Rapid Measurement and Identification Method for the Geometric Errors of CNC Machine Tools

Abstract

1. Introduction

2. Integrated Error Model of 3-Axis MTs

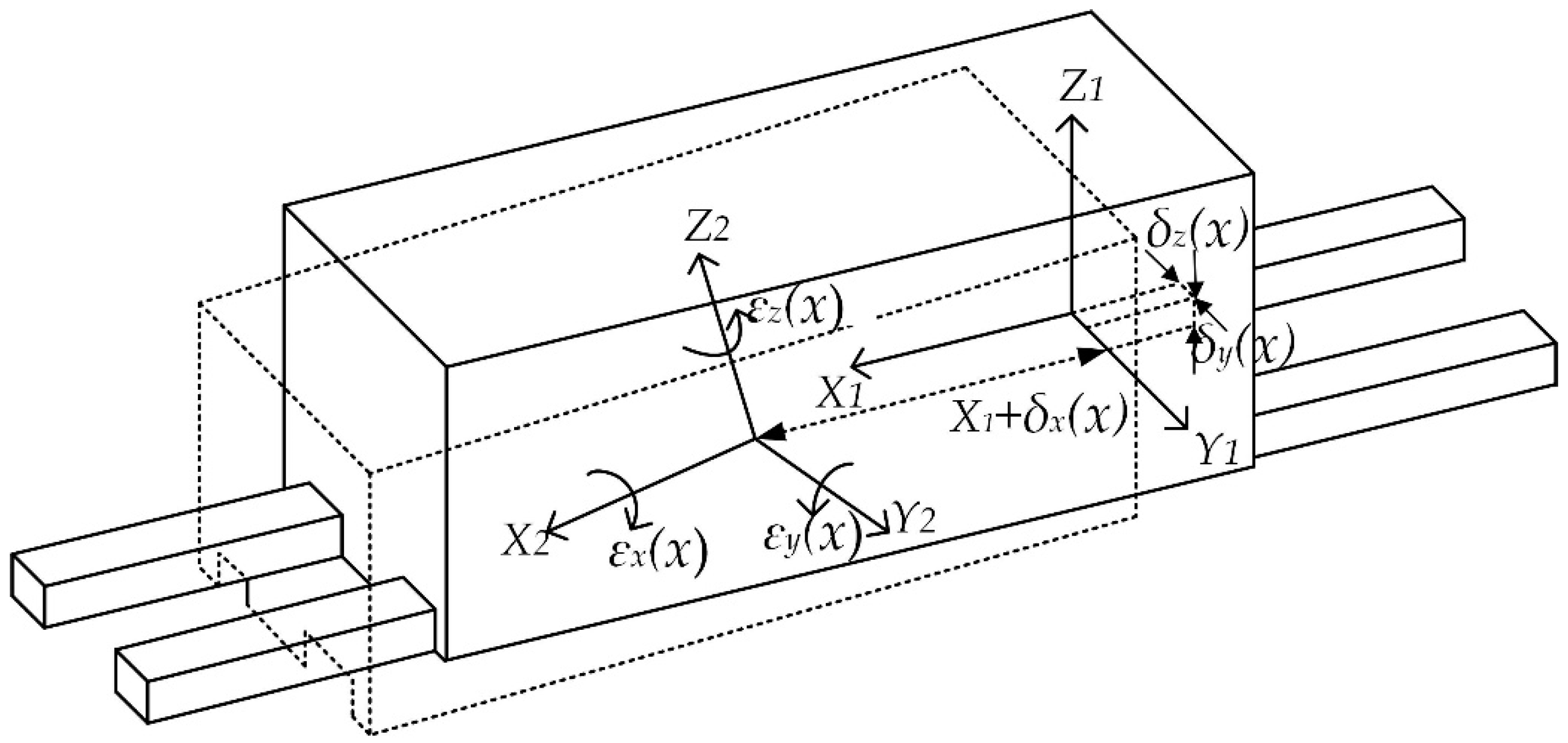

2.1. Geometric Error Sources of 3-Axis MTs

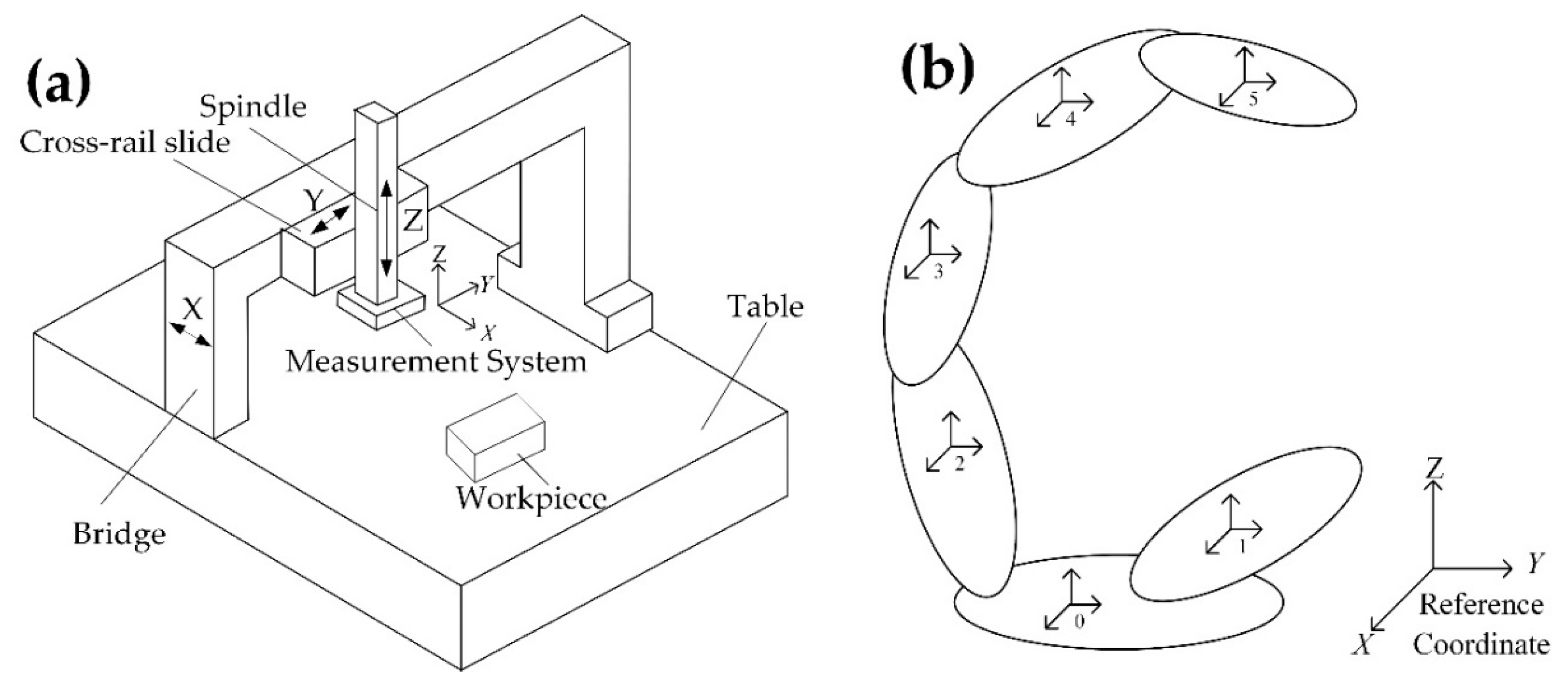

2.2. Structural Analysis of FXYZ 3-Axis MTs

2.3. Integrated Error Model of FXYZ 3-Axis MTs

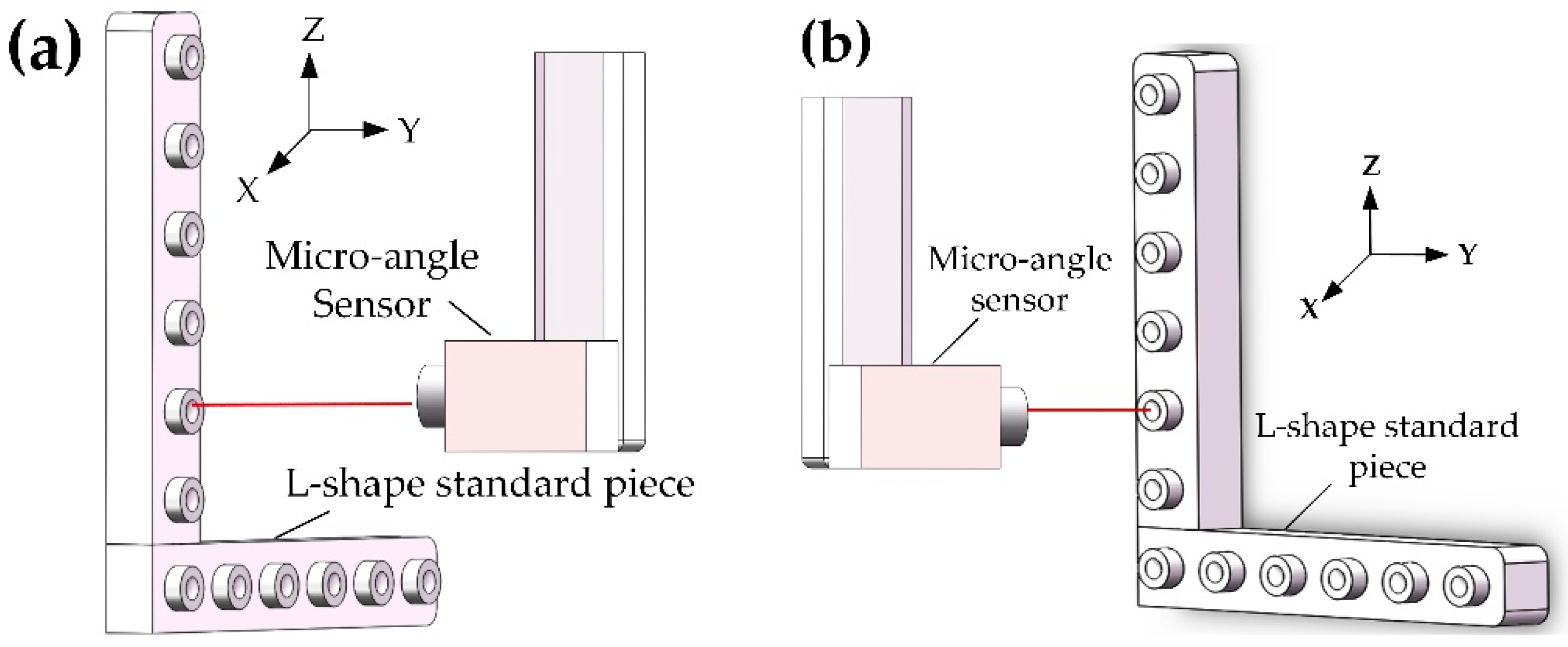

3. Measurement Principles

3.1. Measurement Principle of the Micro-Angle and Displacement

3.1.1. Measurement Principle of the Micro-Angle

3.1.2. Measurement Principle of Micro-Displacement

3.2. Implementation of Large-Scale Measurement

4. Stepwise Identification of Geometric Errors

4.1. Angle Error Identification

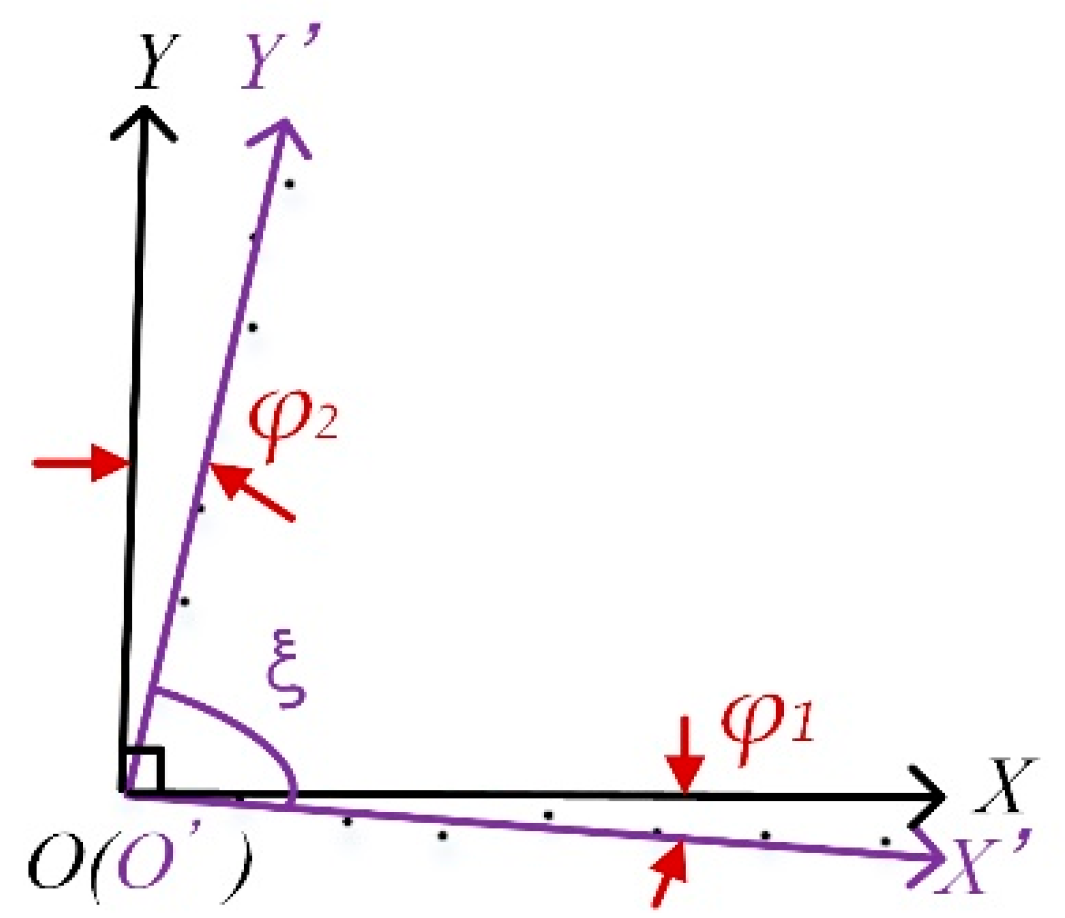

4.2. Squareness Error Identification

4.3. Translation Error Identification

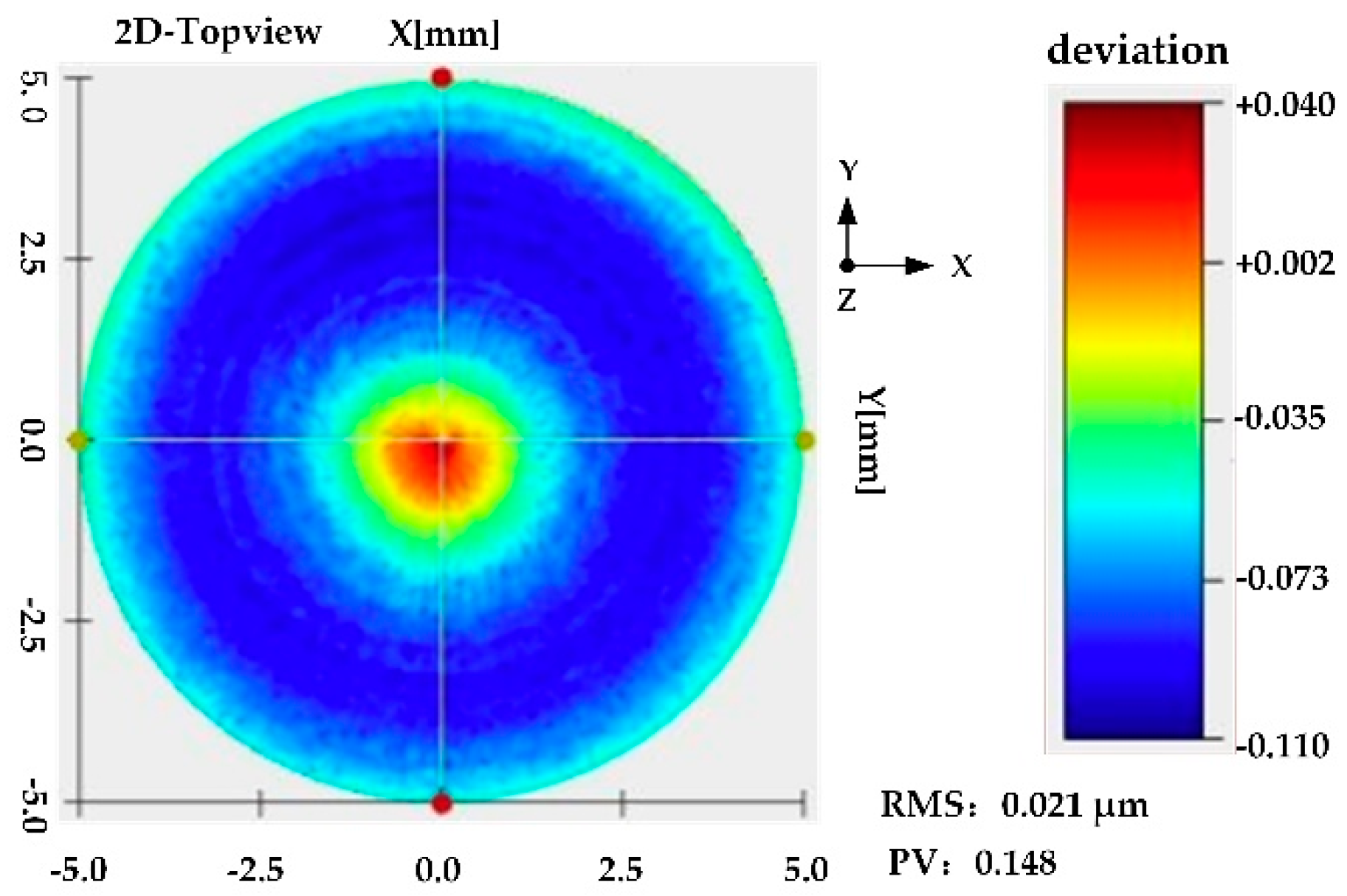

5. System Verification

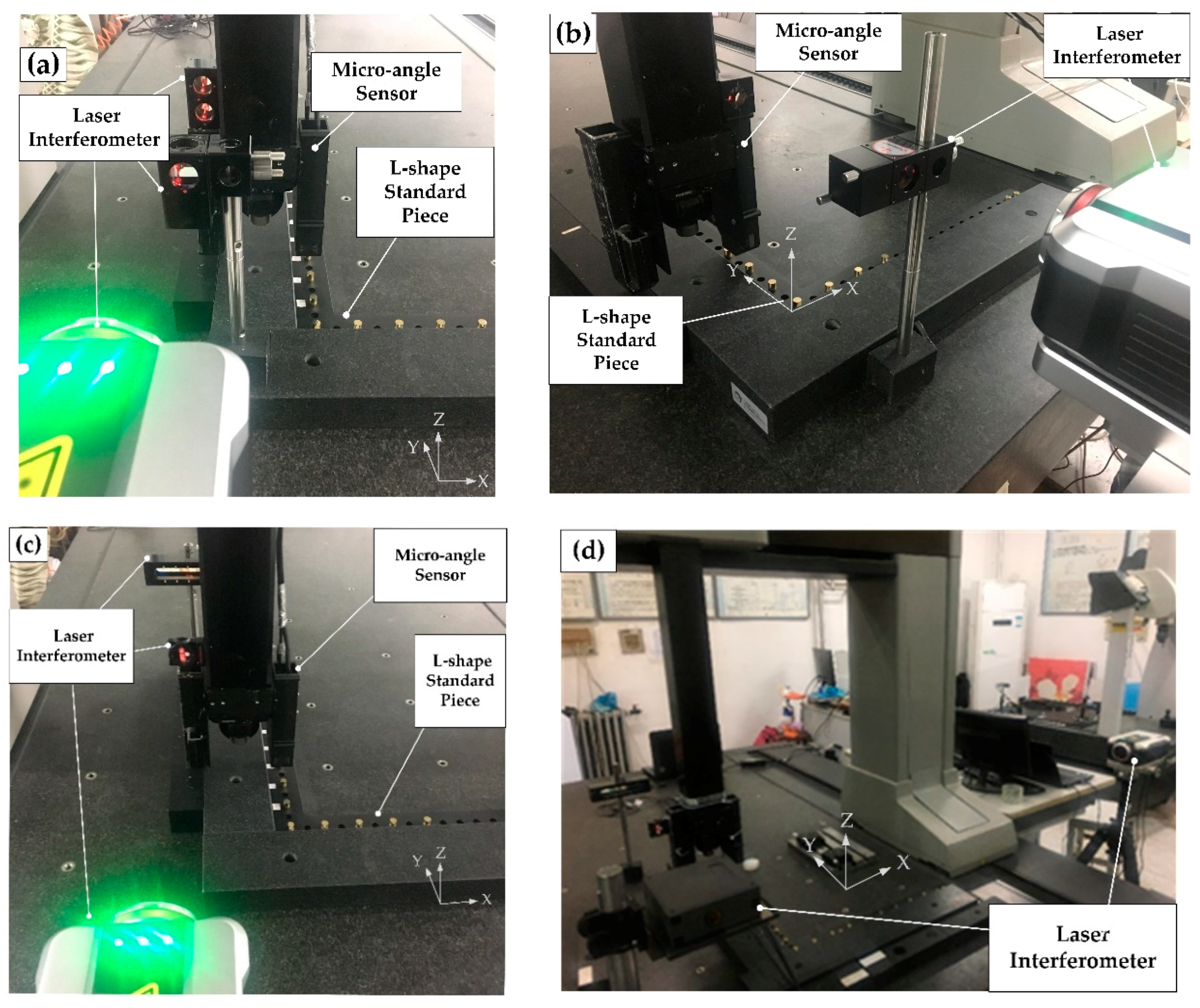

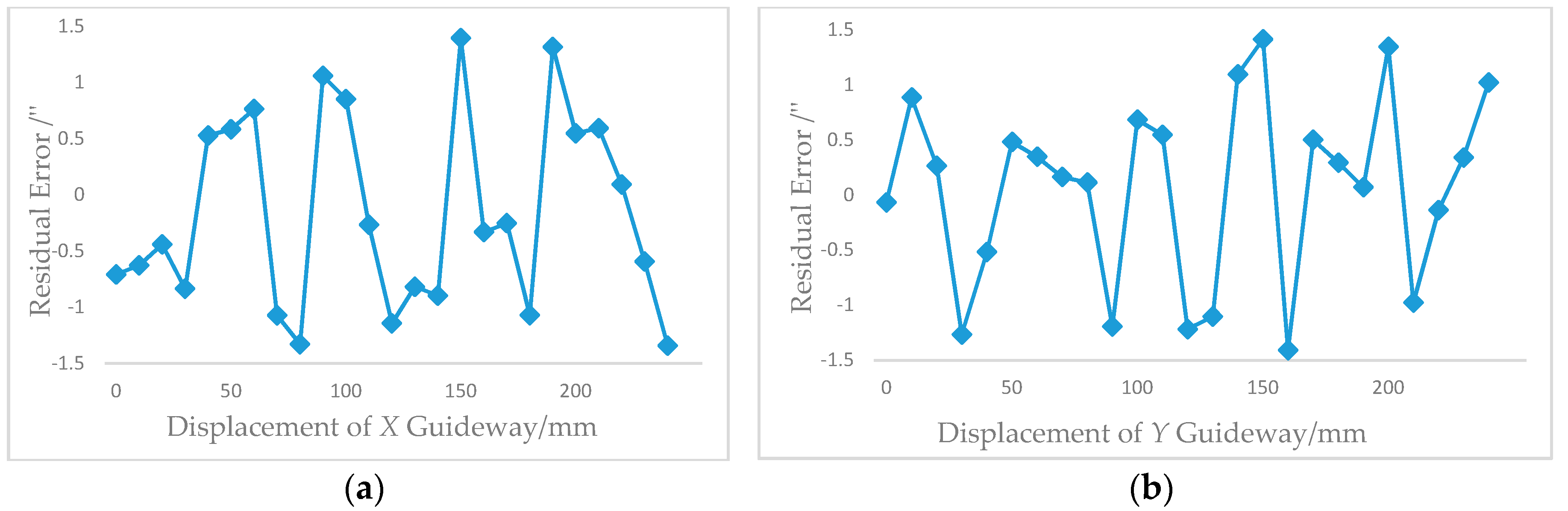

5.1. Angle Measurement

5.2. Displacement Measurement

5.2.1. Squareness Error Identification

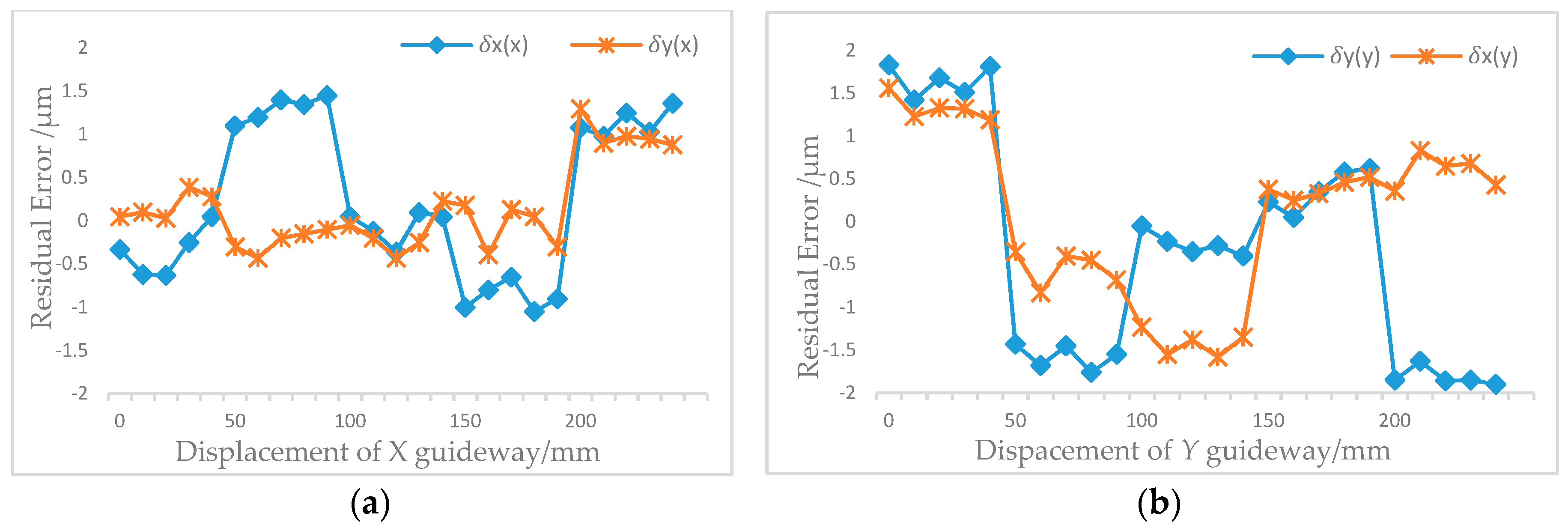

5.2.2. Translation Error Identification

6. Conclusions

- (a)

- The four degrees-of-freedom errors can be obtained in one measurement;

- (b)

- Owing to the L-shape layout of the standard piece, the proposed system is capable of measuring the squareness error between two linear guideways;

- (c)

- The translation errors, including positioning errors and straightness errors, are decoupled by the integrated error model;

- (d)

- The residual error of the angle error, translation error and squareness error are 1.5″, 2 μm and 3.37″ and are compared to those detected by a Renishaw laser interferometer.

Author Contributions

Funding

Conflicts of Interest

References

- Tian, W.J.; Guo, L.Z. Rapid Identification Method for Geometric Errors of CNC Machine Tools. J. Tianjin Univ. (Sci. Technol.) 2016, 49, 171–177. [Google Scholar]

- Han, F.; Zhao, J.; Zhang, L. Synthetical Analysis and Experimental Study of the Geometric Accuracy of CNC Machine Tools. J. Mech. Eng. 2012, 48, 141–148. [Google Scholar] [CrossRef]

- Hong, M.; Su, H.; Li, Z.; Wei, Y. Error motion diagnosis of NC machine tools, comment and countermeasure. Chin. J. Mech. Eng. 2002, 38, 90–94. [Google Scholar] [CrossRef]

- Ikram, M.; Hussain, G. Michelson interferometer for precision angle measurement. Appl. Opt. 1999, 38, 113–120. [Google Scholar] [CrossRef] [PubMed]

- Hsieh, T.; Chen, P.; Jywe, W.; Chen, G.; Wang, M. A Geometric Error Measurement System for Linear Guideway Assembly and Calibration. Appl. Sci. 2019, 9, 574. [Google Scholar] [CrossRef]

- Gao, W.; Saito, Y.; Sato, H. Development of a Sensitive Two-Axis Micro-Angle Sensor. J. Jpn. Soc. Precis. Eng. Contrib. Pap. 2006, 72, 1174–1178. [Google Scholar] [CrossRef][Green Version]

- Gao, W.; Kimura, A. A Three-axis Displacement Sensor with Nanometric Resolution. CIRP Ann. 2007, 56, 529–532. [Google Scholar] [CrossRef]

- Weckenmann, A.; Estler, T.; Peggs, G. Probing systems in dimensional metrology. CIRP Ann. Manuf. Technol. 2004, 53, 657–684. [Google Scholar] [CrossRef]

- Donmez, M.A.; Blomquist, D.S.; Hocken, R.J.; Liu, C.R.; Barash, M.M. A general methodology for machine tool accuracy enhancement by error compensation. Precis. Eng. 1986, 8, 187–196. [Google Scholar] [CrossRef]

- Paraskevopoulos, E.; Natsiavas, S. A new look into the kinematics and dynamics of finite rigid body rotations using Lie group theory. Int. J. Solids Struct. 2013, 50, 57–72. [Google Scholar] [CrossRef]

- Khan, A.W. Systematic Geometric Error Modeling for Workspace Volumetric Calibration of a 5-axis Turbine Blade Grinding Machine. Chin. J. Aeronaut. 2010, 23, 604–615. [Google Scholar] [CrossRef]

- Lei, W.T.; Hsu, Y.Y. Accuracy test of five-axis CNC machine tool with 3D probe–ball. Part I: Design and modeling. Int. J. Mach. Tools Manuf. 2002, 42, 1153–1162. [Google Scholar] [CrossRef]

- Lei, W.T.; Hsu, Y.Y. Accuracy test of five-axis CNC machine tool with 3D probe-ball. Part II: Errors estimation. Int. J. Mach. Tools Manuf. 2002, 42, 1163–1170. [Google Scholar] [CrossRef]

- Du, Z.; Zhang, S.; Hong, M. Development of a multi-step measuring method for motion accuracy of NC machine tools based on cross grid encoder. Int. J. Mach. Tools Manuf. 2010, 50, 270–280. [Google Scholar] [CrossRef]

- Xiang, S.; Li, H.; Deng, M.; Yang, J. Geometric error identification and compensation for non-orthogonal five-axis machine tools. Int. J. Adv. Manuf. Technol. 2018, 96, 2915–2929. [Google Scholar] [CrossRef]

- Giacomo, B.; Morais, C.A. Calibration of Positional Errors in Coordinate Measuring Machines and Machine Tools Using a Laser Interferometer System. Appl. Mech. Mater. 2015, 798, 303–307. [Google Scholar] [CrossRef]

- Liu, H.; Xiang, H.; Chen, J.; Yang, R. Measurement and compensation of machine tool geometry error based on Abbe principle. Int. J. Adv. Manuf. Technol. 2018, 98, 2769–2774. [Google Scholar] [CrossRef]

- Zhu, S.; Dinga, G.; Jiang, L.; Li, Z.; Yana, K. Integrated geometric error modeling, identification and compensation of CNC machine tools. Int. J. Mach. Tools Manuf. 2012, 52, 24–29. [Google Scholar] [CrossRef]

- Chen, J.; Lin, S.; He, B. Geometric error compensation for multi-axis CNC machines based on differential transformation. Int. J. Adv. Manuf. Technol. 2014, 71, 635–642. [Google Scholar] [CrossRef]

- Cao, L.; Zhong, J.L.; Jie, M.I. Space Geometry Error Modeling for Five-Axis NC Machine Tools Based on Multi-Body System Kinematics. Mech. Res. Appl. 2014, 27, 33–36. [Google Scholar]

- Zhong, G.; Wang, C.; Yang, S.; Zheng, E.; Ge, Y. Position geometric error modeling, identification and compensation for large 5-axis machining center prototype. Int. J. Mach. Tools Manuf. 2015, 89, 142–150. [Google Scholar] [CrossRef]

- Su, S.P.; Li, S.Y. A Universal Synthetic Volumetric Error Model of Multi-axis NC Machine Tool Based on Kinematics. J. Natl. Univ. Def. Technol. 2001, 23, 45–50. [Google Scholar]

- Bi, Q.; Huang, N.; Chao, S.; Wang, Y.; Zhu, L.; Han, D. Identification and compensation of geometric errors of rotary axes on five-axis machine by on-machine measurement. Int. J. Adv. Manuf. Technol. 2016, 84, 505–512. [Google Scholar] [CrossRef]

- Fang, F.Z.; W., Y. Three-Dimensional Displacement Measurement System Based on Optical Free-Form Surface. J. Tianjin Univ. (Sci. Technol.) 2014, 47, 934–940. [Google Scholar]

| Axis | PDGEs | PIGEs |

|---|---|---|

| X | δx(x) δy(x) δz(x) εx(x) εy(x) εz(x) | — |

| Y | δx(y) δy(y) δz(y) εx(y) εy(y) εz(y) | αxy |

| Z | δx(z) δy(z) δz(z) εx(z) εy(z) εz(z) | αxz αyz |

| (Arcsec/MM) | The First Order | The Second Order | The Third Order |

|---|---|---|---|

| εy(x) | −1.01 × 10−2 | 2.59 × 10−5 | −6.50 × 10−8 |

| εx(y) | −3.29 × 10−3 | 1.44 × 10−4 | −4.53 × 10−7 |

| (μm/mm) | First Order | Second Order | Third Order |

|---|---|---|---|

| δx(x) | −1.18 × 10−2 | −3.99 × 10−4 | 1.95 × 10−6 |

| δy(x) | 1.42 × 10−1 | −1.19 × 10−3 | 2.48 × 10−6 |

| δy(y) | 8.60 × 10−3 | −1.42 × 10−3 | 8.42 × 10−6 |

| δx(y) | 9.47 × 10−2 | −2.01 × 10−3 | 9.46 × 10−6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Yang, X.; Gao, L.; Su, Z.; Wei, X.; Lv, Z.; Liang, J.; Li, H.; Fang, F. Rapid Measurement and Identification Method for the Geometric Errors of CNC Machine Tools. Appl. Sci. 2019, 9, 2701. https://doi.org/10.3390/app9132701

Li X, Yang X, Gao L, Su Z, Wei X, Lv Z, Liang J, Li H, Fang F. Rapid Measurement and Identification Method for the Geometric Errors of CNC Machine Tools. Applied Sciences. 2019; 9(13):2701. https://doi.org/10.3390/app9132701

Chicago/Turabian StyleLi, Xinghua, Xiaohuan Yang, Lingyu Gao, Zhikun Su, Xuan Wei, Zekui Lv, Jiaqi Liang, Haopeng Li, and Fengzhou Fang. 2019. "Rapid Measurement and Identification Method for the Geometric Errors of CNC Machine Tools" Applied Sciences 9, no. 13: 2701. https://doi.org/10.3390/app9132701

APA StyleLi, X., Yang, X., Gao, L., Su, Z., Wei, X., Lv, Z., Liang, J., Li, H., & Fang, F. (2019). Rapid Measurement and Identification Method for the Geometric Errors of CNC Machine Tools. Applied Sciences, 9(13), 2701. https://doi.org/10.3390/app9132701