Durability of Functionalized Carbon Structures with Optical Fiber Sensors in a Highly Alkaline Concrete Environment

Abstract

:1. Introduction

2. Materials and Methods

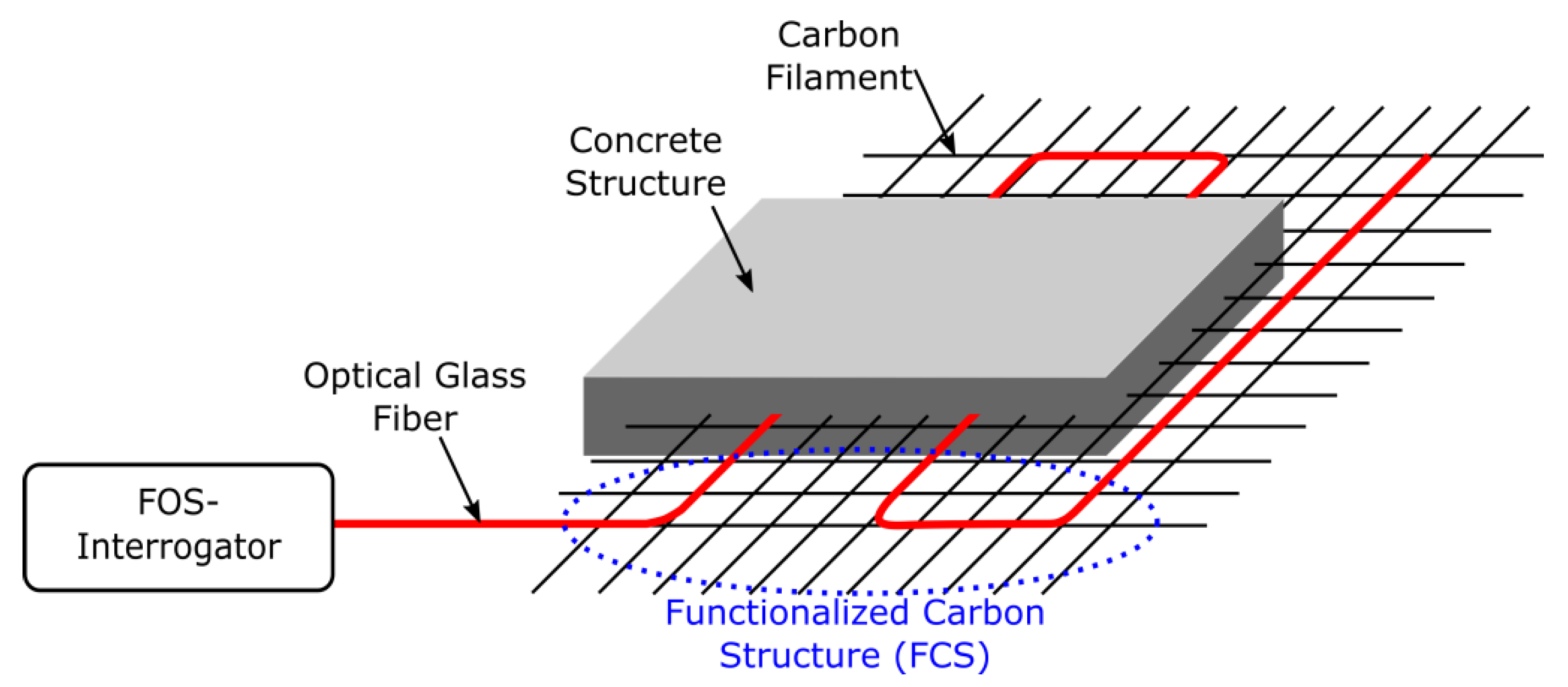

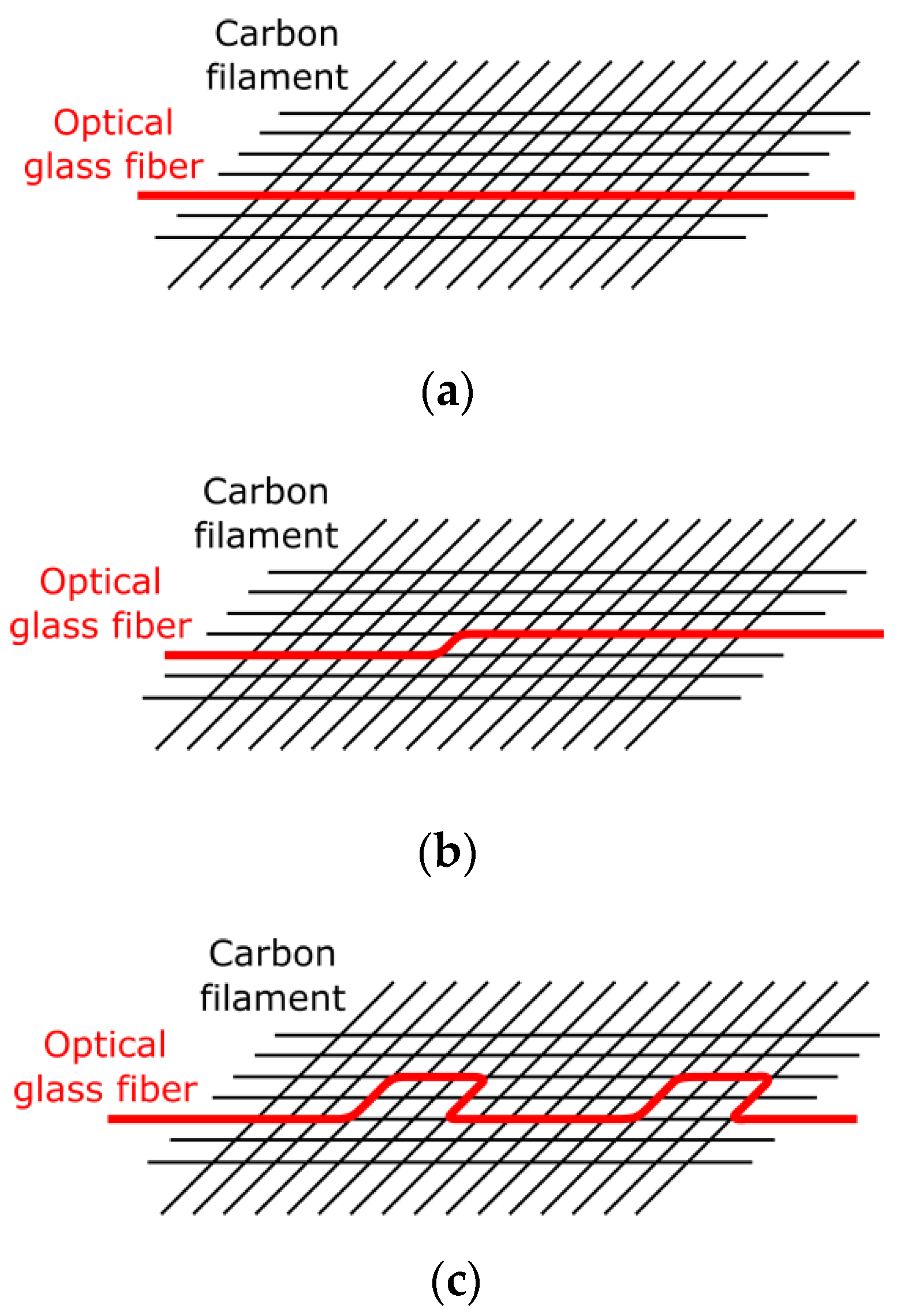

2.1. Fabrication of one Dimensional (1D) and Two Dimensional (2D)-FCS

2.2. Optical Glass Fibers

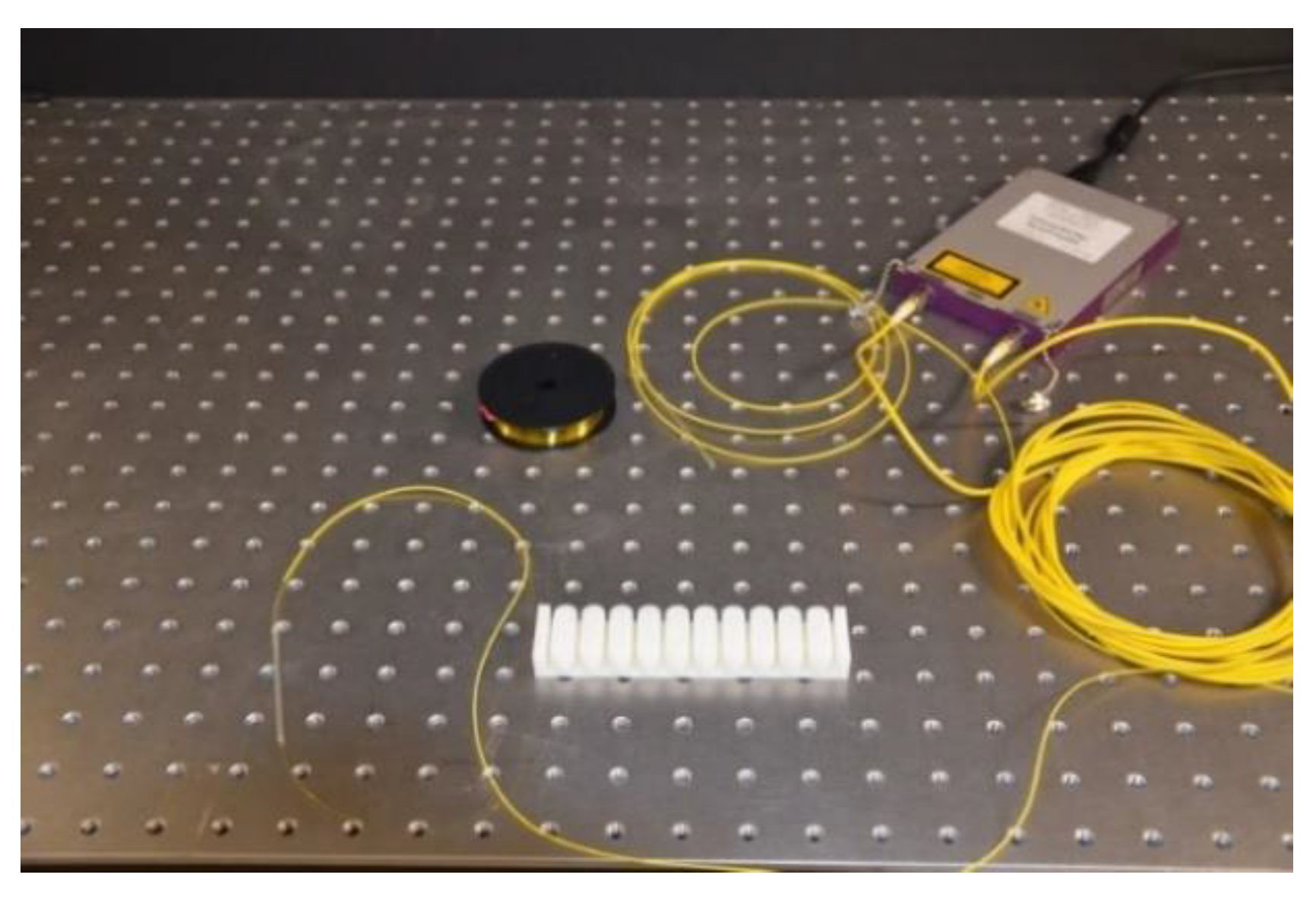

2.3. Evaluating Sensitivity to Micro- and Macro-Bending of Optical Fibers

2.4. Simulated Highly Alkaline Concrete Environment

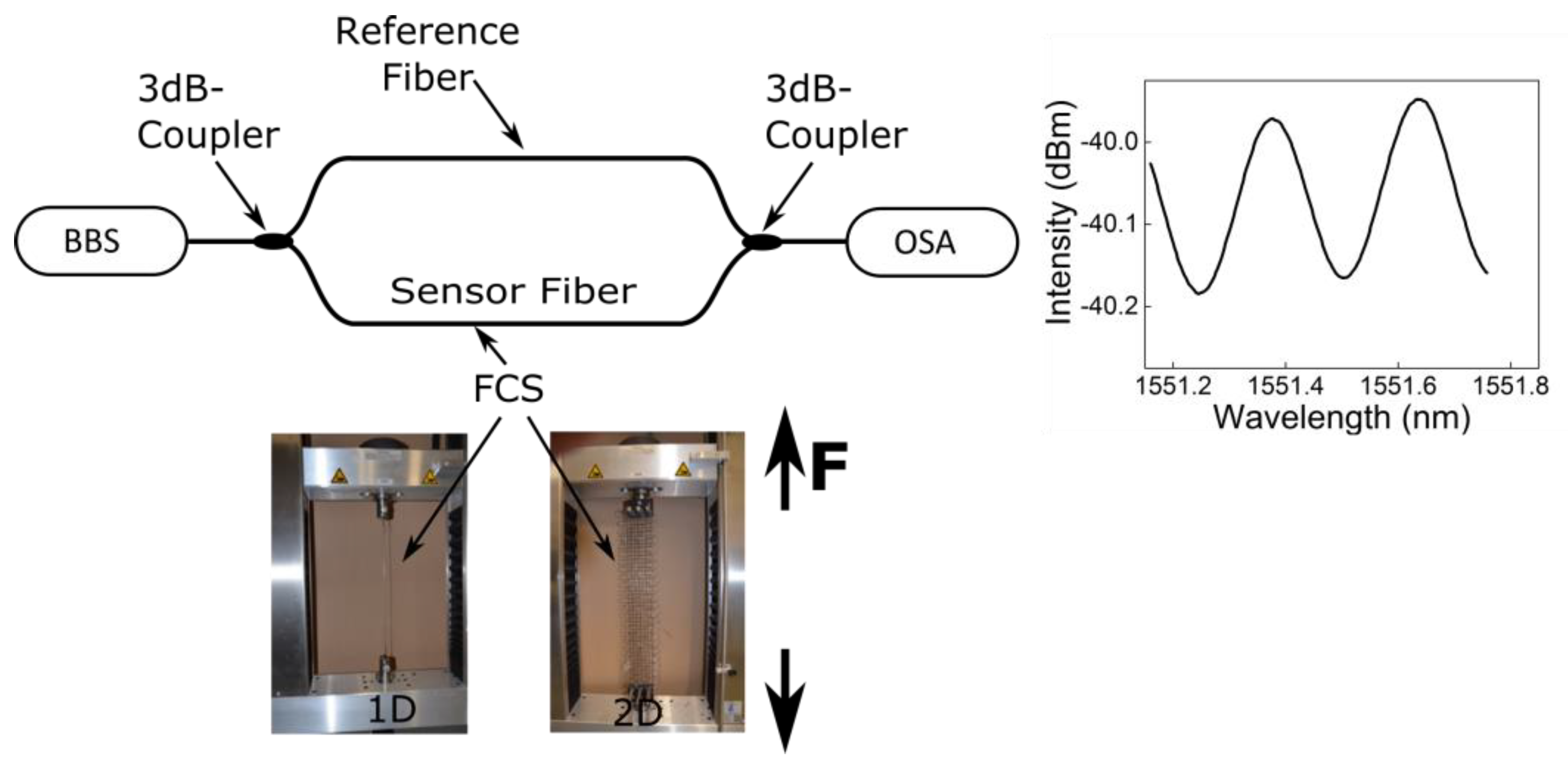

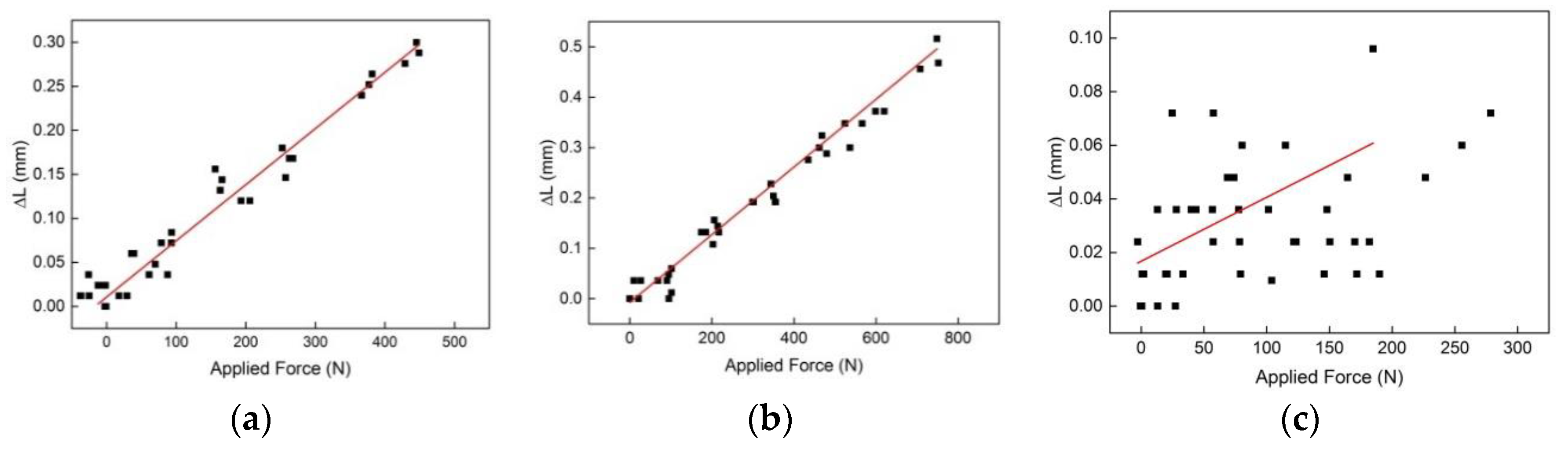

2.5. Evaluating Force Transfer of FCS

3. Results

3.1. Response of Optical Fibers to Macro- and Micro-Bending

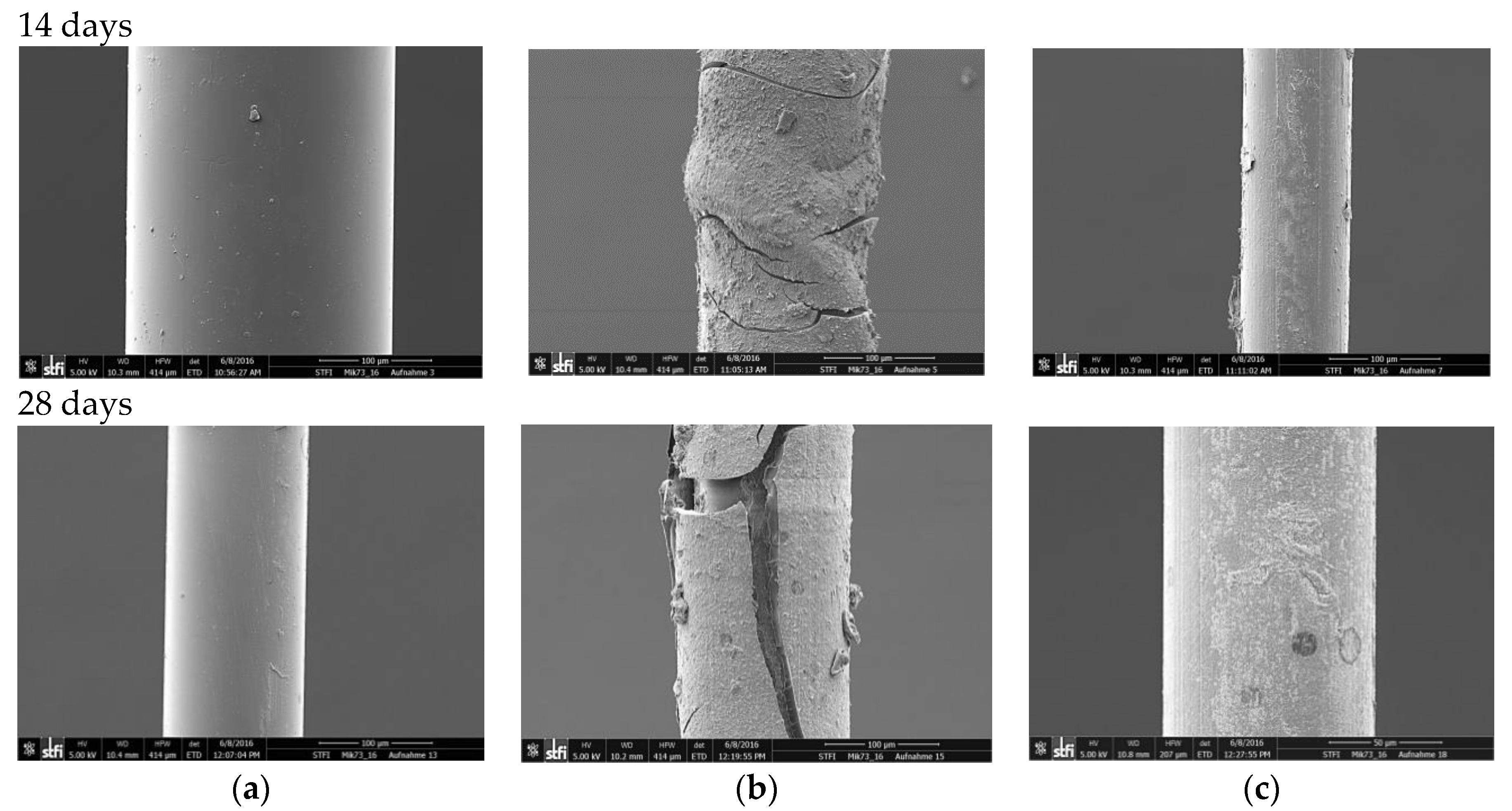

3.2. Response of Optical Fibers to Simulated Alkaline Pore Water

3.3. Response of 1D-FCS to Simulated Alkaline Pore Water

3.4. Sensor Response of FCS with Different Optical Fibre Configurations

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kouroussis, G.; Caucheteur, C.; Kinet, D.; Alexandrou, G.; Verlinden, O.; Moeyaert, V. Review of trackside monitoring solutions: From strain gages to optical fiber sensors. Sensors 2015, 15, 20115–20139. [Google Scholar] [CrossRef] [PubMed]

- Vardanega, P.J.; Webb, G.T.; Fidler, P.R.A.; Middleton, C.R. Innovative Bridge Design Handbook: Construction, Rehabilitation and Maintenance; Elsevier Inc.: Amsterdam, The Netherlands, 2015; pp. 759–775. [Google Scholar]

- Mihailov, S.J. Fiber Bragg grating sensors for harsh environments. Sensors 2012, 12, 1898–1918. [Google Scholar] [CrossRef] [PubMed]

- Pal, A.; Dhar, A.; Ghosh, A.; Sen, R.; Hooda, B.; Rastogi, V.; Ams, M.; Fabian, M.; Sun, T.; Grattan, K.T.V. Sensors for Harsh Environment: Radiation Resistant FBG Sensor System. J. Lightwave Technol. 2016, 35, 3393–3398. [Google Scholar] [CrossRef]

- Berruti, G.; Consales, M.; Giordano, M.; Sansone, L.; Petagna, P.; Buontempo, S.; Breglio, G.; Cusano, A. Radiation hard humidity sensors for high energy physics applications using polyimide-coated fiber Bragg gratings sensors. Sens. Actuators B Chem. 2013, 177, 94–102. [Google Scholar] [CrossRef]

- Hassan, M.R.A.; Bakar, M.H.A.; Dambul, K.; Adikan, F.R.M. Optical-based sensors for monitoring corrosion of reinforcement rebar via an etched cladding Bragg grating. Sensors 2012, 12, 15820–15826. [Google Scholar] [CrossRef]

- Alwis, L.S.M.; Bustamante, H.; Bremer, K.; Roth, B.; Sun, T.; Grattan, K.T.V. Evaluation of the durability and performance of FBG-based sensors for monitoring moisture in an aggressive gaseous waste sewer environment. J. Lightwave Technol. 2017, 35, 3380–3386. [Google Scholar] [CrossRef]

- Bremer, K.; Meinhardt-Wollweber, M.; Thiel, T.; Werner, G.; Sun, T.; Grattan, K.T.V.; Roth, B. Sewerage tunnel leakage detection using a fiber optic moisture-detecting sensor system. Sens. Actuators A Phys. 2014, 220, 62–68. [Google Scholar] [CrossRef]

- Bremer, K.; Weigand, F.; Kuhne, M.; Wollweber, M.; Helbig, R.; Rahlves, M.; Roth, B. Fiber optic sensor systems for the structural health monitoring of building structures. Procedia Technol. 2016, 26, 524–529. [Google Scholar] [CrossRef]

- Thevenaz, L.; Facchini, M.; Fellay, A.; Robert, P.; Inaudi, D.; Dardel, B. Monitoring of large structures using distributed Brillouin fiber sensing. SPIE Proc. 1999, 3746, 345–348. [Google Scholar]

- Measures, R.M.; Alavie, A.T.; Maaskant, R.; Ohn, M.M.; Karr, S.E.; Huang, S.Y. Bragg grating structural sensing system for bridge monitoring. SPIE Proc. 1994, 2294, 53–60. [Google Scholar]

- Ansari, F. Practical Implementation of Optical Fiber Sensors in Civil Structural Health Monitoring. J. Intell. Mater. Syst. Struct. 2007, 18, 879–889. [Google Scholar] [CrossRef]

- Khan, S.; Ali, S.; Bermak, A. Recent Developments in Printing Flexible and Wearable Sensing Electronics for Healthcare Applications. Sensors 2019, 19, 1230. [Google Scholar] [CrossRef] [PubMed]

- Han, T.; Kundu, S.; Nag, A.; Xu, Y. 3D Printed Sensors for Biomedical Applications: A Review. Sensors 2019, 19, 1706. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; An, J.; Cai, G.; Zhang, J.; Chen, W.; Dong, X.; Zhu, L.; Tang, B.; Wang, J.; Wang, X. Environmentally Friendly Flexible Strain Sensor from Waste Cotton Fabrics and Natural Rubber Latex. Sensors 2019, 11, 404. [Google Scholar] [CrossRef]

- Wu, L.; Maheshwari, M.; Yang, Y.; Xiao, W. Selection and Characterization of Packaged FBG Sensors for Offshore Applications. Sensors 2018, 18, 3963. [Google Scholar] [CrossRef] [PubMed]

- Luyckx, G.; Voet, E.; Lammens, N.; Degrieck, J. Strain measurements of composite laminates with embedded fiber Bragg gratings: Criticism and opportunities for research. Sensors 2011, 11, 384–408. [Google Scholar] [CrossRef] [PubMed]

- Barrias, A.; Casas, J.R.; Villalba, S. A review of distributed optical fiber sensors for civil engineering applications. Sensors 2016, 16, 748. [Google Scholar] [CrossRef] [PubMed]

- Scheerer, S.; Schütze, E.; Curbach, M. Strengthening and Repair with Carbon Concrete Composites—The First General Building Approval in Germany. In Proceedings of the International Conference on Strain-Hardening Cement-Based Composites (SHCC 2017), Dresden, Germany, 18–20 September 2018. [Google Scholar]

- Wiederhorn, S.M.; Johnson, H. Effect of electrolyte pH on crack propagation in glass. J. Am. Ceram. Soc. 1973, 56, 192–197. [Google Scholar] [CrossRef]

- Mendez, A.; Morse, T.F.; Mendez, F. Applications of Embedded Optical Fiber Sensors in Reinforced Concrete Buildings and Structures. SPIE Proc. 1990, 1170, 60–70. [Google Scholar]

- Ansari, F. State-of-the-art in the Applications of Fiber-optic Sensors to Cementitious Composites. Cem. Concr. Compos. 1997, 19, 3–19. [Google Scholar] [CrossRef]

- Kuwabara, T.; Katsuyama, Y. Polyetherimide Coated Optical Silica Glass Fiber with High Resistance to Alkaline Solution. In Optical Fiber Communication Conference; Vol. 5 of 1989 OSA Technical Digest Series; Optical Society of America: Washington, DC, USA, 1989; p. WA4. [Google Scholar]

- Habel, W.R.; Hopcke, M.; Basedau, R.; Polster, H. The influence of concrete and alkaline solutions on different surfaces of optical fibers for sensors. In Proceedings of the 2nd European Conference on Smart Structures and Materials, Glasgow, UK, 12–14 October 1994; pp. 168–171. [Google Scholar]

- Habel, W.R.; Hofmann, D.; Hillemeier, B. Deformation measurements of mortars at early ages and of large concrete components on site by means of embedded fiber-optic microstrain sensors. Cem. Concr. Compos. 1997, 19, 81–102. [Google Scholar] [CrossRef]

- Bremer, K.; Weigand, F.; Zheng, Y.; Alwis, L.S.; Helbig, R.; Roth, B. Structural Health Monitoring Using Textile Reinforcement Structures with Integrated Optical Fiber Sensors. Sensors 2017, 17, 345. [Google Scholar] [CrossRef] [PubMed]

- Bremer, K.; Alwis, L.S.; Weigand, F.; Kuhne, M.; Zheng, Y.; Krüger, M.; Helbig, R.; Roth, B. Evaluating the Performance of Functionalized Carbon Structures with Integrated Optical Fiber Sensors under Practical Conditions. Sensors 2018, 18, 3923. [Google Scholar] [CrossRef] [PubMed]

| Fiber-Type | 10 turns [dB] | 20 turns [dB] | 30 turns [dB] | 40 turns [dB] |

|---|---|---|---|---|

| Corning CC | −0.06 | −0.11 | −0.2 | −0.28 |

| OFS PI | 0 | 0 | 0 | 0 |

| OFS C/PI | 0 | 0 | −0.1 | 0 |

| Acrylate | Polyimide | Carbon/Polyimide (Batch #1) | Carbon/Polyimide (Batch #2) | |

|---|---|---|---|---|

| Before exposure | 1.27 GPa N = 5 | 3.29 GPa N = 5 | 2.29 GPa N = 5 | 2.10 GPa N = 5 |

| After exposure | 0.90 GP (14 days) N = 5 | 0.59 GPa (14 days) N = 3 | 2.20 GPa (14 days) N = 5 | 1.94 GPa (14 days) N = 5 |

| 0.83 GPa (3 months) N = 5 | 2.23 GPa (28 days) N = 5 | 0.91 GPa (30 days) N = 5 | ||

| 0.34 GPa (1 year) N = 5 |

| 400 Tex Filament | 800 Tex Filament | 1600 Tex Filament | |

|---|---|---|---|

| Before exposure | 0.0093 mm/N (σ = 3.5 × 10−4) | 0.0065 mm/N (σ = 2.1 × 10−4) | 0.0018 mm/N (σ = 1.1 × 10−4) |

| After exposure | 0.0174 mm/N (σ = 7.3 × 10−4) | 0.0077 mm/N (σ = 4.1 ×10−4) | 0.0023 mm/N (σ = 1.7 × 10−4) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bremer, K.; Alwis, L.S.M.; Zheng, Y.; Weigand, F.; Kuhne, M.; Helbig, R.; Roth, B. Durability of Functionalized Carbon Structures with Optical Fiber Sensors in a Highly Alkaline Concrete Environment. Appl. Sci. 2019, 9, 2476. https://doi.org/10.3390/app9122476

Bremer K, Alwis LSM, Zheng Y, Weigand F, Kuhne M, Helbig R, Roth B. Durability of Functionalized Carbon Structures with Optical Fiber Sensors in a Highly Alkaline Concrete Environment. Applied Sciences. 2019; 9(12):2476. https://doi.org/10.3390/app9122476

Chicago/Turabian StyleBremer, Kort, Lourdes S. M. Alwis, Yulong Zheng, Frank Weigand, Michael Kuhne, Reinhard Helbig, and Bernhard Roth. 2019. "Durability of Functionalized Carbon Structures with Optical Fiber Sensors in a Highly Alkaline Concrete Environment" Applied Sciences 9, no. 12: 2476. https://doi.org/10.3390/app9122476

APA StyleBremer, K., Alwis, L. S. M., Zheng, Y., Weigand, F., Kuhne, M., Helbig, R., & Roth, B. (2019). Durability of Functionalized Carbon Structures with Optical Fiber Sensors in a Highly Alkaline Concrete Environment. Applied Sciences, 9(12), 2476. https://doi.org/10.3390/app9122476