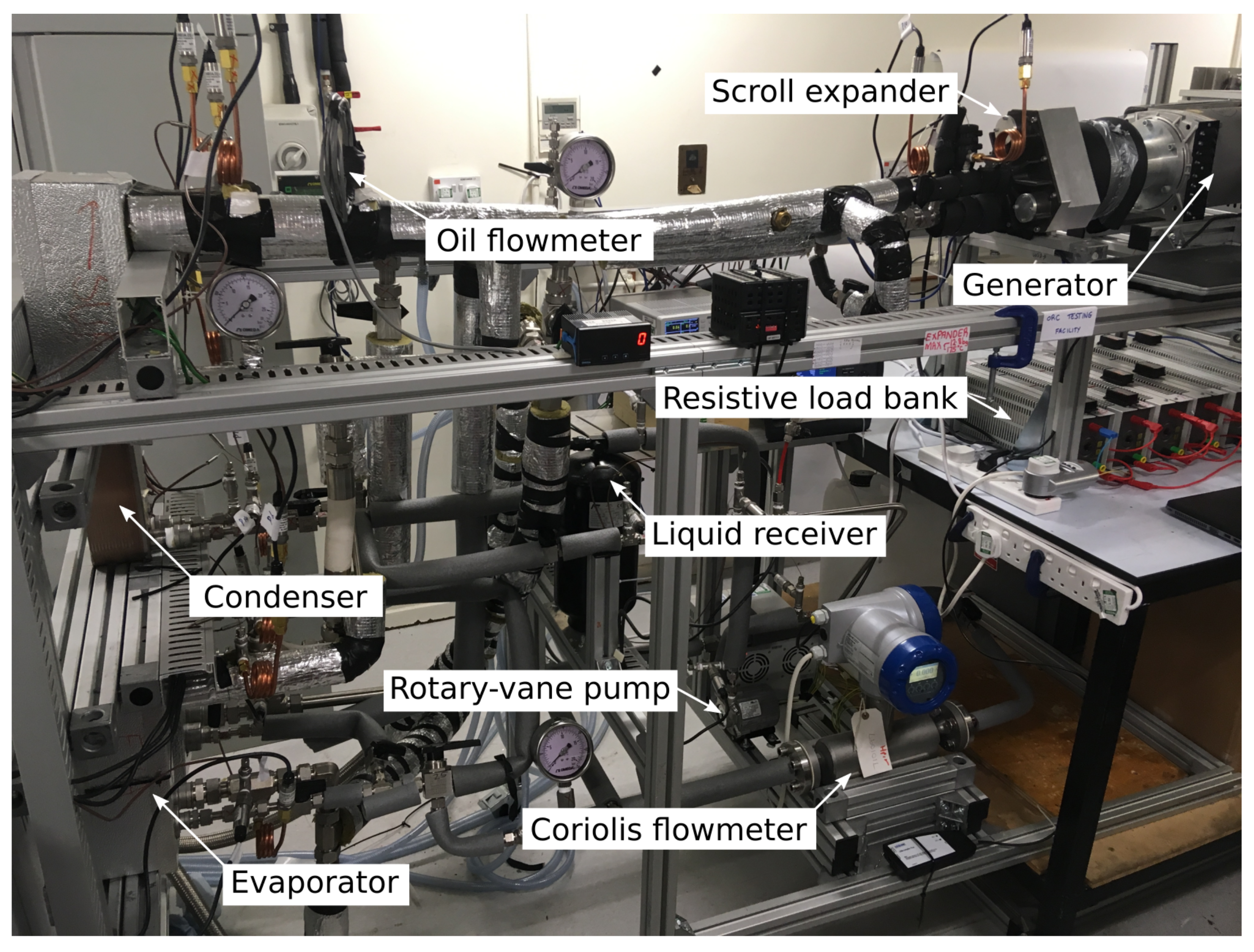

2.1. ORC Testing Facility

2.2. Time-Resolved Data Acquisition

2.3. Experimental Procedures

3. Data Analysis

3.1. Time-Averaging and Error Propagation

3.2. Overall ORC Performance

3.3. Components Performance

3.3.1. Exergy Destruction Rates

3.3.2. Expander Performance

3.4. Transient Data Analysis

4. Steady-State ORC Performance

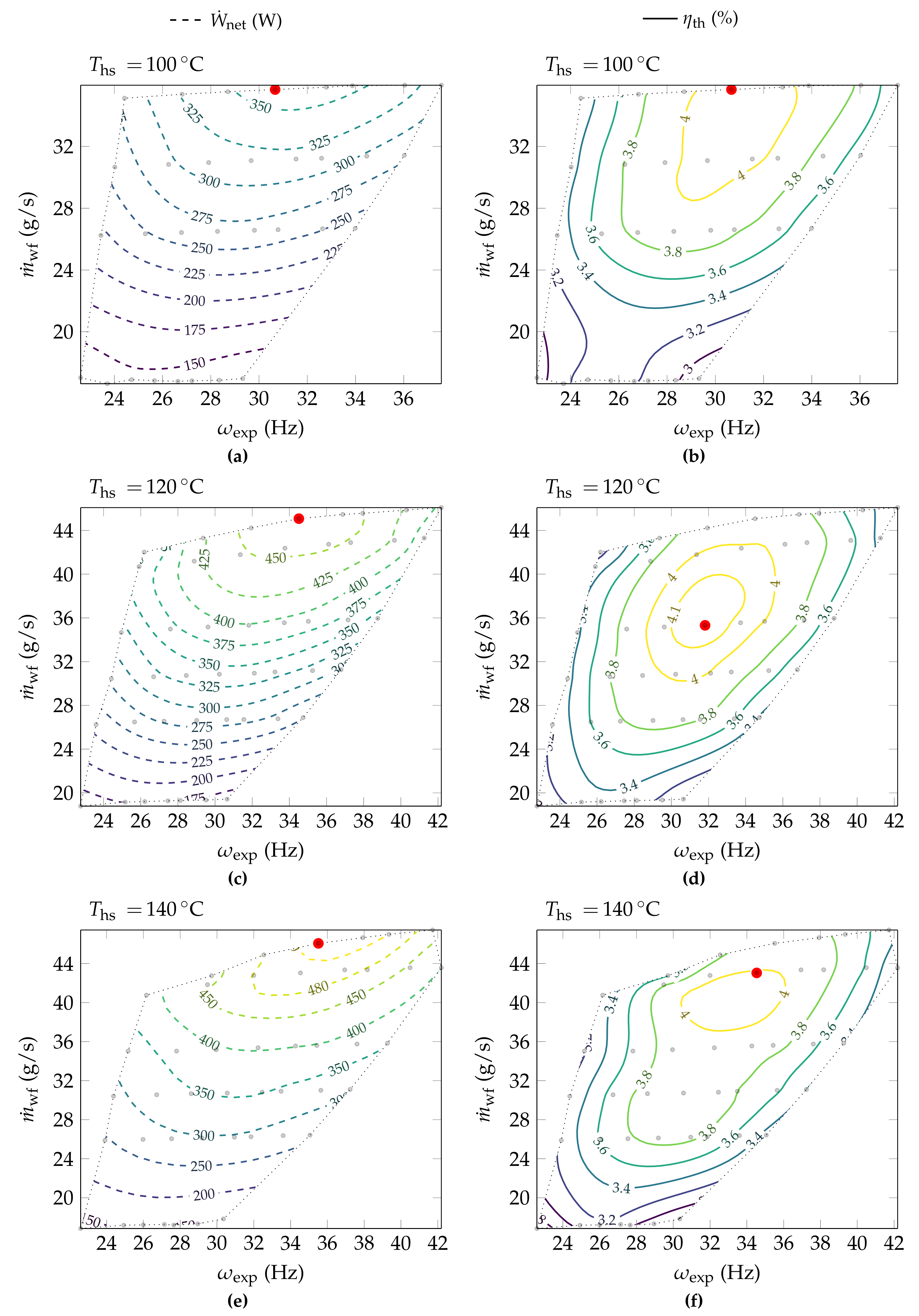

4.1. Operating Parameters Optimisation

4.2. Part-Load Performance Maps

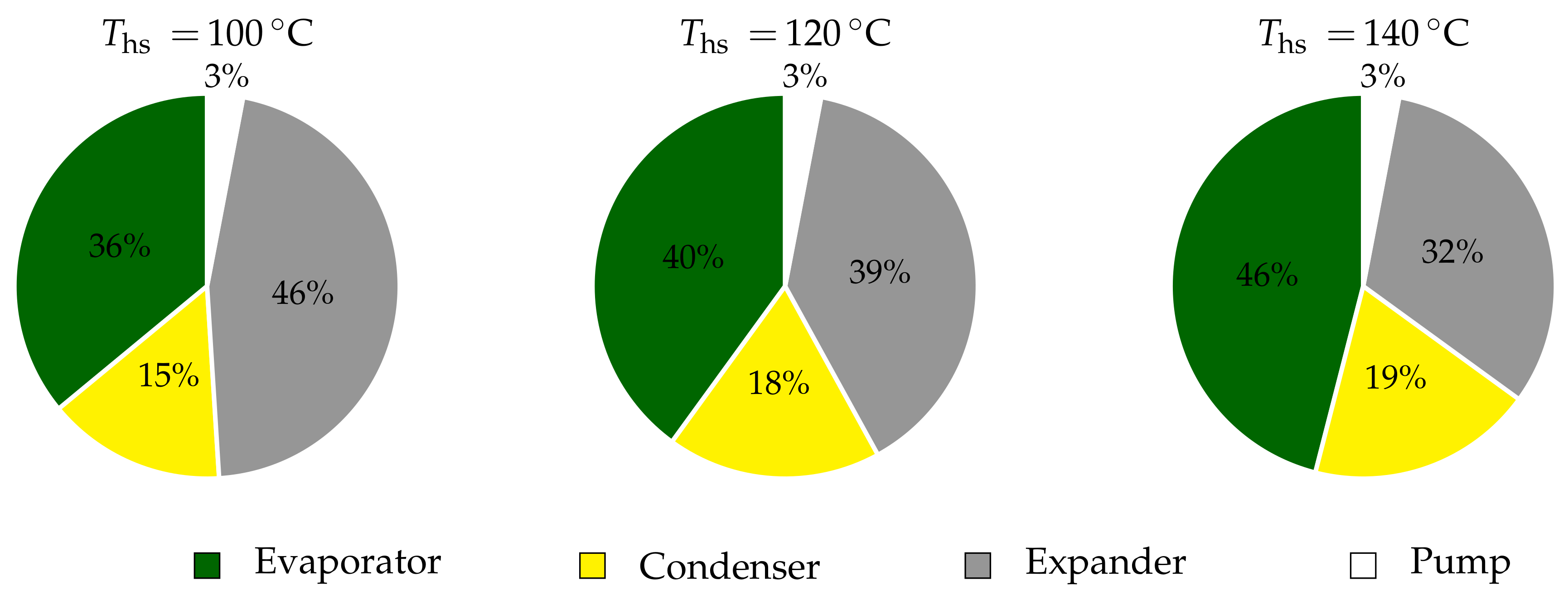

4.2.1. Thermodynamic Analysis of the Optimum Configurations

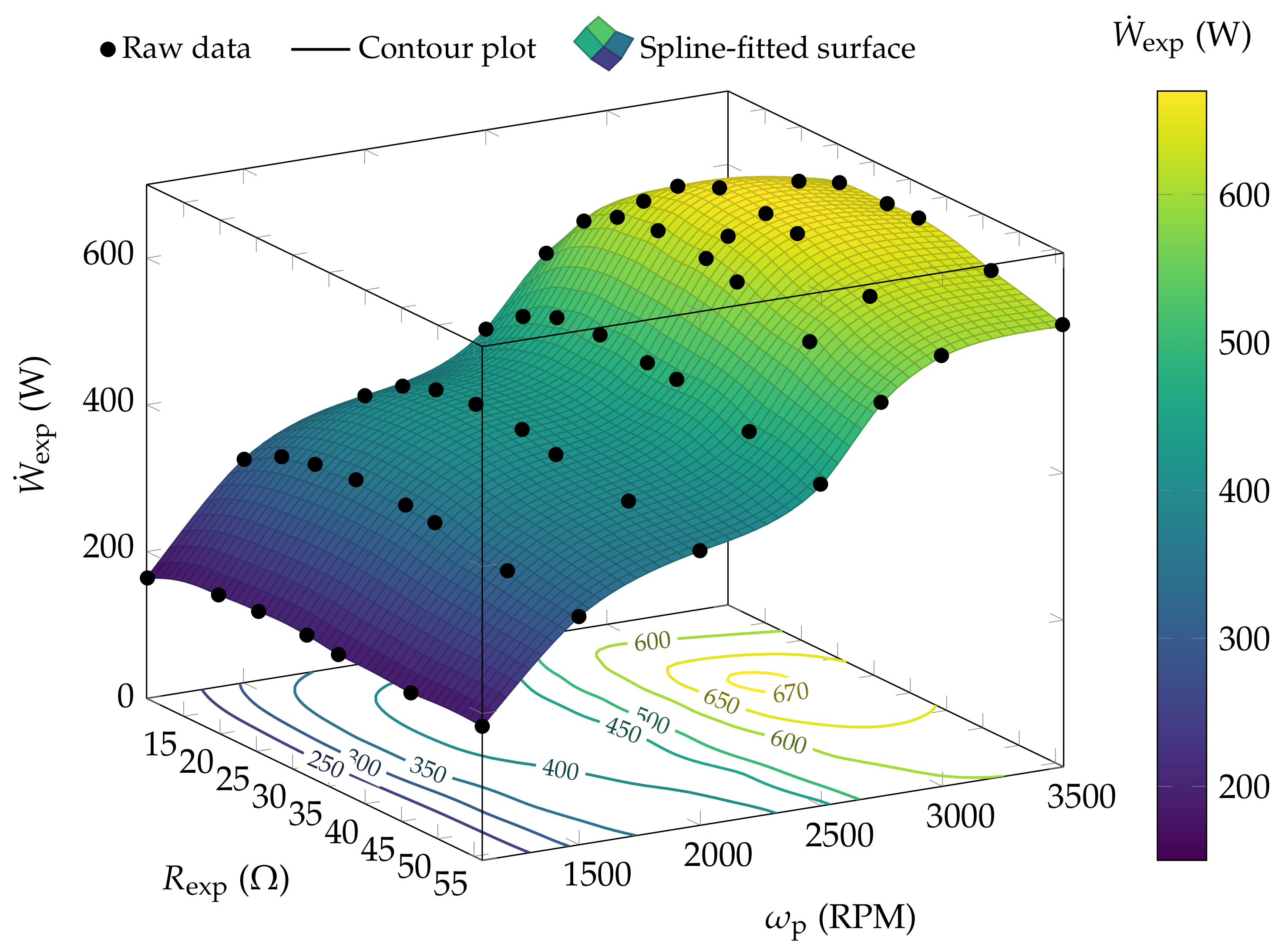

4.2.2. Expander Performance

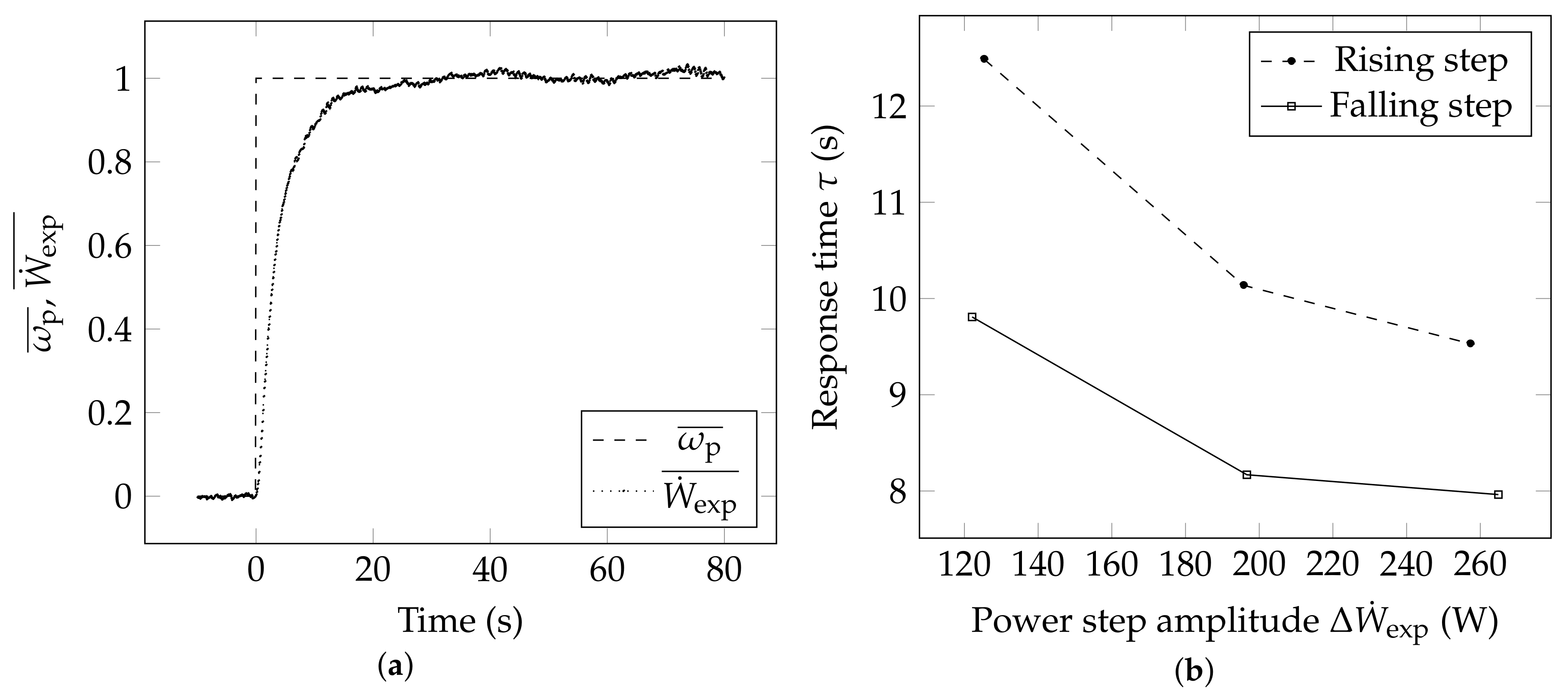

5. Dynamic Characteristics of the ORC Engine

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Exergy destruction rate (W) | |

| Mass flowrate (kg/s) | |

| Number of samples for measurement | |

| Heat flow (W) | |

| Pressure ratio (-) | |

| Volume ratio (-) | |

| u | Uncertainty |

| Power (W) | |

| Exergy flow (W) | |

| Greek characters | |

| Efficiency (%) | |

| Filling factor (-) | |

| Fictive time-resolved measurement | |

| Standard deviation | |

| Rising or falling time (s) | |

| Rotation speed (RPM) | |

| Subscripts and superscripts | |

| Condenser | |

| Cooling water | |

| Displacement | |

| Evaporator | |

| Exergy | |

| Expander | |

| Final | |

| Heat source | |

| Inlet/intake/input | |

| Initial | |

| Isentropic | |

| Outlet/exhaust/output | |

| Pump | |

| Sensor | |

| Subcooling | |

| Superheating | |

| Thermal | |

| Working fluid | |

| Abbreviations | |

| CAMD | Computer-aided molecular design |

| DAQ | Data acquisition system |

| ICE | Internal combustion engine |

| ORC | Organic Rankine cycle |

| PID | Proportional integral derivative |

| P&I | Piping and instrumentation |

| RPM | Revolutions per minute |

| WHR | Waste-heat recovery |

References

- Markides, C.N. The role of pumped and waste heat technologies in a high-efficiency sustainable energy future for the UK. Appl. Therm. Eng. 2013, 53, 47. [Google Scholar] [CrossRef]

- Markides, C.N. Low-concentration solar-power systems based on organic Rankine cycles for distributed-scale applications: Overview and further developments. Front. Energy Res. 2015, 3, 197–209. [Google Scholar] [CrossRef]

- Van Erdeweghe, S.; Van Bael, J.; Laenen, B.; D’haeseleer, W. Optimal combined heat-and-power plant for a low-temperature geothermal source. Energy 2018, 150, 369–409. [Google Scholar] [CrossRef]

- Oyewunmi, O.A.; Kirmse, C.J.; Pantaleo, A.M.; Markides, C.N. Performance of working-fluid mixtures in ORC-CHP systems for different heat-demand segments and heat-recovery temperature levels. Energy Convers. Manag. 2017, 148, 1508–1524. [Google Scholar] [CrossRef]

- Oyewunmi, O.A.; Markides, C.N. Thermo-economic and heat transfer optimization of working-fluid mixtures in a low-temperature organic Rankine cycle system. Energies 2016, 9, 448. [Google Scholar] [CrossRef]

- Pantaleo, A.M.; Camporeale, S.M.; Sorrentino, A.; Miliozzi, A.; Shah, N.; Markides, C.N. Hybrid solar-biomass combined Brayton/organic Rankine-cycle plants integrated with thermal storage: Techno-economic feasibility in selected Mediterranean areas. Renew. Energy 2018. In Press. [Google Scholar] [CrossRef]

- Tchanche, B.F.; Papadakis, G.; Lambrinos, G.; Frangoudakis, A. Fluid selection for a low-temperature solar organic Rankine cycle. Appl. Therm. Eng. 2009, 29, 2468–2476. [Google Scholar] [CrossRef]

- Kang, S.H. Design and experimental study of ORC (organic Rankine cycle) and radial turbine using R245fa working fluid. Energy 2012, 41, 514–524. [Google Scholar] [CrossRef]

- Oyewunmi, O.A.; Taleb, A.I.; Haslam, A.J.; Markides, C.N. An assessment of working-fluid mixtures using SAFT-VR Mie for use in organic Rankine cycle systems for waste-heat recovery. Compt. Therm. Sci. 2014, 6, 301–316. [Google Scholar] [CrossRef]

- Freeman, J.; Guarracino, I.; Kalogirou, S.A.; Markides, C.N. A small-scale solar organic Rankine cycle combined heat and power system with integrated thermal energy storage. Appl. Therm. Eng. 2017, 127, 1543–1554. [Google Scholar] [CrossRef]

- Tian, H.; Liu, L.; Shu, G.; Wei, H.; Liang, X. Theoretical research on working fluid selection for a high-temperature regenerative transcritical dual-loop engine organic Rankine cycle. Energy Convers. Manag. 2014, 86, 764–773. [Google Scholar] [CrossRef]

- Freeman, J.; Hellgardt, K.; Markides, C.N. Working fluid selection and electrical performance optimisation of a domestic solar-ORC combined heat and power system for year-round operation in the UK. Appl. Energy 2017, 186, 291–303. [Google Scholar] [CrossRef]

- Oyewunmi, O.A.; Taleb, A.I.; Haslam, A.J.; Markides, C.N. On the use of SAFT-VR Mie for assessing large-glide fluorocarbon working-fluid mixtures in organic Rankine cycles. Appl. Energy 2016, 163, 263–282. [Google Scholar] [CrossRef]

- Song, J.; Gu, C.W.; Li, X.S. Performance estimation of Tesla turbine applied in small scale organic Rankine cycle (ORC) system. Appl. Therm. Eng. 2017, 110, 318–326. [Google Scholar] [CrossRef]

- Mounier, V.; Olmedo, L.E.; Schiffmann, J. Small scale radial inflow turbine performance and pre-design maps for organic Rankine cycles. Energy 2018, 143, 1072–1084. [Google Scholar] [CrossRef]

- Landelle, A.; Tauveron, N.; Revellin, R.; Haberschill, P.; Colasson, S.; Roussel, V. Performance investigation of reciprocating pump running with organic fluid for organic Rankine cycle. Appl. Therm. Eng. 2017, 113, 962–969. [Google Scholar] [CrossRef]

- Chatzopoulou, M.A.; Simpson, M.; Sapin, P.; Markides, C.N. Off-design optimisation of organic Rankine cycle (ORC) engines with piston expanders for medium-scale combined heat and power applications. Appl. Energy 2019, 238, 1211–1236. [Google Scholar] [CrossRef]

- Shu, G.; Li, X.; Tian, H.; Shi, L.; Wang, X.; Yu, G. Design condition and operating strategy analysis of CO2 transcritical waste heat recovery system for engine with variable operating conditions. Energy Convers. Manag. 2017, 142, 188–199. [Google Scholar] [CrossRef]

- Li, X.; Tian, H.; Shu, G.; Zhao, M.; Markides, C.N.; Hu, C. Potential of carbon dioxide transcritical power cycle waste-heat recovery systems for heavy-duty truck engines. Appl. Energy 2019, 250, 1581–1599. [Google Scholar] [CrossRef]

- Ramos, A.; Chatzopoulou, M.A.; Freeman, J.; Markides, C.N. Optimisation of a high-efficiency solar-driven organic Rankine cycle for applications in the built environment. Appl. Energy 2018, 228, 755–765. [Google Scholar] [CrossRef]

- Ziviani, D.; Gusev, S.; Lecompte, S.; Groll, E.; Braun, J.; Horton, W.; van den Broek, M.; De Paepe, M. Optimizing the performance of small-scale organic Rankine cycle that utilizes a single-screw expander. Appl. Energy 2017, 189, 416–432. [Google Scholar] [CrossRef]

- White, M.T.; Oyewunmi, O.A.; Chatzopoulou, M.A.; Pantaleo, A.M.; Haslam, A.J.; Markides, C.N. Computer-aided working-fluid design, thermodynamic optimisation and thermoeconomic assessment of ORC systems for waste-heat recovery. Energy 2018, 161, 1181–1198. [Google Scholar] [CrossRef]

- Tocci, L.; Pal, T.; Pesmazoglou, I.; Franchetti, B. Small scale organic Rankine cycle (ORC): A techno-economic review. Energies 2017, 10, 413. [Google Scholar] [CrossRef]

- Rahbar, K.; Mahmoud, S.; Al-Dadah, R.K.; Moazami, N.; Mirhadizadeh, S.A. Review of organic Rankine cycle for small-scale applications. Energy Convers. Manag. 2017, 134, 135–155. [Google Scholar] [CrossRef]

- Freeman, J.; Hellgardt, K.; Markides, C.N. An assessment of solar-powered organic Rankine cycle systems for combined heating and power in UK domestic applications. Appl. Energy 2015, 138, 605–620. [Google Scholar] [CrossRef]

- Boyaghchi, F.A.; Heidarnejad, P. Thermoeconomic assessment and multi objective optimization of a solar micro CCHP based on organic Rankine cycle for domestic application. Energy Convers. Manag. 2015, 97, 224–234. [Google Scholar] [CrossRef]

- Garcia-Saez, I.; Méndez, J.; Ortiz, C.; Loncar, D.; Becerra, J.A.; Chacartegui, R. Energy and economic assessment of solar Organic Rankine Cycle for combined heat and power generation in residential applications. Renew. Energy 2019, 140, 461–476. [Google Scholar] [CrossRef]

- Tian, H.; Shu, G.; Wei, H.; Liang, X.; Liu, L. Fluids and parameters optimization for the organic Rankine cycles (ORCs) used in exhaust heat recovery of Internal Combustion Engine (ICE). Energy 2012, 47, 125–136. [Google Scholar] [CrossRef]

- Shu, G.; Liu, L.; Tian, H.; Wei, H.; Yu, G. Parametric and working fluid analysis of a dual-loop organic Rankine cycle (DORC) used in engine waste heat recovery. Appl. Energy 2014, 113, 1188–1198. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, E.; Fan, B. A performance analysis of a novel system of a dual loop bottoming organic Rankine cycle (ORC) with a light-duty diesel engine. Appl. Energy 2013, 102, 1504–1513. [Google Scholar] [CrossRef]

- Lecompte, S.; Huisseune, H.; van den Broek, M.; Vanslambrouck, B.; De Paepe, M. Review of organic Rankine cycle (ORC) architectures for waste heat recovery. Renew. Sustain. Energy Rev. 2015, 47, 448–461. [Google Scholar] [CrossRef]

- Shi, L.; Shu, G.; Tian, H.; Deng, S. A review of modified organic Rankine cycles (ORCs) for internal combustion engine waste heat recovery (ICE-WHR). Renew. Sustain. Energy Rev. 2018, 92, 95–110. [Google Scholar] [CrossRef]

- White, M.T.; Oyewunmi, O.A.; Haslam, A.J.; Markides, C.N. Industrial waste-heat recovery through integrated computer-aided working-fluid and ORC system optimisation using SAFT-γ Mie. Energy Convers. Manag. 2017, 150, 851–869. [Google Scholar] [CrossRef]

- Francisco, S.; Delgado, O.; Lutsey, N.; Rotz, D.; Sisken, K.; Kayes, D.; Damon, K.; Salemme, G.; Koeberlein, D.; Mihelic, R.; et al. The U.S. Supertruck Program Expediting the Development of Advanced Heavy-Duty Vehicle Efficiency Technologies; Technical Report; The International Council on Clean Transportation: Washington, DC, USA, 2014. [Google Scholar]

- Zhao, R.; Zhang, H.; Song, S.; Tian, Y.; Yang, Y.; Liu, Y. Integrated simulation and control strategy of the diesel engine–organic Rankine cycle (ORC) combined system. Energy Convers. Manag. 2018, 156, 639–654. [Google Scholar] [CrossRef]

- Manolakos, D.; Kosmadakis, G.; Kyritsis, S.; Papadakis, G. Identification of behaviour and evaluation of performance of small scale, low-temperature organic Rankine cycle system coupled with a RO desalination unit. Energy 2009, 34, 767–774. [Google Scholar] [CrossRef]

- Li, L.; Ge, Y.; Luo, X.; Tassou, S. Experimental investigations into power generation with low grade waste heat and R245fa organic Rankine cycles (ORCs). Appl. Therm. Eng. 2017, 115, 815–824. [Google Scholar] [CrossRef]

- Pei, G.; Li, J.; Li, Y.; Wang, D.; Ji, J. Construction and dynamic test of a small-scale organic Rankine cycle. Energy 2011, 36, 3215–3223. [Google Scholar] [CrossRef]

- Li, M.; Wang, J.; He, W.; Wang, B.; Ma, S.; Dai, Y. Experimental evaluation of the regenerative and basic organic Rankine cycles for low-grade heat source utilization. J. Energy Eng. 2013, 139, 190–197. [Google Scholar] [CrossRef]

- Zheng, N.; Zhao, L.; Wang, X.; Tan, Y. Experimental verification of a rolling-piston expander that applied for low-temperature organic Rankine cycle. Appl. Energy 2013, 112, 1265–1274. [Google Scholar] [CrossRef]

- Yu, G.; Shu, G.; Tian, H.; Huo, Y.; Zhu, W. Experimental investigations on a cascaded steam-/organic-Rankine-cycle (RC/ORC) system for waste heat recovery (WHR) from diesel engine. Energy Convers. Manag. 2016, 129, 43–51. [Google Scholar] [CrossRef]

- Shu, G.; Zhao, M.; Tian, H.; Huo, Y.; Zhu, W. Experimental comparison of R123 and R245fa as working fluids for waste heat recovery from heavy-duty diesel engine. Energy 2016, 115, 756–769. [Google Scholar] [CrossRef]

- Shi, L.; Shu, G.; Tian, H.; Huang, G.; Chen, T.; Li, X.; Li, D. Experimental comparison between four CO2-based transcritical Rankine cycle (CTRC) systems for engine waste heat recovery. Energy Convers. Manag. 2017, 150, 159–171. [Google Scholar] [CrossRef]

- Li, X.; Shu, G.; Tian, H.; Huang, G.; Liu, P.; Wang, X.; Shi, L. Experimental comparison of dynamic responses of CO2 transcritical power cycle systems used for engine waste heat recovery. Energy Convers. Manag. 2018, 161, 254–265. [Google Scholar] [CrossRef]

- Li, X.; Tian, H.; Shu, G.; Hu, C.; Sun, R.; Li, L. Effects of external perturbations on dynamic performance of carbon dioxide transcritical power cycles for truck engine waste heat recovery. Energy 2018, 163, 920–931. [Google Scholar] [CrossRef]

- Park, B.S.; Usman, M.; Imran, M.; Pesyridis, A. Review of organic Rankine cycle experimental data trends. Energy Convers. Manag. 2018, 173, 679–691. [Google Scholar] [CrossRef]

- Lemort, V.; Quoilin, S.; Cuevas, C.; Lebrun, J. Testing and modeling a scroll expander integrated into an organic Rankine cycle. Appl. Therm. Eng. 2009, 29, 3094–3102. [Google Scholar] [CrossRef]

- Desideri, A.; Hernandez, A.; Gusev, S.; van den Broek, M.; Lemort, V.; Quoilin, S. Steady-state and dynamic validation of a small-scale waste heat recovery system using the ThermoCycle Modelica library. Energy 2016, 115, 684–696. [Google Scholar] [CrossRef]

- Hernandez, A.; Desideri, A.; Gusev, S.; Ionescu, C.M.; Den Broek, M.V.; Quoilin, S.; Lemort, V.; De Keyser, R. Design and experimental validation of an adaptive control law to maximize the power generation of a small-scale waste heat recovery system. Appl. Energy 2017, 203, 549–559. [Google Scholar] [CrossRef]

- van Kleef, L.M.; Oyewunmi, O.A.; Markides, C.N. Multi-objective thermo-economic optimization of organic Rankine cycle (ORC) power systems in waste-heat recovery applications using computer-aided molecular design techniques. Appl. Energy 2019, 251, 112513. [Google Scholar] [CrossRef]

- Lemort, V.; Legros, A. Positive displacement expanders for organic Rankine cycle systems. In Organic Rankine cycle (ORC) power systems: Technologies and applications; Series in Energy: Number 107; Woodhead Publishing: Amsterdam, The Netherlands, 2016; pp. 361–396. [Google Scholar]

- Woodland, B.J.; Braun, J.E.; Groll, E.A.; Horton, W.T. Experimental testing of an organic Rankine cycle with scroll-type expander. In Proceedings of the International Refrigeration and Air Conditioning Conference, West Lafayette, IN, USA, 16–19 July 2012. Paper 1324. [Google Scholar]

- Dumont, O.; Parthoens, A.; Dickes, R.; Lemort, V. Experimental investigation and optimal performance assessment of four volumetric expanders (scroll, screw, piston and roots) tested in a small-scale organic Rankine cycle system. Energy 2018, 165, 1119–1127. [Google Scholar] [CrossRef]

| Working fluid | ||

|---|---|---|

| Refrigerant | - | R245fa |

| Mass flowrate | [20–60] g/s | |

| Heat source | ||

| Thermal fluid | - | Marlotherm oil |

| Mass flowrate | 1.4 kg/s | |

| Available supply temperature | [80–150] C | |

| Heat sink | ||

| Cooling fluid | - | Water |

| Mass flowrate | 0.4 kg/s | |

| Supply temperature | 18C | |

| Pump | ||

| Model | - | TMFR2 (Fluid-o-Tech S.R.L., Milano, Italy) |

| Type | - | Magnet-driven rotary vane pump |

| Pump rotating speed | [1100–3000] RPM | |

| Heat exchangers | ||

| Condenser model | - | CB60-30H-F (Alfa Laval Lund AB, Lund, Sweden) |

| Condenser type | - | Brazed-plate |

| Condenser area | - | 1.62 m |

| Evaporator model | - | B12Lx18 (SWEP, Didcot, United Kingdom) |

| Evaporator type | - | Brazed-plate |

| Evaporator area | - | 0.45 m |

| Expansion machine | ||

| Model | - | E15H22N4.25 (Air Squared Inc., Broomfield, USA) |

| Type | - | Scroll expander |

| Displacement | 14.5cm/rev | |

| Nominal power | - | 1kWe |

| Built-in volume ratio | 3.5 | |

| (C) | (W) | (%) | (%) | (%) | (g/s) | (Hz) | (bar) | (bar) | (C) | (C) |

|---|---|---|---|---|---|---|---|---|---|---|

| max | ||||||||||

| 100 | 359 ± 4 | 4.1 ± 0.1 | 18.7 ± 0.3 | 37 ± 0.4 | 35.7 ± 0.2 | 30.1 ± 0.3 | 9.0 ± 0.06 | 1.5 ± 0.06 | 7 ± 2.1 | 3.4 ± 2.1 |

| 120 | 470 ± 3 | 3.9 ± 0.1 | 15.4 ± 0.2 | 36.4 ± 0.3 | 45.1 ± 0.3 | 34.5 ± 0.1 | 11.2 ± 0.06 | 1.6 ± 0.06 | 18 ± 2.1 | 3.7 ± 2.1 |

| 140 | 508 ± 2 | 3.9 ± 0.1 | 13.5 ± 0.2 | 36.6 ± 0.3 | 46.1 ± 0.3 | 35.5 ± 0.1 | 11.8 ± 0.06 | 1.75 ± 0.06 | 35 ± 2.1 | 4.4 ± 2.1 |

| max (= max ) | ||||||||||

| 100 | 359 ± 4 | 4.1 ± 0.1 | 18.7 ± 0.3 | 37 ± 0.5 | 35.7 ± 0.2 | 30.1 ± 0.3 | 9.0 ± 0.06 | 1.5 ± 0.06 | 7.2 ± 2.1 | 3.4 ± 2.1 |

| 120 | 399 ± 2 | 4.2 ± 0.1 | 16.2 ± 0.3 | 37.3 ± 0.4 | 35.3 ± 0.2 | 31.8 ± 0.1 | 9.6 ± 0.06 | 1.5 ± 0.06 | 26 ± 2.1 | 4.2 ± 2.1 |

| 140 | 493 ± 2 | 4.1 ± 0.1 | 13.9 ± 0.3 | 36.8 ± 0.4 | 43 ± 0.3 | 34.5 ± 0.2 | 11.3 ± 0.06 | 1.73 ± 0.06 | 37.5 ± 2.1 | 4.3 ± 2.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Unamba, C.K.; Sapin, P.; Li, X.; Song, J.; Wang, K.; Shu, G.; Tian, H.; Markides, C.N. Operational Optimisation of a Non-Recuperative 1-kWe Organic Rankine Cycle Engine Prototype. Appl. Sci. 2019, 9, 3024. https://doi.org/10.3390/app9153024

Unamba CK, Sapin P, Li X, Song J, Wang K, Shu G, Tian H, Markides CN. Operational Optimisation of a Non-Recuperative 1-kWe Organic Rankine Cycle Engine Prototype. Applied Sciences. 2019; 9(15):3024. https://doi.org/10.3390/app9153024

Chicago/Turabian StyleUnamba, Chinedu K., Paul Sapin, Xiaoya Li, Jian Song, Kai Wang, Gequn Shu, Hua Tian, and Christos N. Markides. 2019. "Operational Optimisation of a Non-Recuperative 1-kWe Organic Rankine Cycle Engine Prototype" Applied Sciences 9, no. 15: 3024. https://doi.org/10.3390/app9153024

APA StyleUnamba, C. K., Sapin, P., Li, X., Song, J., Wang, K., Shu, G., Tian, H., & Markides, C. N. (2019). Operational Optimisation of a Non-Recuperative 1-kWe Organic Rankine Cycle Engine Prototype. Applied Sciences, 9(15), 3024. https://doi.org/10.3390/app9153024