Effect of Additives, Cement Type, and Foam Amount on the Properties of Foamed Concrete Developed with Civil Construction Waste

Abstract

1. Introduction

2. Materials and Methods

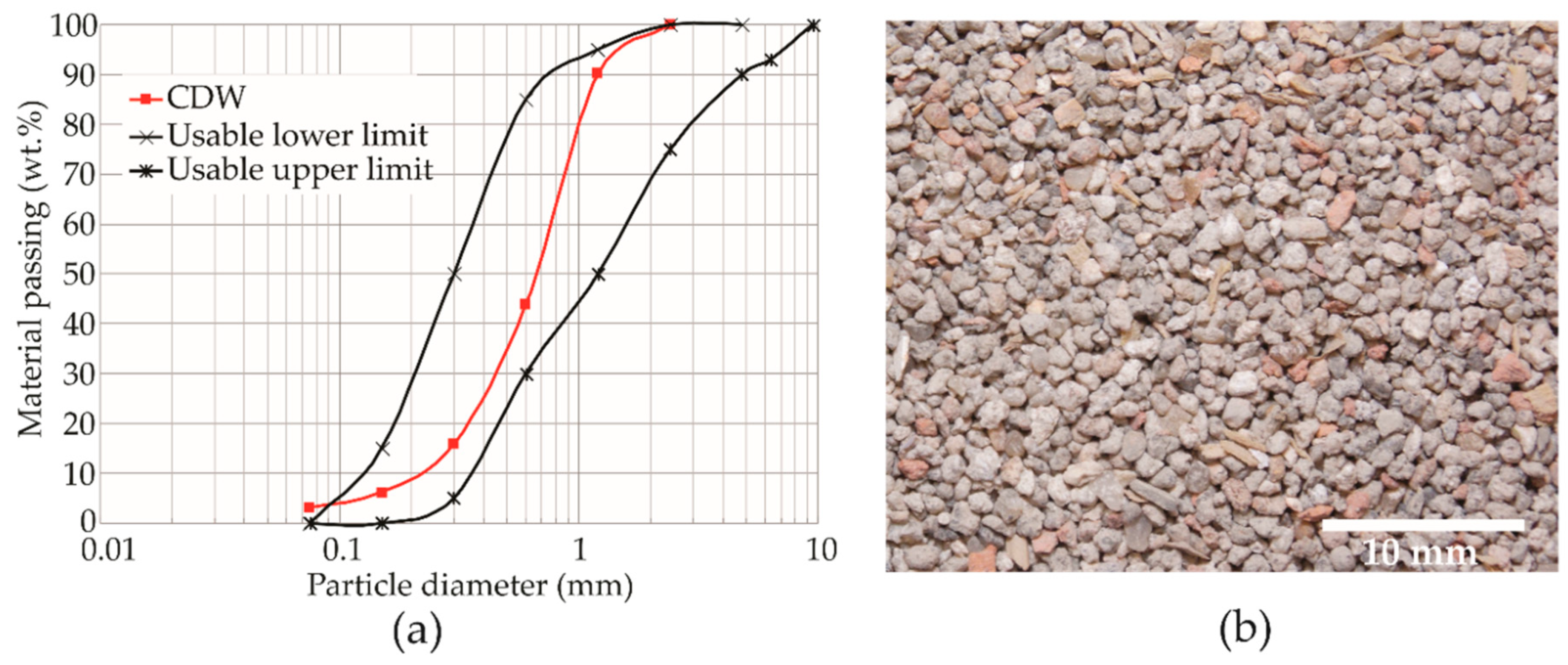

2.1. Materials

2.2. Production of Foamed Concrete Specimens

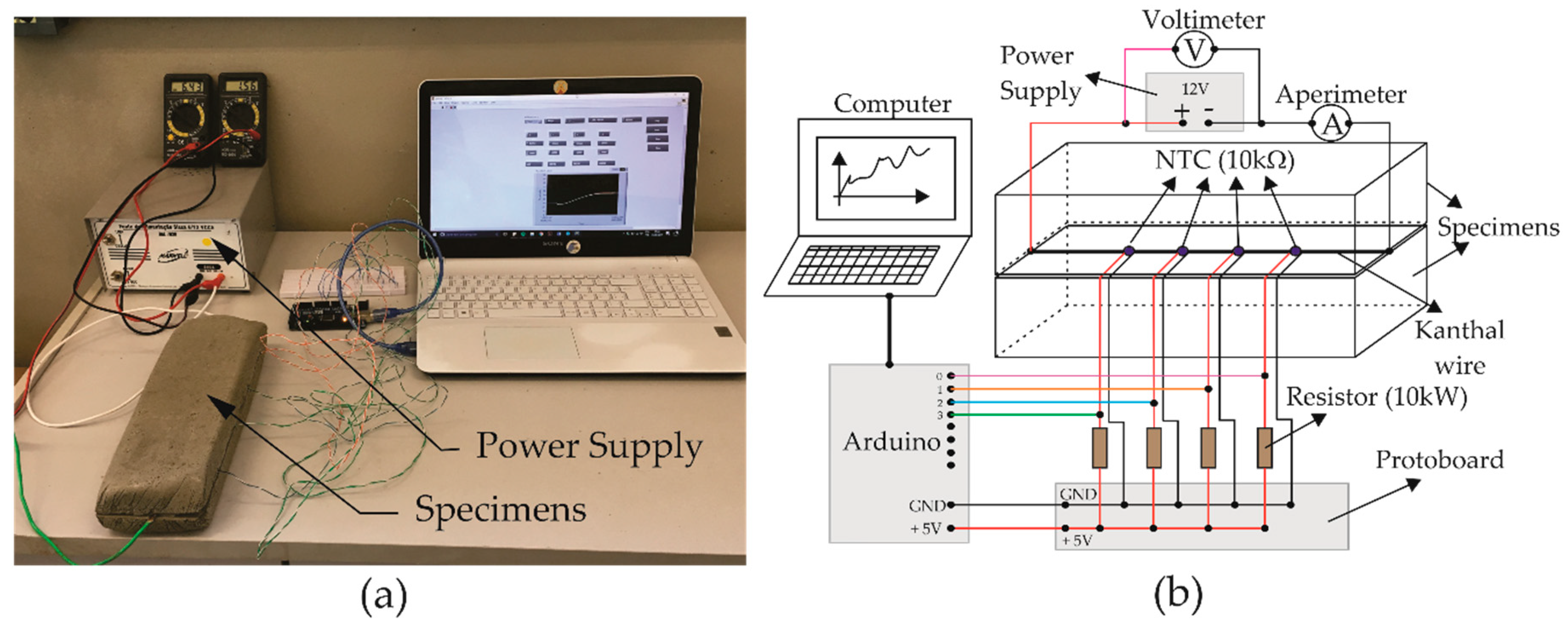

2.3. Characterization of Foamed Concrete Specimens

2.4. Experimental Design

3. Results and Discussion

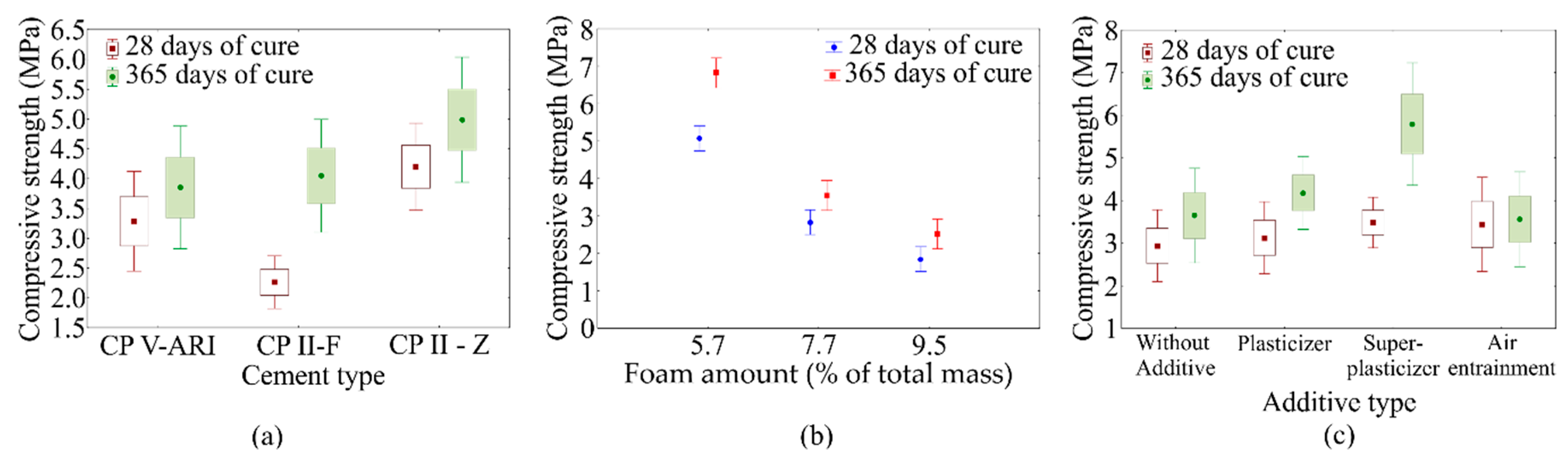

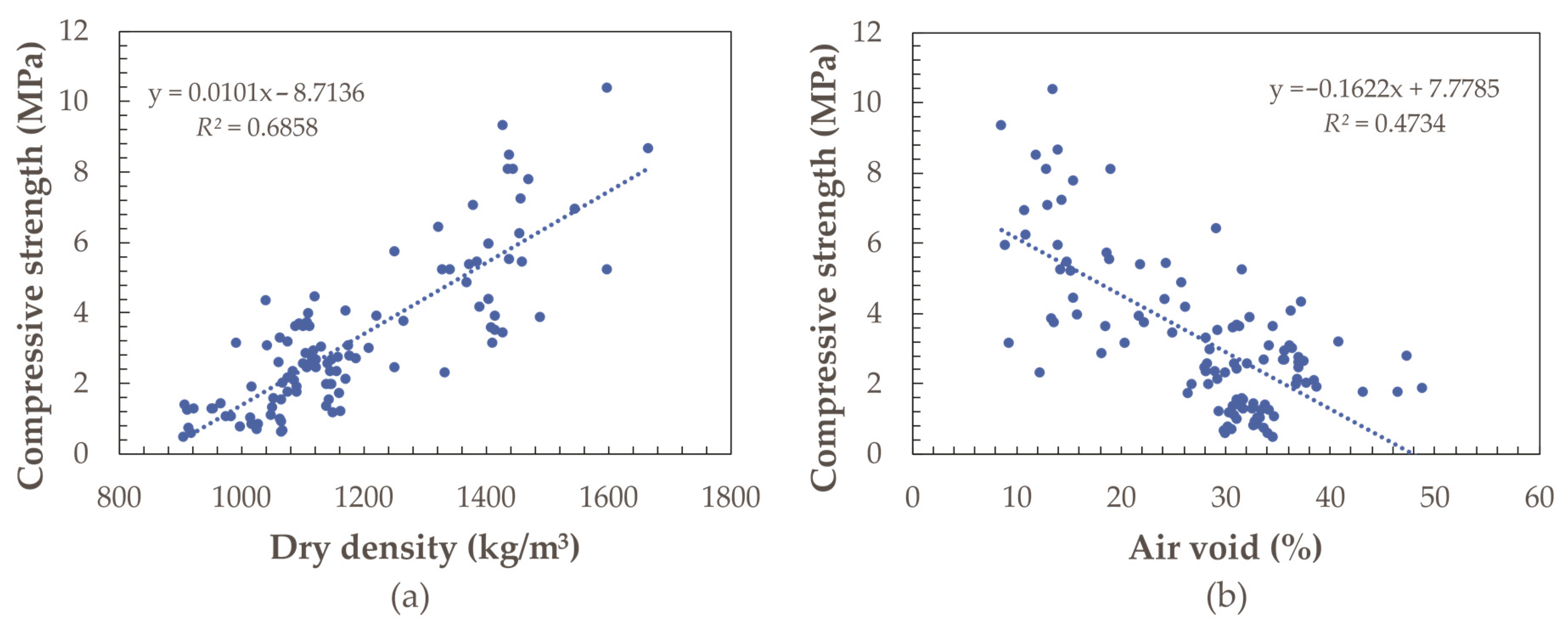

3.1. Compressive Strength

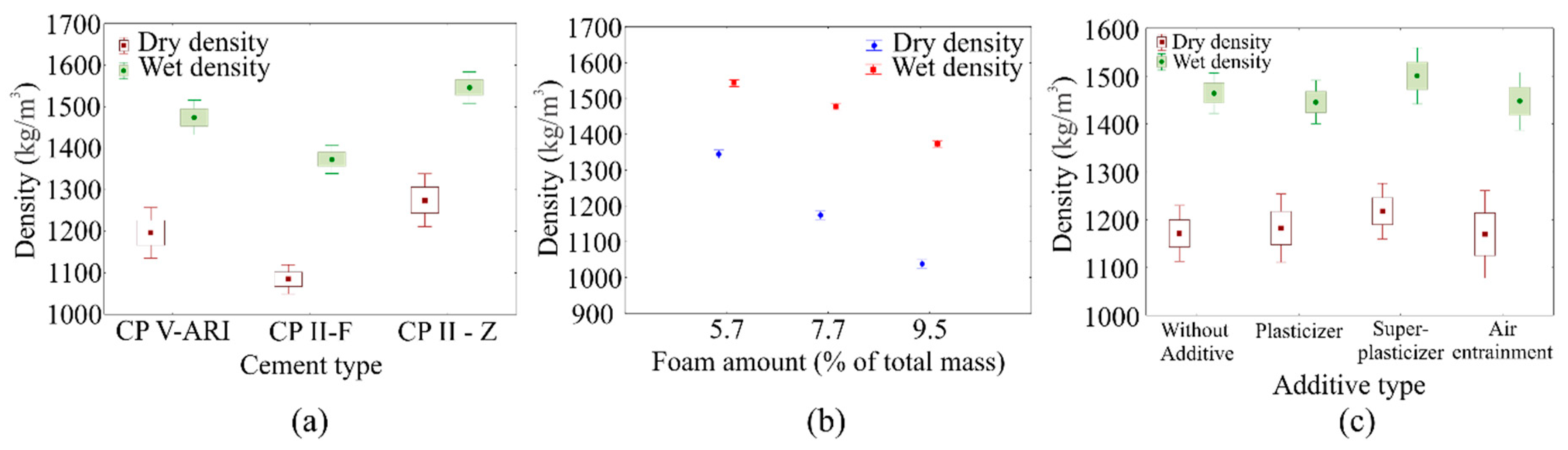

3.2. Dry and Wet Bulk Densities

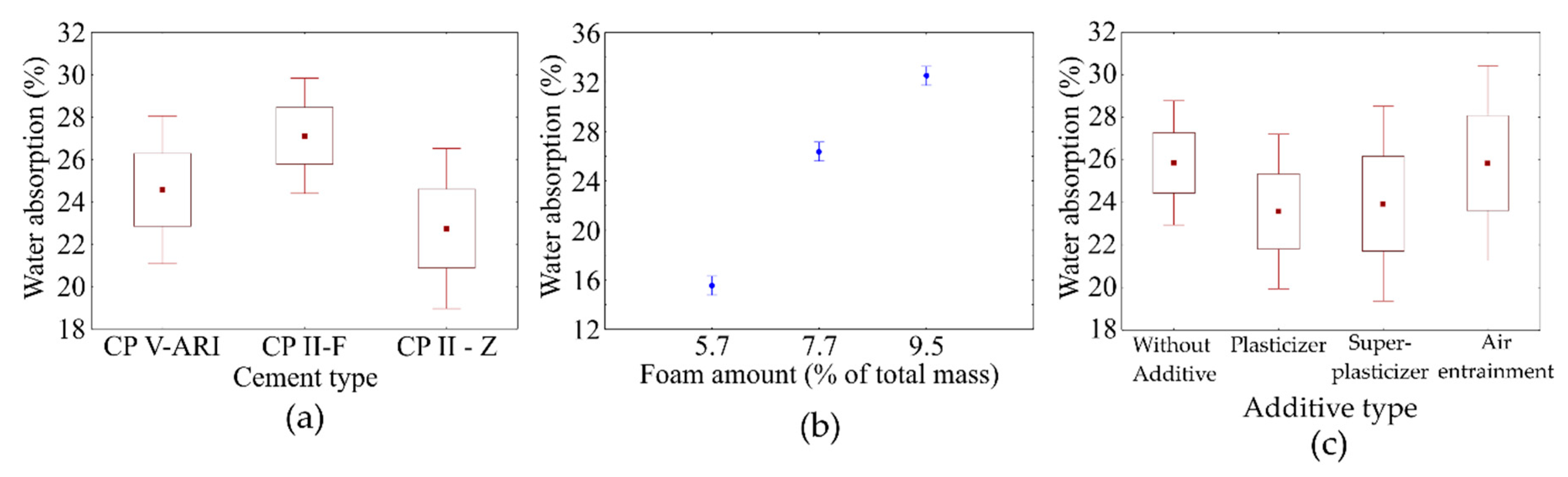

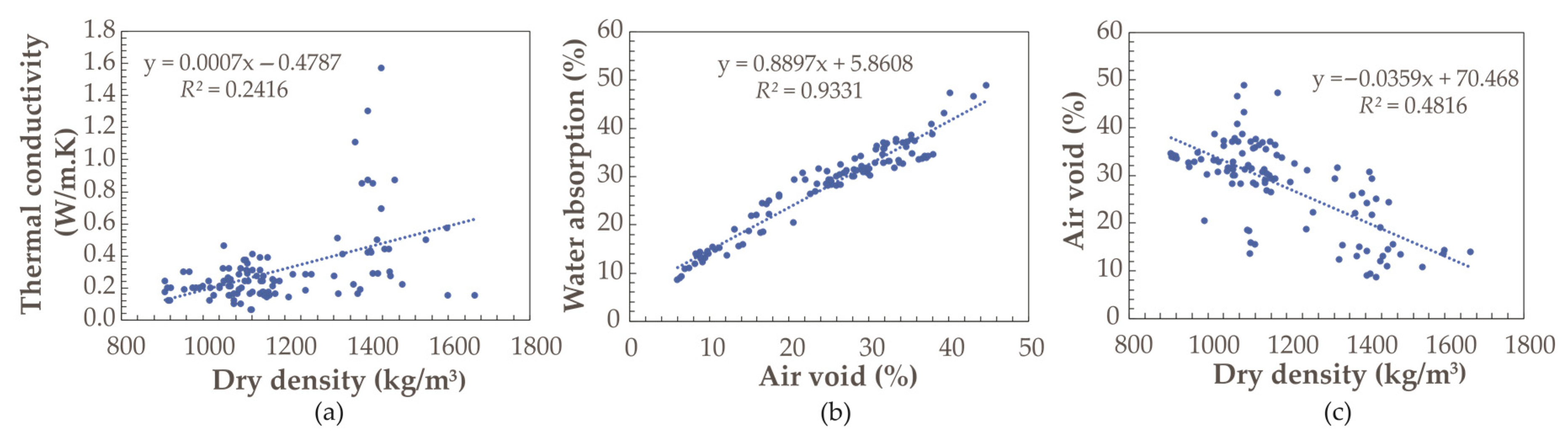

3.3. Water Absorption

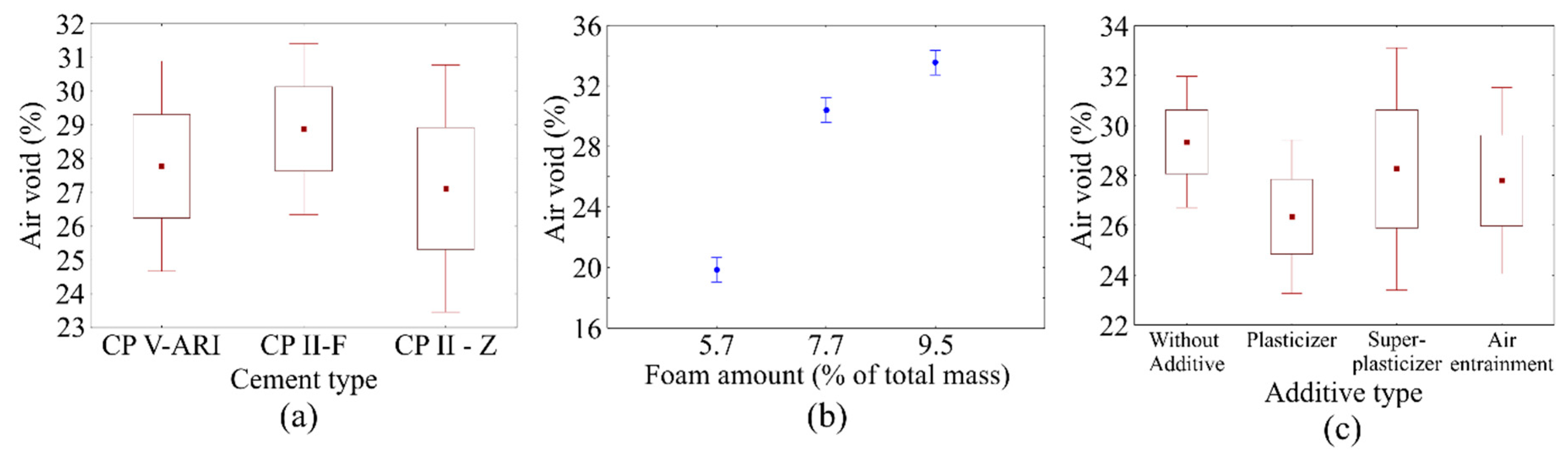

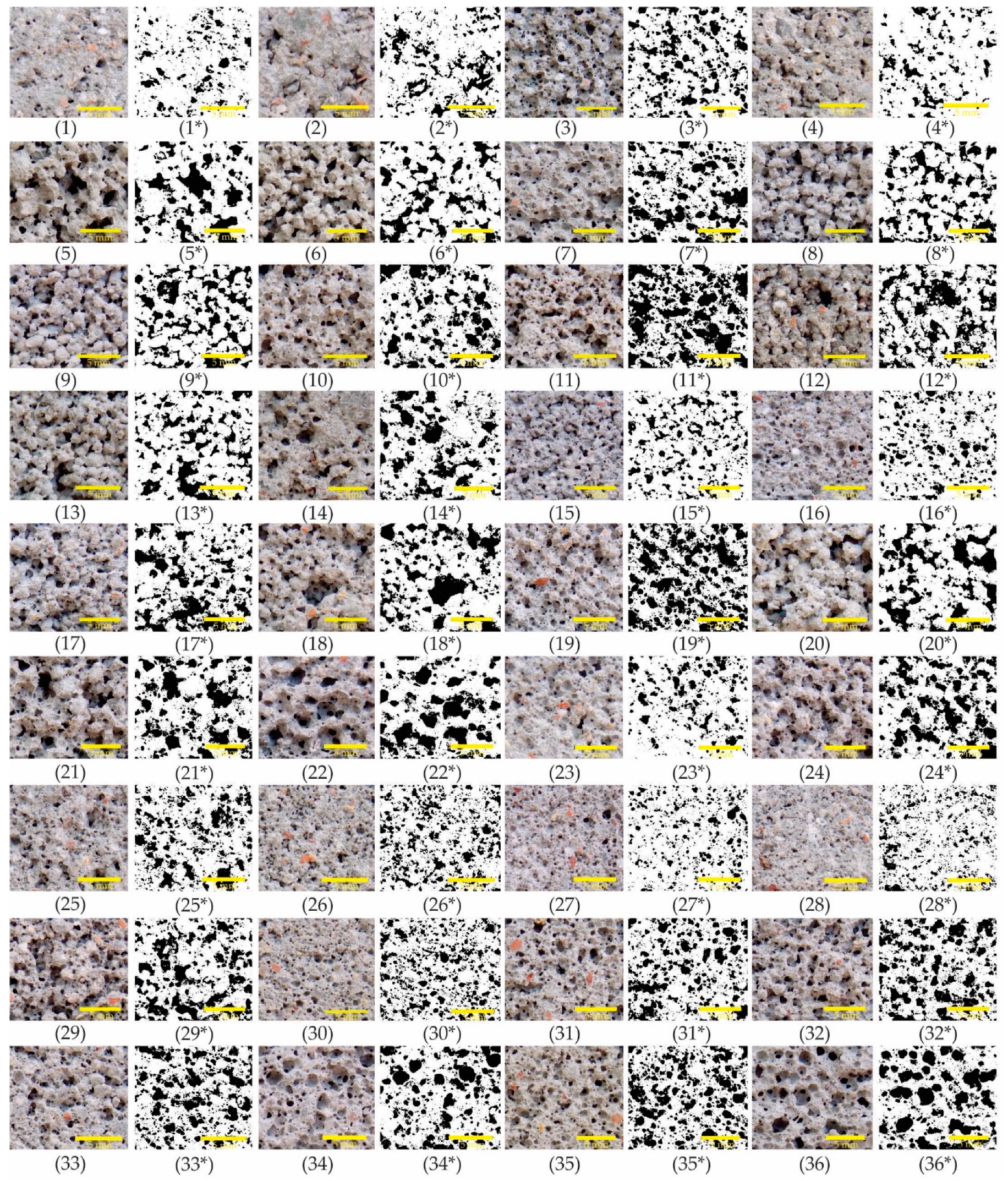

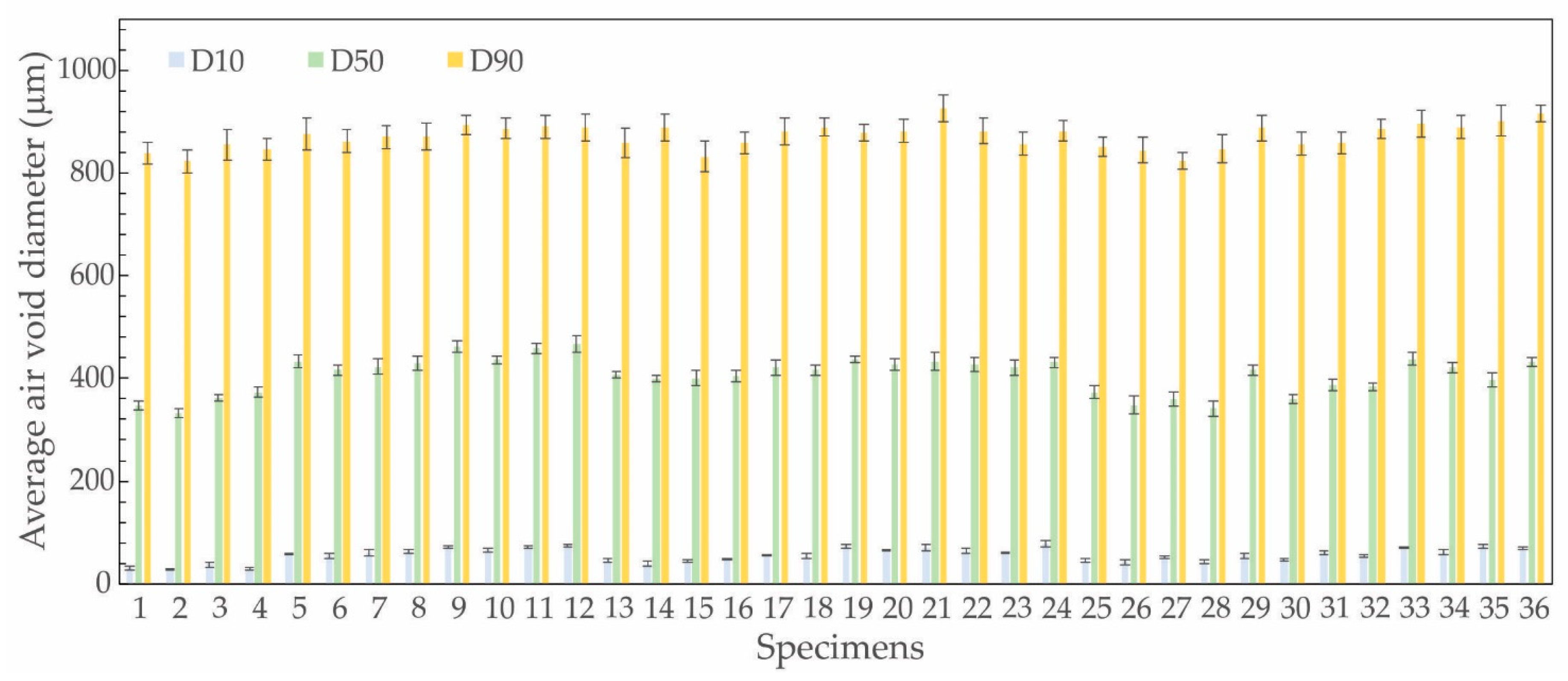

3.4. Air Void

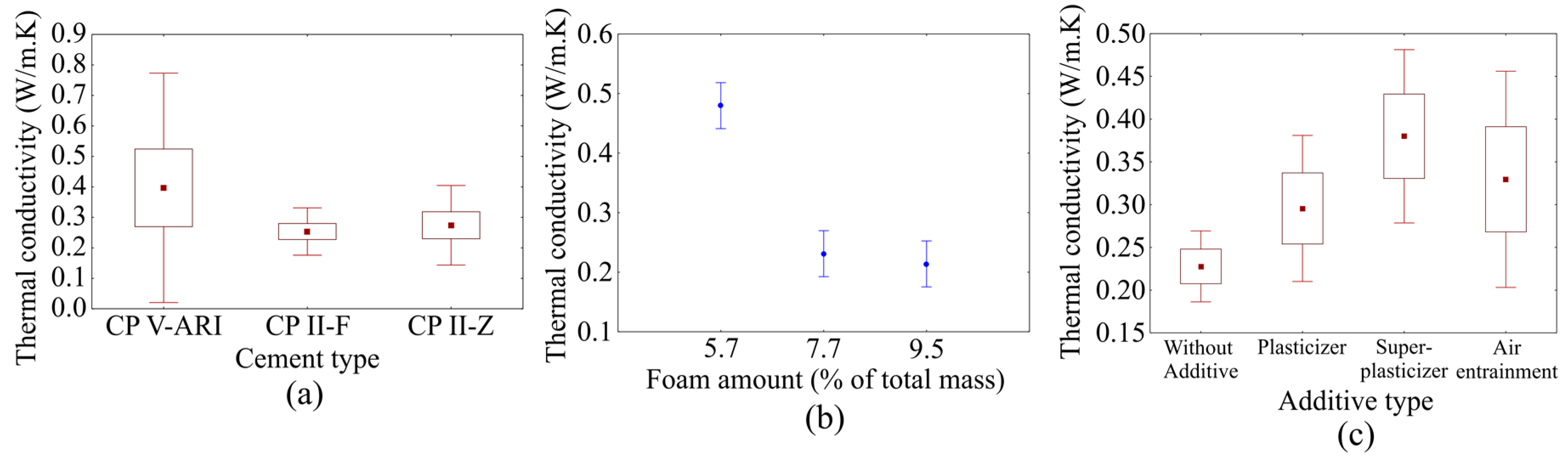

3.5. Thermal Conductivity

3.6. The Relationship between the Response Variables

4. Conclusions

- CCWs can be used integrally as aggregates in the production of foamed concrete blocks, thereby reducing civil construction companies’ liabilities and reducing environmental impacts due to the irregular disposal of waste. In addition, by using this residue, the consumption of natural sand can be reduced. Sand is a finite aggregate and its extraction causes environmental damage, especially in rivers and lakes;

- The additives have little influence on the properties of foamed concrete blocks. Different additive proportions can be evaluated in future works to seek the optimization of the use of additives in concrete foam;

- For the specimens studied it is possible to obtain compressive strength of specimens higher than the minimum value of 1.4 MPa required by ASTM C869/C869M—11, but the values of compressive strength found are still low when compared with other studies on lightweight concrete that used other aggregate types. Therefore, studies should be conducted to try to increase the compressive strength of these materials, for example, studying the use of different curing processes to decrease the connectivity between the pores;

- As expected, the dry density and saturated density decrease when the amount of foam in the structure of the blocks increases. However, the densities are still high for lightweight concrete. Increasing the amount of foam in the fabrication of the blocks and experimenting with other foam agents could be a solution to decrease the density of these materials;

- The air void and the water absorption are strongly influenced by the amount of foam added to the structure, i.e., as the amount of foam increases, the number of pores increases. To minimize the water absorption, the connectivity between the pores must be reduced. For this reason, the foam stability should be studied in more detail;

- Specimens developed with CP II-Z cement showed, on average, the highest compressive strength, the highest densities, the highest thermal conductivity, the lowest air void, and the least absorption of water. Specimens developed with CP II-Z cement showed, on average, the lowest compressive strength, the highest densities, the highest air void and absorption of water, and the lowest thermal conductivity. The cement with pozzolanic addition presented the best results. So, to further improve the results, other materials, under replacement of the cement, can be added in new studies;

- The thermal conductivity found for foamed concrete blocks is in accordance with what NBR 15220 determines, namely that the thermal conductivity must be below 2 W/(m.K). To minimize the thermal conductivity, studies of foamed concretes with the addition of thermal insulation materials (wood, Styrofoam, etc.) can be carried out.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Hu, W.; Nie, Q.; Huang, B.; Shu, X. Investigation of the strength development of cast-in-place geopolymer piles with heating systems. J. Clean. Prod. 2019, 215, 1481–1489. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; Zuo, Y.; Chen, W.; Ye, G. Chemical deformation of metakaolin based geopolymer. Cem. Concr. Res. 2019, 120, 108–118. [Google Scholar] [CrossRef]

- Amorim, N.S.J.; Silva, G.A.; Dias, C.M.; Ribeiro, D.V. Concrete containing recycled aggregates: Estimated lifetime using chloride migration test. Constr. Build. Mater. 2019, 222, 108–118. [Google Scholar] [CrossRef]

- Gomes, P.C.C.; Alencar, T.F.F.D.; Silva, N.V.D.; Moraes, K.A.D.M.; Angulo, S.C. Obtenção de concreto leve utilizando agregados reciclados. Ambiente Construído 2015, 15, 31–46. [Google Scholar] [CrossRef]

- Ulsen, C.; Tseng, E.; Angulo, S.C.; Landmann, M.; Contessotto, R.; Balbo, J.T.; Kahn, H. Concrete aggregates properties crushed by jaw and impact secondary crushing. J. Mater. Res. Technol. 2019, 8, 494–502. [Google Scholar] [CrossRef]

- Angulo, S.C. Caracterização de Agregados de Resíduos de Construção e Demolição Reciclados e a Influência de Suas Características no Comportamento de Concretos. PhD Thesis, Escola Politécnica da Universidade de São Paulo, São Paulo, Brasil, 2005. [Google Scholar]

- Angulo, S.C.; Ulsen, C.; John, V.M.; Kahn, H.; Cincotto, M.A. Chemical-mineralogical characterization of C&D waste recycled aggregates from Sao Paulo, Brazil. Waste Manag. 2009, 29, 721–730. [Google Scholar] [PubMed]

- Martín-Morales, M.; Zamorano, M.; Ruiz-Moyano, A.; Valverde-Espinosa, I. Characterization of recycled aggregates construction and demolition waste for concrete production following the Spanish Structural Concrete Code EHE-08. Constr. Build. Mater. 2011, 25, 742–748. [Google Scholar] [CrossRef]

- Kim, Y.; Hanif, A.; Usman, M.; Park, W. Influence of bonded mortar of recycled concrete aggregates on interfacial characteristics–Porosity assessment based on pore segmentation from backscattered electron image analysis. Constr. Build. Mater. 2019, 212, 149–163. [Google Scholar] [CrossRef]

- Levy, S.; Helène, P. Durability of concrete mixed with fine recycled aggregates. Exacta 2007, 5, 25–34. [Google Scholar] [CrossRef]

- Narayanan, N.; Ramamurthy, K. Structure and properties of aerated concrete: A review. Cem. Concr. Compos. 2000, 22, 321–329. [Google Scholar] [CrossRef]

- Ramamurthy, K.; Kunhanandan Nambiar, E.K.; Indu Siva Ranjani, G. A classification of studies on properties of foam concrete. Cem. Concr. Compos. 2009, 31, 388–396. [Google Scholar] [CrossRef]

- Chica, L.; Alzate, A. Cellular concrete review: New trends for application in construction. Constr. Build. Mater. 2019, 200, 637–647. [Google Scholar] [CrossRef]

- Ma, X.; Liu, J.; Shi, C. A review on the use of LWA as an internal curing agent of high performance cement-based materials. Constr. Build. Mater. 2019, 218, 385–393. [Google Scholar] [CrossRef]

- Mydin, M.A.O.; Awang, H.; Roslan, A.F. Determination of lightweight foamed concrete thermal properties integrating various additives. Cem. Concr. Compos. 2012, 48, 7. [Google Scholar]

- Laukaitis, A.; Fiks, B. Acoustical properties of aerated autoclaved concrete. Appl. Acoust. 2006, 67, 284–296. [Google Scholar] [CrossRef]

- Othuman, M.A.; Wang, Y. Elevated-temperature thermal properties of lightweight foamed concrete. Constr. Build. Mater. 2011, 25, 705–716. [Google Scholar] [CrossRef]

- Freitas, I.M.D. Produção e Propriedades Físicas e Mecânicas do Concreto Celular Espumoso; Universidade Federal Fluminense: Niterói, Brazil, 2004. [Google Scholar]

- Cortelassi, E.M.; Toralles-Carbonari, B.M. Avaliação da resistência mecânica de concretos celulares espumosos de alto desempenho. In XII Encontro Nacional de Tecnologia do Ambiente Construído; Edited by ENTAC: Fortaleza, Brasil, 2008; p. 10. [Google Scholar]

- Bagheri, A.; Samea, S.A. Parameters Influencing the Stability of Foamed Concrete. J. Mater. Civ. Eng. 2018, 30, 04018091. [Google Scholar] [CrossRef]

- Shan, X.-H.; Zhu, E.-Y.; Han, Y.-L. Air-entraining Additive on Concrete Capability [J]. South-to-North Water Trans. Water Sci. Technol. 2004, 6, 024. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-NSBD200406024.htm (accessed on 3 March 2019).

- Favaretto, P.; Hidalgo, G.E.N.; Sampaio, C.H.; Silva, R.D.A.; Lermen, R.T. Characterization and Use of Construction and Demolition Waste from South of Brazil in the Production of Foamed Concrete Blocks. Appl. Sci. 2017, 7, 1090. [Google Scholar] [CrossRef]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. Experimental investigation on the compressive strength of foamed concrete: Effect of curing conditions, cement type, foaming agent and dry density. Constr. Build. Mater. 2018, 165, 735–749. [Google Scholar] [CrossRef]

- Panesar, D.K. Cellular concrete properties and the effect of synthetic and protein foaming agents. Constr. Build. Mater. 2013, 44, 575–584. [Google Scholar] [CrossRef]

- Vieira, F.P.; Kulakowski, M.P.; Dal Molin, D.; Vilela, A.C. Durabilidade e Resistência Mecânica de Concretos e Argamassas com Adição de Sílica Ativa. In Workshop–Durabilidade das Construções; ANTAC: São Leopoldo, RS, Brasil, 1997; pp. 107–116. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw Hill Professional, Access Engineering: New York, NY, USA, 2014. [Google Scholar]

- ASTM. C150/C150M-18—Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ABNT. NBR 7211—Agregados Para Concreto—Especificação; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2005. [Google Scholar]

- Pedro, R.; Tubino, R.; Anversa, J.; De Col, D.; Lermen, R.; Silva, R. Production of Aerated Foamed Concrete with Industrial Waste from the Gems and Jewels Sector of Rio Grande do Sul-Brazil. Appl. Sci. 2017, 7, 985. [Google Scholar] [CrossRef]

- ABNT. NBR 5738—Concreto–Procedimento de Moldagem e Cura de Corpos-de-Prova; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2003. [Google Scholar]

- ABNT. NBR 5739—Concreto–Ensaio de Compressão de Corpos-de-Prova Cilindricos; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2007. [Google Scholar]

- ABNT. NBR 7680-1—Concreto—Extração, Preparo, Ensaio e Análise de Testemunhos de Estruturas de Concreto—Parte 1: Resistência à Compressão Axial; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2015. [Google Scholar]

- ASTM. C 948-81 Standard—Dry and Wet Bulk Density, Water Absorption and Apparent Porosity of Thin Sections of Glass-Fiber Reinforced Concrete; American Society for Testing and Materials: West Conshohocken, PA, USA, 2009. [Google Scholar]

- ABNT. NBR 9778—Argamassa e Concreto Endurecidos—Determinação da Absorção de Água por Imersão—Índice de Vazios e Massa Específica; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 1987. [Google Scholar]

- EN BS 480-11. Admixtures for Concrete, Mortar and Grout-Test Methods-Part 11: Determination of Air Void Characteristics in Hardened Concrete; British Standards Institution: London, UK, 2005. [Google Scholar]

- Hilal, A.A.; Thom, N.H.; Dawson, A.R. On void structure and strength of foamed concrete made without/with additives. Constr. Build. Mater. 2015, 85, 157–164. [Google Scholar] [CrossRef]

- Nambiar, E.K.K.; Ramamurthy, K. Air-void characterisation of foam concrete. Cem. Concr. Res. 2007, 37, 221–230. [Google Scholar] [CrossRef]

- Franco, A. An apparatus for the routine measurement of thermal conductivity of materials for building application based on a transient hot-wire method. Appl. Therm. Eng. 2007, 27, 2495–2504. [Google Scholar] [CrossRef]

- Sacht, H.M.; Rossignolo, J.A.; Santos, W.N. Avaliação da condutividade térmica de concretos leves com argila expandida. Matéria 2010, 15, 31–39. [Google Scholar] [CrossRef]

- Akiyoshi, M.M.; da Silva, A.P.; da Silva, M.G.; Pandolfelli, V.C. Condutividade térmica e sua correlação com a temperatura e a massa específica volumétrica de materiais refratários sílico-aluminosos e aluminosos. Cerâmica 2001, 47, 9. [Google Scholar] [CrossRef]

- Grazzini, G.; Balocco, C. Determination of thermal parameters of poor conductors by transient techniques. Int. J. Energy Res. 1995, 19, 8. [Google Scholar] [CrossRef]

- Grazzini, G.; Balocco, C.; Licia, U. Measuring thermal properties with the parallel wire method: A comparison of mathematical models. Int. J. Heat Mass Transf. 1995, 39, 5. [Google Scholar] [CrossRef]

- Dos Santos, W.N. O método de fio quente: Técnica em paralelo e técnica de superfície (The hot wire method: The hot wire parallel technique and the hot wire surface technique). Cerâmica 2002, 48, 6. [Google Scholar]

- Dos Santos, W.N. Métodos transientes de troca de calor na determinação das propriedades térmicas de materiais cerâmicos: II—O método do fio quente. Cerâmica 2005, 51, 10. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Jitchaiyaphum, K.; Sinsiri, T.; Chindaprasirt, P. Cellular Lightweight Concrete Containing Pozzolan Materials. Procedia Eng. 2011, 14, 1157–1164. [Google Scholar] [CrossRef]

- Batool, F.; Bindiganavile, V. Effect of Pozzolanic Admixtures on the Fresh Properties of Cement-Based Foam. Adv. Civ. Eng. Mater. 2016, 5, 263–275. [Google Scholar] [CrossRef]

- Duval, R.; Kadri, E. Influence of silica fume on the workability and the compressive strength of high-performance concretes. Cem. Concr. Res. 1998, 28, 533–547. [Google Scholar] [CrossRef]

- Neville, A.M. Propriedades do Concreto; Bookman Editora: Porto Alegre, Brazil, 1997. [Google Scholar]

- Uddin, M.; Jameel, M.; Sobuz, H.R.; Hasan, N.M.; Islam, M.; Amanat, K.M. The effect of curing time on compressive strength of composite cement concrete. Appl. Mech. Mater. 2012, 204–208, 4105–4109. [Google Scholar] [CrossRef]

- Jiang, J.; Lu, Z.; Niu, Y.; Li, J.; Zhang, Y. Study on the preparation and properties of high-porosity foamed concretes based on ordinary Portland cement. Mater. Des. 2016, 92, 949–959. [Google Scholar] [CrossRef]

- ABNT. NBR 12646—Paredes de Concreto Celular Espumoso Moldadas No Local; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 1992. [Google Scholar]

- Falliano, D.; De Domenico, D.; Ricciardi, G.; Gugliandolo, E. Compressive and flexural strength of fiber-reinforced foamed concrete: Effect of fiber content, curing conditions and dry density. Constr. Build. Mater. 2019, 198, 479–493. [Google Scholar] [CrossRef]

- Nambiar, E.K.K.; Ramamurthy, K. Models relating mixture composition to the density and strength of foam concrete using response surface methodology. Cem. Concr. Compos. 2006, 28, 752–760. [Google Scholar] [CrossRef]

- Hanif, A.; Diao, S.; Lu, Z.; Fan, T.; Li, Z. Green lightweight cementitious composite incorporating aerogels and fly ash cenospheres—Mechanical and thermal insulating properties. Constr. Build. Mater. 2016, 116, 422–430. [Google Scholar] [CrossRef]

- Morales-Conde, M.; Rodríguez-Liñán, C.; Pedreño-Rojas, M. Physical and mechanical properties of wood-gypsum composites from demolition material in rehabilitation works. Constr. Build. Mater. 2016, 114, 6–14. [Google Scholar] [CrossRef]

- Abbas, N.; Khalid, H.R.; Ban, G.; Kim, H.T.; Lee, H.-K. Silica aerogel derived from rice husk: An aggregate replacer for lightweight and thermally insulating cement-based composites. Constr. Build. Mater. 2019, 195, 312–322. [Google Scholar] [CrossRef]

- Krämer, C.; Schauerte, M.; Kowald, T.L.; Trettin, R.H.F. Three-phase-foams for foam concrete application. Mater. Charact. 2015, 102, 173–179. [Google Scholar] [CrossRef]

- Hilal, A.A.; Thom, N.H.; Dawson, A.R. Failure mechanism of foamed concrete made with/without additives and lightweight aggregate. J. Adv. Concr. Technol. 2016, 14, 511–520. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Farzadnia, N.; Abang Ali, A.A. Properties and applications of foamed concrete; a review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Elrahman, M.A.; El Madawy, M.; Chung, S.-Y.; Sikora, P.; Stephan, D. Preparation and Characterization of Ultra-Lightweight Foamed Concrete Incorporating Lightweight Aggregates. Appl. Sci. 2019, 9, 1447. [Google Scholar] [CrossRef]

- Al-Jumailya, I.A.S.; Najib, N.; Kareem, Q. An overview on the Influence of Pozzolanic Materials on Properties of Concrete. Int. J. Enhanc. Res. Sci. Technol. Eng. 2015, 4, 81–92. [Google Scholar]

- Saiz Martínez, P.; González Cortina, M.; Fernández Martínez, F.; Rodríguez Sánchez, A. Comparative study of three types of fine recycled aggregates from construction and demolition waste (CDW), and their use in masonry mortar fabrication. J. Clean. Prod. 2016, 118, 162–169. [Google Scholar] [CrossRef]

- Kearsley, E.; Wainwright, P. Porosity and permeability of foamed concrete. Cem. Concr. Res. 2001, 31, 805–812. [Google Scholar] [CrossRef]

- Ma, C.; Chen, B. Properties of foamed concrete containing water repellents. Constr. Build. Mater. 2016, 123, 106–114. [Google Scholar] [CrossRef]

- She, W.; Du, Y.; Miao, C.; Liu, J.; Zhao, G.; Jiang, J.; Zhang, Y. Application of organic-and nanoparticle-modified foams in foamed concrete: Reinforcement and stabilization mechanisms. Cem. Concr. Res. 2018, 106, 12–22. [Google Scholar] [CrossRef]

- De Castro, A.L.; Pandolfelli, V.C. Revisão: Conceitos de dispersão e empacotamento de partículas para a produção de concretos especiais aplicados na construção civil. Cerâmica 2009, 55, 18–32. [Google Scholar] [CrossRef]

- Chandni, T.J.; Anand, K.B. Utilization of recycled waste as filler in foam concrete. J. Build. Eng. 2018, 19, 154–160. [Google Scholar] [CrossRef]

- Sacht, H.M. Painéis de Vedação de Concreto Moldados in Loco: Avaliação de Desempenho Térmico e Desenvolvimento de Concreto. PhD Thesis, Universidade de São Paulo, São Paulo, Brazil, 2008. [Google Scholar]

- Kim, H.K.; Jeon, J.H.; Lee, H.K. Workability, and mechanical, acoustic and thermal properties of lightweight aggregate concrete with a high volume of entrained air. Constr. Build. Mater. 2012, 29, 193–200. [Google Scholar] [CrossRef]

- Hilal, A.A.; Thom, N.H.; Dawson, A.R. Pore Structure and Permeation Characteristics of Foamed Concrete. J. Adv. Concr. Technol. 2014, 12, 535–544. [Google Scholar] [CrossRef]

- Jones, M.; McCarthy, A.; Dhir, R. Recycled and Secondary Aggregates in Foamed Concrete; The Waste & Resources Action Programme: Banbury, UK, 2005; Volume 13, Available online: https://d3pcsg2wjq9izr.cloudfront.net/files/8818/articles/4620/4620.pdf (accessed on 10 April 2019).

- Kearsleya, E.P.; Wainwright, P.J. The effect of porosity on the strength of foamed concrete. Cem. Concr. Res. 2002, 32, 7. [Google Scholar] [CrossRef]

- Qu, X.; Zhao, X. Previous and present investigations on the components, microstructure and main properties of autoclaved aerated concrete—A review. Constr. Build. Mater. 2017, 135, 505–516. [Google Scholar] [CrossRef]

- Wei, S.; Yunsheng, Z.; Jones, M.R. Three-dimensional numerical modeling and simulation of the thermal properties of foamed concrete. Constr. Build. Mater. 2014, 50, 421–431. [Google Scholar]

- Wei, S.; Yiqiang, C.; Yunsheng, Z.; Jones, M. Characterization and simulation of microstructure and thermal properties of foamed concrete. Constr. Build. Mater. 2013, 47, 1278–1291. [Google Scholar] [CrossRef]

- Chen, B.; Liu, N. A novel lightweight concrete-fabrication and its thermal and mechanical properties. Constr. Build. Mater. 2013, 44, 691–698. [Google Scholar] [CrossRef]

- Sang, G.; Zhu, Y.; Yang, G.; Zhang, H. Preparation and characterization of high porosity cement-based foam material. Constr. Build. Mater. 2015, 91, 133–137. [Google Scholar] [CrossRef]

- Ramamurthy, K.; Nambiar, E.K.; Ranjani, G.I.S. A classification of studies on properties of foam concrete. Cem. Concr. Compos. 2009, 31, 388–396. [Google Scholar] [CrossRef]

- Nambiar, E.K.K.; Ramamurthy, K. Sorption characteristics of foam concrete. Cem. Concr. Res. 2007, 37, 1341–1347. [Google Scholar] [CrossRef]

| Cement Type | Physical Properties | |||||||||

| Setting Time | Blaine cm2/g | #200% | #325% | Hot Expansion mm | Specific Gravity g/cm3 | Compressive Strength | ||||

| Initial h:min | Last h:min | 3 Days MPa | 7 Days MPa | 28 Days MPa | ||||||

| CP II-F | 03:52 | 04:38 | 3.291 | 2.75 | 13.31 | 0.28 | 3.11 | 28.2 | 34.5 | 42.0 |

| CP II-Z | 04:15 | 05:03 | 3.583 | 2.54 | 9.57 | 0.22 | 2.96 | 25.8 | 33.3 | 42.0 |

| CP V-ARI | 03:19 | 04:01 | 4.448 | 0.08 | 0.52 | 0.25 | 3.05 | 38.4 | 44.9 | 53.6 |

| Cement Type | Chemical Properties | |||||||||

| Al2O3 % | SiO2 % | Fe2O3 % | CaO % | MgO % | SO3 % | L.O.I. % | Free CaO % | I.R. % | A.C. % | |

| CP II-F | 4.17 | 18.46 | 2.93 | 60.60 | 3.78 | 2.78 | 4.85 | 0.60 | 1.16 | 0.69 |

| CP II-Z | 6.01 | 20.14 | 3.10 | 54.60 | 3.45 | 2.69 | 5.51 | 0.57 | 10.96 | 0.84 |

| CP V-ARI | 4.22 | 18.80 | 2.95 | 60.27 | 3.91 | 3.14 | 3.33 | 0.68 | 0.75 | 0.69 |

| Cement Type | C3S (%) | C2S (%) | C3A (%) | C4AF (%) | C4AF + C2F |

|---|---|---|---|---|---|

| CP II-F | 66.3 | 2.9 | 6.1 | 8.9 | |

| CP II-Z | 25.7 | 38.5 | - | - | 17.9 |

| CP V-ARI | 61.0 | 7.9 | 6.2 | 9.0 |

| Order | Cement Type | Cement (kg) | Additive | Foam (kg) | CCW (kg) | Water (kg) | w/c Ratio |

|---|---|---|---|---|---|---|---|

| 1 | CP V-ARI | 1.8 | No additive used | 0.25 | 1.8 | 0.57 | 0.45 |

| 2 | CP V-ARI | 1.8 | Plasticizer | 0.25 | 1.8 | 0.57 | 0.45 |

| 3 | CP V-ARI | 1.8 | Superplasticizer | 0.25 | 1.8 | 0.57 | 0.45 |

| 4 | CP V-ARI | 1.8 | Air entrainment | 0.25 | 1.8 | 0.57 | 0.45 |

| 5 | CP V-ARI | 1.8 | No additive used | 0.34 | 1.8 | 0.48 | 0.45 |

| 6 | CP V-ARI | 1.8 | Plasticizer | 0.34 | 1.8 | 0.48 | 0.45 |

| 7 | CP V-ARI | 1.8 | Superplasticizer | 0.34 | 1.8 | 0.48 | 0.45 |

| 8 | CP V-ARI | 1.8 | Air entrainment | 0.34 | 1.8 | 0.48 | 0.45 |

| 9 | CP V-ARI | 1.8 | No additive used | 0.43 | 1.8 | 0.39 | 0.45 |

| 10 | CP V-ARI | 1.8 | Plasticizer | 0.43 | 1.8 | 0,39 | 0.45 |

| 11 | CP V-ARI | 1.8 | Superplasticizer | 0.43 | 1.8 | 0.30 | 0.45 |

| 12 | CP II-F | 1.8 | Air entrainment | 0.43 | 1.8 | 0.39 | 0.45 |

| 13 | CP II-F | 1.8 | No additive used | 0.25 | 1.8 | 0.57 | 0.45 |

| 14 | CP II-F | 1.8 | Plasticizer | 0.25 | 1.8 | 0.57 | 0.45 |

| 15 | CP II-F | 1.8 | Superplasticizer | 0.25 | 1.8 | 0.57 | 0.45 |

| 16 | CP II-F | 1.8 | Air entrainment | 0.25 | 1.8 | 0.57 | 0.45 |

| 17 | CP II-F | 1.8 | No additive used | 0.34 | 1.8 | 0.48 | 0.45 |

| 18 | CP II-F | 1.8 | Plasticizer | 0.34 | 1.8 | 0.48 | 0.45 |

| 19 | CP II-F | 1.8 | Superplasticizer | 0.34 | 1.8 | 0.48 | 0.45 |

| 20 | CP II-F | 1.8 | Air entrainment | 0.34 | 1.8 | 0.48 | 0.45 |

| 21 | CP II-F | 1.8 | No additive used | 0.43 | 1.8 | 0.39 | 0.45 |

| 22 | CP II-F | 1.8 | Plasticizer | 0.43 | 1.8 | 0,39 | 0.45 |

| 23 | CP II-F | 1.8 | Superplasticizer | 0.43 | 1.8 | 0.30 | 0.45 |

| 24 | CP II-F | 1.8 | Air entrainment | 0.43 | 1.8 | 0.39 | 0.45 |

| 25 | CP II-Z | 1.8 | No additive used | 0.25 | 1.8 | 0.57 | 0.45 |

| 26 | CP II-Z | 1.8 | Plasticizer | 0.25 | 1.8 | 0.57 | 0.45 |

| 27 | CP II-Z | 1.8 | Superplasticizer | 0.25 | 1.8 | 0.57 | 0.45 |

| 28 | CP II-Z | 1.8 | Air entrainment | 0.25 | 1.8 | 0.57 | 0.45 |

| 29 | CP II-Z | 1.8 | No additive used | 0.34 | 1.8 | 0.48 | 0.45 |

| 30 | CP II-Z | 1.8 | Plasticizer | 0.34 | 1.8 | 0.48 | 0.45 |

| 31 | CP II-Z | 1.8 | Superplasticizer | 0.34 | 1.8 | 0.48 | 0.45 |

| 32 | CP II-Z | 1.8 | Air entrainment | 0.34 | 1.8 | 0.48 | 0.45 |

| 33 | CP II-Z | 1.8 | No additive used | 0.43 | 1.8 | 0.39 | 0.45 |

| 34 | CP II-Z | 1.8 | Plasticizer | 0.43 | 1.8 | 0,39 | 0.45 |

| 35 | CP II-Z | 1.8 | Superplasticizer | 0.43 | 1.8 | 0.30 | 0.45 |

| 36 | CP II-Z | 1.8 | Air entrainment | 0.43 | 1.8 | 0.39 | 0.45 |

| Factor | Sum of Squares | Degrees of Freedom | Mean of Squares | F-Value | p-Value | % Contribution |

|---|---|---|---|---|---|---|

| Cement Type (CT) | 67.697 | 2 | 33.848 | 34.159 | 0.0000 | 13.4 |

| Foam Amount (FA) | 196.517 | 2 | 98.258 | 99.160 | 0.0000 | 39.0 |

| Additive Type (AT) | 5.425 | 3 | 1.808 | 1.825 | 0.1502 | 1.1 |

| CT*FA | 67.534 | 4 | 16.883 | 17.038 | 0.0000 | 13.4 |

| CT*AT | 18.880 | 6 | 3.147 | 3.176 | 0.0080 | 3.7 |

| FA*AT | 49.273 | 6 | 8.212 | 8.288 | 0.0000 | 9.8 |

| CT*FA*AT | 27.378 | 12 | 2.281 | 2.302 | 0.0151 | 5.4 |

| Error | 71.345 | 72 | 0.991 | 14.2 | ||

| Total | 504.048 | 107 | 100.0 |

| Factor | Sum of Squares | Degrees of Freedom | Mean of Squares | F-Value | p-Value | % Contribution |

|---|---|---|---|---|---|---|

| Cement Type (CT) | 26.618 | 2 | 13.309 | 9.28 | 0.0002 | 2.8 |

| Foam Amount (FA) | 362.858 | 2 | 181.429 | 126.43 | 0.0000 | 37.8 |

| Additive Type (AT) | 86.817 | 3 | 28.939 | 20.17 | 0.0000 | 9.0 |

| CT*FA | 69.851 | 4 | 17.463 | 12.17 | 0.0000 | 7.3 |

| CT*AT | 114.476 | 6 | 19.079 | 13.30 | 0.0000 | 11.9 |

| FA*AT | 68.998 | 6 | 11.500 | 8.01 | 0.0000 | 7.2 |

| CT*FA*AT | 127.327 | 12 | 10.611 | 7.39 | 0.0000 | 13.3 |

| Error | 103.318 | 72 | 1.435 | 10.8 | ||

| Total | 960.263 | 107 | 100.0 |

| Factor | Sum of Squares | Degrees of Freedom | Mean of Squares | F-Value | p-Value | % Contribution |

|---|---|---|---|---|---|---|

| Cement Type (CT) | 659,792 | 2 | 329,896 | 275.9 | 0.0000 | 19.4 |

| Foam Amount (FA) | 1,696,582 | 2 | 848,291 | 709.6 | 0.0000 | 50.0 |

| Additive Type (AT) | 40,996 | 3 | 13,665 | 11.4 | 0.0000 | 1.2 |

| CT*FA | 324,870 | 4 | 81,218 | 67.9 | 0.0000 | 9.6 |

| CT*AT | 50,929 | 6 | 8488 | 7.1 | 0.0000 | 1.5 |

| FA*AT | 314,349 | 6 | 52,392 | 43.8 | 0.0000 | 9.3 |

| CT*FA*AT | 219,660 | 12 | 18,305 | 15.3 | 0.0000 | 6.5 |

| Error | 86,077 | 72 | 1196 | 2.5 | ||

| Total | 3,393,255 | 107 | 100.0 |

| Factor | Sum of Squares | Degrees of Freedom | Mean of Squares | F-Value | p-Value | % Contribution |

|---|---|---|---|---|---|---|

| Cement Type (CT) | 542,783 | 2 | 271,392 | 344.4 | 0.0000 | 29.1 |

| Foam Amount (FA) | 526,782 | 2 | 263,391 | 334.3 | 0.0000 | 28.2 |

| Additive Type (AT) | 52,151 | 3 | 17,384 | 22.1 | 0.0000 | 2.8 |

| CT*FA | 165,006 | 4 | 41,251 | 52.4 | 0.0000 | 8.8 |

| CT*AT | 86,025 | 6 | 14,337 | 18.2 | 0.0000 | 4.6 |

| FA*AT | 271,135 | 6 | 45,189 | 57.3 | 0.0000 | 14.5 |

| CT*FA*AT | 164,559 | 12 | 13,713 | 17.4 | 0.0000 | 8.8 |

| Error | 56,735 | 72 | 788 | 3.0 | ||

| Total | 1,865,175 | 107 | 100.0 |

| Factor | Sum of Squares | Degrees of Freedom | Mean of Squares | F-Value | p-Value | % Contribution |

|---|---|---|---|---|---|---|

| Cement Type (CT) | 347.91 | 2 | 173.95 | 32.59 | 0.0000 | 3.3 |

| Foam Amount (FA) | 5317.99 | 2 | 2659.00 | 498.20 | 0.0000 | 49.7 |

| Additive Type (AT) | 120.47 | 3 | 40.16 | 7.52 | 0.0001 | 1.1 |

| CT*FA | 901.98 | 4 | 225.49 | 42.25 | 0.0000 | 8.4 |

| CT*AT | 1314.68 | 6 | 219.11 | 41.05 | 0.0000 | 12.3 |

| FA*AT | 998.08 | 6 | 166.35 | 31.17 | 0.0000 | 9.3 |

| CT*FA*AT | 1310.15 | 12 | 109.18 | 20.46 | 0.0000 | 12.2 |

| Error | 384.28 | 72 | 5.34 | 3.6 | ||

| Total | 10,695.54 | 107 | 100.0 |

| Factor | Sum of Squares | Degrees of Freedom | Mean of Squares | F-Value | p-Value | % Contribution |

|---|---|---|---|---|---|---|

| Cement Type (CT) | 57.18 | 2 | 28.59 | 4.85 | 0.0105 | 0.6 |

| Foam Amount (FA) | 3697.69 | 2 | 1848.84 | 313.80 | 0.0000 | 40.7 |

| Additive Type (AT) | 124.85 | 3 | 41.62 | 7.06 | 0.0003 | 1.4 |

| CT*FA | 987.53 | 4 | 246.88 | 41.90 | 0.0000 | 10.9 |

| CT*AT | 1578.10 | 6 | 263.02 | 44.64 | 0.0000 | 17.4 |

| FA*AT | 961.67 | 6 | 160.28 | 27.20 | 0.0000 | 10.6 |

| CT*FA*AT | 1243.12 | 12 | 103.59 | 17.58 | 0.0000 | 13.7 |

| Error | 424.20 | 72 | 5.89 | 4.7 | ||

| Total | 9074.343 | 107 | 100.0 |

| Factor | Sum of Squares | Degrees of Freedom | Mean of Squares | F-Value | p-Value | % Contribution |

|---|---|---|---|---|---|---|

| Cement Type (CT) | 0.43250 | 2 | 0.21625 | 15.9986 | 0.0000 | 7.0 |

| Foam Amount (FA) | 1.59326 | 2 | 0.79663 | 58.9368 | 0.0000 | 25.7 |

| Additive Type (AT) | 0.33054 | 3 | 0.11018 | 8.1513 | 0.0000 | 5.3 |

| CT*FA | 1.91944 | 4 | 0.47986 | 35.5013 | 0.0000 | 31.0 |

| CT*AT | 0.21060 | 6 | 0.03510 | 2.5968 | 0.0246 | 3.4 |

| FA*AT | 0.27106 | 6 | 0.04518 | 3.3423 | 0.0058 | 4.4 |

| CT*FA*AT | 0.46158 | 12 | 0.03846 | 2.8457 | 0.0029 | 7.5 |

| Error | 0.97320 | 72 | 0.01352 | 15.7 | ||

| Total | 6.192 | 107 | 100.0 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lermen, R.T.; Favaretto, P.; Silva, R.d.A.; Hidalgo, G.E.N.; Tubino, R.M.C.; Tiecher, F. Effect of Additives, Cement Type, and Foam Amount on the Properties of Foamed Concrete Developed with Civil Construction Waste. Appl. Sci. 2019, 9, 2998. https://doi.org/10.3390/app9152998

Lermen RT, Favaretto P, Silva RdA, Hidalgo GEN, Tubino RMC, Tiecher F. Effect of Additives, Cement Type, and Foam Amount on the Properties of Foamed Concrete Developed with Civil Construction Waste. Applied Sciences. 2019; 9(15):2998. https://doi.org/10.3390/app9152998

Chicago/Turabian StyleLermen, Richard Thomas, Patrícia Favaretto, Rodrigo de Almeida Silva, Gelsa Edith Navarro Hidalgo, Rejane M. C. Tubino, and Francieli Tiecher. 2019. "Effect of Additives, Cement Type, and Foam Amount on the Properties of Foamed Concrete Developed with Civil Construction Waste" Applied Sciences 9, no. 15: 2998. https://doi.org/10.3390/app9152998

APA StyleLermen, R. T., Favaretto, P., Silva, R. d. A., Hidalgo, G. E. N., Tubino, R. M. C., & Tiecher, F. (2019). Effect of Additives, Cement Type, and Foam Amount on the Properties of Foamed Concrete Developed with Civil Construction Waste. Applied Sciences, 9(15), 2998. https://doi.org/10.3390/app9152998